Preparation method of environment-friendly PVA-based film

An environmentally friendly, thin-film technology, applied in the direction of cleaning methods, separation methods, cleaning methods and utensils using gas flow, which can solve problems such as insufficient tension, wrinkles, and low product quality, and achieve easy replacement and improved quality. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of an environment-friendly PVA base film, comprising the following steps:

[0038] Step 1: PVA-based raw materials are added to the extruder 1, and the extruder 1 extrudes the PVA-based film from the die;

[0039] Step 2: The PVA-based film extruded in step 1 is cooled by cooling roll 4, and then cooled and formed;

[0040] Step 3: The formed PVA-based film is stretched and passed under the cutting blade 29, and fixed on the reel;

[0041] Step 4: Rewind the reel 13, and adjust the tension by using the fixed roller 23. After the rewinding is completed, cut the edge with the cutting blade 29, and then remove the reel to complete the finished product.

Embodiment 2

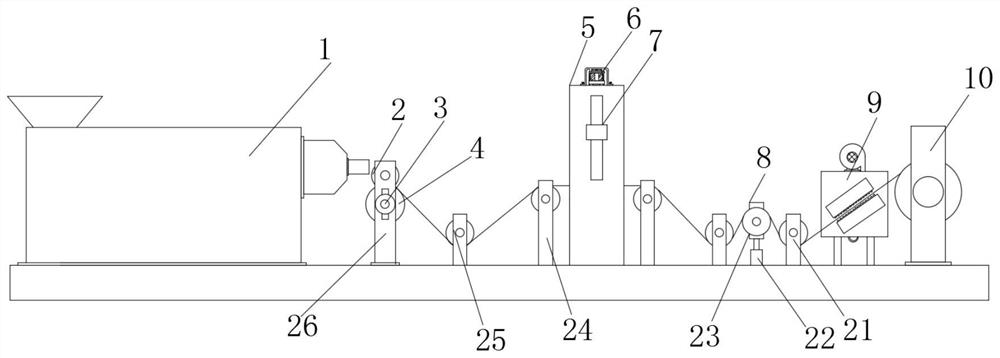

[0043]As an option, see figure 1 , Figure 2-6 , Figure 9 A cooling roll 4 is arranged below the discharge die of the extruder 1, and the two ends of the cooling roll 4 are connected to a support rod 26 in rotation, and the first motor 3 is fixed on the support rod 26, and the output end of the first motor 3 is connected to One end of the cooling roller 4, the top of the cooling roller 4 is provided with a pressure roller 2, one side of the pole 26 is provided with a steering roller 25, one side of the steering roller 25 is provided with a bracket 5, and one side of the bracket 5 is provided with a support plate 8, One side of the support plate 8 is provided with a cleaning mechanism 9, one side of the cleaning mechanism 9 is provided with a reel 13, the inside of the reel 13 is provided with a socket 15, and both ends of the reel 13 are provided with a fixing mechanism 14;

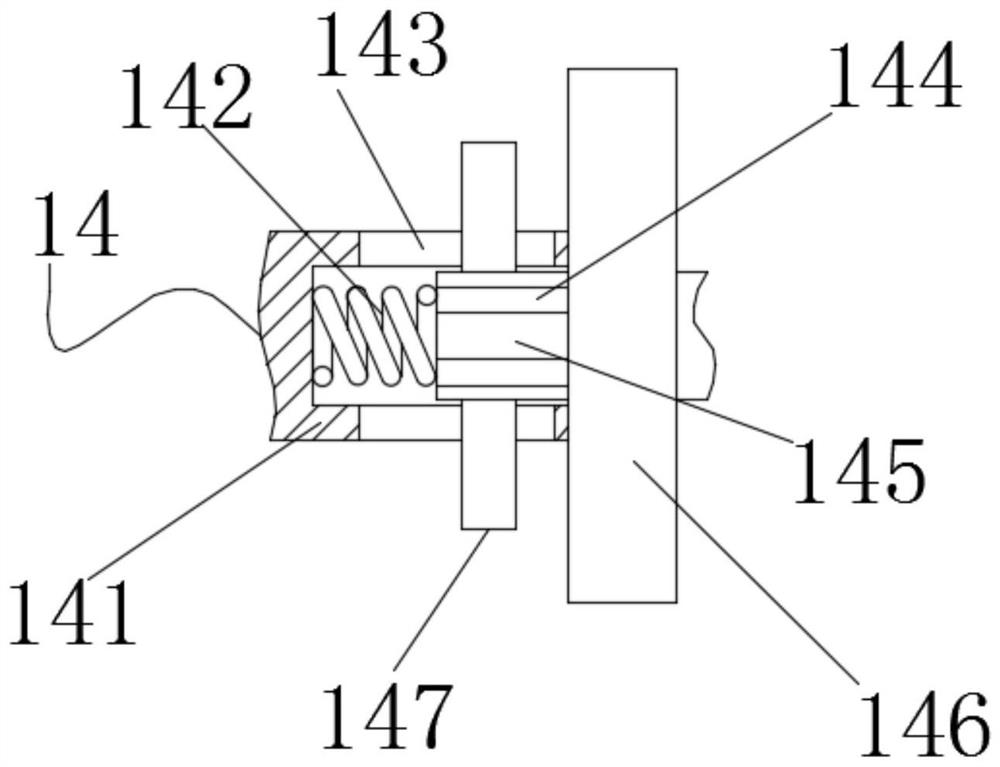

[0044] The fixing mechanism 14 includes a movable shaft 145 arranged inside the socket 15, the oute...

Embodiment 3

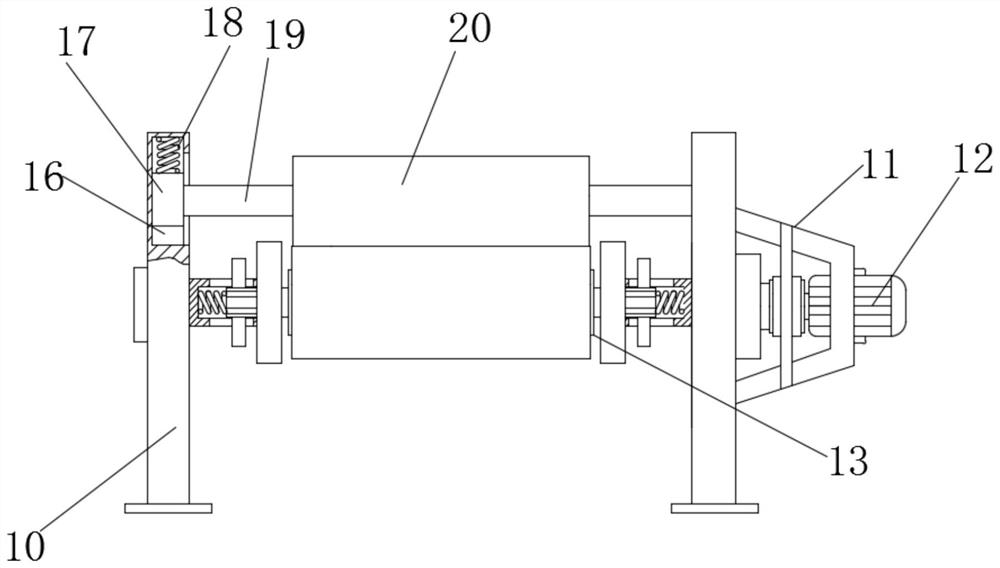

[0048] As an option, see figure 2 , Figure 7 , the top of the reel 13 is provided with a leveling roller 20, the inner rotation of the leveling roller 20 is connected with a first cross bar 19, the two ends of the first cross bar 19 are provided with a moving column 17, and the outside of the moving column 17 is provided with a limit Groove 16, the upper end of moving column 17 is connected with second spring 18 one end, and the other end of second spring 18 is connected with the top inside limit groove 16, and limit groove 16 is opened in the inside of support seat 10, and limit groove 16 is close to the first One side of a cross bar 19 is provided with a second notch 27 , and the first cross bar 19 passes through the second notch 27 .

[0049] Specifically, the processed plastic film is rewound. At this time, the leveling roller 20 is close to the upper end of the roll film wound on the outside of the reel 13. Due to the return pressure of the second spring 18, the leveli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com