Preparation process of three-layer plastic coextrusion-lamination film

A co-extruded composite film and a preparation process technology, applied in the field of plastic co-extruded composite films, can solve the problems of no good shading performance and fresh-keeping performance, poor barrier performance and air tightness, poor physical properties, etc., to achieve improved shading performance and Fresh-keeping ability, good uniformity, smooth winding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

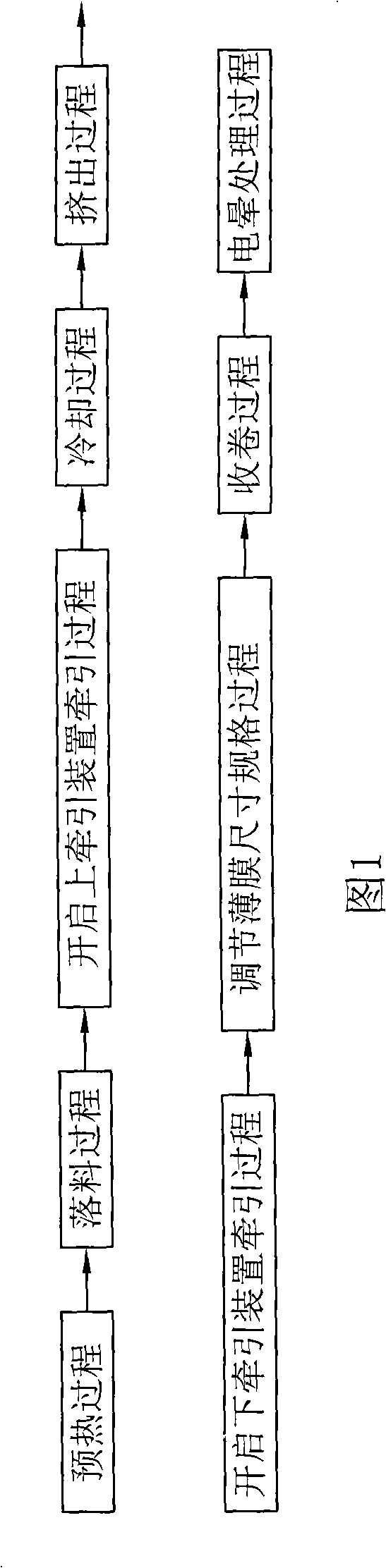

[0025] As shown in Figure 1, the preparation process of three-layer plastics co-extruded composite film of the present invention, its preparation steps are:

[0026] (1) Preheating process: Turn on three electric heating extruders, and preheat the head and body of each extruder evenly. The preheating time is: first, preheat the die head of the extruder for 60 minutes to 90 minutes; Then preheat the homogenization section of each extruder for 40-60 minutes; then preheat the compression section for 40-50 minutes; finally preheat the feeding section for 25-35 minutes. When the temperature of each part is 5-10 degrees higher than the temperature required for production, the plastic pellets can be fully heated and melted at this time.

[0027] (2) Blanking process: start the three extruders at a slow speed that can extrude pellets, and check whether the current and pressure of the screw motor and other instruments are overloaded. Add a small amount of plastic granules into the tro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com