A kind of mildew-proof and color-protecting method of corn husk

A technology of corn husk and color protection, applied in reed/straw treatment, low temperature treatment, wood treatment details, etc., can solve the problems of affecting the use value of woven products, increasing transportation and storage costs, and adverse effects on human health, so as to prevent and control mold Effects of discoloration, avoiding mold and discoloration, and saving transportation and storage costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

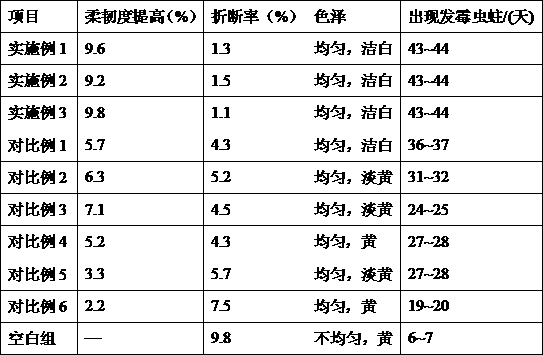

Examples

Embodiment 1

[0021] A method for preventing mold and coloring of corn husks includes the following steps:

[0022] (1) One-time drying: Choose corn husks with soft texture, uniform color and no wormholes, and place them in a drying room to dry to a moisture content of 10-12%, to maintain the color and softness of the corn husks, and avoid causing problems during storage. Moldy and discoloration, to maintain the use value of corn husks, the corn husks must be dried once;

[0023] (2) Wetting: soak the dried corn husks in a wetting solution, soak it at 7°C for 20 hours, and perform low-temperature long-term soaking. The wetting solution contains a variety of ingredients, such as sodium bicarbonate, glutathione and activated carbon. It can maintain the color of corn husk. Aloe extract, Melaleuca extract and methimazole are safe and healthy, increase the softness and antibacterial function of corn husk, prevent mold and discoloration, increase the application method of methimazole, remove and drain...

Embodiment 2

[0036] A method for preventing mold and coloring of corn husks includes the following steps:

[0037] (1) One-time drying: Choose corn husks with soft texture, uniform color and no wormholes, and place them in a drying room to dry to a moisture content of 10-12%, to maintain the color and softness of the corn husks, and avoid causing problems during storage. Moldy and discoloration, to maintain the use value of corn husks, the corn husks must be dried once;

[0038] (2) Wetting: Soak the dried corn husks in a wetting solution, soak at 8°C for 22 hours, and then perform low-temperature long-term soaking. The wetting solution contains a variety of ingredients, such as sodium bicarbonate, glutathione and activated carbon. It can maintain the color of corn husk. Aloe extract, Melaleuca extract and methimazole are safe and healthy, increase the softness and antibacterial function of corn husk, prevent mold and discoloration, increase the application method of methimazole, remove and dra...

Embodiment 3

[0051] A method for preventing mold and coloring of corn husks includes the following steps:

[0052] (1) One-time drying: Choose corn husks with soft texture, uniform color and no wormholes, and place them in a drying room to dry to a moisture content of 10-12%, to maintain the color and softness of the corn husks, and avoid causing problems during storage. Moldy and discoloration, to maintain the use value of corn husks, the corn husks must be dried once;

[0053] (2) Wetting: soak the dried corn husks in a wetting solution, soak it at 9°C for 24 hours, and perform low-temperature long-term soaking. The wetting solution contains a variety of ingredients, such as sodium bicarbonate, glutathione and activated carbon. It can maintain the color of corn husk. Aloe extract, Melaleuca extract and methimazole are safe and healthy, increase the softness and antibacterial function of corn husk, prevent mold and discoloration, increase the application method of methimazole, remove and drain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com