Method for preparing microcrystalline cellulose from Chinese herb residue

A technology for microcrystalline cellulose and traditional Chinese medicine residues, which is applied in the field of preparing microcrystalline cellulose, can solve the problem of not seeing microcrystalline cellulose, etc., and achieve the effects of improving purity and whiteness, easy operation and moderate particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

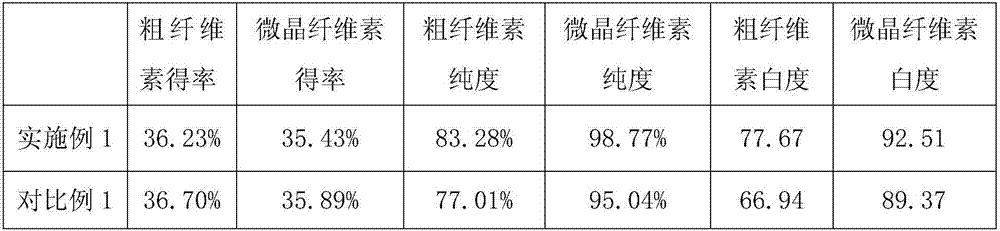

Embodiment 1

[0029] a. Weigh 10g of Chinese medicine dregs in a digestion bottle, mix the Chinese medicine dregs with deionized water at a solid-to-liquid ratio of 1:20g / mL, that is, add 1g of Chinese herbal medicine dregs to 20ml of deionized water, boil for 120min, and centrifuge at 3500r / min for 10min , get filter residue;

[0030] b. Alkali treatment: add 0.04 g / ml sodium hydroxide solution to the filter residue obtained in step a at a solid-to-liquid ratio of 1:10 g / ml, treat in a water bath at 60° C. for 100 min, centrifuge to obtain the filter residue, wash and precipitate until neutral, and collect the filter residue;

[0031] c. Acid treatment: add distilled water to the filter residue obtained in step b at a solid-to-liquid ratio of 1:10 g / ml, adjust the pH value to 1.5 with hydrochloric acid with a mass concentration of 3%, and treat it at a constant temperature in a water bath at 80° C. for 60 minutes, centrifuge to obtain the filter residue, and wash to medium properties, dehy...

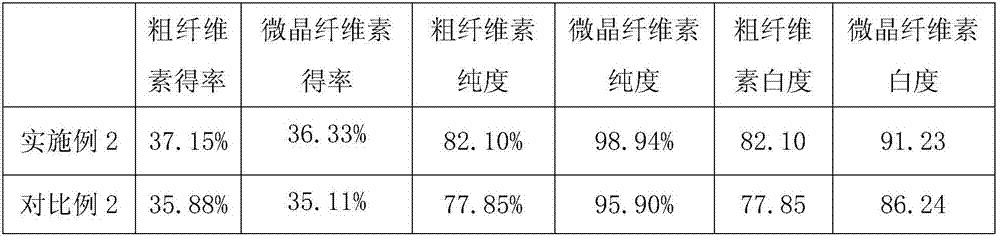

Embodiment 2

[0036] a. Weigh 10g of Chinese medicine dregs into a digestion bottle, mix the Chinese medicine dregs with deionized water at a solid-to-liquid ratio of 1:15g / mL, that is, add 15ml of deionized water to 1g of Chinese medicine dregs, boil for 120min, and centrifuge at 3500r / min for 5min , get filter residue;

[0037] b. Alkali treatment: add 0.08g / ml sodium hydroxide solution to the filter residue obtained in step a at a solid-to-liquid ratio of 1:15g / ml, treat in a water bath at 80°C for 60min, centrifuge to obtain the filter residue, wash and precipitate until neutral, and collect the filter residue;

[0038]c. Acid treatment: add distilled water to the filter residue obtained in step b at a solid-to-liquid ratio of 1:2g / ml, adjust the pH value to 1 with sulfuric acid with a mass concentration of 5%, and treat it at a constant temperature in a water bath at 60°C for 80 minutes, centrifuge to obtain the filter residue, and wash to medium properties, dehydration and drying;

...

Embodiment 3

[0043] a. Weigh 10g of Chinese medicine dregs in a digestion bottle, mix the Chinese medicine dregs with deionized water at a solid-to-liquid ratio of 1:30g / mL, that is, add 1g of Chinese herbal medicine dregs to 30ml of deionized water, boil for 100min, and centrifuge at 3000r / min for 20min , get filter residue;

[0044] b. Alkali treatment: add 0.02 g / ml sodium hydroxide solution to the filter residue obtained in step a at a solid-to-liquid ratio of 1:12 g / ml, treat in a water bath at 50° C. for 120 min, centrifuge to obtain the filter residue, wash and precipitate until neutral, and collect the filter residue;

[0045] c. Acid treatment: Add distilled water to the filter residue obtained in step b at a solid-to-liquid ratio of 1:5g / ml, adjust the pH value to 2 with phosphoric acid with a mass concentration of 5%, and treat it at a constant temperature in a water bath at 50°C for 90 minutes, centrifuge to obtain the filter residue, and wash to medium properties, dehydration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com