Miniature transformer manufacturing method and miniature transformer

A technology of micro-transformer and manufacturing method, which is applied in the directions of transformer/inductor magnetic core, inductance/transformer/magnet manufacturing, transformer/inductor coil/winding/connection, etc. Connection, enameled wire waste and other problems, to achieve the effect of stable and reliable fixed connection, saving enameled wire, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

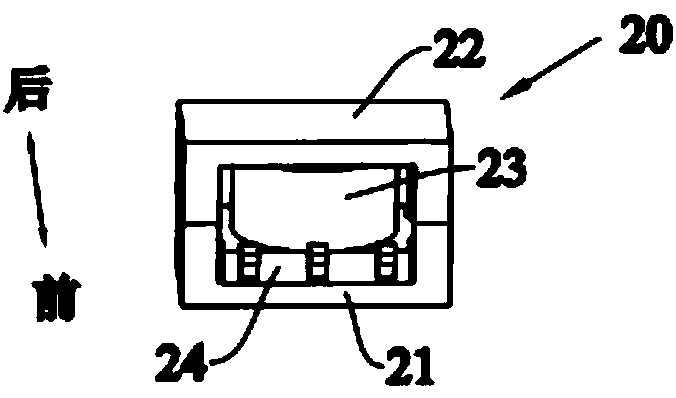

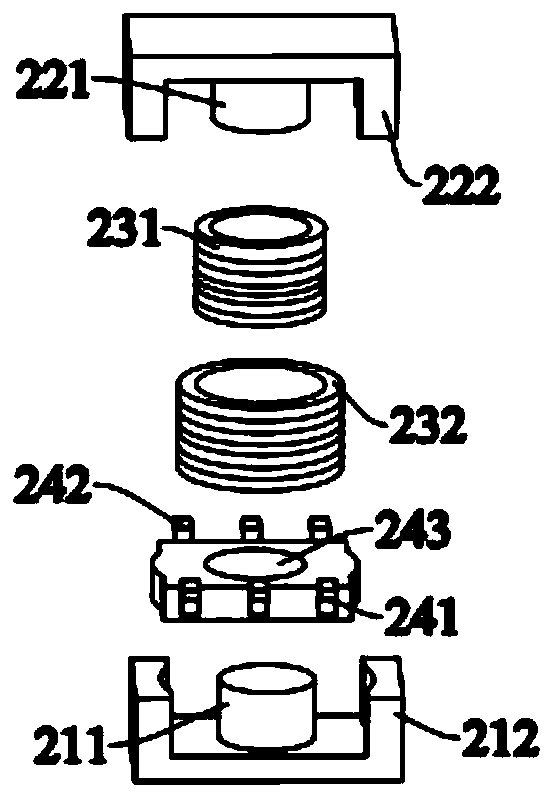

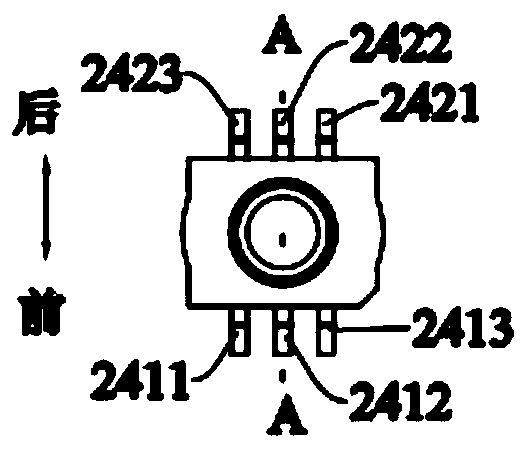

[0030] figure 1 and figure 2 A schematic structural view of an embodiment of the microtransformer of the present invention is shown. like figure 1 and figure 2 As shown, the microtransformer 20 includes a microtransformer including a first magnetic core 21, a second magnetic core 22, a first coil 231, a second coil 232, and a wiring base 24, wherein the first magnetic core includes a first outer peripheral portion 212 and a second magnetic core. A core part 211, the second magnetic core includes a second outer peripheral part 222 and a second core part 221, when the first magnetic core 21 and the second magnetic core 22 are installed together, the two ends of the first outer peripheral part 212 and the second Both ends of the outer peripheral portion 222 are in contact, the first outer peripheral portion 212 and the second outer peripheral portion 222 form a closed frame, and the first core portion 211 and the second core portion 221 are in contact to form a magnetic core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com