Cloth winding device and cloth winding method

A winding device and fabric technology, applied in the field of warp knitting machines, can solve problems such as uneven winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following is attached Figure 1-7 The application is described in further detail.

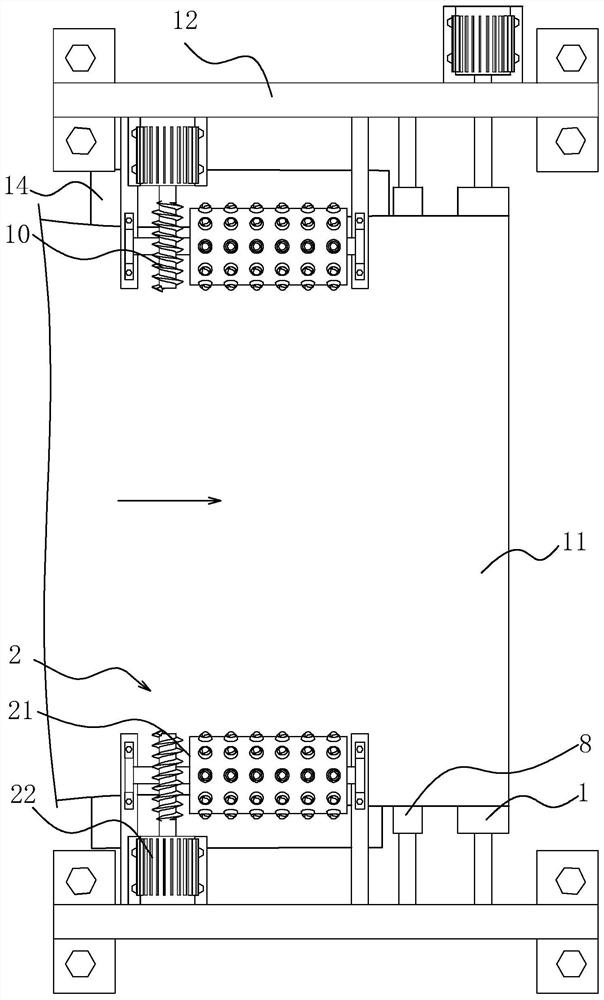

[0038] The embodiment of the present application discloses a cloth winding device. refer to figure 1 , including a cloth roll 1 for winding the cloth 11 in the knitting area, and the cloth roll 1 winds the cloth 11 through a motor 22 .

[0039] refer to figure 1 , also includes a frame 12 and a fabric spreading mechanism 2 installed on the frame 12, the fabric spreading mechanism 2 includes two eccentric rollers 21, and the fabric spreading mechanism 2 also includes a driving member for driving the eccentric rollers 21 to rotate. The cloth 11 passes under the two eccentric rollers 21, which are correspondingly located on both sides of the cloth 1; the length direction of the eccentric rollers 21 is the same as the conveying direction of the cloth 11.

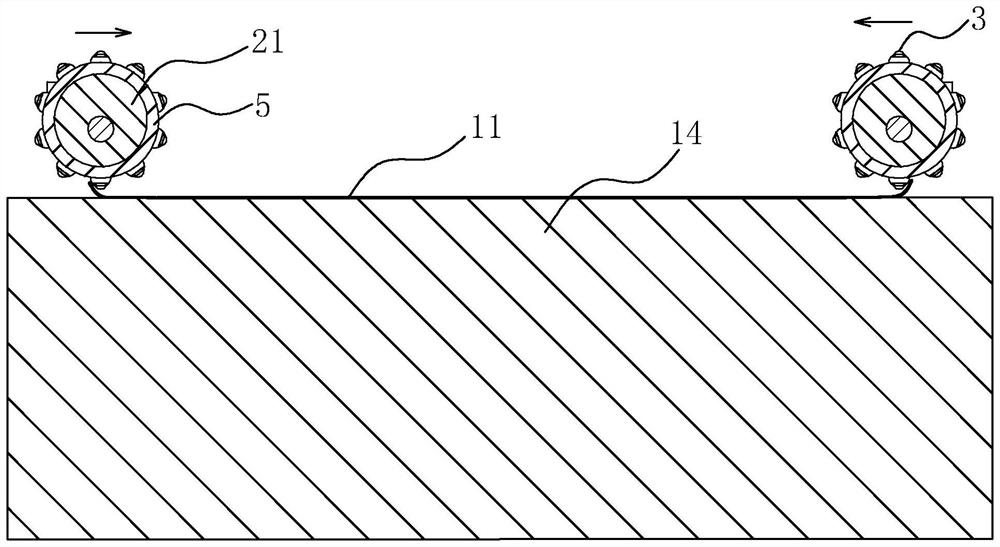

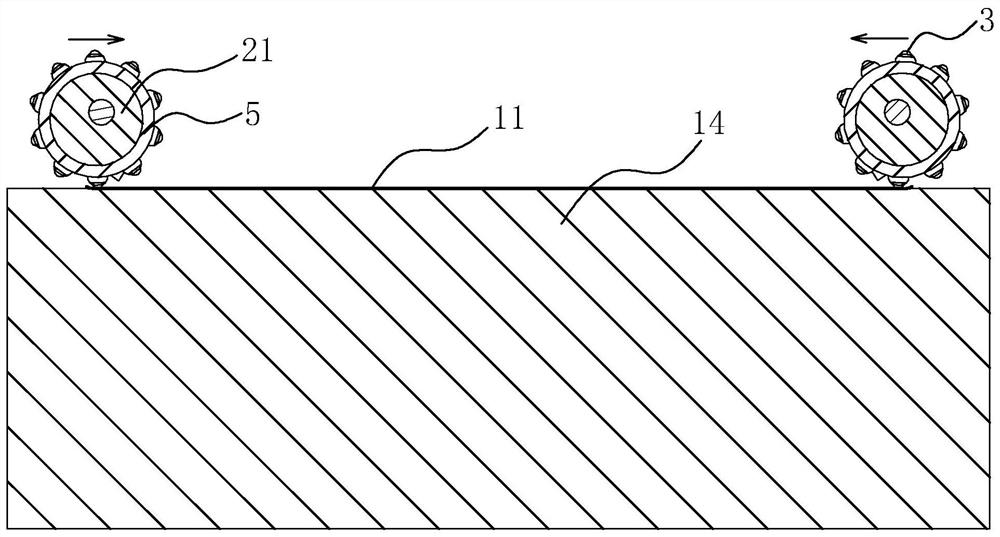

[0040] refer to figure 2 , the cloth edge spreading mechanism 2 also includes a platform 14 , when the cloth 11 passes under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com