Patents

Literature

44results about How to "Winding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

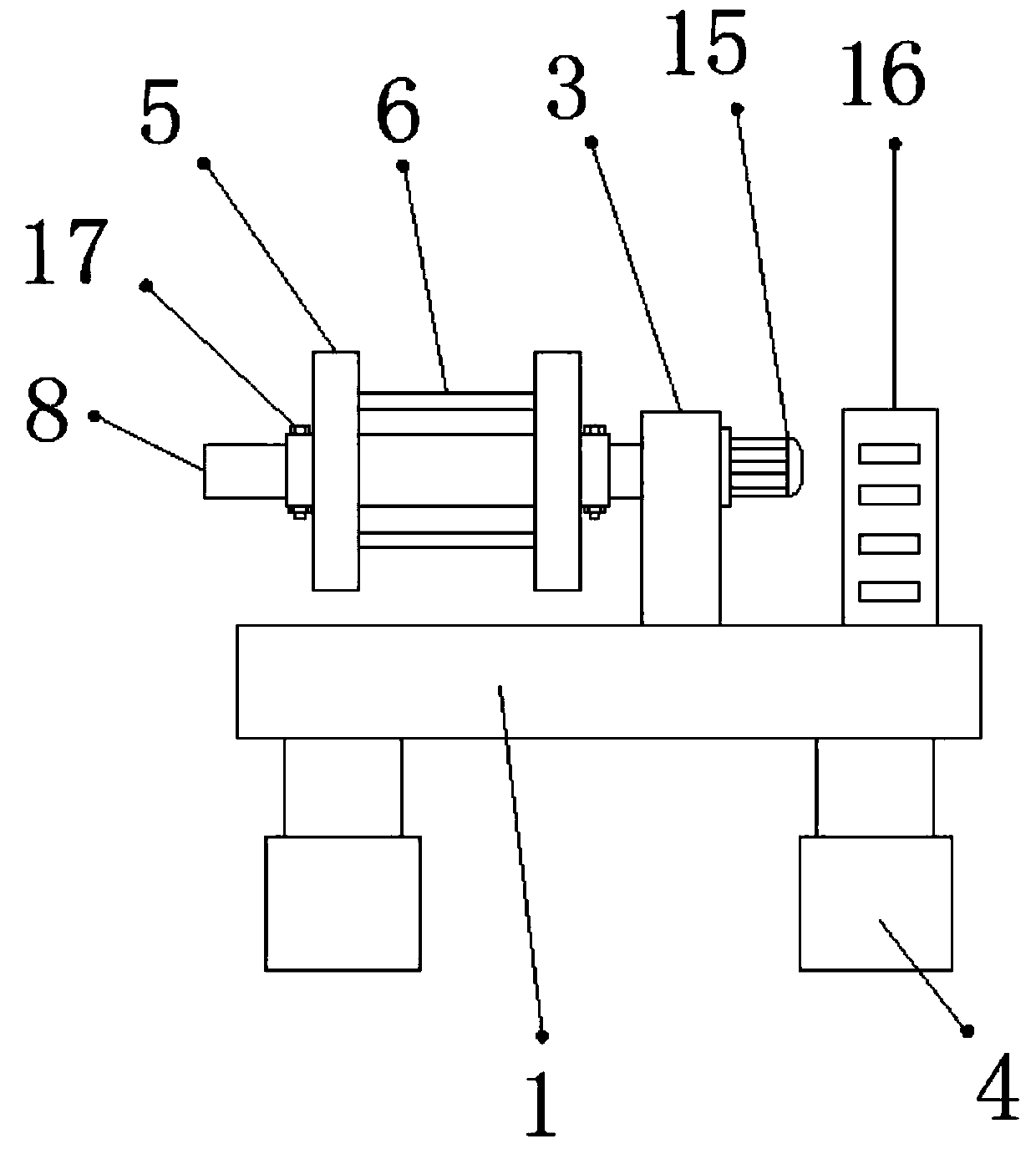

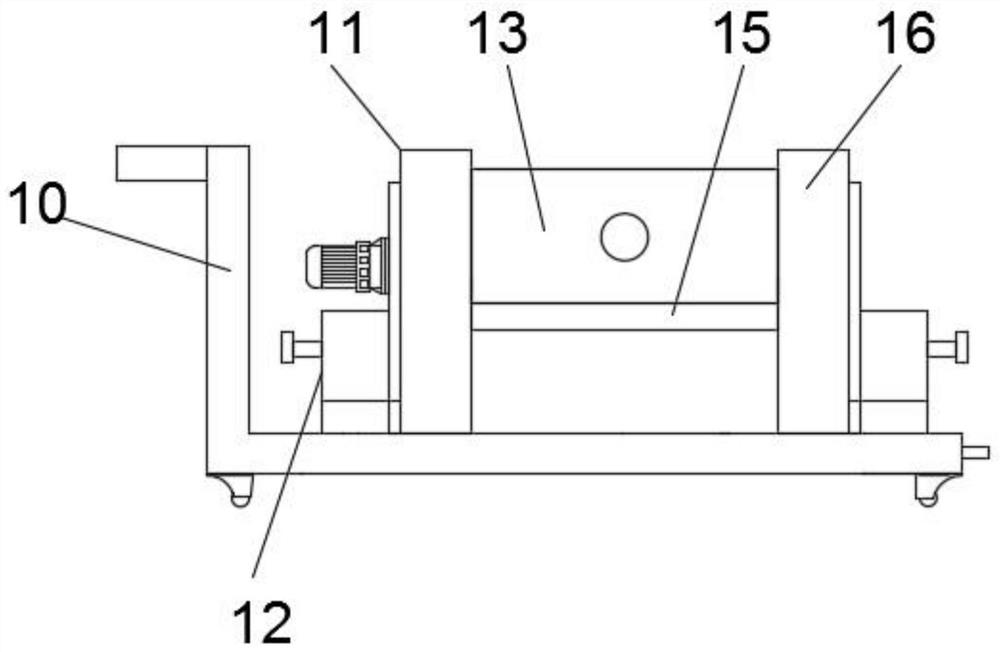

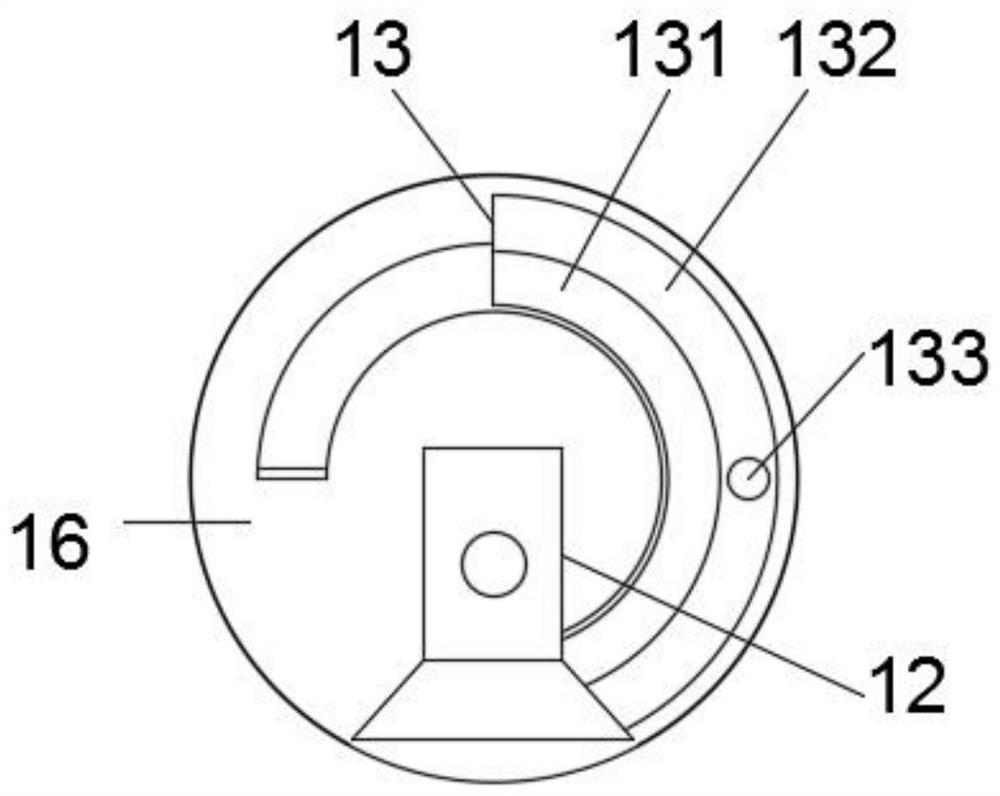

Cable winding disc

InactiveCN111204609AWinding effectContinuous and orderly winding and tilingFilament handlingControl theoryElectric cables

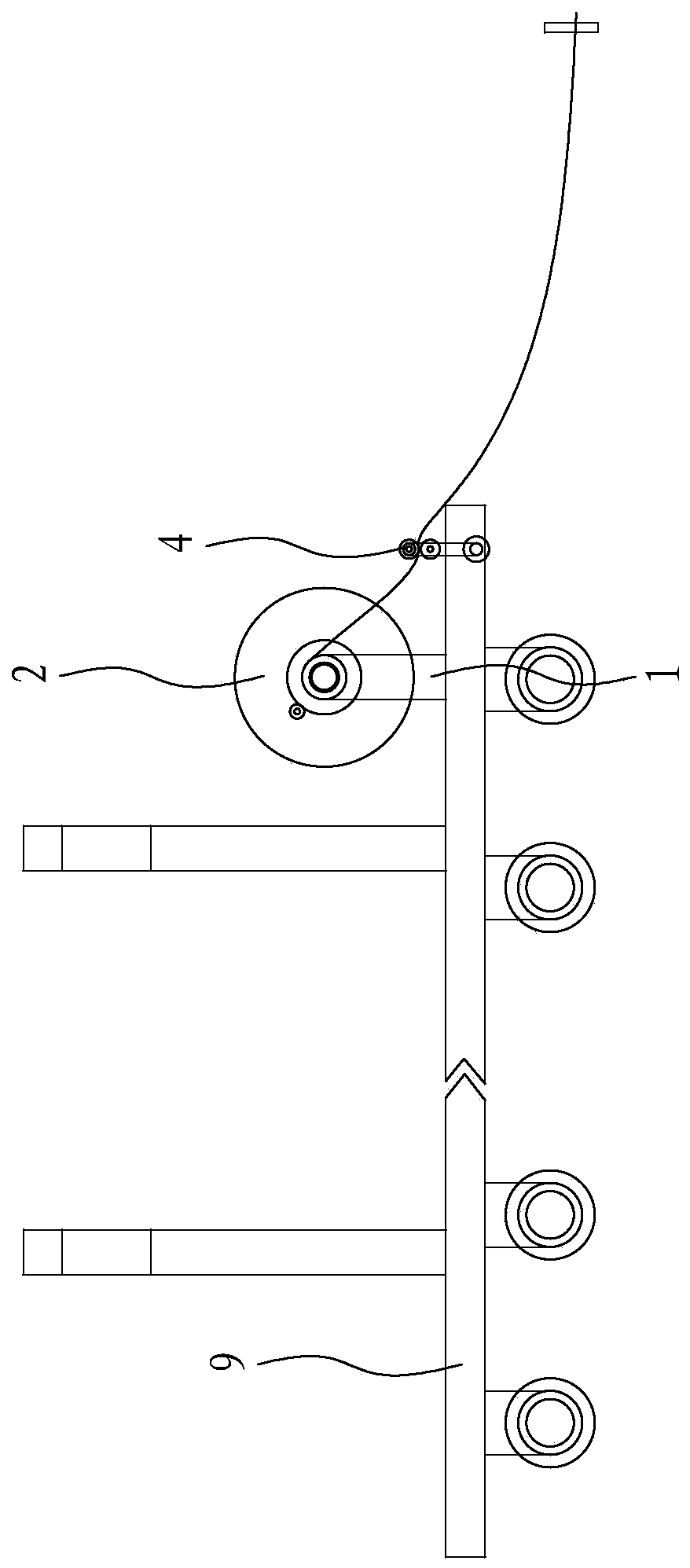

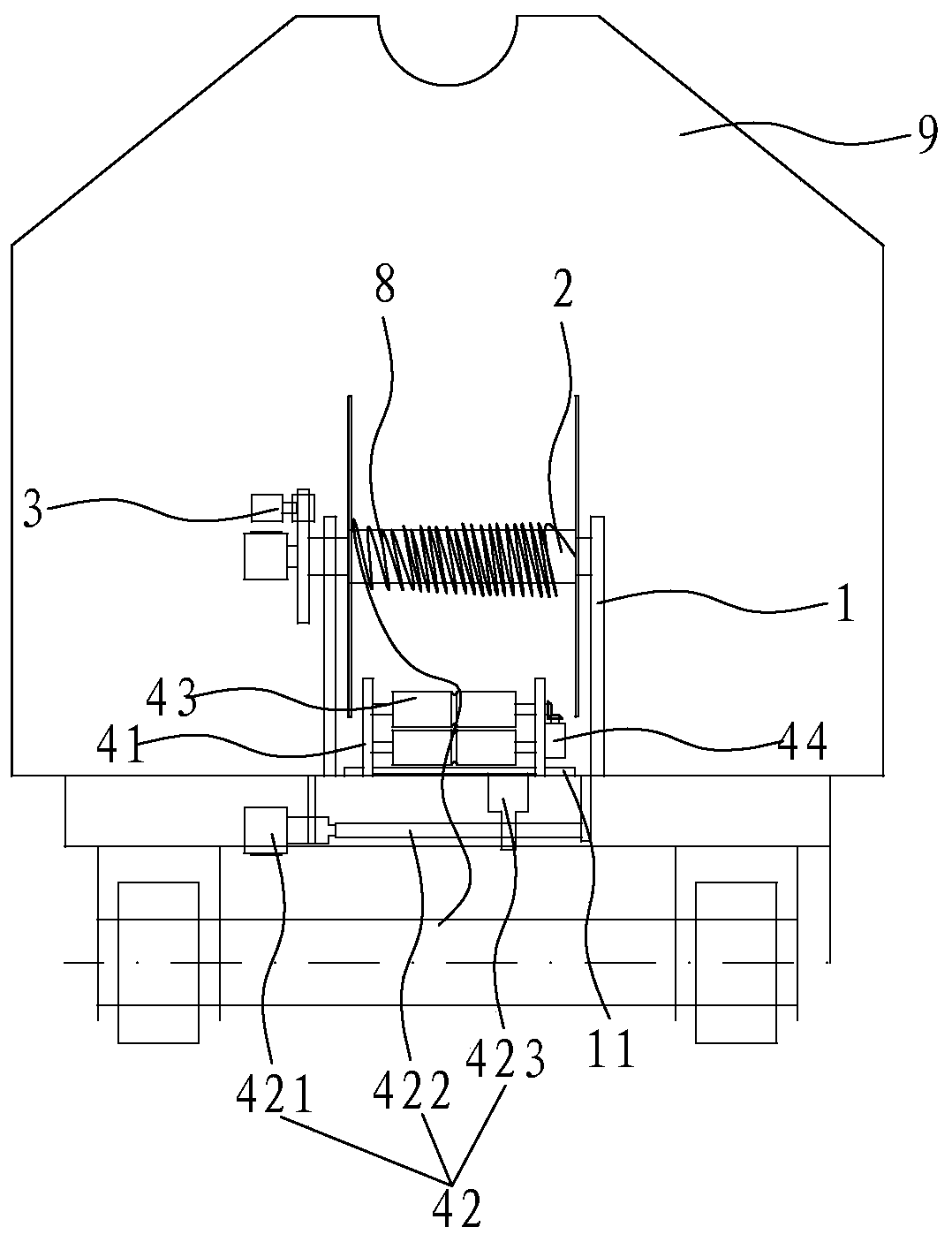

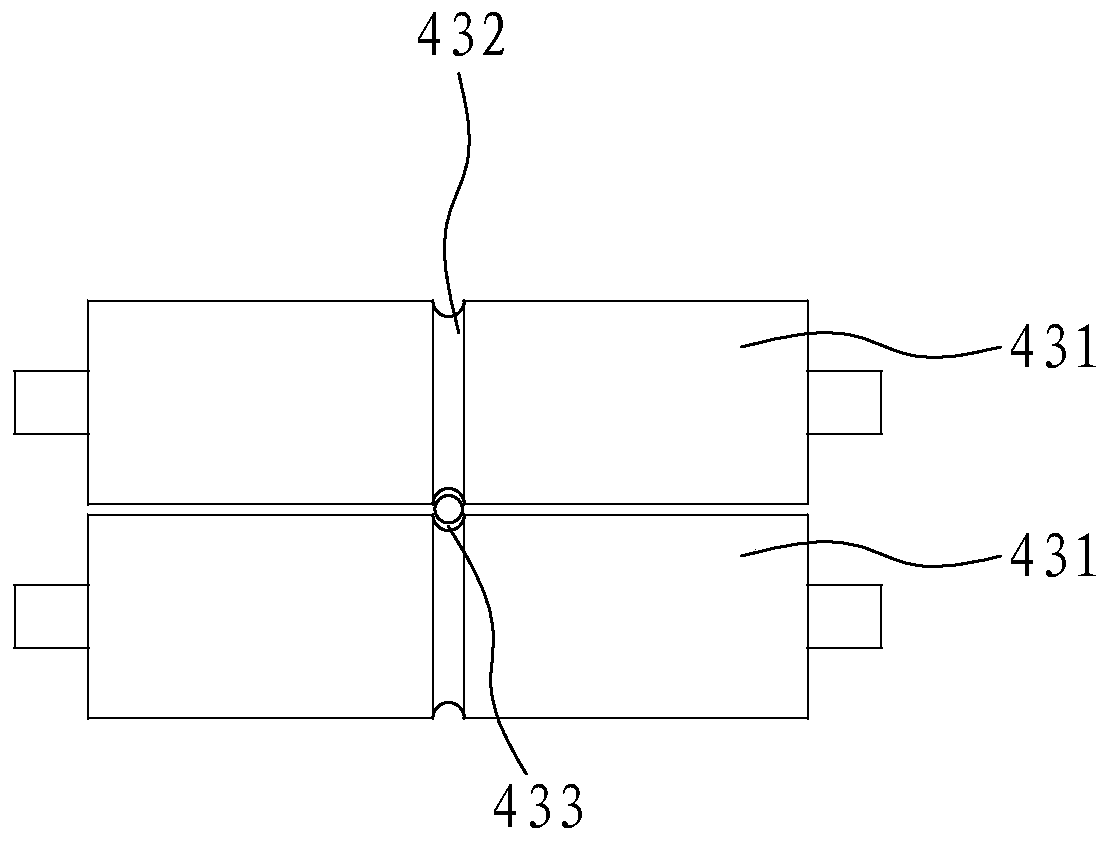

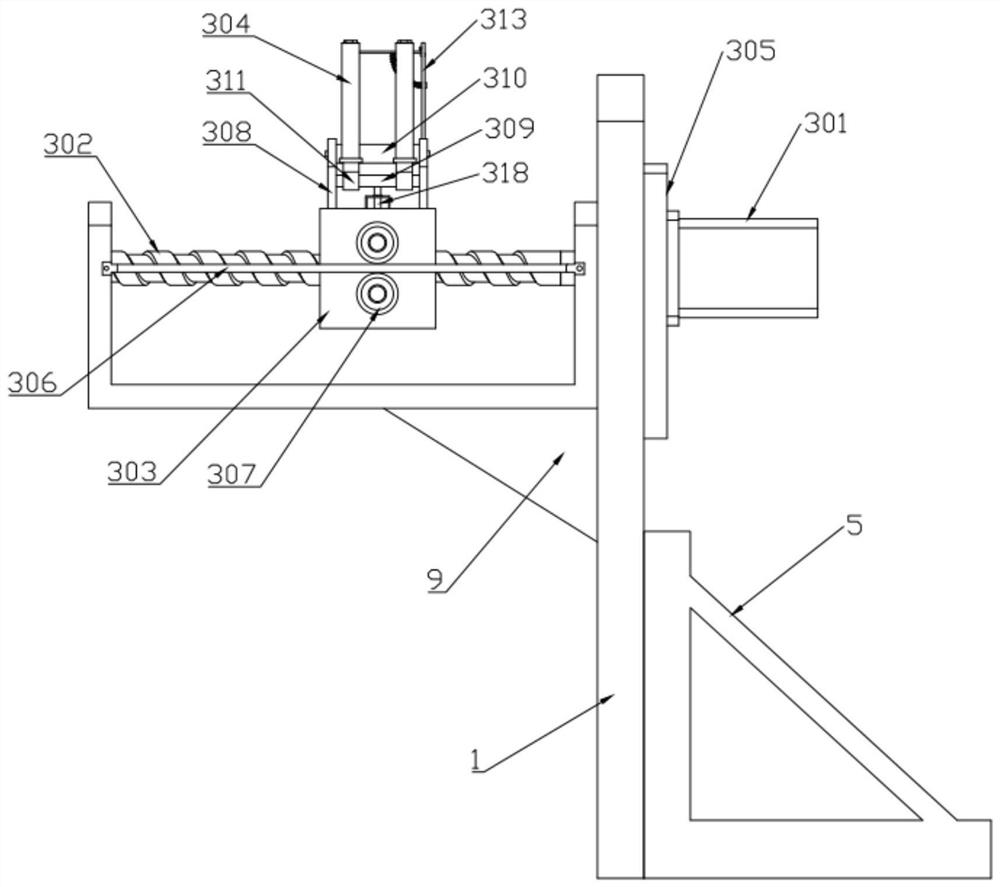

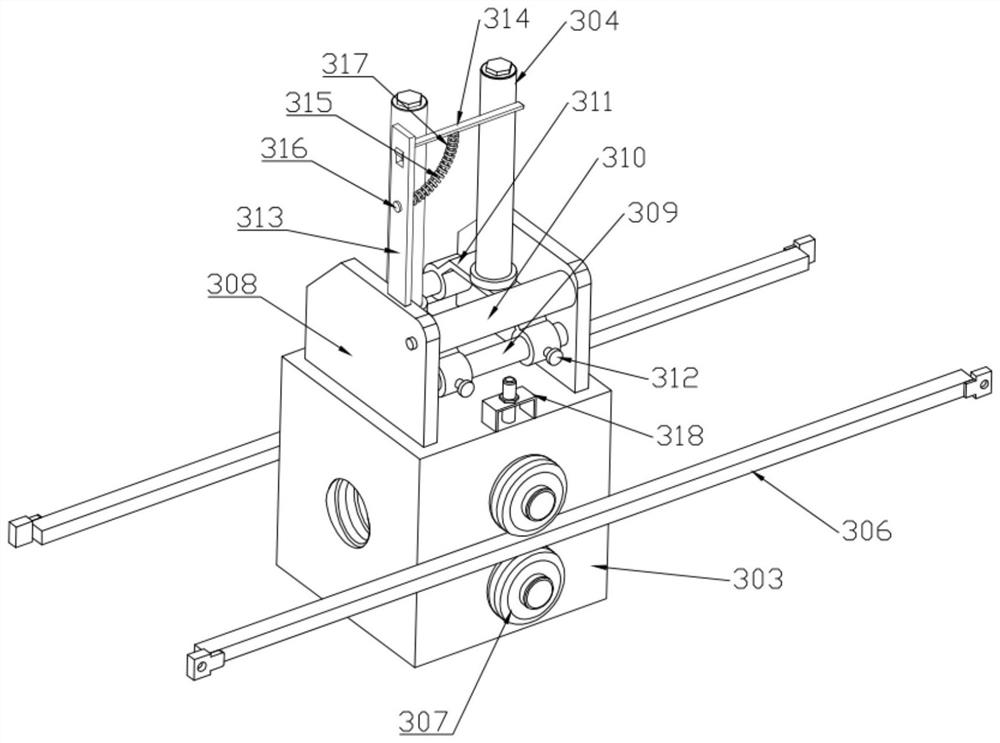

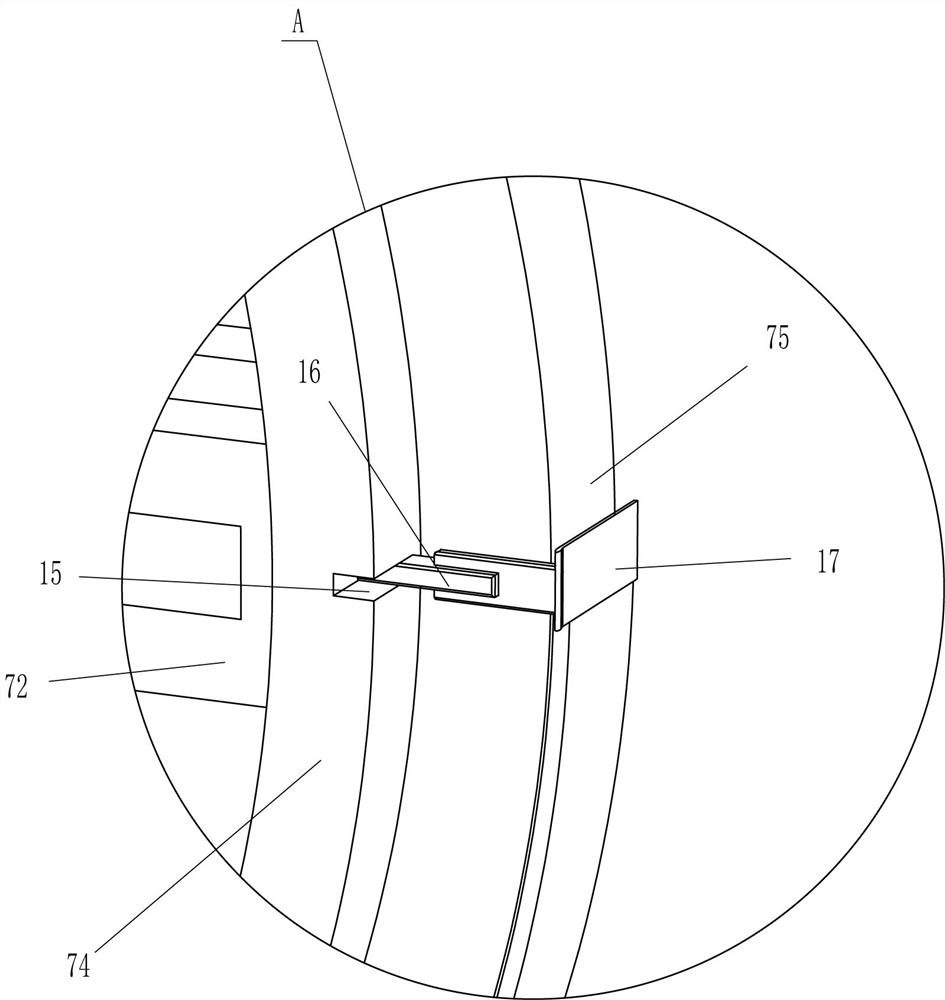

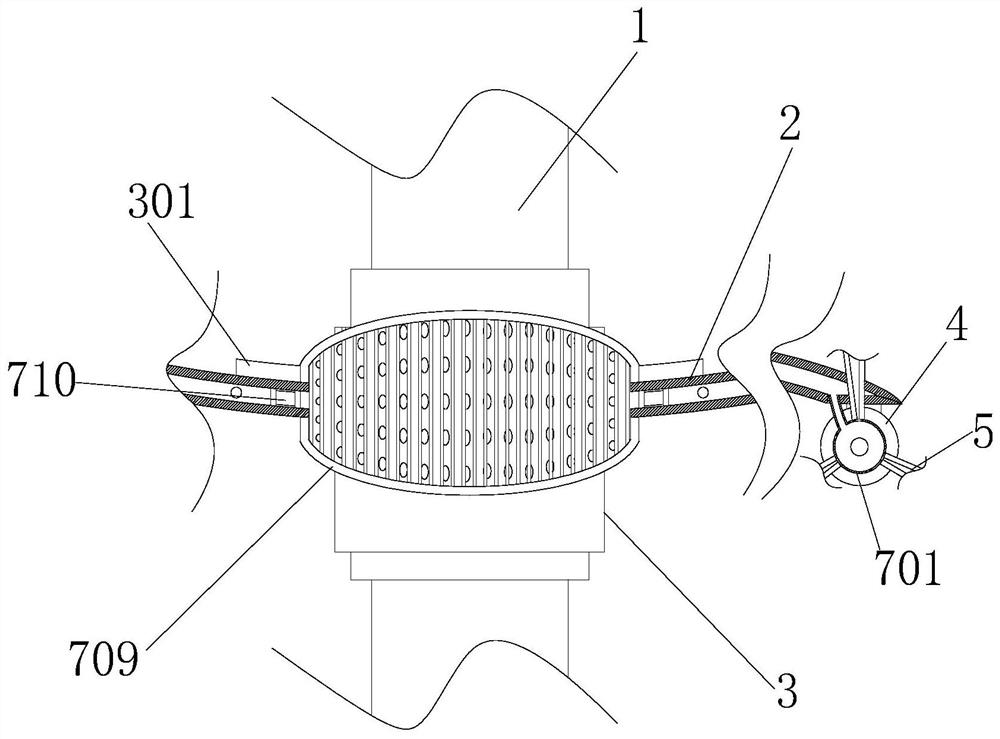

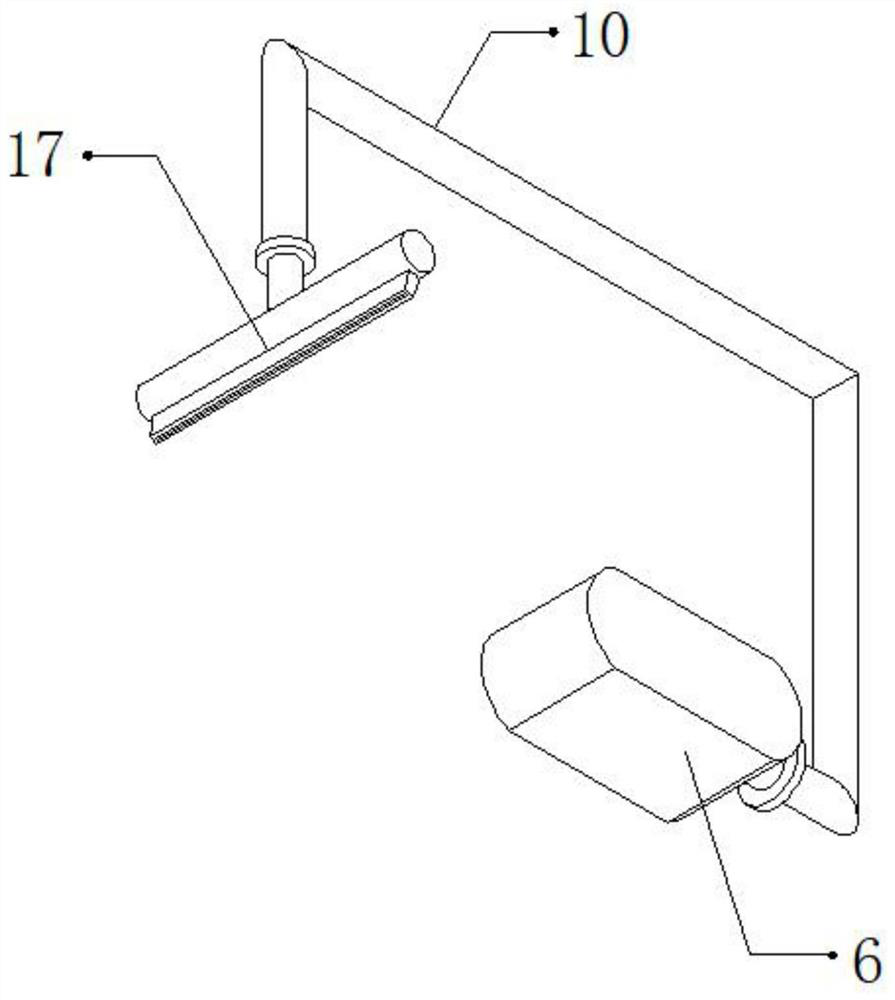

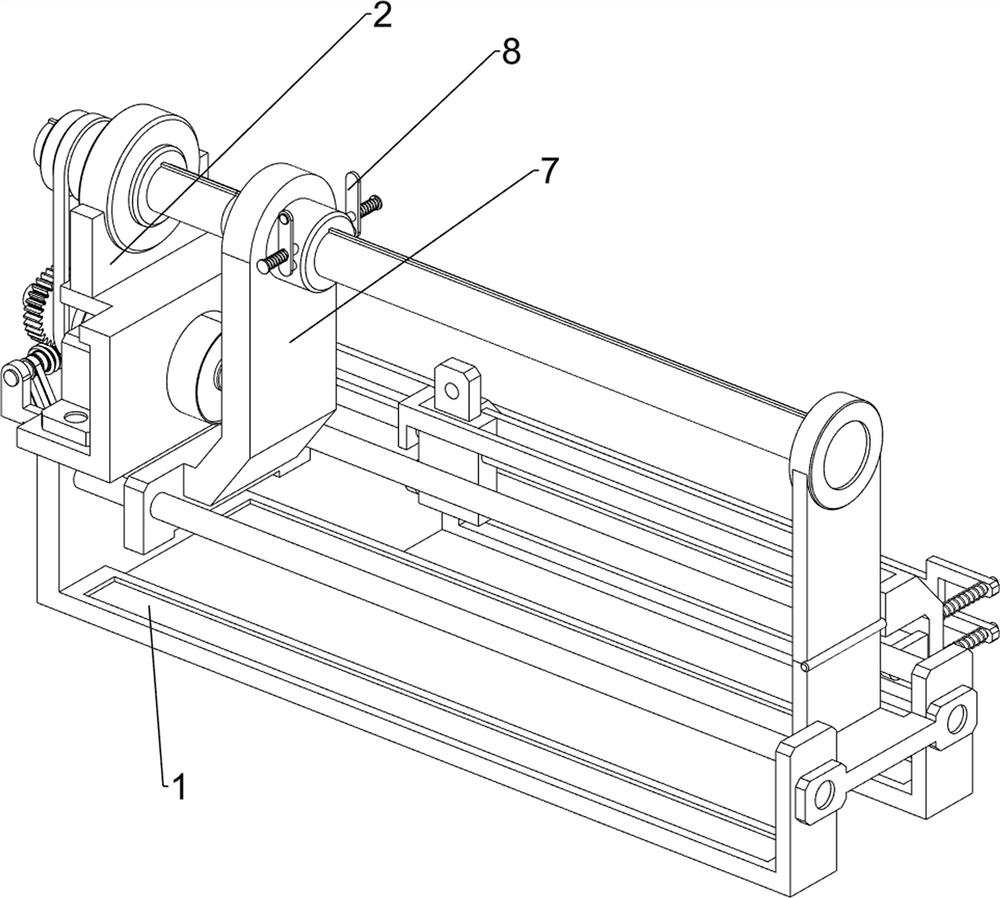

The invention relates to the field of tissue manufacturing equipment, in particular to a cable winding disc. The cable winding disc comprises a rack, a winding disc body rotationally arranged on the rack and used for winding a cable, a winding servo motor arranged on the rack and used for driving the winding disc body, and a guide device arranged on the rack, located in front of the winding disc body and used for guiding the cable, a sliding rail parallel to the axial direction of the winding disc is arranged at the position, in front of the winding disc, of the rack, the guiding device comprises an installation base capable of sliding along the sliding rail, a sliding driving device arranged on the rack and used for driving the installation base to slide, a clamping guiding wheel set arranged on the installation base and a guiding servo motor used for driving the clamping guiding wheel set to rotate, the clamping guiding wheel set comprises two guide wheels close to each other, arc-shaped guide grooves are formed in the circumferences of the guide wheels, and the arc-shaped guide grooves of the two guide wheels are matched to form a guide channel allowing the cable to pass through. According to the cable winging disc, the technical problems that cable winding tightness degree is inconsistent, and cables are stacked in a certain area are solved.

Owner:HENGAN (CHINA) PAPER IND CO LTD

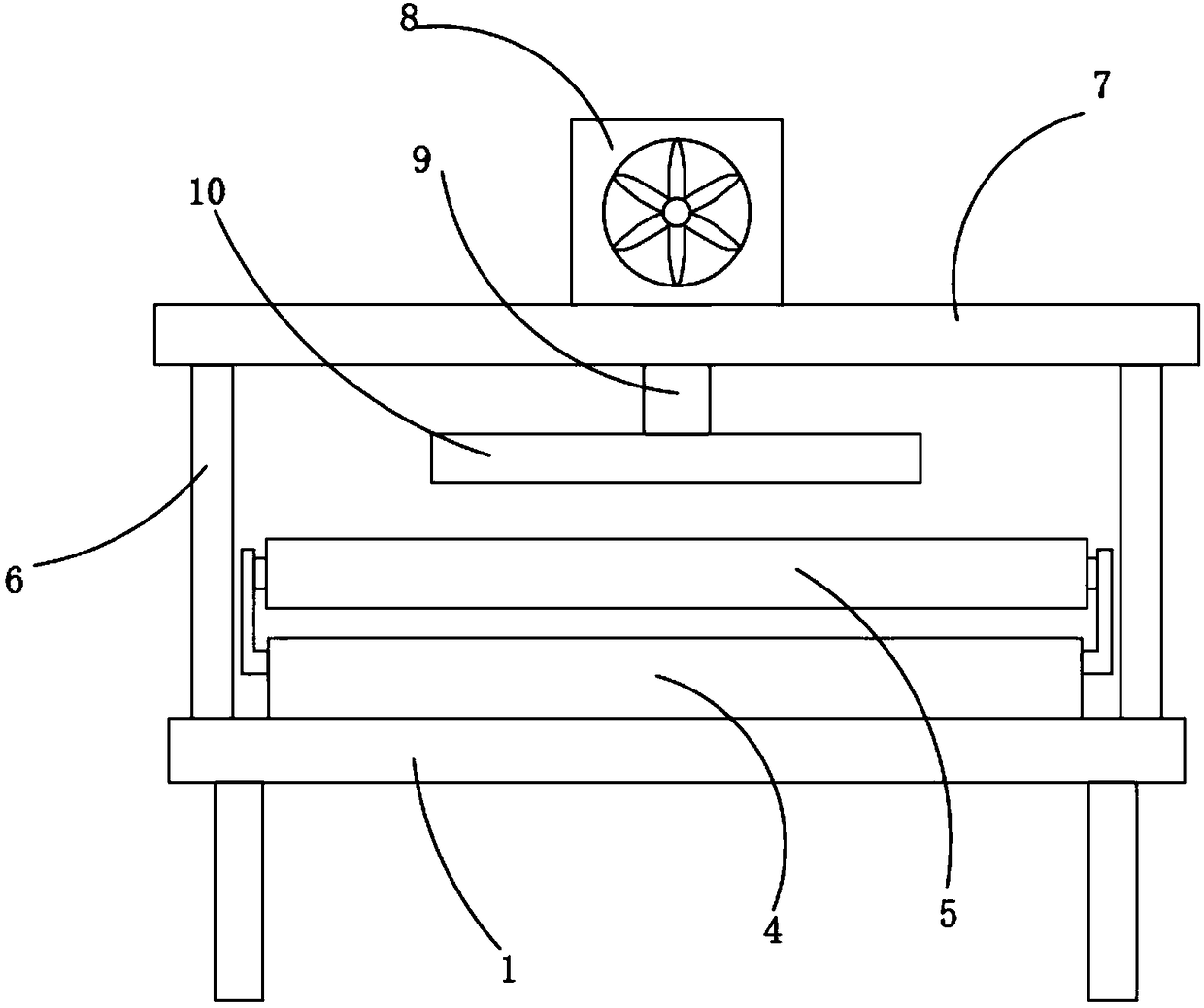

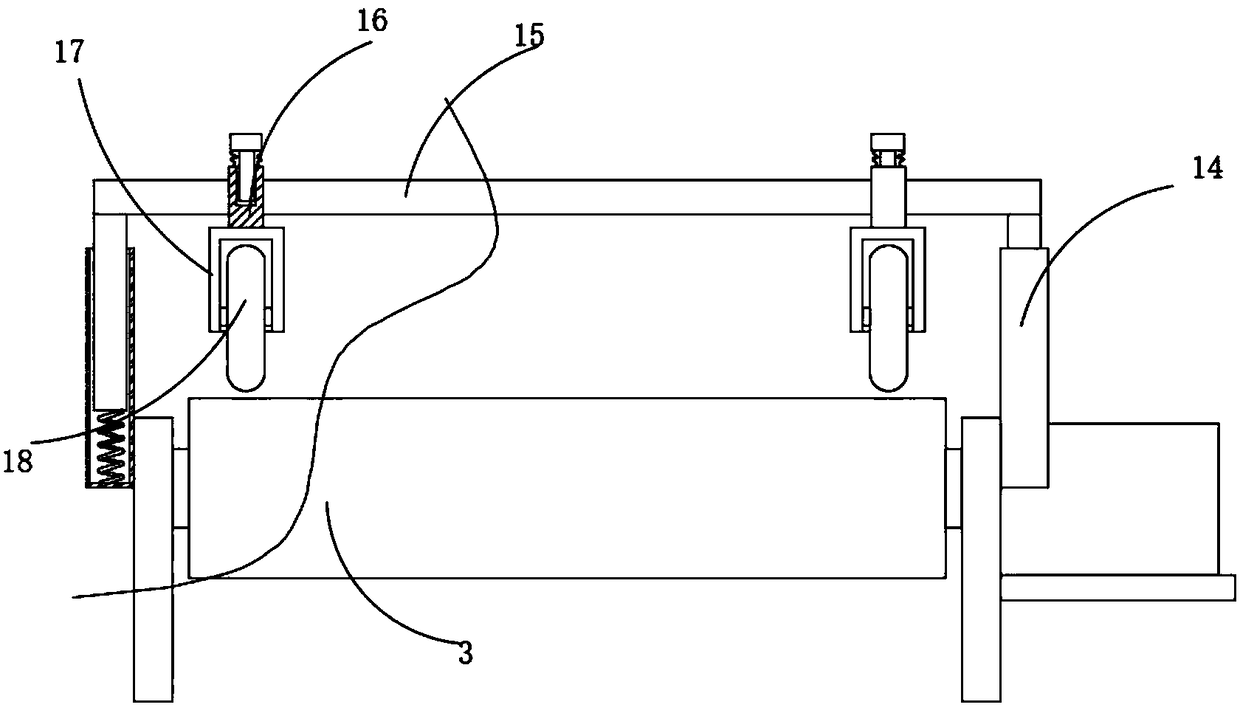

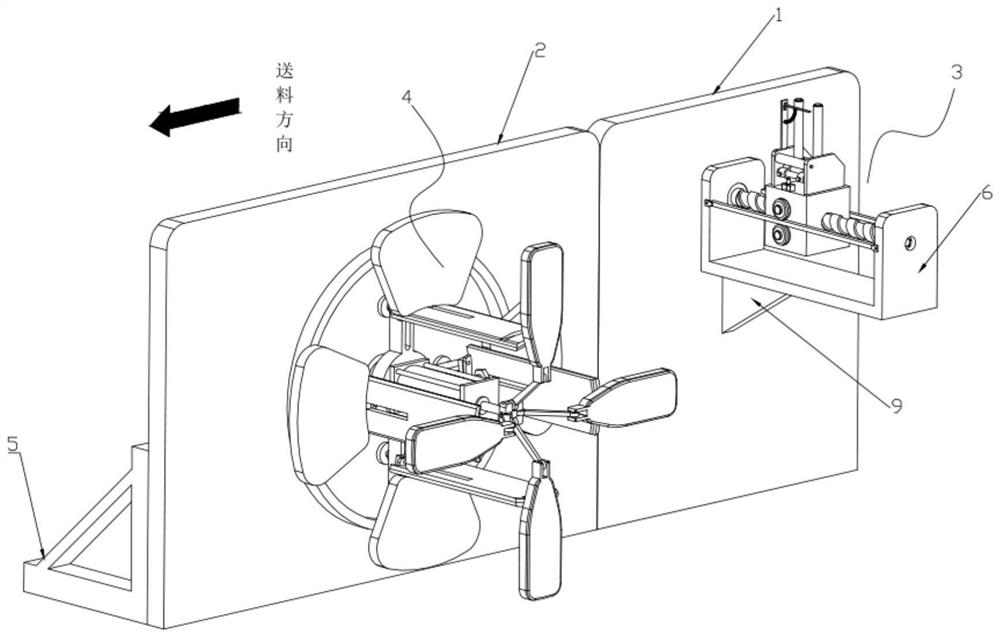

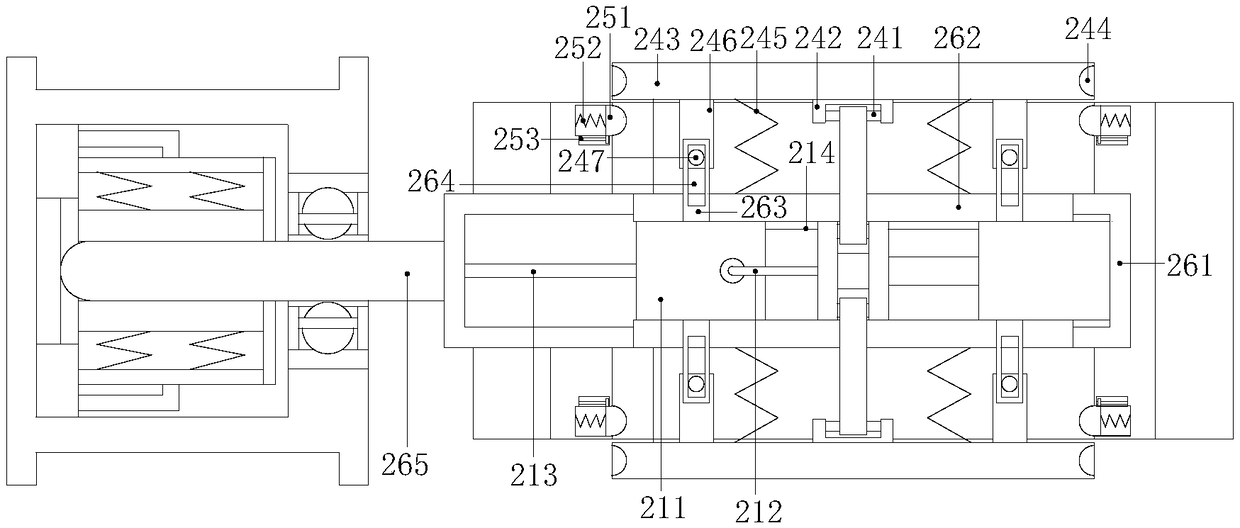

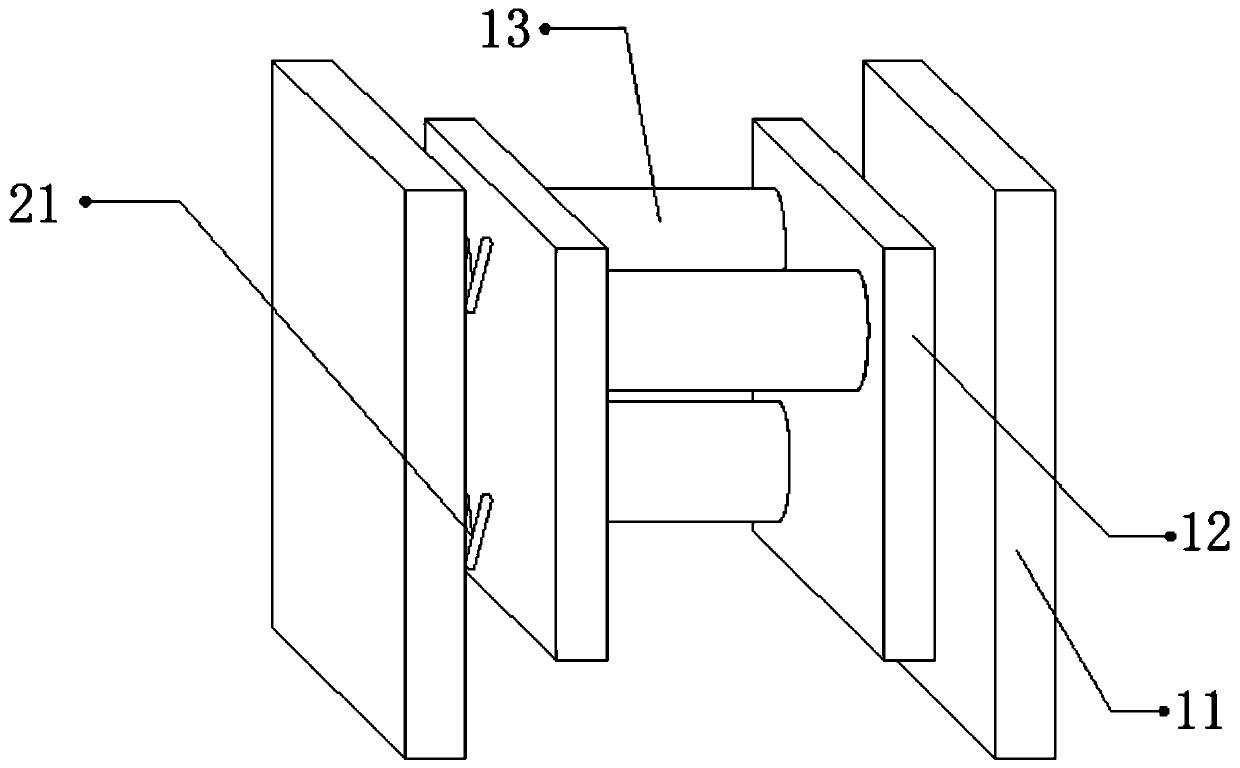

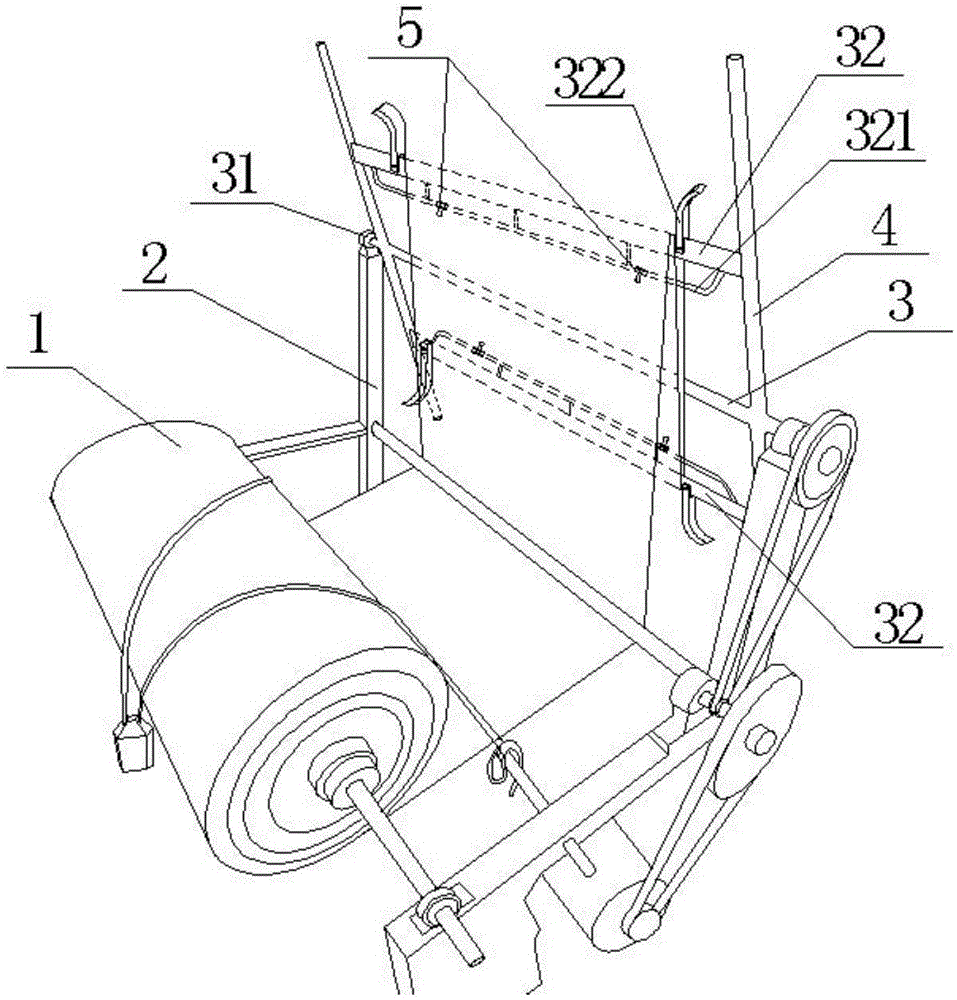

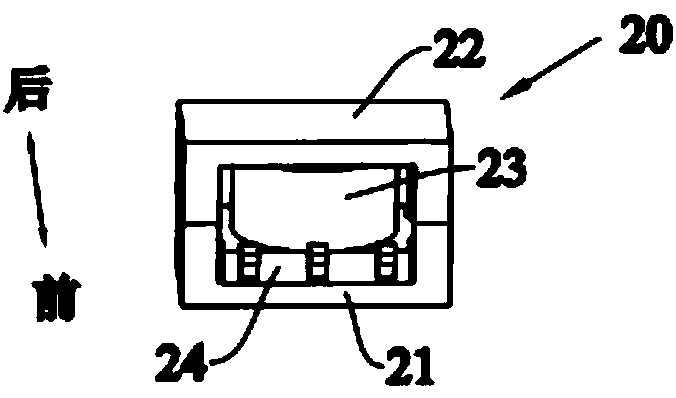

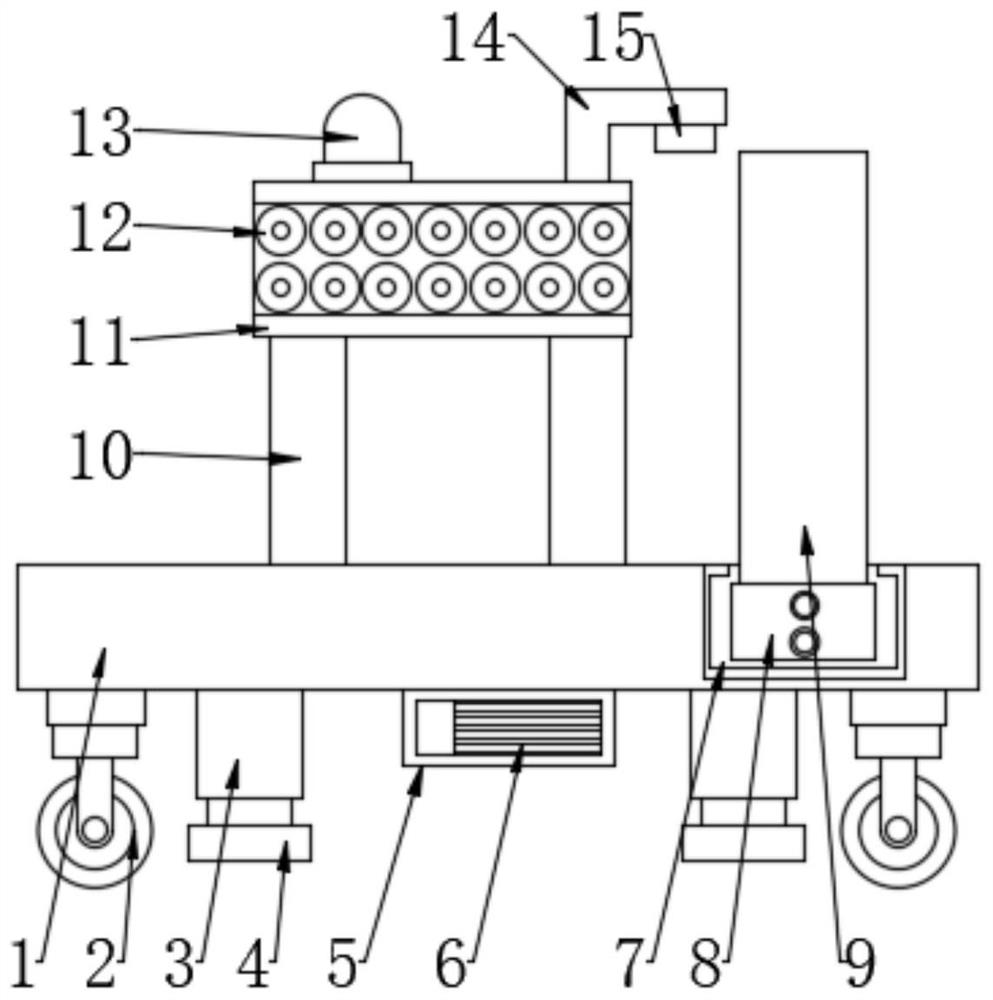

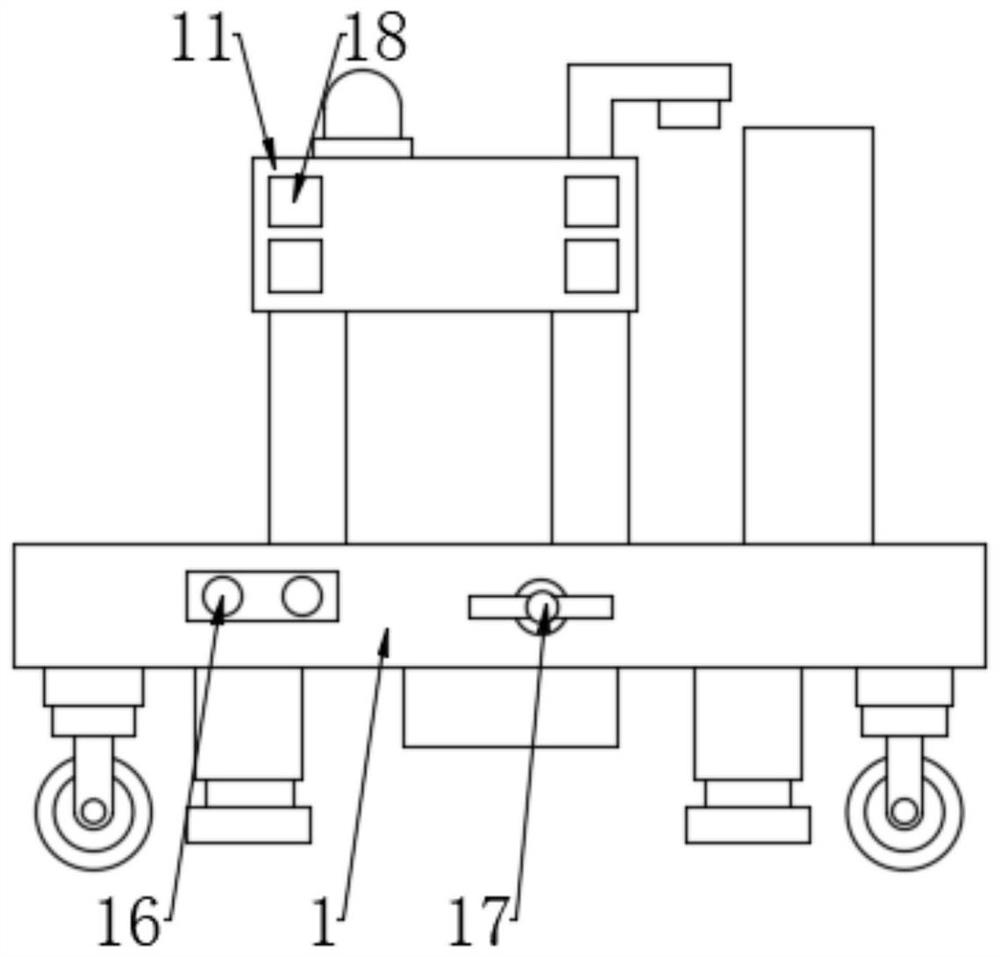

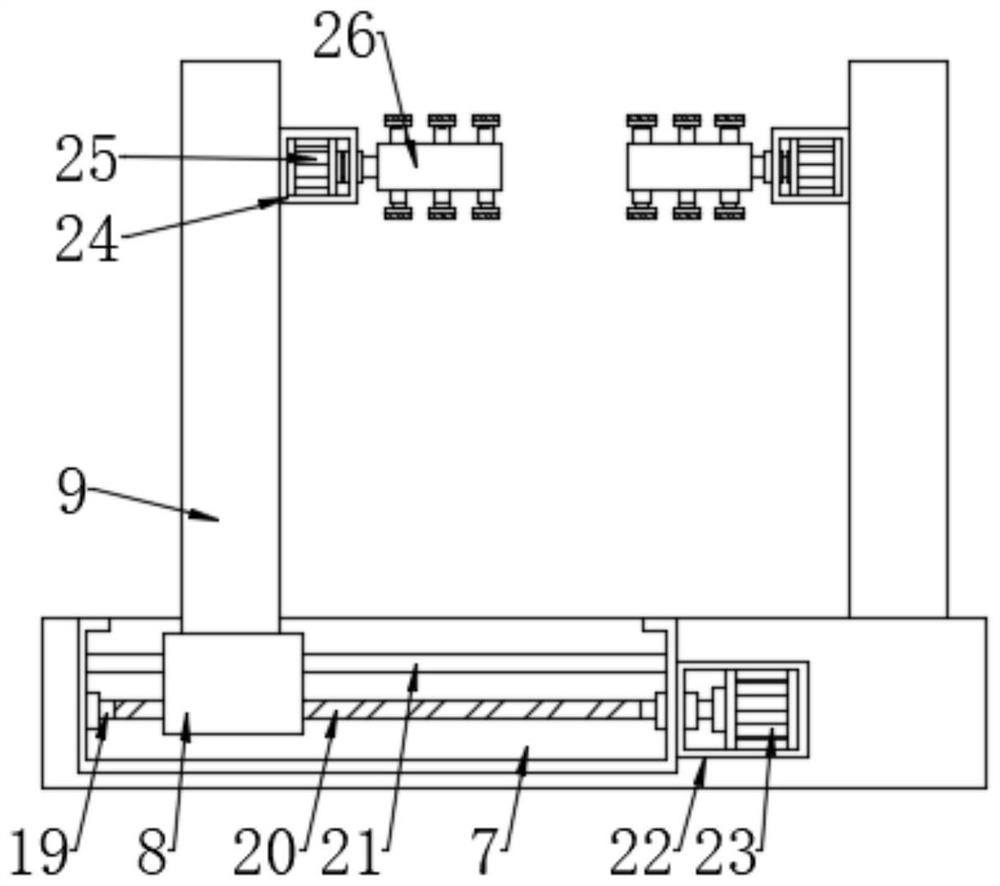

Transmission equipment for jacquard fabric

InactiveCN108438991AImprove cleanlinessReasonable structureJacquardsTextile shapingEngineeringTransmission equipment

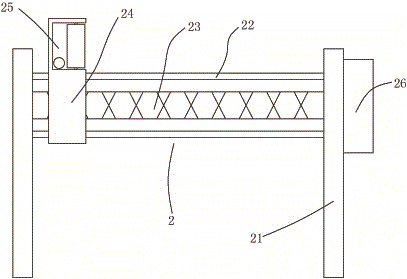

The invention discloses transmission equipment for jacquard fabric. The transmission equipment comprises a transmission platform. An unrolling device and a rolling device are fixed to the two ends above the transmission platform correspondingly. A conveying belt is arranged between the unrolling device and the rolling device. Conveying pressing rollers are arranged at the two ends of the conveyingbelt correspondingly. Four supporting rods are vertically arranged above the transmission platform. Top plates are connected to the tops of the four supporting rods. A fan is fixed to the tops of thetop plates through screws. A waste box is arranged on one side of the fan. A ventilation pipe is connected between the waste box and the fan. A wind sucking pipe is connected to the bottom of the fan. The transmission equipment is reasonable in structure and novel in design, when the jacquard fabric is conveyed into the rolling device from the unrolling device, the jacquard fabric can be ironed fast, thread residues and crushed materials on the jacquard fabric are cleared away, the jacquard fabric is kept clean and smooth, when the jacquard fabric is rolled, two ends of the jacquard fabric are effectively prevented from rolling up, and therefore the jacquard fabric can be rolled conveniently.

Owner:ZHEJIANG XINGFEIER TECH CO LTD

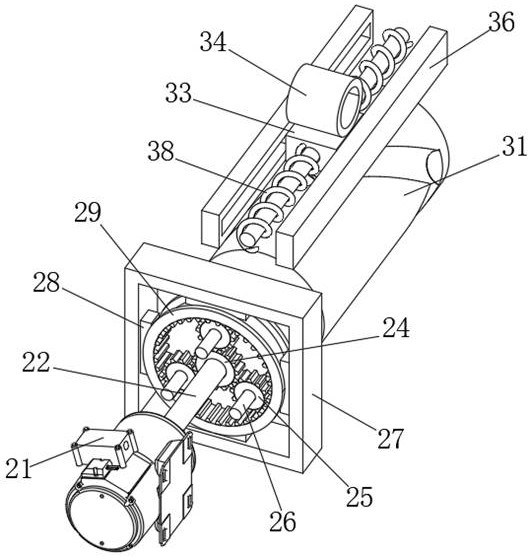

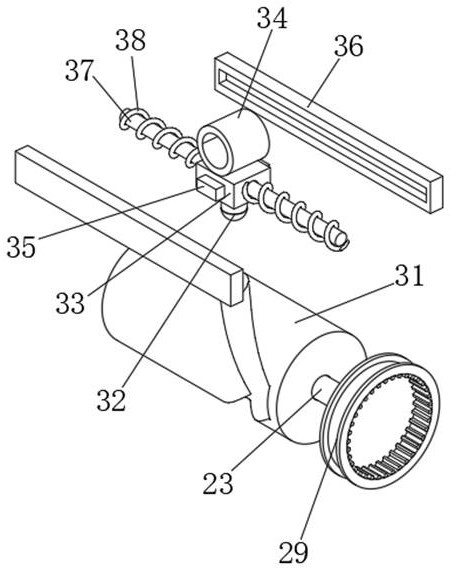

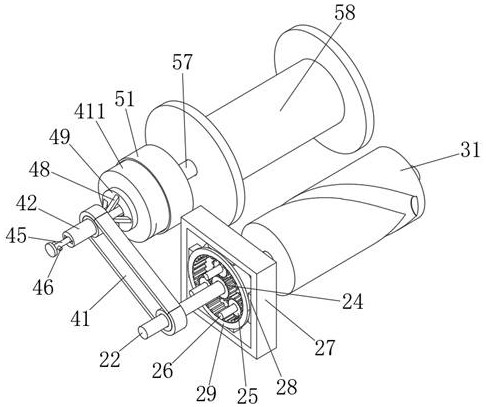

Electric wire winding device with anti-twining mechanism for electrical engineering

The invention relates to the technical field of engineering electric wires, in particular to an electric wire winding device with an anti-twining mechanism for electrical engineering. The electric wire winding device comprises an electric wire winding device main body, a speed reducing mechanism is arranged in the electric wire winding device main body, a guide mechanism is arranged on the surfaceof the speed reducing mechanism, the guide mechanism comprises a fixed rotating roller, the surface of one end, away from the electric wire winding device main body, of the speed reducing mechanism is sleeved with the fixed rotating roller, and a driving rod is arranged in the inner wall of the fixed rotating roller in an inserted mode. According to the electric wire winding device with the anti-twining mechanism for electrical engineering, a fixed rotating ring and the fixed rotating roller are arranged, through rotation of the fixed rotating roller, a first driving block can move in the interior of a fixed supporting rod in a reciprocating mode, so that an electric wire is uniformly and tidily wound; meanwhile, through a guide ring, removing is carried out on garbage adhering to the surface of the electric wire during electric wire winding; and three sets of second gears drive the fixed rotating ring to rotate, and therefore the effect of decelerating the fixed rotating roller can be achieved, and the fixed rotating roller is prevented from rotating too fast.

Owner:陈芸芳

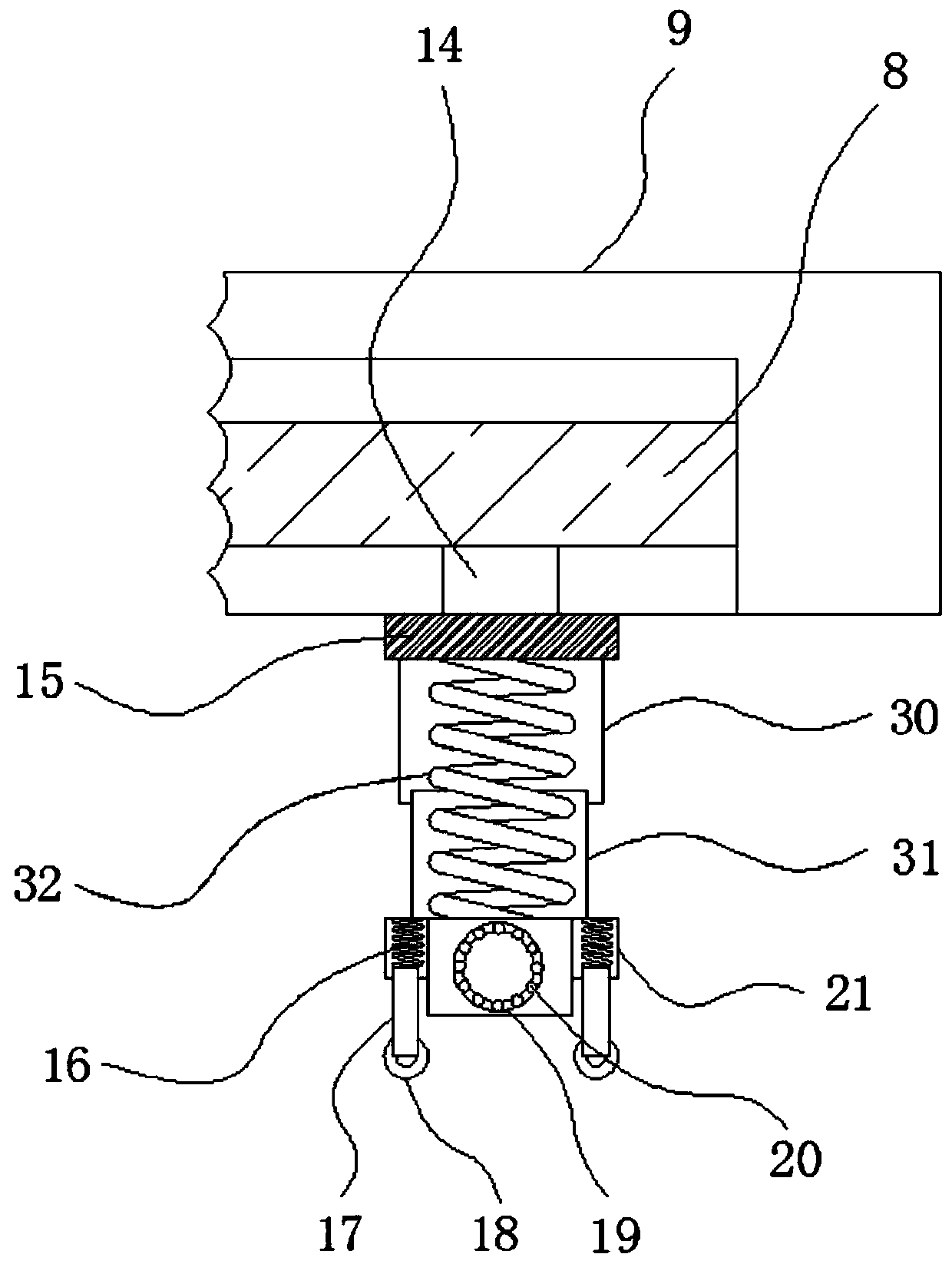

Cable traction winding device for ocean engineering

InactiveCN110884962ARealize the winding effectSave energyCleaning using toolsWater flowElectric machinery

The invention belongs to the technical field of ocean engineering, and particularly relates to a cable traction winding device for ocean engineering. The cable traction winding device aims at solvingthe problems that a cable traction winding device in the prior art is driven by a motor to wind cables, and energy consumption is large. According to the scheme, the cable traction winding device comprises a supporting base, first grooves are formed in the outer walls of the two sides of one end of the supporting base, the inner walls of the two first grooves are connected with first electric guide rails through bolts, the outer wall of one end of each of the two first electric guide rails is in sliding connection with a first electric sliding block, and the outer walls of the other ends of the two first electric sliding blocks are connected with third supporting columns through bolts. According to the cable traction winding device for ocean engineering, a water baffle and a winding shaftare arranged, the supporting base is fixed to a stern, and in the ship moving process, water flow drives the water baffle to rotate, then the winding shaft is driven to rotate, the winding effect is achieved, and compared with traditional winding conducted through motor rotation, the energy is greatly saved.

Owner:QIANSHUI QINGYUAN HUBEI TECH CO LTD

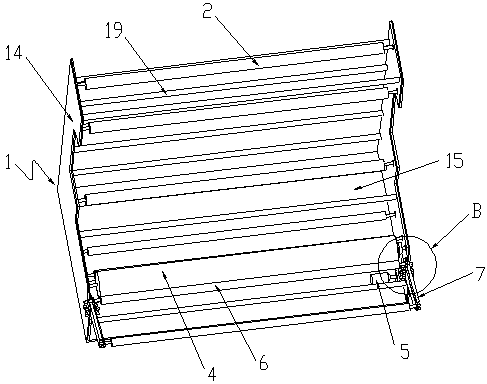

Textile fabric winder

ActiveCN109592510AReduce the number of winding turnsFast winding speedWebs handlingEngineeringScrew thread

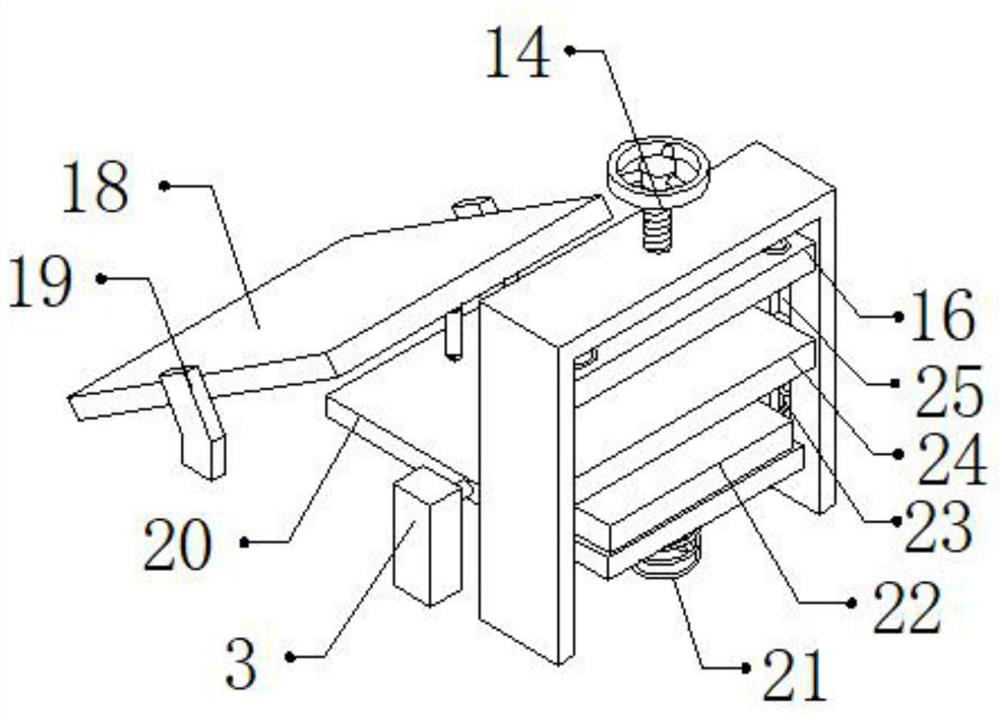

The invention relates to a winder, in particular to a textile fabric winder. The invention aims to solve the technical problem so as to provide the textile fabric winder convenient to fix cloth and capable of adjusting the winding diameter size and soothing and compacting the cloth. The textile fabric winder comprises a base, a bearing seat, a rotary rod, a first bolt, a connecting pillar, a rotating column, an adjusting device, a second spring, lifting plates, a first pressing block, a straight sliding rail, a support rod and the like, wherein the bearing seat is arranged on the right side ofthe top part of the base; the rotary rod is in interference connection into the bearing seat; a first threaded hole is formed in the left part of the rotary rod; a cross-shaped hole is formed in theright part of the connecting pillar; the left part of the rotary rod is located in the cross-shaped hole; and the first bolt is screwed in the first threaded hole. According to the textile fabric winder provided by the invention, working personnel presses one end of the cloth through the first pressing block, so that the cloth can be conveniently and quickly fixed; and through screwing a nut, thelifting plates on the upper part and the lower part are opened toward the outer side, and the cloth winding diameter size can be adjusted according to the needs, so that the winding turn number can bereduced, and the winding speed is accelerated.

Owner:平顶山市碧盈家纺有限公司

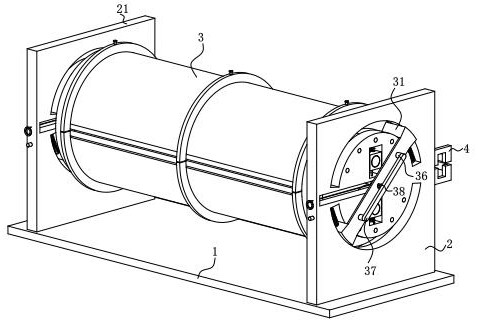

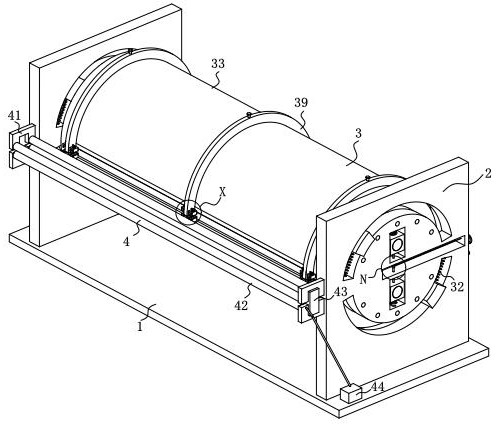

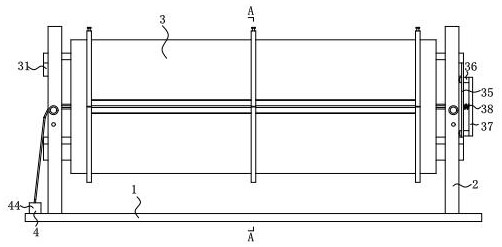

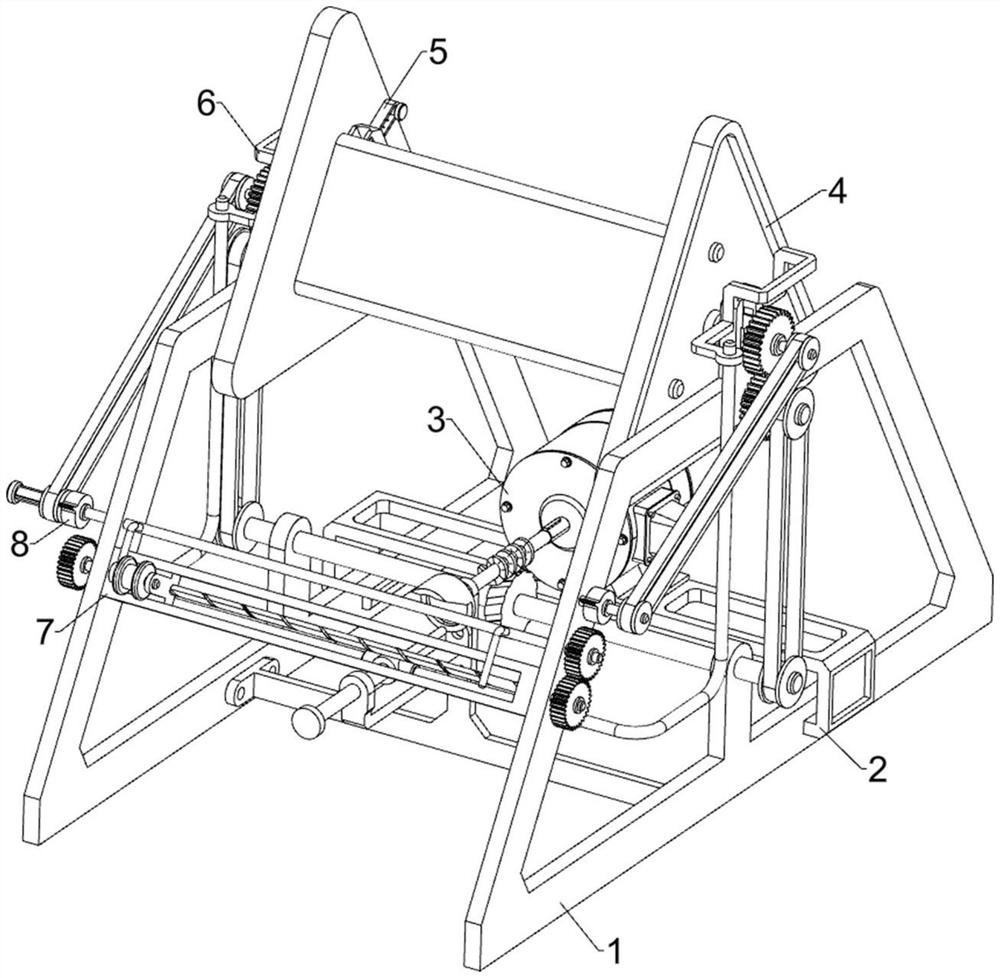

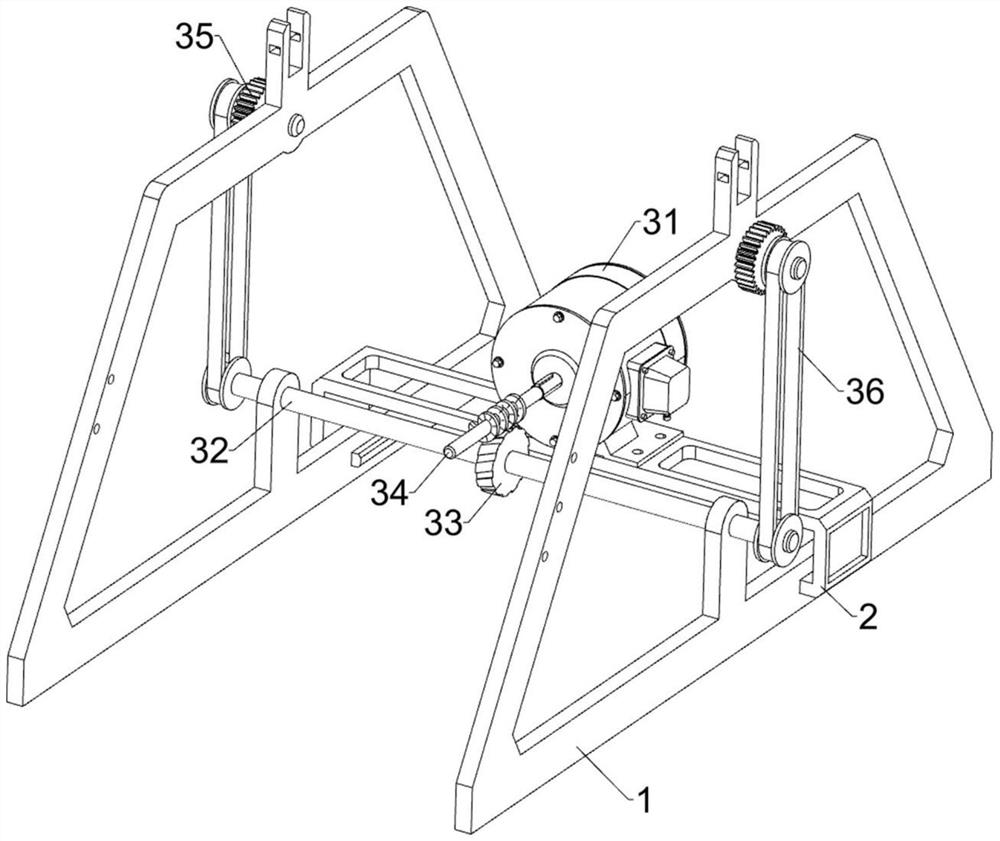

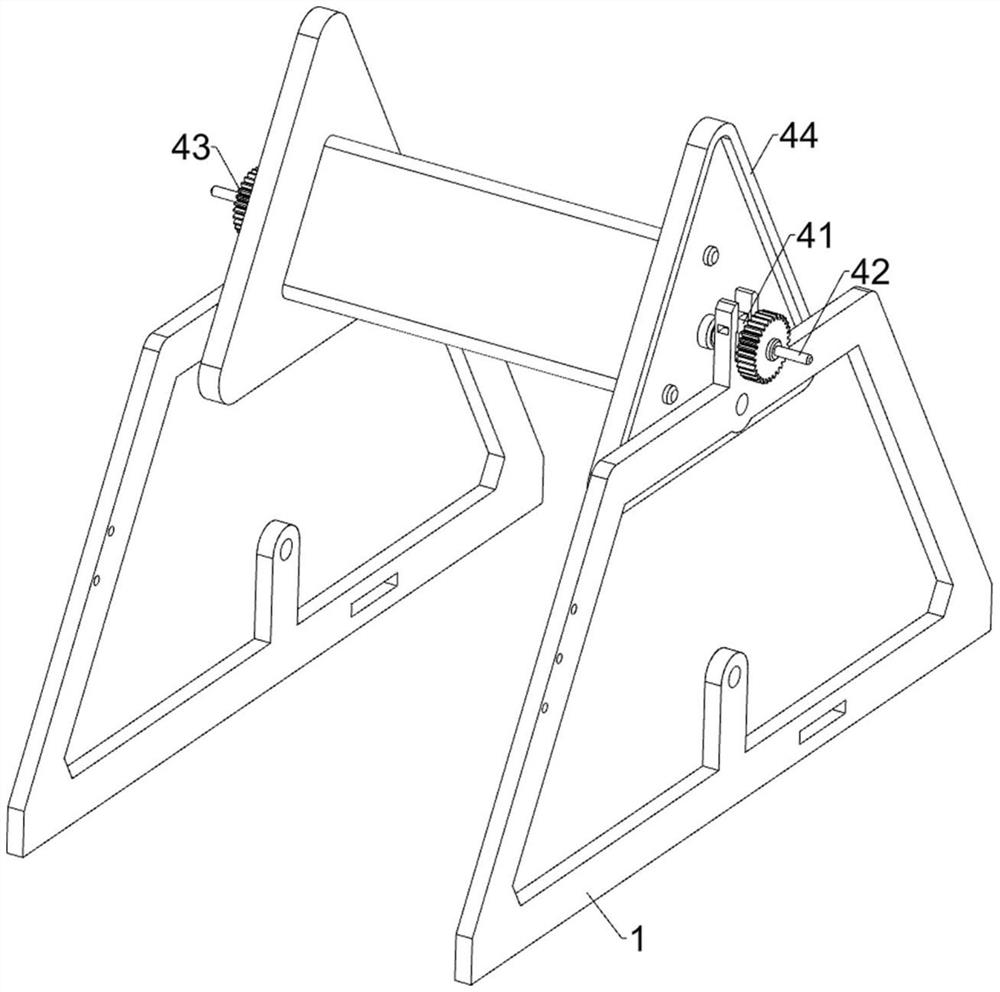

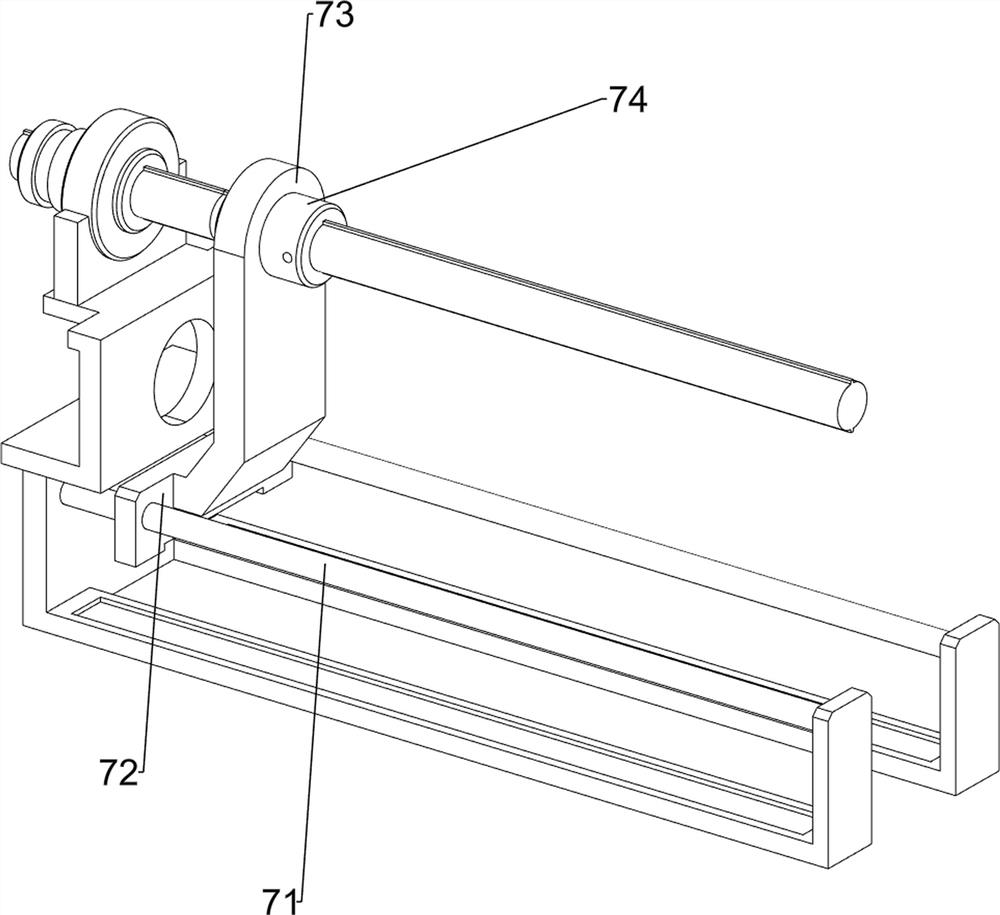

A winding device for plastic pipe extrusion molding

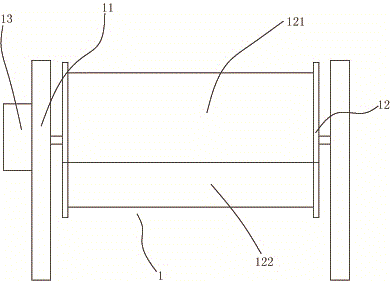

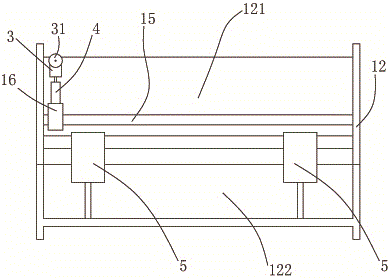

The invention discloses a rewinding device for plastic pipe extrusion molding, which relates to the technical field of industrial rewinding equipment. Connection, the base plate 1 and the base plate 2 are respectively fixed with fixing brackets at the bottoms of the side ends. By setting the conveying mechanism, the present invention ensures that the plastic pipes are closely attached between the pipe bodies on the winding reel, and the circles are arranged in parallel; , in the process of driving the outer baffle to rotate to the horizontal position, the tube head will be squeezed into the inner ring of the tube coil, so as to ensure that the inner ring of the tube coil will not be loosened; by setting the sliding table on the sliding rod which is positioned by the lead screw , the distance between the longitudinal guide rollers can be adjusted, so that the device can adapt to plastic pipes of different diameters and specifications, and avoid the accumulation and winding of the plastic pipes at the position of turning and changing layers.

Owner:芜湖富田电子科技有限公司

Silk yarn winding roller for textile machinery

The invention discloses a silk yarn winding roller for textile machinery. The silk yarn winding roller for textile machinery structurally comprises a fixed mounting rod, a winding roller internal device capable of controlling the deceleration, a left protection block, a winding roller body, a right separation protection block, a power strip connecting rod, an anti-skid plate and a connecting mounting block, wherein the right side of the fixed mounting rod is connected with the left side of the inner device of the winding roller of the controllable speed reducer through an electric welding mode, the axis of the fixed mounting rod is perpendicular to the left side of the inner device of the winding roller of the controllable speed reducer, and the inner device of the winding roller capable of controlling the deceleration is arranged on the left surface and the right surface of the left protection block in a penetrating mode and is in interference fit. According to the silk yarn winding roller for the textile machinery, expanding is carried out from the inner side to tension and fix the cylinder, so that the rotation of the roller cylinder is synchronous and consistent, the phenomenonthat the threads are interwoven and knotted when the threads are wound is avoided, rotation speed caused by inertia during rotation of the roller is controlled by reducing rotation speed through friction, and the silk thread is prevented against breakage caused by tension increase when pulled from a single direction.

Owner:湖州丰硕纺织有限公司

Plastic film winding mechanism

The invention discloses a plastic film winding mechanism. The plastic film winding mechanism comprises a support, a first conveying roller, a second conveying roller, a driving roller, a driving motorand a winding roller; the second conveying roller and the winding roller are located on the front side and the rear side of the driving roller respectively, and the height of the second conveying roller is less than the height of the driving roller; supporting frames are arranged on the left side and the right side of the support respectively, each supporting frame comprises a fixing plate and asupporting plate, the end, away from the support, of each fixing plate is inclined upwards, the two supporting plates are arranged on the opposite surfaces of the two fixing plates respectively, a rack is arranged at the top of each supporting plate, gears are arranged at the two ends of the winding roller, and the gears can be meshed with the racks. The winding mechanism has the beneficial effects that the supporting frames are arranged for supporting a winding shaft; and the racks on the supporting frames are meshed with the gears at the two ends of the winding shaft, are used for limiting the movement speed of the winding shaft on the support frames, so that tight contact between the winding shaft and a driving shaft is maintained, and winding of a plastic film is well achieved.

Owner:NANJING GAOSHENG FIRE EXTINGUISHING AGENT CO LTD

Automotive engine transportation storage device

InactiveCN109018632AWinding effectReduce the probability of entanglementPackaging vehiclesContainers for machinesEngineeringTorsion spring

The invention provides an automotive engine transportation storage device. The automotive engine transportation storage device comprises box bodies, strip-shaped openings, elastic bands, hooks, rotating shafts, limiting discs and torsion springs. The box bodies are fixed to the rear end of the interior of a U-shaped frame. The rotating shafts are installed in the box bodies, the torsion springs sleeve the left ends of the rotating shafts, the left ends of the torsion springs are fixed to the left end faces of the interiors of the box bodes, and the right ends of the torsion springs are fixed to the left end faces of the limiting discs. The limiting discs are fixed to the annular side faces of the rotating shafts, and the strip-shaped openings are formed in the lower sides of the front endfaces of the box bodies. The elastic bands are wound around the rotating shafts, and one end of each elastic band penetrates through the corresponding strip-shaped opening, extends to the front side of the corresponding box body and allows the corresponding hook to be installed. By the adoption of the design, the elastic bands are wound around the rotating shafts by use of the torsion springs, andtherefore the purpose that the elastic bands are hidden in the box bodies is achieved, and the phenomenon that due to the fact that the elastic bands are randomly placed in the U-shaped frame, loading of an automotive engine is affected is avoided. The automotive engine transportation storage device is convenient to use, neat in appearance and convenient to stack.

Owner:安妥驰(张家港)汽车零部件再制造有限公司

Water pipe winding equipment for garden watering

InactiveCN111362053AWinding effectAvoid wear and tearFilament handlingDrying gas arrangementsEngineeringWater pipe

The invention discloses water pipe winding equipment for garden watering. The water pipe winding equipment comprises a fixing seat, wherein a connecting plate is fixedly connected to the outer wall ofone side of the fixing seat, a fixing opening is formed in the outer wall of the top of the connecting plate, two springs are fixedly connected to the inner wall of each of the two opposite sides ofthe fixing opening, clamping plates are fixedly connected to the outer walls of one sides of the springs, ball grooves are formed in the outer walls of the opposite sides of the two clamping plates, balls are connected to the inner walls of the ball grooves in a rolling mode, a supporting frame is fixedly connected to one side of the outer wall of the top of the fixing seat, a rotating shaft is rotationally connected to the outer walls of the opposite sides of the supporting frame, and a winding roller is fixedly connected to the outer wall of the rotating shaft. The equipment can prevent water stains from remaining in a water pipe to cause heavy weight of the water pipe, can prevent the surface of the water pipe from being abraded due to friction, can prevent the water pipe from being scattered on equipment due to inertia generated during winding, and can treat large-size debris attached to the surface of the water pipe.

Owner:郭振

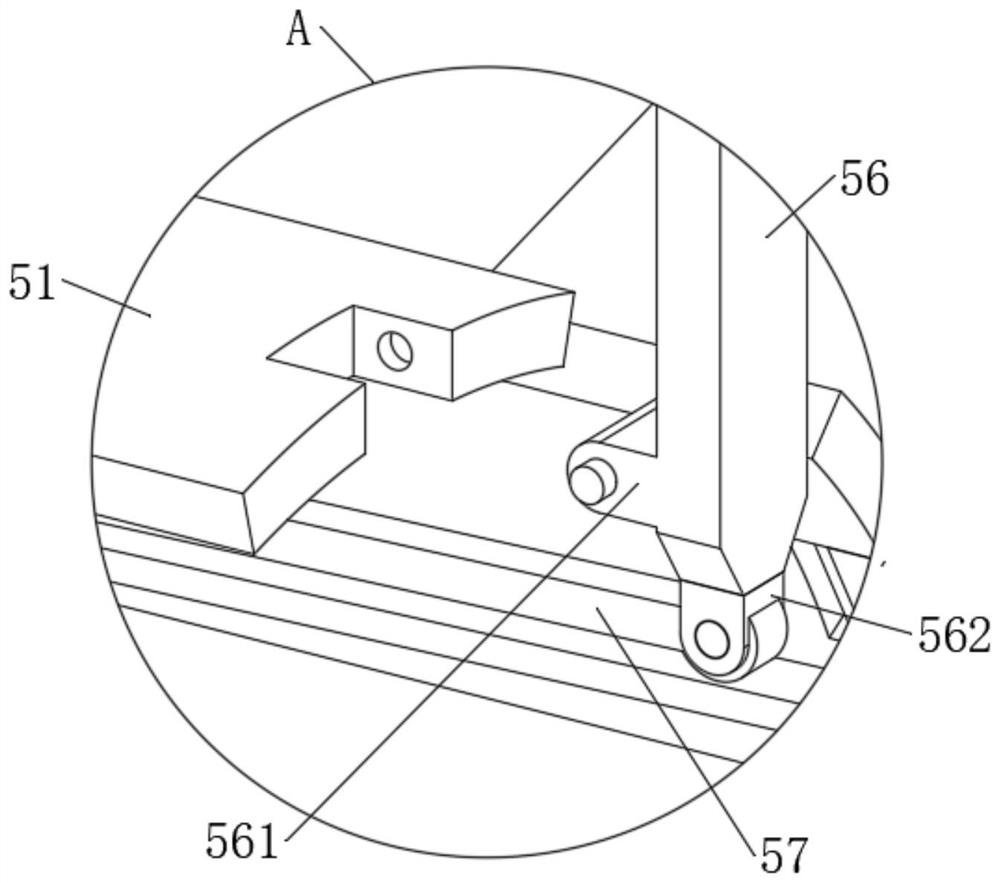

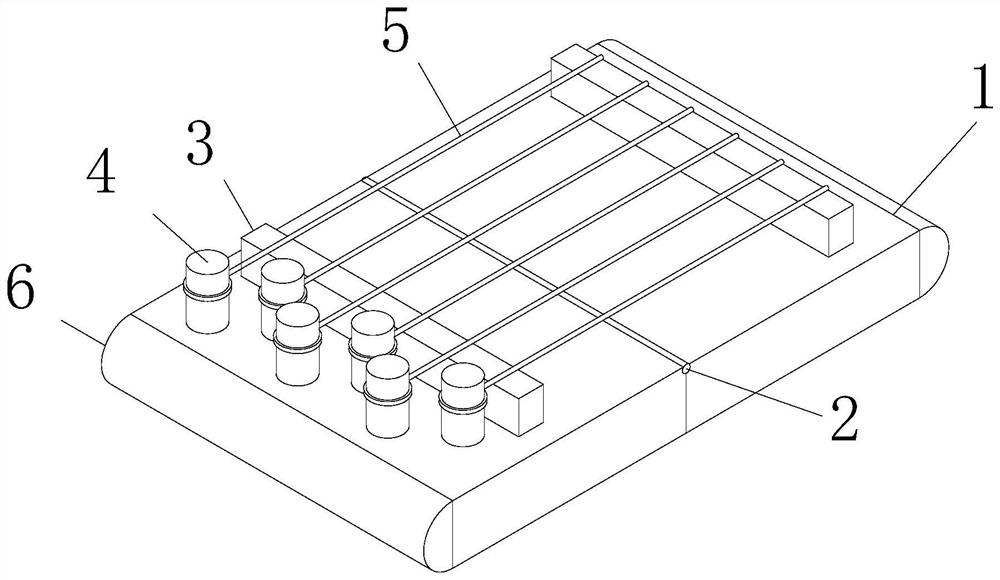

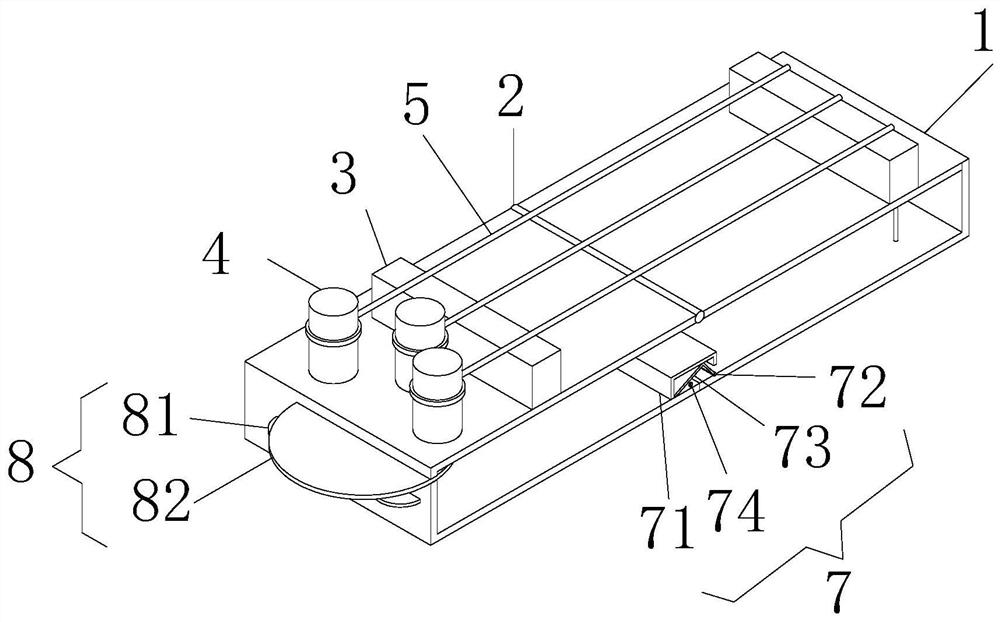

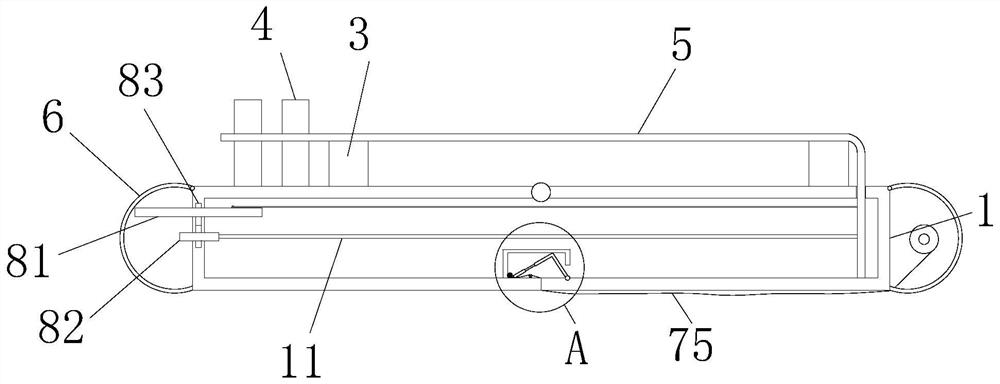

Straw plaited winding device

ActiveCN111689303AWinding levelWinding effectFilament handlingAgricultural engineeringStraw plaiting

The invention relates to a winding device, and particularly relates to a straw plaited winding device. The technical problem is how to design the straw plaited winding device which can be more convenient for people to wind straw ropes, is high in working efficiency and can wind the straw ropes neatly. The straw plaited winding device comprises a base, wherein a supporting block is fixedly connected to the middle of one side of the base; a vertical plate is fixedly connected to the edge of one side of the supporting block; a bearing seat is installed on the portion, away from the supporting block, of the vertical plate in an embedded mode; and a rotating shaft is rotationally connected into the bearing seat in a penetrating mode. According to the straw plaited winding device, the straw ropes are wound around all top blocks by a circle, then a rocker is pulled to rotate forwards, so that the top blocks rotate forwards to wind the straw ropes; after the straw ropes are wound, a handle ispulled to move forwards, so that the top blocks move inwards to loosen the straw ropes; and then the wound straw ropes are taken down, and the straw ropes do not need to be pulled by people to be wound on a tool for winding, so that the winding device is more convenient, and the working efficiency is improved.

Owner:邓志香

Electric wire cutter

The invention discloses an electric wire cutter. The electric wire cutter comprises a winding device, a distribution device and a cutting device; the winding device comprises a first bracket and a winding drum arranged on the first bracket, and the winding drum is connected with a first motor; the distribution device comprises a second bracket; a lead rail and a bidirectional screw are arranged on the second bracket, gliding mechanisms are arranged on the lead rail and the bidirectional screw; line passing holes are arranged on the gliding mechanisms, and the bidirectional screw is connected with a second motor; the winding drum is axially provided with an opening, and a slide rail is arranged in the winding drum, and a slide block is arranged on the slide rail; a first cylinder is arranged on the slide block, and a cutting device is connected to a cylinder rod of the first cylinder; a cutting slice of the cutting device is located in the opening. The wire cutter adopting the structure evenly winds the electric wire on the winding drum by means of the distribution device; through the cutting device, the electric wire wound on the winding drum is cut off; for the electric wire is uniformly wound, the length of the electric wire after cutting is the same.

Owner:宁波保税区明德工业设计有限公司

Rotating frame of simple bag making machine

The invention discloses a rotating frame of a simple bag making machine. The rotating frame comprises a main shaft rod and two side supporting rods. The two ends of the main shaft rod are arranged on two base supporting arms of the bag making machine through bearings. The two side supporting rods are parallel and are vertically arranged on the main shaft rod. Two auxiliary rods are arranged at the position where the two side supporting rods are connected and the two sides of the main shaft rod respectively. The inner side of each auxiliary rod is provided with an n-shaped auxiliary circular rod and a clamp. The two auxiliary rods are each provided with a pair of sliding limiting plates. Groove-shaped notches are formed in the bottoms of the sliding limiting plates and clamped with the auxiliary rods, and the sliding limiting plates are fixed to the auxiliary rods through bolts. The rotating frame of the simple bag making machine is simple in structure, convenient to use, good in limitation performance on bag making raw materials, firm and durable, and winding of the bag making raw materials is not affected.

Owner:TONGCHENG FURUN PACKAGING MATERIAL

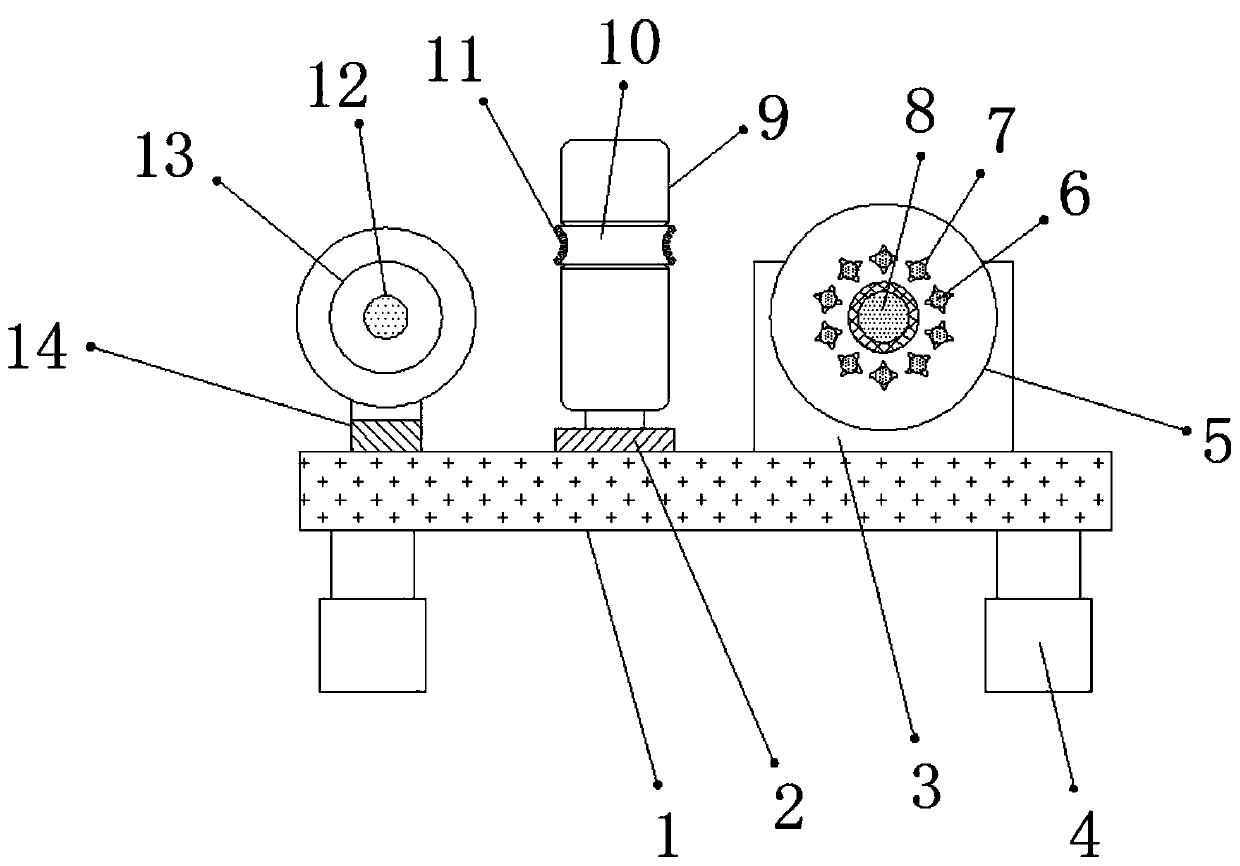

Automatic winding machine for steel cable production

PendingCN110158340AEasy to wind and rollReduced service lifeRope making machinesWinding machineArchitectural engineering

The invention discloses an automatic winding machine for steel cable production. The automatic winding machine comprises a fixing seat and is characterized in that a support plate is fixed to one sideof the outer wall of the top of the fixing seat, a rotary rod is rotatably connected to the outer wall of one side of the support plate through a bearing, a winding plate is connected to the outer wall of the rotary rod in a sleeved manner, the outer walls on two sides of the winding plate and the outer walls on two sides of the rotary rod are provided with threaded holes, fixing bolts are connected to the inner walls of the threaded holes in a threaded manner, a winding rod is fixed between the outer walls of the opposite sides of the winding plate, flanges distributed in an equal-distance manner are arranged on the outer wall of the winding rod, and a fixing plate is fixed to a positon, close to the middle, of the outer wall of the top of the fixing seat. By the automatic winding machine, steel cable service life shortening caused by the fact the surface of the steel cable is corroded by dust can be prevented, the influence of winding plate idling caused by steel cable surface smoothness on steel cable winding can be prevented, and steel cable collapse caused by excessively large steel cable winding height can be prevented.

Owner:天津中诚科信传动科技有限公司

A straw winding device

ActiveCN111689303BEasy to rewindImprove work efficiencyFilament handlingAgricultural engineeringStraw plaiting

The invention relates to a winding device, in particular to a straw winding device. The technical problem is how to design a straw braided winding device that can be more convenient for people to wind up the straw rope, has high work efficiency, and the straw rope that is rolled up is also neat. A straw weaving and rolling device, including a base, a support block is fixedly connected to the middle part of one side of the base, a vertical plate is fixedly connected to the edge of one side of the support block, and the bearing seat is embedded and installed on the side far away from the support block. One part of the vertical plate, the shaft is rotatably connected in the bearing seat. In the present invention, by winding the straw rope around all the top blocks, and then pulling the rocker to rotate forward, the top block can be rotated forward to wind up the straw rope. After the straw rope is rolled up, pull the handle to move forward to make the top block Move inward to loosen the straw rope, and then take off the rolled straw rope, so that people don't need to pull the straw rope to wrap it around the tool for winding, which is more convenient and improves work efficiency.

Owner:邓志香

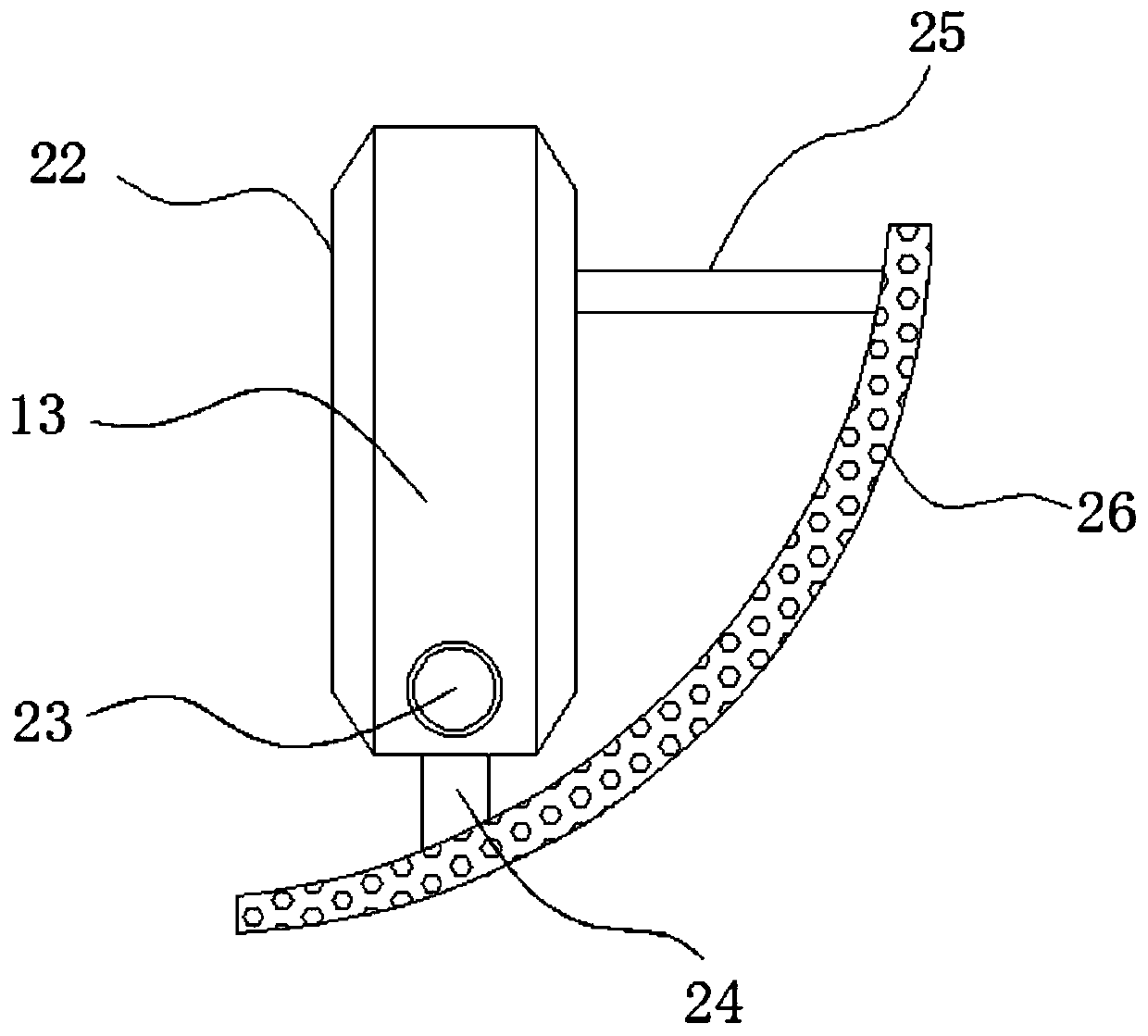

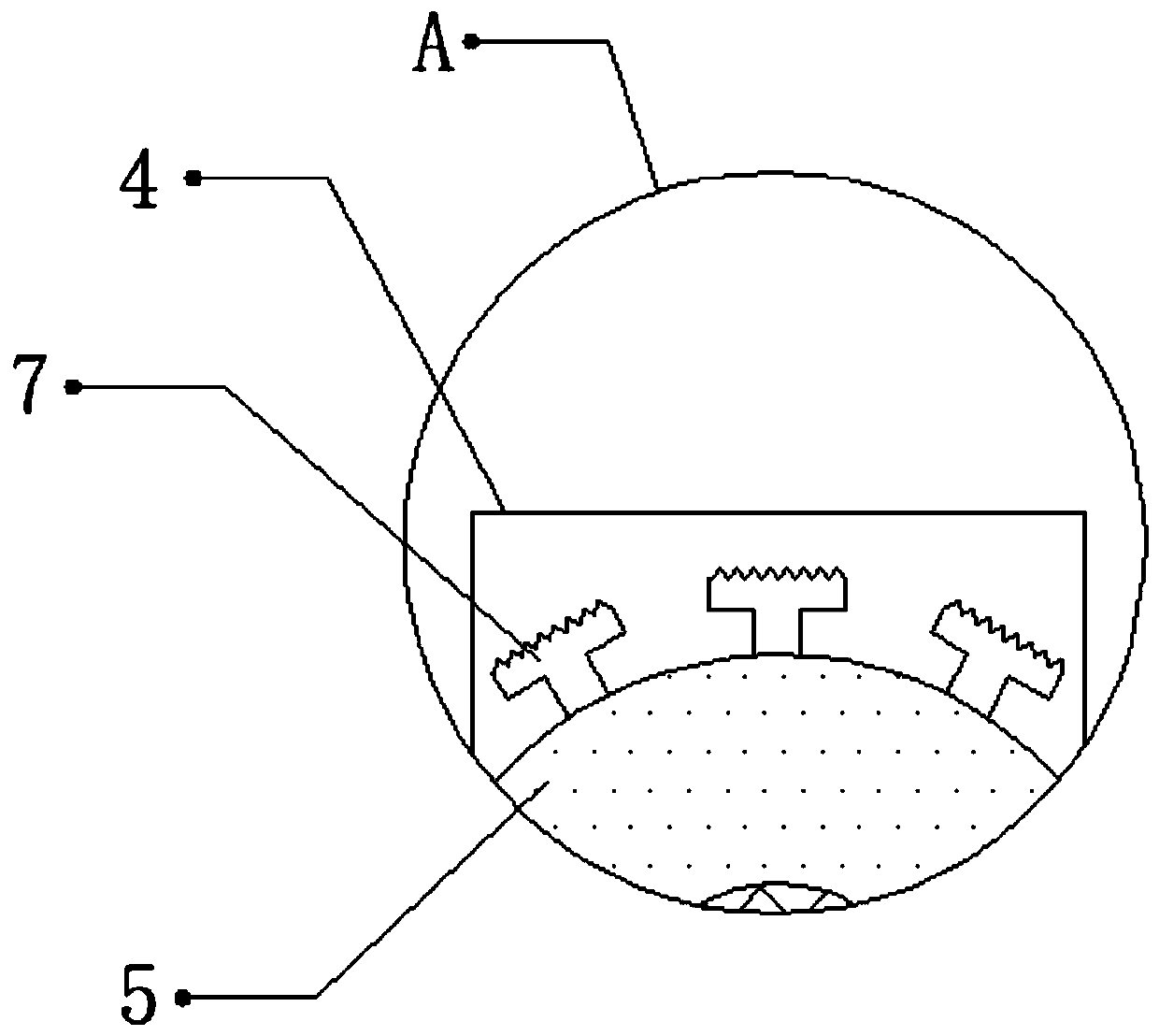

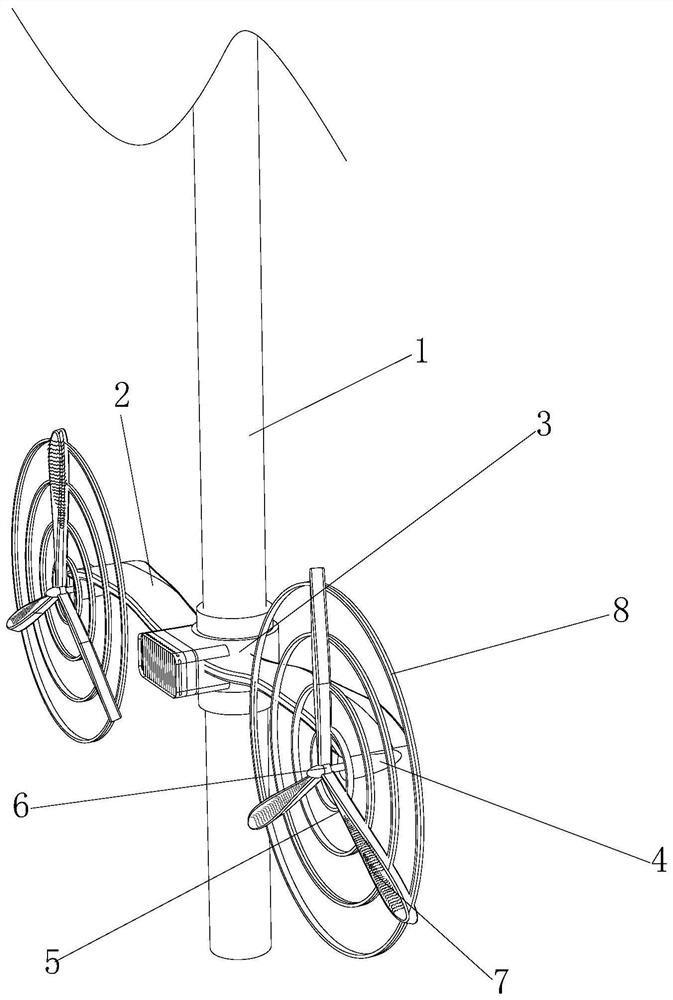

Anti-winding tidal power generation device

InactiveCN113250897AWinding effectRotation effectHydro energy generationReaction enginesNew energyEngineering

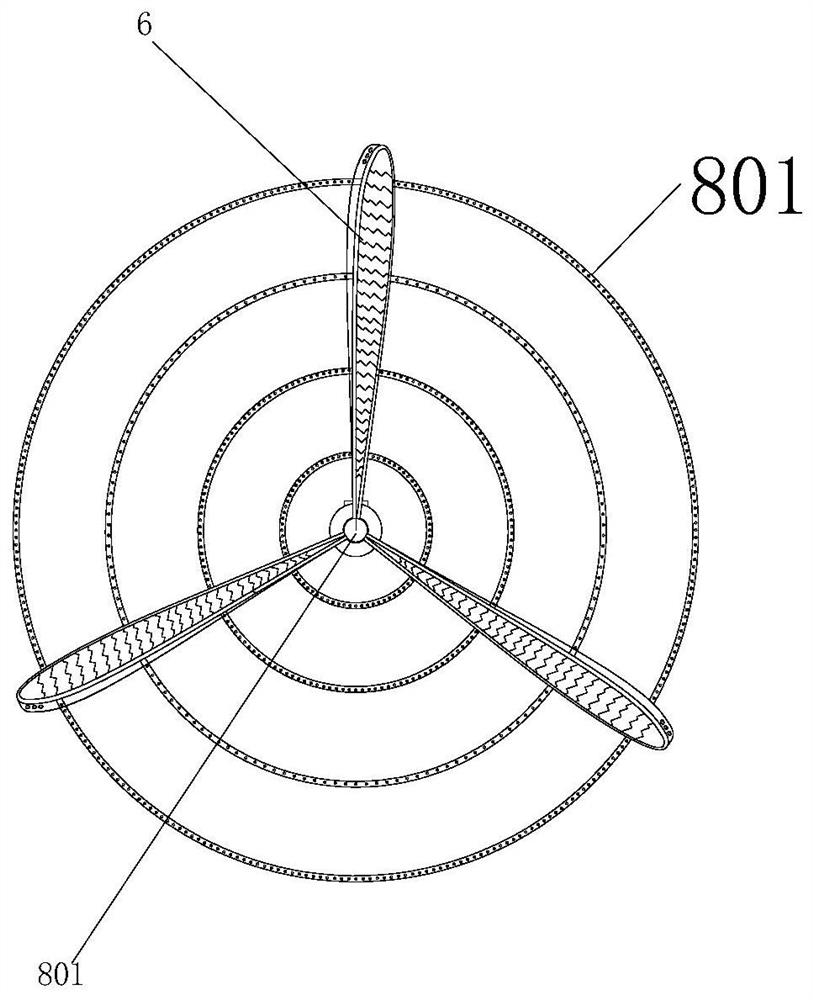

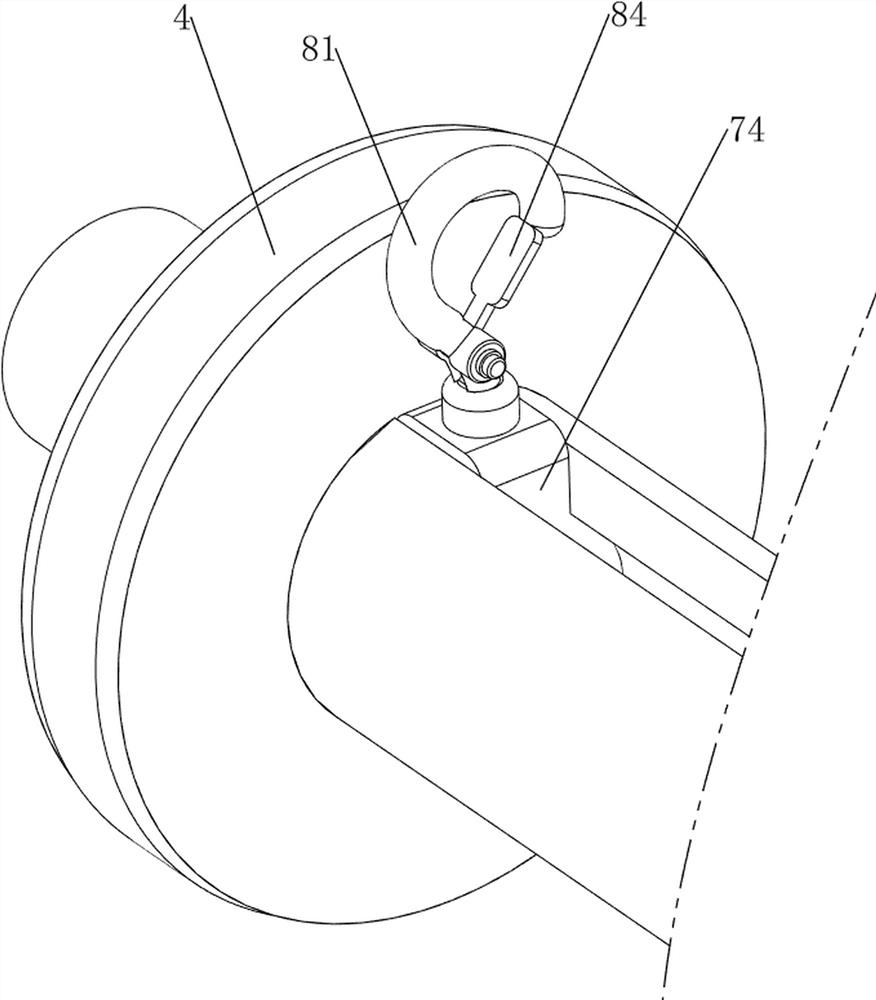

The invention provides an anti-winding tidal power generation device, and relates to the technical field of new energy. The anti-winding tidal power generation device comprises a fixing rod, a support, a waterproof pumping machine, power generation devices, fan blades, a connecting piece, a first anti-winding mechanism and a second anti-winding mechanism, wherein the support is fixedly connected to the position, close to the upper portion of the bottom end, of the fixing rod, the waterproof pumping machine is fixedly connected to the joint of the support and the fixing rod, and the power generation devices are fixedly connected to the lower portions of the two ends of the support; the left side of the power generation device is rotationally connected with the connecting piece, the left side of the connecting piece is fixedly connected with fan blades, the first anti-winding mechanism is fixedly connected into the fan blades, net-shaped garbage is prevented from being wound around the fan blades, and rotation of the fan blades is not affected. The fan blades are fixedly connected with the second anti-winding mechanism, and bag-shaped garbage is prevented from being wound around the fan blades. The invention provides an anti-winding tidal power generation device. The problem that the power generation efficiency of the tidal power generation device is affected due to the fact that net-shaped garbage and bag-shaped garbage in seawater are wound on fan blades of the tidal power generation device is solved.

Owner:叶坤

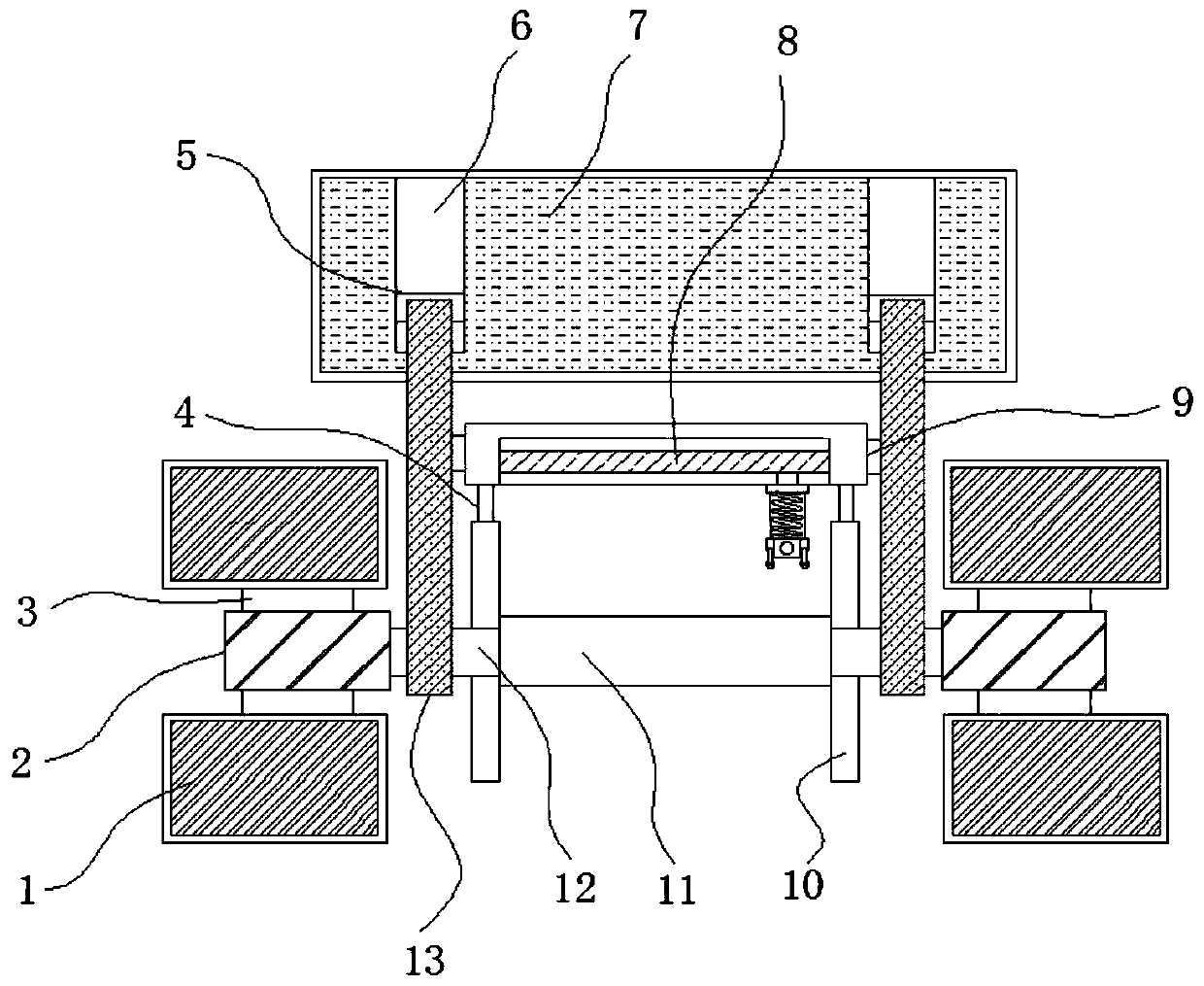

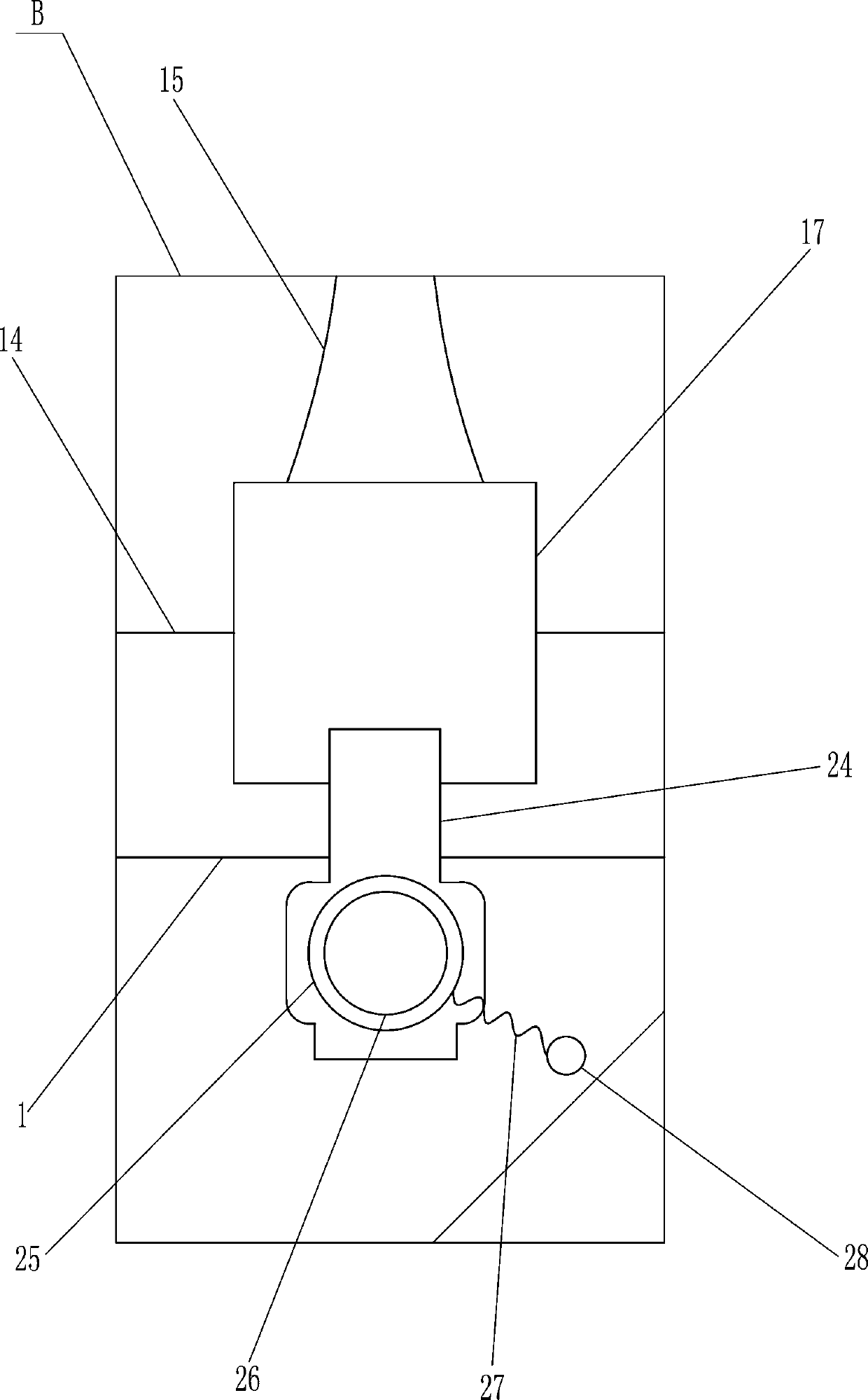

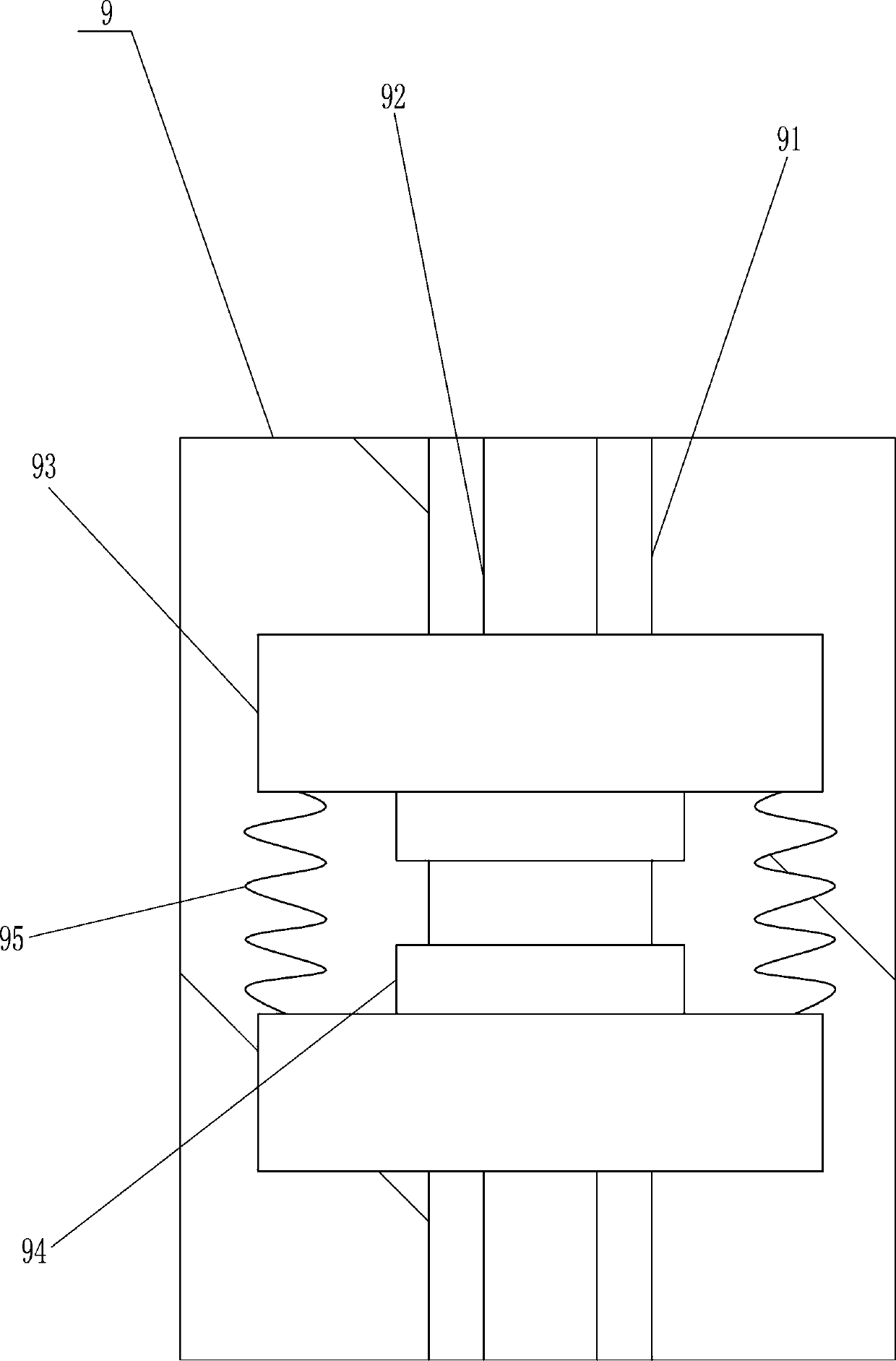

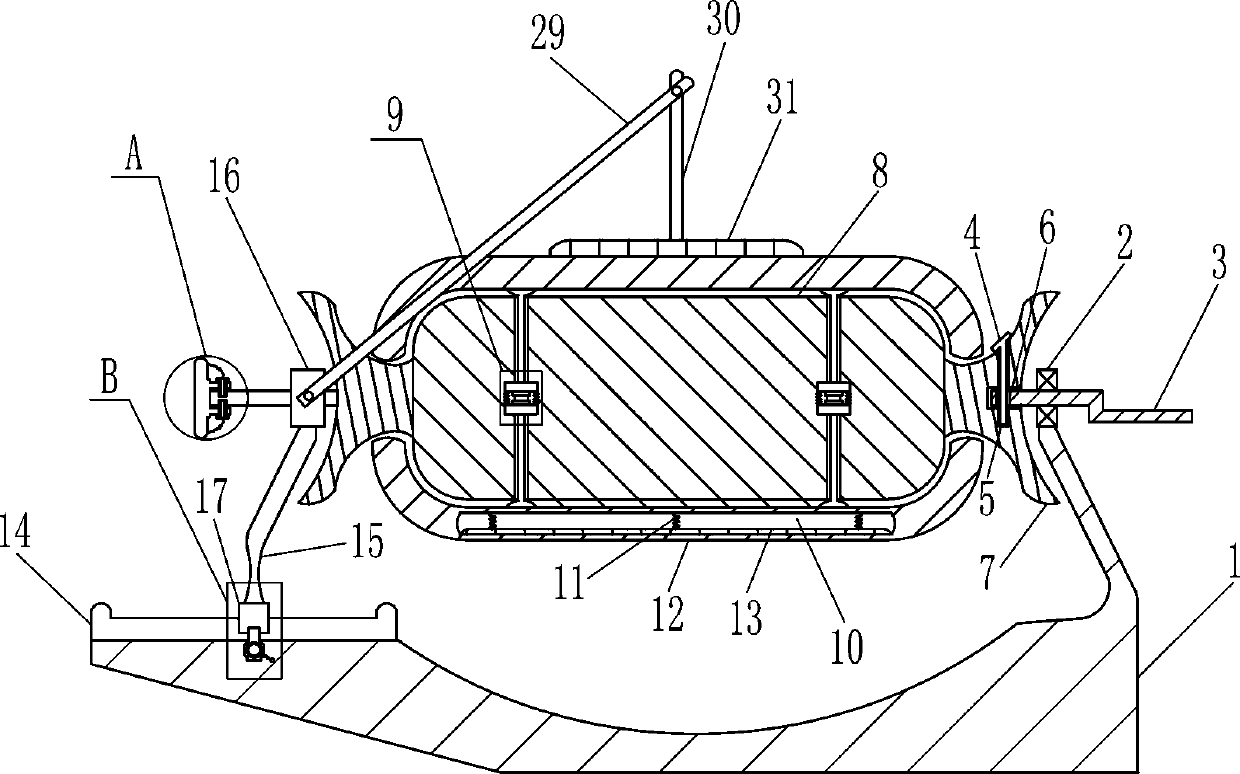

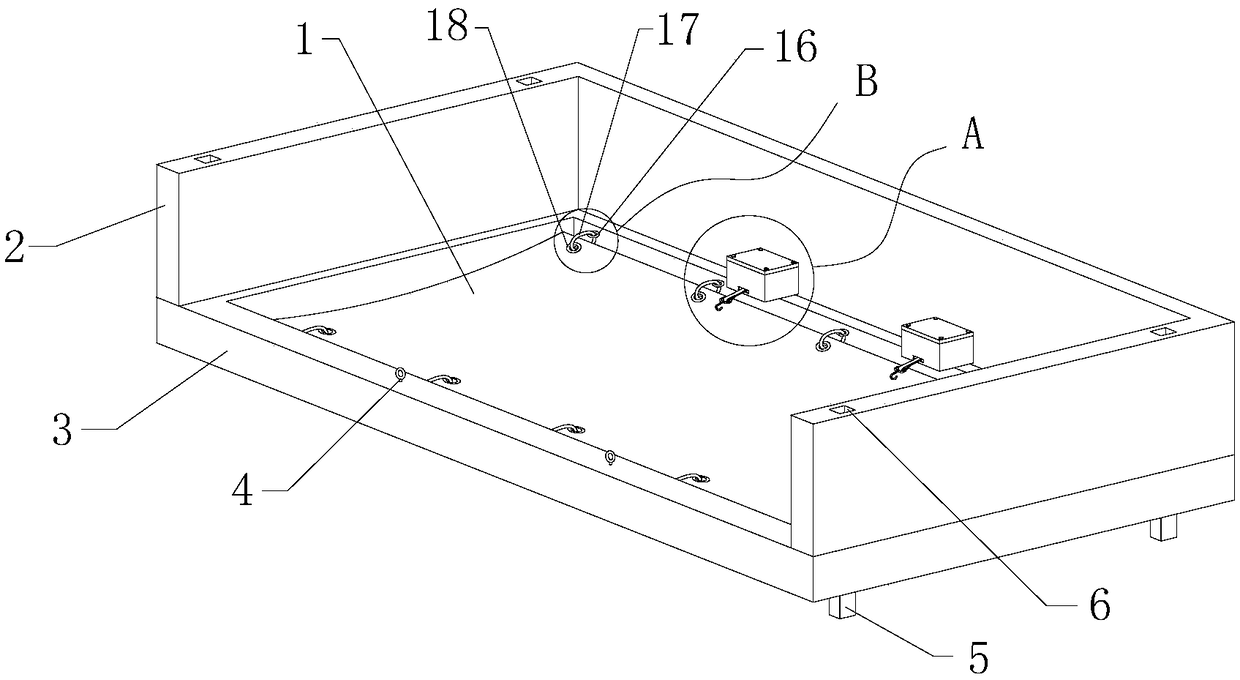

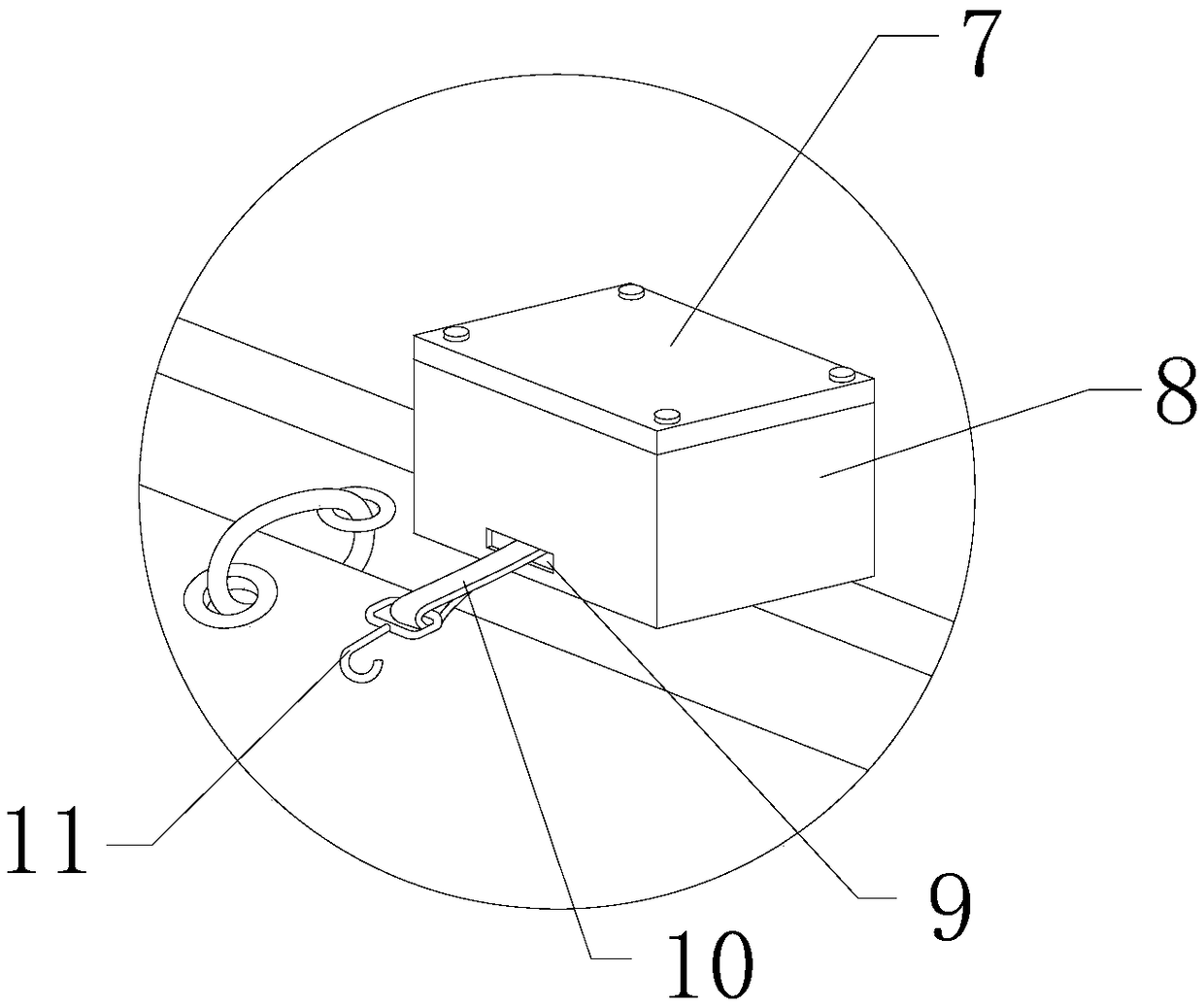

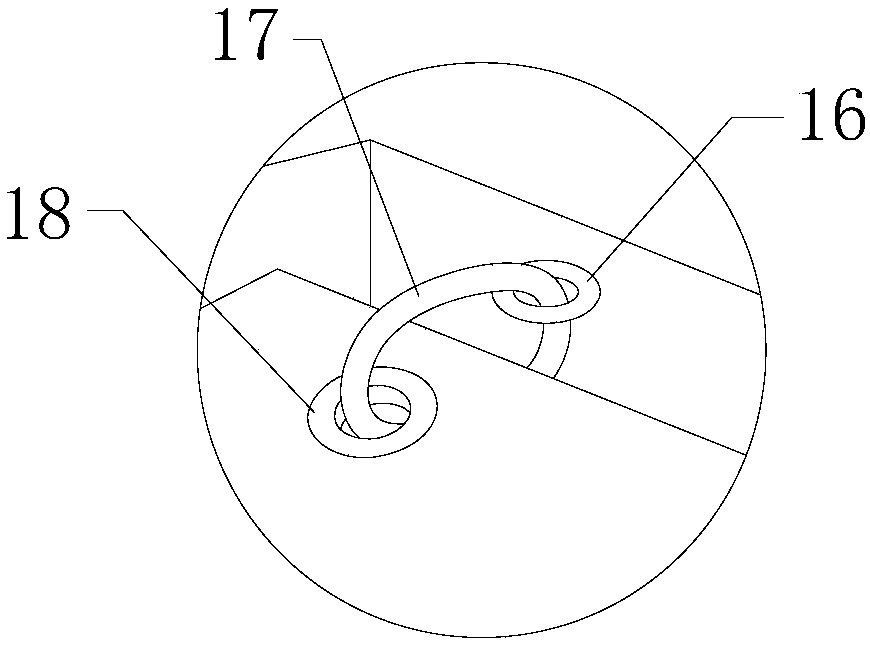

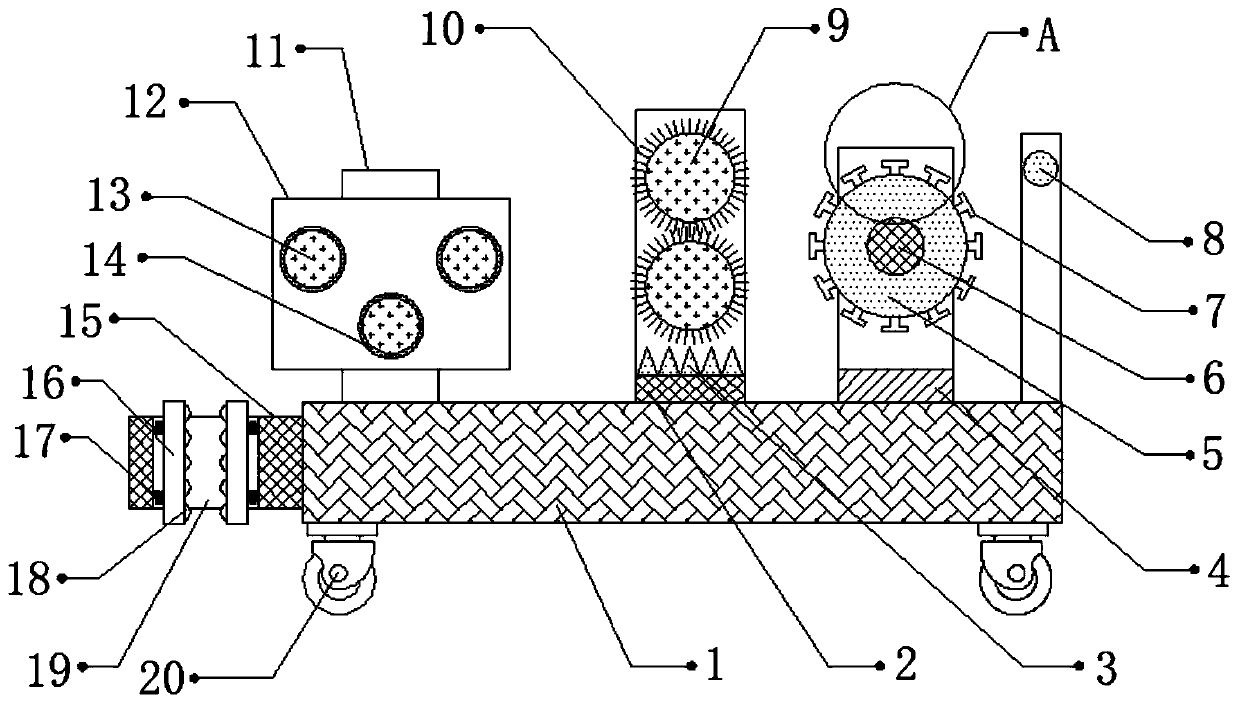

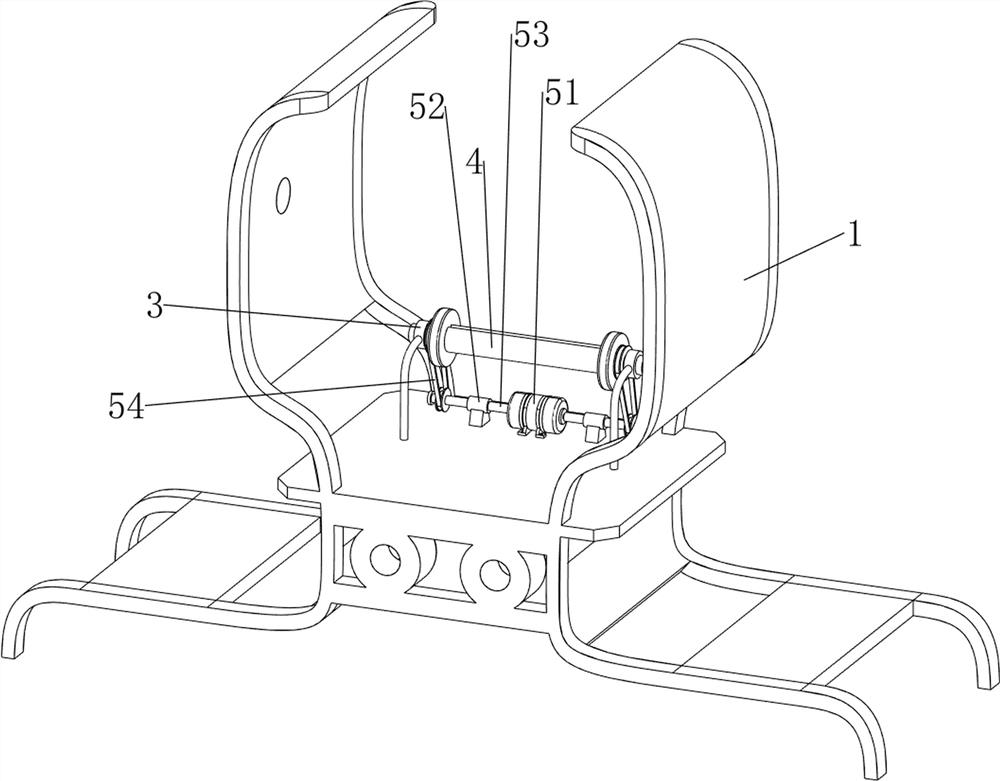

Device for quickly fixing mooring rope for ship docking

PendingCN114475916AFast control windingImprove winding efficiencyWaterborne vesselsStructural engineeringMechanical engineering

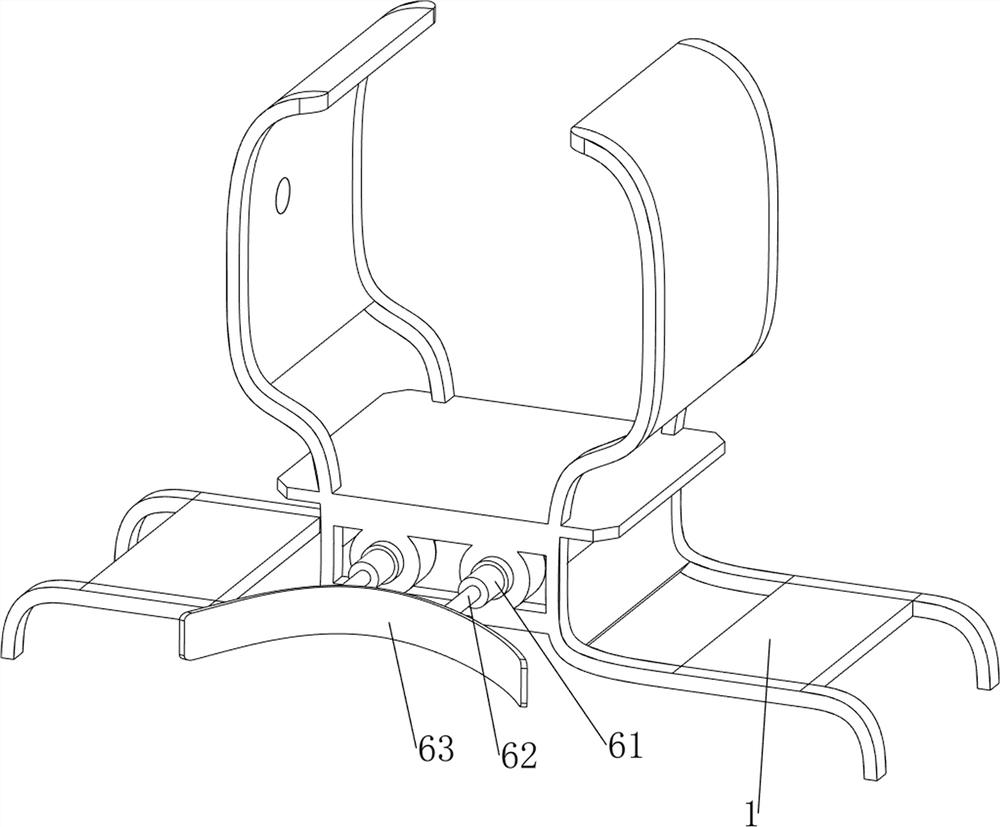

The invention relates to a device for fixing a mooring rope, in particular to a device for quickly fixing the mooring rope for ship docking. According to the device for rapidly fixing the mooring rope for ship docking, the mooring rope can be automatically wound, then manpower can be greatly saved, meanwhile, a ship body can be buffered to a certain degree in the ship docking process, and therefore the ship body can be protected to a certain degree. The device for rapidly fixing the mooring rope for ship docking comprises expansion bolts, and the expansion bolts are symmetrically arranged on the two sides of the lower portion of a main frame in a sliding mode; the two first shaft sleeves are arranged in the middle of the main frame at intervals; and the reel is rotationally arranged between the upper parts of the two first shaft sleeves. Through cooperation of the rotating mechanism and the pushing mechanism, the rotating mechanism can rapidly control winding of the mooring rope, the pushing mechanism can cooperate with the rotating mechanism to assist in winding of the mooring rope, and then the winding efficiency of the mooring rope can be greatly improved.

Owner:陈翠连

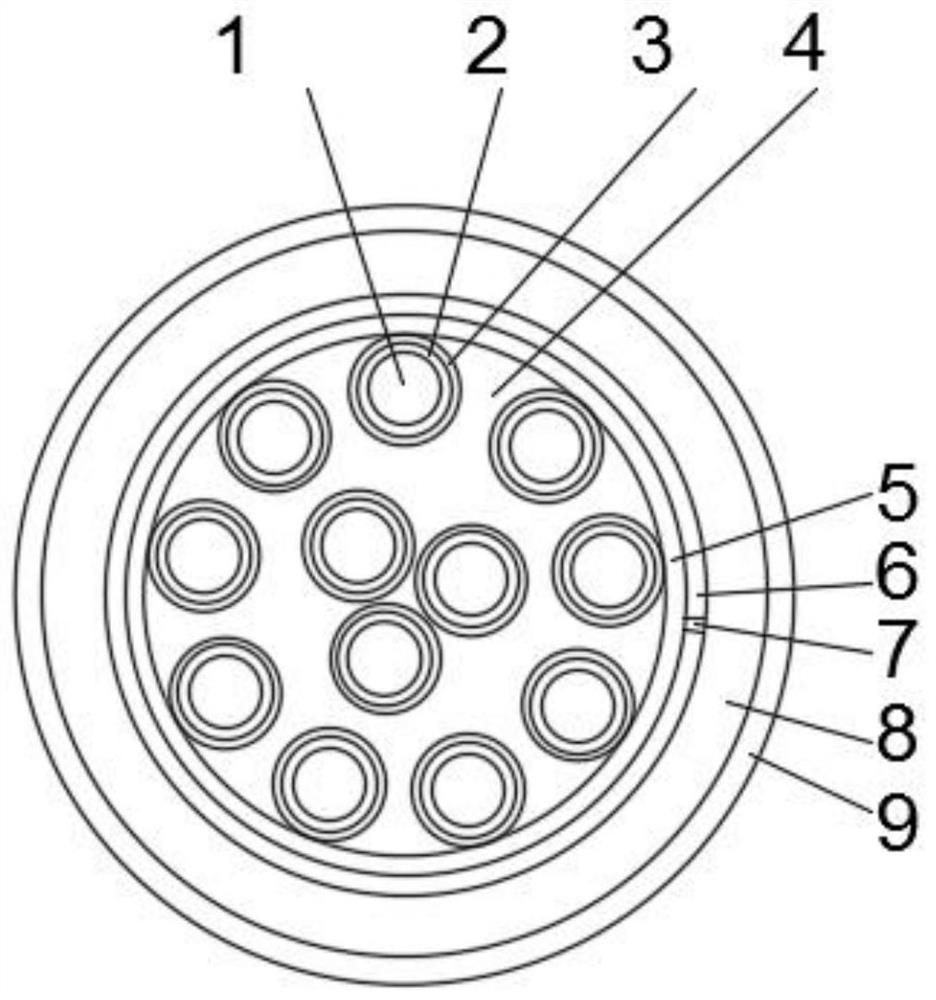

Cross-linked polyethylene insulated parallel bunched aerial cable and processing equipment

PendingCN114873369AWinding effectIncrease the winding rangePlastic/resin/waxes insulatorsFilament handlingAerial cableEngineering

The invention discloses a cross-linked polyethylene insulated parallel bunched aerial cable and processing equipment, the cross-linked polyethylene insulated parallel bunched aerial cable comprises a supporting seat, one side of the outer wall of the top of the supporting seat is provided with a winding mechanism, the outer wall of the top of the supporting seat is provided with a sliding groove, the inner wall of the sliding groove is slidably connected with a sliding block, and the outer wall of the top of the sliding block is provided with an auxiliary mechanism. A moving mechanism is arranged between the winding mechanism and the auxiliary mechanism and comprises an air cushion and an air bag, an air pipe is arranged between the air cushion and the air bag, the air cushion is located between the supporting base and the winding mechanism, the air bag is located between the sliding block and the sliding groove, and the air cushion and the air bag are both made of hollow elastic materials. According to the cross-linked polyethylene insulated parallel bunched aerial cable winding device, the winding range of cross-linked polyethylene insulated parallel bunched aerial cables can be widened, and the situation that adjacent cross-linked polyethylene insulated parallel bunched aerial cables are wound, and winding of the cross-linked polyethylene insulated parallel bunched aerial cables is affected is prevented.

Owner:陈登远

A high tensile signal transmission reel cable

ActiveCN112201388BGuaranteed heat resistanceGuaranteed flame retardant performancePlastic/resin/waxes insulatorsFilament handlingCopper wireEngineering

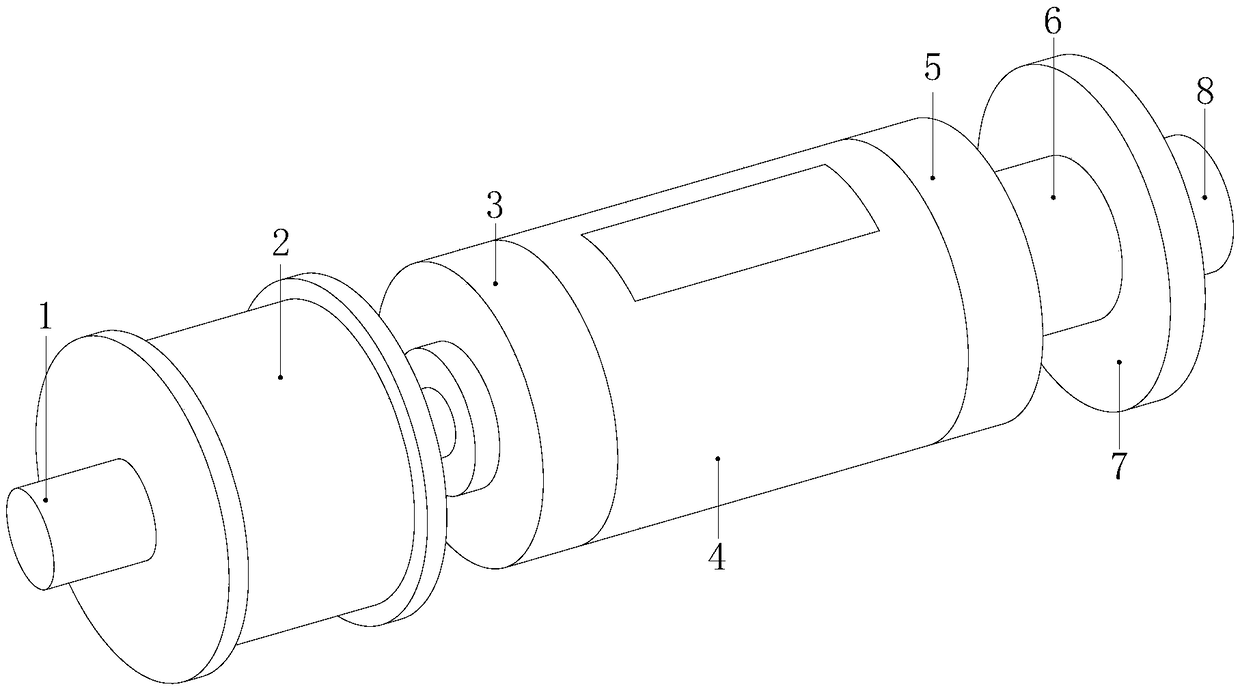

The invention discloses a high-tensile signal transmission reel cable, which comprises a cable body, the cable body contains soft steel wires, a copper wire braid layer and an insulating layer, the copper wire braid layer is provided with soft steel wires, and the copper wire braid The outer surface of the inner layer is covered with an insulating layer, and the outer surface of the cable body is covered with an inner lining layer, and hemp rope is filled between the inner lining layer and the cable body, and the outer side of the inner lining layer is wrapped with a shielding layer, so The inside of the shielding layer is provided with a drain wire, the outer surface of the shielding layer is covered with an outer protective cover, and the outer surface of the outer protective cover is provided with a steel wire braided layer; the insulating layer is made of a highly flexible flame-retardant PVC insulating material, On the premise of ensuring the excellent electrical insulation performance of the cable, the heat resistance, flexibility, flame retardancy and mechanical properties of the cable are guaranteed; the cable in the present invention has good flexibility, tensile resistance and mechanical properties, and can withstand large tensile forces and bend.

Owner:ANHUI MENTOR CABLE GROUP

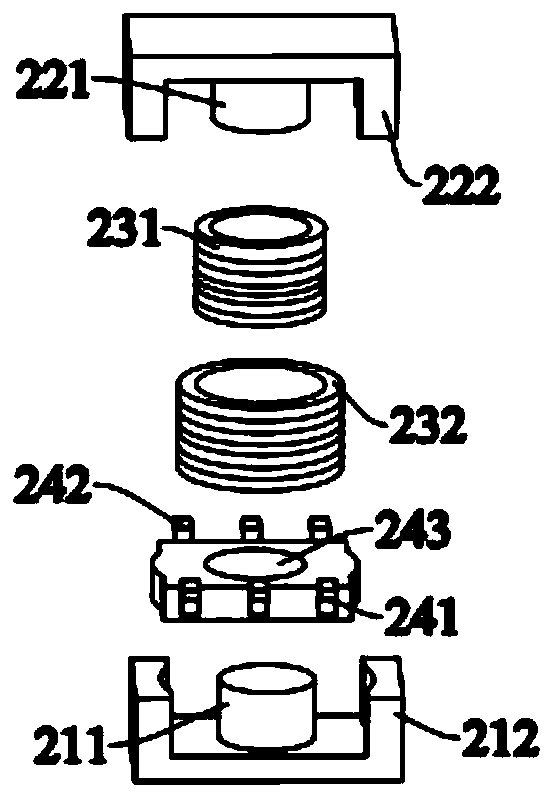

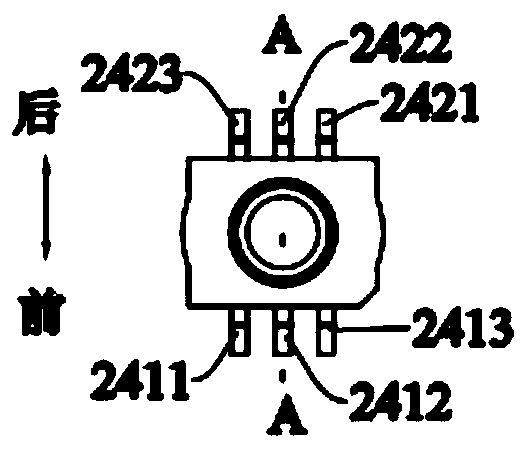

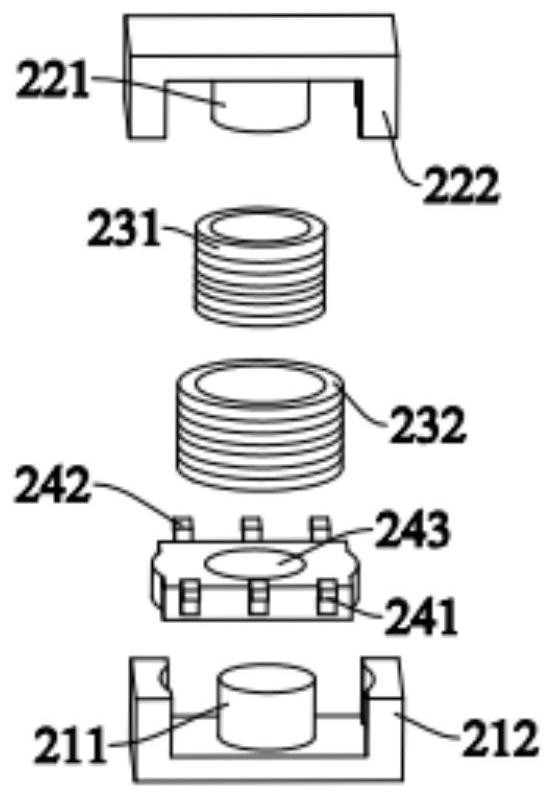

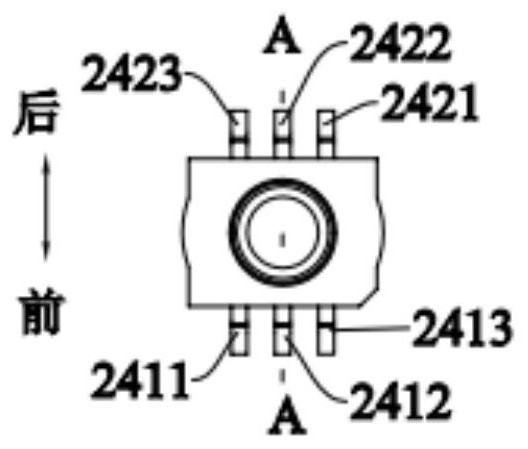

Miniature transformer manufacturing method and miniature transformer

ActiveCN111554510AFixed connection is firmEasy to operateTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresTransformerEngineering

The invention provides a miniature transformer manufacturing method and a miniature transformer. The manufacturing method comprises the following steps: 1, providing a wiring base fixed with a wrapping post; 2, winding a first coil; 3, sequentially completing winding of other coils in the coil assembly; 4, removing the wrapping post; and 5, assembling a miniature transformer. When the coil is wound, the coil leading-out wire and the binding post of the wiring base are fixed together, so that the coil does not need to be fixed again after being wound, the operation is convenient, and the process is simple.

Owner:ZHUHAI HAIWER ELECTRIC APPLIANCE CO LTD

Tension adjusting bracket for PVC (polyvinyl chloride) heat shrinkage film production

The invention relates to the technical field of film production, in particular to a PVC (polyvinyl chloride) thermal shrinkage film production tension adjusting frame which comprises a placing plate, a clamping piece, a tensioning piece and a cleaning piece, the clamping piece is mounted at the upper end of the placing plate, the tensioning piece is connected to the clamping piece, and the cleaning piece is mounted at the rear end of the clamping piece. The problems that in the prior art, tension borne by a thermal shrinkage film needs to be adjusted in the winding process, an existing adjusting frame has the function of achieving self-adaptive adjustment of the tension borne by the thermal shrinkage film, but adjustment is generally conducted through a plurality of rotating rollers, and therefore a large number of space resources are occupied, and the utilization rate of the space around the thermal shrinkage film is reduced are solved. According to the tension adjusting frame for production of the PVC heat shrinkage film, the tension pipe on the tension piece is used for pulling and pulling the heat shrinkage film through self-rotation, so that the tension borne by the heat shrinkage film is changed, the space needed for changing the tension of the heat shrinkage film is reduced, and the influence on the surrounding environment is reduced.

Owner:徐州金太阳包装材料有限公司

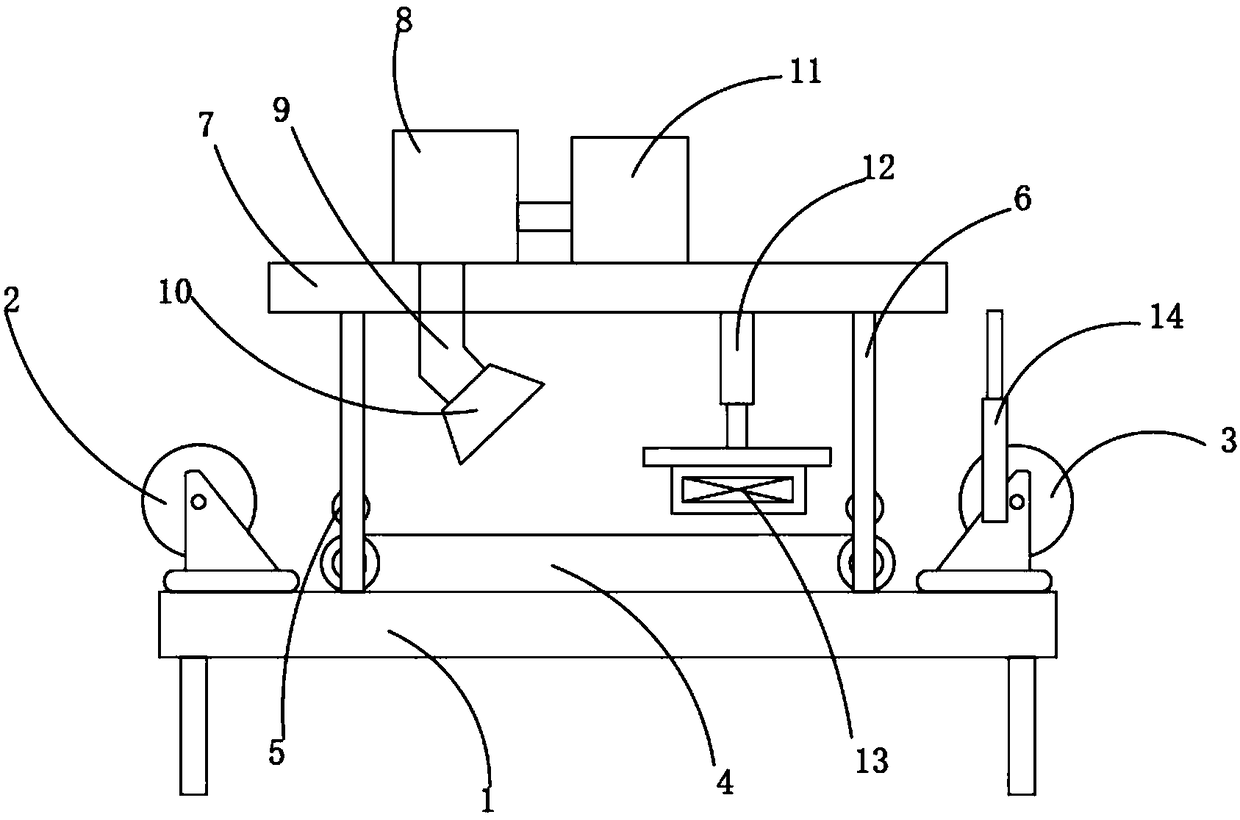

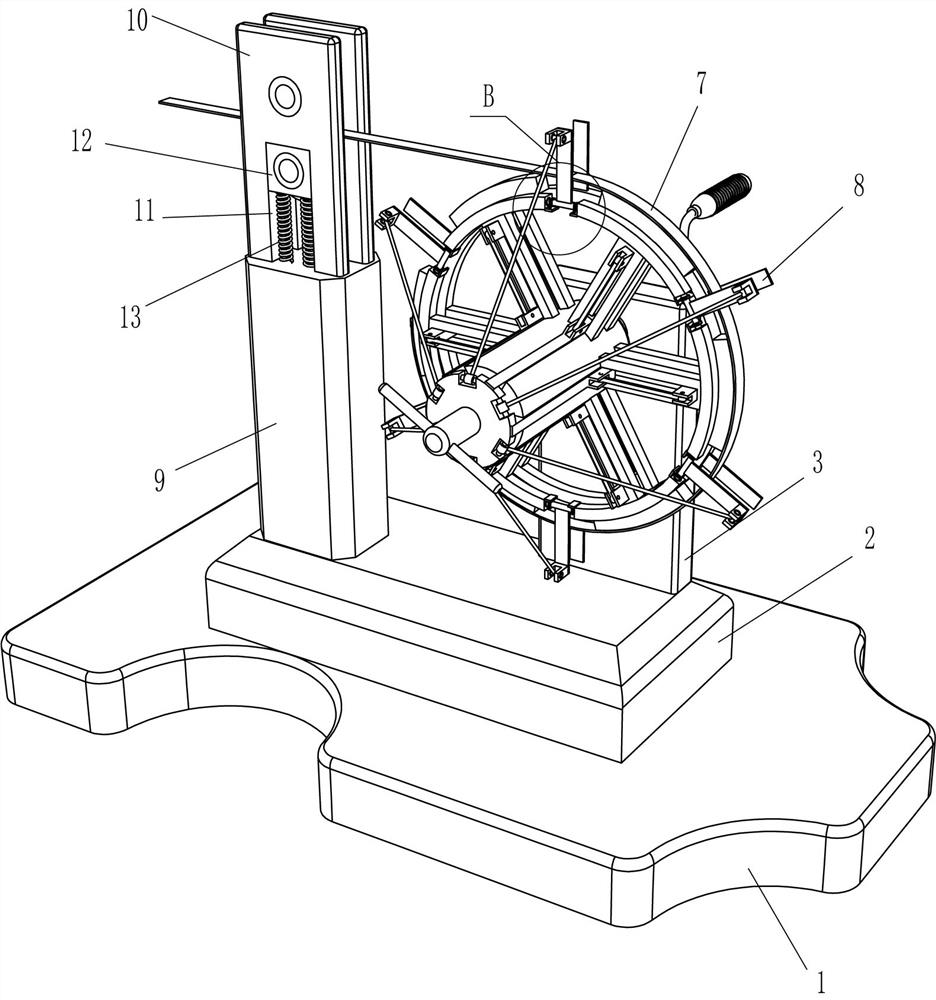

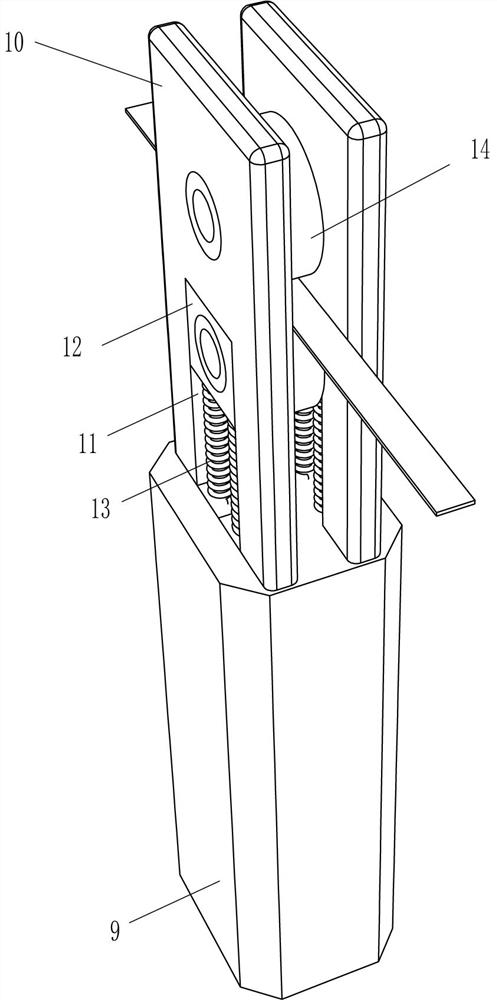

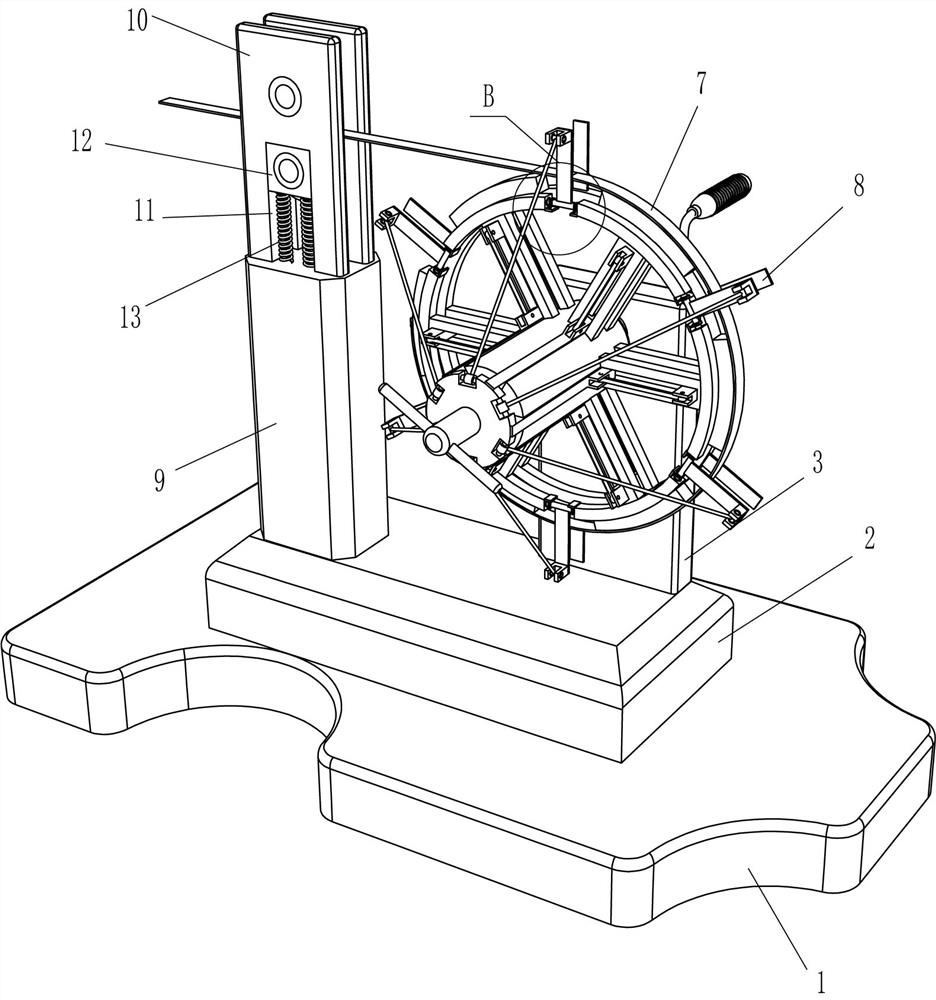

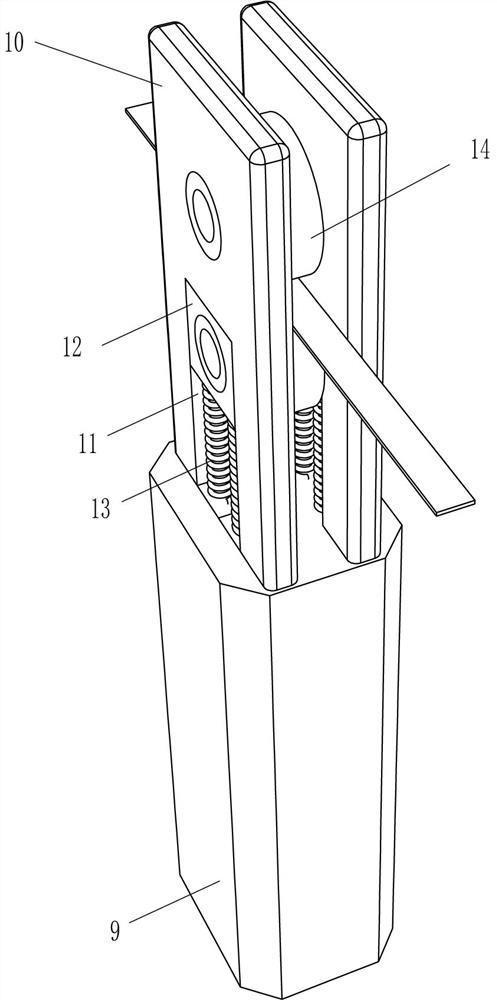

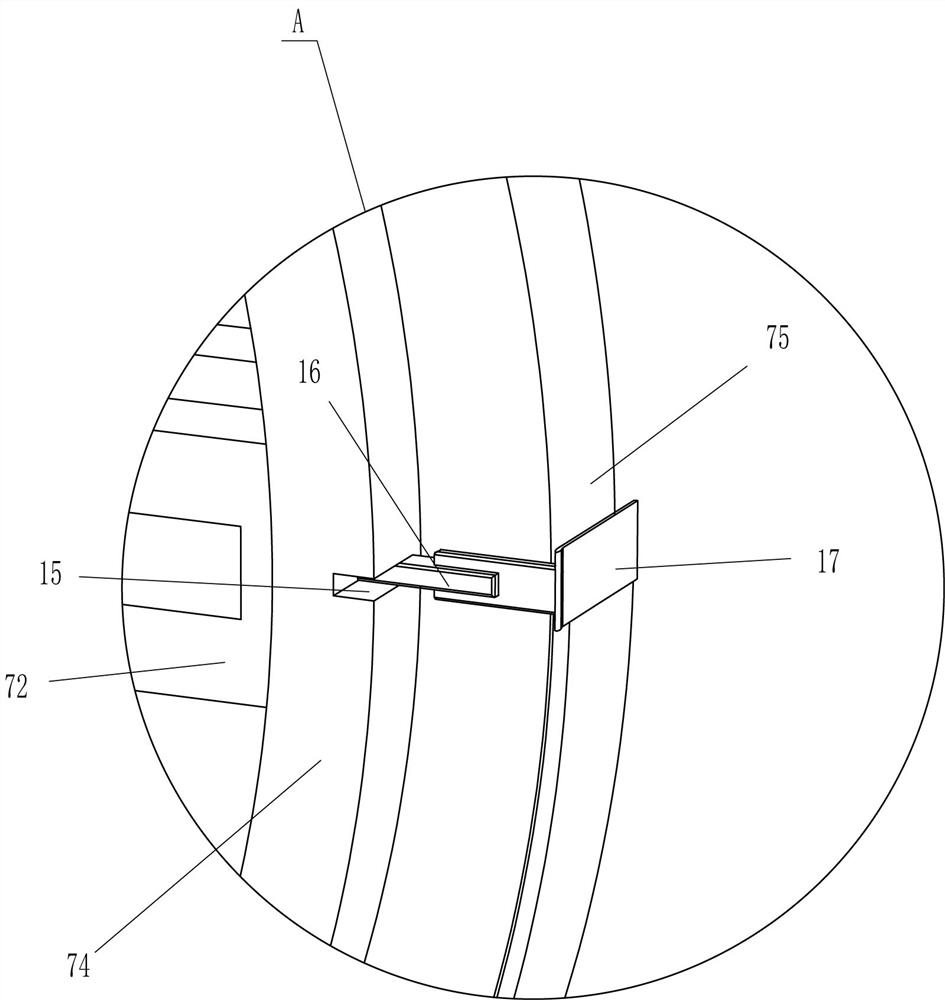

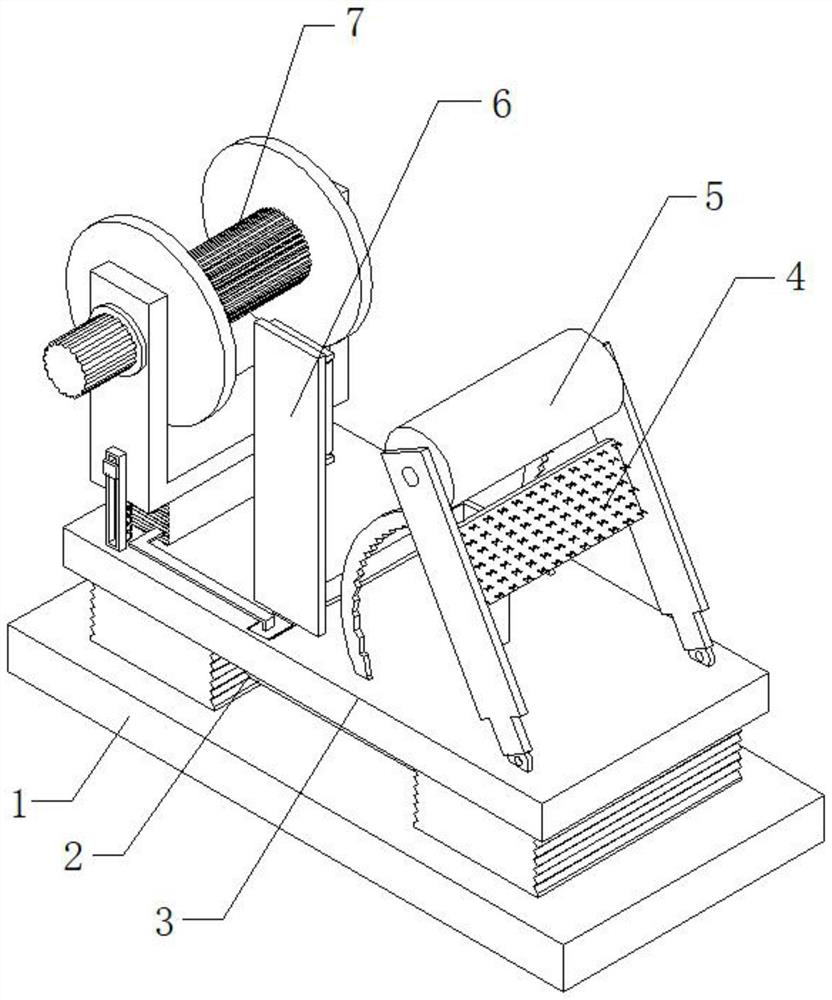

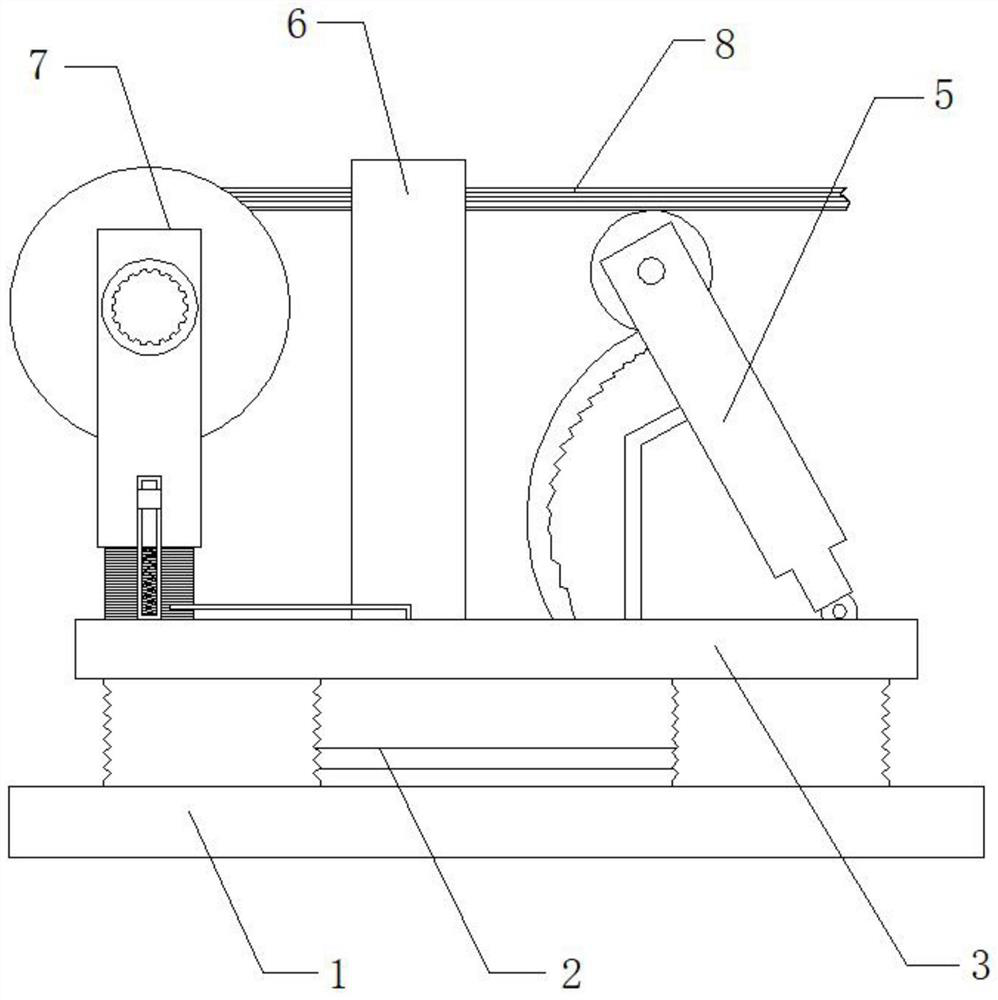

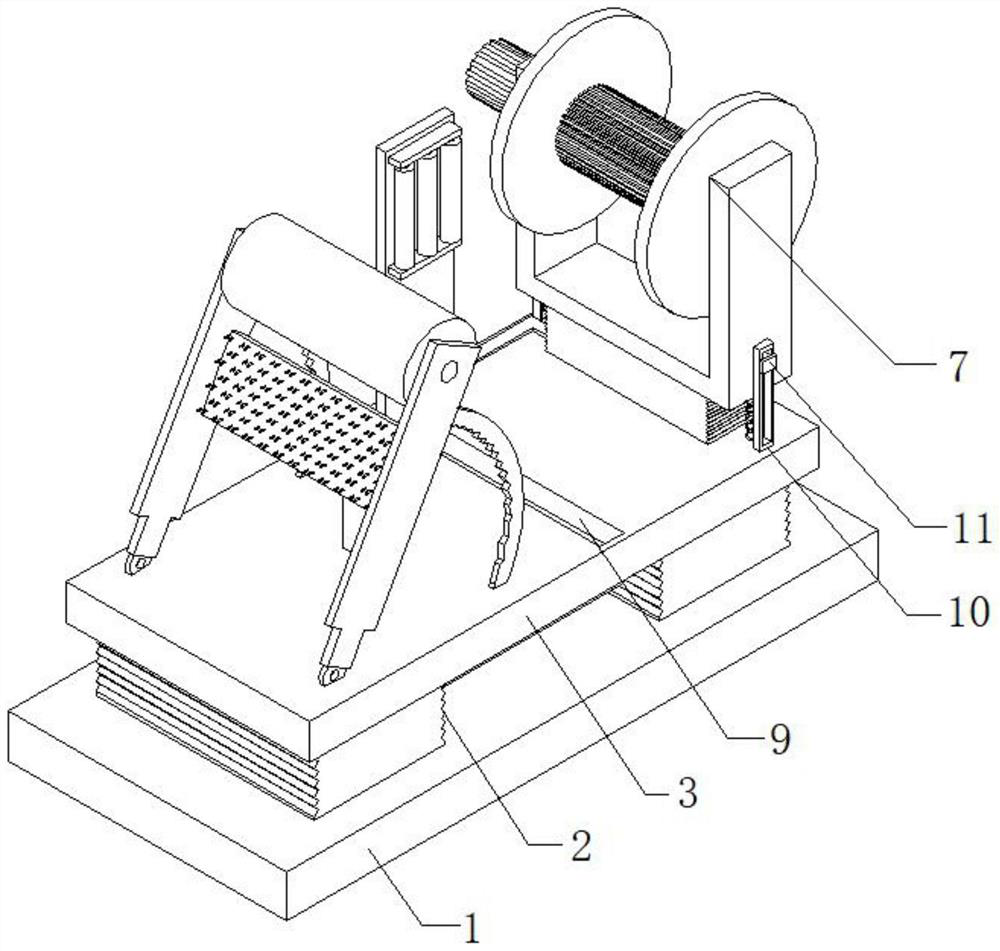

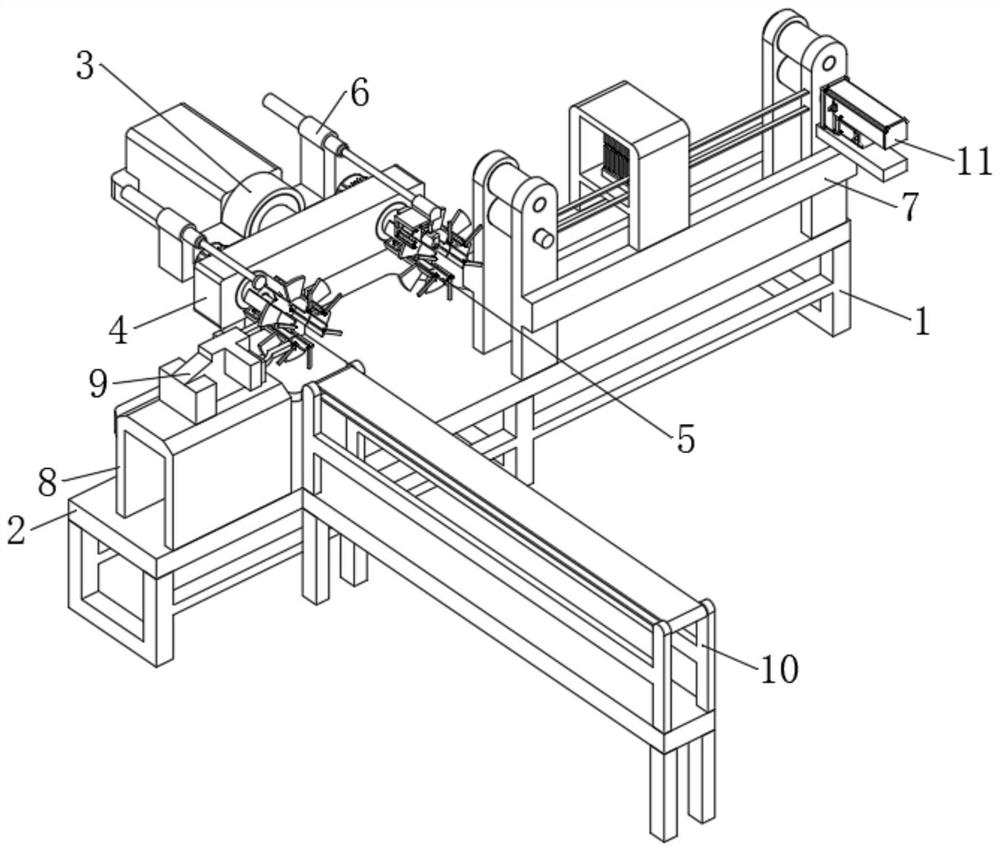

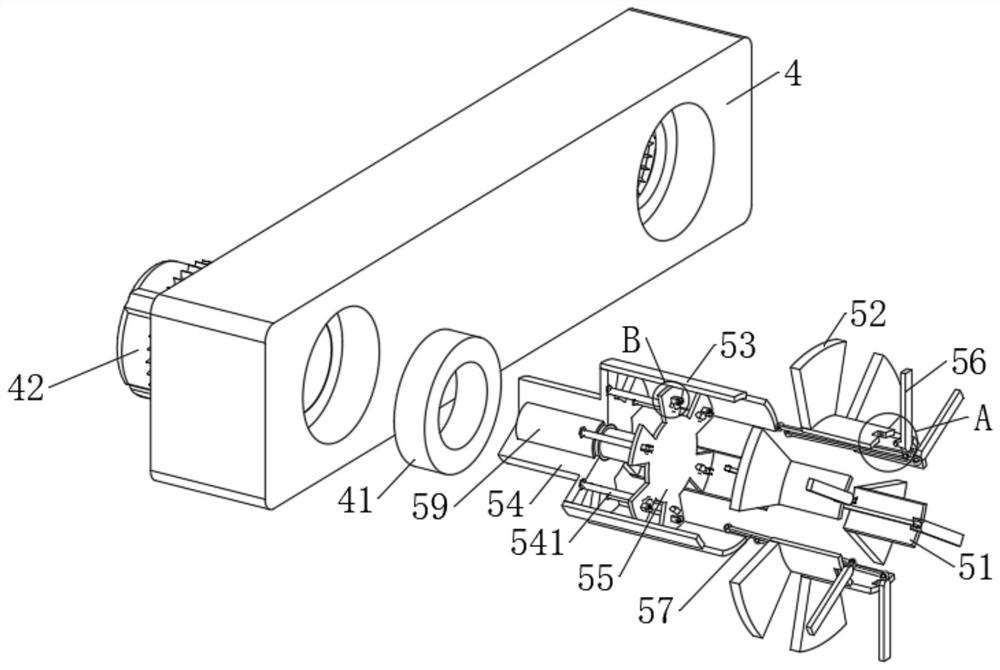

Automatic winding machine for industrial detonating cord production

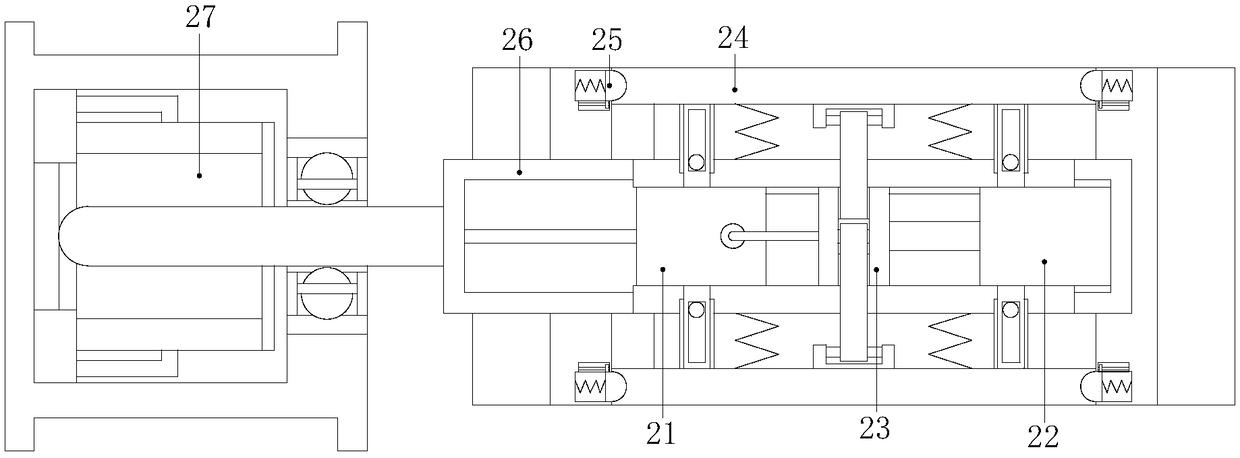

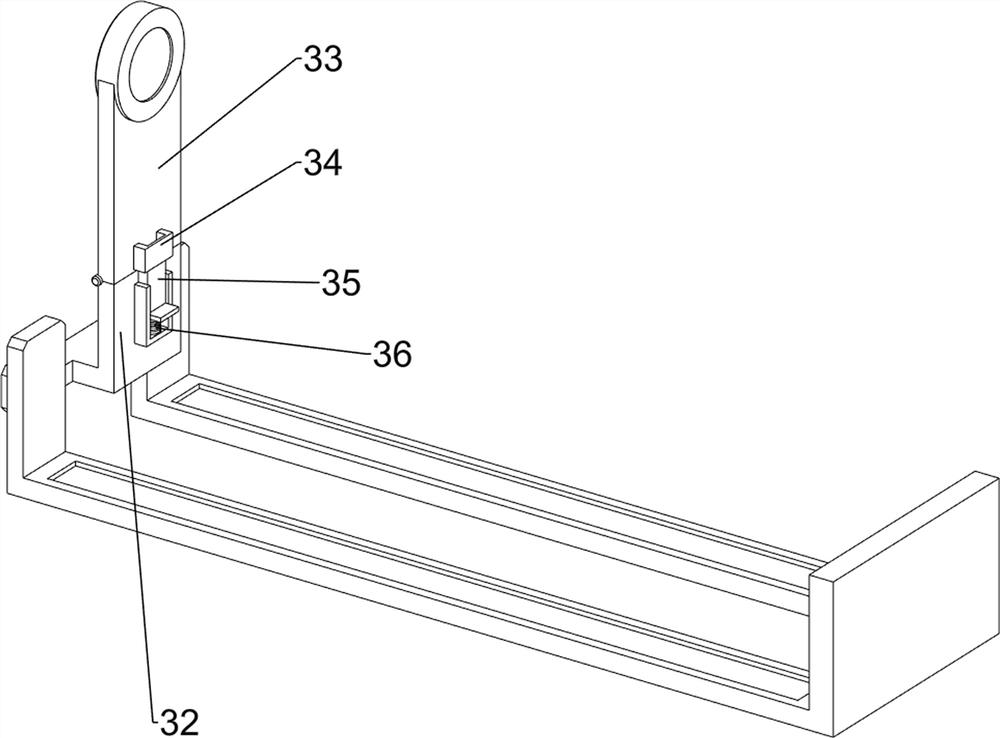

The invention relates to a winding machine, in particular to an automatic winding machine for industrial detonating cord production. The technical problem to be solved by the invention is to provide the automatic winding machine for industrial detonating cord production, which does not need to consume manpower and is efficient. The automatic winding machine for industrial detonating cord production comprises: a rack; a support frame which is mounted on the rack; a driving assembly which is mounted on the support frame; a winding assembly which is mounted on the rack; and a pressing assembly which is mounted on the winding assembly. The automatic winding machine is provided with the fixing assembly, and when the automatic winding machine is started, the limiting plate can be automatically matched with the rack, so that the sliding block is fixed, and the situation that when an industrial detonating cord is wound, the sliding block can automatically slide out of the rack, and winding of the industrial detonating cord is affected is prevented; and the automatic winding machine is provided with the guide assembly, and the industrial detonating cord can be evenly wound on the winding reel by controlling the lead screw to rotate.

Owner:JIANGXI GANZHOU GUOTAI SPECIALTY CHEM

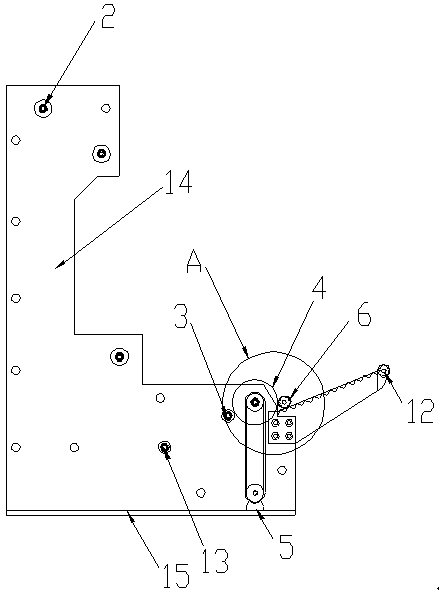

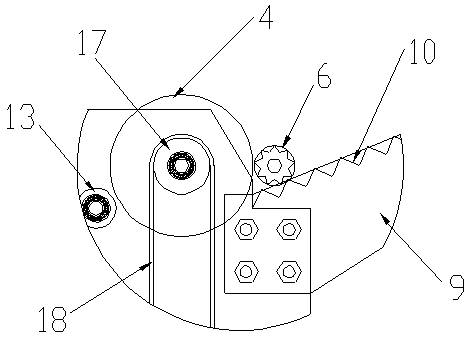

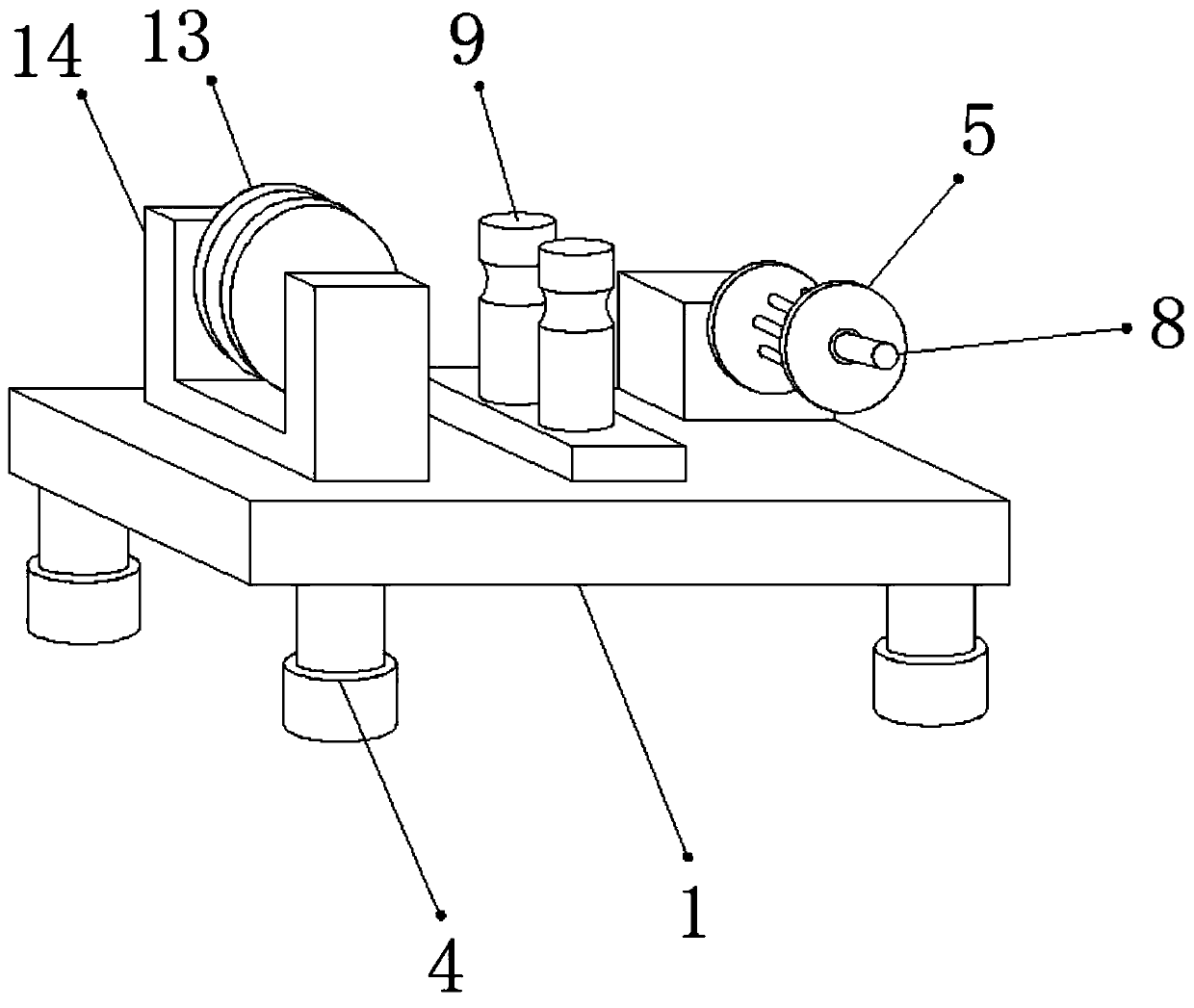

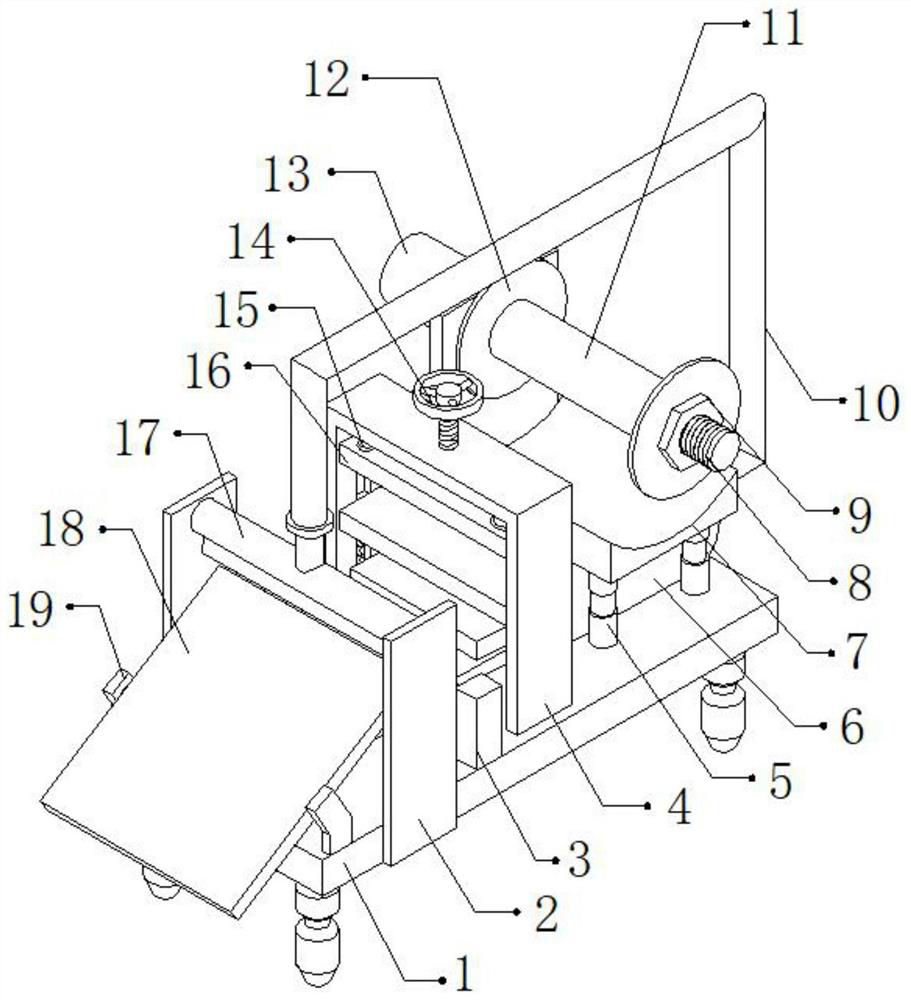

A device and method for winding aluminum tape on a power transmission wire

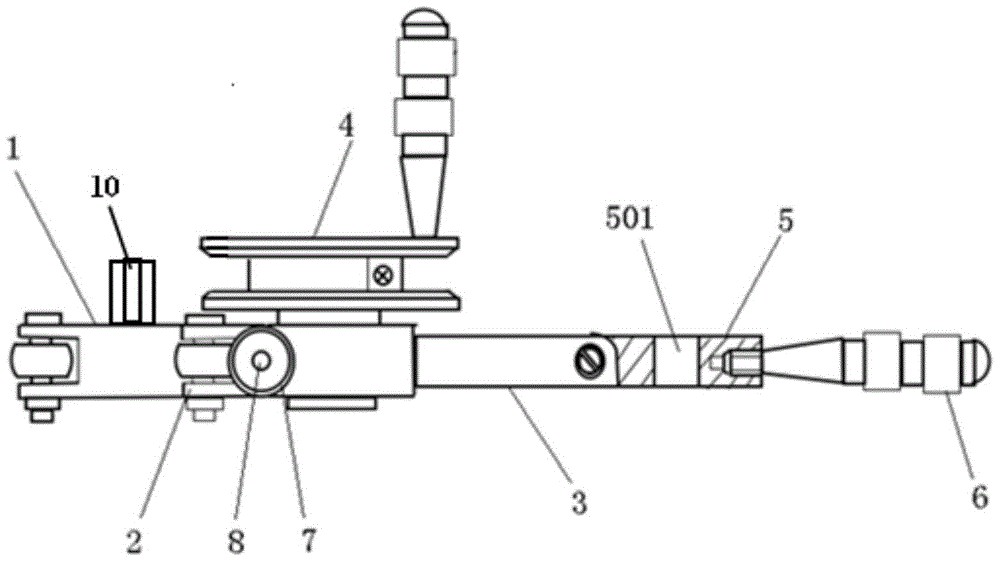

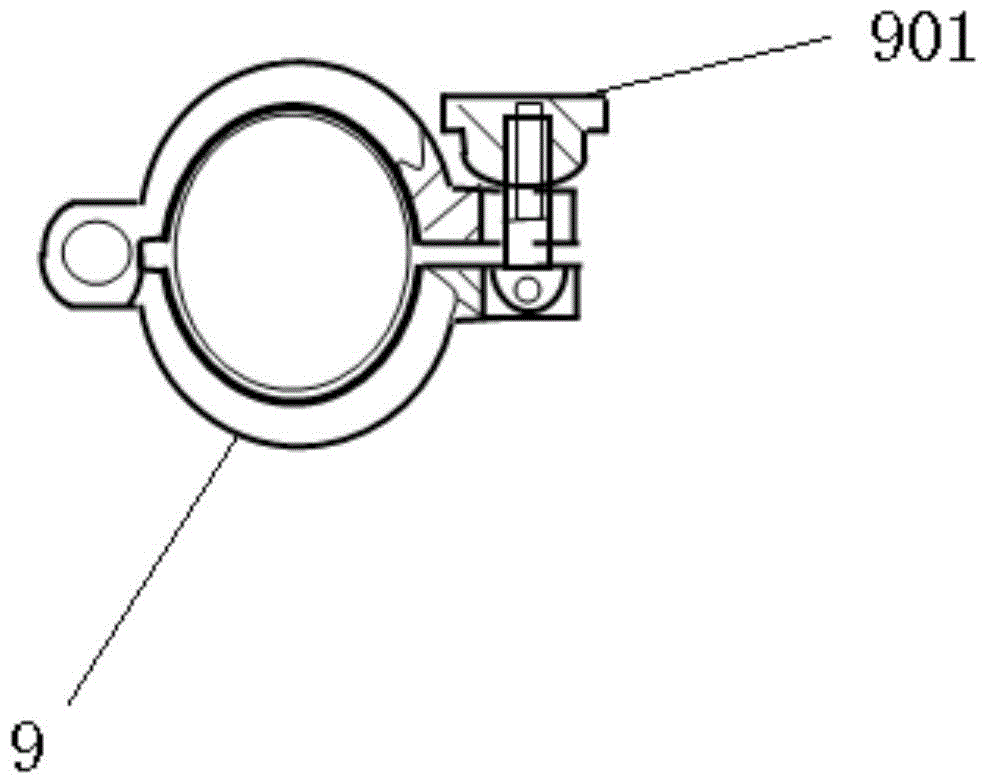

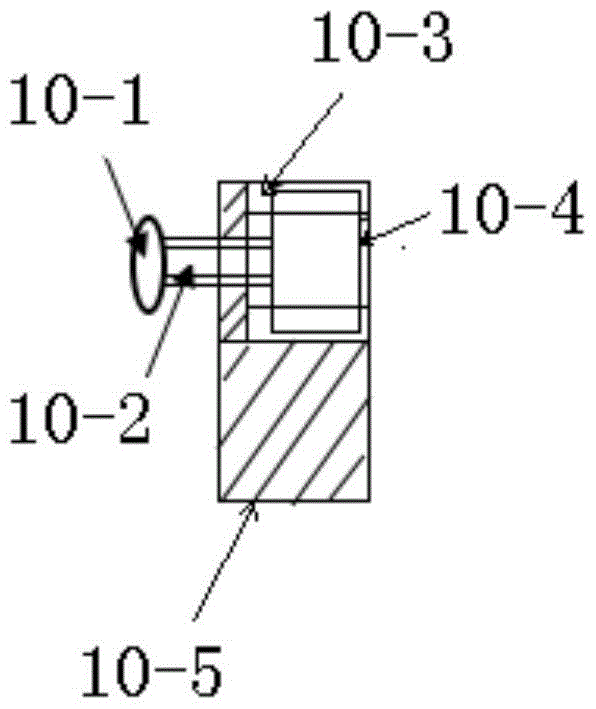

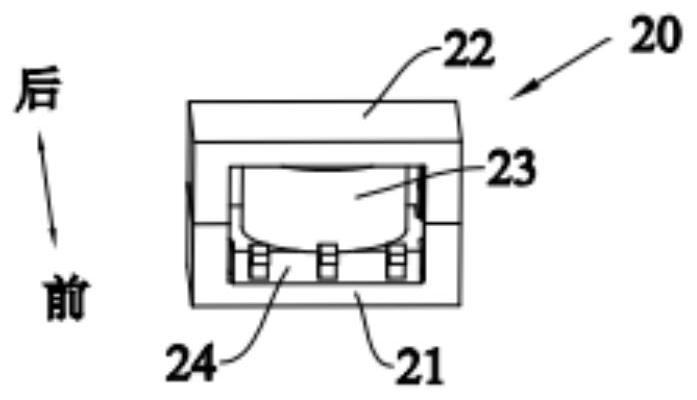

ActiveCN104795756BWinding is firm and reliableNo overlapApparatus for overhead lines/cablesBlock matchMechanical engineering

The invention discloses a device for winding an aluminum armor tape on a transmission line and an application method of the device. The device comprises a support block, a pressing down block, a tape reel and a connection pin shaft, the pressing down block is matched with the support block to lock the transmission line, and the support block is parallel to two lateral sides of the pressing down block. A concave block is arranged at the front end of the support block, a hollow clamping plate is arranged in the middle of the support block, and a handrail block is arranged at the rear end of the support block. A first cuboid block is arranged at front end of the pressing down block, an arc block is arranged in the middle of the pressing down block, and a second cuboid block matched with the clamping plate in shape is arranged at the rear end of the pressing down block. An aluminum armor tape groove is formed in the tape wheel, an aluminum armor tape fixing device is arranged on the inner wall of the aluminum armor tape groove, a through hole corresponding to through holes in the clamping plate is formed in a tape wheel axle, and round projections centering on the center of the tape wheel are arranged on one side, adjacent to the clamping plate, of the tape wheel. The connection pin shaft fixes one side of the clamping plate, the second cuboid block, the other side of the clamping plate and the tape wheel sequentially via the through hole in one side of the clamping plate, a through hole in the second cuboid block, the through hole in the other side of the clamping block and the through hole in the tape wheel.

Owner:STATE GRID CORP OF CHINA +1

Microtransformer manufacturing method and microtransformer

ActiveCN111554510BSimple processEasy to prepareTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresTransformerWire wrap

Owner:ZHUHAI HAIWER ELECTRIC APPLIANCE CO LTD

Rapid winding and bundling integrated device for fire hose production

PendingCN114248963AEasy to rewind automaticallyImprove winding efficiencyFilament handlingBundling machine detailsElectric machineFirewater

The invention discloses a rapid winding and bundling integrated device for fire hose production, and particularly relates to the technical field of fire hose production, the rapid winding and bundling integrated device comprises a bottom frame, a bottom plate is fixedly mounted at the top end of the bottom frame, a supporting frame is fixedly mounted in the middle of the top end of the bottom plate, and a rotating frame is arranged at the top of the supporting frame; two winding assemblies are arranged on the side, away from the supporting frame, of the rotating frame, the two winding assemblies are symmetrically distributed, and an auxiliary assembly used in cooperation with the winding assemblies is fixedly installed at the top of the supporting frame. Further, the winding efficiency of the fire hose is improved; according to the fire hose winding device, the two winding assemblies are arranged and used in cooperation with the rotating motor and the auxiliary assembly, the stations of the two winding assemblies are flexibly changed, and therefore seamless connection type fire hose winding of the two winding assemblies is facilitated, and the overall winding efficiency of the fire hose is improved.

Owner:泰州市神龙消防科技有限公司

Portable guzheng finger training device

The invention relates to the technical field of musical instruments, and discloses a portable guzheng finger training device. A hinge shaft is arranged on the piano board, and the left and right ends of the hinge shaft are fixedly connected with the piano board. It is installed at the divided position of the inner bottom of the piano board. There is a winding device on the left side of the piano board. The winding device is installed through the left side wall of the piano board. There is also a cover on the left side of the piano board. The cover is an arc-shaped board. And the upper end of the cover is provided with a movable shaft. This portable guzheng finger training device uses the hinge shaft to change the entire piano board into two parts that can be folded, so that the user can fold the piano board when carrying it. The method reduces its size to make it more convenient to carry. At the same time, the user can also roll up the strings through the winding device to avoid damage or winding of the strings, so that the piano board can be more compact when carried, increasing the the practicality of the device.

Owner:SHANDONG UNIV +1

Polyurethane film winding equipment and using method

The invention belongs to the technical field of film winding, and relates to polyurethane film winding equipment. The polyurethane film winding equipment comprises a moving plate, wherein a conveyingcabin is fixedly connected to the top of the moving plate through a vertical plate, and a conveying wheel is arranged in the conveying cabin through a bearing and a wheel shaft in a penetrating mode;gears are fixedly connected to the wheel shaft of the conveying wheel, and the gears are in engaged connection through a toothed chain; and a first motor box is fixedly connected to the surface of theconveying cabin. The polyurethane film winding equipment and a using method have the beneficial effects that through the conveying cabin, a film can be protected during film winding, and film breakage caused by external factors is avoided; meanwhile, the conveying angle of the film can be limited, and the situation that the film wound on a material roller is very messy is avoided; and through a first rotating motor, the first rotating motor works to drive a rotating shaft and a lead screw to rotate, the lead screw rotates to drive a threaded block to move, and therefore the distance between two cylinders can be adjusted according to the length of the material roller.

Owner:湖南宝铂新材料科技有限公司

Lithium ion battery pole piece winding device

PendingCN113809407AEasy to adjustAvoid bendingFinal product manufactureSecondary cellsLithium electrodeStructural engineering

The invention discloses a lithium ion battery pole piece winding device, which comprises a fixing seat, wherein one side of the outer wall of the top of the fixing seat is fixedly connected with a mounting plate, the outer wall of one side of the mounting plate is provided with a winding mechanism, one side of the outer wall of the top of the fixing seat is fixedly connected with a supporting frame, a connecting plate is rotationally connected between the outer walls of the two opposite sides of the supporting frame through bearings, two supporting rods are fixedly connected to one side of the outer wall of the top of the fixing base, a balance plate is rotationally connected between the outer walls of the opposite sides of the two supporting rods through bearings, and one side of the top outer wall of the balance plate is connected with one side of the bottom outer wall of the connecting plate through a hinge. According to the invention, the phenomenon that the battery pole piece is bent due to insufficient tension of the battery pole piece and the phenomenon that the battery pole piece is broken due to the fact that the battery pole piece is in a tight state for a long time can be prevented, dust adhered to the battery pole piece can be treated, and dust is prevented from adhering to the surface of the battery pole piece to corrode the battery pole piece.

Owner:周秀

Glass fiber yarn auxiliary winding device

The invention relates to a winding device, in particular to a glass fiber yarn auxiliary winding device. The glass fiber yarn auxiliary winding device is convenient to operate, even in winding and not prone to breakage. The glass fiber yarn auxiliary winding device comprises a bottom plate, and a first bearing seat is arranged on one side of the bottom plate; a first sliding sleeve arranged on the first bearing seat; a first rotating shaft rotatably arranged on the first sliding sleeve; and a rotating motor arranged on one side of the bottom plate. The first rotating shaft is clamped through a clamping mechanism, the rotating motor rotates to drive the first rotating shaft to rotate through a first belt conveying device, and the first rotating shaft rotates to drive a sleeve to rotate to wind glass fiber yarn, after the glass fiber yarn is wound, by pushing a moving mechanism to move rightwards, the sleeve with the glass fiber yarn after winding is pushed out to be collected.

Owner:季秀梅

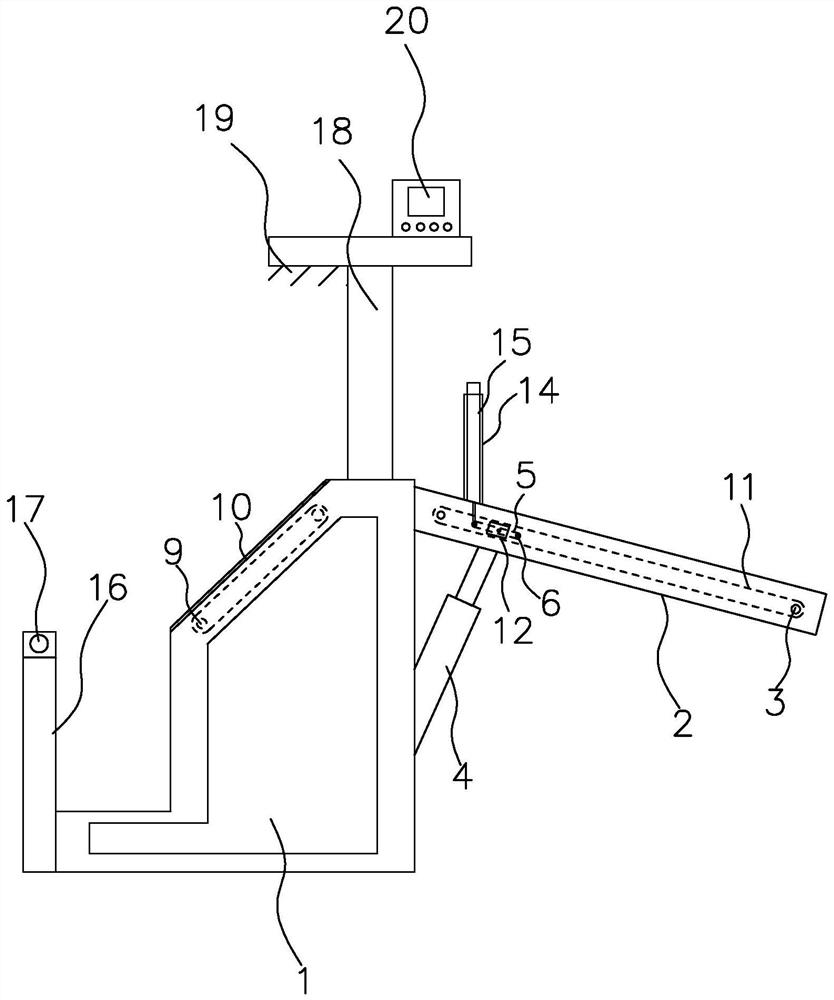

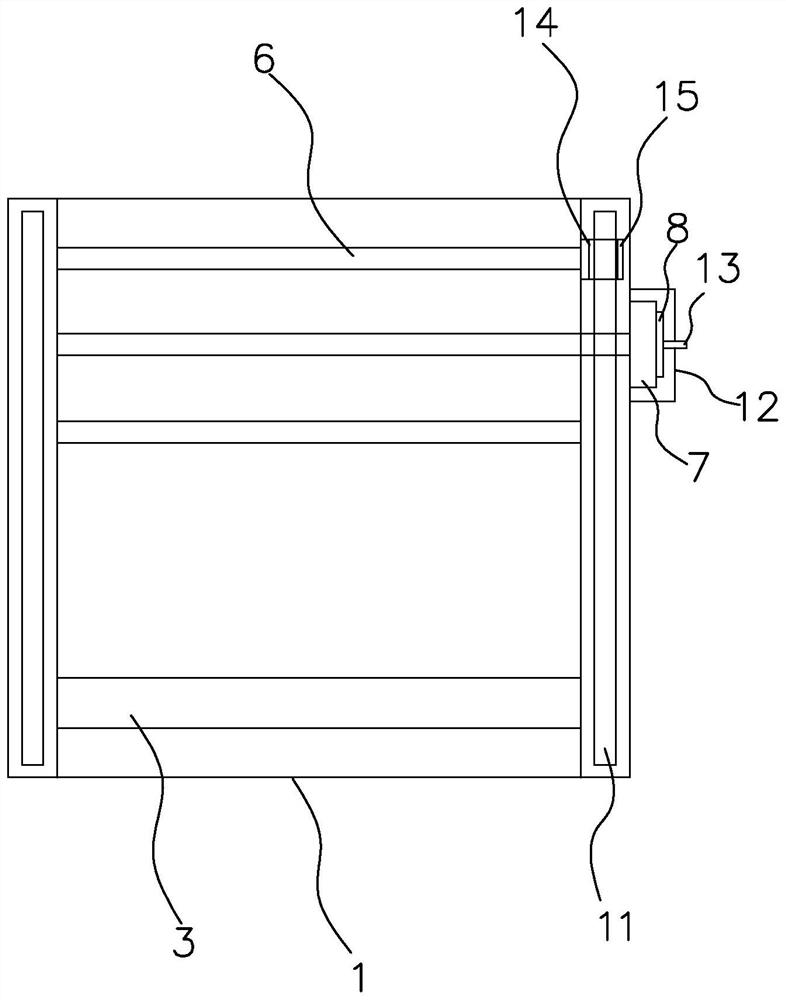

Tension-adjustable cloth rolling and inspecting all-in-one machine

InactiveCN114476788AChange the tensionEasy windingInspecting textilesWebs handlingEngineeringCotton material

The invention relates to a tension-adjustable cloth rolling and inspecting all-in-one machine. The machine comprises a rack; the cloth feeding mechanism is located on one side of the rack and comprises a cloth feeding supporting frame, a rotating roller rotationally arranged on the cloth feeding supporting frame and an angle adjusting device used for adjusting the angle between the cloth feeding supporting frame and the rack; the auxiliary bearing support is rotationally arranged on the cloth feeding supporting frame, an auxiliary rotating roller is rotationally arranged on the auxiliary bearing support, and a tension adjusting device for adjusting the tension of the cloth is installed on the auxiliary rotating roller; and the bearing control mechanism is positioned between the cloth feeding mechanism and the rolling cloth inspecting mechanism and is arranged on the rack. Through the arrangement of the tension adjusting device, the tension of the cloth on the auxiliary rotating roller is adjusted, and therefore the problem that in the cloth rolling process, the tension is changed, and cloth rolling is affected is solved; and meanwhile, due to the arrangement of the angle adjusting device, the position of the cloth feeding supporting frame is adjusted, and the cloth winding effect is improved.

Owner:苏州宏江机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com