Patents

Literature

64results about How to "Winding level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

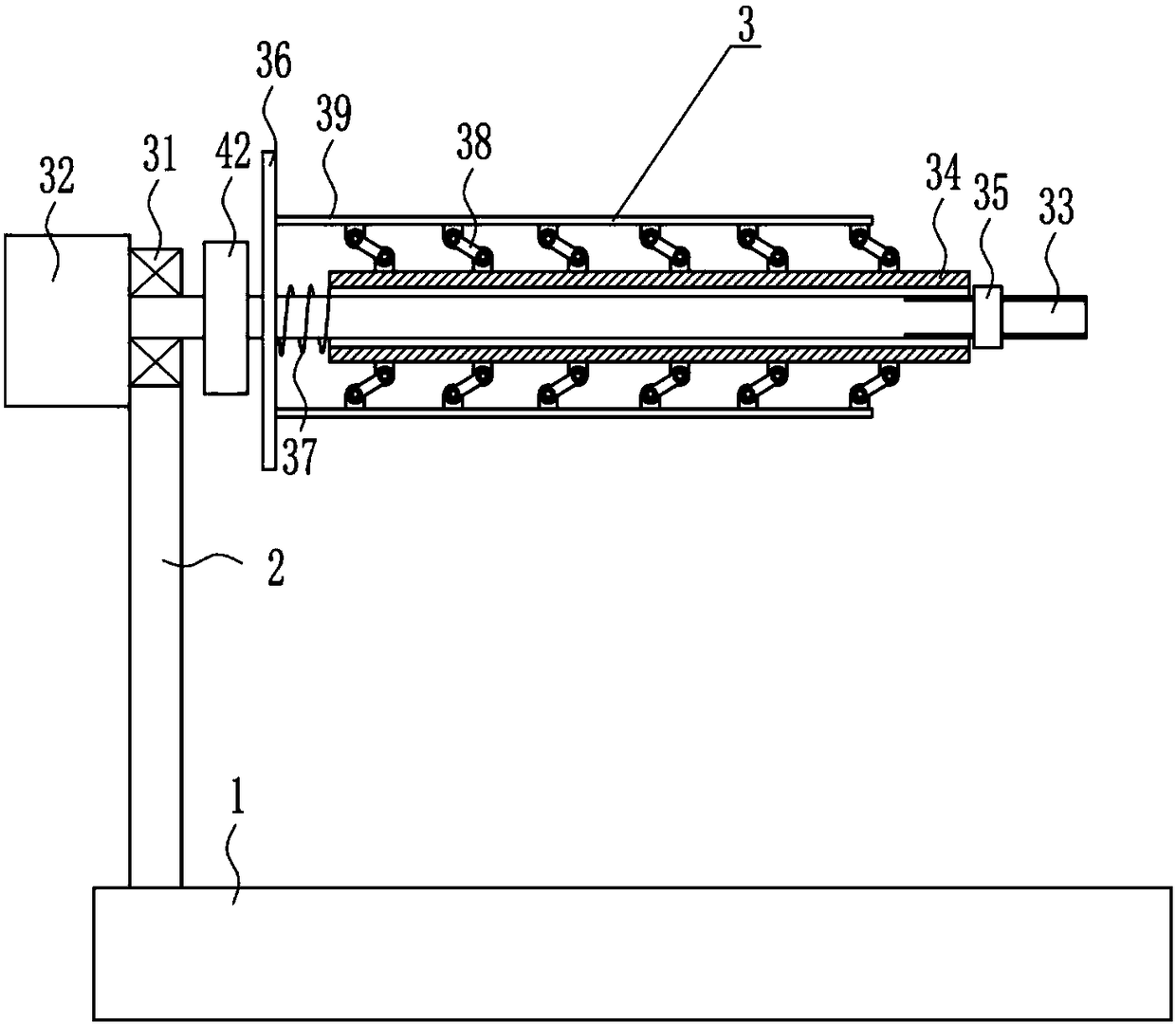

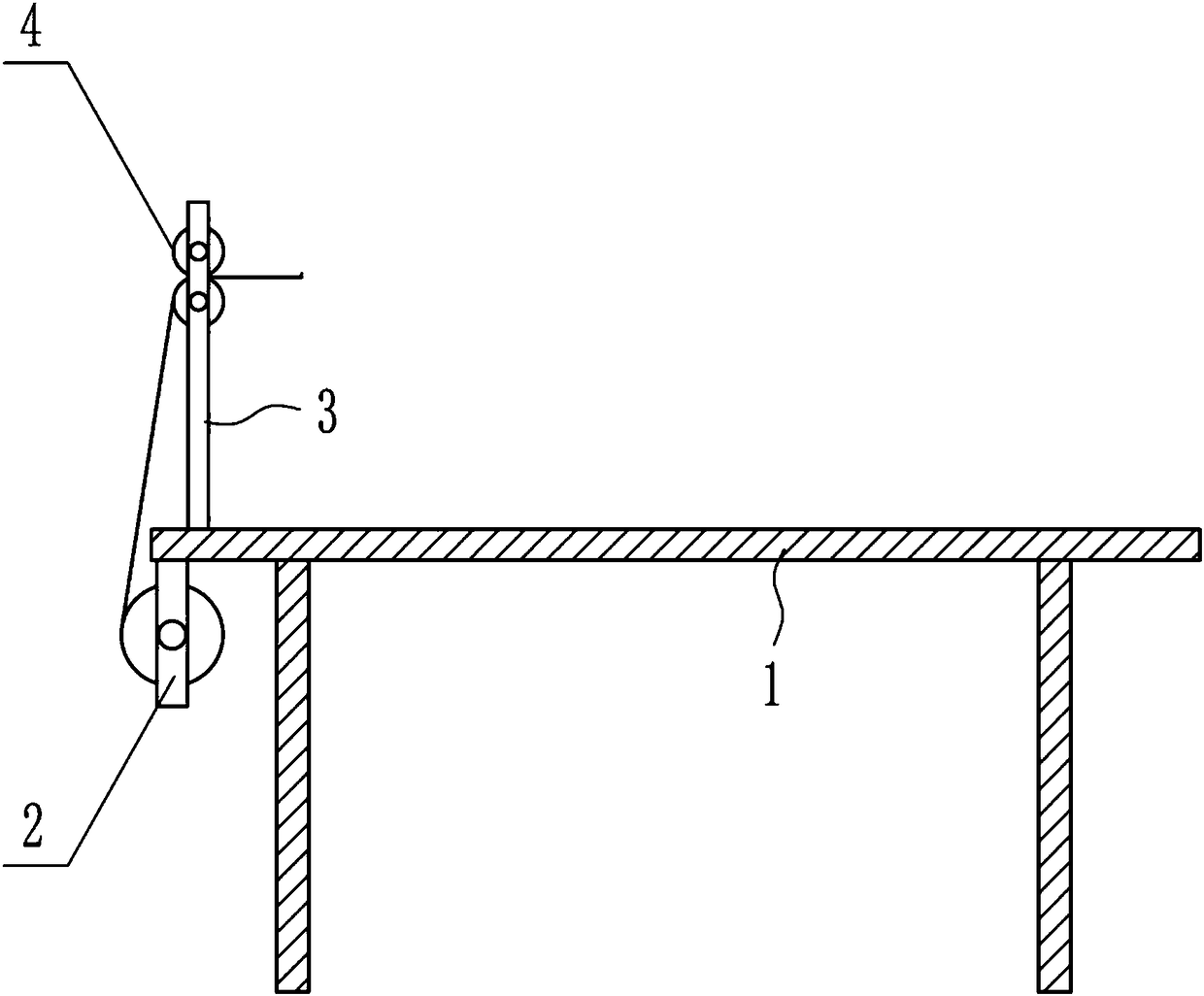

Non-woven lifting dye device for garment production

InactiveCN106835555AEasy to dyeEasy to rewindTextile treatment machine arrangementsTextile treatment carriersNonwoven fabricMechanical engineering

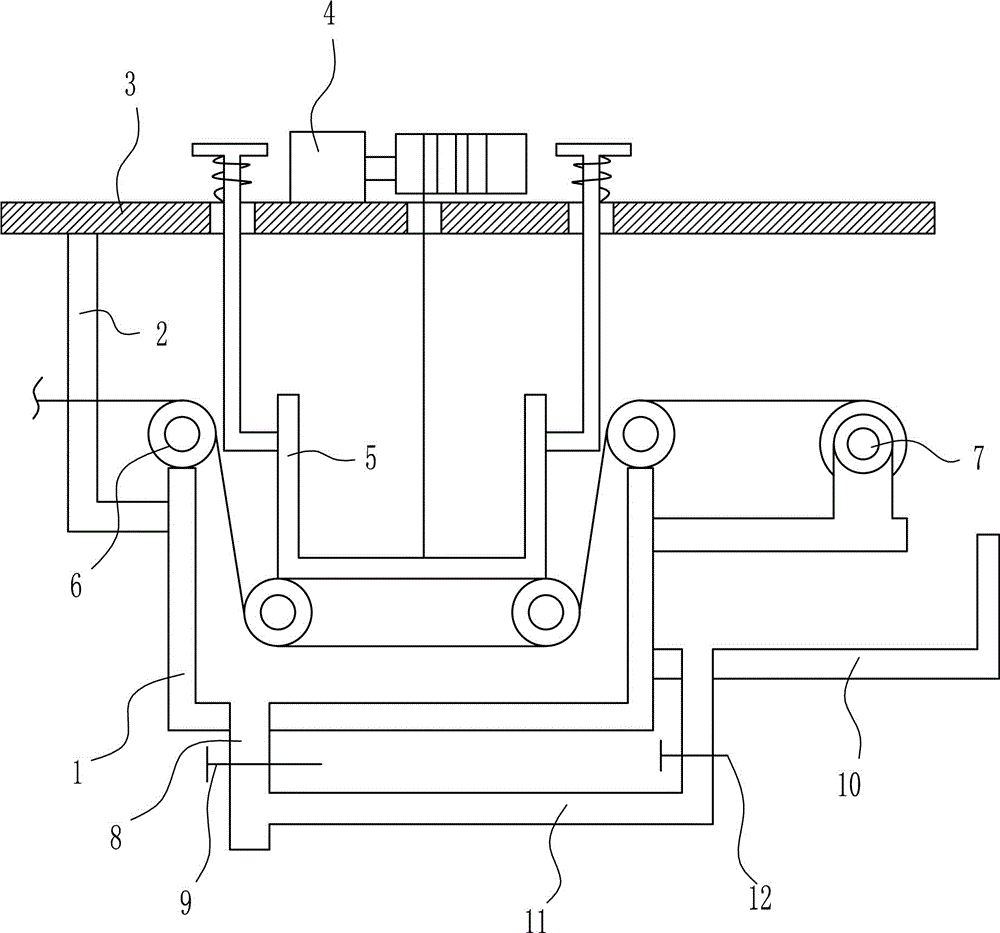

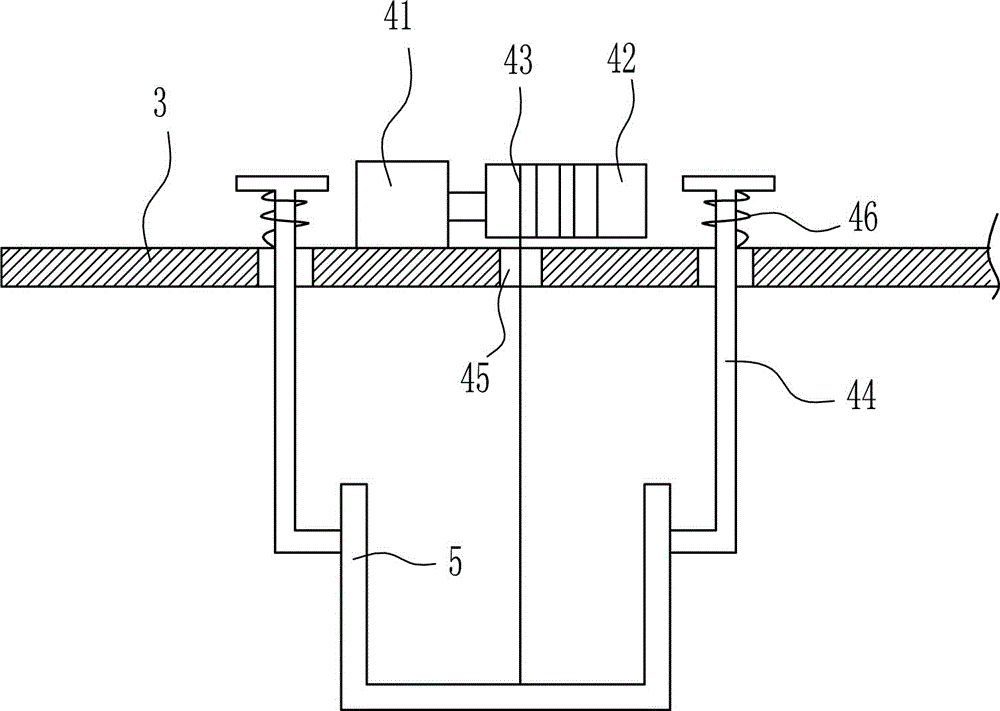

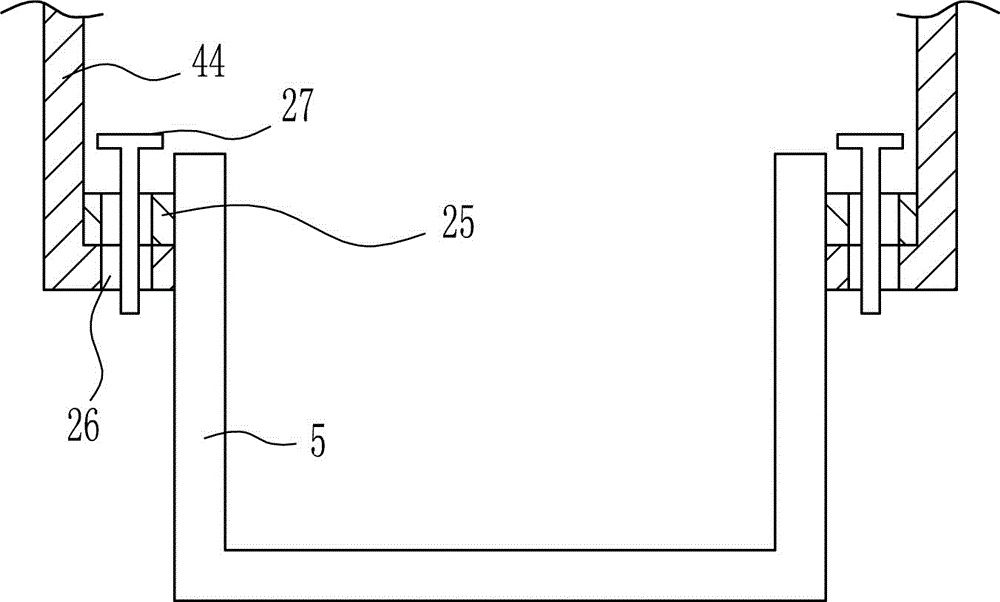

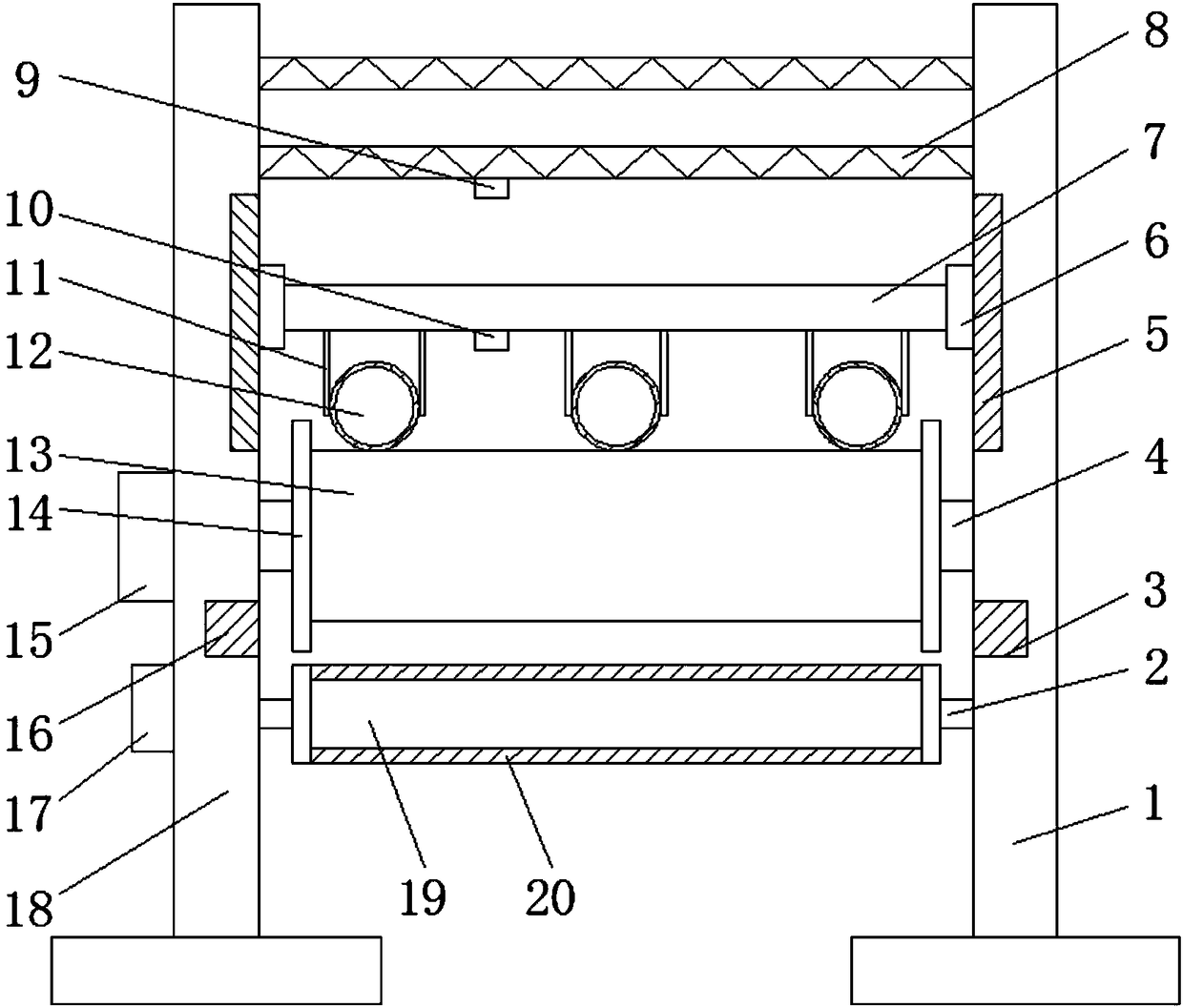

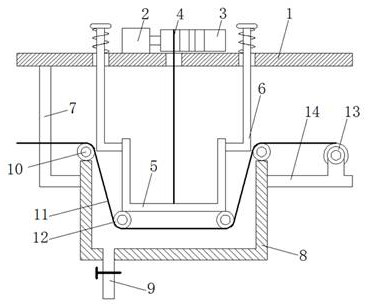

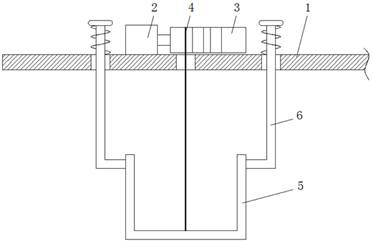

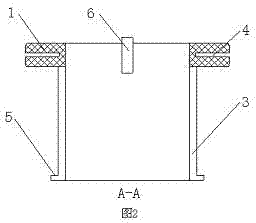

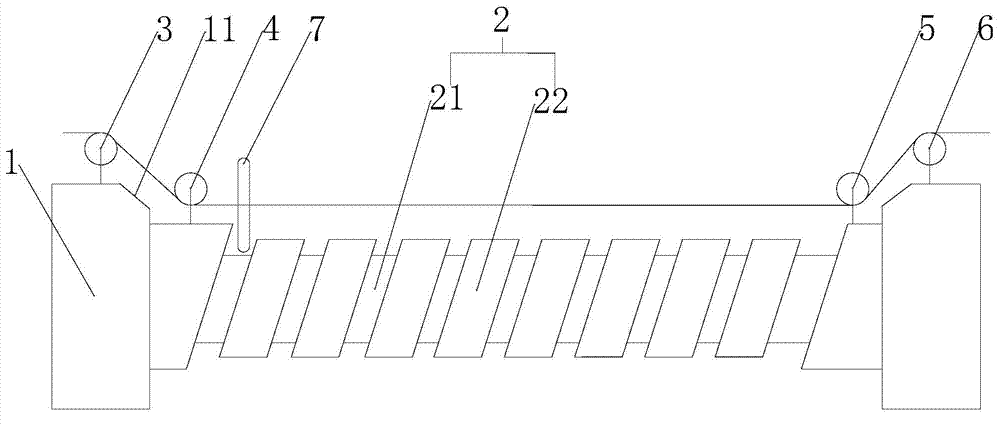

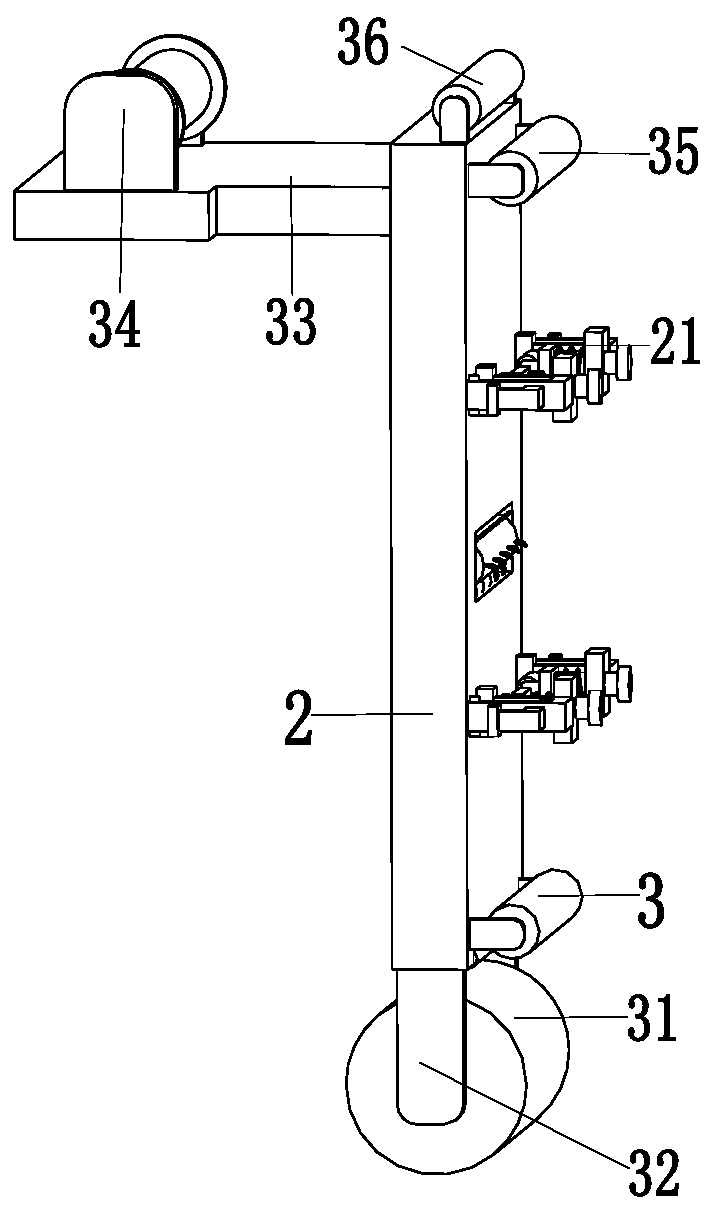

The invention relates to a dye device, particularly relates to a non-woven lifting dye device for garment production, and aims at solving the technical problem of providing a non-woven lifting dye device for garment production, which is capable of flatly putting non-woven into a dye for dyeing. In order to solve the technical problem, the invention provides the non-woven lifting dye device for garment production. The non-woven lifting dye device for garment production comprises a dye box, a connecting rod, a support rod, a lifting mechanism, a lifting frame, a guide roller and the like, wherein the upper part of the left side outside the dye tank is connected with the connecting rod; the top of the connecting rod is connected with the support rod; the support rod is connected with the lifting mechanism; and the lower side of the lifting mechanism is connected with the lifting frame. Through the lifting mechanism, the targets of driving the lifting frame to descend through the lifting mechanism, driving the guide roller at the inner side to descend through the lifting frame and flatly pressing the non-woven into the dye box for dip dyeing through the guide roller at the inner side are achieved.

Owner:绍兴金祥惠纺织印染有限公司

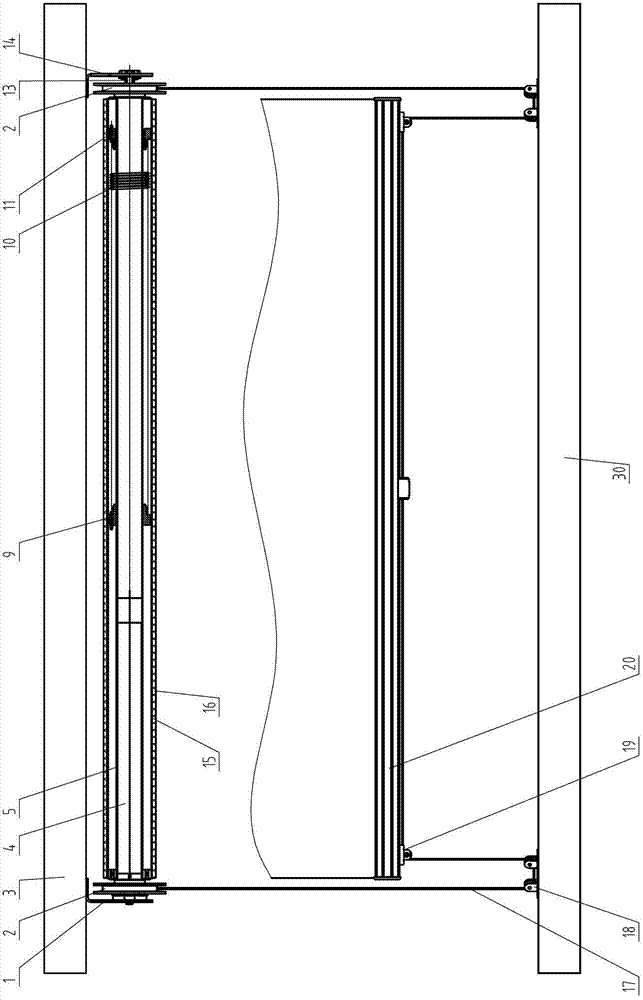

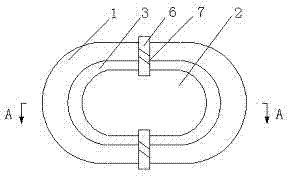

Torsion-reeled differential type awning curtain or rolling curtain

The invention discloses a torsion-reeled differential type awning curtain or rolling curtain which comprises an outer pipe, a piece of curtain cloth and a traction rod, wherein the outer pipe is reeled on the outer pipe and spread from the outer pipe, and the traction rod is connected with the lower edge of the curtain cloth, wherein each of the two ends of the outer pipe is provided with a retractor; a guiding device is arranged below each retractor; an inner pipe which can rotate freely in the outer pipe is arranged inside the outer pipe; a tubular motor capable of driving the inner pipe to rotate is arranged inside the inner pipe; the outer wall of the inner pipe is provided with at least one tubular spring for tightening the part between the outer pipe and the curtain cloth; and the tubular spring is indirectly or directly connected with the inner wall of the outer pipe. According to the torsion-reeled differential type awning curtain or rolling curtain, the tubular spring is arranged after being pre-tightened, therefore, when reeling or unreeling is carried out, the tubular spring is in a work state and outputs certain torsion to tighten the part between the outer pipe and the curtain cloth, and the curtain cloth can be conveniently reeled or unreeled smoothly. Therefore, the torsion-reeled differential type awning curtain or rolling curtain can be applied widely as the awning curtain or the rolling curtain.

Owner:GUANGDONG CHUANGMING SUN SHADE TECH CO LTD

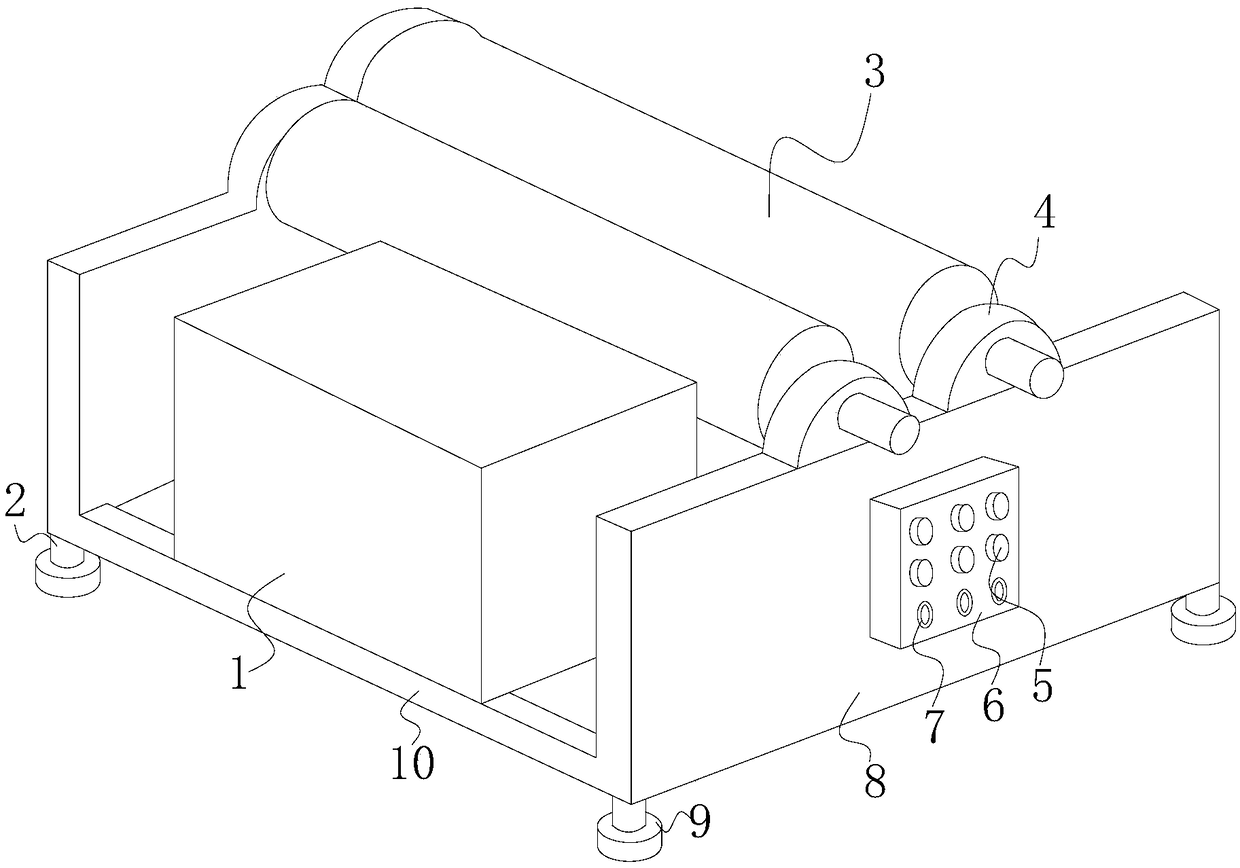

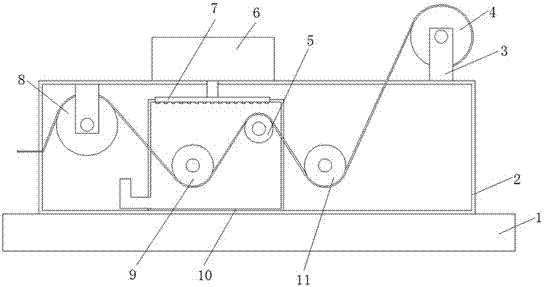

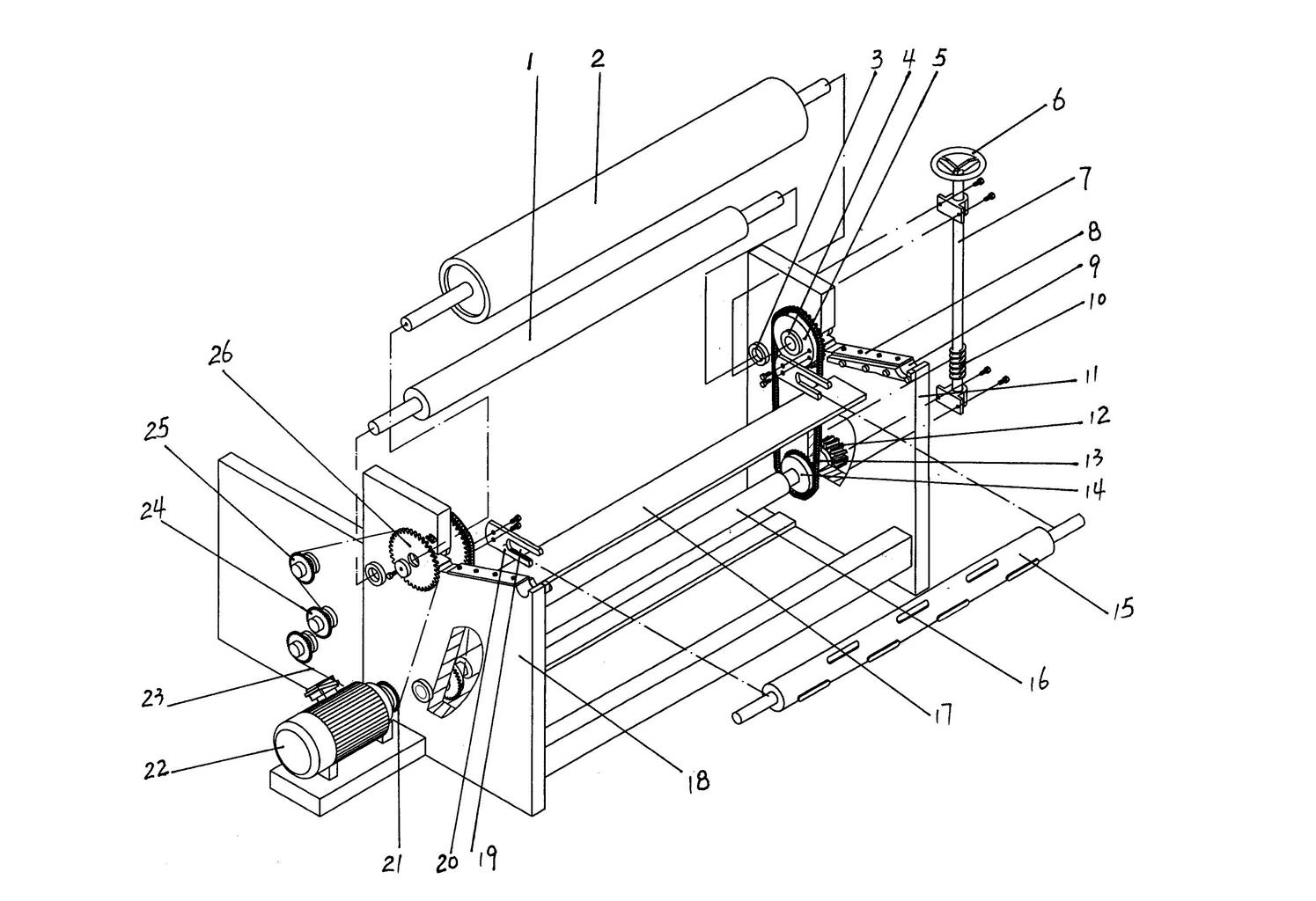

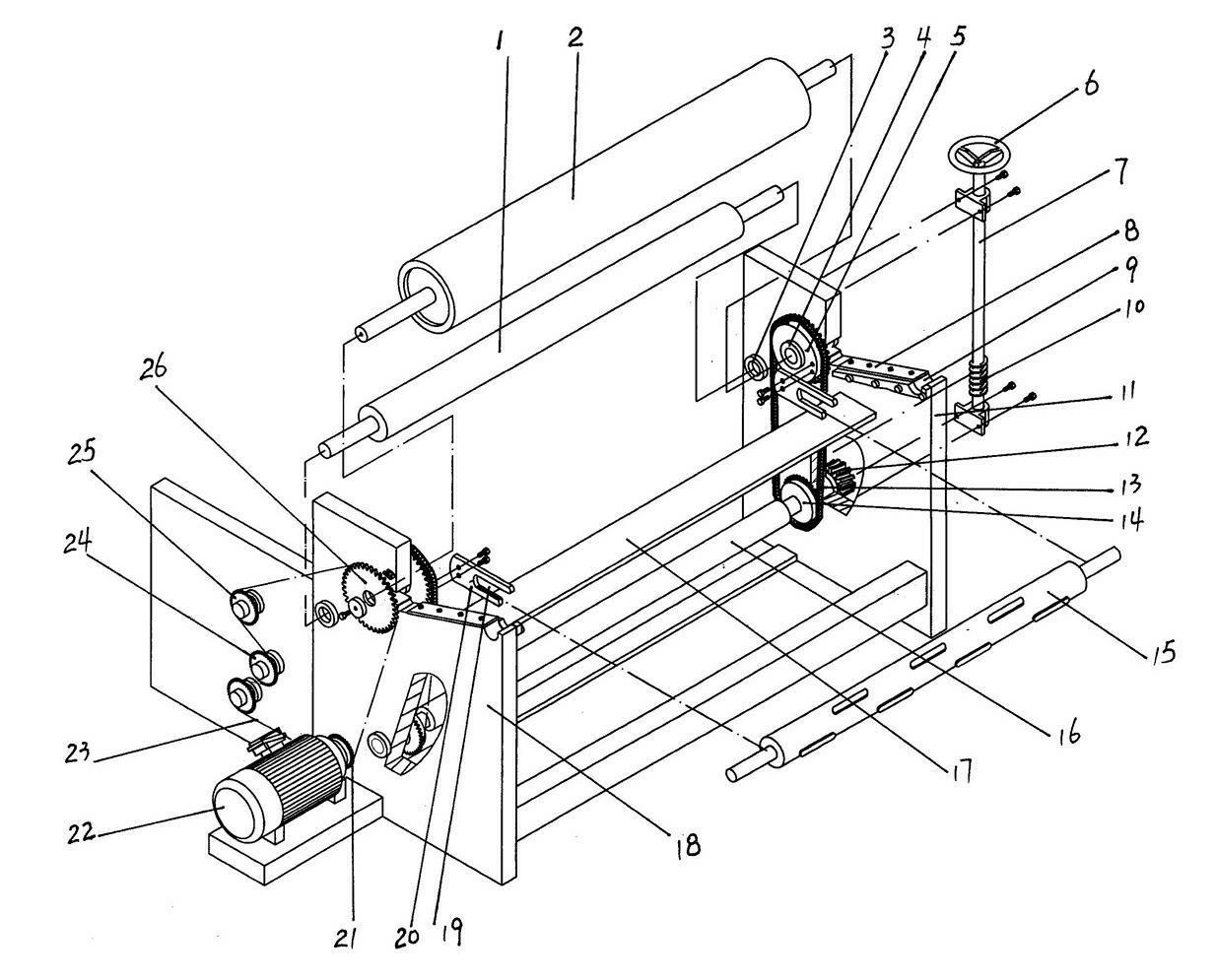

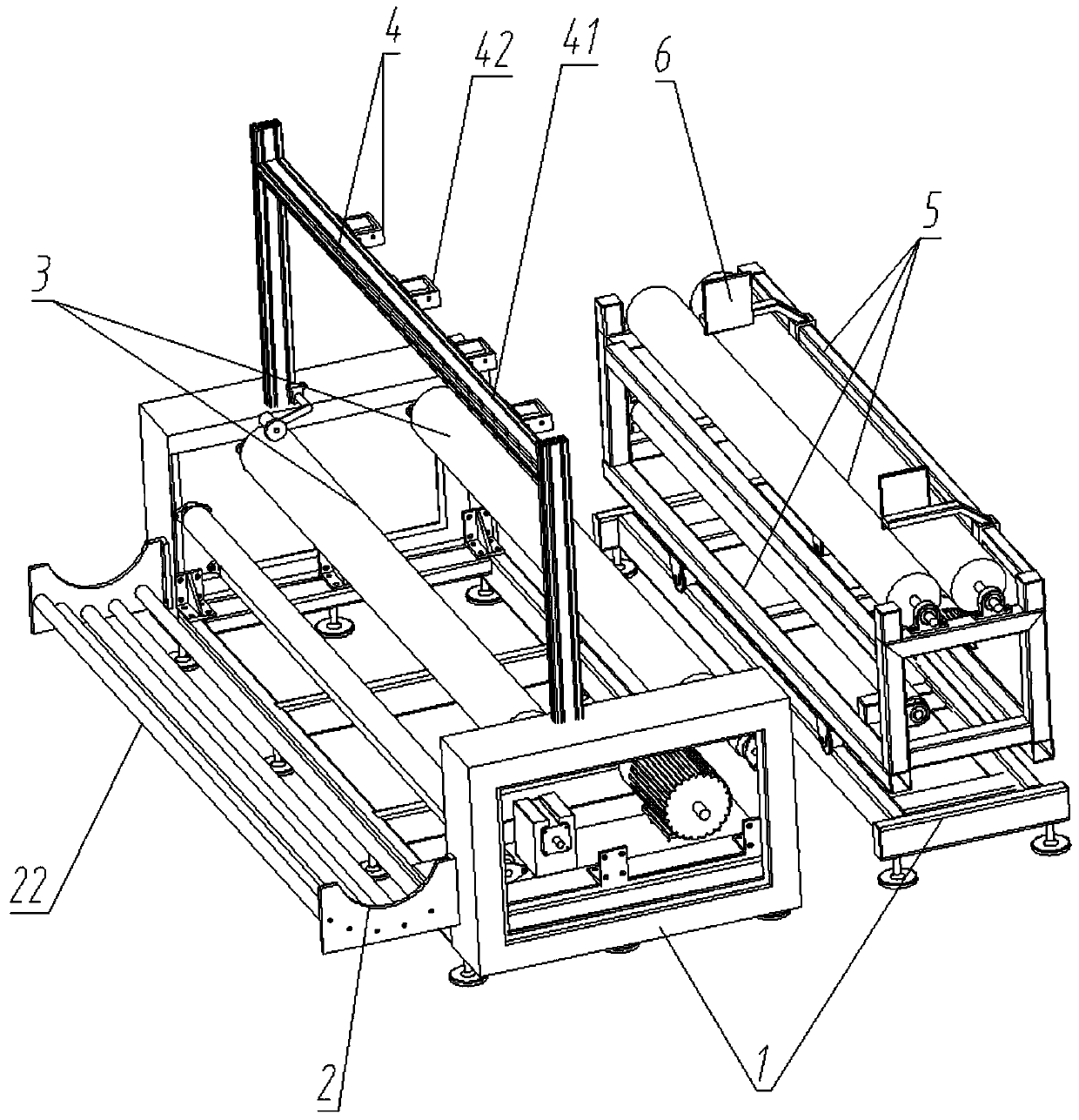

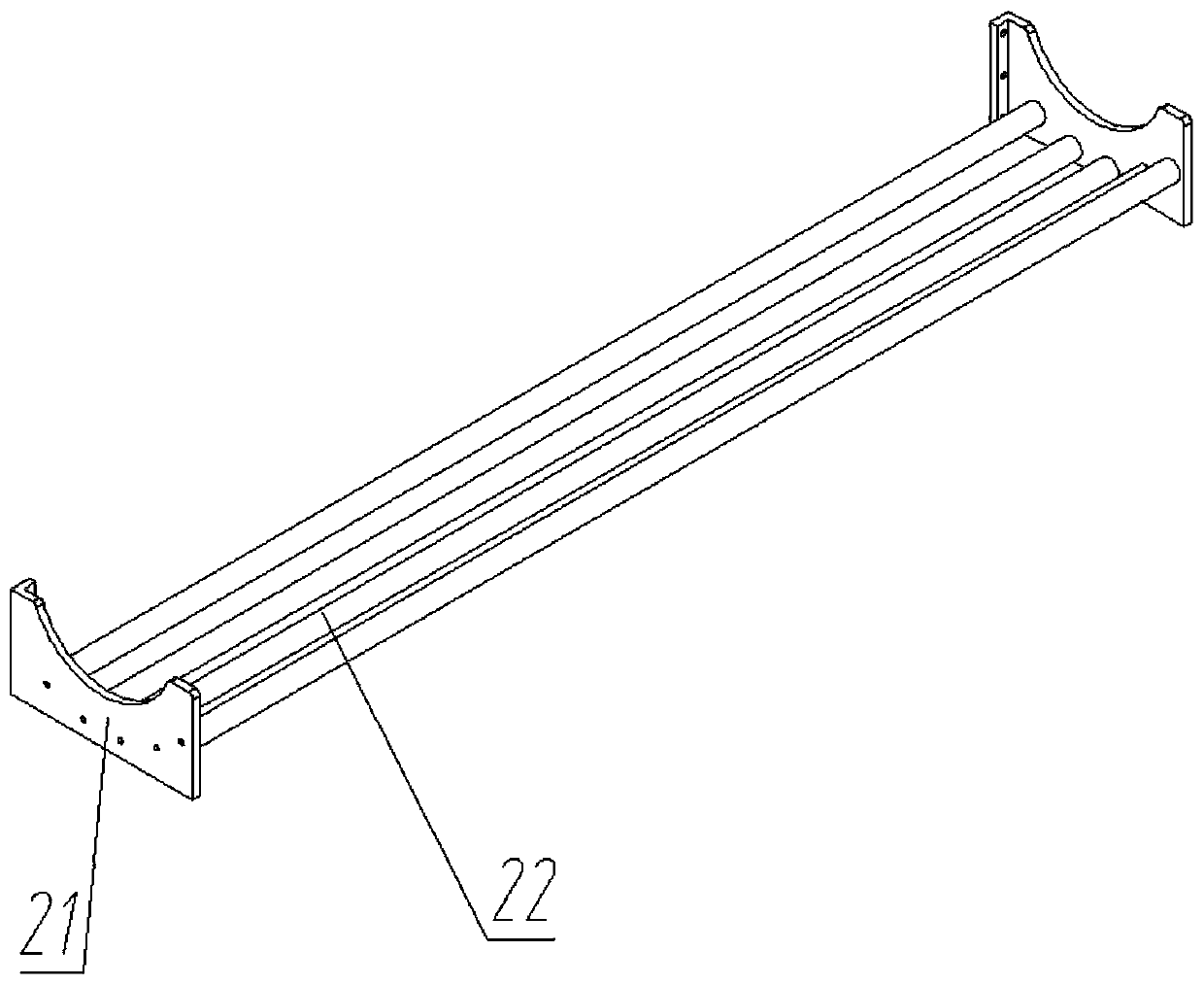

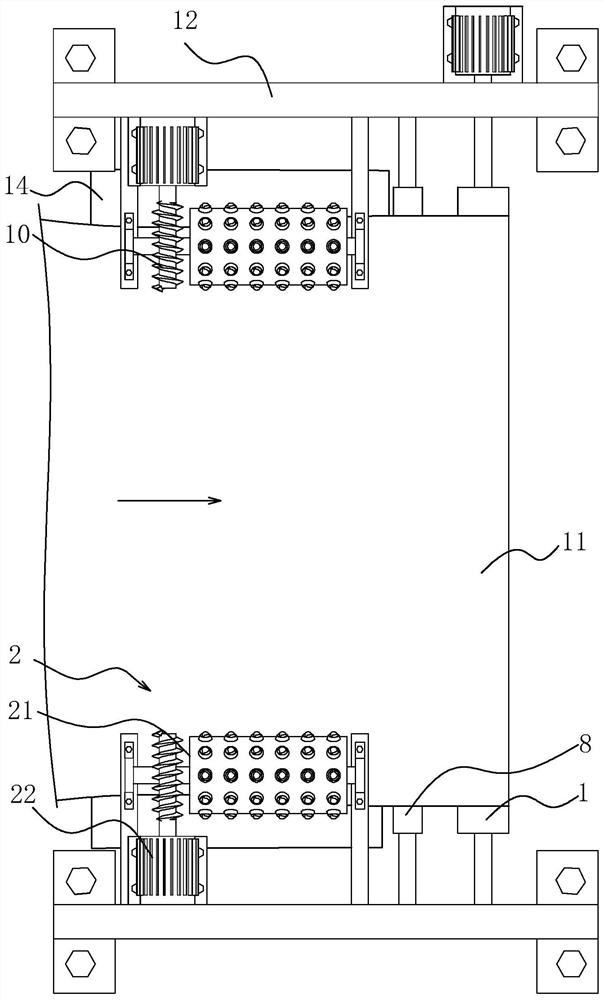

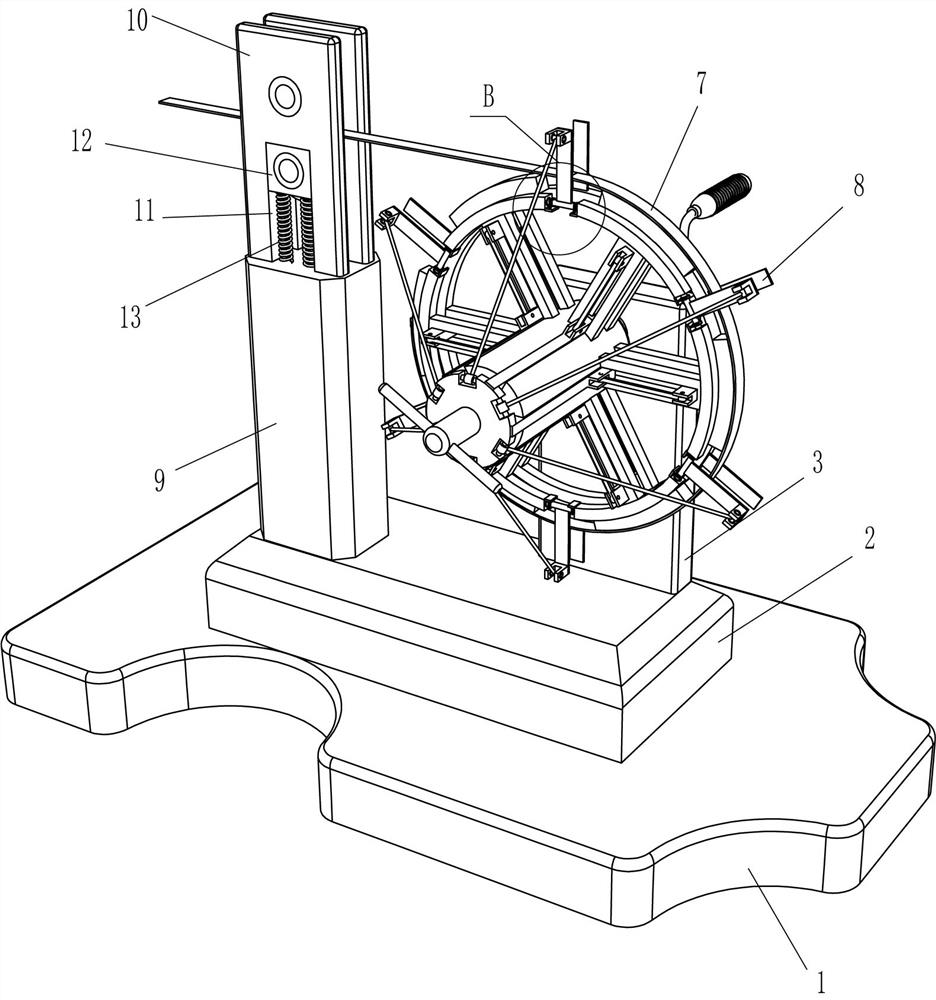

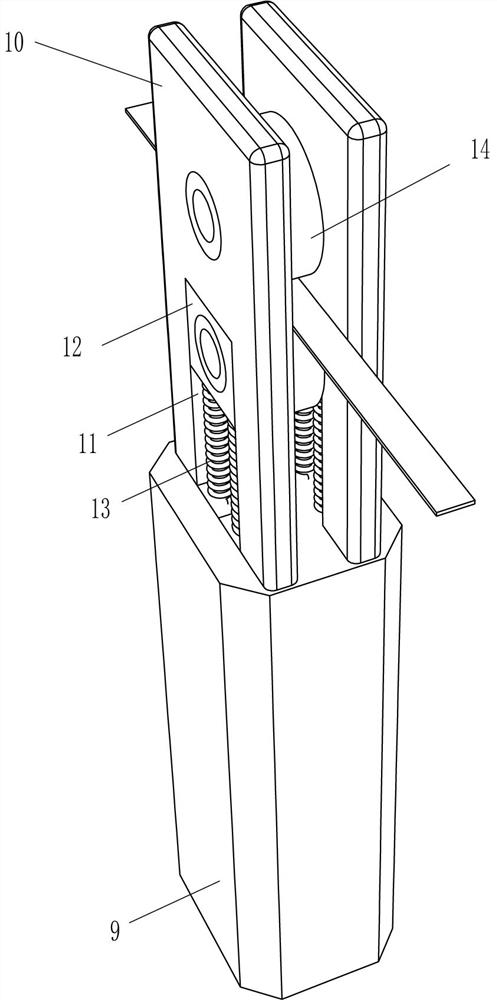

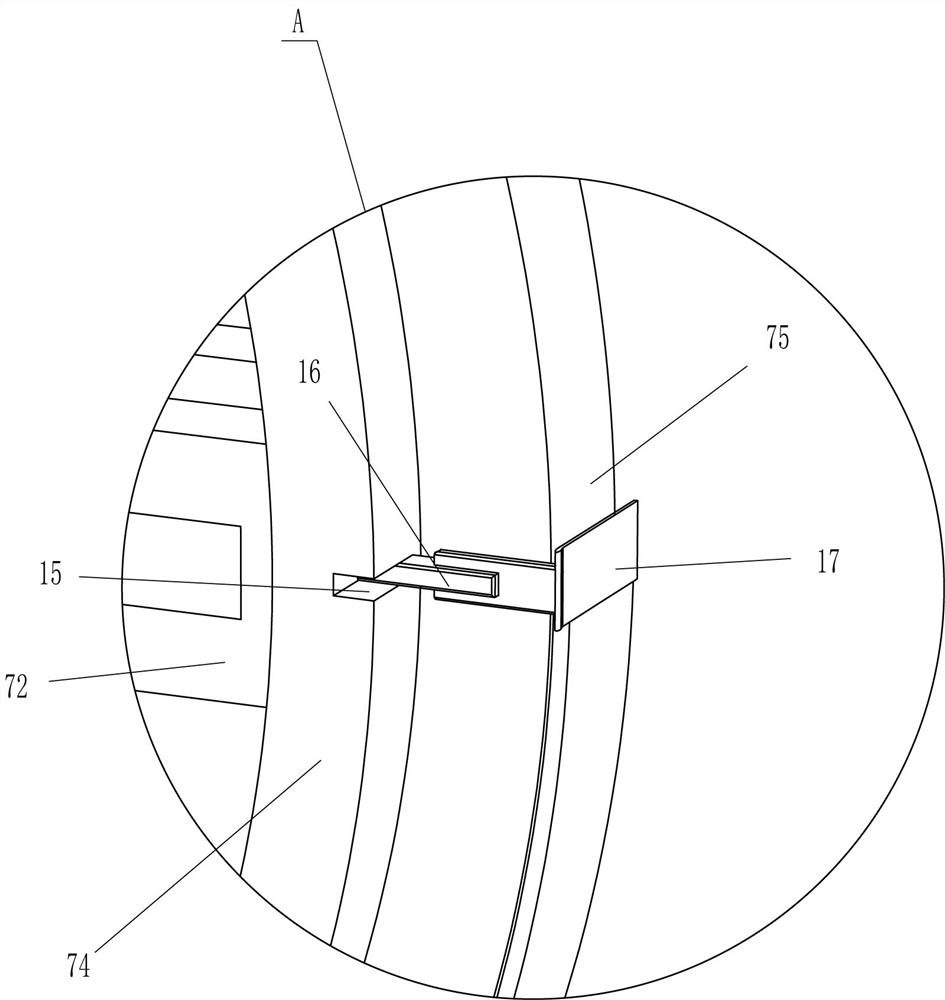

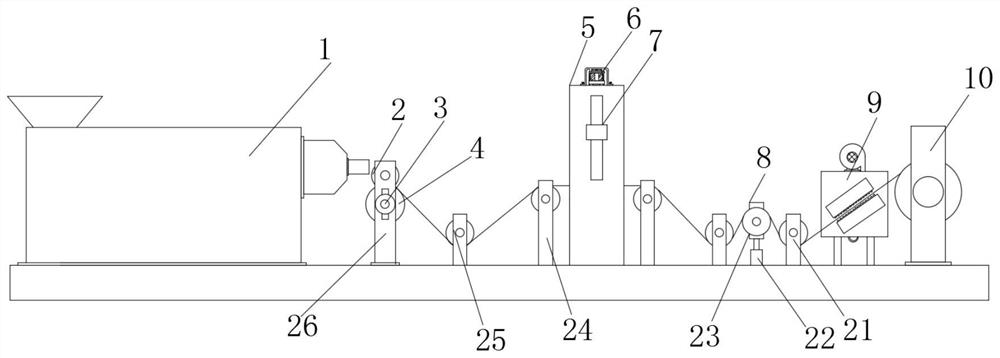

Cloth cutting device

PendingCN107088898AAutomatic pressure adjustmentAutomatically adjust the degree of tensionSevering textilesMetal working apparatusEngineeringConductor Coil

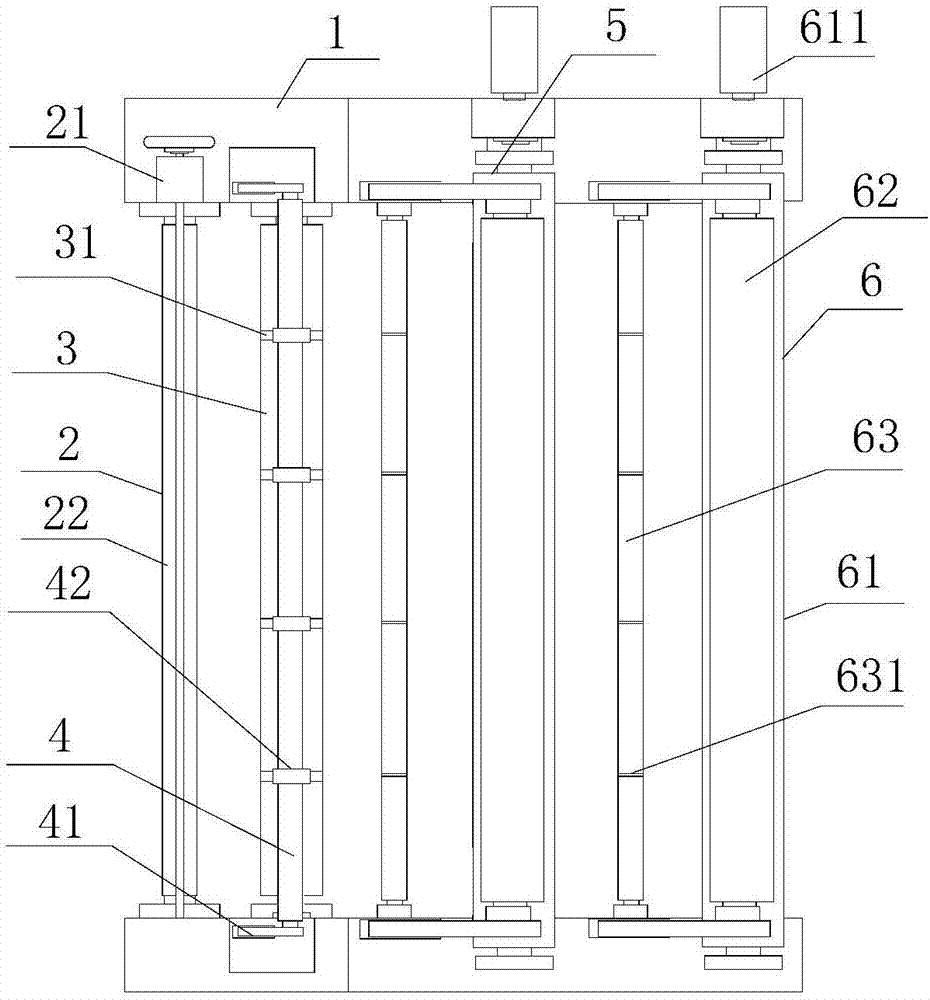

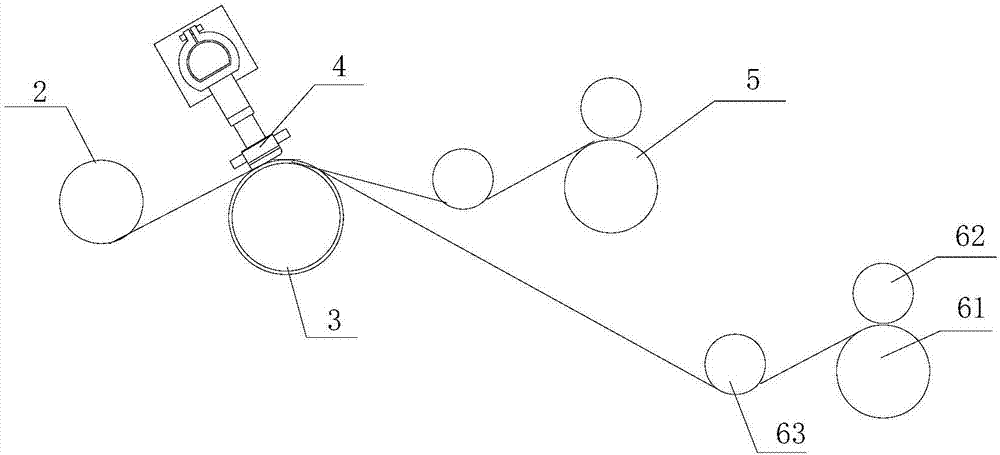

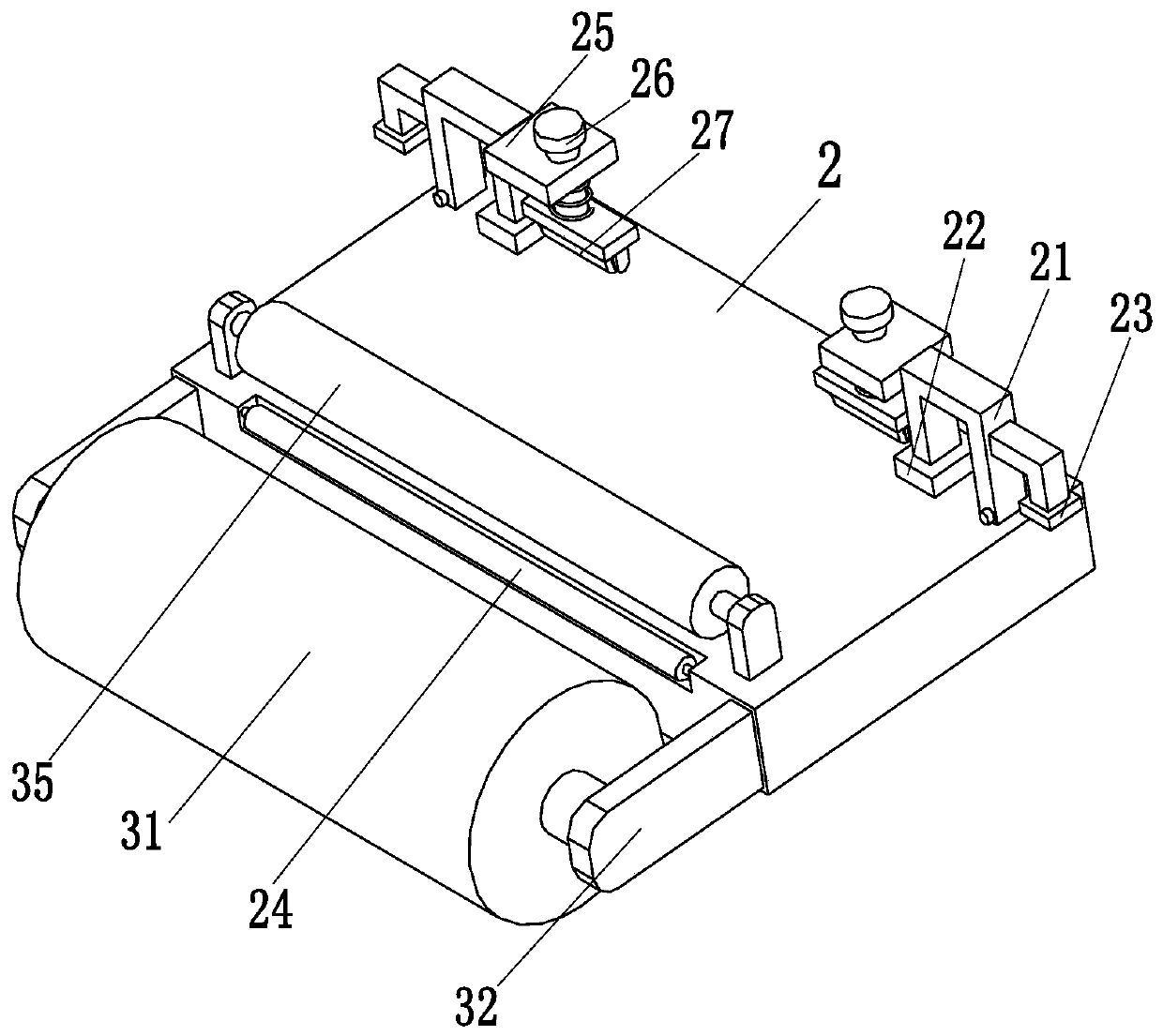

The invention provides a cloth cutting device. The cloth cutting device comprises a rack, an adjustable guide roller mechanism, a cutting roller component, a cutting device, a first rolling device and a second rolling device, wherein an adjusting device is arranged on each of two sides of the adjustable guide roller mechanism; a guide roller component is mounted between the adjusting devices; a plurality of tool aprons are mounted on the cutting roller component; the cutting device is arranged above the cutting roller component; a driving mechanism is arranged on each of two sides of the cutting device; a mounting support is mounted between the driving mechanisms; a plurality of cutter components are mounted on the mounting support; the guide roller component, the cutting roller component, the first rolling device and the second rolling device are sequentially arranged on the rack in the cloth moving direction; and a buffer spring is arranged on each cutter component. The pressure between hot cutters and cutter rests can be automatically adjusted, so that cutter abrasion is reduced, cloth is guaranteed by a compression roller component to be always clung to a wind-up roller component, and accordingly, even and no-fold winding is ensured.

Owner:杭州世佳布艺有限公司

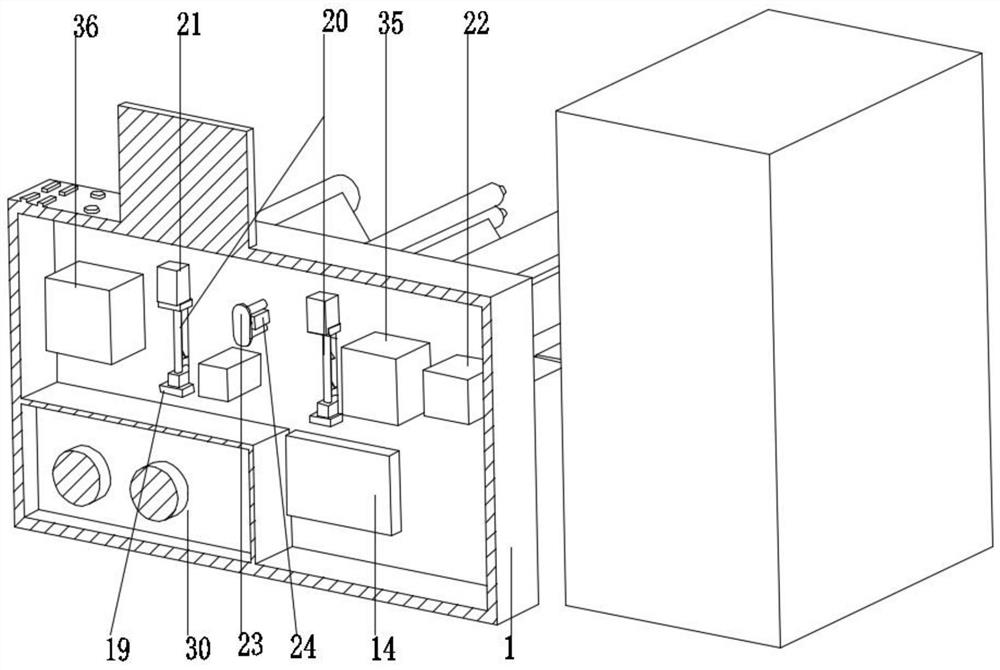

Textile processing equipment

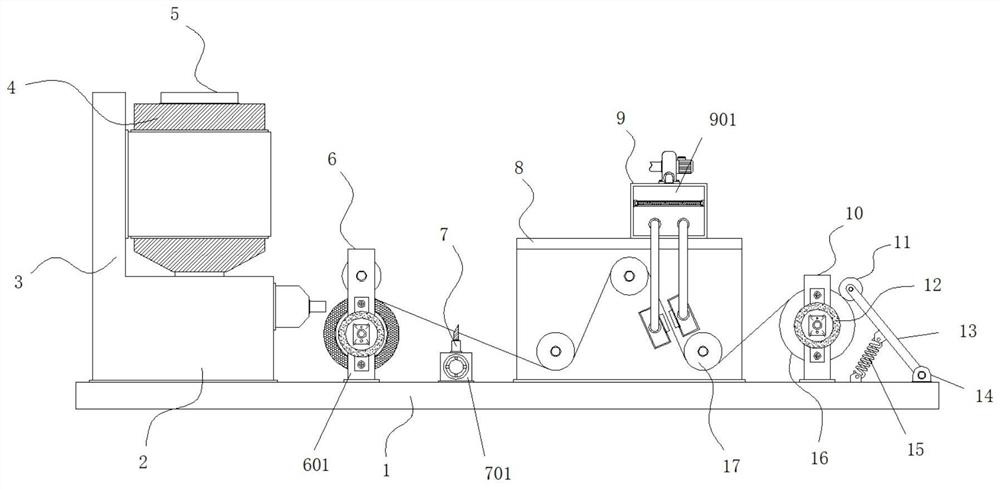

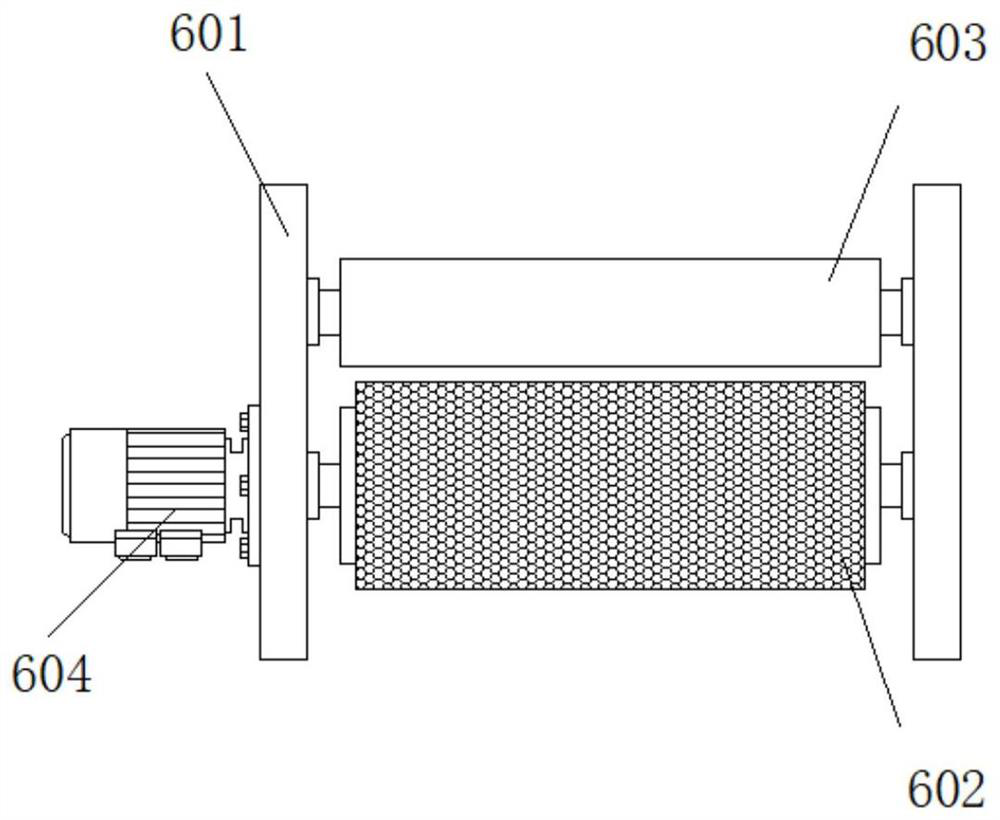

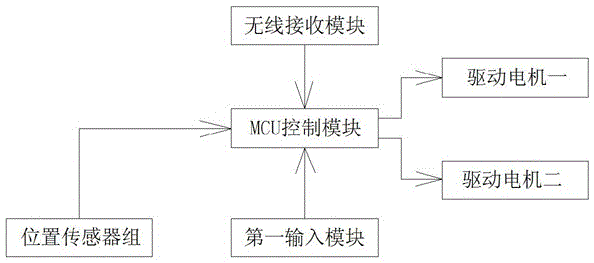

ActiveCN108517639AReduce speedHigh degree of automationLiquid/gas/vapor removal by suctionTextile treatment machine arrangementsMotor driveElectric machinery

The invention relates to the field of textile processing, and particularly discloses textile processing equipment. The textile processing equipment comprises a rack, and further comprises a water wiping mechanism, a water absorbing roller, an ironing mechanism, a drying roller, a material collecting roller, a first motor and a second motor, wherein the water wiping mechanism, the water absorbing roller, the ironing mechanism, the drying roller, the material collecting roller, the first motor and the second motor are arranged on the rack in the horizontal direction in sequence, the first motordrives the water absorbing roller, and the second motor drives the material collecting roller; the water wiping mechanism is arranged at the discharging end of a textile, the material collecting roller is arranged at the material collecting end of the textile, the water wiping mechanism comprises several water wiping rollers facing the water absorbing roller, the water wiping rollers are divided into a first water wiping set and a second water wiping set, the first water wiping set and the second water wiping set are opposite, the first water wiping set is rotatably connected with the rack, and a water wiping plate is fixedly connected to the second water wiping set. The textile is processed through the four motions of water wiping, water absorbing, ironing and drying in sequence, and thenthe textile is also reeled after being processed; the automated degree is high, and the processing efficiency is high; moreover, when processed by multiple processing steps, the textile does not needto be carried and can be processed at a time, and the time and labor are saved.

Owner:NINGBO WENZE TEXTILE CO LTD

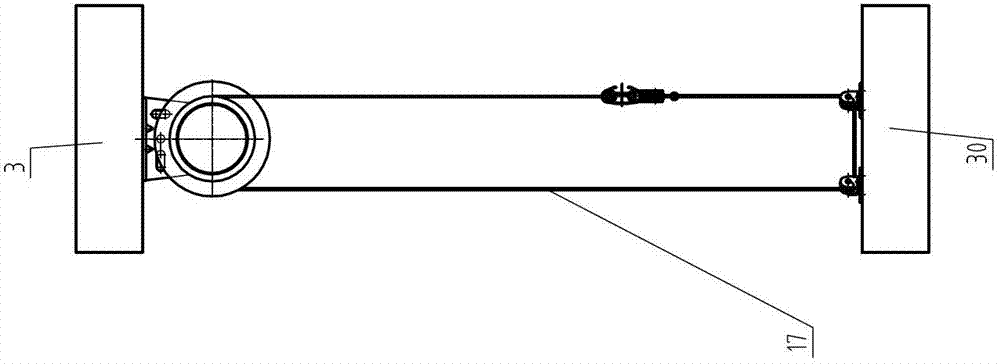

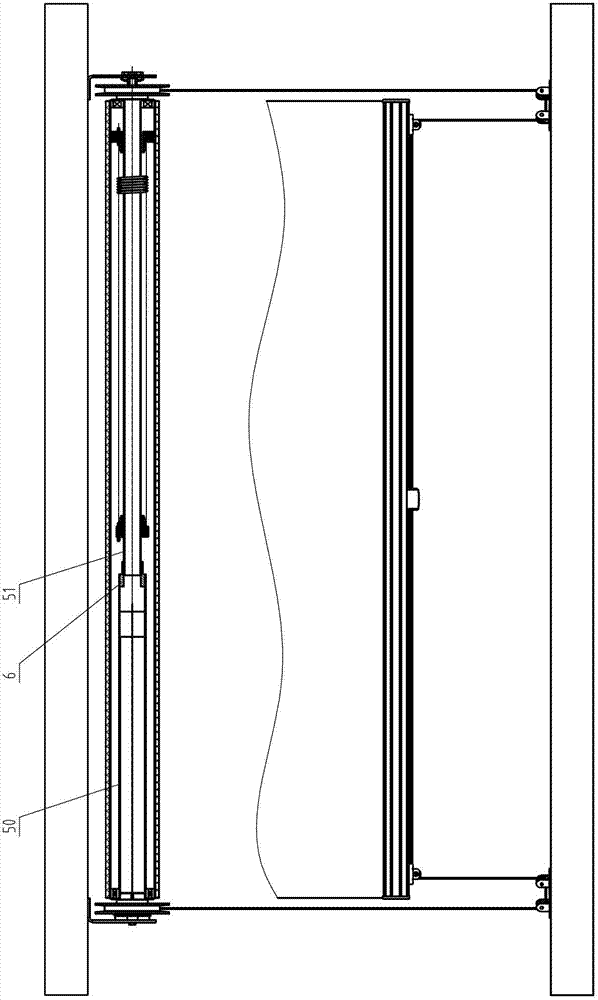

Cloth winding device

Owner:钱杭健

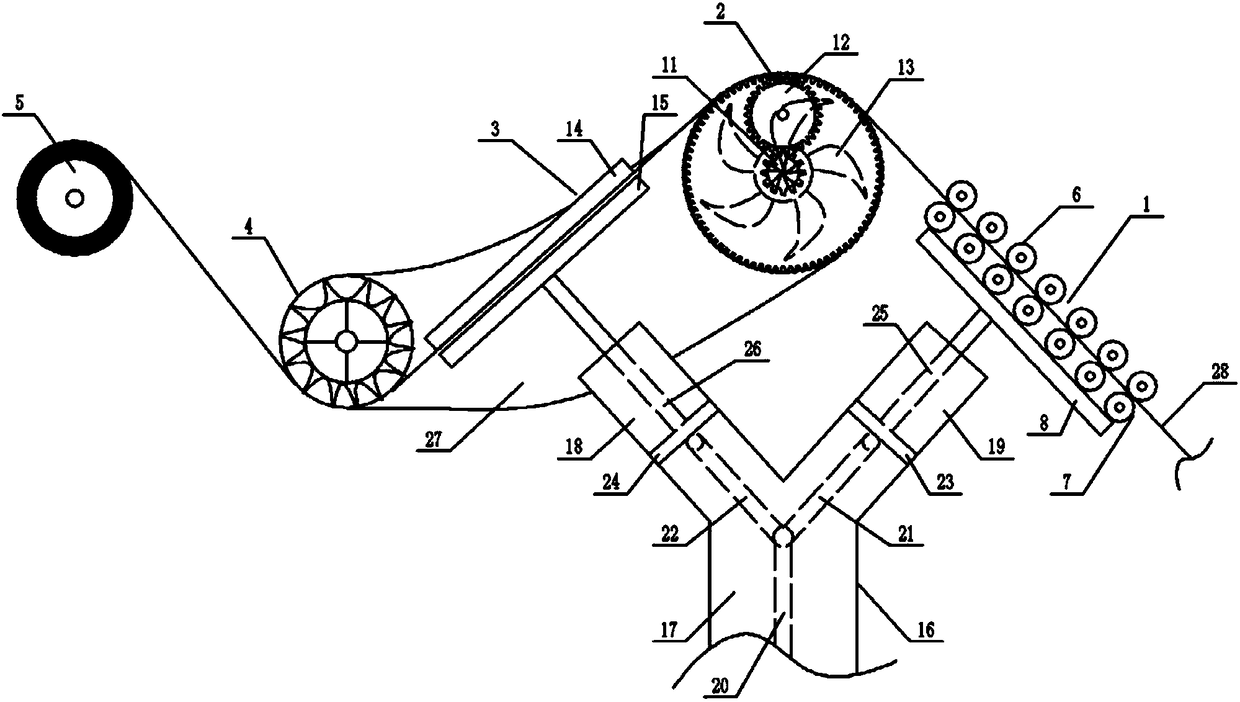

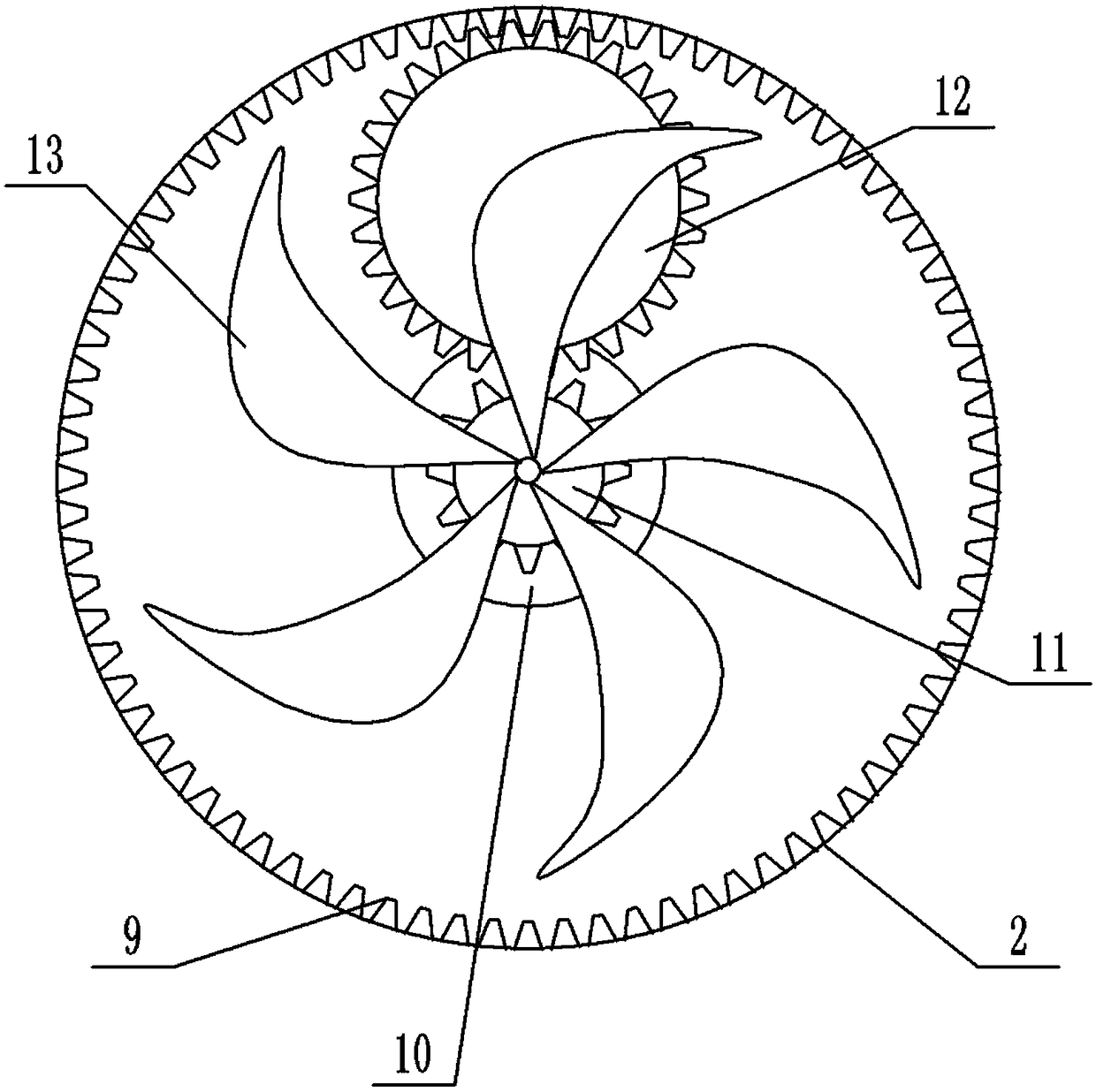

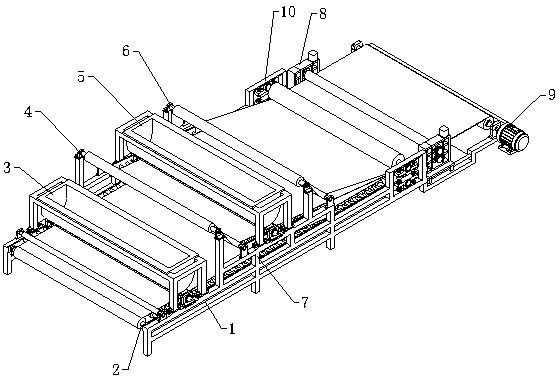

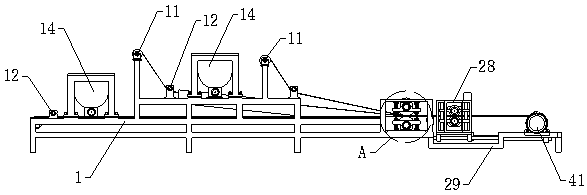

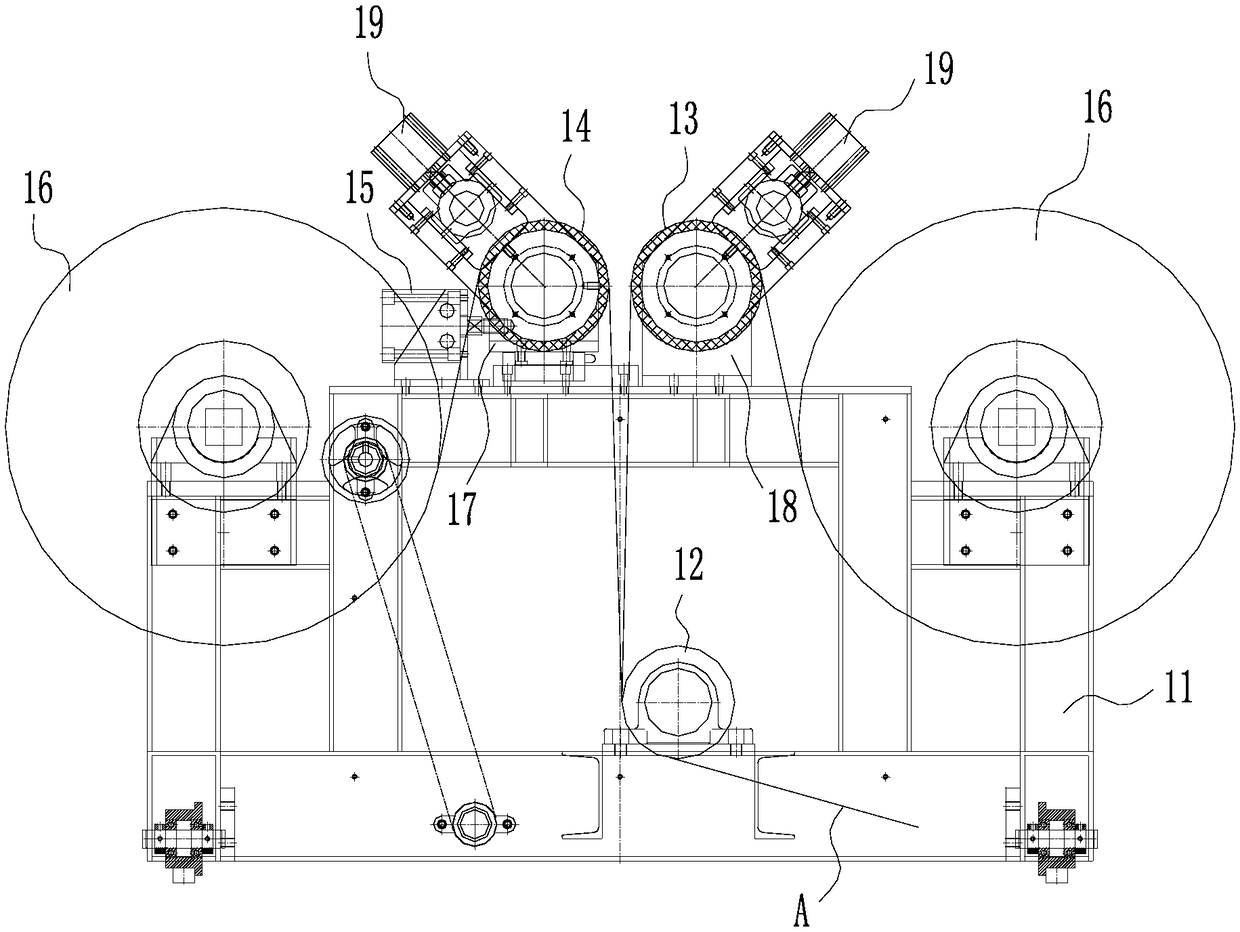

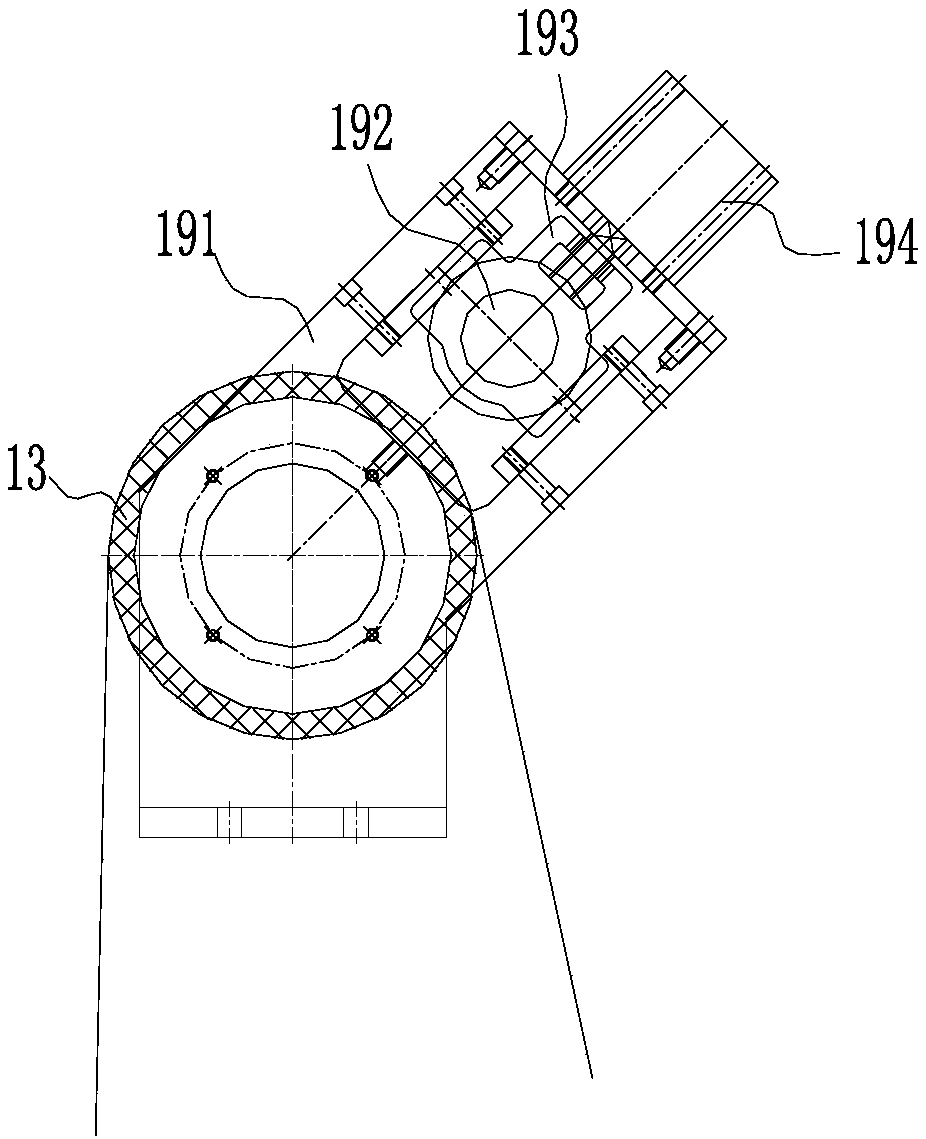

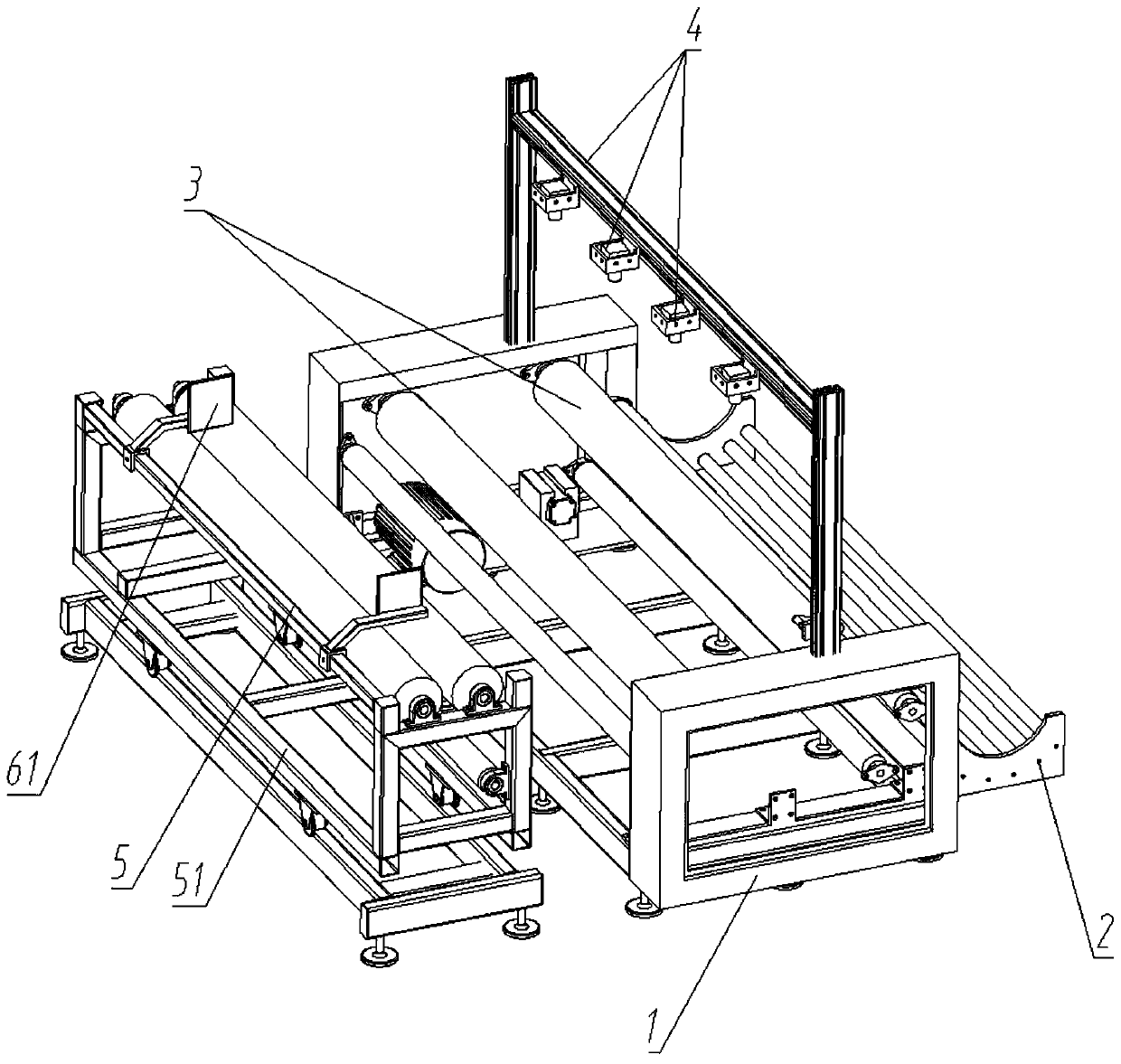

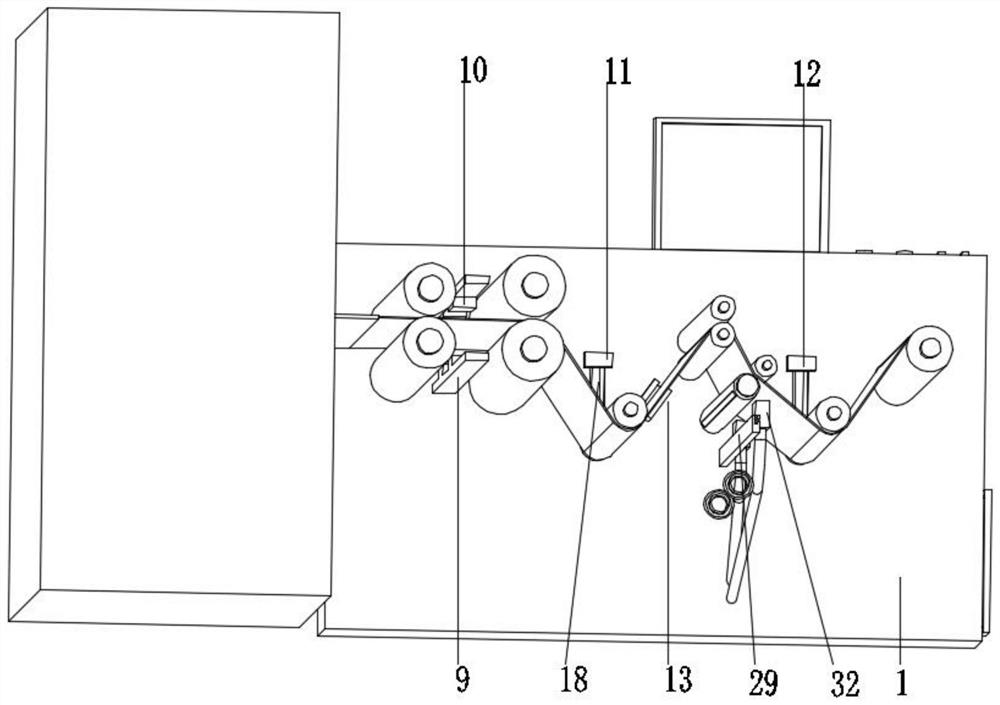

Winder for composite molding of multiple layers of geotechnical cloth

ActiveCN110697467AApply glue evenlyUniform contact coatingLaminationLamination apparatusMechanical engineeringGeotechnical engineering

The invention relates to the field of geotechnical cloth production processing, in particular to a winder for the composite molding of multiple layers of geotechnical cloth. The winder for the composite molding of the multiple layers of geotechnical cloth comprises a bottom conveying frame, an unwinding mechanism, a pressing mechanism and a winding mechanism, wherein the unwinding mechanism comprises a bottom unwinding assembly, a first gluing assembly, a middle unwinding assembly, a second gluing assembly and a top unwinding and gluing assembly; the bottom unwinding assembly is located at oneend of the bottom conveying frame; the first gluing assembly is located on the upper part, close to the bottom unwinding assembly, of the bottom conveying frame; an overlaying frame is arranged on the top part of the bottom unwinding and gluing assembly; the middle unwinding assembly, the second gluing assembly and the top unwinding and gluing assembly are arranged above the overlaying frame; thepressing mechanism comprises a composite levelling assembly; the winding mechanism comprises a winding drive assembly; and the winding drive assembly is located at one end of the composite levellingassembly. According to the winder for the composite molding of the multiple layers of geotechnical cloth, the multiple layers of geotechnical cloth can be automatically composite molded and can be winded, meanwhile, the levelness can be ensured, and the efficiency and the quality are improved.

Owner:潍坊驼王实业有限公司

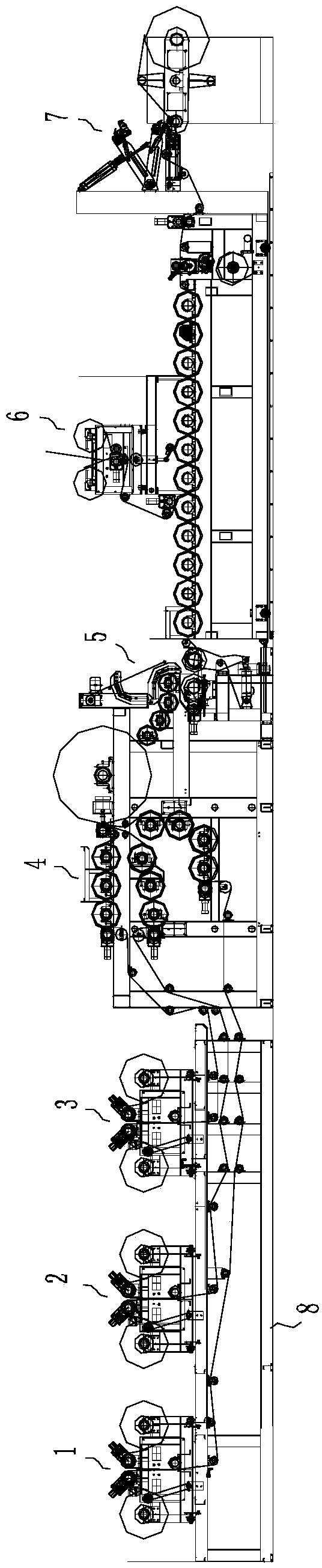

Multilayer film laminating machine

InactiveCN108861751AAdhere fullyEfficient removalLamination ancillary operationsLaminationComposite filmEngineering

The invention discloses a multilayer film laminating machine which comprises a first center unwinding machine, a second center unwinding machine, a third center unwinding machine, a primary laminatingdevice, an embossing device and a dual-station winding device, all of which are arranged on a rack in sequence. Films are output by the first center unwinding machine, the second center unwinding machine and the third center unwinding machine, various layers of films are subjected to primary pressing-laminating forming on the primary laminating device, the composite film is conveyed to the embossing device to be subjected to pattern hot pressing, and the finally-output composite film is wound on the winding device. According to the multilayer film laminating machine, through the primary laminating device, the multiple layers of films are subjected to primary laminating in the laminating device, bubbles are removed effectively, it is guaranteed that no gas exists in an interlayer, the various layers of films are fully laminated firmly, the laminating effect is improved, and the yield is increased.

Owner:佛山市高明正一机械设备有限公司

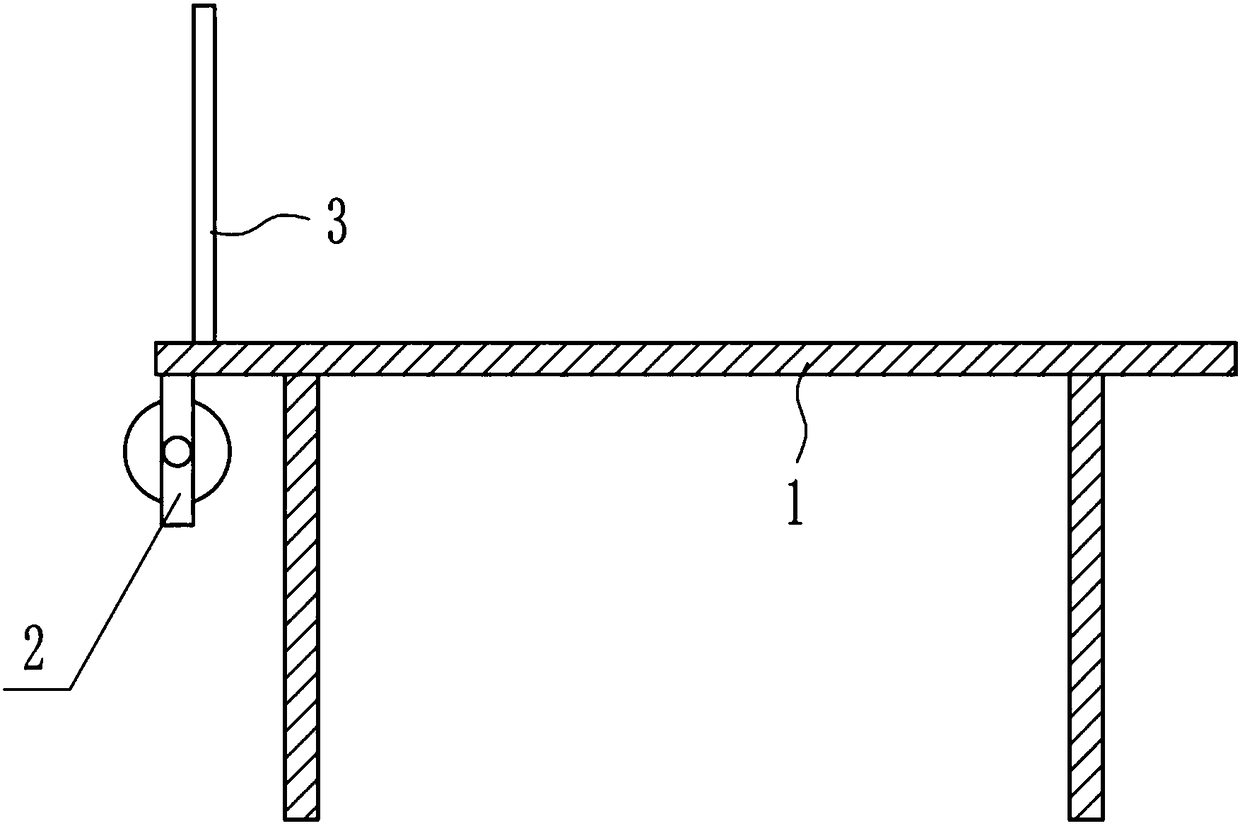

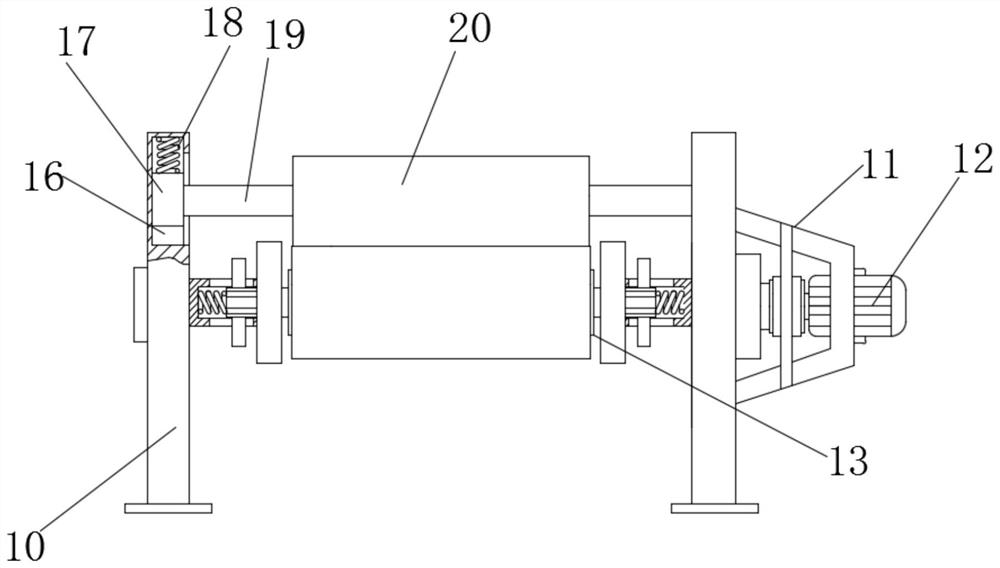

Textile fabric winding equipment

The invention relates to winding equipment, in particular to textile fabric winding equipment. The textile fabric winding equipment aims at achieving the technical effects that the winding efficiencyis high, and winding is smooth. The textile fabric winding equipment comprises a bottom plate and the like, a first supporting plate is installed on the rear side on the right of the top of the bottomplate, a fixing device is arranged on the first supporting plate, and a flattening device is arranged on the left of the top of the bottom plate. A winding drum is fixed through the fixing device, anoperator fixes the fabric to the winding drum and then carries out winding, the fabric is flattened through the flattening device, and therefore the effects that the winding efficiency is high, and winding is smooth are achieved.

Owner:江苏三昌纺织有限公司

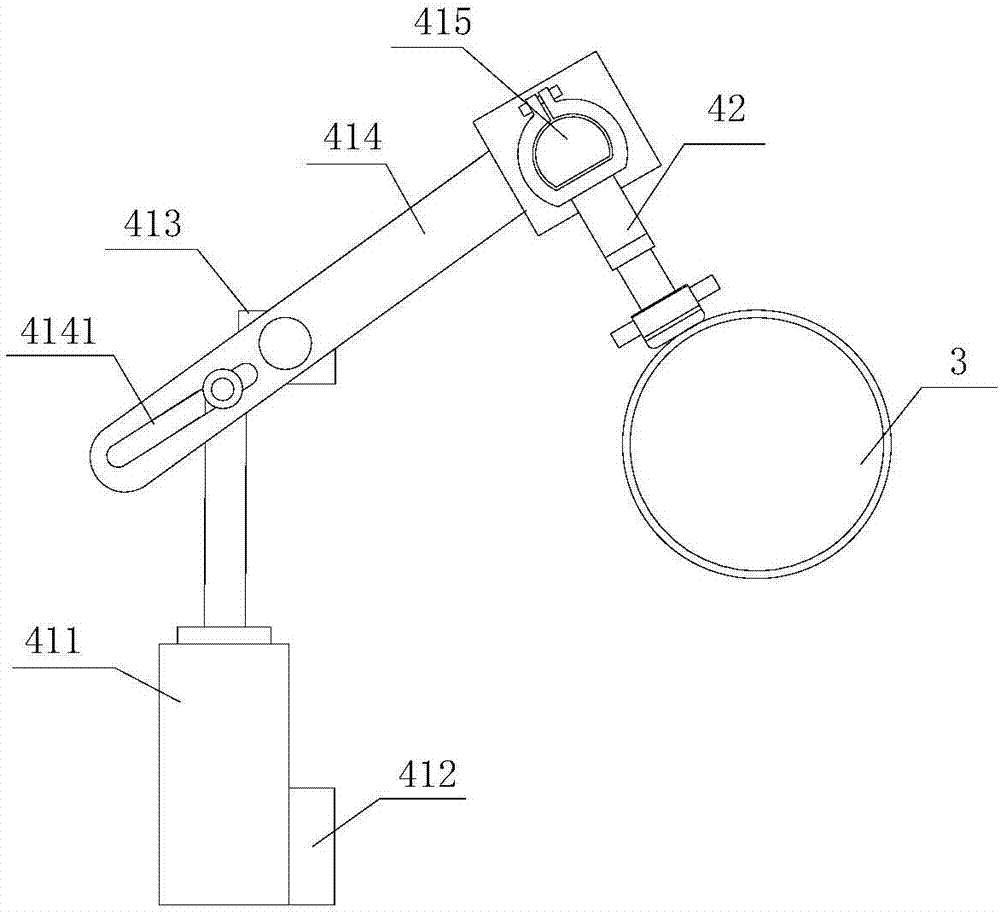

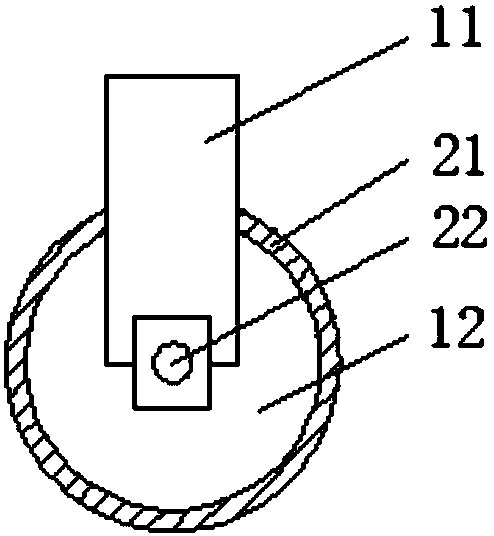

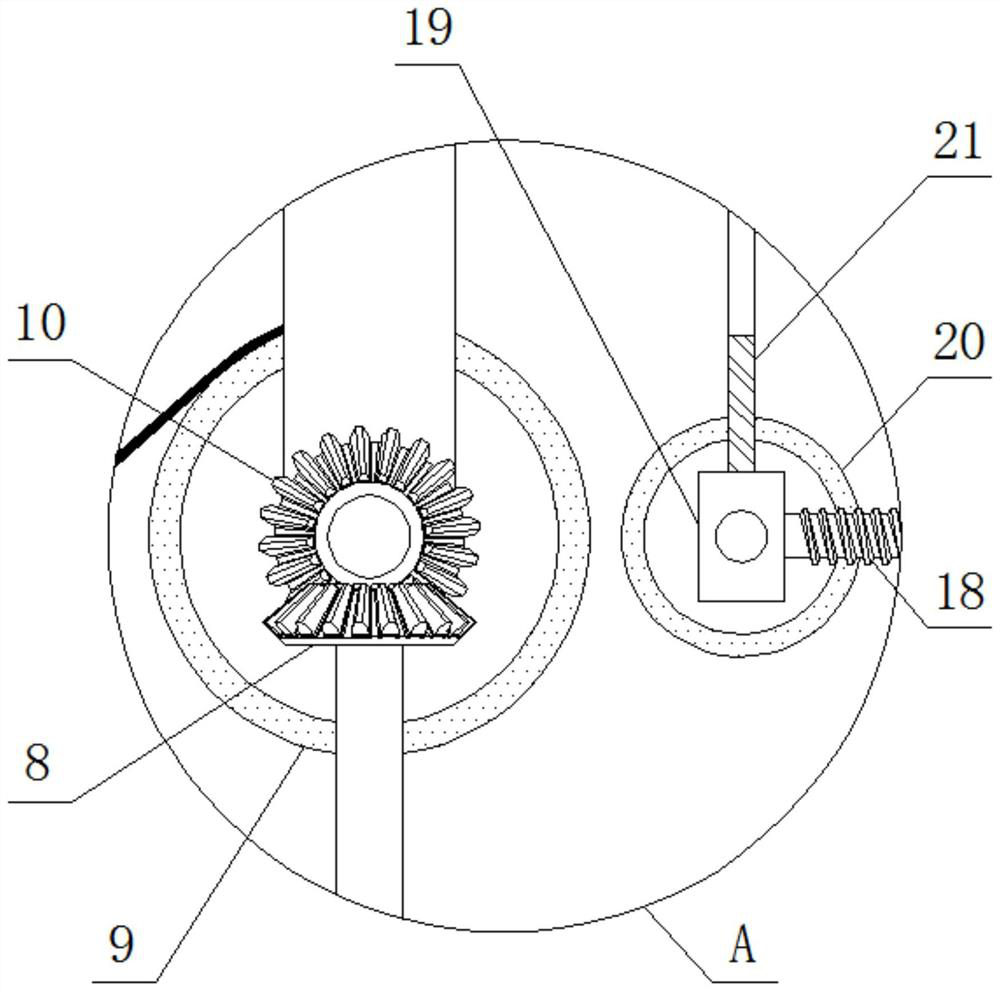

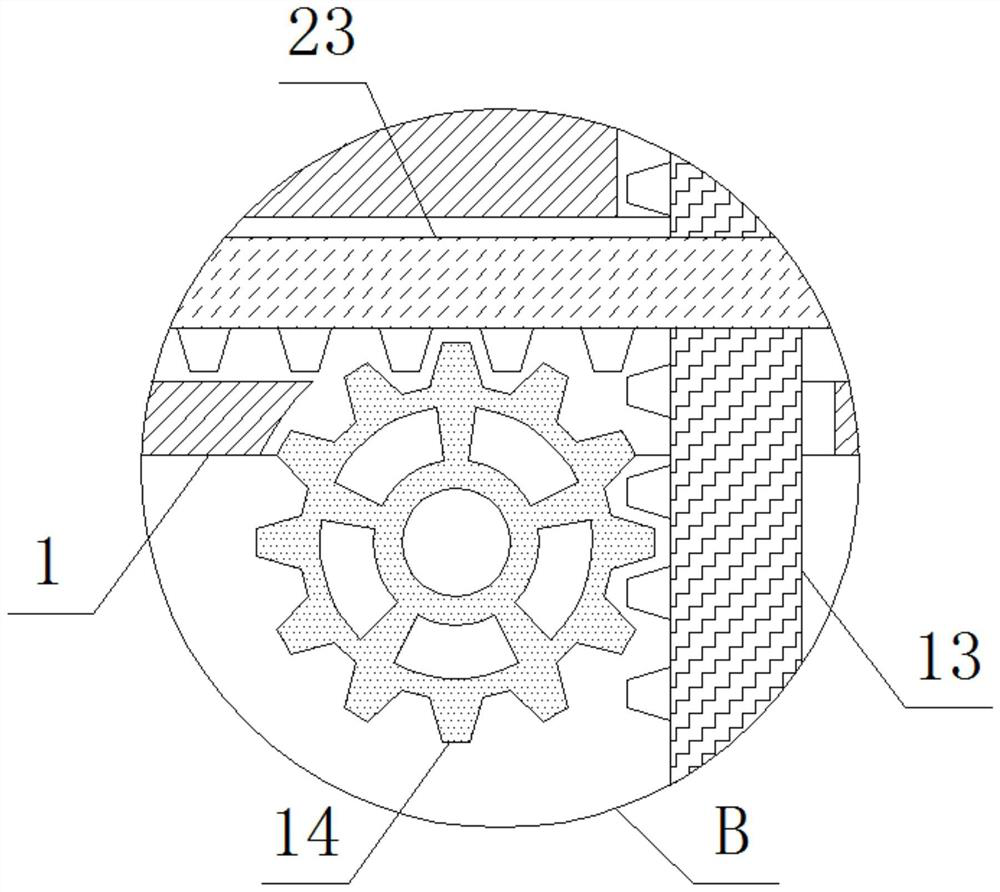

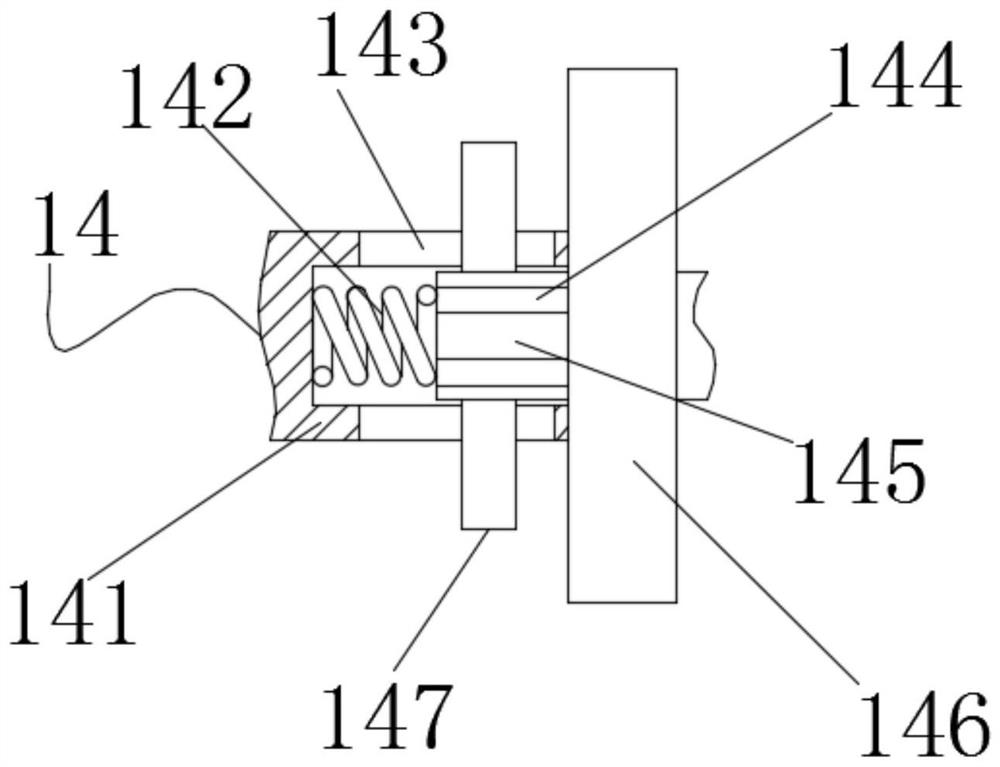

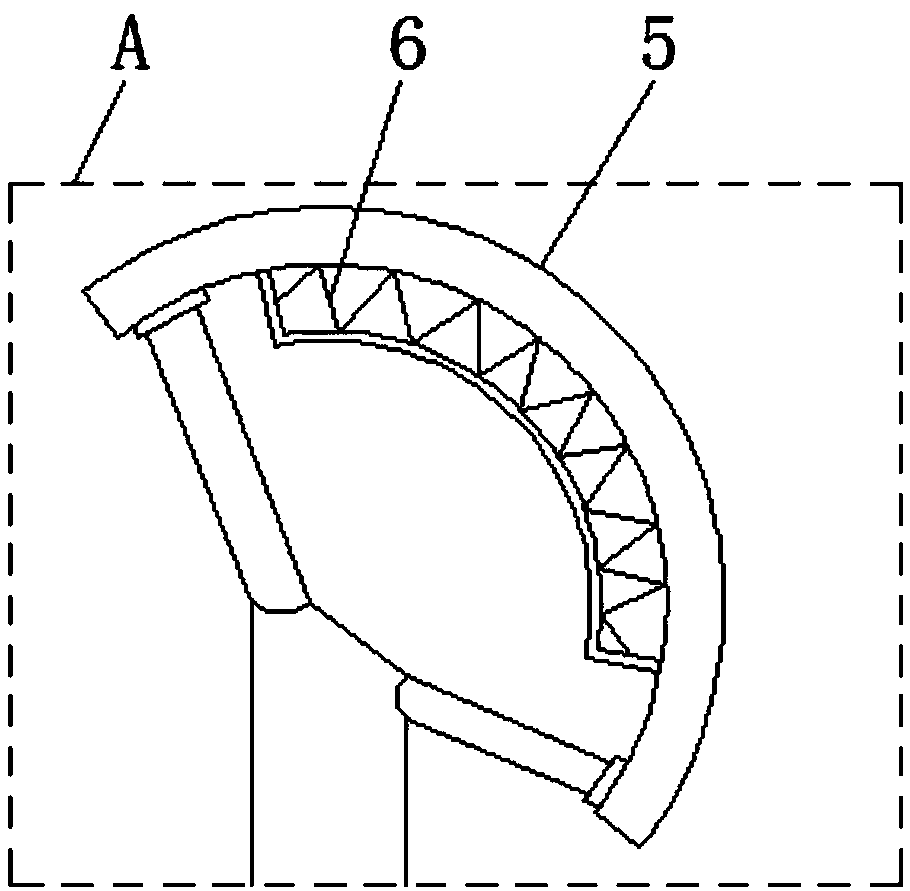

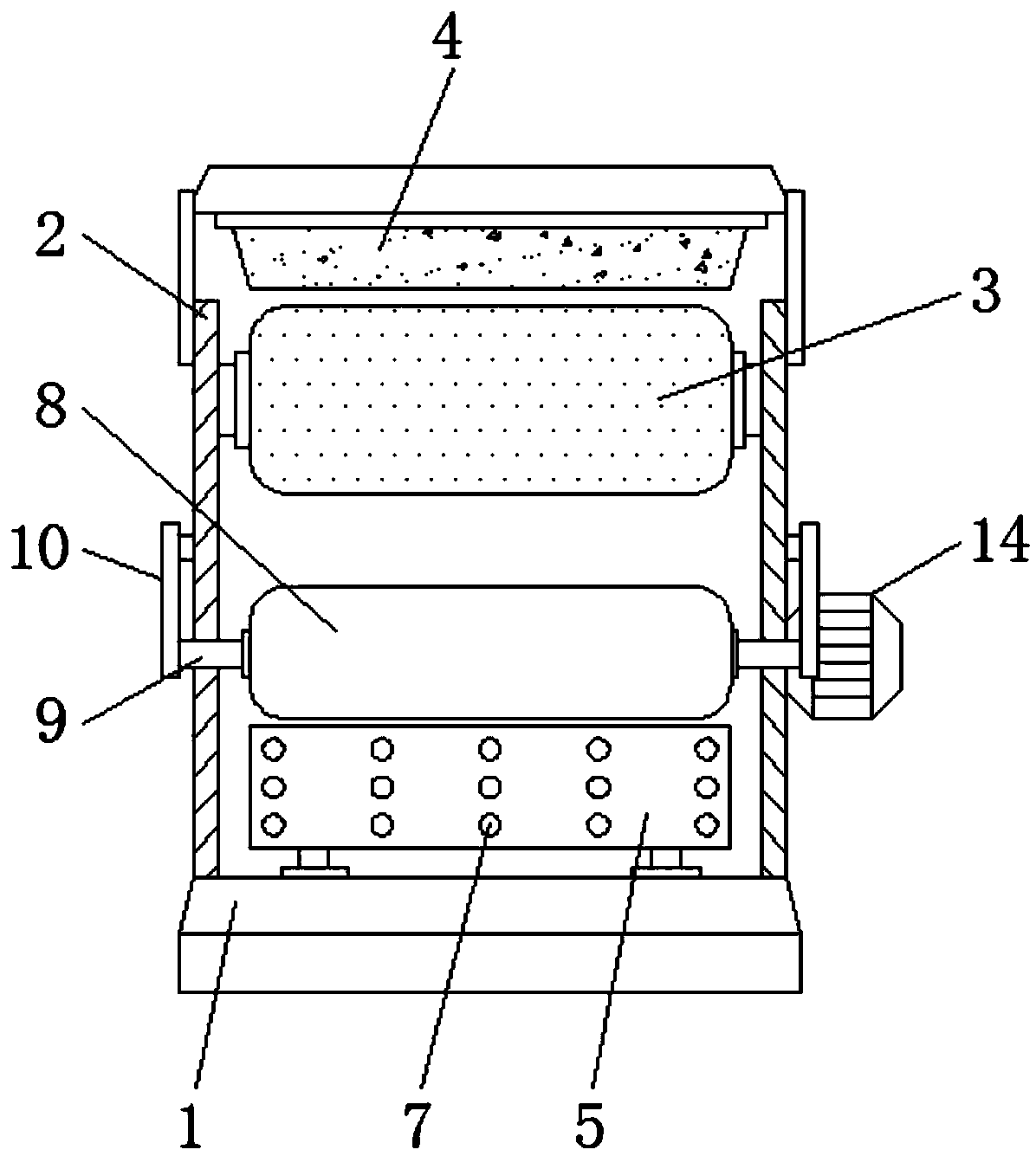

Reeling device for warp knitting machine

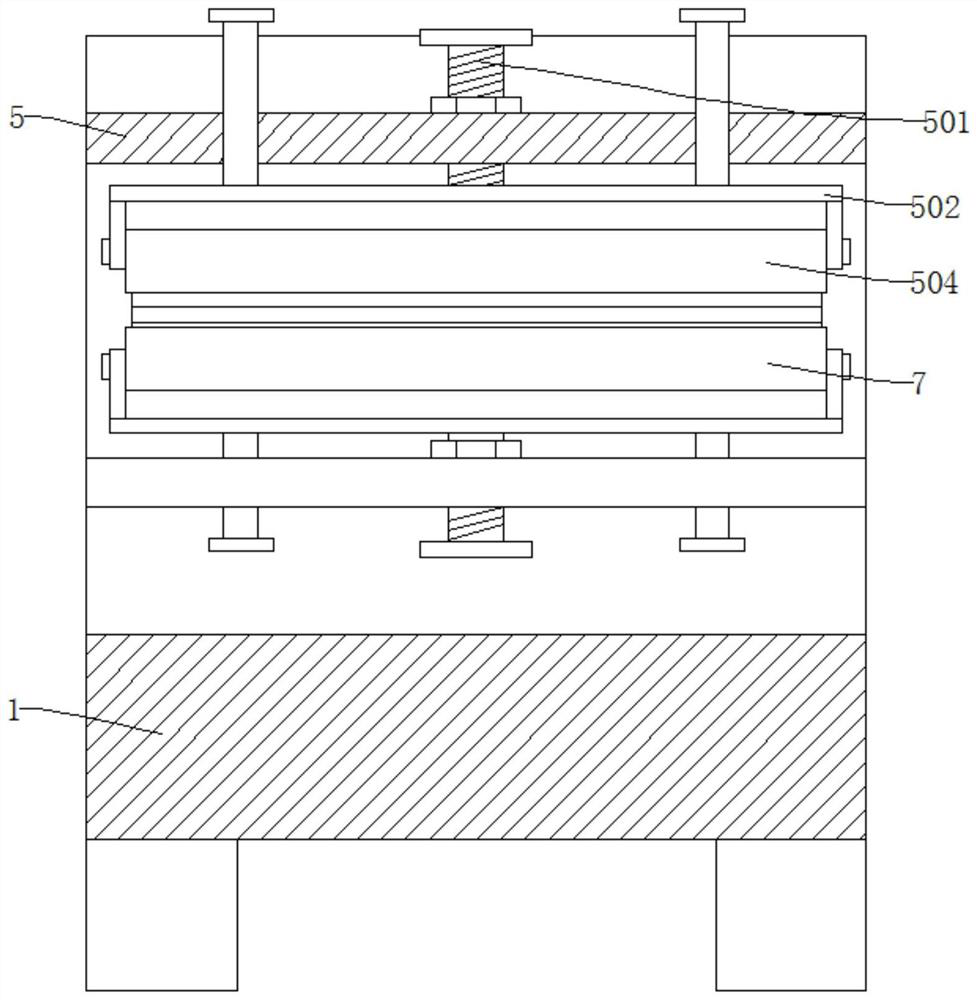

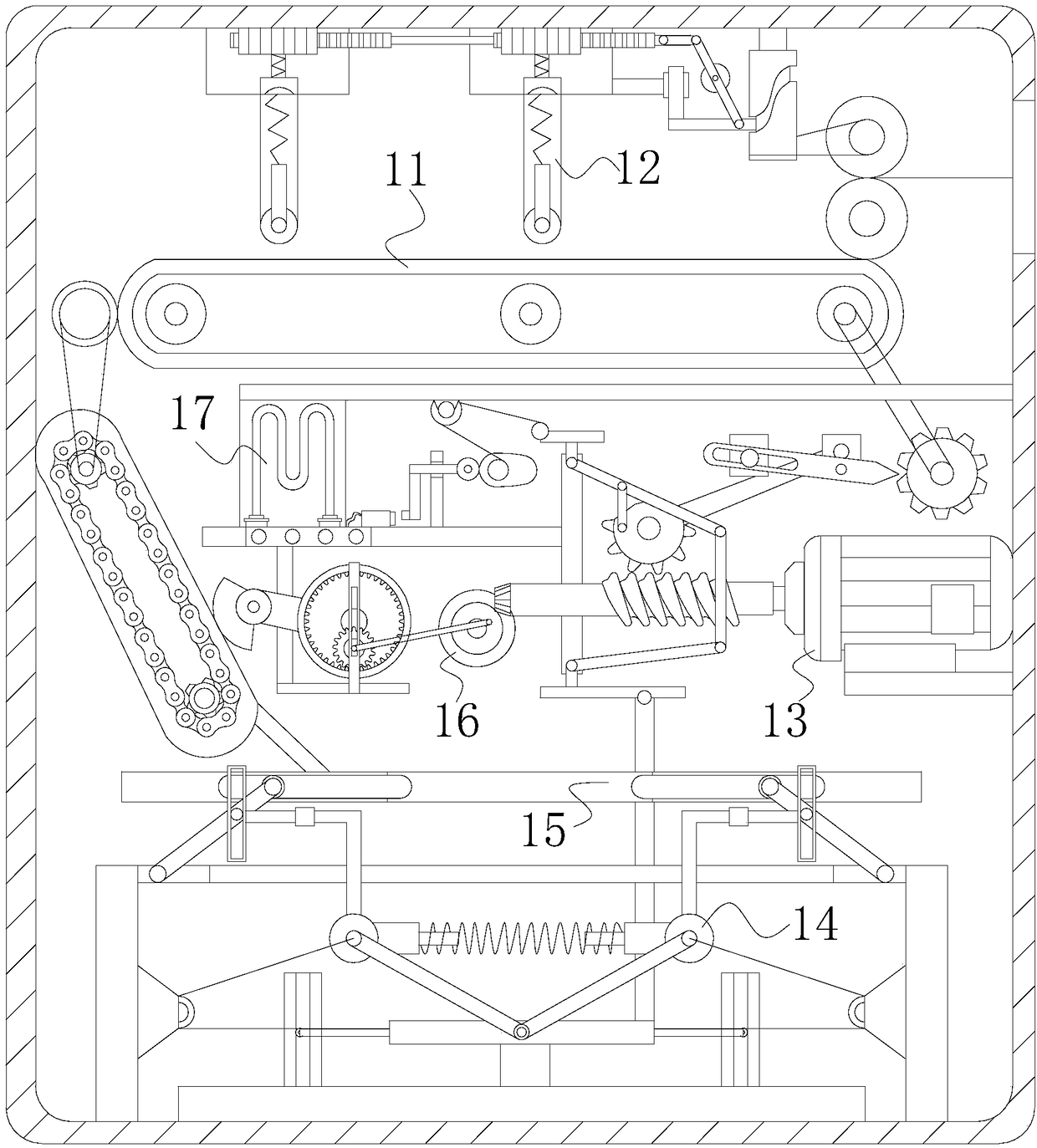

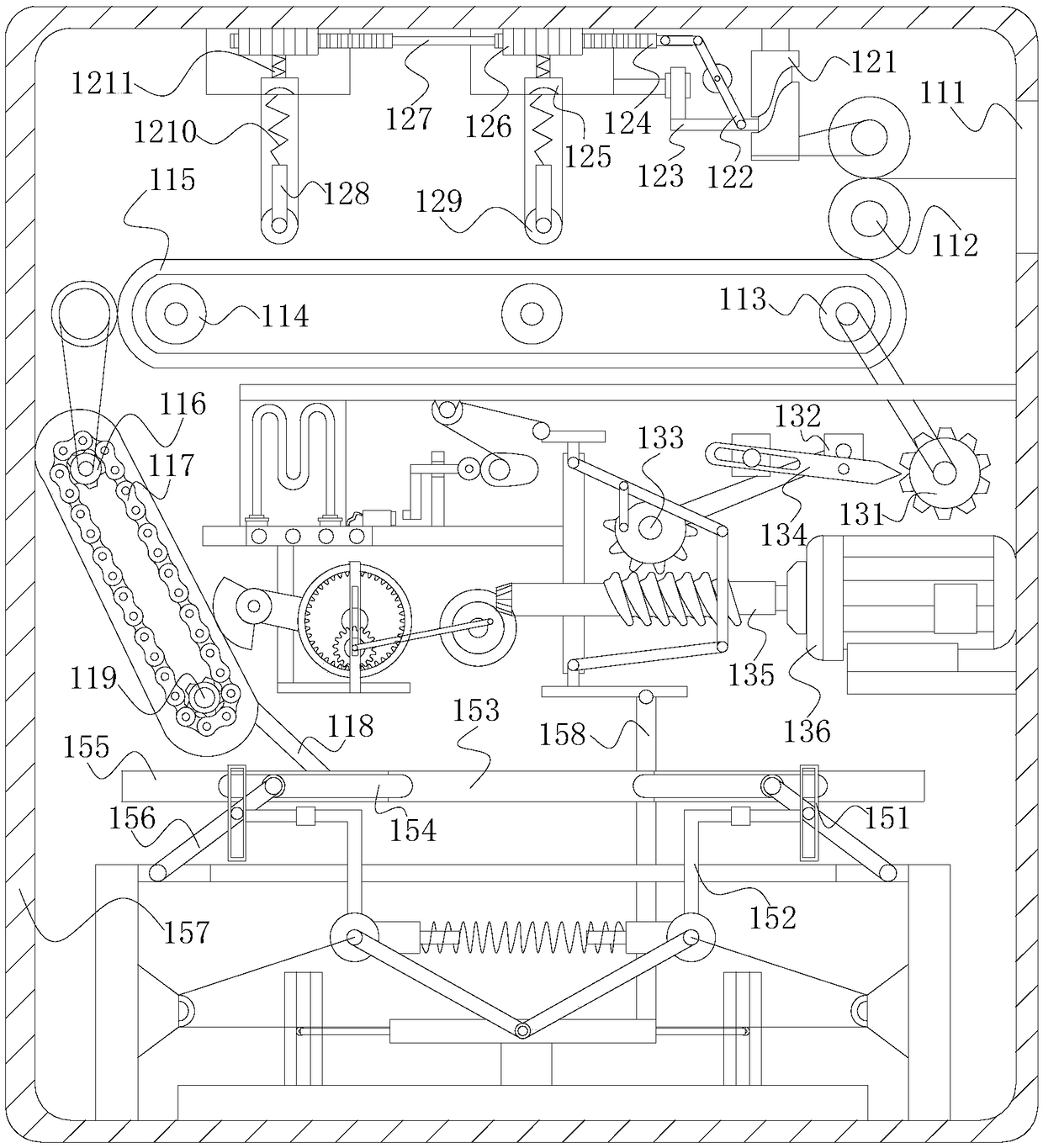

InactiveCN108796809AWinding levelNeatly rolledWarp knittingHeating/cooling textile fabricsEngineeringConductor Coil

The invention discloses a reeling device for a warp knitting machine. The reeling device structurally comprises a cloth reeling device, a connecting column, a winding roll, a mounting seat, a controlpanel, a control tank, indication lamps, a support frame, a support frame, anti-sliding bottom legs and a support base plate. According to the reeling device for the warp knitting machine, the cloth reeling device comprises a guiding device, a pressurizing mechanism, a starting mechanism, a transmission mechanism, an anti-meandering device, a stirring mechanism and a cooling device, so that a compression force can be applied to cloth when the cloth is reeled, the cloth can be flatly reeled, the situation that the slack cloth falls to the ground is avoided, and the cleanness of the cloth is increased; meanwhile, the cloth can be adjusted and reeled according to the width of the cloth, so that the reeled cloth is relatively order, and the reeling quality is improved; and meanwhile, the clothcan be well cooled in the working process of the winding roll, so that the situation that the cloth is deformed due to an over-high temperature, and the appearance of the cloth is influenced to a certain degree are solved.

Owner:FOSHAN XUNTUOAO TECH CO LTD

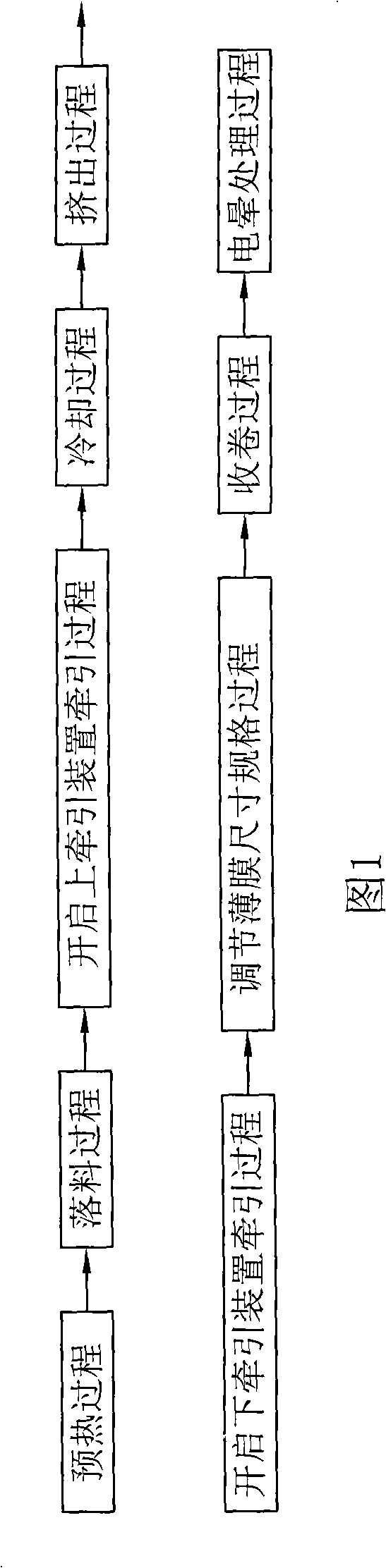

Preparation process of three-layer plastic coextrusion-lamination film

InactiveCN101298183AImprove physical performanceImprove barrier propertiesFlat articlesComposite filmCo extrusion

The invention discloses a preparation technology of three-layer plastic co-extrusion composite film, comprising the preparation steps as follows: (1) pre-heating process; (2) material falling process; (3) the starting of an upper traction device; (4) cooling process; (5) extruding process; (6) the starting of a lower traction device; (7) the adjusting of the size specification of the film; (8) roll-up process: carrying out the roll-up operation by utilizing a roll-up machine; (9) corona treatment process: starting an electric corona machine to carry out the corona treatment. The three-layer plastic co-extrusion composite film prepared by the preparation technology has high strength and good barrier property and air-tightness; meanwhile, different colours can be adopted, and the shading property and the fresh-keeping capability of the film are effectively improved.

Owner:JIANGMEN GUANGWEI PLASTIC BAG PRINTING ENTERPRISECO

Wrap-up device for textile

The invention discloses a wrap-up device for textile. The wrap-up device comprises a first bracket, wherein the vertical inner side wall of one side of the first bracket is fixedly connected with an ultraviolet lamp tube; the lower surface of the ultraviolet lamp tube is fixedly connected with a first distance sensor; the outer wall of one side, away from the first bracket, of the ultraviolet lamptube is fixedly connected with a second bracket; the vertical inner side wall of the first bracket and the vertical inner side wall of the second bracket are movably connected with the same first rotary rod and the same second rotary rod; the second rotary rod is arranged above the first rotary rod; the outer surface of the first rotary rod is fixedly connected with a rolling barrel; and the outer surface of the rolling barrel is movably connected with a first adhesive pad. The wrap-up device is simple in structure, is convenient to operate, and is additionally equipped with an electrostatic-elimination and distance-sensing device, so that hands of a worker do not easily generate an aching feeling, follow-up use of cloth is not affected, working efficiency is improved, compacting effect is more ideal, and wrapped textile fabric is more flat.

Owner:响水县奕杰制衣有限公司

Self-drying compound machine winding device

InactiveCN107416575AAchieve the purpose of dryingShorten the timeWebs handlingEvaporationConductor Coil

The invention discloses a rewinding device of a self-drying compound machine, which comprises a base, on which a machine body is arranged, two connecting frames are symmetrically arranged on the inner wall of the body, and a rotating frame is arranged between the two connecting frames. A transmission roller, a stretching roller is arranged to rotate in the body, a drying box is arranged in the body, a first drying roller and a second drying roller are arranged to rotate in the drying box, and a drying roller is arranged on the body. The surface is provided with a water steam box, and the lower end of the water steam box is provided with a communication pipe, and the end of the communication pipe far away from the water steam box is provided with a steam branch pipe frame, and the lower surface of the steam branch pipe frame is equidistantly provided with steam branch pipes, the The upper surface of the body is symmetrically provided with rectangular through holes, and the upper surface of the body is symmetrically provided with two grooves. The invention is ingenious in structure, easy to use, does not need additional drying equipment to dry the composite glue, and has smooth winding, and is convenient to disassemble and collect after winding, which can save a lot of time and energy of the staff, and is worth popularizing.

Owner:JIANGSU HONGHUA SPECIAL EQUIP CO LTD

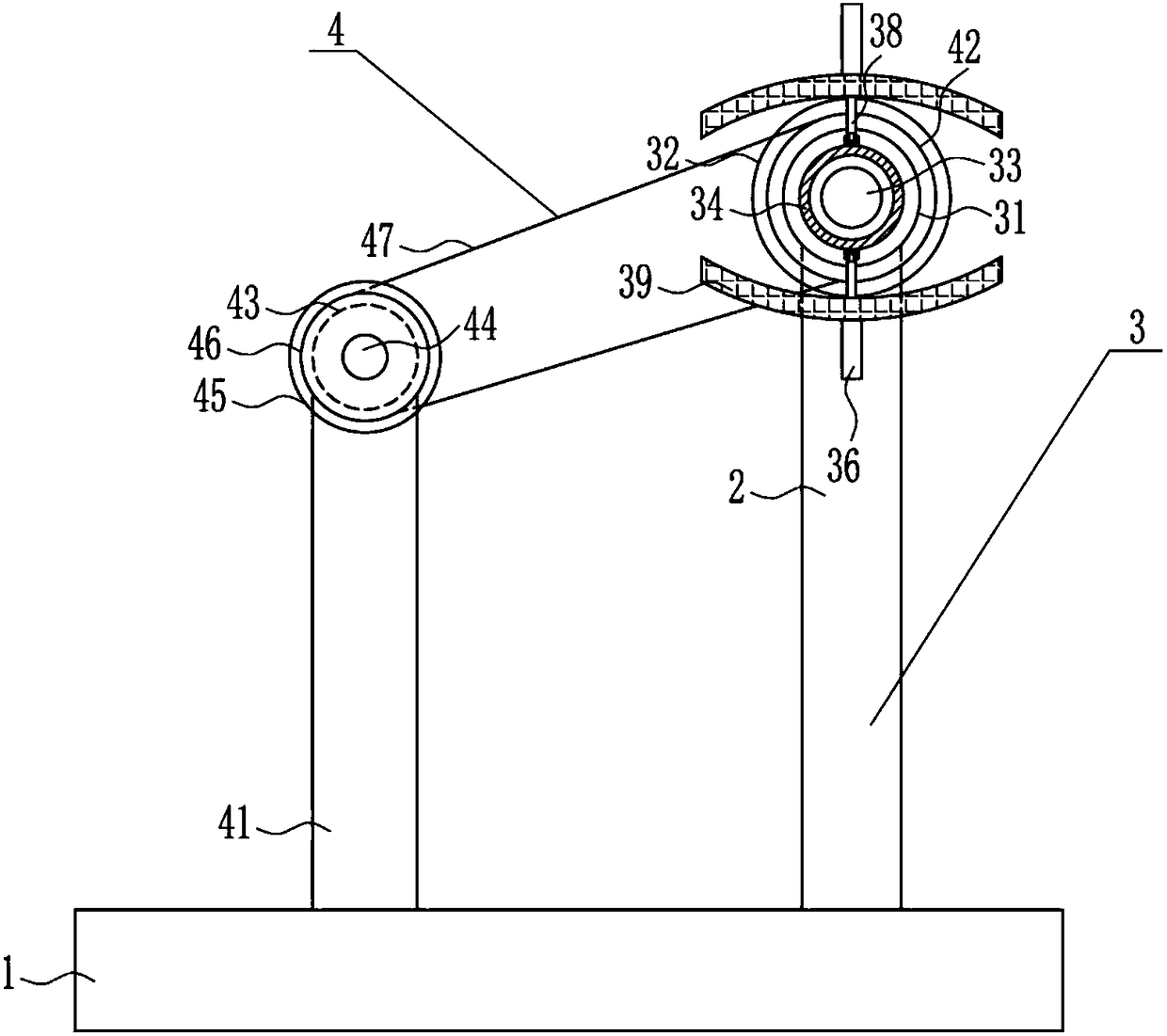

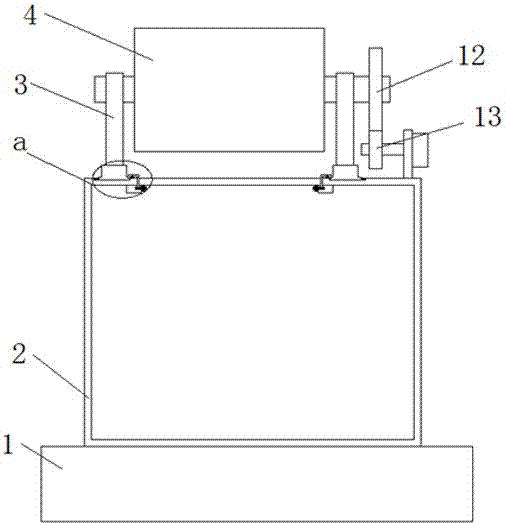

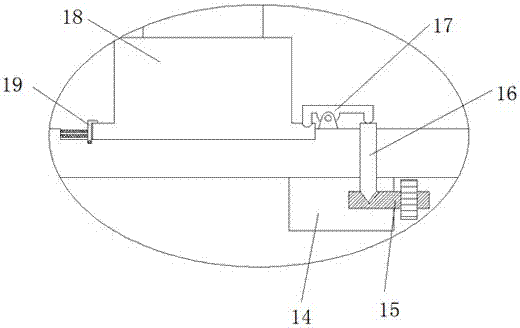

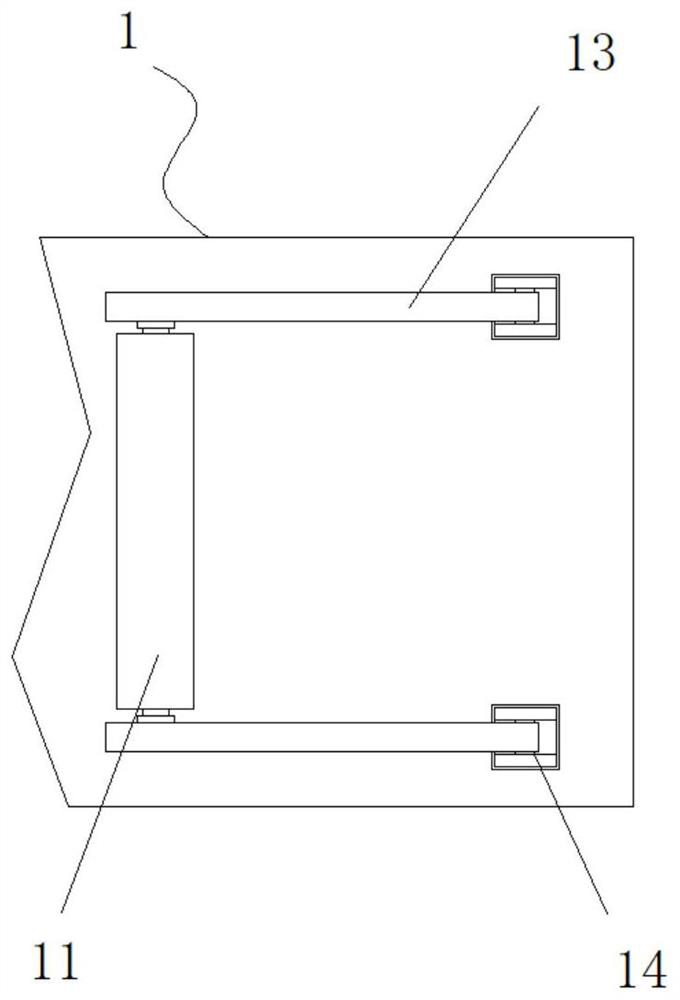

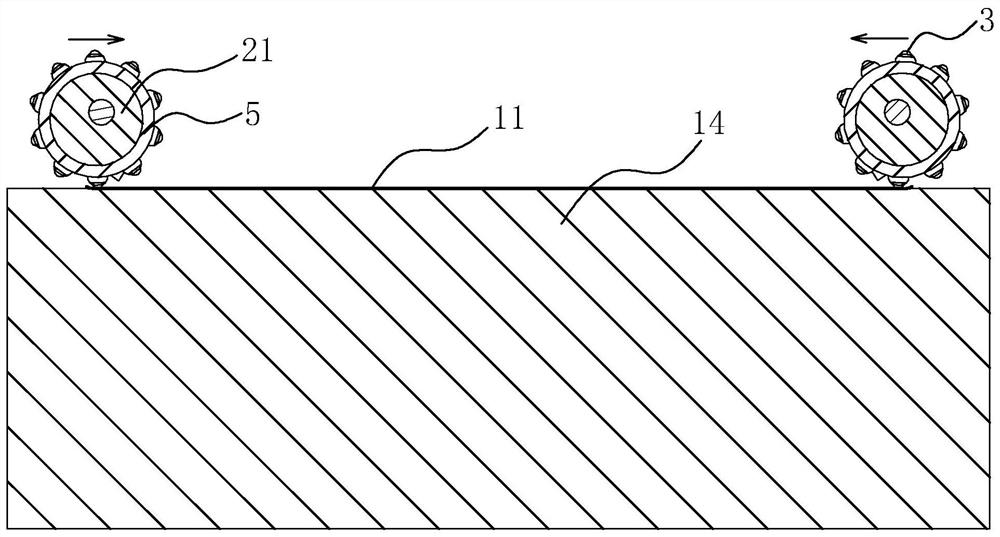

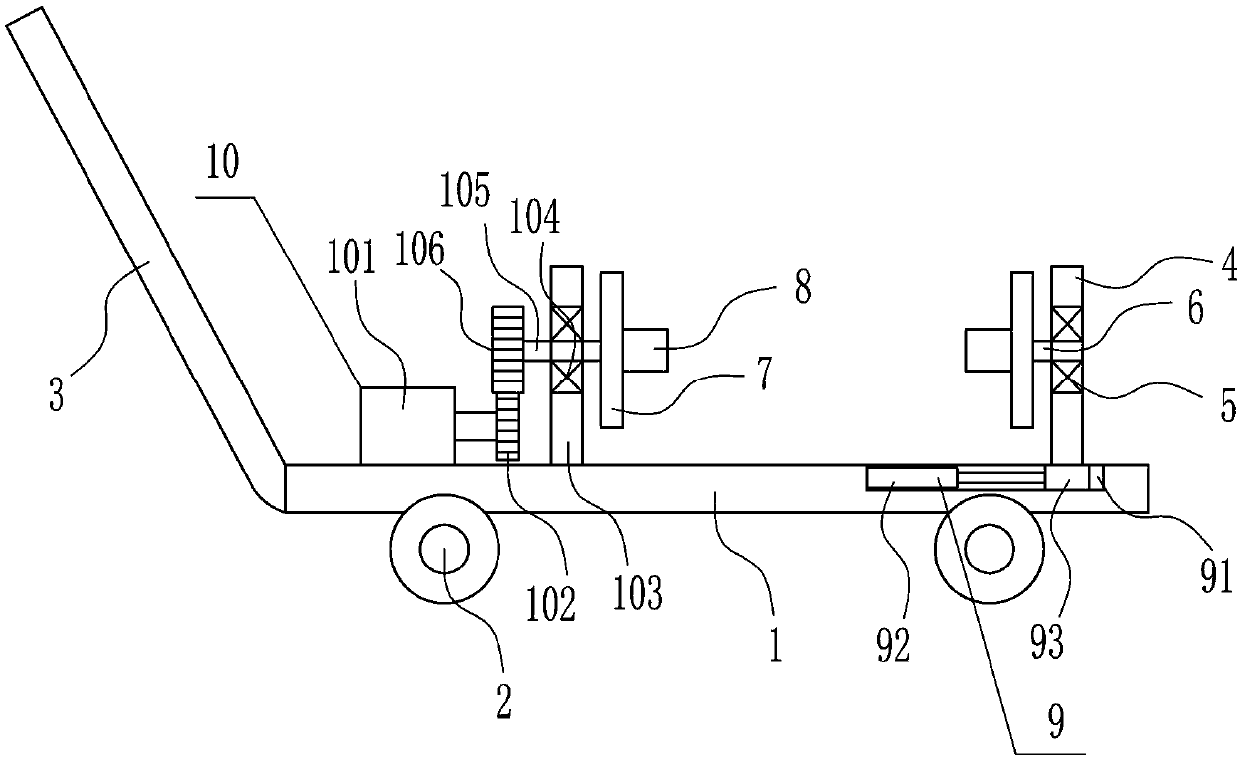

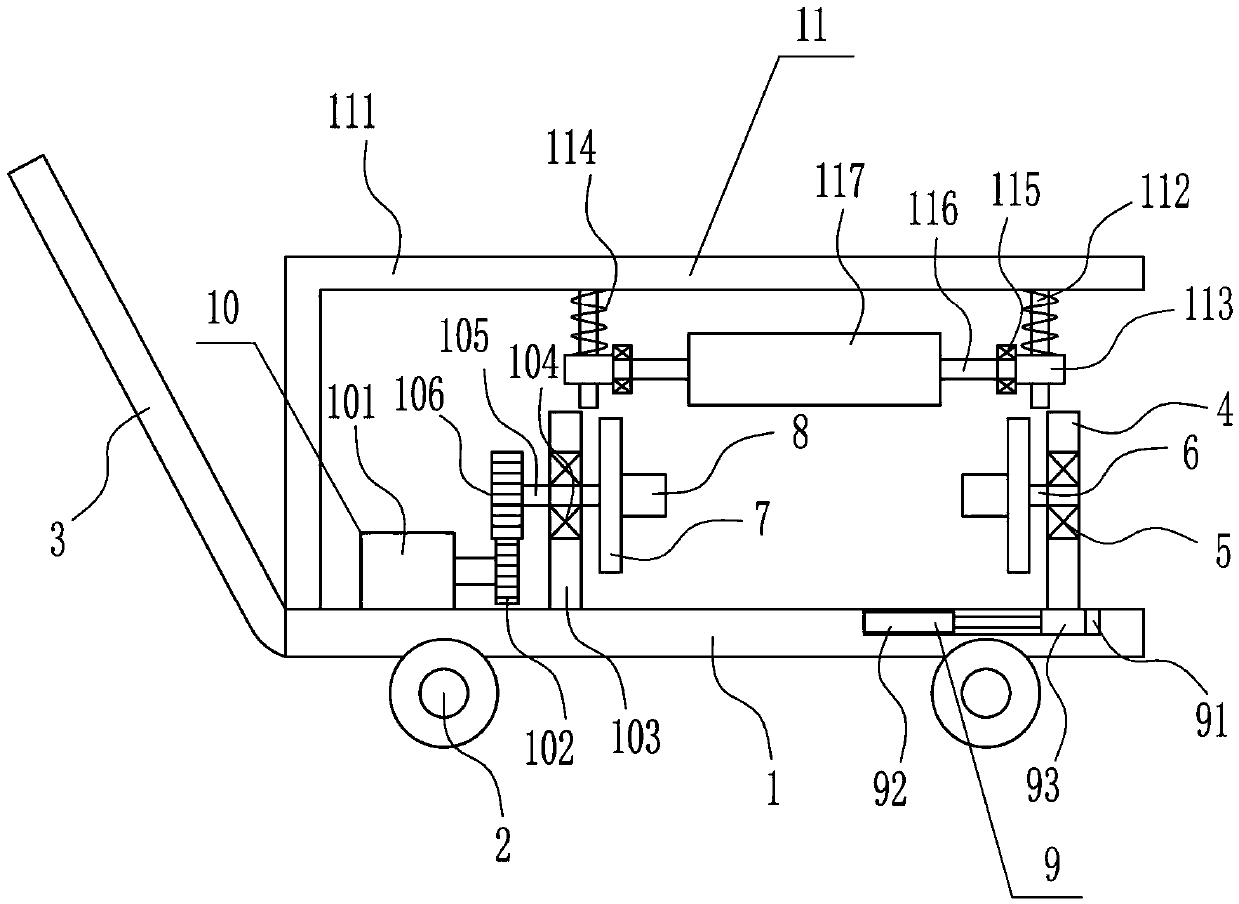

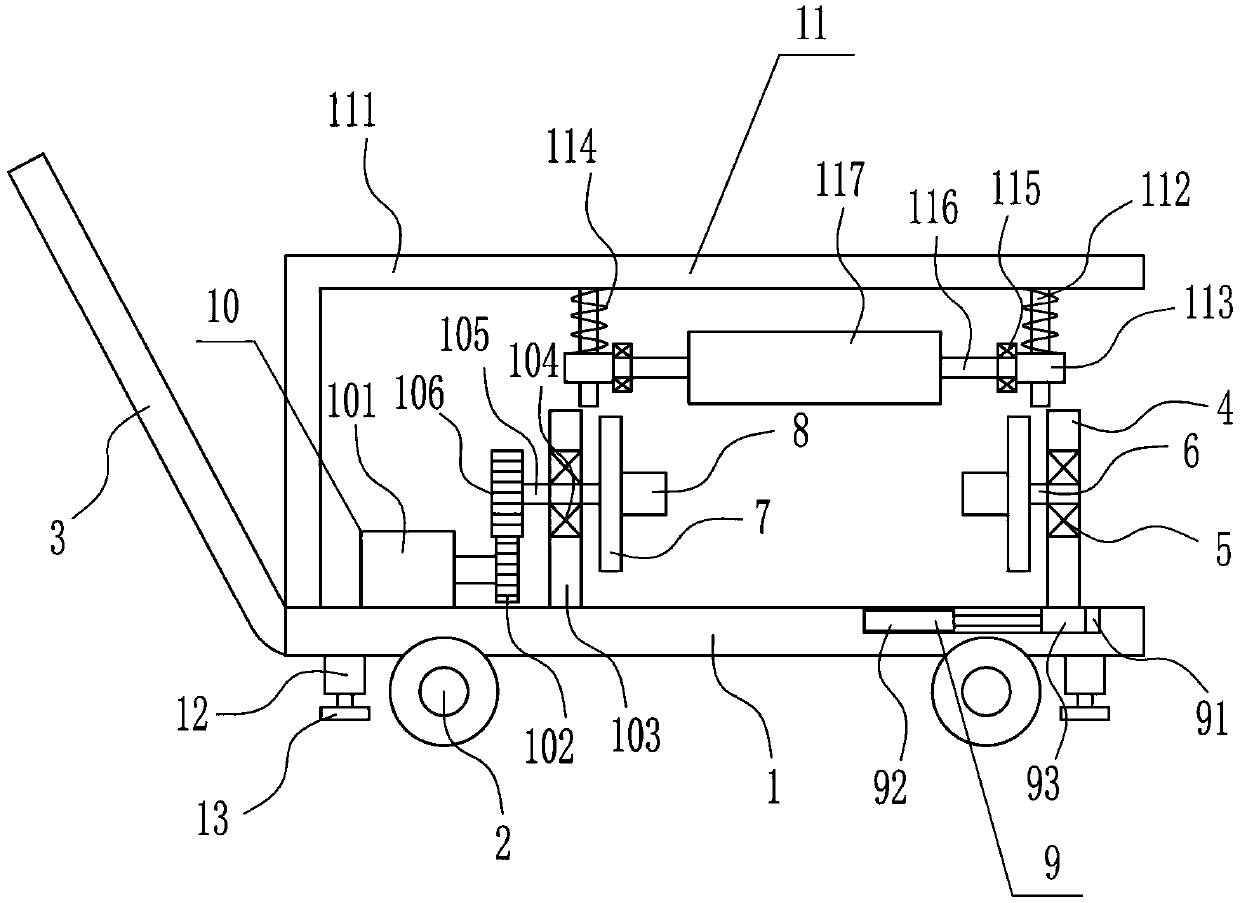

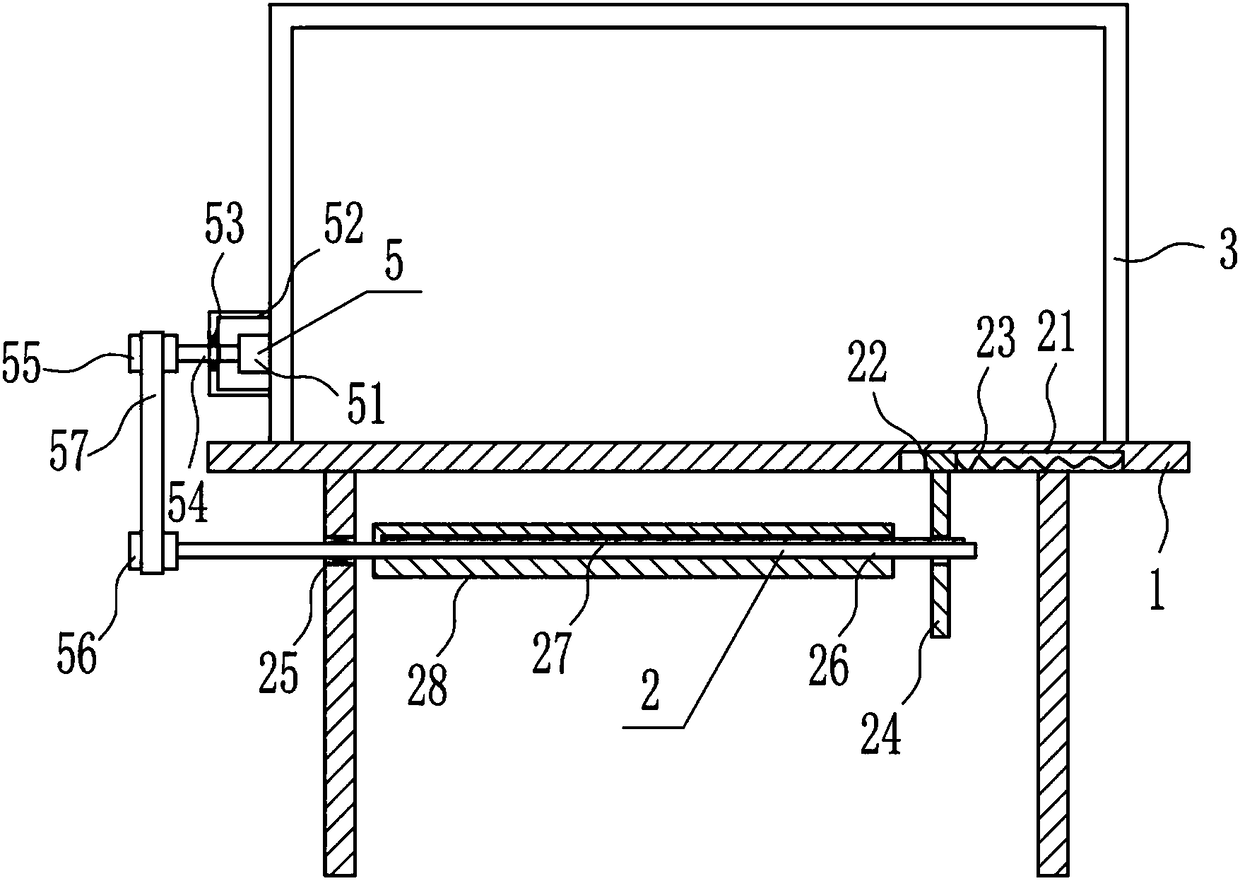

Clothing production dye device based on non-woven fabric lifting principle

InactiveCN112824573AIncrease distanceIncrease contactTextile treatment carriersLiquid/gas/vapor textile treatmentElectric machineryNonwoven fabric

The invention relates to the technical field of garment production, and discloses a clothing production dye device based on a non-woven fabric lifting principle. The clothing production dye device comprises a top plate; the upper end of the top plate is movably connected with a motor; the right end of the motor is movably connected with a roller; the interior of the roller is movably connected with a steel wire rope; a lifting frame is movably connected to the end, away from the roller, of the steel wire rope; a sliding rod is movably connected to the right end of the lifting frame; and a connecting rod is movably connected to the left side of the bottom end of the top plate. According to the clothing production dye device based on the non-woven fabric lifting principle, the roller, the steel wire rope, the lifting frame, the sliding rod and other structures are matched for use, so that the effect of uniform dye is achieved; in addition, the effect of flat dyeing is achieved through cooperative use of the structures such as a guide cylinder, gauze, a movable roller, a bearing pedestal and the like; and the effect of flat winding is achieved through cooperative use of the structures such as a sliding rail, a sliding block, a movable block, a pressing plate and the like.

Owner:HUNAN UNIV OF TECH

Soft base material winding device

The invention discloses a soft base material winding device, belonging to the technical field of soft base material machining. A rack comprises a first wall board and a second wall board; two ends of an anti-sticking roller are connected on the first wall board and the second wall board; two ends of a winding roller are connected on the first wall board and the second wall board; a pair of big sprockets are arranged on a pair of second bearing seats; a pair of roller forks are fixed inside the pair of big sprockets; a fork opening is arranged on each of the roller forks; two ends of a winding shaft are arranged in a pair of fork openings; a pair of small sprockets are arranged below the pair of big sprockets; two ends of a connecting roller are arranged on the pair of small sprockets; a pair of first chains are connected between the pair of big sprockets and the pair of small sprockets; a roller fork angle adjusting mechanism is arranged outside the first wall board; and a power transmission mechanism is arranged outside the second wall board. The soft base material winding device has the following advantages: a soft base material film is enabled to be flat in a winding process, so that the product quality is improved; and the film is convenient and fast to wind and easy to change, so that the product quality can be better controlled.

Owner:江苏双成新材料有限公司

Plastic film processing and forming device

InactiveCN113352643AGood molding effectImprove hygiene qualityDispersed particle filtrationFlat articlesDust controlPlastic film

The invention discloses a plastic film processing and forming device, and particularly relates to the technical field of plastic film processing. The plastic film processing and forming device comprises a bottom plate and an extruder, wherein one side of the top end of the bottom plate is fixedly connected with the extruder, one side of the top end of the extruder is fixedly connected with a fixing plate, one side of the fixing plate is fixedly connected with a charging barrel, the top end of the charging barrel is fixedly connected with a feeding port, and one side of the extruder is provided with a rapid cooling and pressing mechanism. According to the plastic film processing and forming device, a negative pressure box, an exhaust fan, a dust filtering net, an exhaust pipe, dust suction covers, a clamping block and a clamping groove are arranged, when the plastic film processing and forming device is used, the exhaust fan is started, the exhaust fan is used for pumping the interior of the negative pressure box into negative pressure, so that dust and impurities attached to a plastic film passing through the dust suction covers can be pumped into the negative pressure box through the exhaust pipe, and are collected in the negative pressure box after being filtered by the dust filtering net, and as a result, dust removal before the plastic film is wound can be realized, and the sanitary quality of the plastic film is improved.

Owner:刘和斌

Intelligent cloth inspecting machine

PendingCN110144719ABar rotationSmooth rotationInspecting textilesEngineeringUltimate tensile strength

The invention discloses an intelligent cloth inspecting machine which comprises a rack as well as a unwinding device, a cloth tensioning device, a cloth image collecting unit, a correcting device anda controller disposed on the rack, wherein the unwinding device comprises two supporting plates which are disposed opposite to each other; the supporting plates are fixedly connected with the rack; aplurality of cross bars disposed in an arc shape are connected between the supporting plates; two ends of each cross bar are respectively and rotationally connected with the supporting plates. By adopting the intelligent cloth inspecting machine, the accuracy of the cloth inspection can be improved, the occurrence of the wrong inspection and the missed inspection can be effectively prevented, thelabor intensity of an operator can be reduced, and cloth winding is uniform and consistent, and meets the requirements of the batch inspection of cloth.

Owner:苏州艾恩西精密五金有限公司

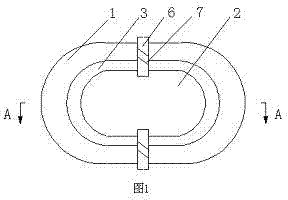

Framework type wire passing ring

Owner:汪正新

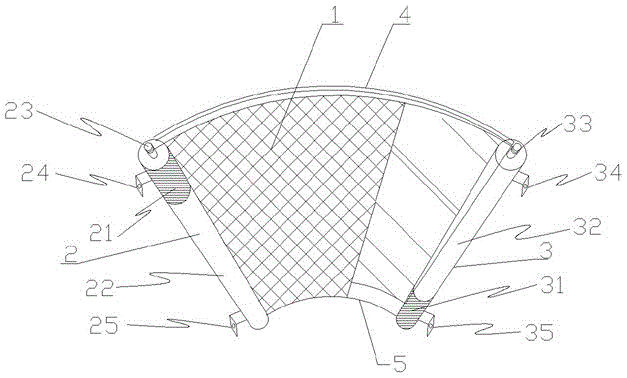

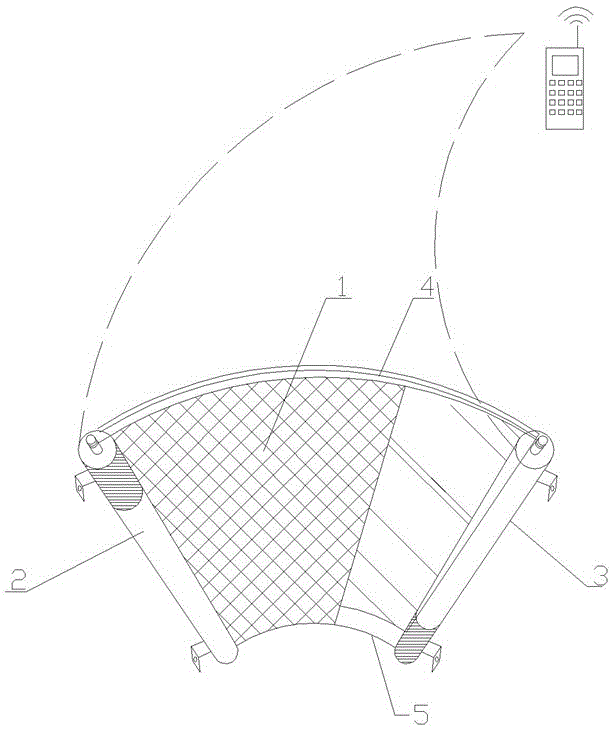

Marine electric curtain, control system and control method

The invention discloses a marine electric curtain, a control system and a control method. The marine electric curtain is arranged on a window and is provided with a curtain body, a first electric winding device arranged on one side of the window, a second electric winding device arranged on the other side of the window and having a winding speed different from that of the first electric winding device, an upper traction piece fixedly connected with the upper edge of the curtain body and connected with the first electric winding device, and a lower traction piece fixedly connected with the lower edge of the curtain body and connected with the second electric winding device. The upper traction piece is connected with the second electric winding device in a driven mode. The lower traction piece is connected with the first electric winding device in a driven mode. The control system of the marine electric curtain comprises a circuit board and a remote controller. The marine electric curtain can be used for various types of inequilateral arc-shaped glass; appearance can be smooth, laminated and attractive; cost and the energy consumption can be lowered; meanwhile, the marine electric curtain has the advantages of being convenient to carry, flexible to control and convert, small in noise and convenient to install and maintain.

Owner:澳龙船艇科技有限公司

A kind of cloth winding device and winding method

This application discloses a method of receiving device and scrolls of fabrics, involving the technical field of the scripture machine. The roll -up device includes roll rollers, roll rollers and weaving areas used to collect the fabrics in the weaving area for roll rolled roll rolls, roll rollers and weaving areas.There is a fabric exhibition mechanism between the fabrics. The fabric exhibition mechanism includes the two -hearted roller that is used to drive the side of the fabric to the center of the fabric.The platform that supports fabrics is located below the eccentric roller; rolling beads on the eccentric roller; the roller is evenly distributed;The top is higher than the radial bottom of the eccentric roller. The length of the top roller is parallel to the length direction of the roller roller;This application improved the phenomenon of rolls caused by rolls due to elastic fabrics during the collection.

Owner:福建豪丰纺织有限公司

Winding device for cloth

Owner:钱杭健

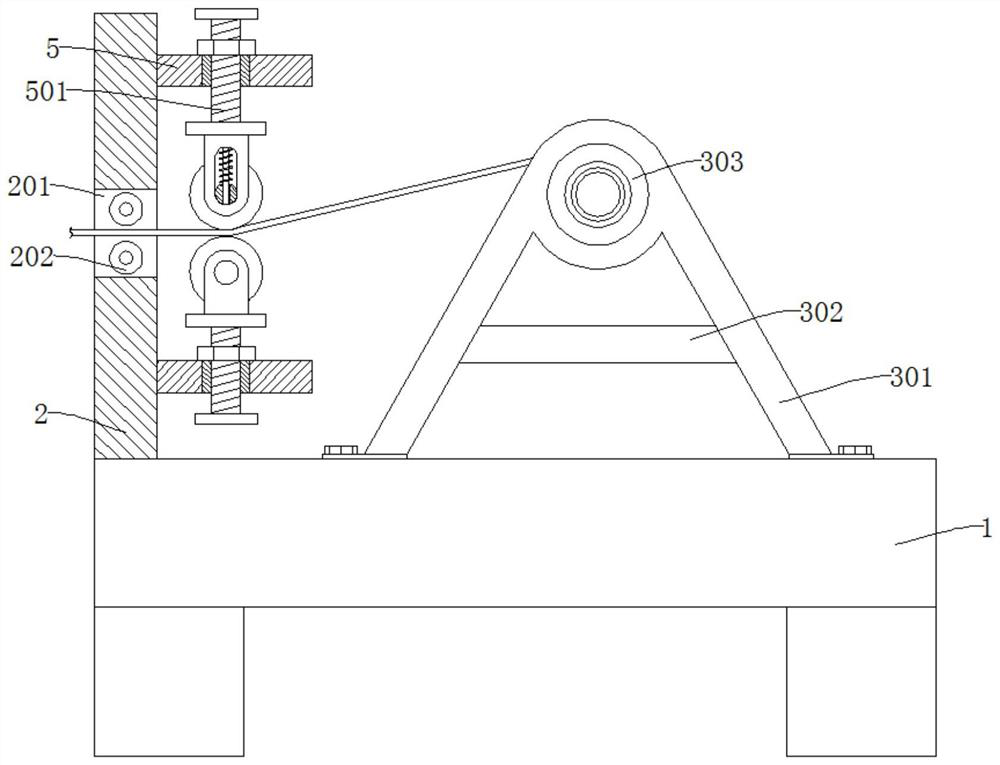

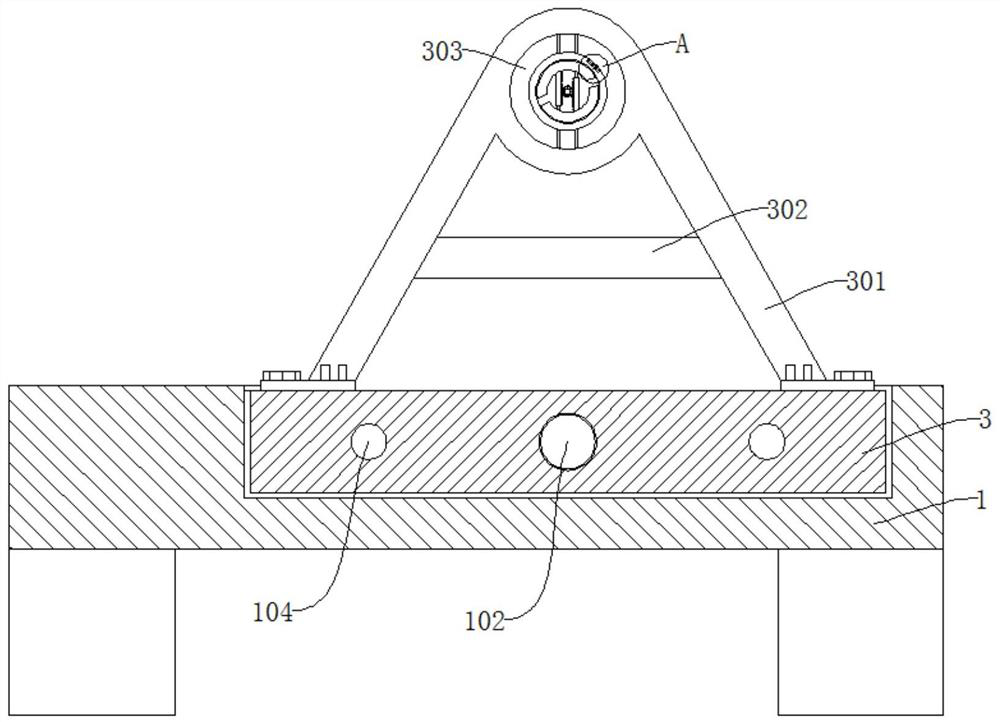

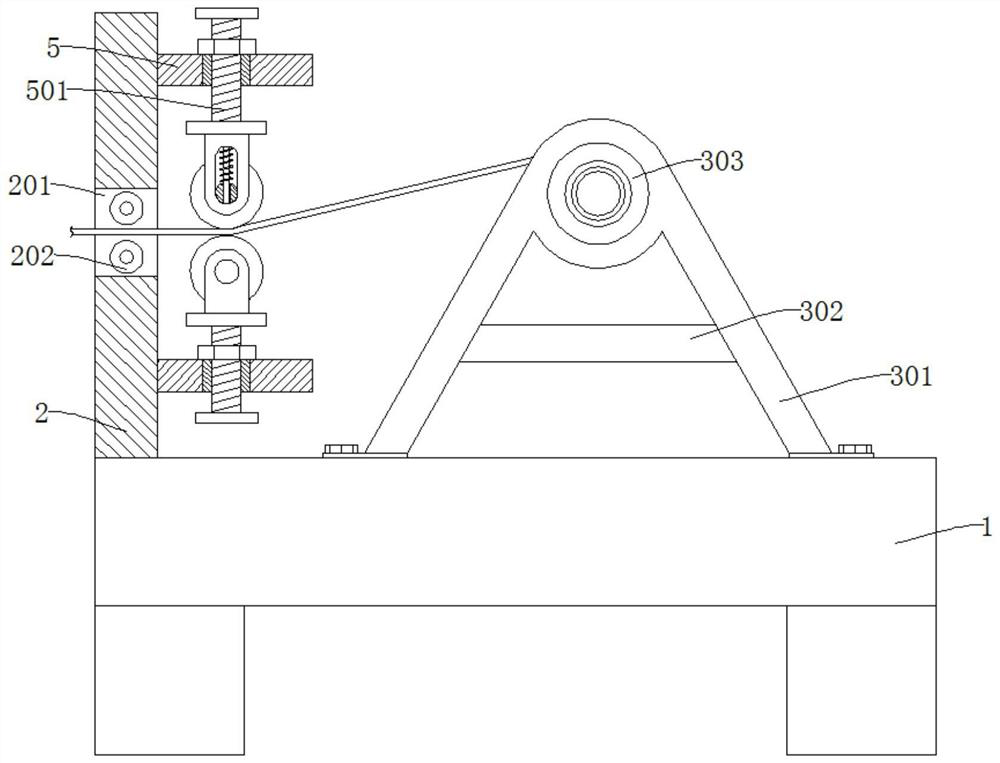

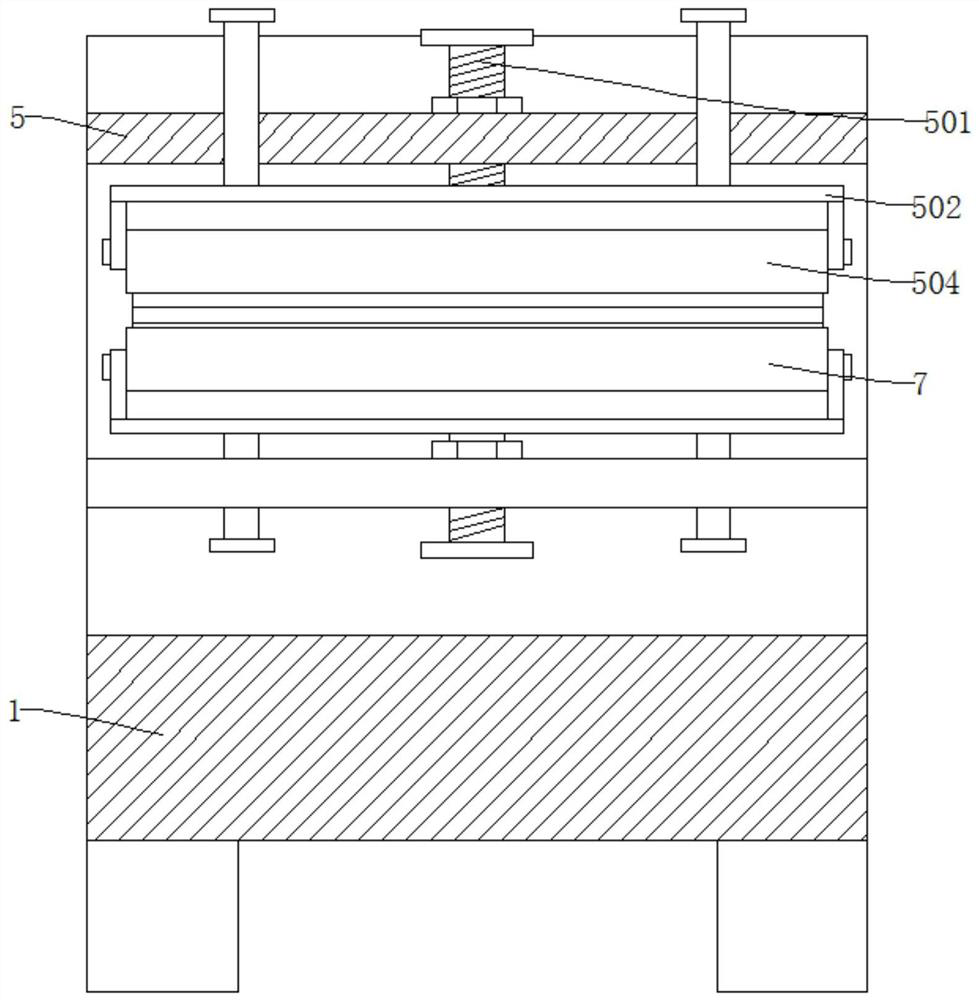

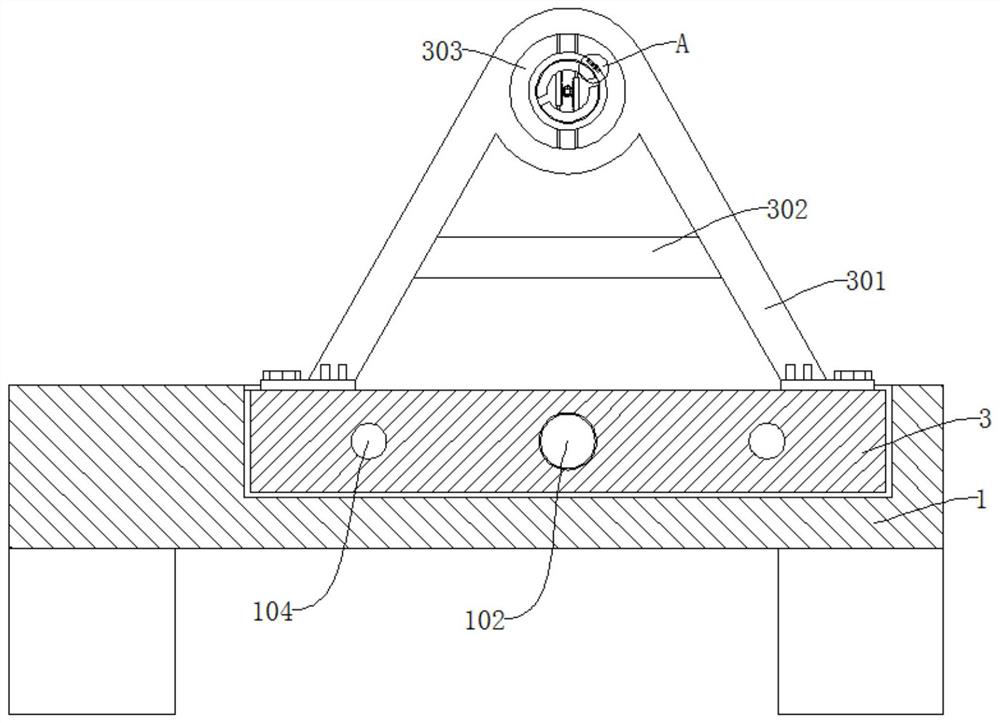

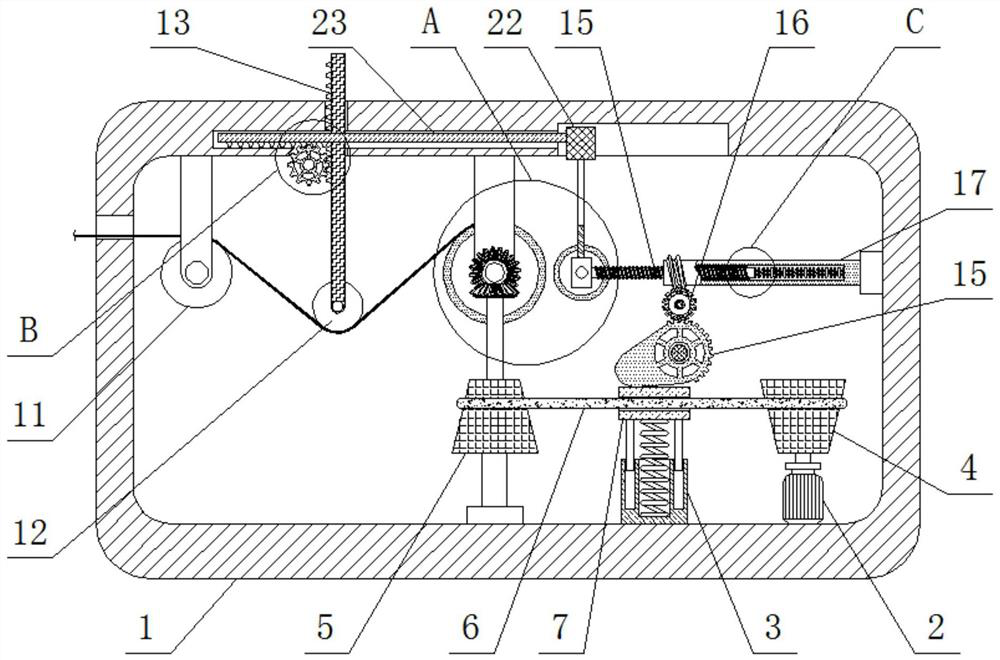

Winding speed regulating mechanism for polyethylene terephthalate (PET) aluminum foil production

InactiveCN112224942ATransmission ratio is smallReduce rotation speedFunction indicatorsWebs handlingPolyethylene terephthalatePolyethylene terephthalate glycol

The invention relates to the technical field of aluminum foil winding, and discloses a winding speed regulating mechanism for polyethylene terephthalate (PET) aluminum foil production. The winding speed regulating mechanism for PET aluminum foil production comprises a box body, wherein a movable rod is inserted into the top of the box body; a movable roller is rotatably connected to the bottom ofthe movable rod; a first gear is rotatably connected to the inner bottom wall of the box body; two rotating cylinders are rotatably connected to the inner right wall of the box body; threaded rods areinserted into the left sides of the two rotating cylinders correspondingly; fixing blocks are fixedly connected to the left sides of the two threaded rods correspondingly; a triangular frame is fixedly connected to the tops of the two fixing blocks; a sliding block is fixedly connected to the top of the triangular frame; and a transverse rod is fixedly connected to the left side of the sliding block. When the fixing blocks move rightwards, the movable roller is driven to press an aluminum foil downwards through cooperation of the triangular frame, the sliding block, the transverse rod, the first gear and the movable rod, so that the aluminum foil is in a tensioned state, and the situation that after the rotating speed of the winding roller is reduced, the aluminum foil behind passes through the rotating roller at the original speed under the inertia effect, and consequently the tension of the aluminum foil is too small before winding so as to generate gaps is prevented.

Owner:广东芭沐思日化有限公司

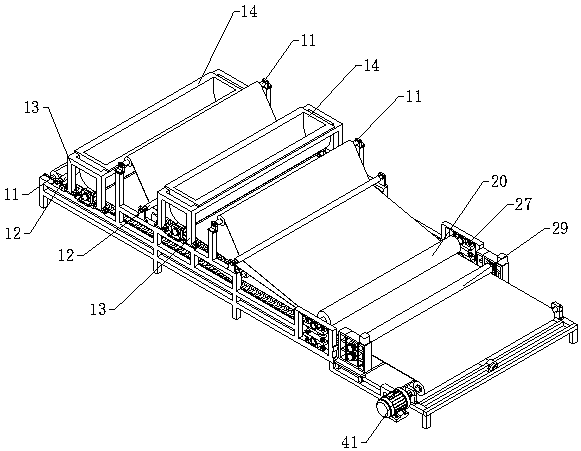

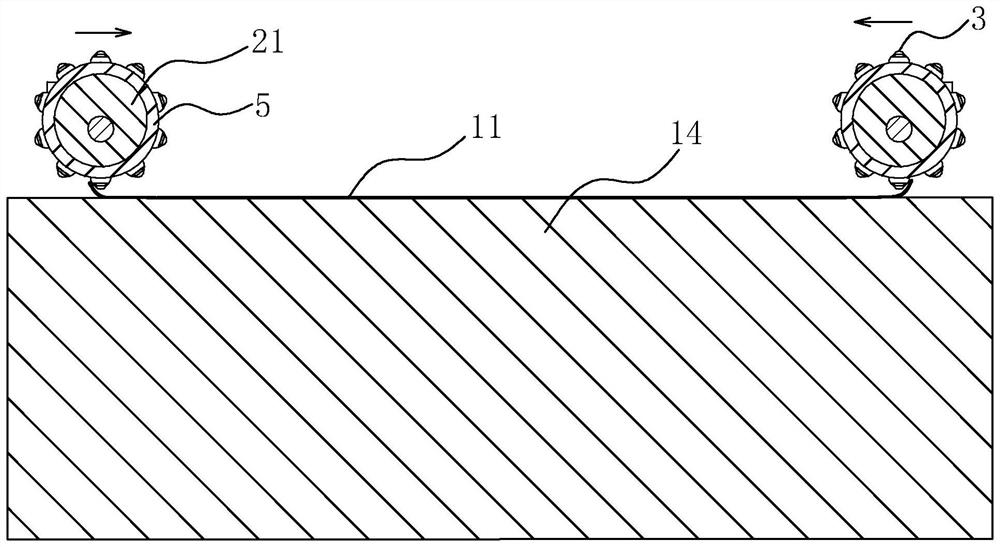

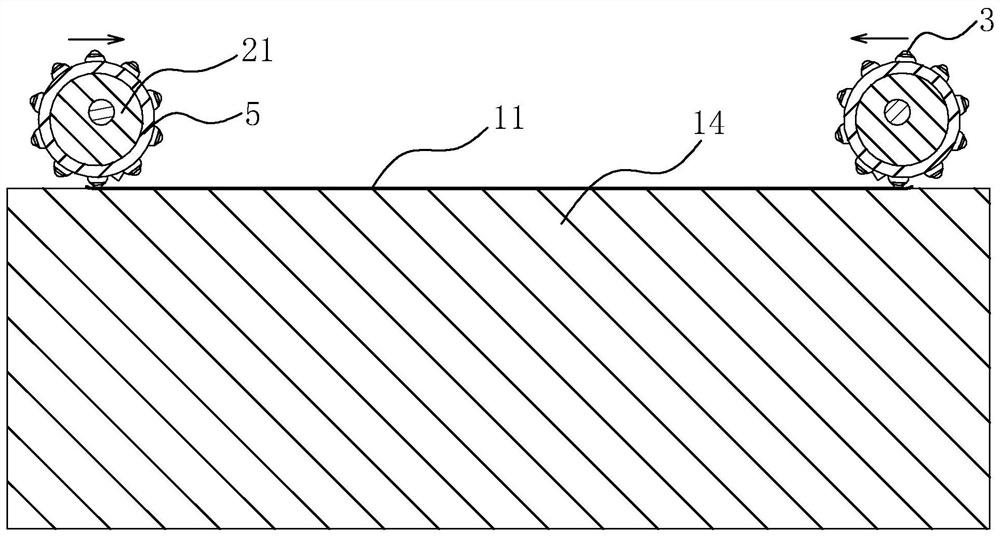

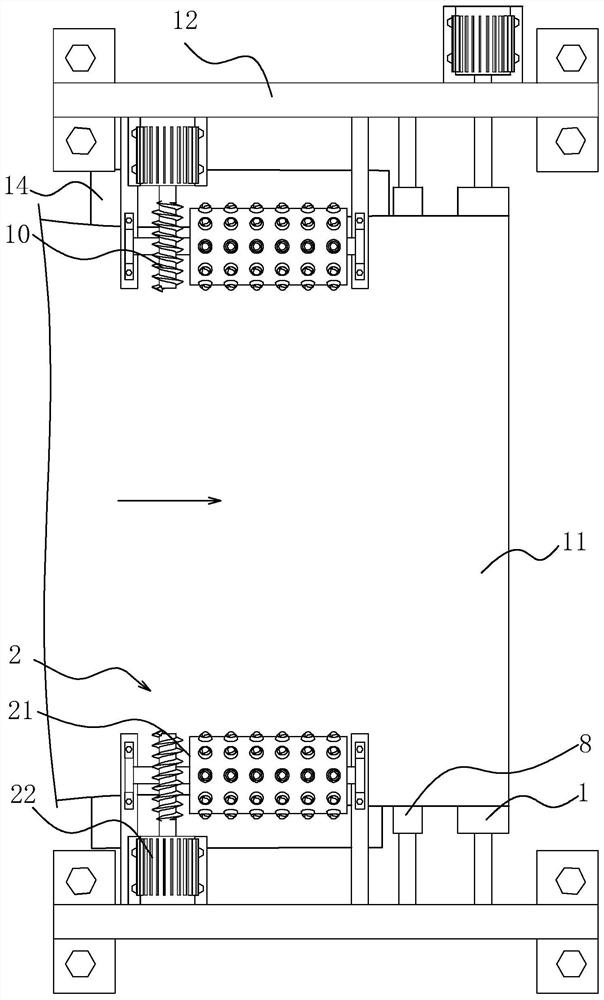

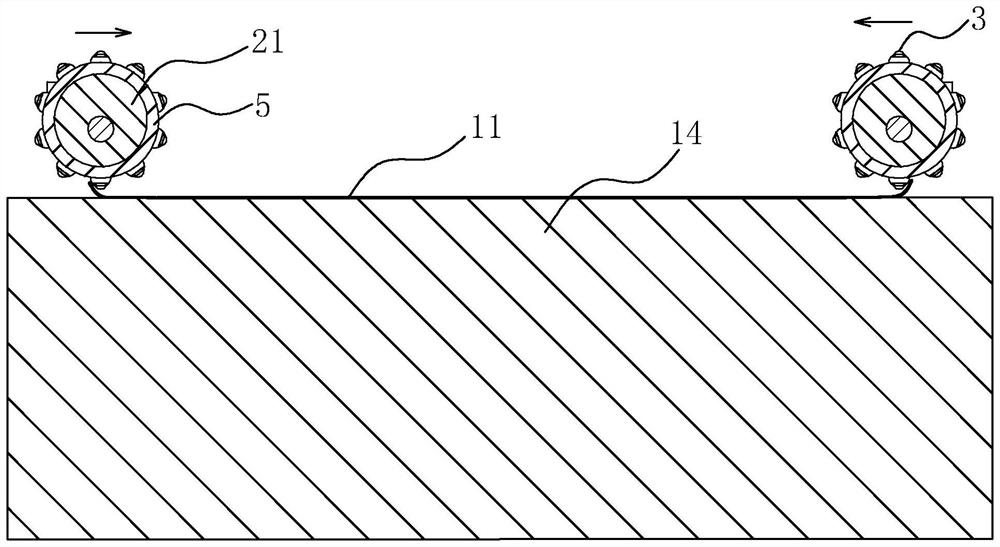

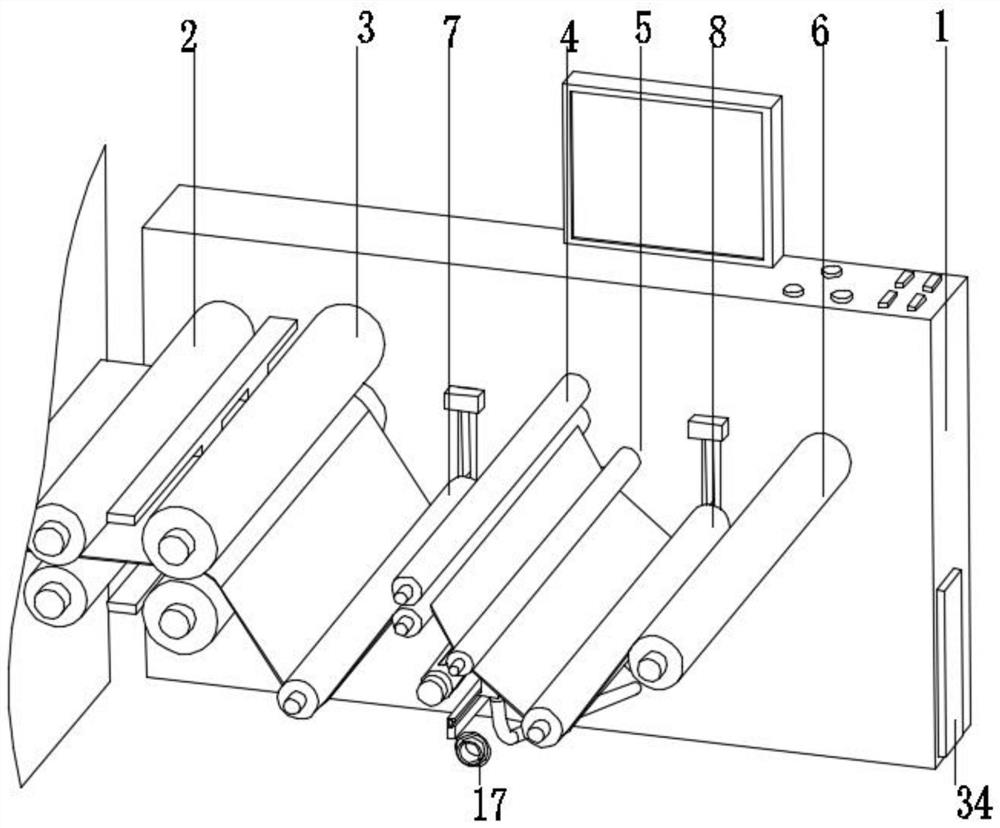

Cloth winding device and cloth winding method

The invention discloses a cloth winding device and a cloth winding method, and relates to the technical field of warp knitting machines. The winding device comprises a cloth winding roller used for winding cloth in a knitting area, and a cloth edge unfolding mechanism is arranged between the cloth winding roller and the knitting area; the cloth edge unfolding mechanism comprises two eccentric rollers used for driving the two side edges of cloth to be away from the center of the cloth, and the length direction of the eccentric rollers is the same as the conveying direction of the cloth; the cloth edge unfolding mechanism further comprises a platform used for supporting cloth, and the platform is located below the eccentric rollers; balls are mounted on the eccentric rollers in a rolling manner; the balls are uniformly distributed; and the cloth edge unfolding mechanism further comprises a top roller, the top roller is located between the eccentric rollers and the cloth winding roller, the radial top end of the top roller is higher than the radial bottom ends of the eccentric rollers, and the length direction of the top roller is parallel to the length direction of the cloth windingroller. The cloth edge unfolding mechanism further comprises a driving piece used for driving the eccentric rollers to rotate. According to the device and the method, the phenomenon of uneven windingcaused by hemming of the elastic cloth in the winding process is avoided.

Owner:福建豪丰纺织有限公司

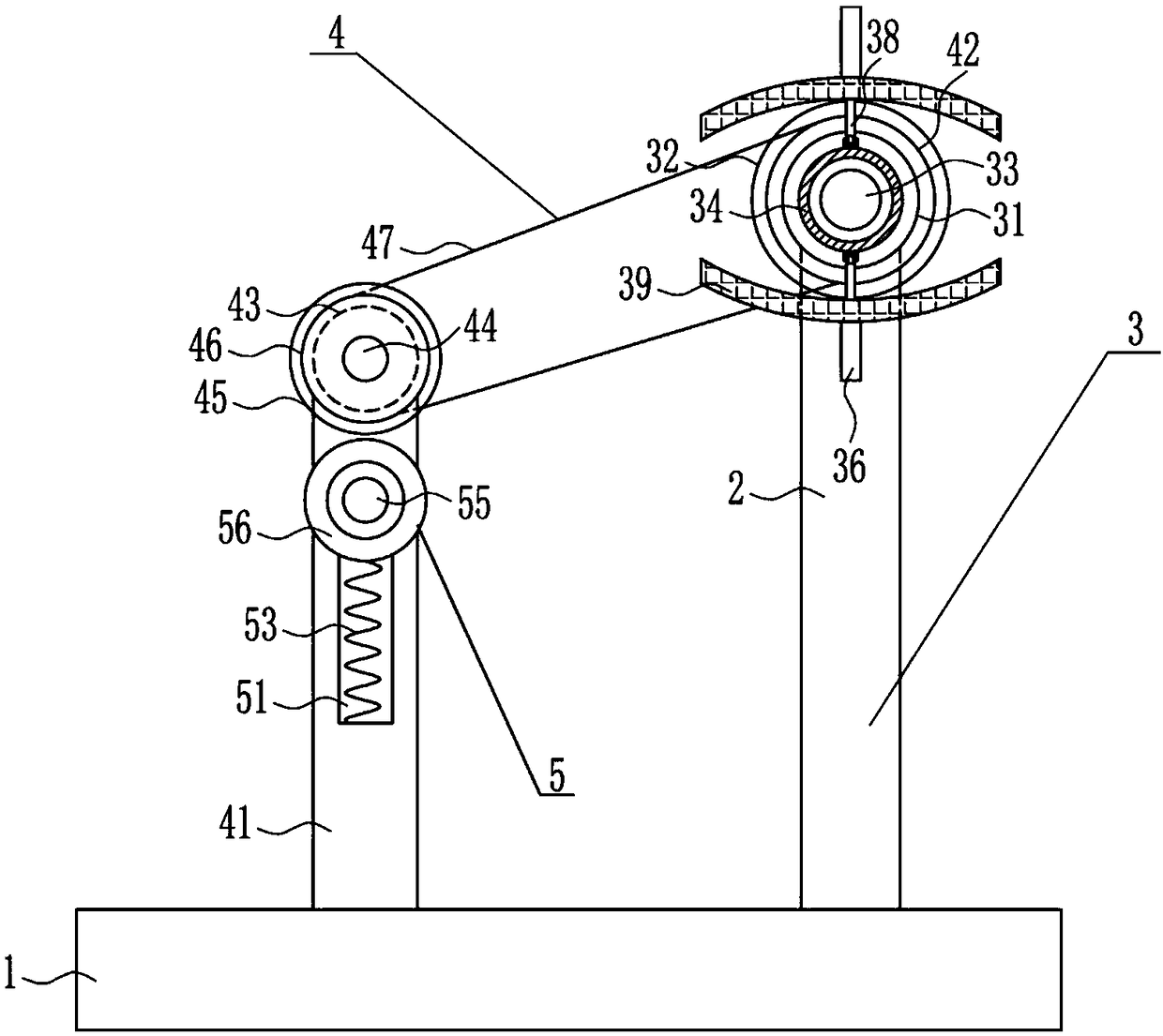

A cable winding device for power station construction

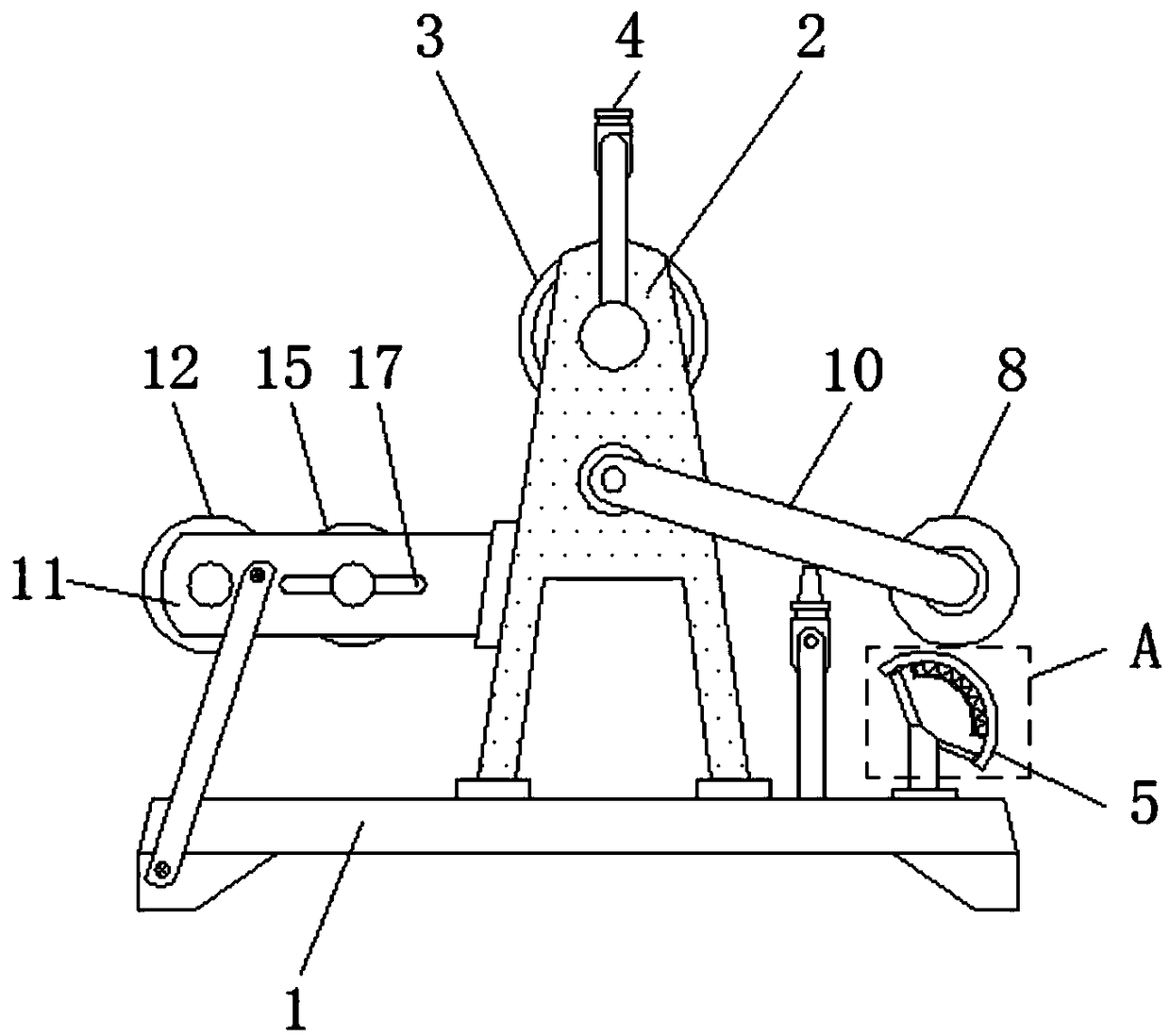

The invention relates to a winding device, in particular to a cable winding device for power plant construction. In order to solve the technical problems, the cable winding device which saves time and labor, is flat in winding, can well pull a cable out of a winding drum for use, and improves the work efficiency is provided. The cable winding device comprises a bottom plate, wheels, a handle, a first fixed plate, a first bearing base, a first rotating shaft and the like. The wheels are installed on the left side and the right side of the bottom of the bottom plate in a bolt connection mode. The handle is installed on the left side face of the bottom plate in a bolt connection mode. The handle is obliquely installed. A movable device is arranged on the right side of the top of the bottom plate. The first fixed plate is connected with a movable part of the movable device. The cable winding device has the advantages of saving time and labor, being flat in winding, being capable of well pulling the cable out of the winding drum for use and improving the work efficiency.

Owner:SHENZHEN POWER SUPPLY BUREAU +1

Straw plaited winding device

ActiveCN111689303AWinding levelWinding effectFilament handlingAgricultural engineeringStraw plaiting

The invention relates to a winding device, and particularly relates to a straw plaited winding device. The technical problem is how to design the straw plaited winding device which can be more convenient for people to wind straw ropes, is high in working efficiency and can wind the straw ropes neatly. The straw plaited winding device comprises a base, wherein a supporting block is fixedly connected to the middle of one side of the base; a vertical plate is fixedly connected to the edge of one side of the supporting block; a bearing seat is installed on the portion, away from the supporting block, of the vertical plate in an embedded mode; and a rotating shaft is rotationally connected into the bearing seat in a penetrating mode. According to the straw plaited winding device, the straw ropes are wound around all top blocks by a circle, then a rocker is pulled to rotate forwards, so that the top blocks rotate forwards to wind the straw ropes; after the straw ropes are wound, a handle ispulled to move forwards, so that the top blocks move inwards to loosen the straw ropes; and then the wound straw ropes are taken down, and the straw ropes do not need to be pulled by people to be wound on a tool for winding, so that the winding device is more convenient, and the working efficiency is improved.

Owner:邓志香

Winding equipment for plastic bag production

The invention relates to winding equipment, in particular to winding equipment for plastic bag production. The winding equipment comprises a workbench and the like and is characterized in that a winding device is mounted on the left side of the workbench, an n-shaped plate is connected to the left side of the top of the workbench, a drive device is mounted on the rear side of the n-shaped plate, and the drive device is connected with the winding device. The winding equipment has the advantages that plastic bag winding is achieved through the drive device, a guide device is used for guidance, and the winding equipment is capable of achieving flat winding and convenient to use.

Owner:方宣崇

Automatic winding equipment for lithium strip production

InactiveCN112278939AImprove uneven winding thicknessWinding levelDirt cleaningWebs handlingWinding machineBatch production

The invention discloses automatic winding equipment for lithium strip production in the technical field of lithium strip production. A winding machine is included, the side wall of the winding machineis rotatably connected with a group of traction rollers, a group of balance rollers, a group of deviation rectifying rollers, a group of edge cropping rollers and a winding roller, and the side wallof the winding machine is slidably connected with a middle transition roller and a rear end adjusting roller. A monitoring frame is fixedly connected to the front wall of the winding machine, a thickness measuring sensor is fixedly installed on the inner wall of the monitoring frame, a middle tension sensor and a rear end tension sensor are fixedly installed on the front wall of the winding machine, a deviation rectifying sensor is fixedly installed on the front wall of the winding machine, and a controller is fixedly installed in the winding machine. Each edge cropping roller comprises a wrapping roller and an edge cutting roller, wherein the outer wall of the edge cutting roller is in sliding connection with an edge cropping round cutter. According to the automatic winding equipment, thefull process is automatically carried out, no manpower is consumed, winding is efficient, the thickness and the width of a lithium strip can be guaranteed, the quality of a lithium strip coil is high, the rate of finished products is high, and mechanical winding is suitable for large-batch production.

Owner:李雄富

Preparation method of environment-friendly PVA-based film

PendingCN114379124AQuality assuranceEasy to replaceDispersed particle filtrationDirt cleaningThin membranePolymer chemistry

The invention discloses a preparation method of an environment-friendly PVA-based film, and belongs to the technical field of film preparation, and the preparation method comprises the following steps: step 1, adding a PVA-based raw material into an extruder, and extruding the PVA-based film from a die head by the extruder; 2, cooling the PVA-based film extruded in the step 1 through a cooling roller, and cooling and molding the PVA-based film; thirdly, the formed PVA-based thin film is pulled and stretched to pass through the lower portion of a cutting blade and fixed to a winding drum; fourthly, a winding drum is used for winding, the tensioning force is adjusted through a fixing roller, and after winding is completed, a cutting blade is used for edge cutting; according to the plastic film rolling device, rolling can be flat, and the quality of a produced plastic film rolling film is guaranteed; the plastic film winding drum is convenient to replace, and the production efficiency is improved; the phenomenon that wrinkles occur due to insufficient tension in the film forming and rolling process is achieved, and the film processing efficiency is greatly improved; the two sides of the film can be dedusted, and the hygienic quality of the film is improved.

Owner:安徽瑞鸿新材料科技有限公司

Winding device

The invention discloses a winding device which comprises a rotating shaft. The two ends of the rotating shaft are provided with mounting bases. The rotating shaft is provided with a plurality of wire grooves, the two sides of each wire groove are ridge-shaped portions, and the side edges of the wire grooves are not perpendicular to the center line of the rotating shaft; the two ends, close to the mounting bases, of the rotating shaft are provided with end plates; the mounting bases at the two ends of the rotating shaft and the end plates are sequentially provided with a first pulley, a second pulley, a third pulley and a fourth pulley; a pull wire is fed from the first pulley, wound around the second pulley and the third pulley and drawn out from the fourth pulley, the drawn-out end of the pull wire is connected with a take-up device which drives the drawn-out end of the pull wire to move, the fed end of the pull wire is connected with an unwinding device used for discharging a wire, the part, located between the second pulley and the third pulley, of the pull wire is rotatably connected with a first load, the two end of the first load is provided with a flat and smooth curved surface, and the upper portions, close to one side of the rotating shaft, of the mounting bases are provided with slopes. The improvement to the winding device is achieved, and the winding device is simple in structure and can allow the wire to be wound to be compact and flat.

Owner:WUHAN KATTOR IND

Flattening and winding device of plastic films

InactiveCN110203743AWinding tensionStatic electricity will not existElectrostatic chargesWebs handlingWrinkle skinWinding machine

The invention relates to a flattening and winding device of plastic films. The flattening and winding device comprises side vertical plates and a winding device. The flattening and winding device is characterized in that the winding device is mounted on the side vertical plates; the winding device comprises a containing roller, containing connecting plates, a winding supporting plate, a winding machine, guide rollers and a conveying roller; and the containing roller is located below the side vertical plates, the front end and the rear end of the containing roller are connected with the bottomsof the side vertical plates through the containing connecting plates, the winding supporting plate is mounted on the left side faces of the upper ends of the side vertical plates, the winding machineis mounted at the left end of the winding supporting plate, the guide rollers are distributed at the upper ends and the lower ends of the side vertical plates, the guide rollers are mounted on the right side faces of the side vertical plates, and the conveying roller is mounted on the tops of the side vertical plates. The problems that when existing large-roll plastic films are divided, the plastic films cannot be tensioned when wound, static exists on the plastic films, and wrinkles and turned edges easily exist on the plastic films can be solved.

Owner:安庆市明盛塑业有限公司

Batching structure for textile processing and with ironing and dedusting functions

InactiveCN108622729AFast rolling operationEfficient dust removal operationFilament handlingWebs handlingDevice PlateEngineering

The invention discloses a batching structure for textile processing and with ironing and dedusting functions. The batching structure comprises a base plate, a cleaning brush, an ironing plate and a spool. A containing plate is mounted on the upper end face of the base plate. A bearing cylinder is arranged at the top end of the containing plate. The cleaning brush is mounted on the containing plate. The ironing plate is arranged on the base plate. A cloth pressing cylinder is arranged above the ironing plate. Transverse plates are mounted on the side of the device plate. The spool is positionedbetween the transverse plates. The spool is connected with a motor through a rotary shaft. A limiting cylinder is connected with a connecting shaft. One end of the connecting shaft is positioned on the inner sides of adjusting grooves. The adjusting grooves are formed in the transverse plates. By the adoption of the batching structure for textile processing and with the ironing and dedusting functions, fast batching operation can be carried out on finished textile products, ironing with the better effect can be carried out on the cloth, meanwhile the efficient dedusting operation can be carried out on the cloth, the design is more reasonable, and the processing quality of the finished textile products is improved greatly.

Owner:YANCHENG JUNLONG YARN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com