Bleaching water for preventing elastic jeans from loss of elasticity by washing and application of bleaching water

A beautiful, denim technology, used in bleached products, dry cleaning fiber products, textiles and papermaking, etc., can solve the problems of high neutralization pressure, easy loss of spandex yarn, long bleaching time, etc., to reduce acid-base neutralization acid , Wide range of applications, the effect of shortening the bleaching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

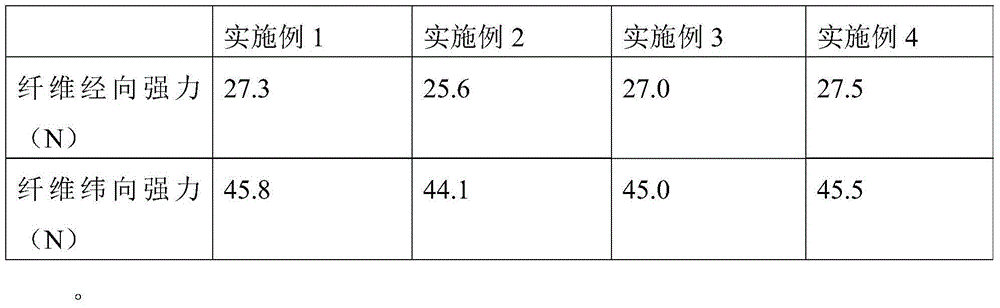

Examples

Embodiment 1

[0037] A process for applying beautiful water to prevent elastic denim from losing its elasticity after washing, the process steps are as follows:

[0038] (1) Put 100 strips of elastic denim into a 600-pound industrial washing machine, feed 800-1000L of water, add 1000ml of beautiful water, 1500ml of white soap oil (1:10 dilution), 2000ml of anti-staining agent, heat up to 60°C, and turn on the machine 10-15 minutes, drain the liquid, and pass through clean water;

[0039] (2) Enter 800-1000L of water, add 1000ml of beautiful water, 2000ml of anti-staining agent, heat up to 50°C, add 300g of citric acid or glacial acetic acid, add 100g of neutral cellulase, turn the machine for 30 minutes, drain, and pass clean water together;

[0040] (3) Enter 800-1000L of water, add 2000ml of beautiful water, run for 5 minutes, heat up to 55°C, add 8L of bleaching water, run for 2 minutes, add 16L of bleaching water, run for 2 minutes, add 16L of bleaching water, and bleach for 15 minutes...

Embodiment 2

[0042] A process for applying beautiful water to prevent elastic denim from losing its elasticity after washing, the process steps are as follows:

[0043] (1) First, 120 strips of elastic denim are hand-rubbed, put them into a 600-pound washing machine, enter 1000L of water, add 1200ml of beautiful water, 2000ml of white soap oil (1:10 dilution), 2000ml of anti-staining agent, and turn the machine to heat up to 60°C, run for 10-15 minutes, drain and clean;

[0044] (2) Add 1000L of water, add 2 bags of Turkish pumice, add 1500mL of beautiful water, 3000ml of anti-staining agent, heat up to 45°C, add 300g of citric acid or glacial acetic acid, add 200g of neutral cellulase, and turn the machine for 25 minutes , drainage, fishing machine;

[0045](3) Then put it into another 600-pound washing machine, fill in 1000L of water, wash it once, and drain;

[0046] (4) Enter 1000L of water, add 2000ml of beautiful water, run for 5 minutes, heat up to 50°C, add 10L of bleaching water...

Embodiment 3

[0048] Production of beautiful water: Weigh raw materials by weight: 30 polysulfonamide derivatives, 5 mixtures of monoamines and polyamines, 1 tetrasodium ethylenediaminetetraacetic acid, 15 polyamino acid derivatives.

[0049] Then add water into the reaction kettle one by one, add tetrasodium ethylenediaminetetraacetic acid, start stirring, after fully stirring and dissolving, add the mixture of unit amine and polyamine (according to 3:1 mass ratio), stir and mix for 10 minutes, and finally Add polyamino acid derivatives and polysulfonamide derivatives, mix and stir until clear, transparent and homogeneous liquid is obtained. At this time, the detected pH value is 8-9, and the appearance is light yellow transparent liquid.

[0050] The application of the above-mentioned beautiful water in preventing elastic denim from losing its elasticity after washing specifically includes the following steps:

[0051] (1) Beautiful water desizing: Put the elastic denim into the industri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com