Patents

Literature

38 results about "Straw plaiting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Straw plaiting is a method of manufacturing textiles by braiding straw and the industry that surrounds the craft of producing these straw manufactures. Straw is plaited to produce products including straw hats and ornaments, and the process is undertaken in a number of locations worldwide.

Method for afforesting desert and retaining water

InactiveCN102160483ABlock flowConserve waterClimate change adaptationAfforestationVegetationEcological environment

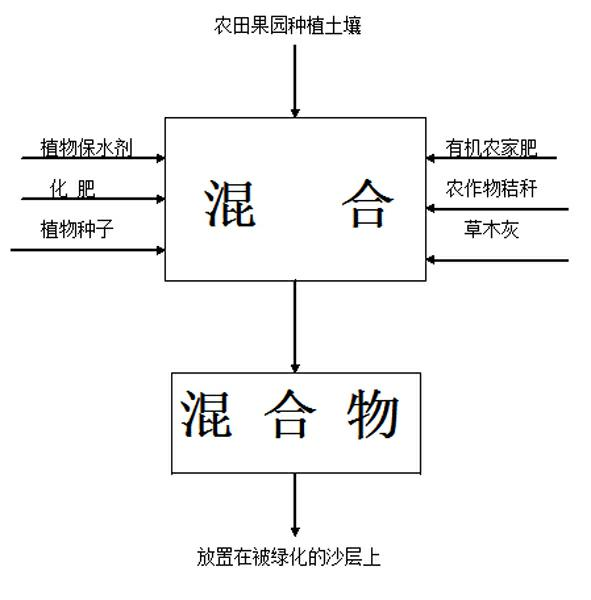

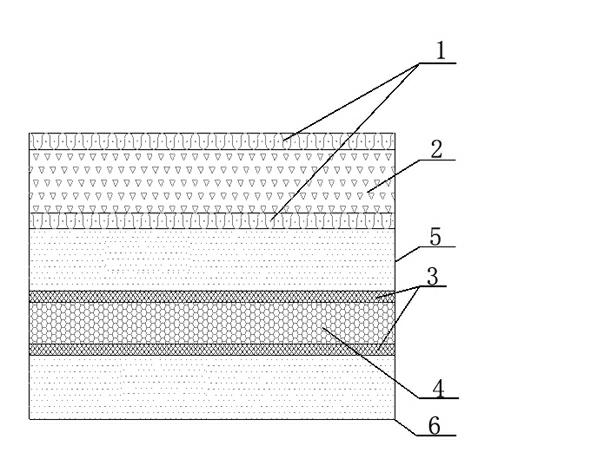

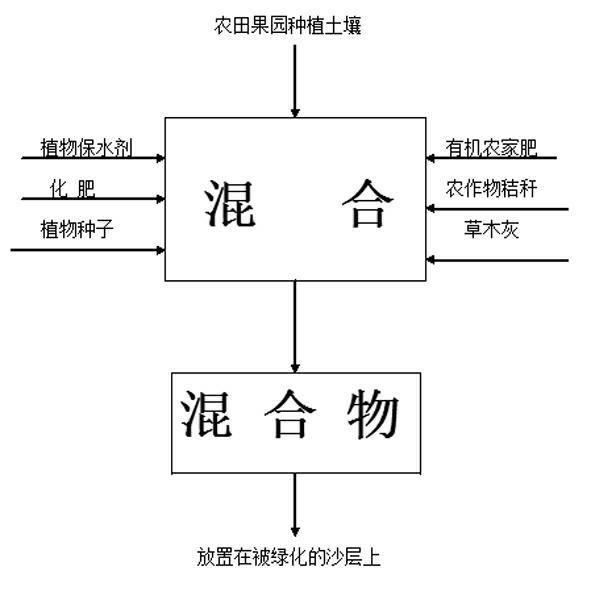

The invention relates to the field of ecological environment protection, in particular to a method used for afforesting a desert. The method used for afforesting the desert comprises the following steps of: 1, excavating a filling slot; 2, paving a waterproof impervious layer; 3, paving a sand layer; 4, paving a plant growing layer; and 5, paving a straw plaited grid. The waterproof impervious layer is arranged in the sand layer, the waterproof impervious layer stops flow direction of water, and water can not leak everywhere deep in the sand layer, thus the aim of saving water is achieved; the used material is environmentally friendly, and human and natural environment can not be polluted; water supply is reasonable, water can be uniformly supplied to plants used for afforesting, the plants can rapidly grow, and the problems of water for afforesting the desert and rainwater seepage control can be effectively solved. The method has a wide application field and is convenient for standardization construction. By applying the method to afforest the desert, a conditioned desert can be afforested, desert vegetation coverage rate can be improved, and a local ecological environment of the desert can be improved.

Owner:甘肃源岗农林开发有限公司

Mould preventing treatment method for straw plaited articles

InactiveCN106182265AEnhance the effect of anti-mildew treatmentGood for protecting flexibilityRadiation/waves wood treatmentWood treatment detailsSecondary radiationMedicine

The invention discloses a mould preventing treatment method for straw plaited articles. The method comprises the first step of raw material treatment, the second step of drying treatment, the third step of radiation treatment, the fourth step of mould preventing treatment liquid preparing, the fifth step of immersing treatment, the sixth step of secondary drying treatment, the seventh step of secondary radiation treatment, the eighth step of secondary immersing treatment and the ninth step of airing weaving. Straw plaited article raw materials treated through the method have high mould preventing performance and are safe, harmless, good in flexibility and high in tensile strength and folding strength, and weaving is better facilitated.

Owner:FUNAN YONGXING ARTS & CRAFTS

Ecological ornamental plate and production method thereof

InactiveCN101590777AReduce releaseNot easy to fall offDecorative surface effectsFilm/foil adhesivesAdhesiveEngineering

The invention relates to an ornamental plate and a production method thereof. The ecological ornamental plate comprises a base plate and an ornamental layer compounded on the base plate, wherein the ornamental layer is made from plant class ecological materials. The ornamental plate has the advantages of water resistance, moisture resistance, fire resistance, impact resistance, pollution resistance, little probability of falling off after being stuck and used, no mildew, little probability of burning when encountering fire and automatic extinguishing when being away from the fire; the surface of the ornamental plate is easy to clean; an aldehyde-containing adhesive is not applied to the surface, and the emission quantity of formaldehyde is low; the style is diversiform, the ornamental layer is formed by weaving and sticking natural materials of straw plaiting articles, bamboo plaiting articles, the stems and leaves of plants, and the like, and the form is diversiform; the ornamental layer does not need glue dipping, glue spraying and glue brushing, and is suitable for large-scale production; the ornamental layer and base materials adopt a prepreg film as a sticking material and are formed by one step; and the operation is simple and easy.

Owner:HENAN YONGWEI SECURITY

Sun-block raffia straw hat dyeing method

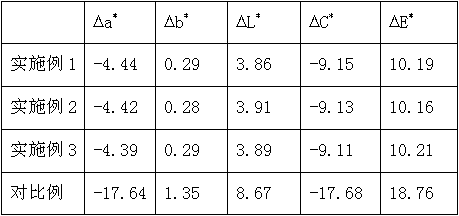

InactiveCN107627424AEven and thorough dyeingBright colorWood treatment detailsReed/straw treatmentCelluloseStraw plaiting

The invention belongs to the technical field of dyeing of straw-weaved products and particularly relates to a sun-block raffia straw hat dyeing method. The specific method comprises the steps of (1) conducting vapor treatment on weaved raffia straw hats, taking out the raffia straw hats, soaking the raffia straw hats in a dyeing agent, introducing ultrasonic waves to conduct ultrasonic treatment and putting the raffia straw hats into a magnetic field for magnetization treatment; and (2) conducting hot pressing and drying on the raffia straw hats, soaking the raffia straw hats in a sodium alginate aqueous solution, taking out the raffia straw hats and conducting hot pressing and drying on the raffia straw hats. The infiltration capacity of dyeing agent molecules is effectively enhanced. Thepolymerization capacity between the dyeing agent molecules and cellulose is improved. The raffia straw hats are dyed uniformly and thoroughly, are bright in color and extremely stable in dyeing performance, have remarkable anti-ultraviolet performance and cannot discolor after long-time sun exposure or rain drenching. The use quality of the raffia straw hats is effectively improved. The service life of the raffia straw hats is prolonged. Moreover, the anti-corrosion and anti-mildew capacity of the raffia straw hats can be further improved. Breeding of harmful bacteria is inhibited. The raffiastraw hats have not pungent smell and tangy light flower fragrance. The popularity degree of the raffia straw hats is effectively improved.

Owner:安徽省创安体育用品有限公司

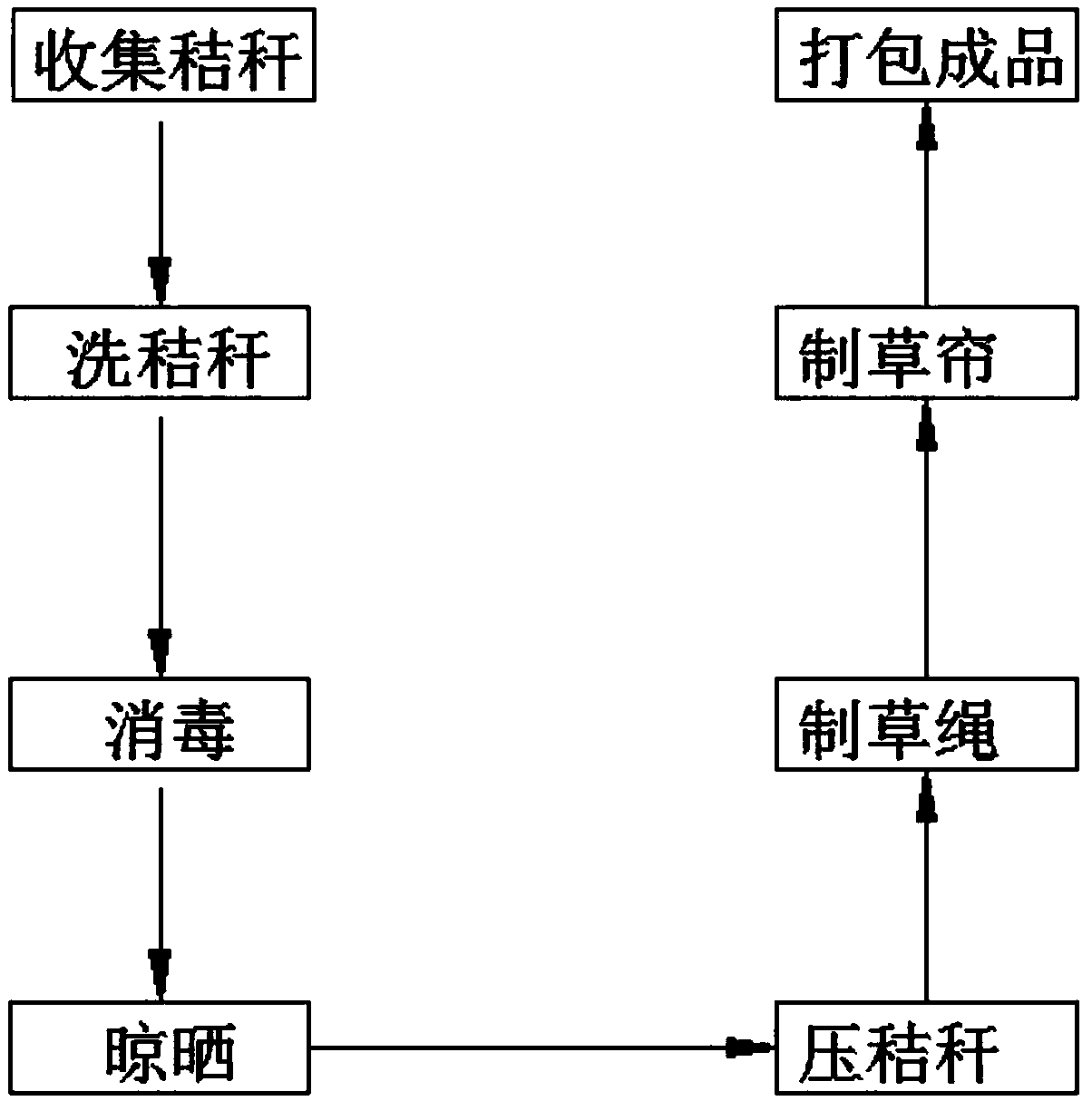

Environment-friendly straw weaving product manufacturing method

InactiveCN108656268AImprove pass rateQuality improvementWood treatment detailsCane mechanical workingEnvironmental resistancePulp and paper industry

The invention discloses an environment-friendly straw weaving product manufacturing method, and relates to the technical field of straw weaving. The method comprises the following steps of straw collecting, straw washing, disinfecting, airing, straw rope manufacturing, straw curtain manufacturing and finished product packaging. According to the environment-friendly straw weaving product manufacturing method, multiple production processes are adopted, and the produced straw products are high in percent of pass and good in quality; the straws are used for replacing other raw materials, so that the environment-friendly effect is facilitated, the waste recycling rate is increased, and the product cost is reduced; the straws are made into ropes, and then the manufactured ropes are made into straw curtains, so that the strength and the tenacity of the straw curtains are enhanced; and hemp ropes are used for replacing conventional plastic ropes in the process of producing the straw curtains,the hemp ropes can be automatically degraded after being abandoned, the environmental protection is facilitated to a greater extent, and the white pollution is reduced.

Owner:宁夏德琴农业科技开发有限公司

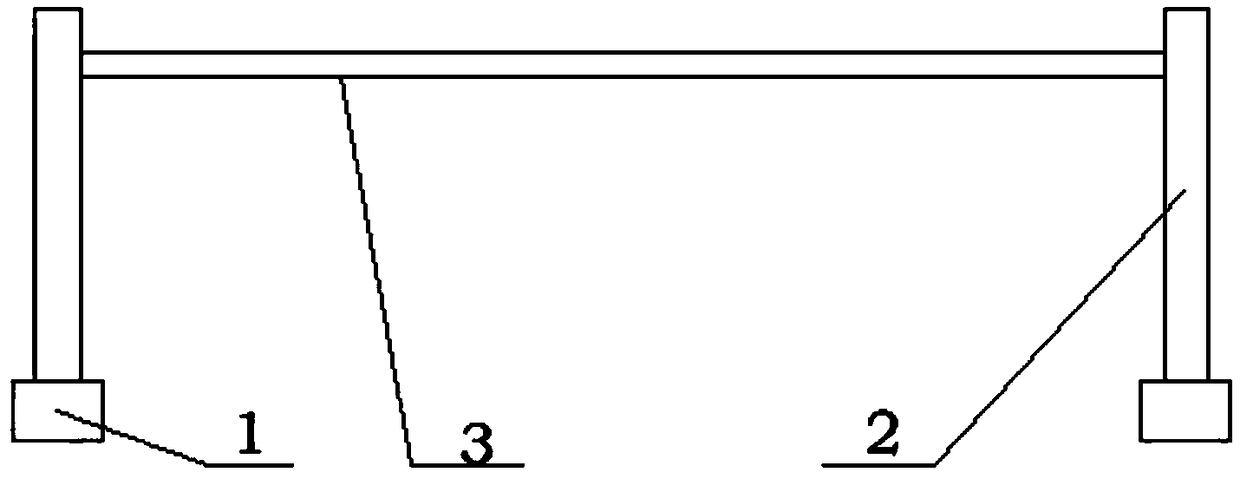

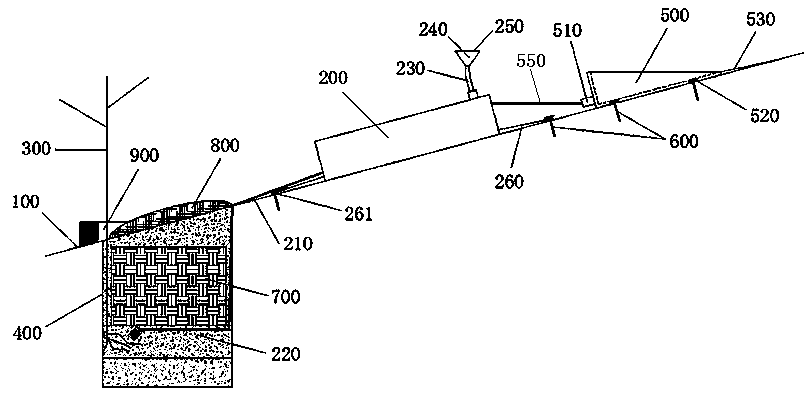

Method for desert greening

InactiveCN106069271AIncrease coverageImprove the ecological environmentClimate change adaptationAfforestationVegetationGrowth plant

The invention discloses a method for desert greening. The method is characterized by comprising the following steps of 1, digging a filling groove, and a water resistant impermeable layer is laid on the surface of the filling groove; 2, a sand layer is laid on the water resistant impermeable layer, and a plant growth layer is laid on the sand layer; 3, straw plaited meshes are laid on the plant growth layer, a straw mattress on a winch is connected to a hook of a mountain bike, the mountain bike is started and moves forwards, operation at uniform speed is kept till the straw mattress on the winch is completely laid; 4, plant seeds are sprayed on the straw plaited meshes, and then water spraying is performed. The method is used for desert greening, if conditions permit, the desert capable of being greened can be greened, the application region is wide, large-scale construction is convenient, the desert vegetation coverage is increased, and ecological environment of local desert can be improved.

Owner:周连惠

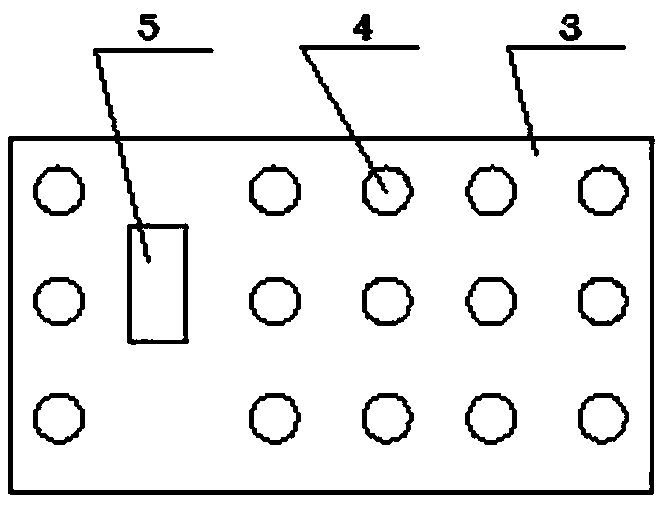

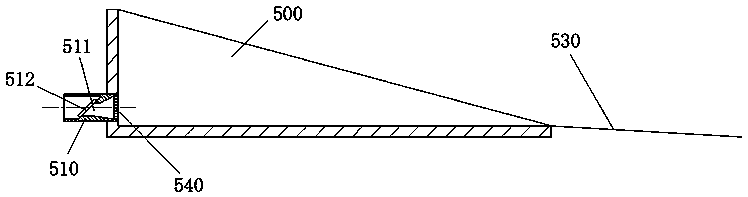

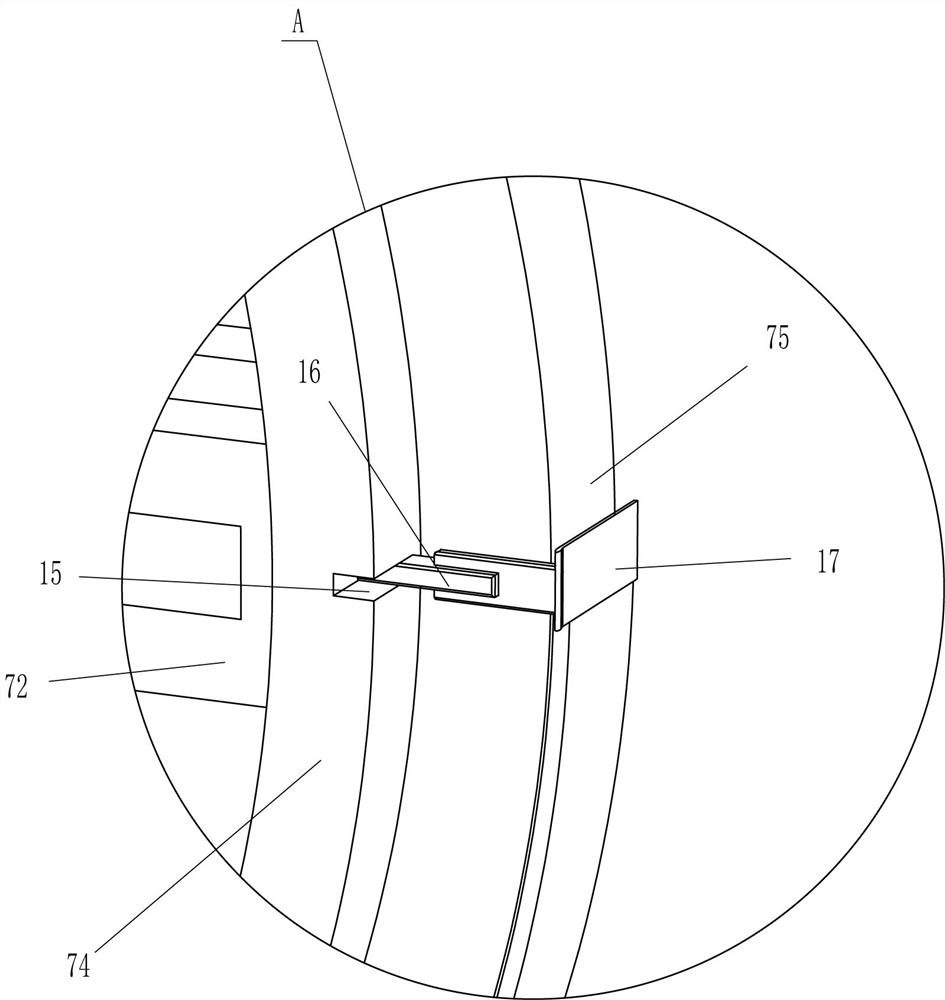

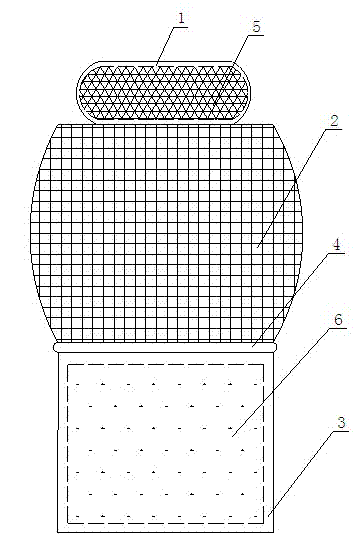

Water-fertilizer storage system for barren mountain planting and cultivation method thereof

PendingCN107646605AMeet the needs necessary for growthImprove survival rateClimate change adaptationWatering devicesEvaporationEngineering

The invention relates to a water-fertilizer storage system for barren mountain planting and a cultivation method thereof. The system includes a pit body which is positioned on a slope body and used for planting saplings, and the pit body is filled with soil; a straw-plaited bag is buried in the pit body and filled with fertilizer, and the surface of the soil in the pit body is covered with a strawbag, and the straw bag is filled with soil and grass seeds; the slope body is provided with a water storage bag positioned on the upslope side of the pit body, and the side, toward the pit body, of the water storage is connected with a water duct which is inserted into the pit body and extends to the place of the roots of the saplings; the water outlet end of the water duct is provided with an infiltrating irrigation head. The system can provide adequate water and nutrients for the saplings to meet the required needs of sapling growth and improve the survival rate of the saplings; the systemcan collect and store rainwater by itself for long-acting irrigation of the saplings, and make full use of natural water resources, and the system has the advantages of saving transportation and laborcosts, saving labor and water, reducing water evaporation, reducing water resource waste, improving the efficiency of artificial afforestation, and remarkably improving economic benefits.

Owner:INST OF ANIMAL HUSBANDRY & VETERINARY FUJIAN ACADEMY OF AGRI SCI

Method for blanching straw plaited articles

InactiveCN107756574AAvoid color reversalReduce dosageWood treatment detailsReed/straw treatmentBreaking strengthAfter treatment

The invention relates to the technical field of straw plaiting processing and treatment, in particular to a method for blanching straw plaited articles. The method comprises the following steps: inoculating lactobacillus acidophilus to activating liquid, performing activating cultivation to obtain activated liquid, soaking the straw plaiting material into the activated liquid to perform treatment,adding 3 to 3.8 percent by weight of hydrogen peroxide into the treatment liquid, mixing uniformly, performing treatment again, completely washing the straw plaiting material after treatment, and drying. According to the method, the use amount of the hydrogen peroxide is reduced, the effect of protecting the straw plaiting raw material is achieved, the breaking strength of the blanched raw material is enhanced, the blanching effect is good, the blanching time is obviously shortened, and drying is conducted after blanching.

Owner:阜南佳利工艺品股份有限公司

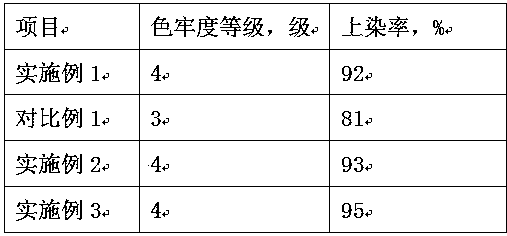

Straw plaited article dyeing method

InactiveCN107584601AIncrease ionization rateHigh viscosityWood treatment detailsReed/straw treatmentVacuum pumpingFiber

The invention relates to the technical field of straw plaited article processing, in particular to a straw plaited article dyeing method. The method comprises treatment steps as follows: a dyeing solution I with certain concentration is prepared from basic dye and water, locust bean gum is added to the dyeing solution I, a dyeing solution II is obtained after high-speed grinding, a to-be-treated straw plaited article raw material is soaked in the dyeing solution II and subjected to vacuum pumping for 12-16 min, then a vacuum pump is closed, the straw plaited article raw material is subjected to pressurizing treatment, the treated straw plaited article raw material is placed in an environment with temperature being 38-40 DEG C and relative humidity being 43%-46% until water content of strawplaited fiber is reduced to 9%-10%, and the straw plaited fiber is sent to a treatment tank again and subjected to vacuum pumping again. On the premise that no dyeing auxiliary is added, higher dyeing rate and dyeing fastness can still be guaranteed.

Owner:阜南佳利工艺品股份有限公司

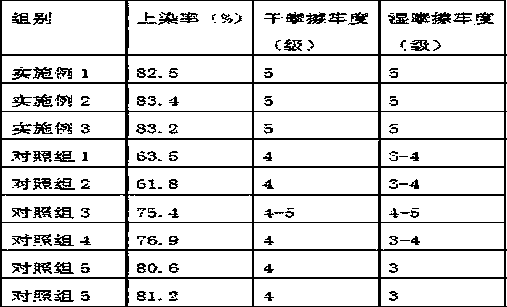

Dyeing method of Eulaliopsis binata for straw braiding

The invention belongs to the technical field of the dyeing of Eulaliopsis binata, and particularly relates to a dyeing method of Eulaliopsis binata for straw braiding. The method comprises the following steps: soaking collected Eulaliopsis binata in a proanthocyanidin aqueous solution with a mass concentration of 1.2 to 1.6%, and irradiating by using a 60Co-gamma-ray irradiation device in the soaking process, wherein the total irradiation dose is 16-20 kGy; dyeing the treated Eulaliopsis binate in a coloring agent; washing after dyeing is completed, then steeping Eulaliopsis binate by using atreating fluid, then radiating for 1-2 minutes by using a UV lamp, soaping and washing to obtain the Eulaliopsis binata for straw braiding. Compared with the prior art, the method has the advantages that the method can promote reaction of dye and fibers to form bonding of covalent bonds, steeping in the treating fluid and radiation of the UV lamp are performed to fix color of the dye, so that thewet fastness is improved, and the overall dyeing performance is improved.

Owner:阜南县宏达工艺品厂

Method for fabricating corn husk handicraft picture

Owner:HARBIN ARTS & CRAFTS

Moisture resistant paint for straw plaited handicrafts

The invention discloses a moisture resistant paint for straw plaited handicrafts. The moisture resistant paint is prepared by stirring the following raw materials, by weight, 60-66 parts of a styrene acrylic emulsion, 10-14 parts of a vinegar emulsion, 10 parts of rosin, 20-30 parts of a plasticizer, 6 parts of methylcyclohexanone, 10 parts of paraffin and 100-120 parts of water. Industrial tests prove that the moisture resistant paint of the invention has the advantages of good moisture resistance, and luster increase and service life prolongation of the straw plaited handicrafts.

Owner:WUJIANG TIANYUAN PLASTIC

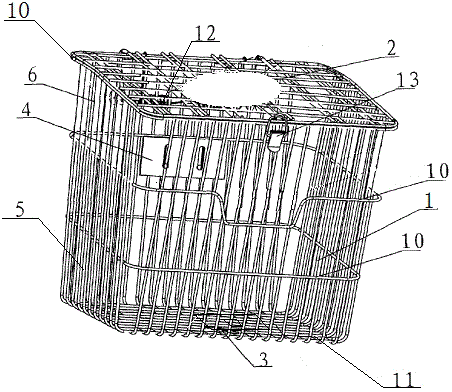

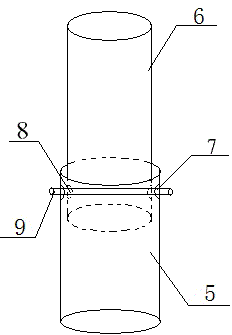

Special vehicle basket for electric vehicle

InactiveCN105314014AIncrease volumeAvoid being caughtCycle containersAgricultural engineeringElectric cars

The invention relates to a special vehicle basket for an electric vehicle. The special vehicle basket comprises a vehicle basket main body, the vehicle basket main body is provided with a basket cover, the bottom of the vehicle basket main body is provided with a bottom fixing block connected with the electric vehicle, and the outer side of the vehicle basket main body is provided with a side fixing block connected with the electric vehicle. The special vehicle basket is characterized in that the vehicle basket main body is composed of the upper end face of the vehicle basket main body and the lower end face of the vehicle basket main body, the lower end face of the vehicle basket main body is formed by weaving a plurality of hollow first metal pipes, the upper end face of the vehicle basket main body is formed by weaving a plurality of hollow second metal pipes, the middle of the basket cover is of a hollow structure, and the bottom of the vehicle basket main body is provided with a straw braid lining. The special vehicle basket is high in volume capacity, attractive in appearance and favorable for pet placing by users.

Owner:JIANGSU PAVEL ELECTRIC TECH CO LTD

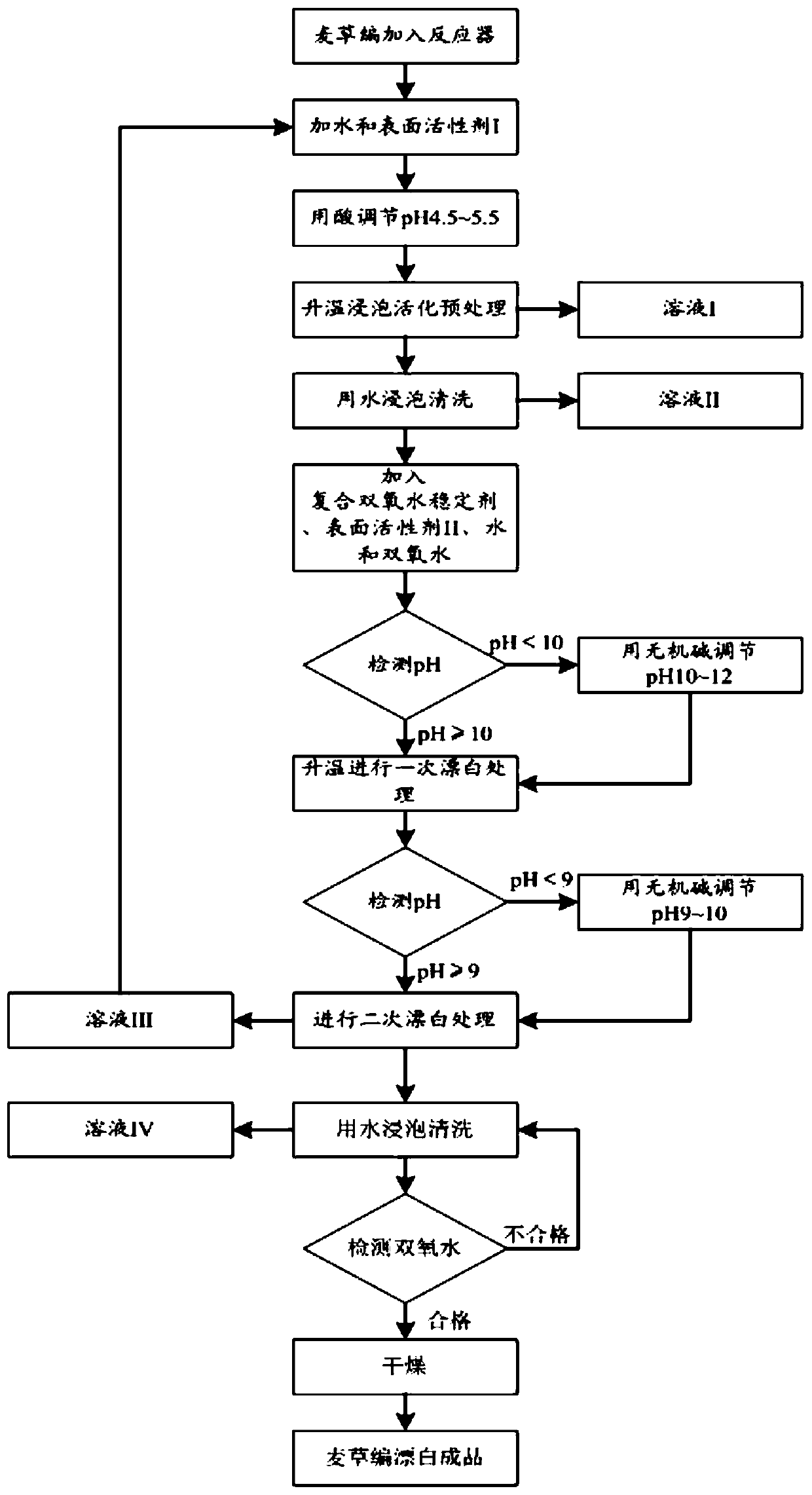

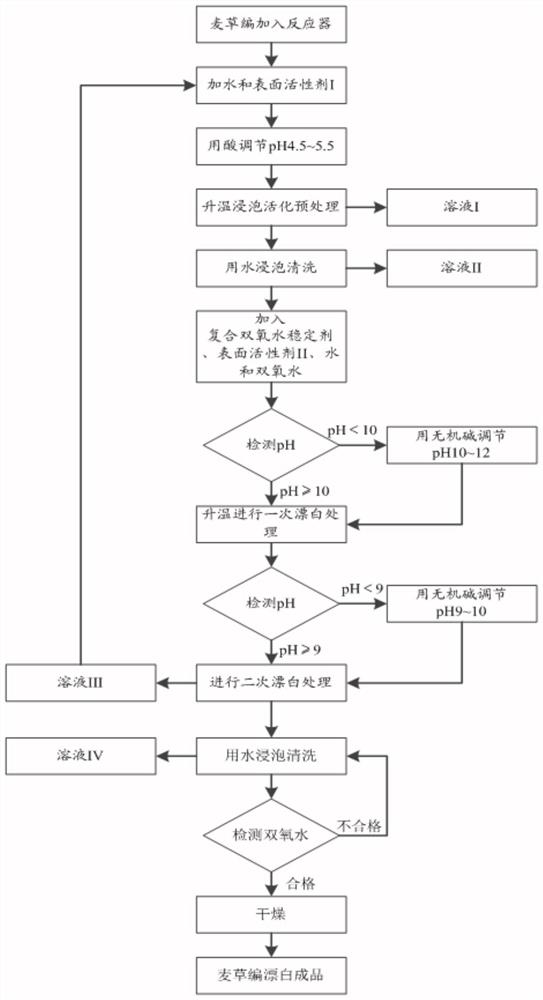

New straw weaving product bleaching treatment method

ActiveCN110936455AReduce pollution factorReduce processing difficultyWood treatment detailsReed/straw treatmentBleachPulp and paper industry

The invention provides a new straw weaving product bleaching treatment method, and belongs to the technical field of straw weaving product bleaching and dyeing processing. The method comprises: S1, carrying out activation pretreatment: adding a straw weaving product into a reactor, adding an aqueous solution of a surfactant I, adjusting the pH value of the solution to 4.5-5.5, heating, soaking, and carrying out activation pretreatment; S2, adding water and carrying out soaking cleaning; S3, carrying out bleaching treatment: soaking the straw weaving product in a bleaching agent solution, adjusting the pH value of the solution to 10-12, heating, carrying out first bleaching treatment, adjusting the pH value of the solution to 9-10 by using an inorganic alkali, and carrying out second bleaching treatment, wherein the bleaching agent solution is prepared from a composite hydrogen peroxide stabilizer, a surfactant II, water and hydrogen peroxide; and S4, carrying out water adding and soaking cleaning multiple times until hydrogen peroxide is detected to be qualified, taking out the straw weaving product, and drying to obtain a bleached finished straw weaving product. According to the invention, the method reduces the sewage treatment cost, is convenient to operate and easy to control, and is suitable for industrial production.

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD

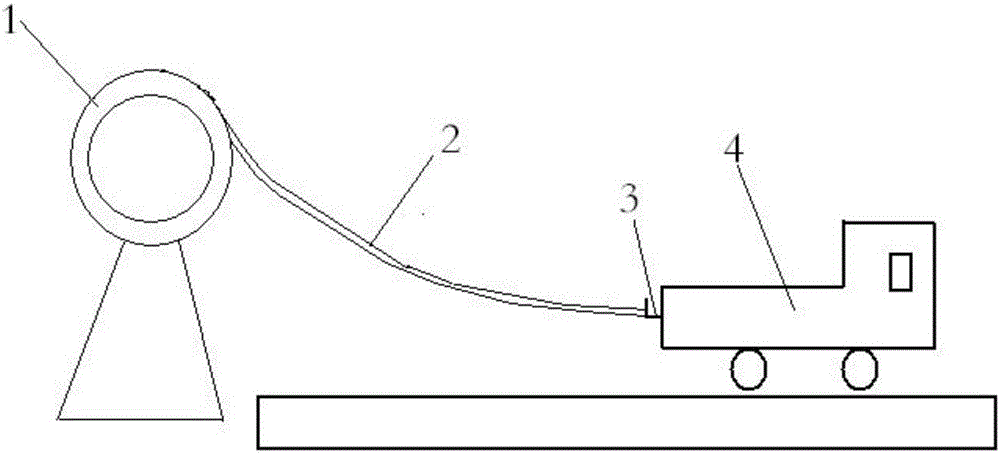

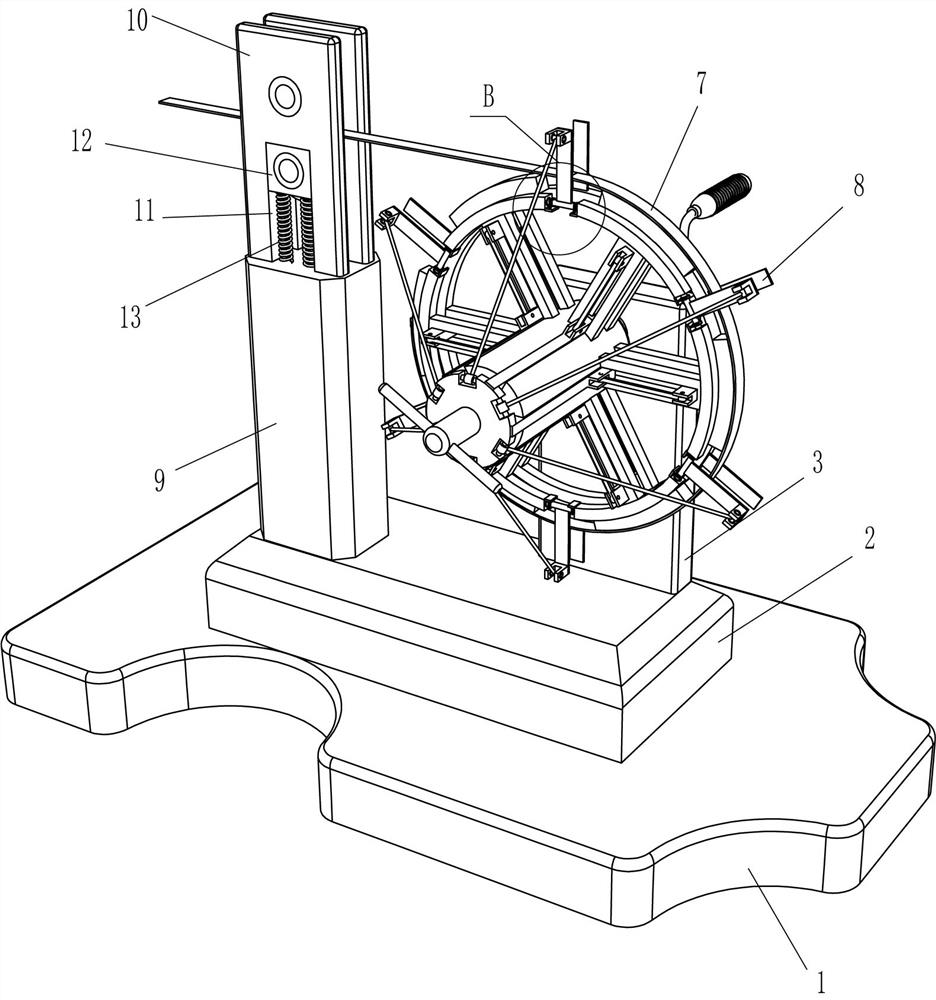

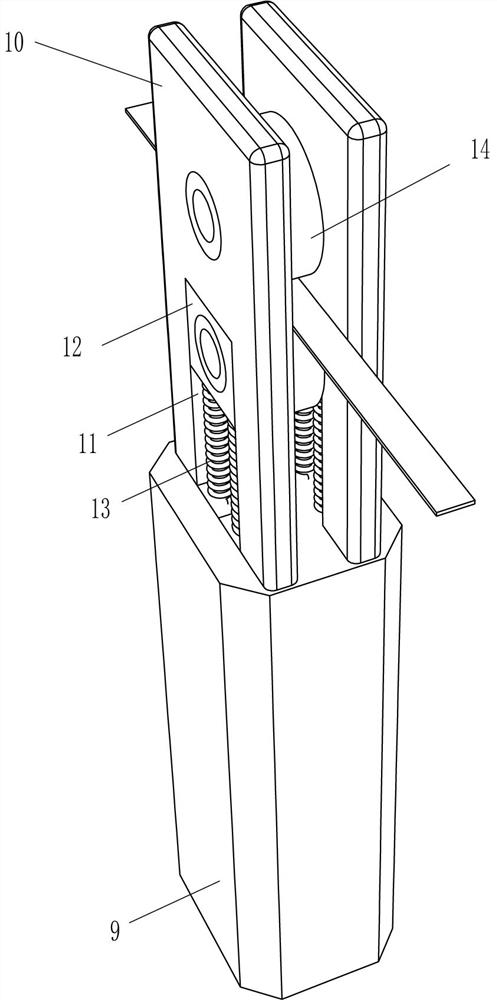

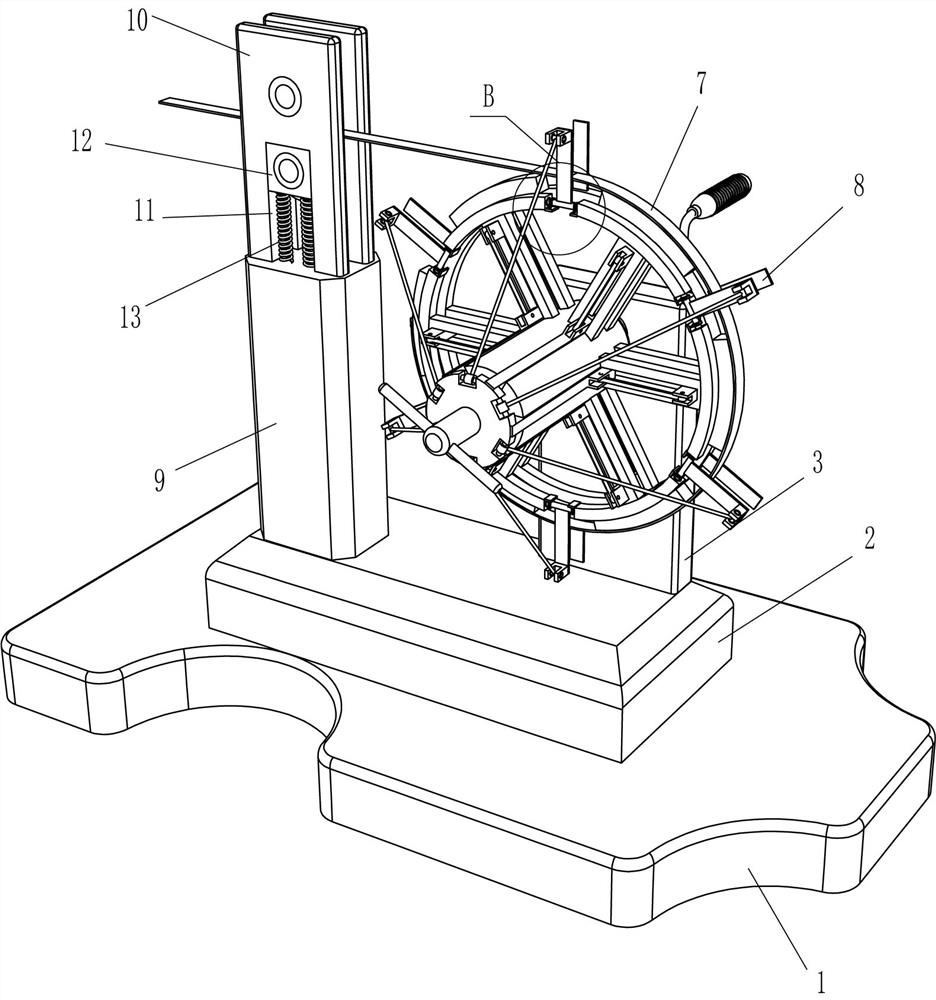

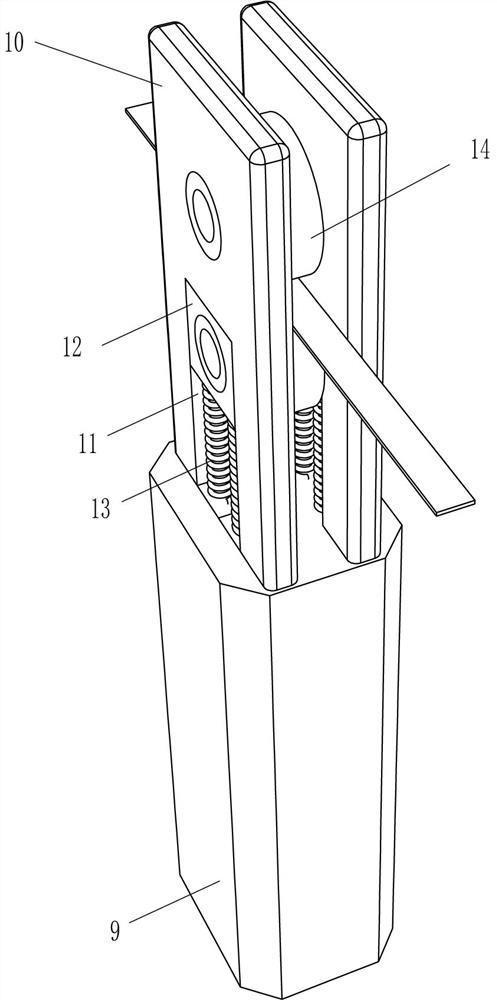

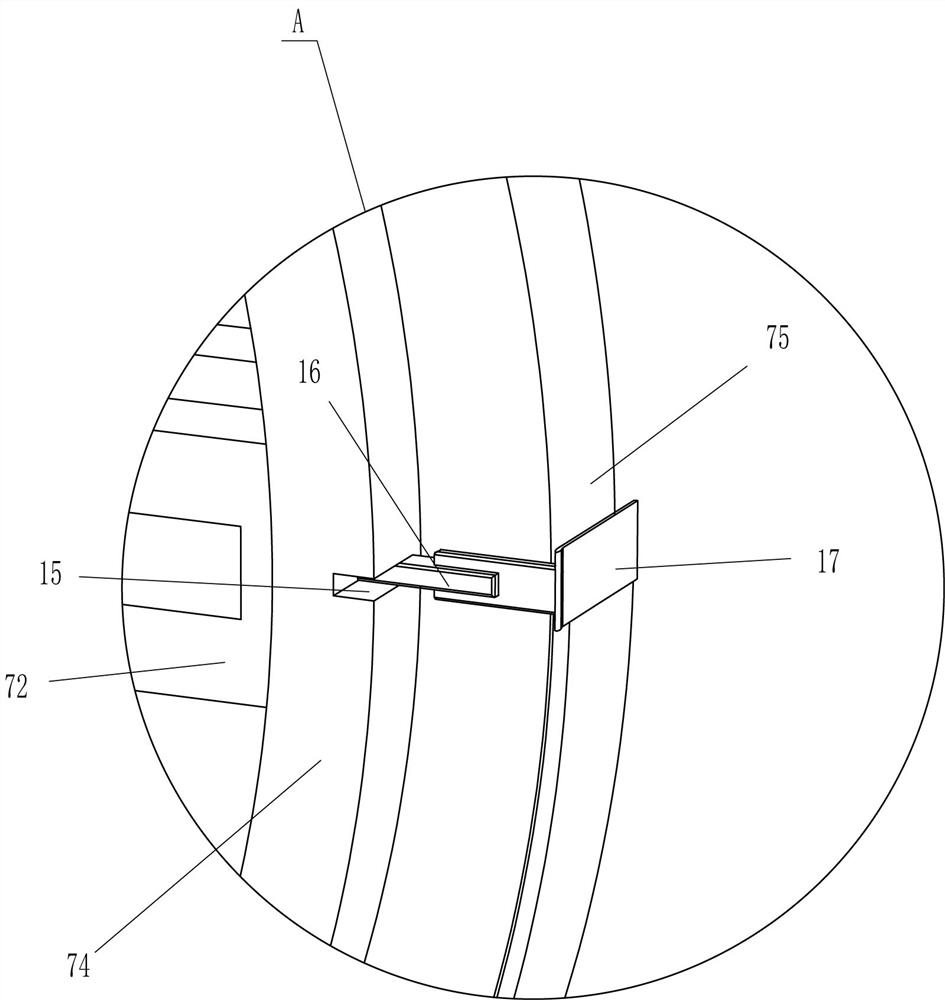

Straw plaited winding device

ActiveCN111689303AWinding levelWinding effectFilament handlingAgricultural engineeringStraw plaiting

The invention relates to a winding device, and particularly relates to a straw plaited winding device. The technical problem is how to design the straw plaited winding device which can be more convenient for people to wind straw ropes, is high in working efficiency and can wind the straw ropes neatly. The straw plaited winding device comprises a base, wherein a supporting block is fixedly connected to the middle of one side of the base; a vertical plate is fixedly connected to the edge of one side of the supporting block; a bearing seat is installed on the portion, away from the supporting block, of the vertical plate in an embedded mode; and a rotating shaft is rotationally connected into the bearing seat in a penetrating mode. According to the straw plaited winding device, the straw ropes are wound around all top blocks by a circle, then a rocker is pulled to rotate forwards, so that the top blocks rotate forwards to wind the straw ropes; after the straw ropes are wound, a handle ispulled to move forwards, so that the top blocks move inwards to loosen the straw ropes; and then the wound straw ropes are taken down, and the straw ropes do not need to be pulled by people to be wound on a tool for winding, so that the winding device is more convenient, and the working efficiency is improved.

Owner:邓志香

Processing process for straw-willow-knitted artware

InactiveCN104960369AImprove yieldQuality improvementSpecial ornamental structuresCane mechanical workingYarnEngineering

The invention discloses a processing process for straw-willow-knitted artware. The processing process comprises the following steps: 1) spinning a warp rope; 2) suspending the warp rope; 3) knitting sides: starting from one corner of a bottom, lapping corn bran to be 1cm wide, shearing the head of the corn bran, pressing the head-sheared corn bran under the warp rope to start knitting, continuously connecting and lifting wefts to knit from bottom to top ring by ring by virtue of warps according to the length of the corn bran, changing a craft method or changing various colors of corn bran in middle, thereby changing textures to reach desired effect; 4) knitting edges: knitting wefts according to a set dimension and bringing the knifed wefts together, breaking the warp rope on the bottom of a basket, knitting and twisting the edges of the basket in a split mode, and pressing the rest of warp rope head on the inner wall of the basket mouth in the form of a string; 5) fixing a handle: fixing a basket handle strap on a basket body; 6) decorating: after sizing a straw-knitted product, combining a pattern by nylon straw, corn bran, flax, wool yarns and a figured cloth material as accessory decoration; and 7) preparing an artware finished product and warehousing the artware finished product. The straw-willow-knitted artware (a straw basket) processed by the process method is high in yield and good in quality, so that benefits are increased for manufacturers.

Owner:柳州启智信息科技有限公司

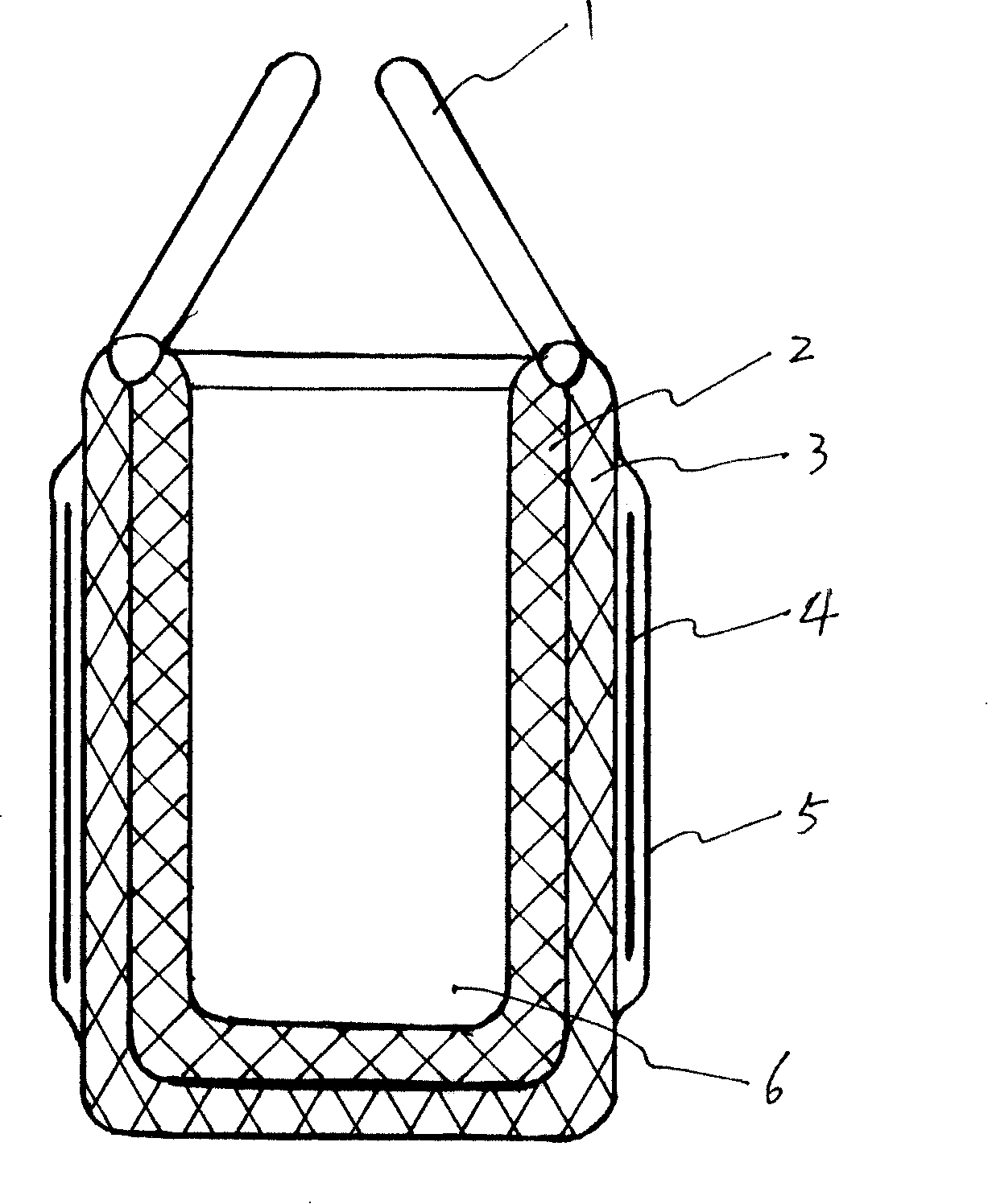

Straw plaited handicraft article case

The invention discloses a luggage, belonging to a straw-weaved artwork; the invention is provided with a body and a hand belt. The inner layer of the body is a reed-weaved frame, the outer layer is a calamus-weaved jacket and a sealing and modeling handicraft picture is embedded at the outer side of the calamus-weaved jacket. The invention not only is characterized by environmental protection, fashion, simplicity and low cost, but also improves the traditional straw-weaved artwork to a higher level. The invention is suitable for carrying by the masses when travelling and being taken as an artwork to be collected.

Owner:侯庆佩

Improved heat insulation type automotive seat cushion

InactiveCN102897067ANot easy to absorb heatGood heat insulationBack restsThigh restsPhysical healthEngineering

The invention relates to an improved heat insulation type automotive seat cushion, comprising a headrest, a backrest and a main seat cushion body. The improved heat insulation type automotive seat cushion is characterized in that the headrest is connected with the backrest, the backrest is connected with the main seat cushion body through a connecting device, health care material is arranged in the headrest, the backrest is fabricated by straw plaited articles, the main seat cushion body is fabricated by bamboo mat, and filler is arranged in the main seat cushion body. The improved heat insulation type automotive seat cushion has the advantages that the backrest of the automotive seat cushion is fabricated by straw plaited articles, the straw plaited articles do not absorb heat easily and have good heat insulation effect, the main seat cushion body is fabricated by the bamboo mat, a user feels cool when sitting on the main seat cushion body, the health care material arranged in the headrest also has the efficacy of health care, so that a driver can keep clear mind when driving a vehicle, and the improved heat insulation type automotive seat cushion is beneficial to physical health.

Owner:张向萍

Mold-proof dye-fixing liquid for wheat straw for straw plaiting

InactiveCN108972790AImprove performanceImprove antioxidant capacityReed/straw treatmentWood impregnation detailsEpoxy1-Naphthaleneacetic acid

The invention belongs to the technical field of processing of straw and willow plaited products, and particularly relates to mold-proof dye-fixing liquid for wheat straw for straw plaiting. The mold-proof dye-fixing liquid is prepared from the following raw materials in parts by weight: 12-16 parts of epoxy modified styrene-acrylic emulsions, 3-5 parts of polyethyleneimine, 1-3 parts of Alpha-substituted benzyl isocyanate, 6-10 parts of hydroxyapatite, 1-3 parts of 2,2',4,5,5'-pentachlorobiphenyl, 2-6 parts of 7-methoxy-1-naphthaleneacetic acid, 1-3 parts of calcium chloride, 1-2 parts of emulsifiers and 3-6 parts of dye-fixing agents. Compared with the prior art, the mold-proof dye-fixing liquid has the advantages that the mold-proof dye-fixing liquid with stable performance is obtained by reasonably blending raw materials with different functions, a dense protective layer can be formed on the surface of the straw after treatment, the straw has high anti-oxidation and anti-fading capability, and the commercial property is improved.

Owner:安徽嘉美工艺品有限公司

A straw winding device

ActiveCN111689303BEasy to rewindImprove work efficiencyFilament handlingAgricultural engineeringStraw plaiting

The invention relates to a winding device, in particular to a straw winding device. The technical problem is how to design a straw braided winding device that can be more convenient for people to wind up the straw rope, has high work efficiency, and the straw rope that is rolled up is also neat. A straw weaving and rolling device, including a base, a support block is fixedly connected to the middle part of one side of the base, a vertical plate is fixedly connected to the edge of one side of the support block, and the bearing seat is embedded and installed on the side far away from the support block. One part of the vertical plate, the shaft is rotatably connected in the bearing seat. In the present invention, by winding the straw rope around all the top blocks, and then pulling the rocker to rotate forward, the top block can be rotated forward to wind up the straw rope. After the straw rope is rolled up, pull the handle to move forward to make the top block Move inward to loosen the straw rope, and then take off the rolled straw rope, so that people don't need to pull the straw rope to wrap it around the tool for winding, which is more convenient and improves work efficiency.

Owner:邓志香

A kind of mildew-proof and color-protecting method of corn husk

ActiveCN107186847BLow water absorptionMaintain colorWood treatment detailsReed/straw treatmentAgricultural engineeringMildew

Owner:阜南县猛发工艺品有限公司

Braided fabric and its production process

This invention relates to a weaving cloth and its production method. This invention is made of the paper weaving rope, the method is that firstly making the paper weaving rope, then weaving it into cloth by weaving machine; the paper weaving rope production method as follows: using wooden slurry board as material, after breaking up, smearing slurry, adding wet strength agent which takes up 25% of the wooden board dry weight, stirring, then using paper pulp to manufacture paper, wherein when making paper, adding some dispersing agent according to the water level, then wrapping again, cutting, drenching and twisting.

Owner:张桂荣

Preparation method for water-soaking-resistant grass plaited article of everyday use

InactiveCN108724375AShort stayImprove mechanical propertiesWood treatment detailsCane mechanical workingEmulsionStraw plaiting

The invention discloses a preparation method for a water-soaking-resistant grass plaited article of everyday use. The preparation method comprises the following steps: (1) removing roots of harvestedfresh grass, putting the grass in a soaking liquid to be fully soaked, and taking out the grass to be air-dried naturally for 8-10 days; (2) plaiting three pieces of grass to a pigtail, and then coating the surface of the pigtail with a polymerized emulsion uniformly; and (3) putting the grass pigtail coated with the polymerized emulsion in an oven, drying the grass pigtail and knitting and forming the grass plaited article of everyday use. The preparation method for the water-soaking-resistant grass plaited article of everyday use disclosed by the invention is simple to operate and low in cost; mechanical properties of the grass plaited article can be enhanced effectively, and the water-soaking-resistant ability of the grass plaited article can be also improved effectively; and the service life of the grass plaited article is prolonged greatly.

Owner:ANHUI DAIJIA CRAFT CO LTD

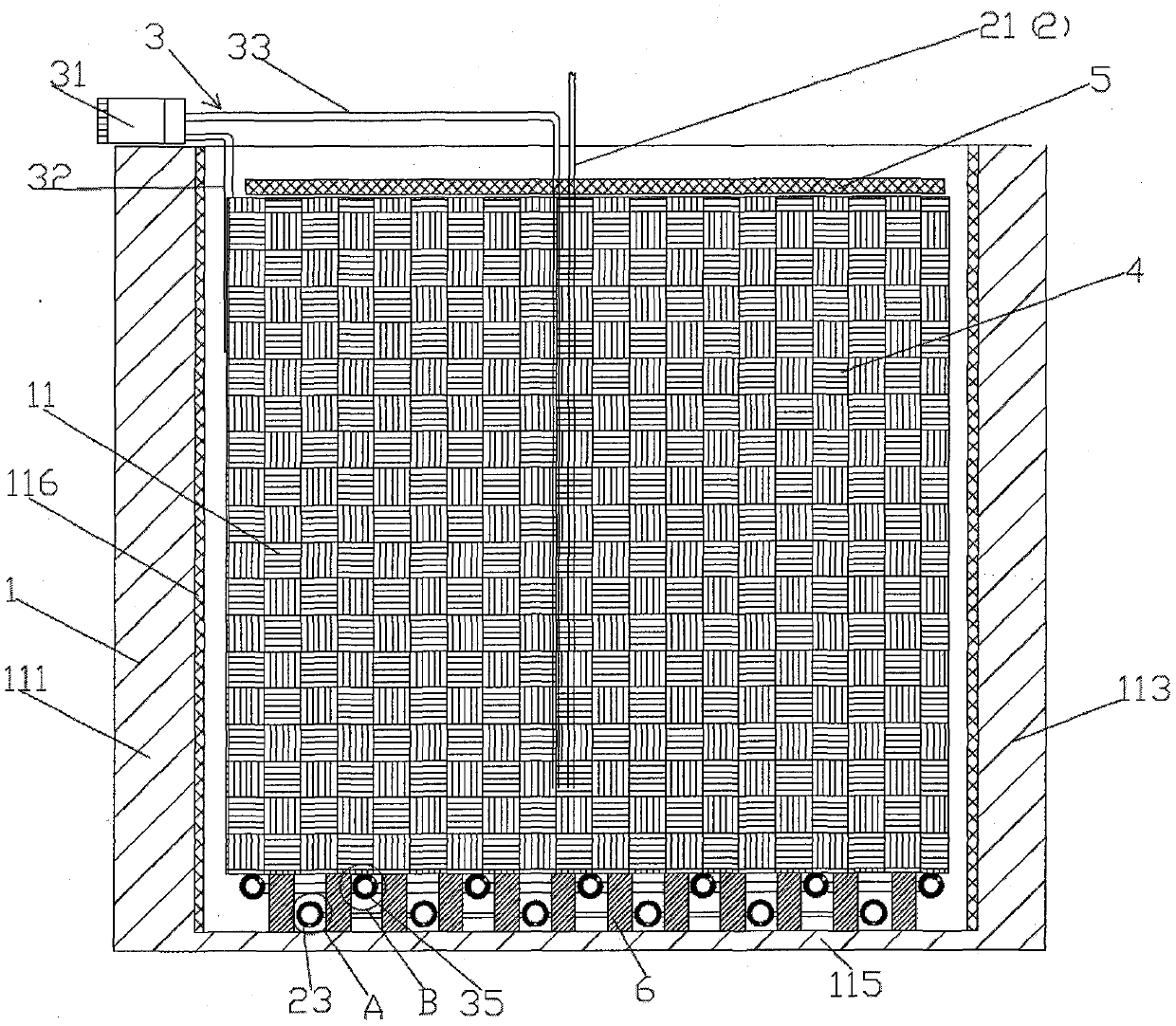

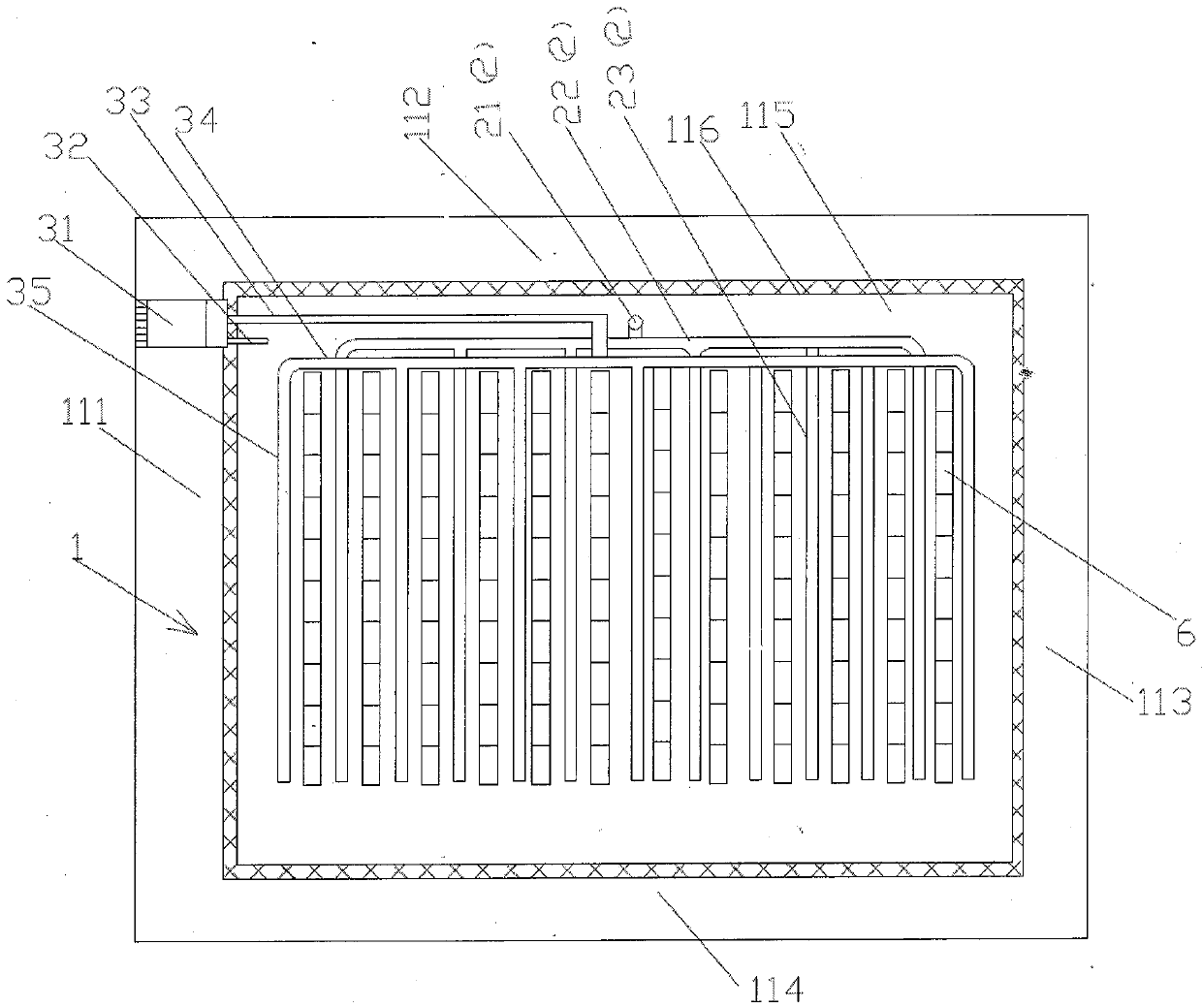

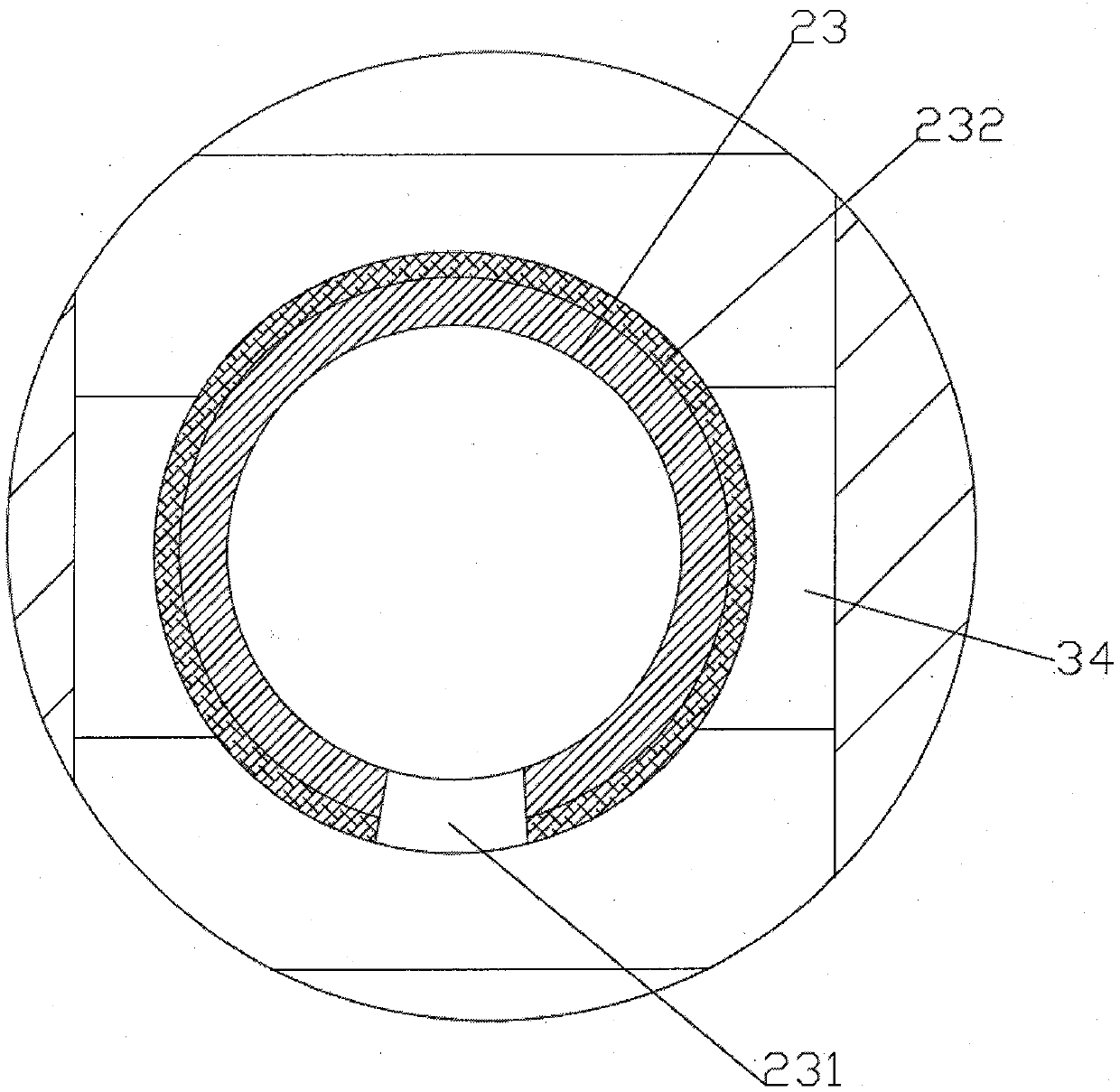

Device for straw plaited article bleaching and dyeing

PendingCN111283839AUniform responseUniform temperatureWood treatment detailsReed/straw treatmentPulp and paper industryStraw plaiting

The invention relates to the field of straw plaited article production, in particular to a device for straw plaited article bleaching and dyeing. The device comprises a concrete pool body, a steam pipe assembly and a circulating liquid assembly, and the steam pipe assembly and the circulating liquid assembly are arranged in the concrete pool body. The steam pipe assembly comprises a steam main pipe, a steam side pipe and steam branch pipes. The steam main pipe is vertically arranged downwards towards the bottom of the concrete pool body, the bottom of the steam main pipe is communicated with the steam side pipe, the steam side pipe is transversely arranged at the bottom of the concrete pool body, and the steam branch pipes are evenly arranged on one side of the steam side pipe and are perpendicular to and communicated with the steam side pipe. The temperature in a reaction tank is more uniform, liquid medicine is in uniform contact with straw plaited articles, the bleached and dyed straw plaited articles are not damaged, the colors of the bleached and dyed straw plaited articles are more attractive, the reaction time is shortened, the energy consumption is lower, the steam pipe assembly and the circulating liquid assembly are arranged in the reaction tank, the solution temperature is increased through the steam pipe assembly, and the reaction of the reaction liquid is more uniform.

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD

Straw plaited article raw material treating fluid

InactiveCN107877644AExtended service lifeFully killWood treatment detailsReed/straw treatmentRubus parvifoliusBiotechnology

The invention provides straw plaited article raw material treating fluid. The straw plaited article raw material treating fluid comprises the following components of, by weight, 20-30 parts of perillaleaves, 20-30 parts of pepper leaves, 20-30 parts of portulaca oleracea, 10-15 parts of cortex moutan, 10-15 parts of corydalis bungeana, 10-15 parts of rubus parvifolius Linn., 8-10 parts of polygonum aviculare, and 15-20 parts of pomegranate bark. According to the straw plaited article raw material treating fluid, the raw material straw is treated before being plaited, the multiple kinds of natural Chinese herbal medicines with the sterilization and deinsectization functions are reasonably prepared, parasites and bacteria in the straw can be sufficiently killed, the insect, moth and corrosion prevention effects of a straw plaited article product are improved, mold is not easy to grow in a humid environment, and the service life of the straw plaited article product is greatly prolonged.

Owner:宾阳县东弘五金工艺品有限公司

A New Bleaching Method for Straw

ActiveCN110936455BReduce pollution factorReduce processing difficultyWood treatment detailsReed/straw treatmentActive agentBleach

The invention provides a new method for bleaching straw weaving, which belongs to the technical field of straw weaving bleaching and dyeing, and comprises the following steps: S1, activation pretreatment: adding straw weaving to a reactor, then adding an aqueous solution of surfactant I, and adjusting the pH of the solution to 4.5- 5.5, soaking activation pretreatment after heating up; S2, soaking and cleaning with water; S3, bleaching treatment: soak the straw weaving in the bleach solution, adjust the pH of the solution to 10-12, and perform a bleaching treatment after heating up; adjust the pH of the solution to 9 with inorganic alkali ~10, carry out secondary bleaching treatment; wherein, the bleaching agent solution is prepared from a composite hydrogen peroxide stabilizer, surfactant II, water and hydrogen peroxide; S4, add water to soak and wash several times until the hydrogen peroxide is detected to be qualified, take out The straw is dried to obtain the bleached straw. The method reduces the sewage treatment cost, is convenient to operate and easy to control, and is suitable for industrial production.

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD

Straw plaited product brushing dyeing method

InactiveCN108994998AHigh color fastnessStrong color fastnessImpregnation spraying apparatusWood treatment detailsMass ratioOxygen

The invention discloses a straw plaited product brushing dyeing method which comprises the following operation steps of (1) uniformly mixing a self-crosslinking polyurethane modified emulsion, ethyl 4-bromophenylacetate, 1,2-cyclohexanediaminetetraacetic acid, 3-oxooctanoates with 1-sodium heptanesulfonate to prepare a component A; (2) uniformly mixing deionized water, a defoamer, a pigment, a pigment dispersing agent, nanometer AZO with ammonium pentaborate to prepare a component B; (3) uniformly mixing the component A and the component B according to a mass ratio of (8-12) to 1 to prepare astraw plaited coating; and (4) after spraying the surface of a straw plaited product formed in weaving manner with an accelerant, brushing the surface with the straw plaited coating, putting the strawplaited product in an oven, and performing drying treatment to prepare a finished product. The straw plaited product brushing dyeing method provided by the invention is simple in technology and shortin flow and saves the time and the labor; and the prepared straw plaited product is high in colour fastness, is difficult in generating the decoloration phenomenon and is bright in colour and remarkable in decorative effect at the same time.

Owner:阜南佳利工艺品股份有限公司

Method for improving color fastness of straw plaited products

InactiveCN108908579AHigh color fastnessHigh surface energyWood treatment detailsReed/straw treatmentStraw plaitingMoisture

The invention discloses a method for improving the color fastness of straw plaited products. The method comprises the following steps: (1) drying braided straw plaited products until the moisture content is 8 to 12 percent and spraying a modification solution on the surfaces of the braided straw plaited products; then carrying out natural airing treatment; (2) adding the straw plaited products subjected to the airing treatment into a dyeing solution; then raising the temperature to 85 to 95 DEG C; after carrying out heat preservation treatment for 35 to 40min, taking out the straw plaited products; washing with water and drying to obtain finished products. The method for improving the color fastness of the straw plaited products, provided by the invention, is simple to operate, low in costand green and environmentally friendly; the prepared straw plaited product have high color fastness, do not easily have a discoloring phenomenon and have excellent quality.

Owner:ANHUI HUAYU CRAFTS GRP

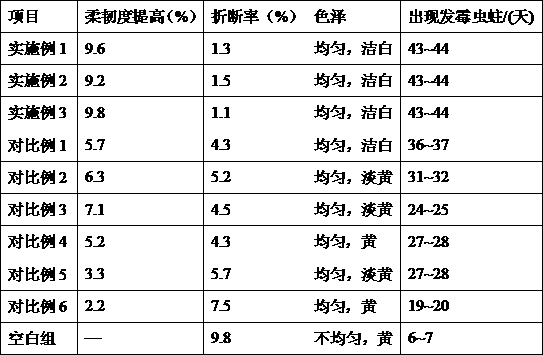

Mouldproof and color protection method for corn bran

ActiveCN107186847ALow water absorptionMaintain colorWood treatment detailsReed/straw treatmentBranFermentation

The invention mainly relates to the technical field of straw-weaved product processing and discloses a mouldproof and color protection method for corn bran. The method comprises the steps of primary drying, moistening, fermentation, secondary drying, trimming and packaging; the method is simple, operating is convenient, batch treatment can be conducted, the corn bran is kept to be pure white and soft, treatment marks are avoided, the water absorbing capacity is lowered, the corn bran can keep not mouldy for 43-44 days when being placed into the environment where the temperature is 35 DEG C and the humidity is 85%, the transporting and storing cost is saved, and the service life of corn bran weaving products is obviously prolonged; and the corn bran is placed into a drying room for low-temperature weak-light drying firstly after being harvested, the color and softness of the corn bran are kept, the situations that in the storing process, the corn bran goes mouldy, and the color of the corn bran is changed are avoided, and the use value of the corn bran is kept.

Owner:阜南县猛发工艺品有限公司

A manufacturing method of a health-care straw woven futon cushion

InactiveCN104873019BEasy to makeEasy to manufactureSenses disorderNervous disorderMedicineStraw plaiting

The invention belongs to the technical field of medical and health appliances, and in particular relates to a method for making a health-care straw woven futon cushion. The manufacturing method of the health-care straw woven futon cushion comprises the following steps: selecting raw materials, making traditional Chinese medicine, and preparing the futon cushion. The beneficial effects are: the manufacturing method of the health-care straw woven futon cushion is simple and convenient, has the functions of health care and disease treatment, and guarantees people's health.

Owner:刘中孝

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com