Cable winding disc

A technology for winding reels and cables, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc. It can solve the problems of inconsistent tightness and accumulation of cable windings, so as to avoid uneven winding and prevent wear and tear , the effect of a flat posture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

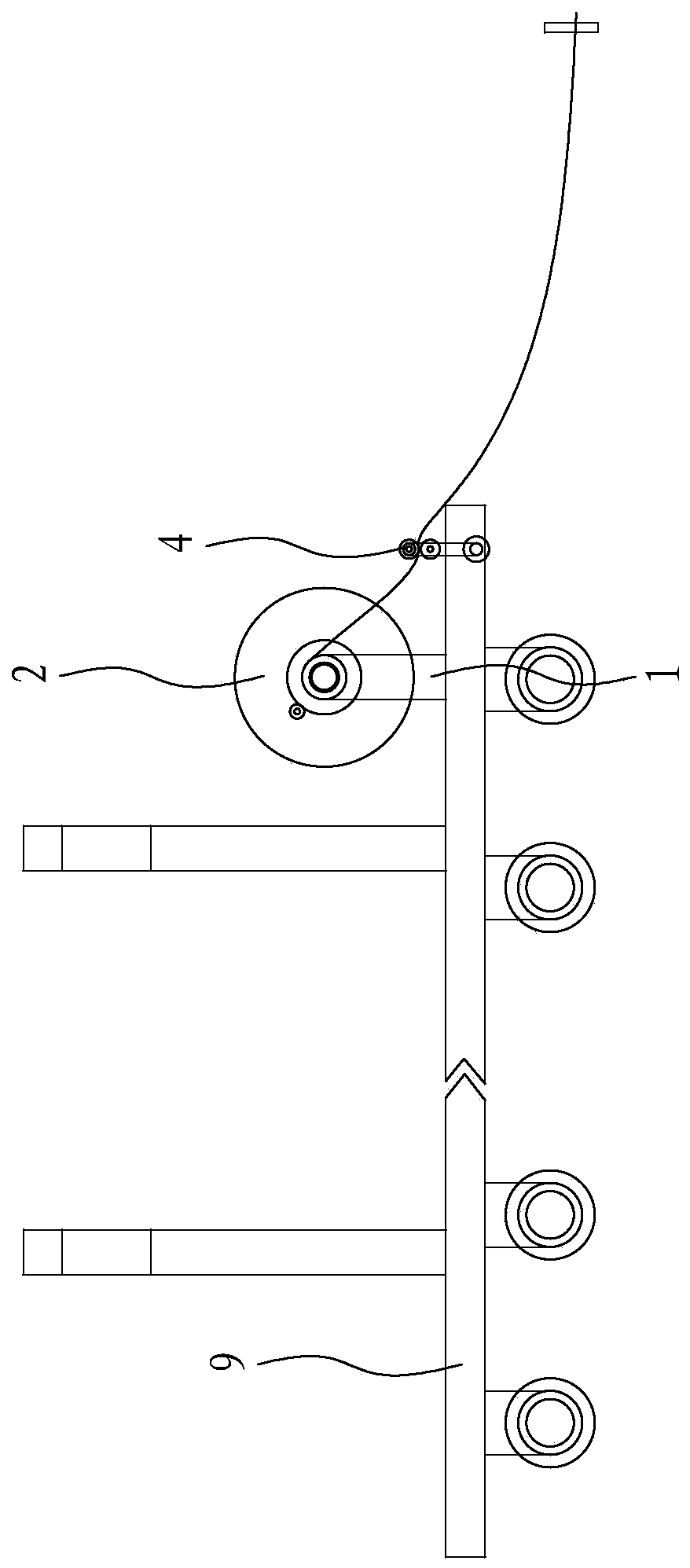

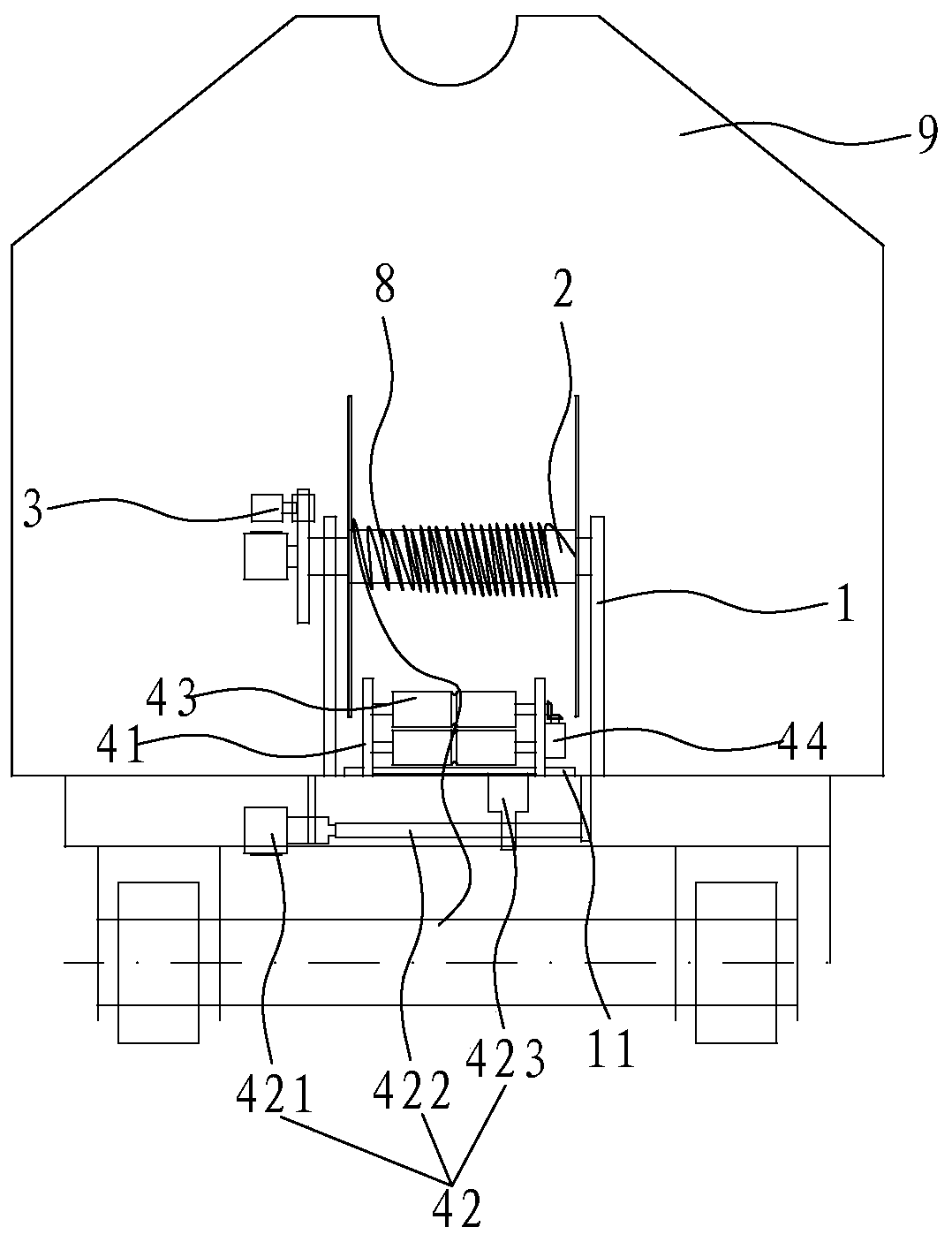

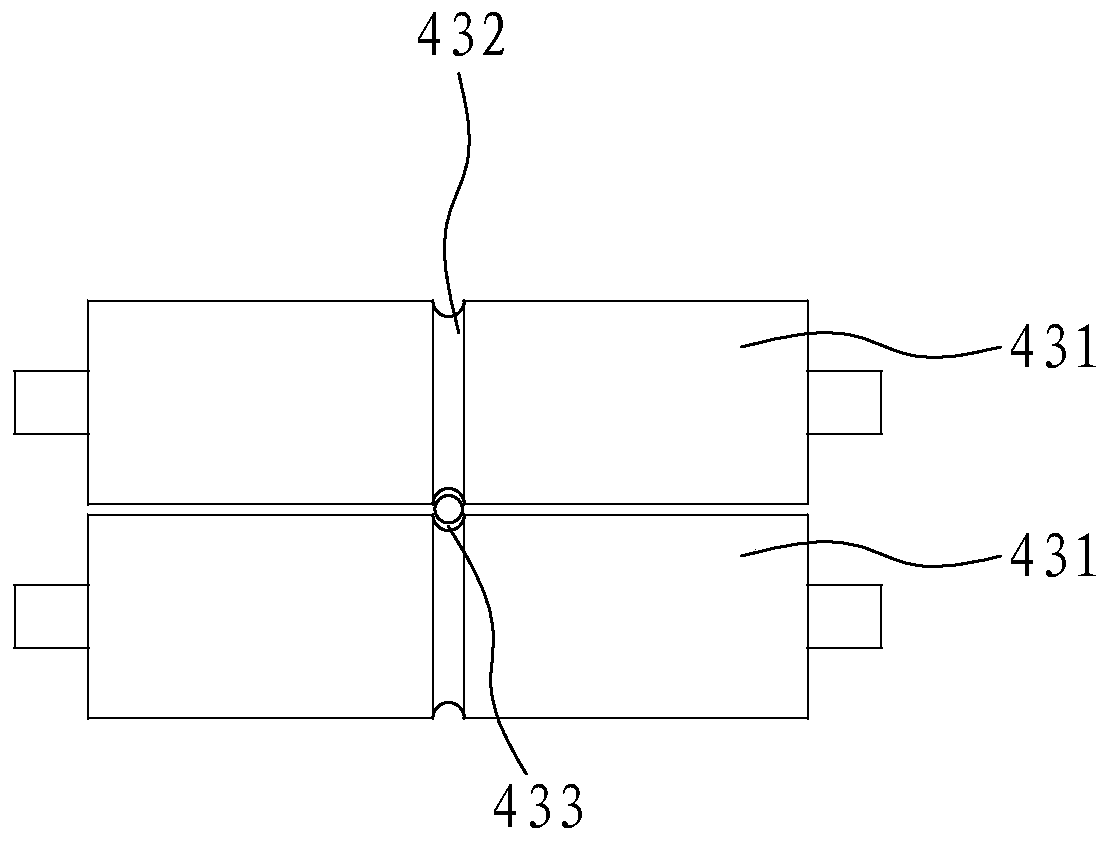

[0035] refer to figure 1 , figure 2 , image 3 , present embodiment one provides a kind of cable reel, and it is located on the trolley 9, comprises frame 1, is rotatably arranged on frame 1 and is used for the reel 2 of cable 8 coiling, is located on The winding servo motor 3 for driving the winding reel 2 on the frame, the guide device 4 for cable guidance located in front of the winding reel 2 on the frame, the parallel On the sliding rail 11 in the axial direction of the winding reel 2, the guide device 4 includes a mounting seat 41 that can slide along the sliding rail 11, a sliding drive device 42 that is arranged on the frame for driving the sliding of the mounting seat 41, The set of clamping guide wheels 43 located on the mounting base 41, the guide servo motor 44 for driving the set of clamping guide wheels to rotate, the set of clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com