Bleaching method capable of maintaining mechanical strength of corn bracts

A corn husk, mechanical strength technology, used in reed/straw treatment, wood treatment, wood processing appliances, etc., can solve the problems of long bleaching time, respiratory mucosal irritation, air pollution, etc., achieves a simple bleaching method, and maintains mechanical Strength, the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

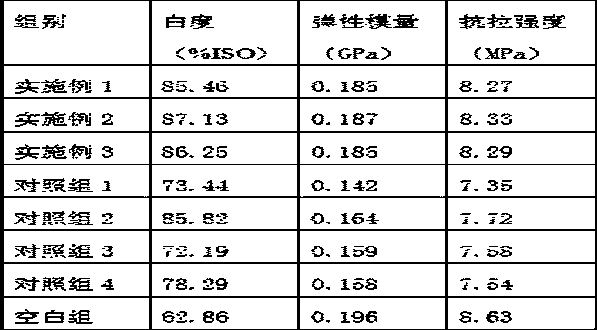

Examples

Embodiment 1

[0014] A bleaching method for maintaining the mechanical strength of corn husks, comprising the following steps: soaking pretreated corn husks in a bleaching compound solution, controlling the temperature at 50°C during the soaking process, and the bleaching time is 35 minutes. Ultrasonic treatment with a power of 100W, ultrasonic treatment is periodic treatment, ultrasonic treatment for 20 seconds every 5 minutes, after completion, dry at a temperature of 65°C until the water content is lower than 15%;

[0015] The bleaching composite solution includes the following raw materials in parts by weight: 50 parts of hydrogen peroxide with a mass concentration of 20%, 7 parts of aluminum monostearate, 3 parts of polyoxyethylene mono-stearate, 1.2 parts of triethanolamine dilaurate, hydroxyl 0.4 parts of carboxylic acid, 0.2 parts of carbamate, 2.5 parts of potassium carbonate, 1.5 parts of activator, 30 parts of N,N-dimethylformamide, 500 parts of magnetized water;

[0016] The act...

Embodiment 2

[0021] A bleaching method for maintaining the mechanical strength of corn husks, comprising the following steps: soaking pretreated corn husks in a bleaching compound solution, controlling the temperature at 45°C during the soaking process, and the bleaching time is 30 minutes. Ultrasonic treatment with a power of 120W, ultrasonic treatment is periodic treatment, ultrasonic treatment for 20 seconds every 5 minutes, after completion, dry at a temperature of 70°C until the water content is lower than 15%;

[0022] The bleaching composite solution includes the following raw materials in parts by weight: 55 parts of hydrogen peroxide with a mass concentration of 20%, 8 parts of aluminum monostearate, 2 parts of polyoxyethylene mono-stearate, 1.5 parts of triethanolamine dilaurate, hydroxyl 0.2 parts of carboxylic acid, 0.3 parts of carbamate, 2 parts of potassium carbonate, 1 part of activator, 40 parts of N,N-dimethylformamide, 500 parts of magnetized water;

[0023] The activato...

Embodiment 3

[0028] A bleaching method for maintaining the mechanical strength of corn bracts, comprising the following steps: soaking pretreated corn bracts in a bleaching compound solution, controlling the temperature at 55°C during the soaking process, and the bleaching time is 40 minutes. Ultrasonic treatment with a power of 80W, ultrasonic treatment is periodic treatment, ultrasonic treatment for 20 seconds every 5 minutes, after completion, dry at a temperature of 60°C until the water content is lower than 15%;

[0029] The bleaching composite solution includes the following raw materials in parts by weight: 45 parts of hydrogen peroxide with a mass concentration of 20%, 6 parts of aluminum monostearate, 4 parts of polyoxyethylene mono-stearate, 0.8 parts of triethanolamine dilaurate, hydroxyl 0.6 parts of carboxylic acid, 0.1 part of carbamate, 3 parts of potassium carbonate, 2 parts of activator, 20 parts of N,N-dimethylformamide, 500 parts of magnetized water;

[0030] The activat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com