Spandex fabric bleaching method

A fabric and spandex technology, applied in the field of textile bleaching and dyeing, can solve the problems of fabrics not being stretched, unable to complete bleaching quickly and effectively, and increasing costs, so as to avoid damage, shorten bleaching process time, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

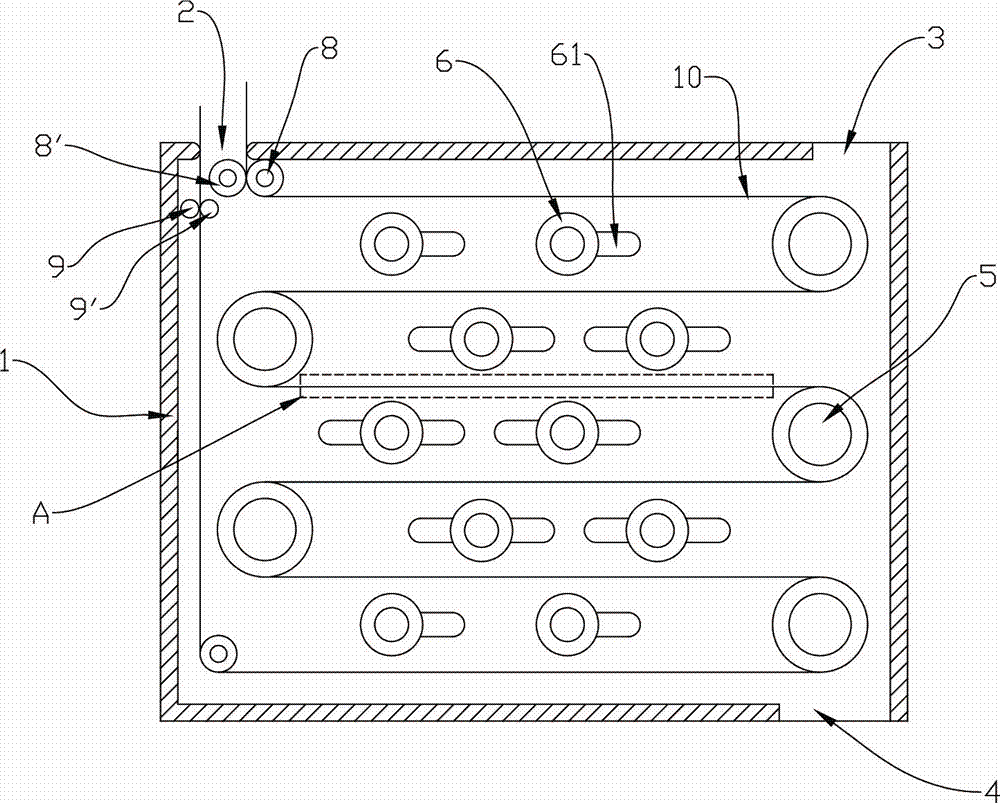

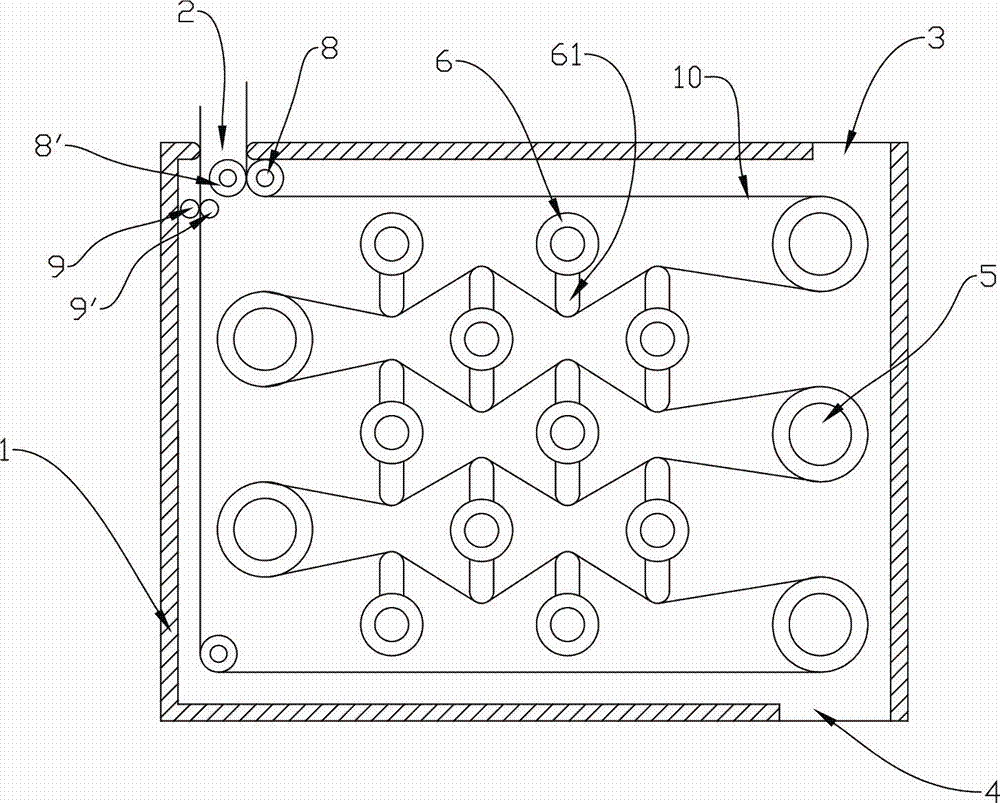

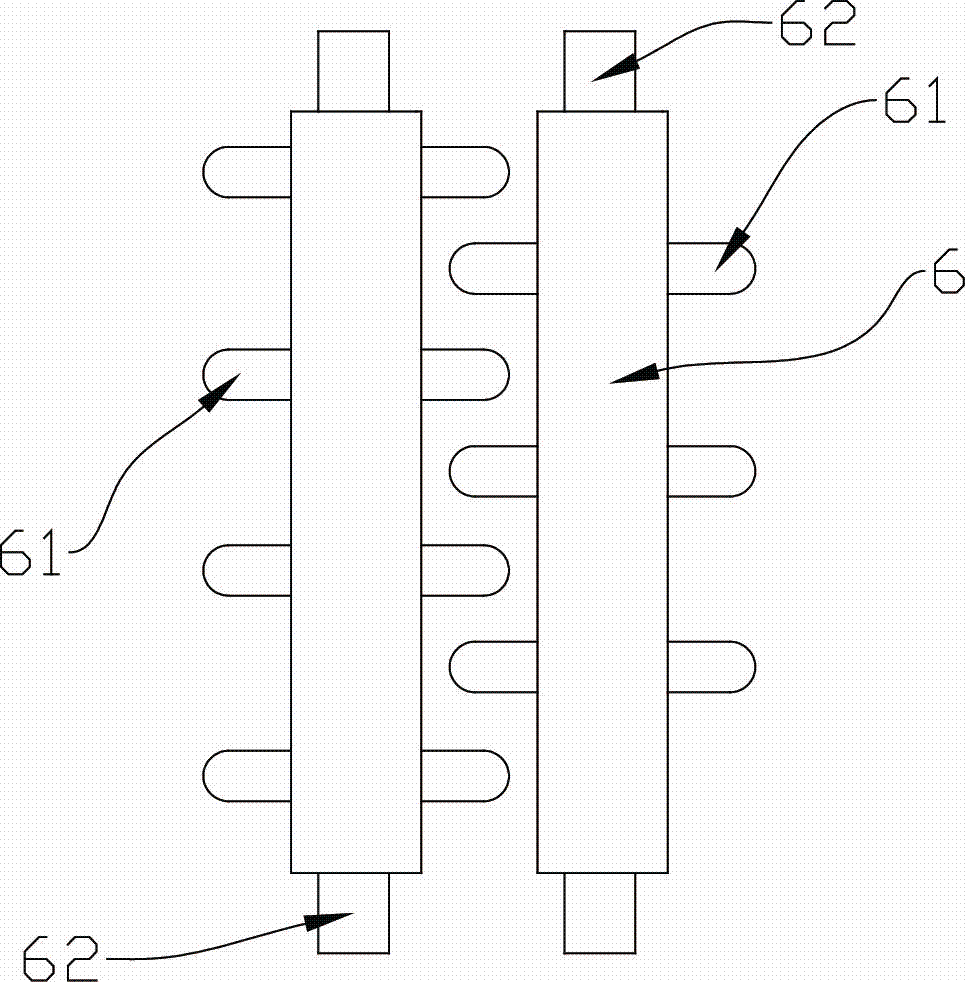

[0021] Embodiment 1: A bleaching method for spandex cloth, comprising the following steps: a. Put the spandex cloth 10 into the bleaching machine 1, add water, heat it to 58°C, and keep it for 9 minutes; b. Change the water to lower the water temperature to room temperature; c. add whitening agent OB-1 and scouring enzyme J-301L at room temperature and soak for 27 minutes; d. raise the temperature to 82°C, then add hydrogen peroxide, and soak for 9 minutes; e. raise the temperature to 96°C, and the heating rate is 1.5 °C / min, keep it for 45 minutes after rising to this temperature, and at the same time stretch and expand the cloth intermittently through the cloth support roller 6;

[0022] The bleaching method of this embodiment has short time, high efficiency and good bleaching effect. The bleaching time of the spandex cloth in the traditional technique is generally 1.5 hours-2 hours, and the procedure of the present invention shortens the time significantly.

Embodiment 2

[0023] Embodiment 2: A bleaching method for spandex cloth, comprising the following steps: a. Put the spandex cloth 10 into the bleaching machine 1, add water, heat to 60°C, and keep it for 11 minutes; b. Change the water to lower the water temperature to room temperature; c. add whitening agent OB-1 and scouring enzyme J-301L at room temperature and soak for 22 minutes; d. raise the temperature to 78°C, then add hydrogen peroxide, and soak for 12 minutes; e. raise the temperature to 98°C, and the heating rate is 1.5 °C / min, keep it for 40 minutes after rising to this temperature, and at the same time stretch and expand the cloth intermittently through the cloth support roller 6;

[0024] The bleaching method of this embodiment has short time, high efficiency and good bleaching effect. The bleaching time of the spandex cloth in the traditional technique is generally 1.5 hours-2 hours, and the procedure of the present invention shortens the time significantly.

Embodiment 3

[0025] Embodiment 3: a bleaching method for spandex cloth, comprising the following steps: a. Put the spandex cloth 10 into the bleaching machine 1, add water, heat to 62°C, and keep it for 10 minutes; b. Change the water to lower the water temperature to room temperature; c. add whitening agent OB-1 and scouring enzyme J-301L at room temperature and soak for 25 minutes; d. raise the temperature to 80°C, then add hydrogen peroxide, and soak for 10 minutes; e. raise the temperature to 97°C, and the heating rate is 1.5 °C / min, keep it for 42 minutes after rising to this temperature, and at the same time stretch and expand the cloth intermittently through the cloth support roller 6;

[0026] The bleaching method of this embodiment has short time, high efficiency and good bleaching effect. The bleaching time of the spandex cloth in the traditional technique is generally 1.5 hours-2 hours, and the procedure of the present invention shortens the time significantly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com