A kind of hydrogen peroxide bleaching catalyst and preparation method thereof

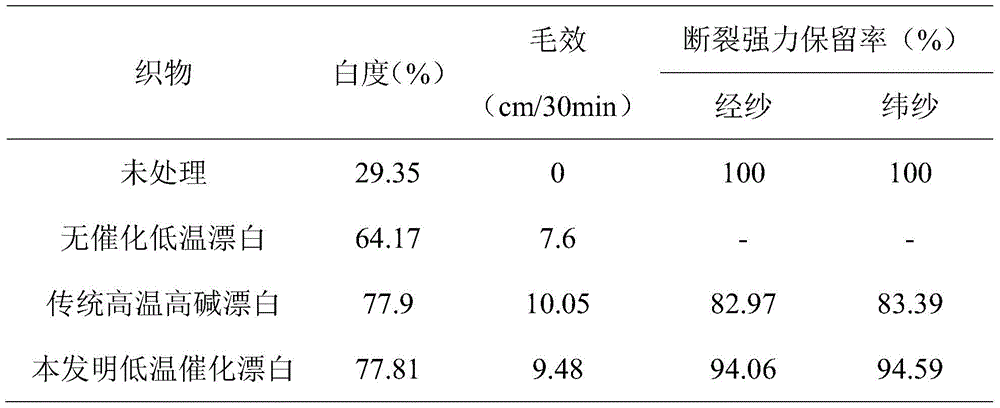

A bleaching catalyst and hydrogen peroxide technology, applied in the field of textile printing and dyeing, can solve the problems of environmental pollution, large fiber damage, high energy consumption, etc., and achieve the effects of shortening bleaching time, reducing dosage, and solving high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Step 1, prepare gelatin protein solution:

[0038] Weigh 15kg of gelatin protein and 30kg of water, add the gelatin protein into the water, control the temperature at 80°C, dissolve for 40min, and obtain the gelatin protein solution;

[0039] Step 2, prepare copper sulfate solution:

[0040] Weigh 1 kg of copper sulfate and 2 kg of water, add copper sulfate to water, control the temperature at 40 ° C, dissolve for 20 minutes, and obtain a copper sulfate solution;

[0041] Step 3, prepare hydrogen peroxide bleaching catalyst:

[0042] Evenly mix the gelatin protein solution prepared in step 1 with the copper sulfate solution prepared in step 2, control the temperature at 20°C, and stir at a speed of 400rpm, add 60g / L sodium hydroxide solution dropwise, and adjust the pH value of the solution to 9 , and continue to stir for 5 minutes to obtain a hydrogen peroxide bleaching catalyst.

Embodiment 2

[0044] Step 1, prepare gelatin protein solution:

[0045] Weigh 10kg of gelatin protein and 50kg of water, add the gelatin protein into the water, control the temperature at 30°C, dissolve for 60min, and obtain the gelatin protein solution;

[0046] Step 2, prepare copper sulfate solution:

[0047] Weigh 0.5kg of copper sulfate and 2.5kg of water, add copper sulfate to water, control the temperature at 60°C, dissolve for 5min, and obtain copper sulfate solution;

[0048] Step 3, prepare hydrogen peroxide bleaching catalyst:

[0049] Evenly mix the gelatin protein solution prepared in step 1 with the copper sulfate solution prepared in step 2, control the temperature at 40°C, stir at 500 rpm, add 80 g / L sodium hydroxide solution dropwise, and adjust the pH value of the solution to 10 , and continue to stir for 10 minutes to obtain a hydrogen peroxide bleaching catalyst.

Embodiment 3

[0051] Step 1, prepare gelatin protein solution:

[0052] Weigh 7kg of gelatin protein and 70kg of water, add the gelatin protein into the water, control the temperature at 60°C, dissolve for 10min, and obtain the gelatin protein solution;

[0053] Step 2, prepare copper sulfate solution:

[0054] Weigh 0.1kg of copper sulfate and 1kg of water, add copper sulfate to water, control the temperature at 20°C, and dissolve for 30min to obtain copper sulfate solution;

[0055] Step 3, prepare hydrogen peroxide bleaching catalyst:

[0056] Evenly mix the gelatin protein solution prepared in step 1 with the copper sulfate solution prepared in step 2, control the temperature at 60°C, and the stirring speed at 600rpm, add dropwise 100g / L sodium hydroxide solution, and adjust the pH value of the solution to 12 , and continue to stir for 30 minutes to obtain a hydrogen peroxide bleaching catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com