Patents

Literature

81results about How to "Evenly wound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

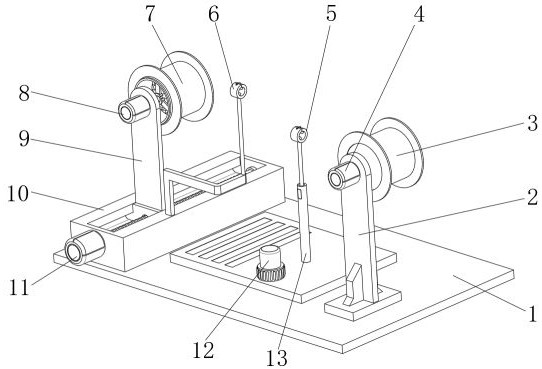

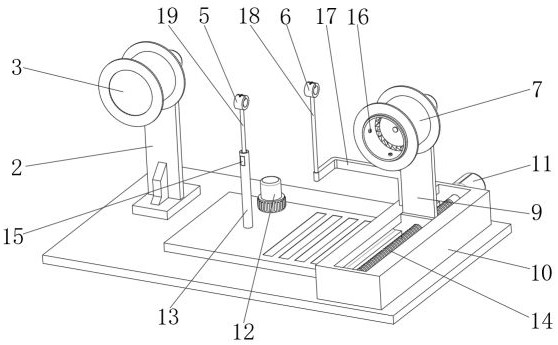

Copper wire winding device with cleaning function

InactiveCN108059032AGood dust removal effectImprove winding qualityFilament handlingCopper wireEngineering

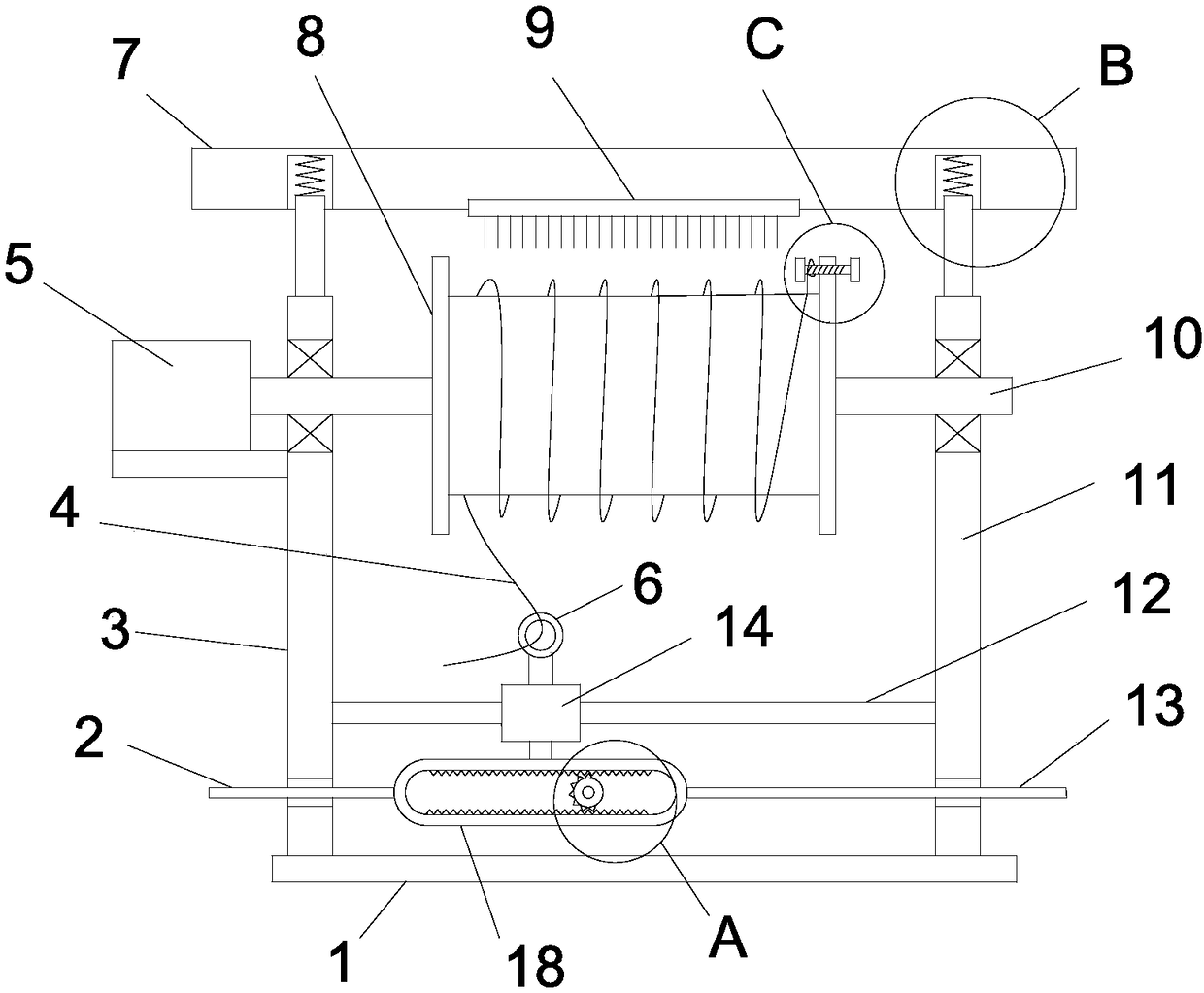

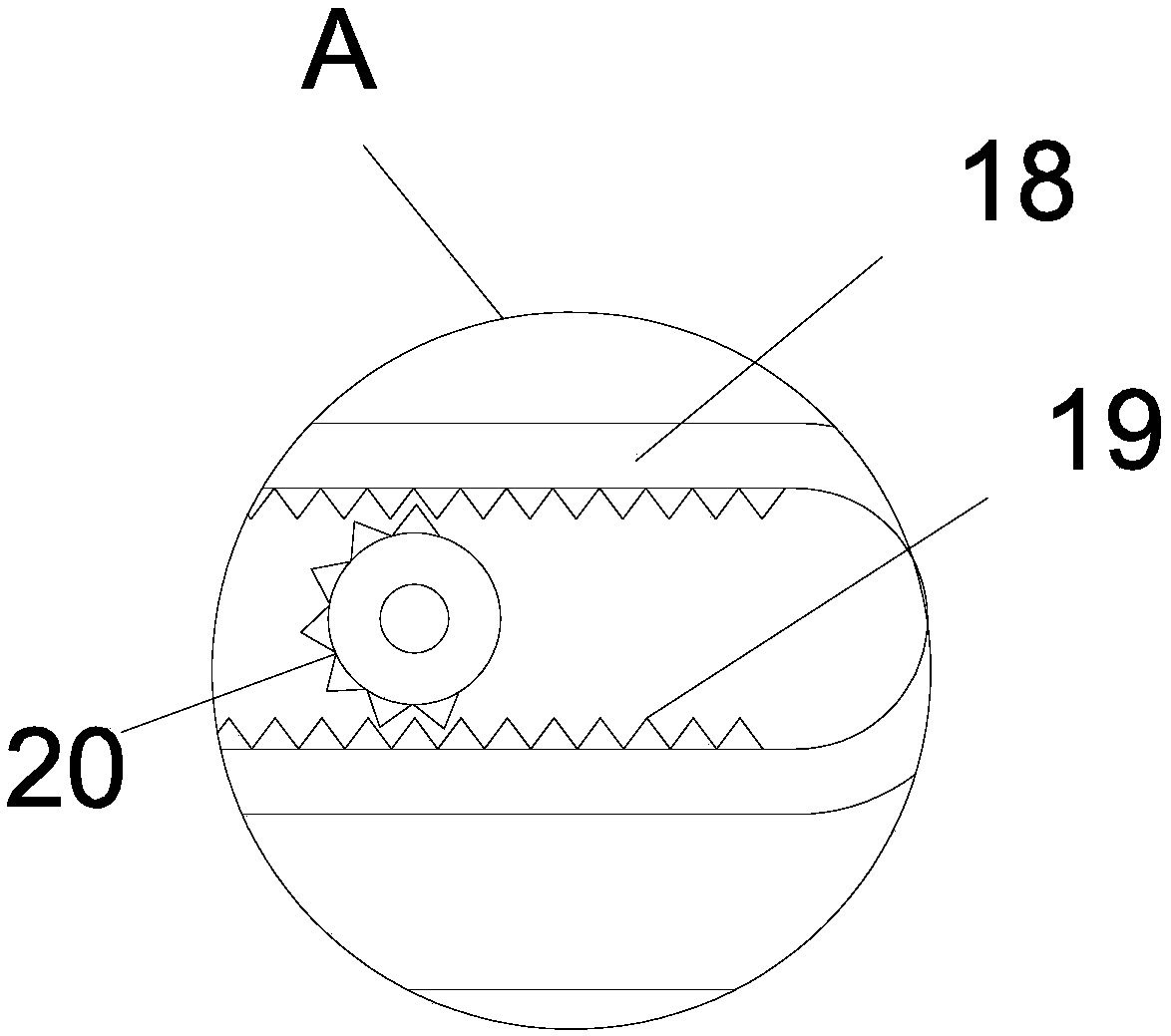

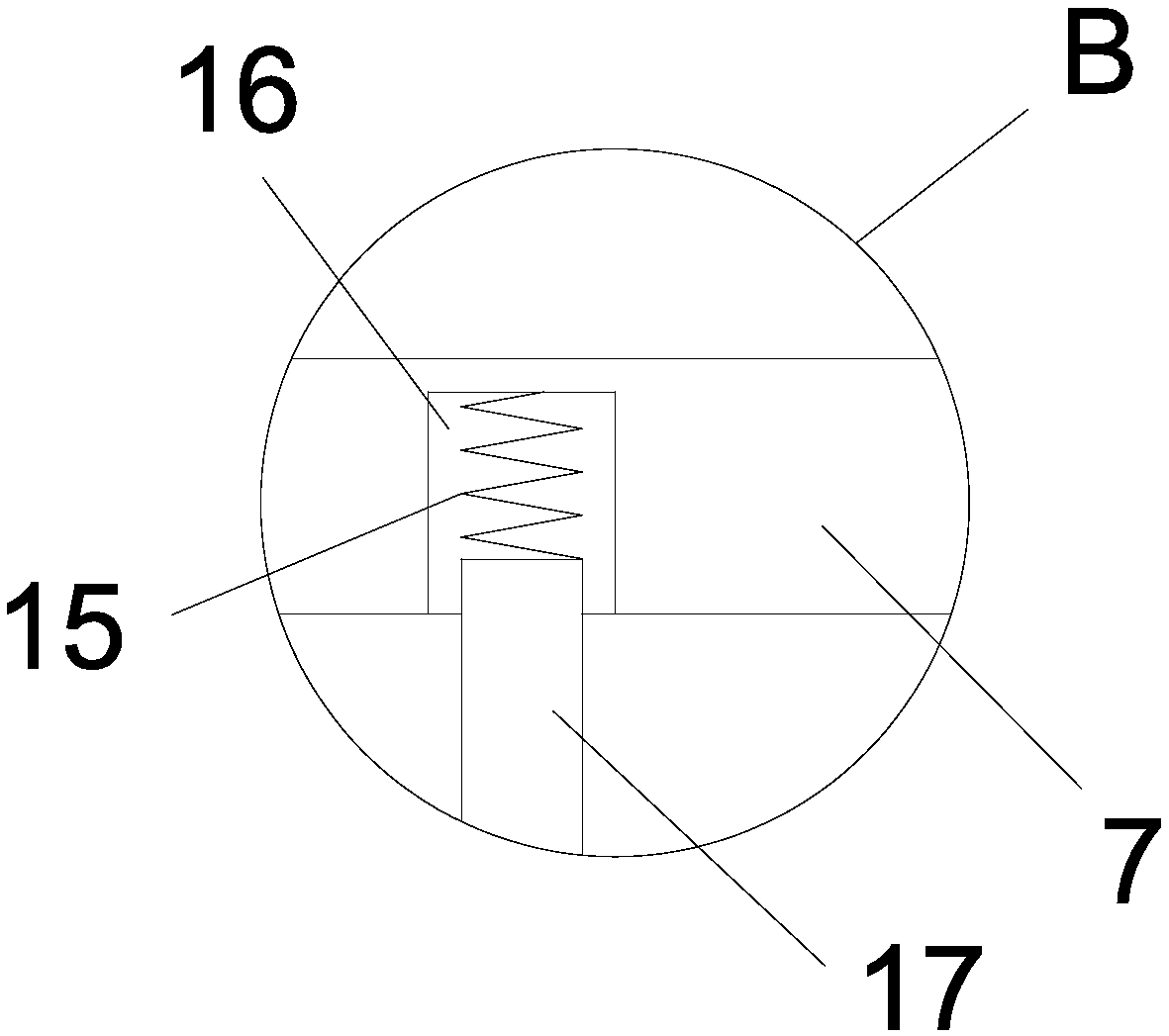

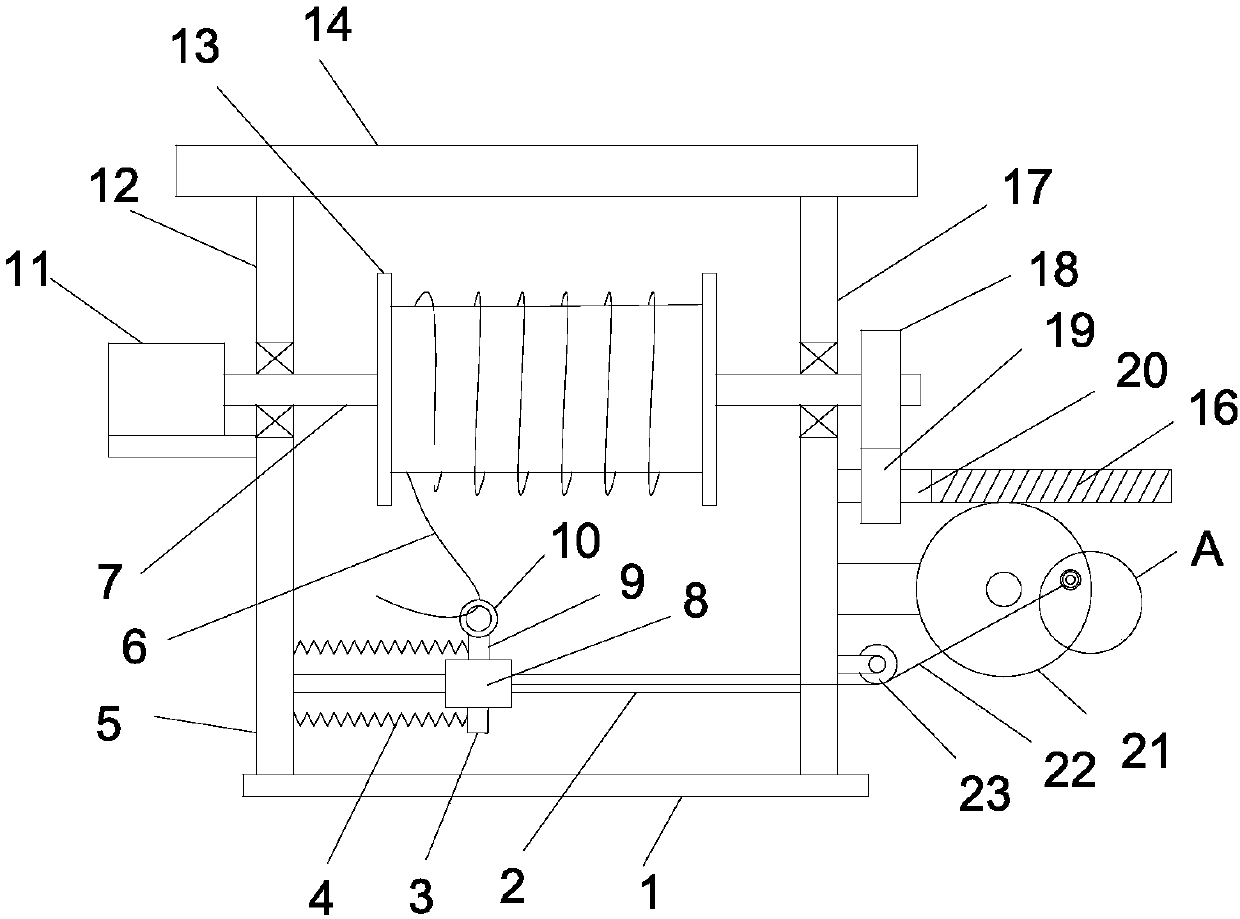

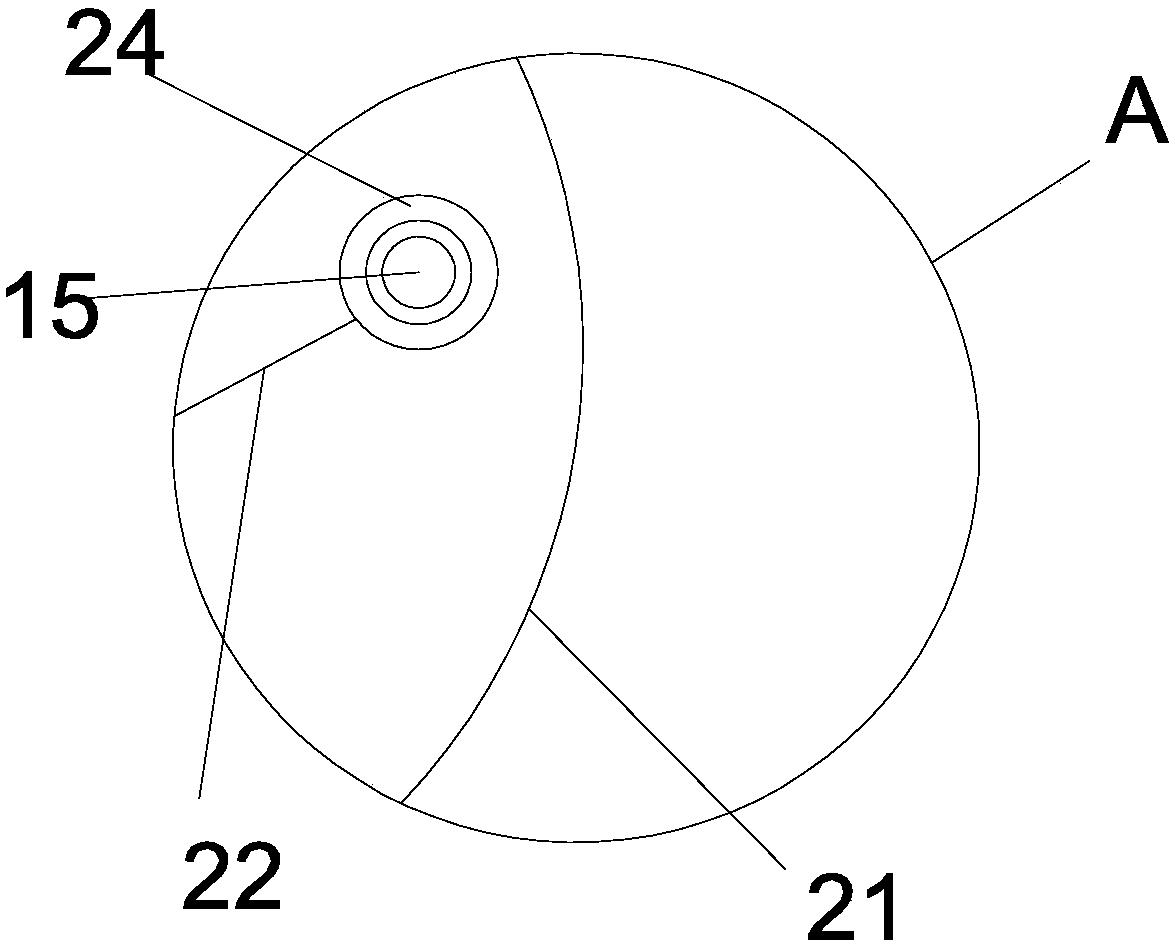

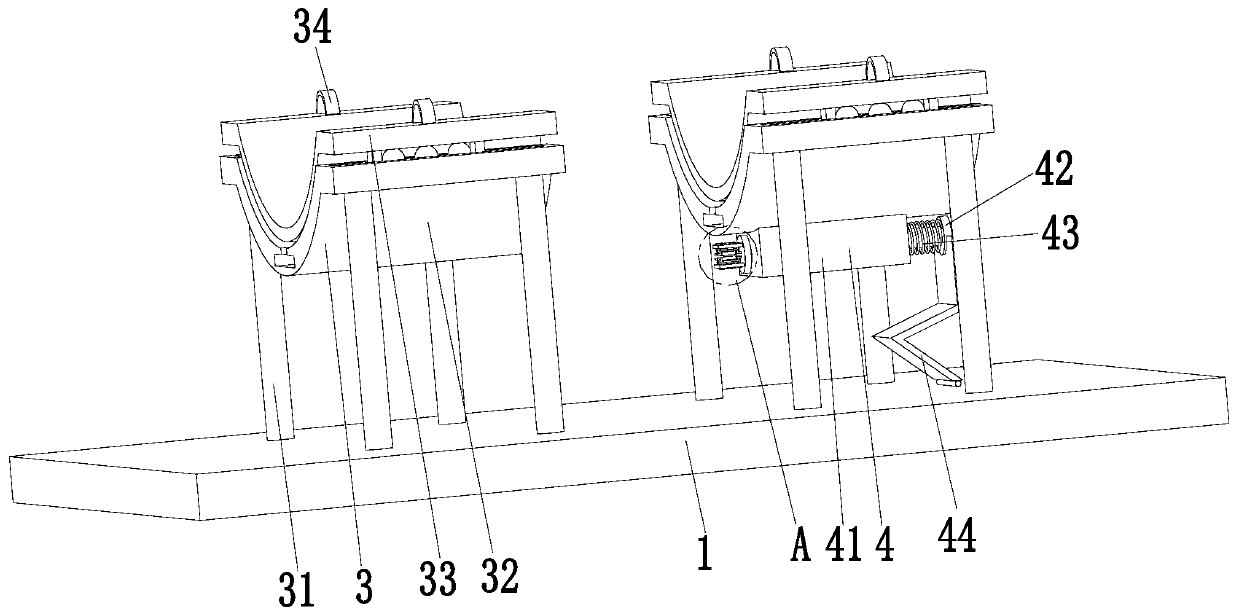

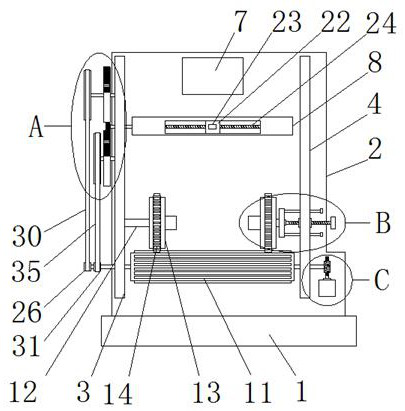

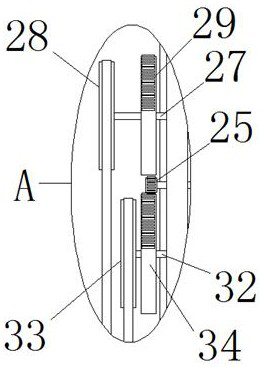

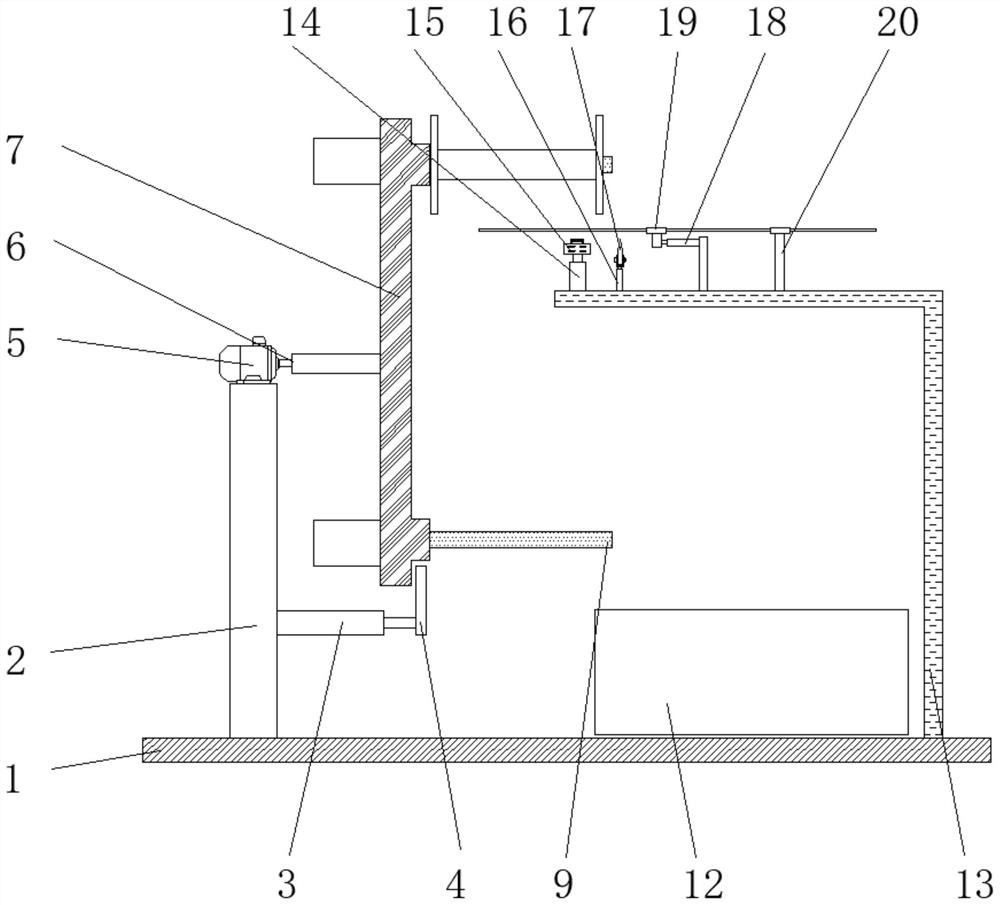

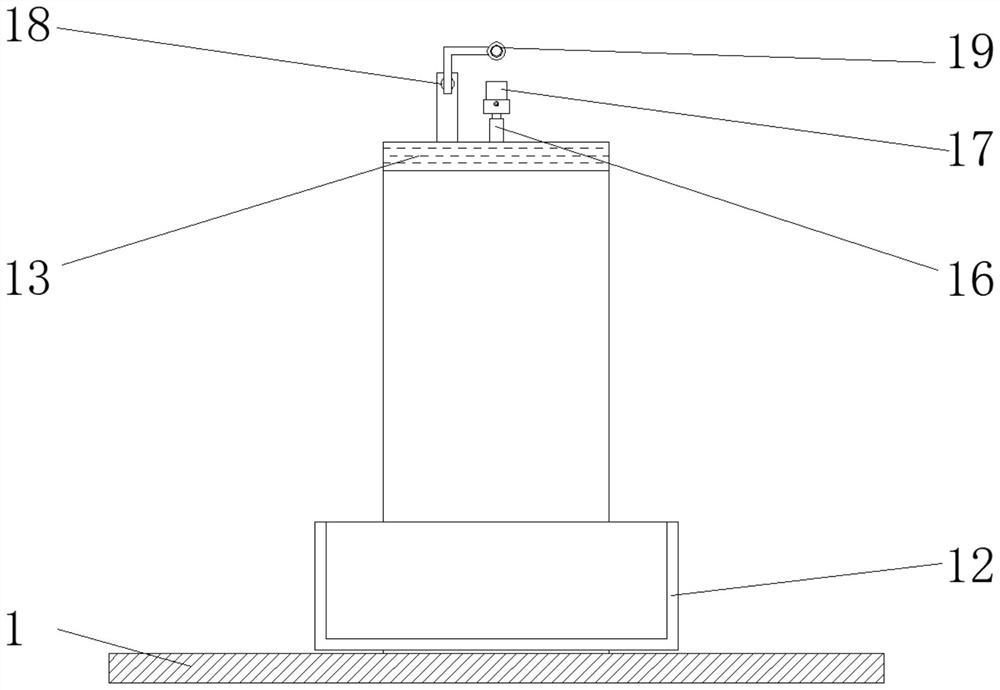

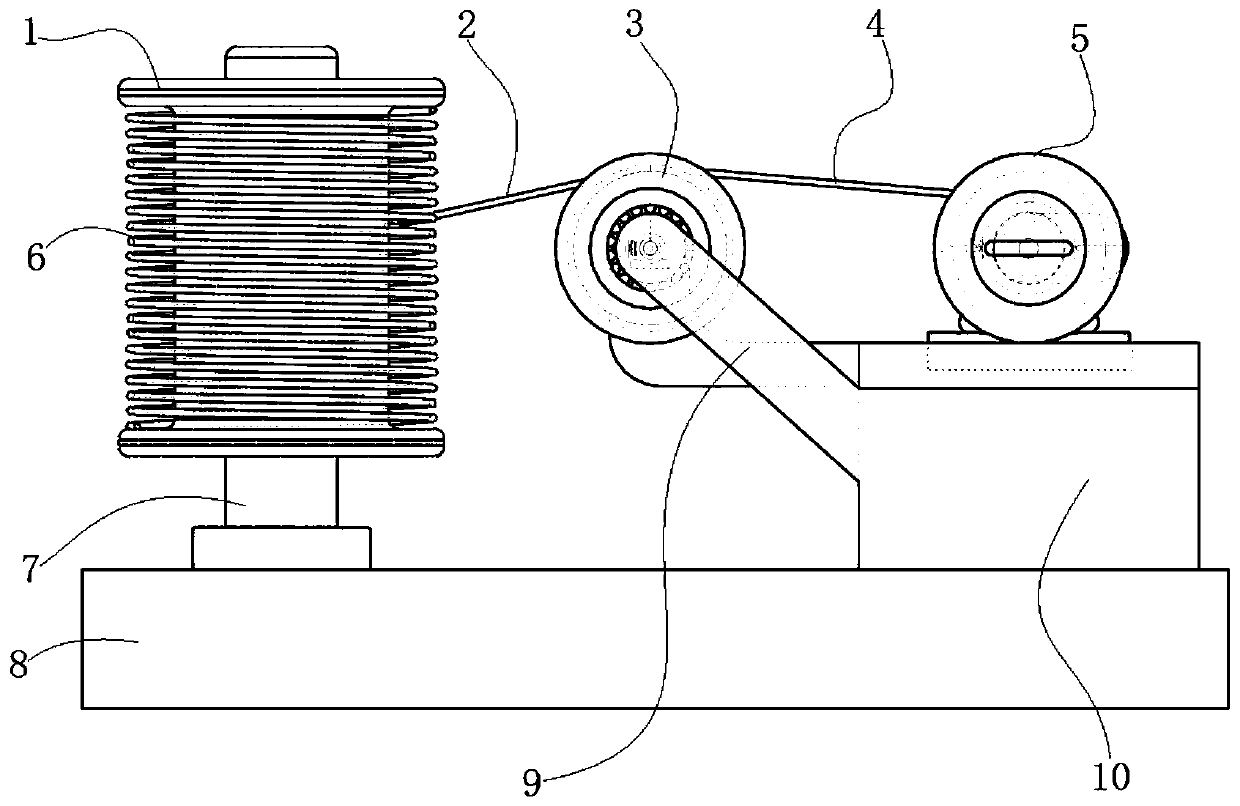

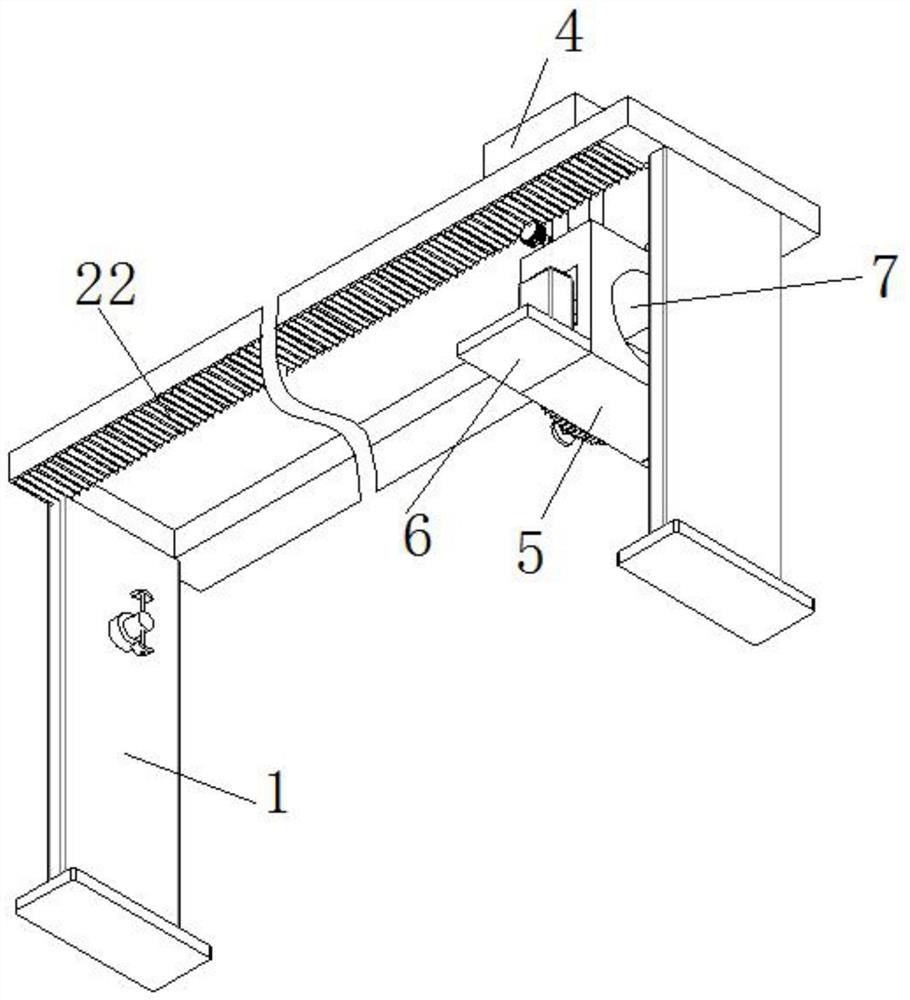

The invention discloses a copper wire winding device with a cleaning function. The copper wire winding device comprises a bottom plate. A left vertical plate and a right vertical plate are verticallyand fixedly arranged on the bottom plate. The upper end of each of the left vertical plate and the right vertical plate is vertically and fixedly provided with a vertical shaft. A pressing plate is horizontally arranged above the left vertical plate and the right vertical plate. The outer surface of a driving shaft is sleeved with and fixedly provided with a winding roller. A horizontal rod is horizontally and fixedly arranged between the left vertical plate and the right vertical plate. A sliding sleeve is fixedly provided with a limiting ring, and a copper wire penetrates the limiting ring.Straight racks are horizontally and fixedly arranged on the upper inner side wall and the lower inner side wall of a concentric-square-shaped frame. The copper wire is wound through the winding roller, the sliding sleeve is driven by the concentric-square-shaped frame to reciprocate left and right along the horizontal rod, accordingly, the limiting ring is used for driving the copper wire to reciprocate left and right, the copper wire is prevented from being excessively centralized at one position of the winding roller, and the copper wire is evenly wound around the winding roller; and a brushand the copper wire relatively rotate in the copper wire winding process, a very good dust removing effect is achieved, and the winding quality is improved.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

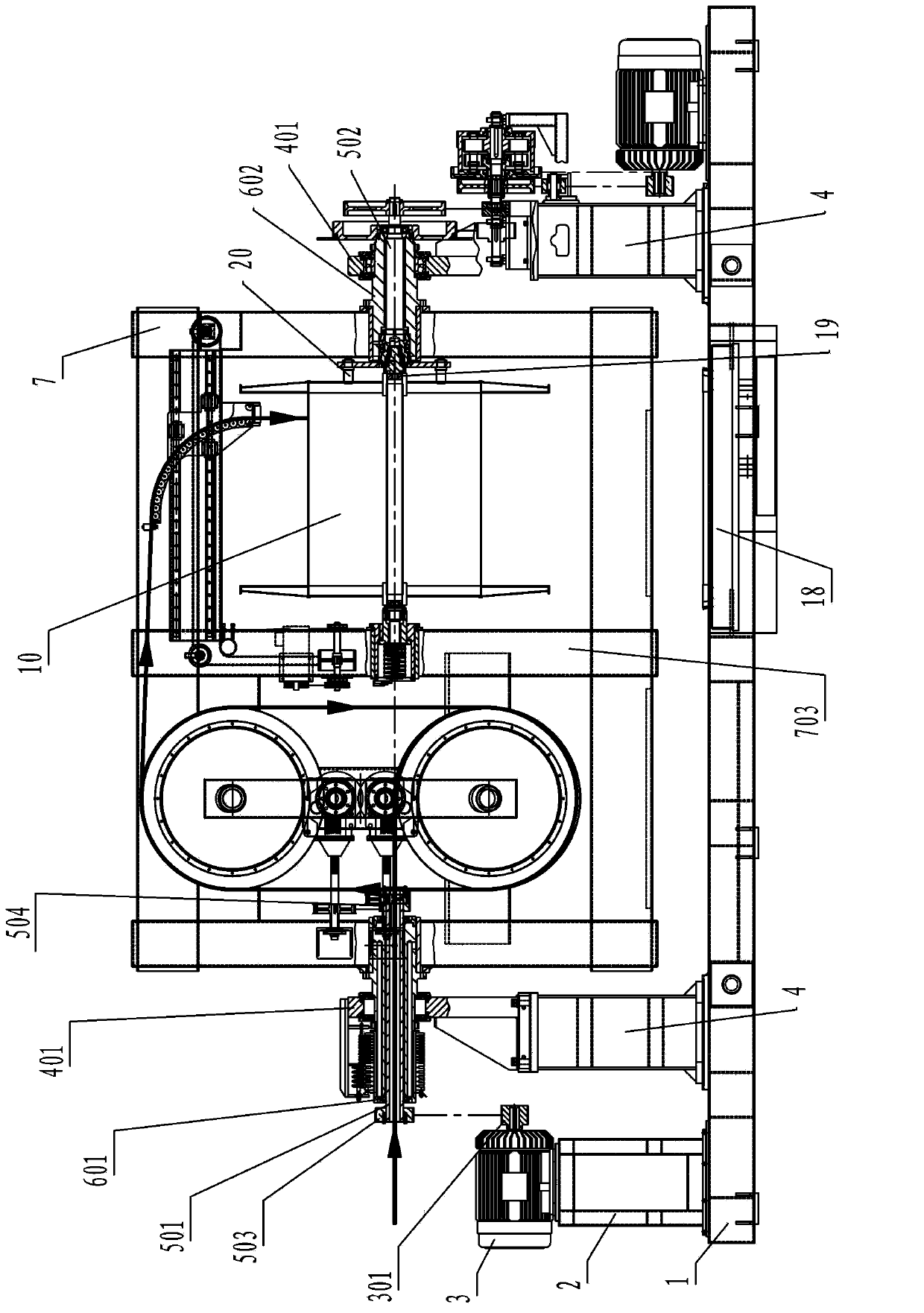

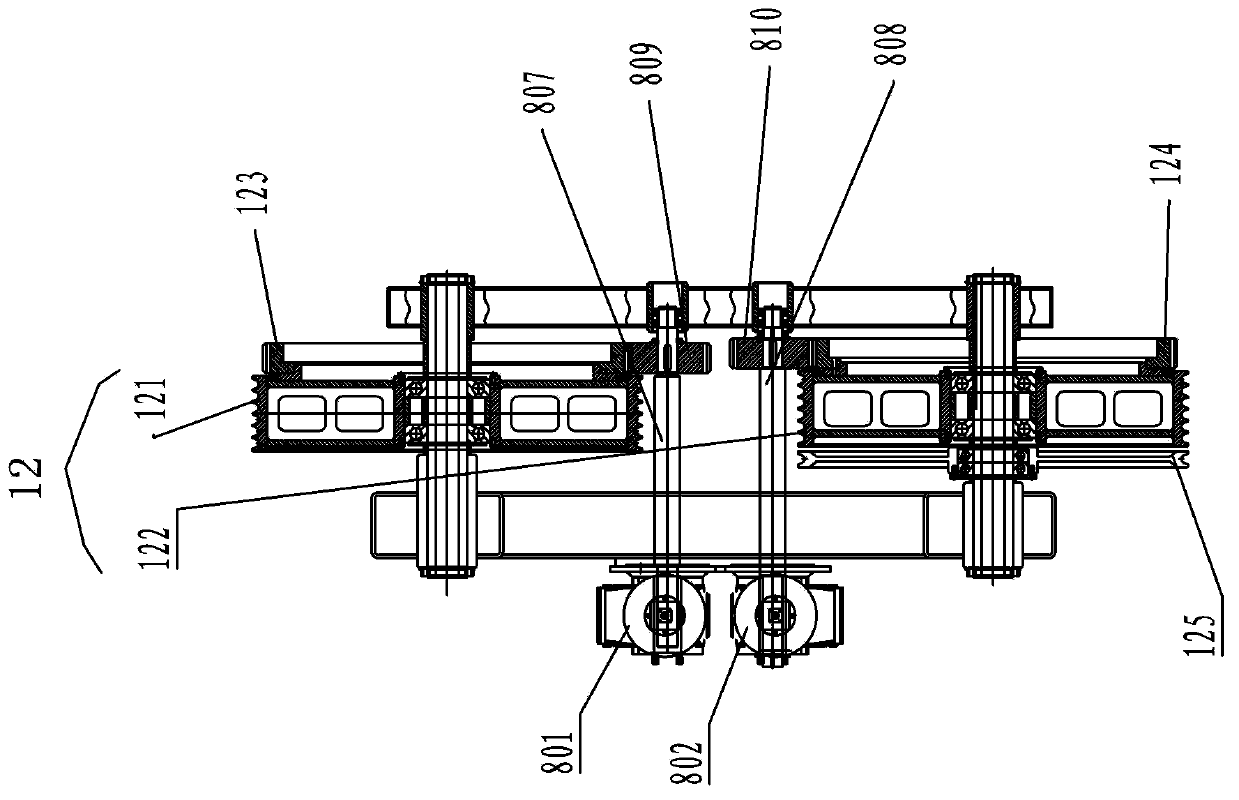

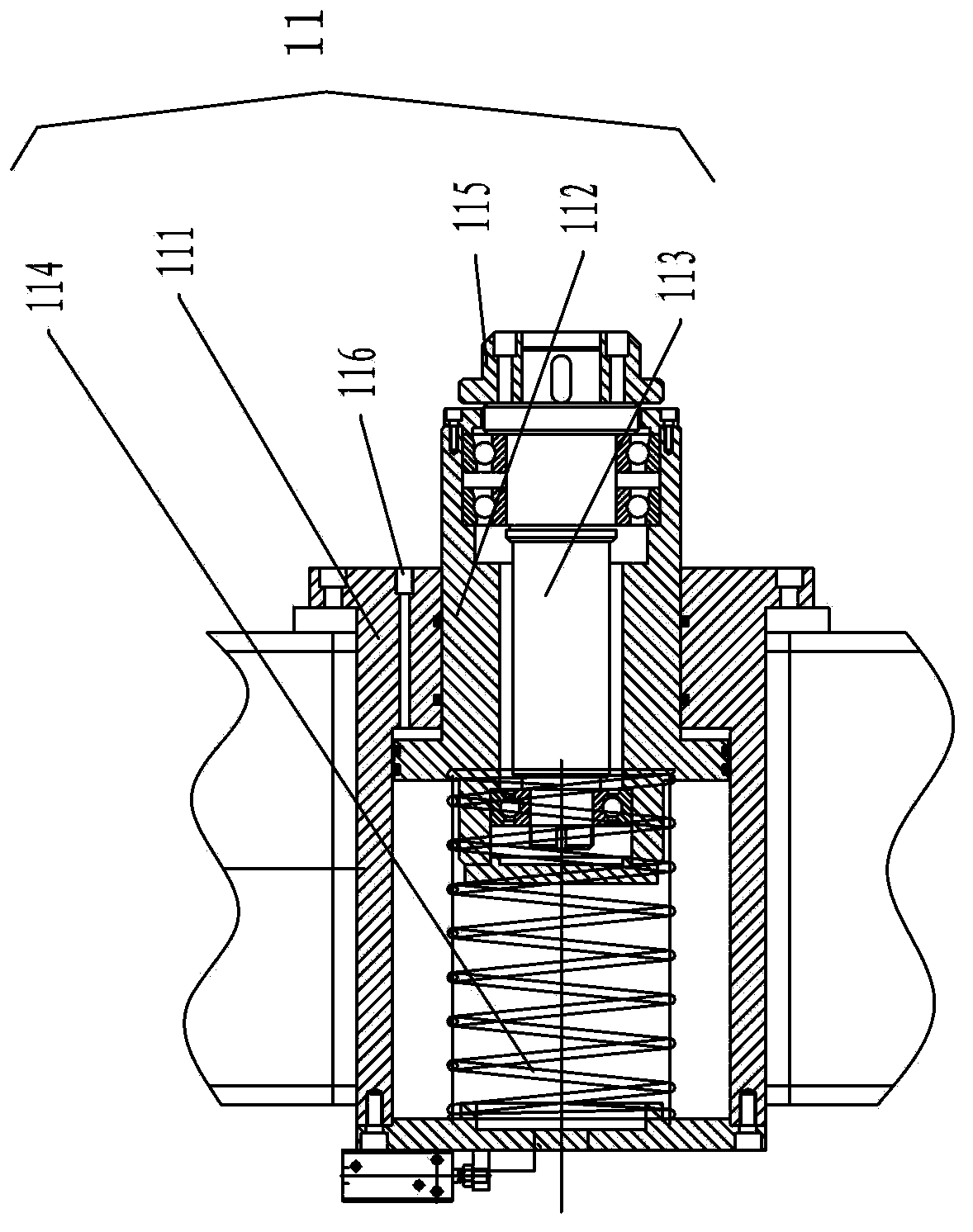

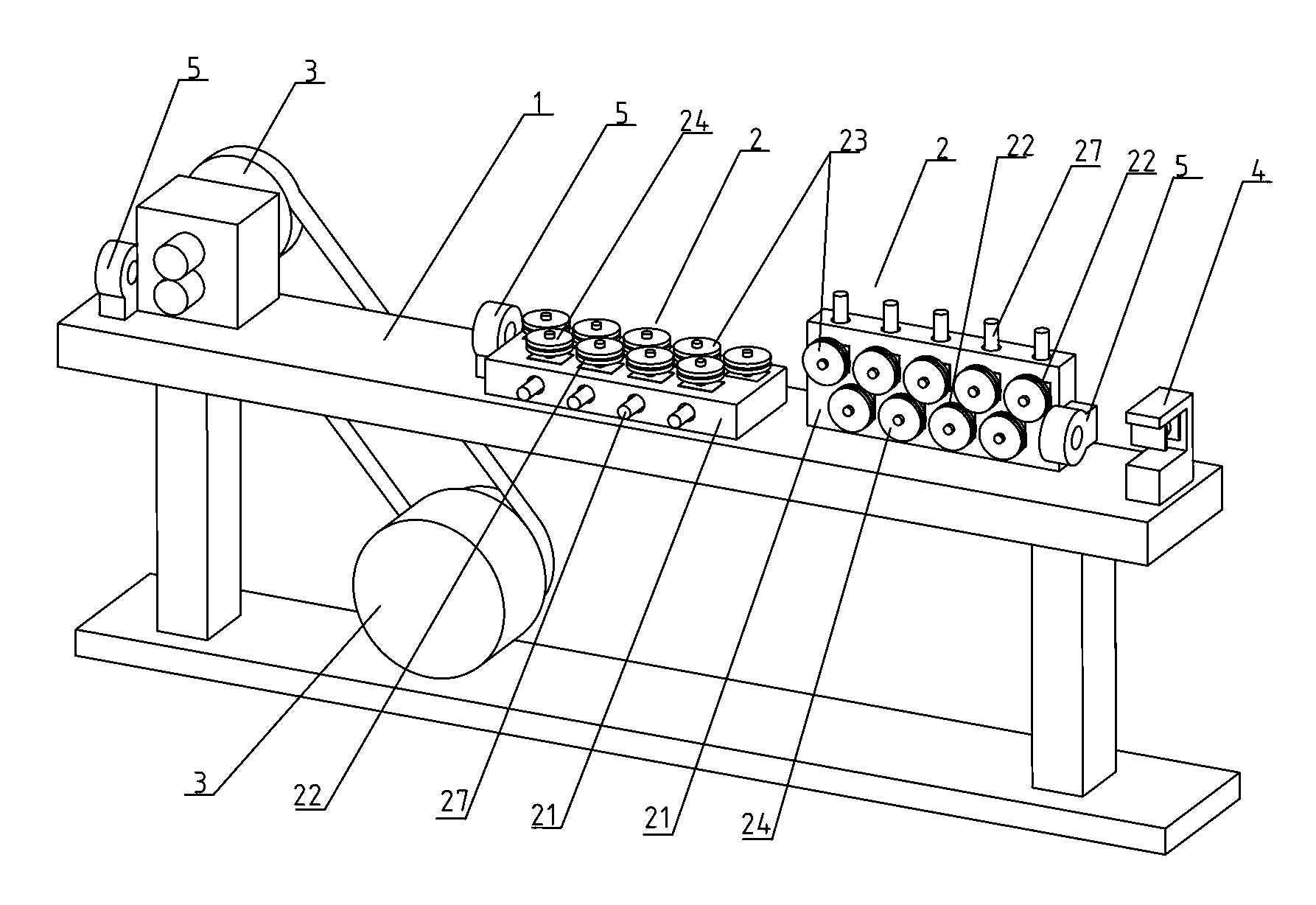

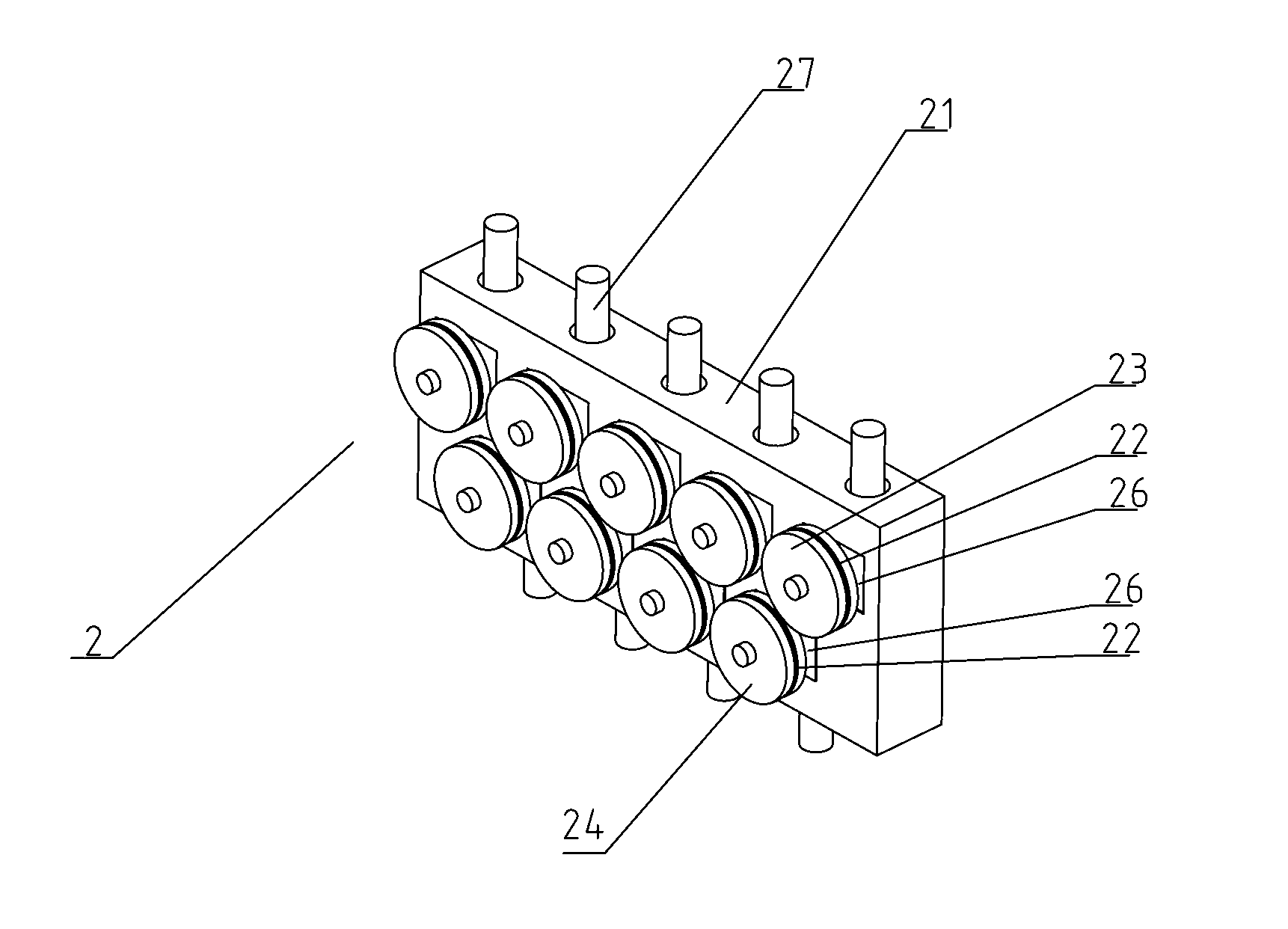

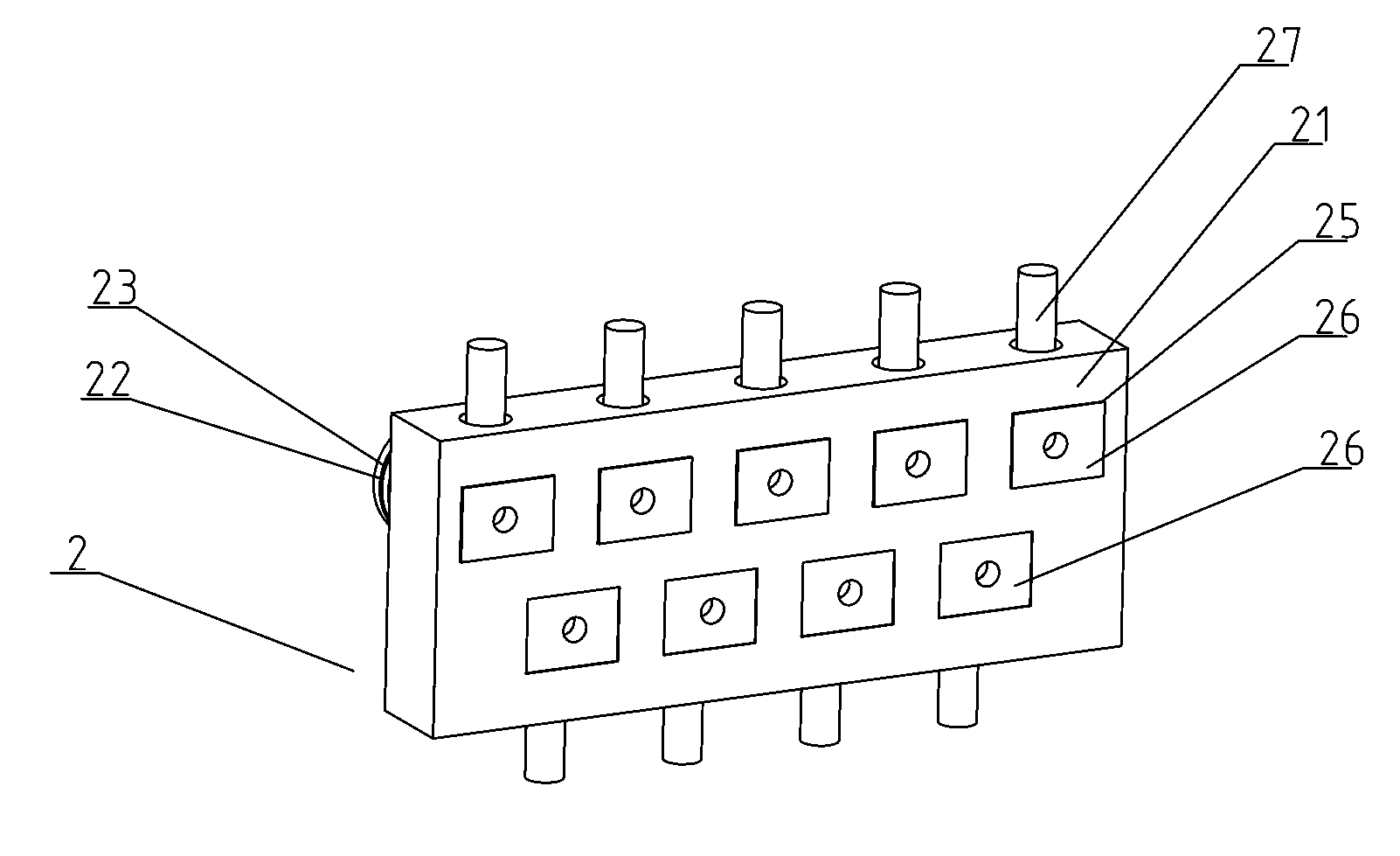

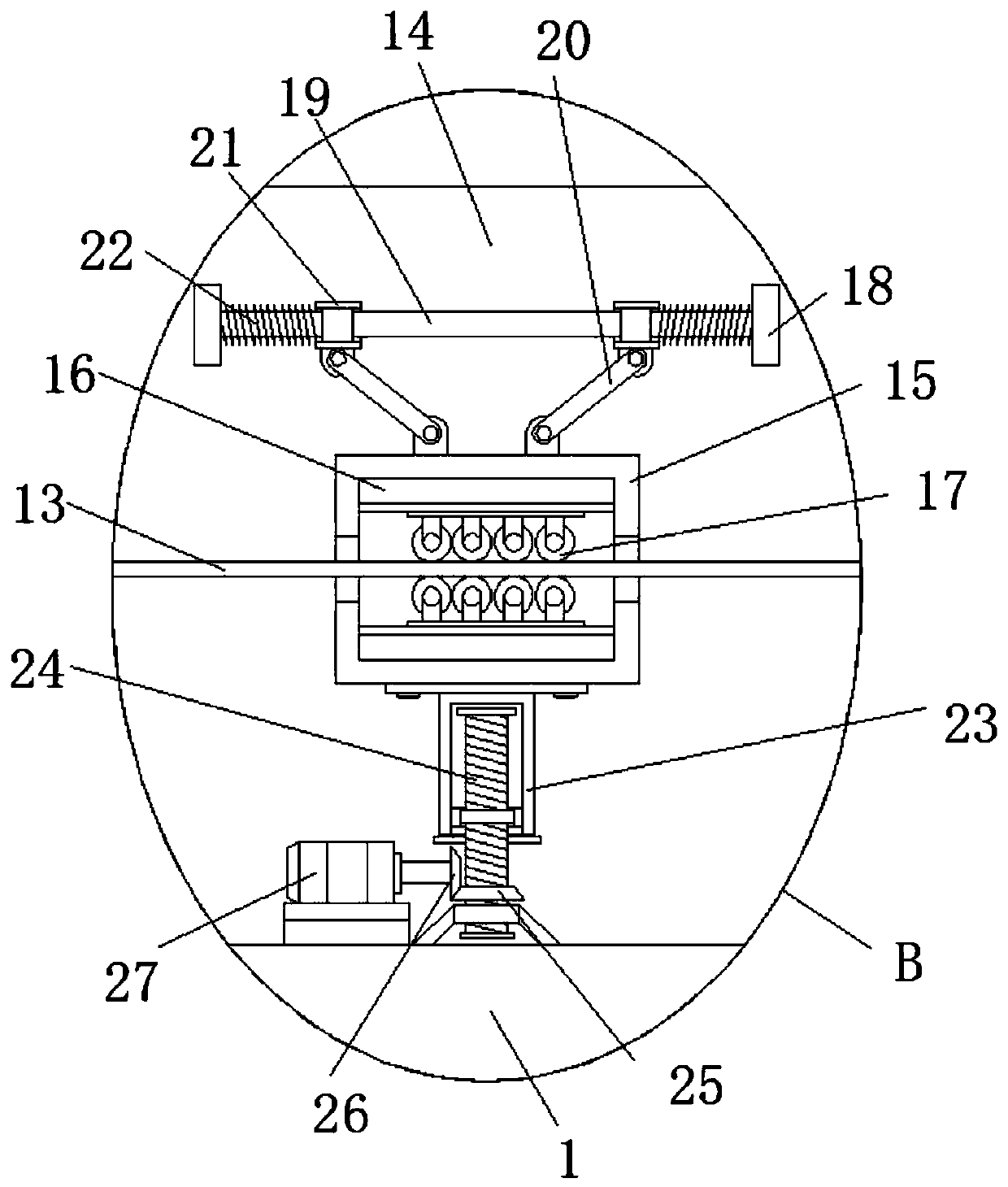

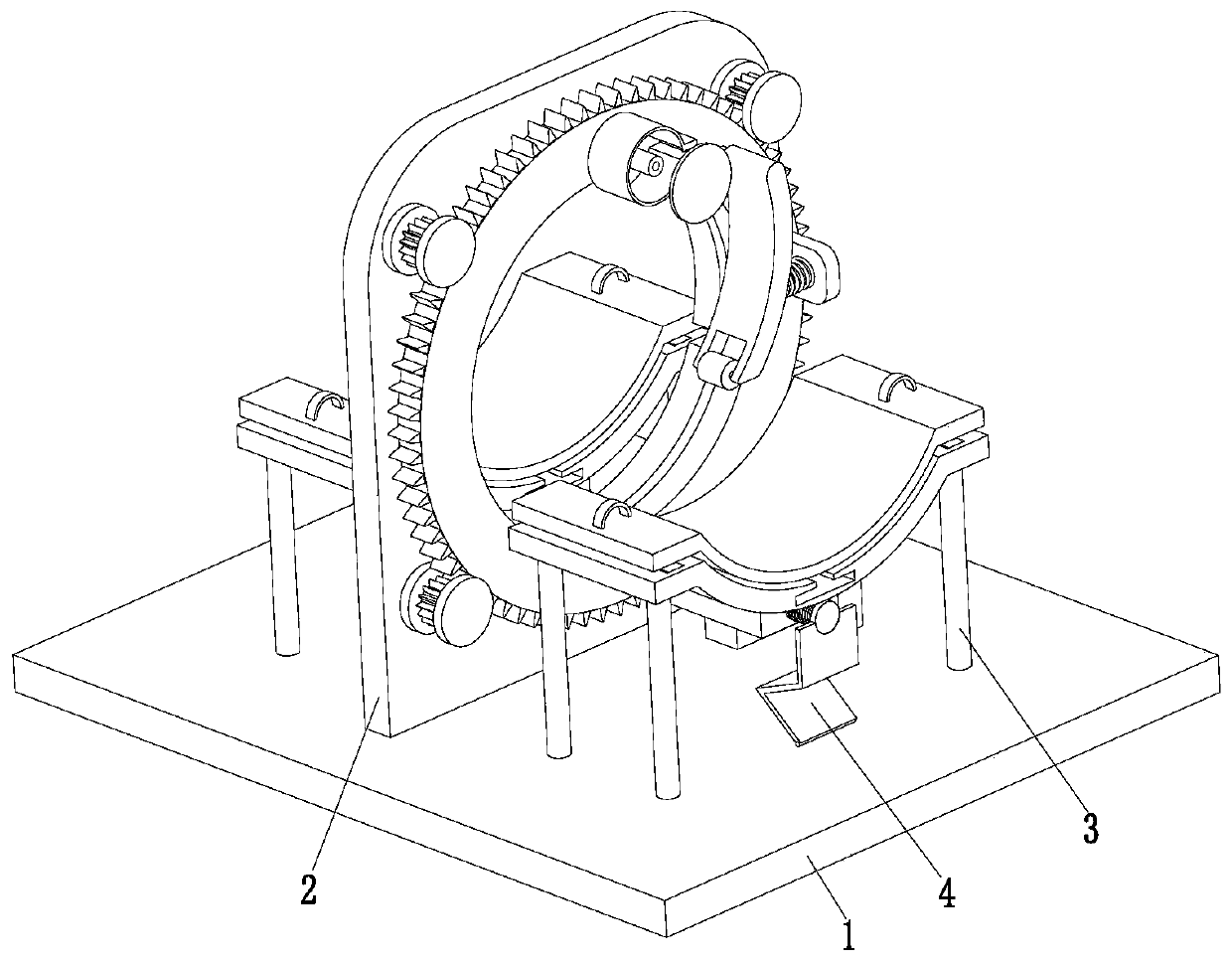

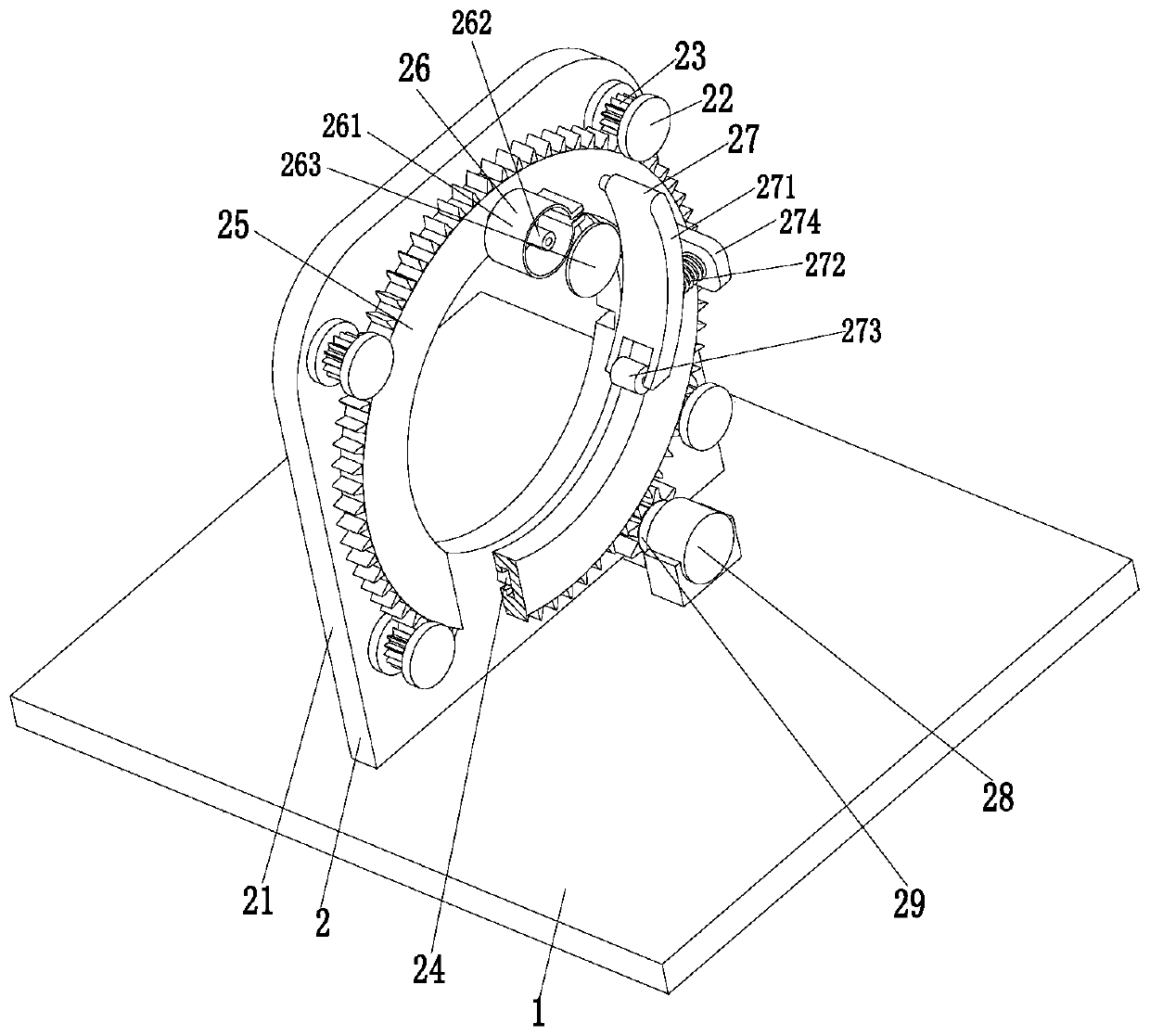

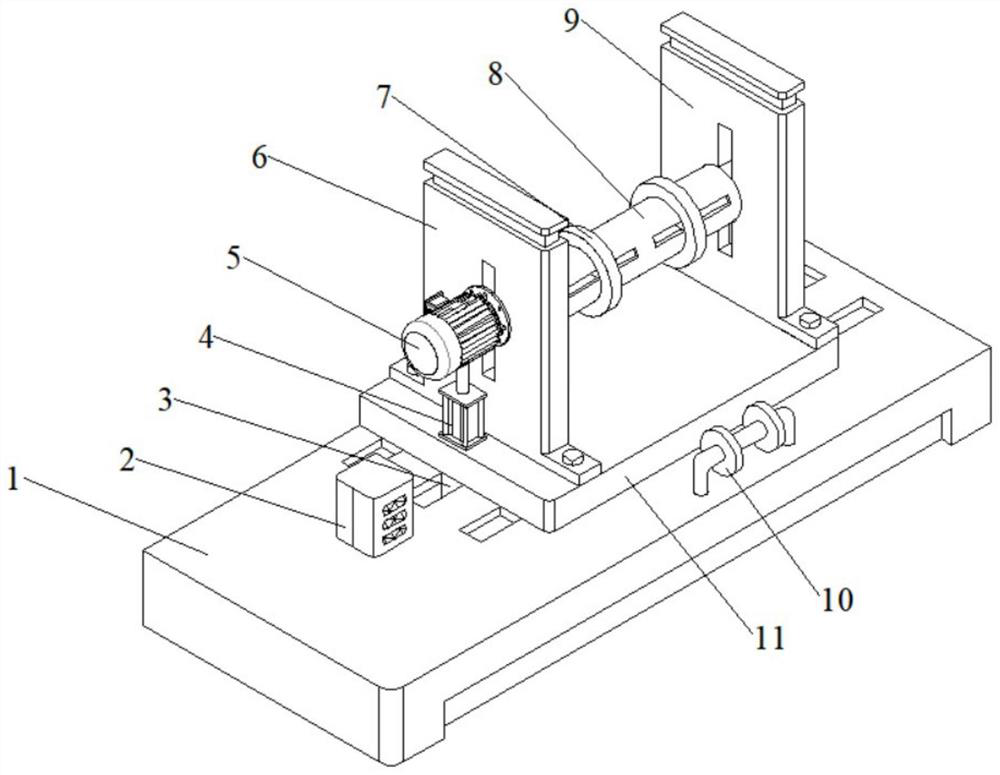

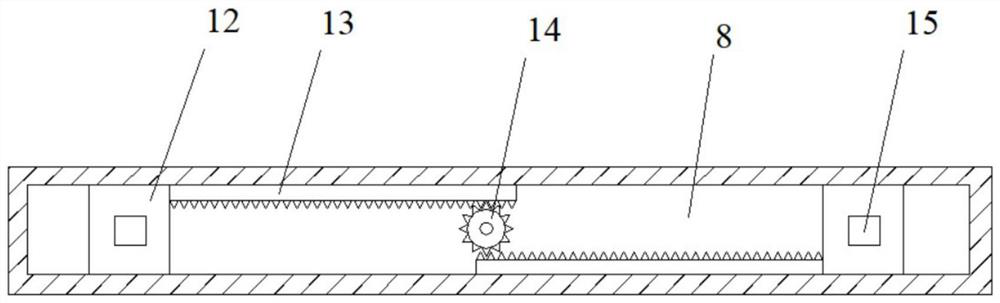

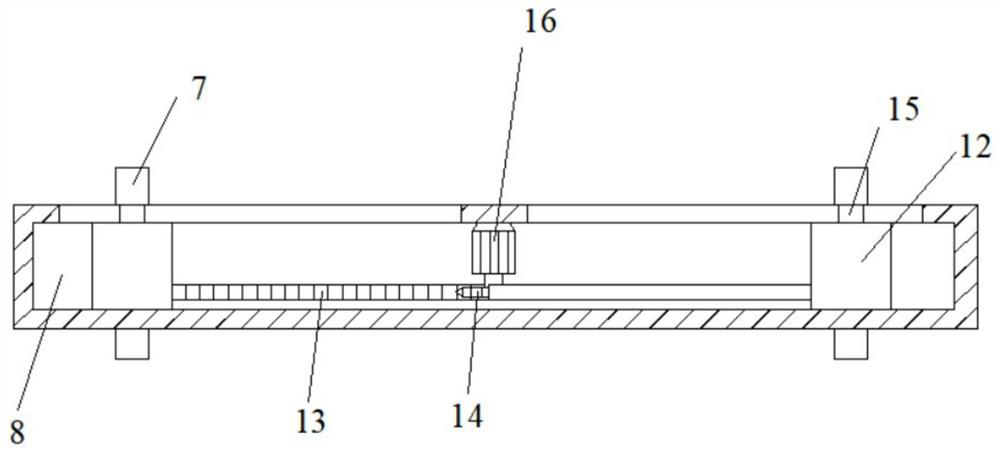

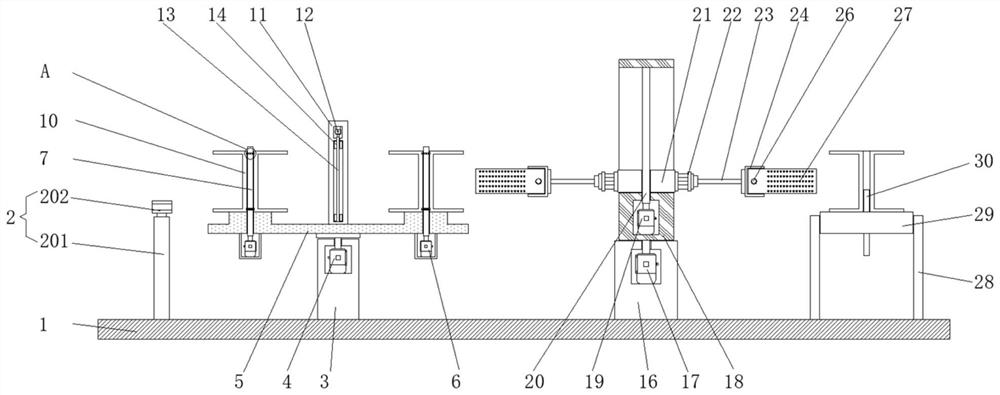

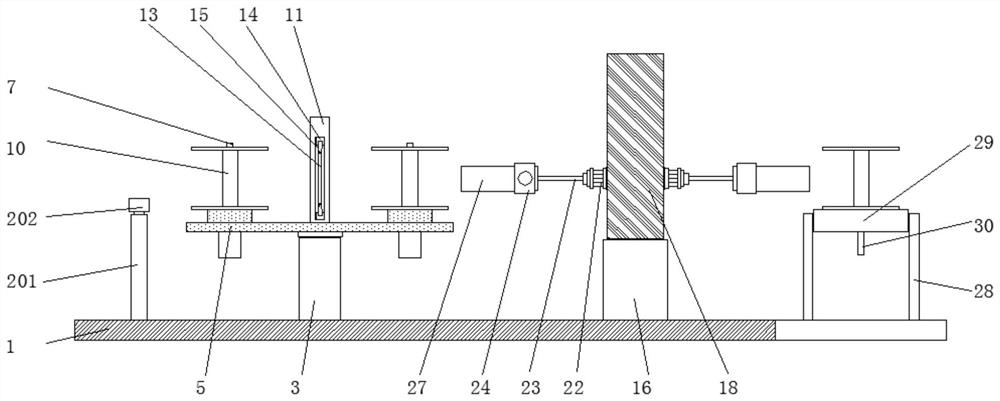

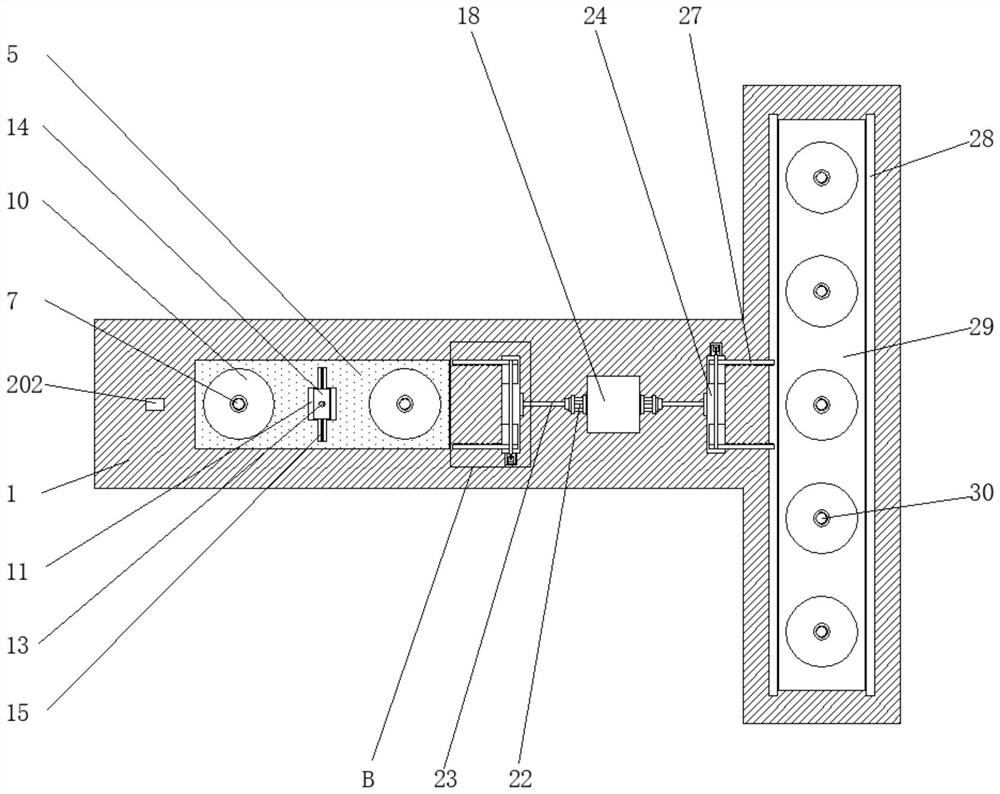

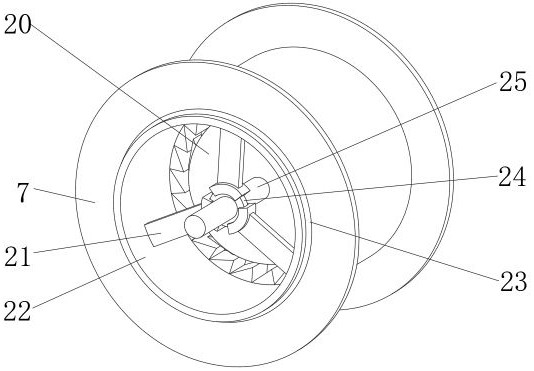

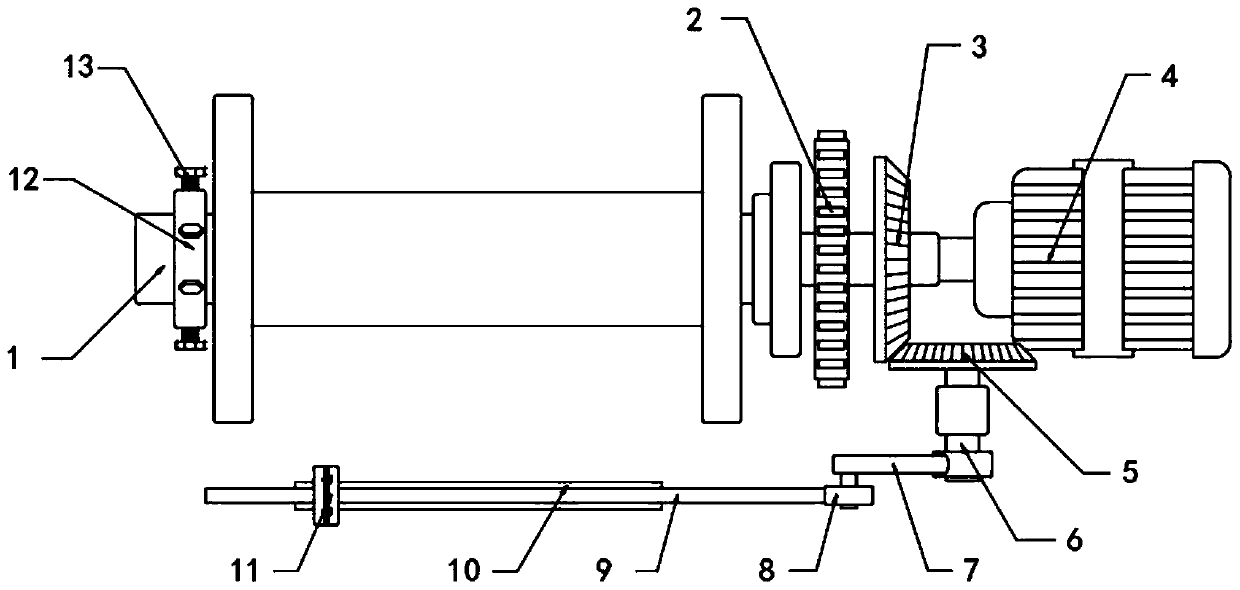

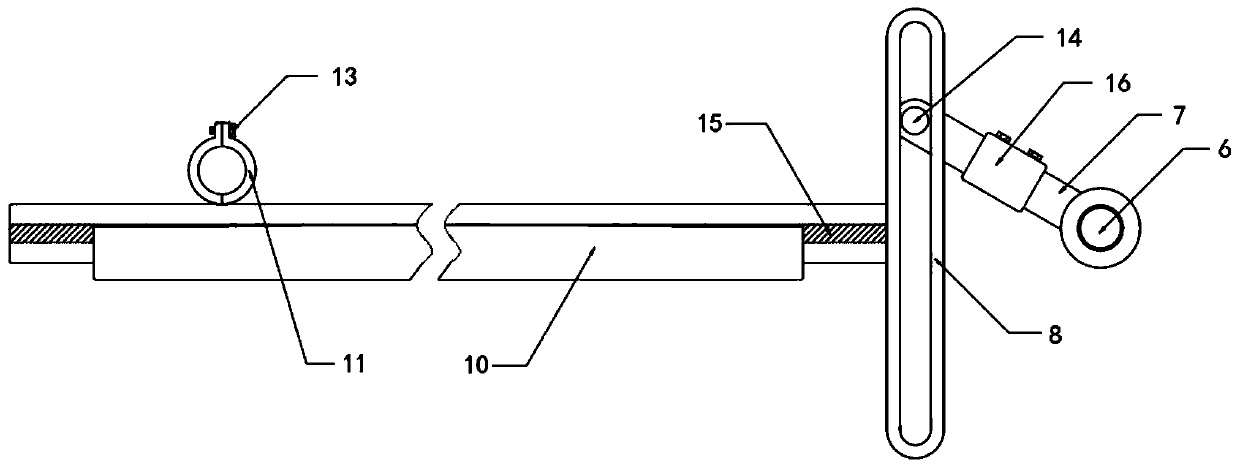

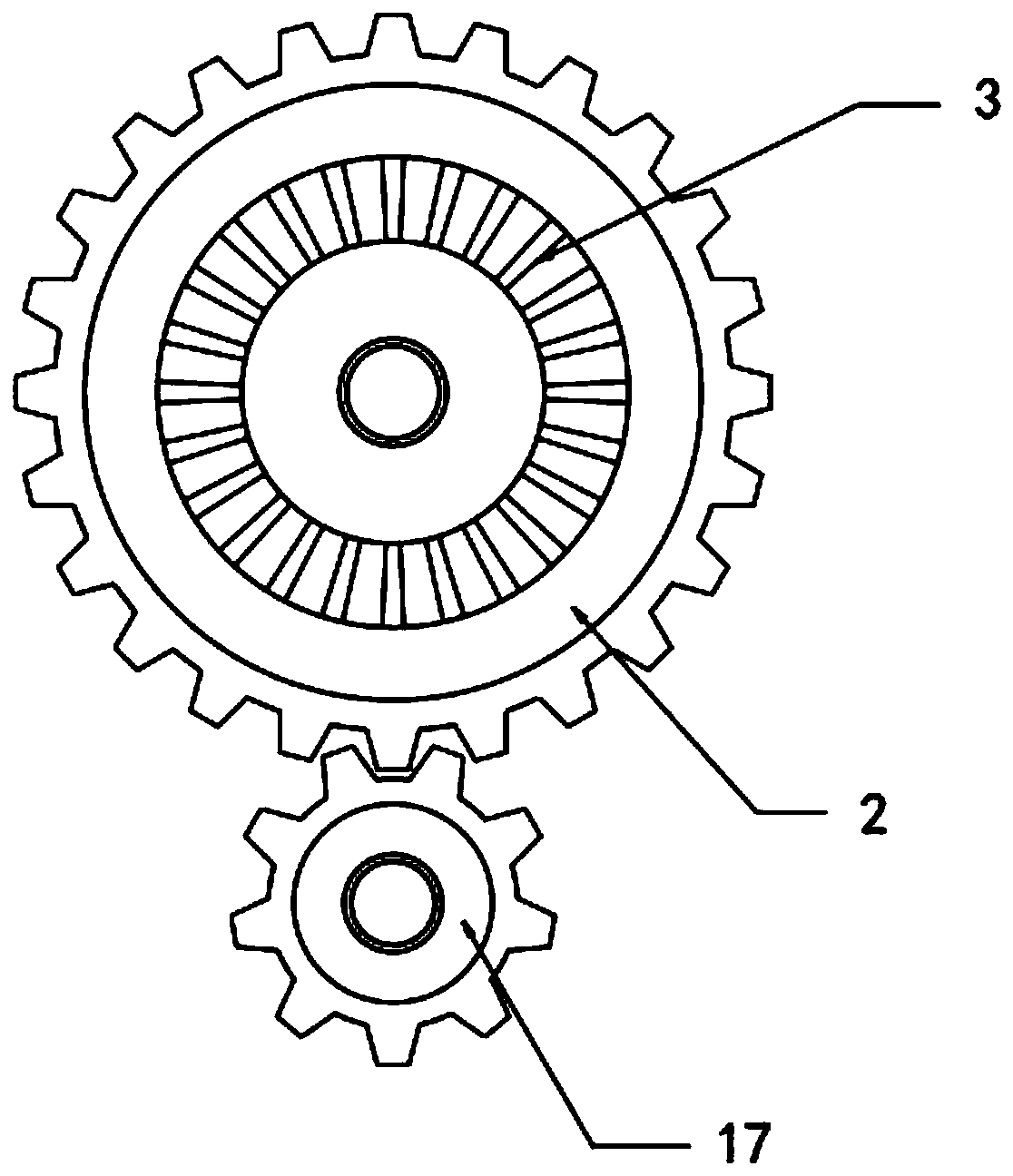

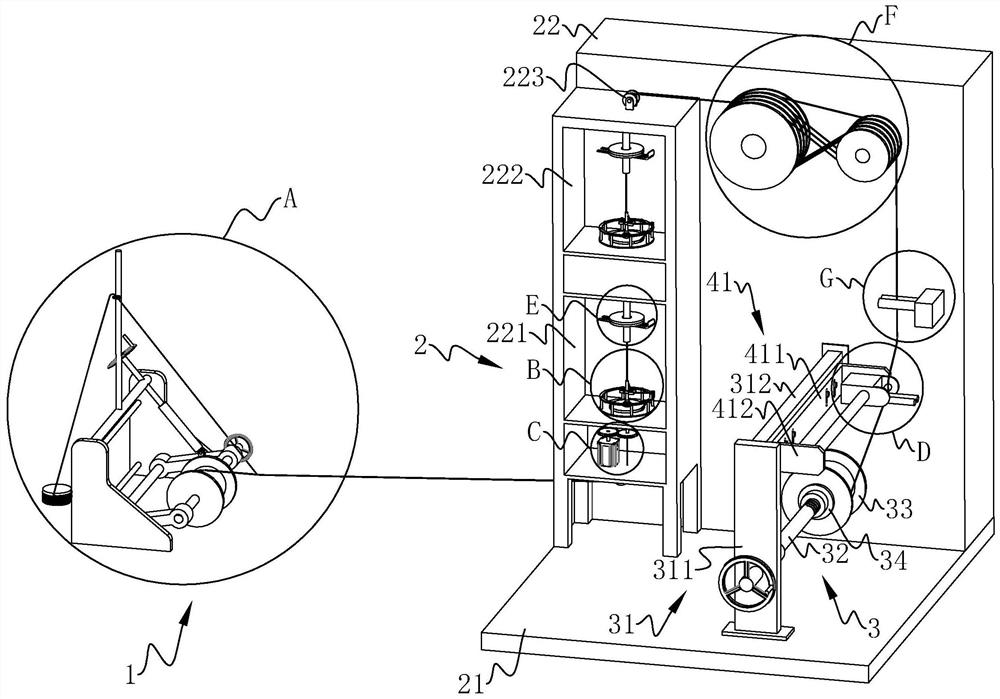

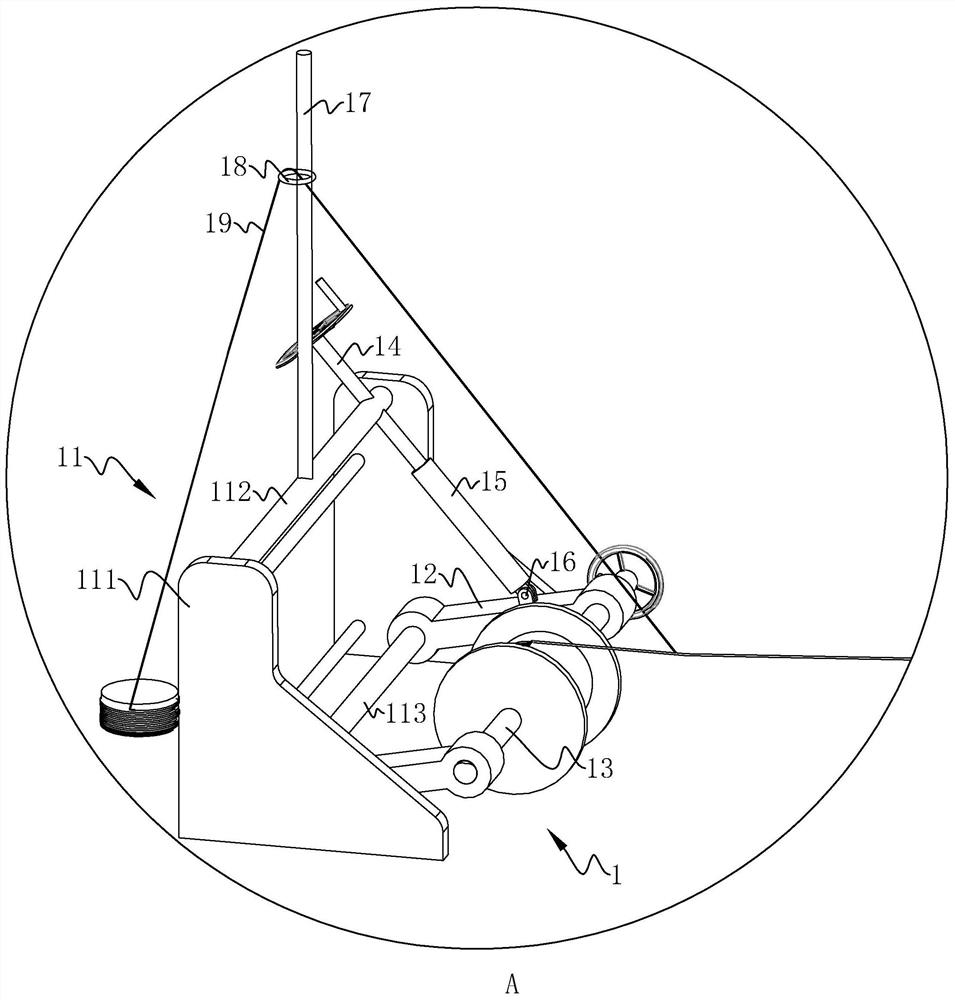

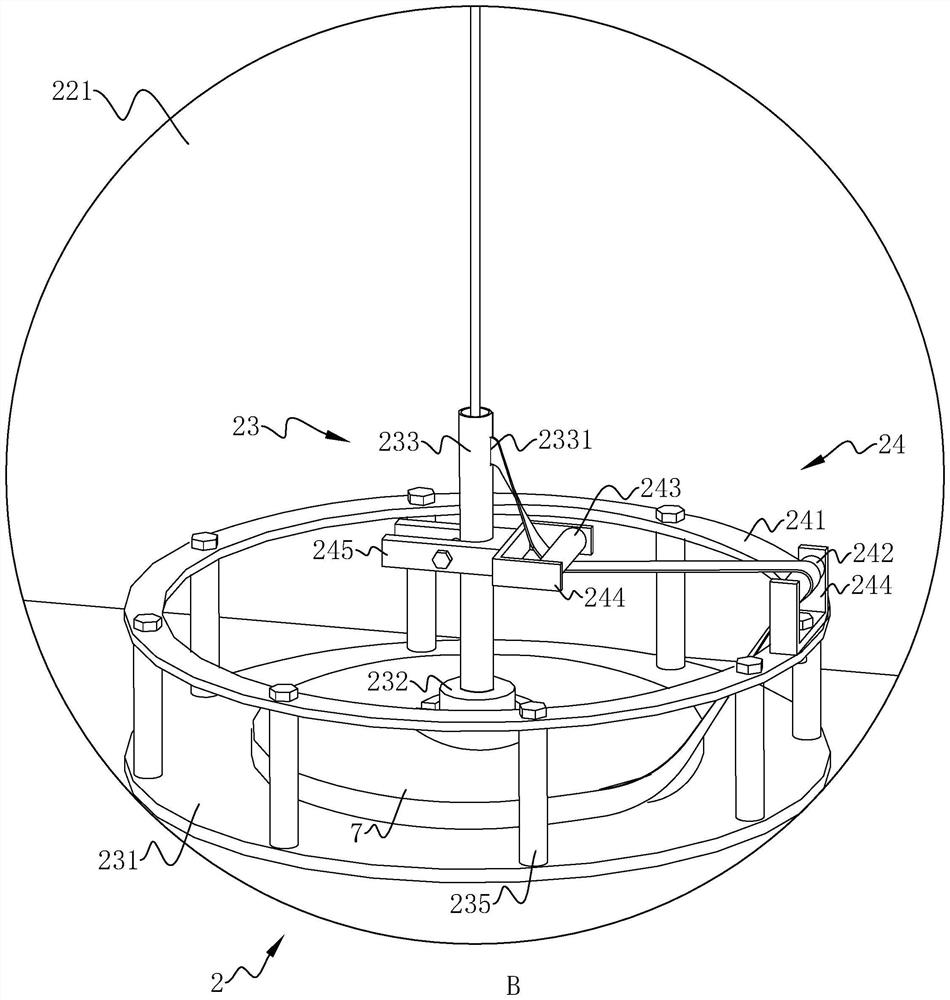

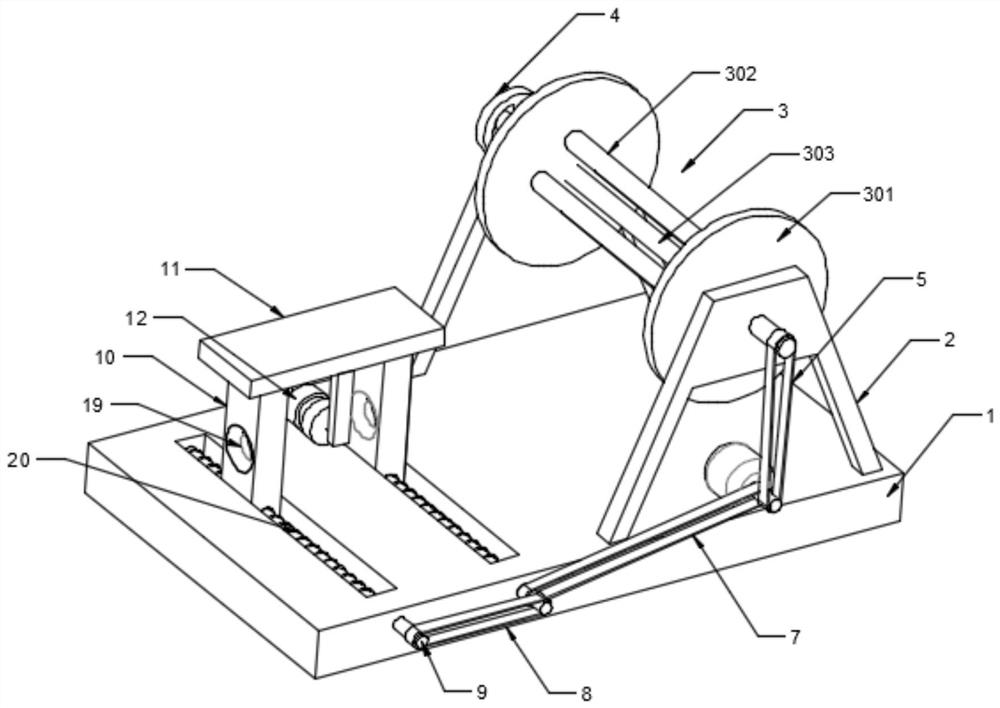

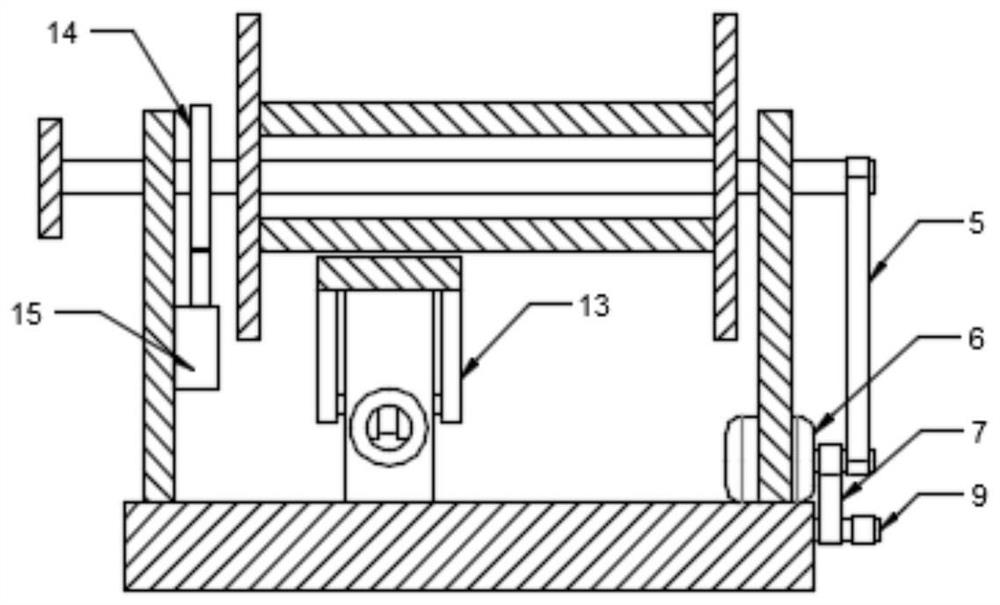

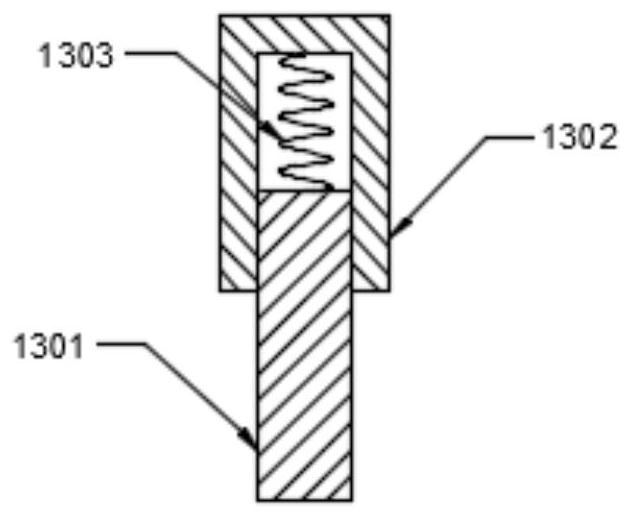

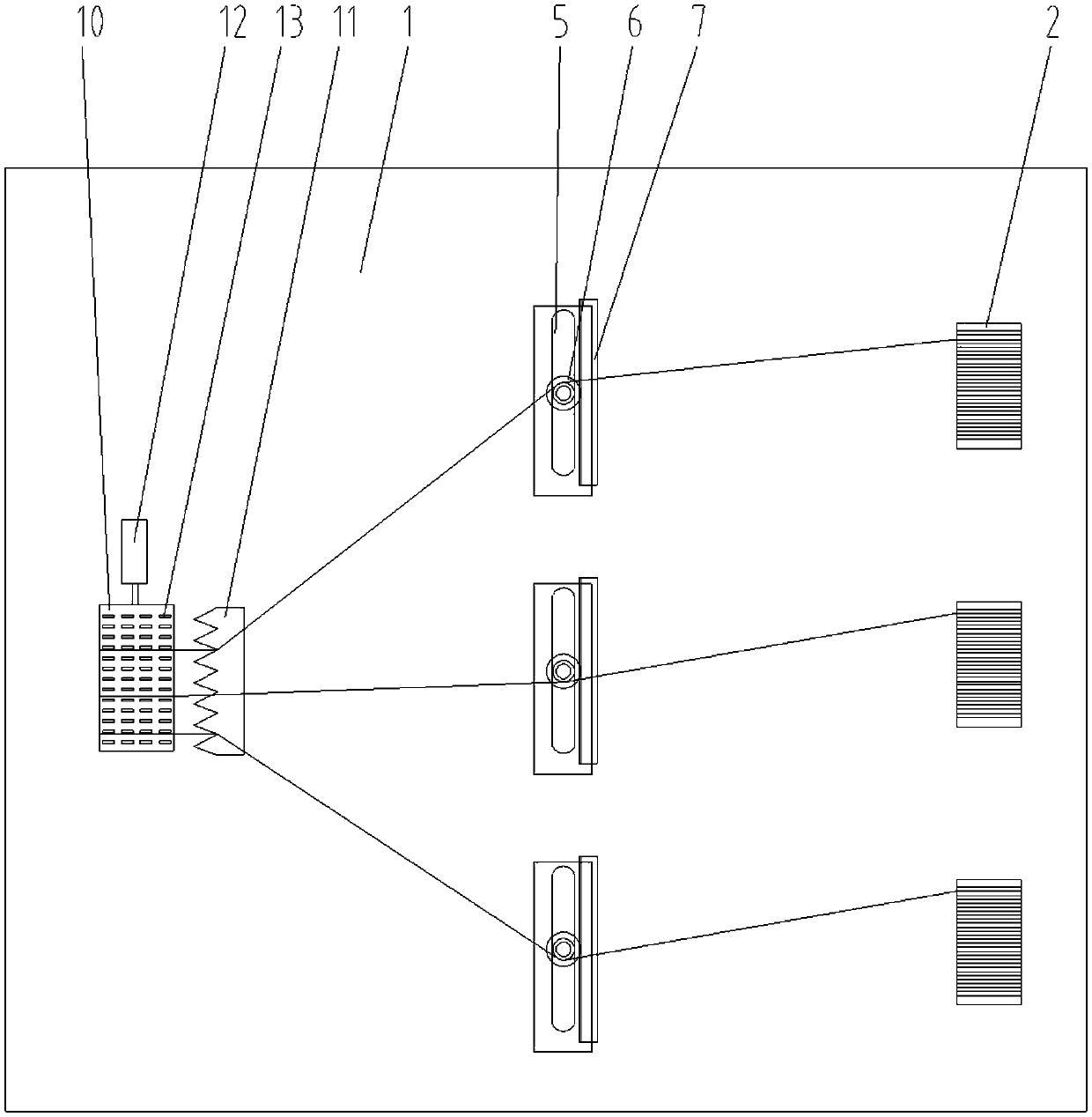

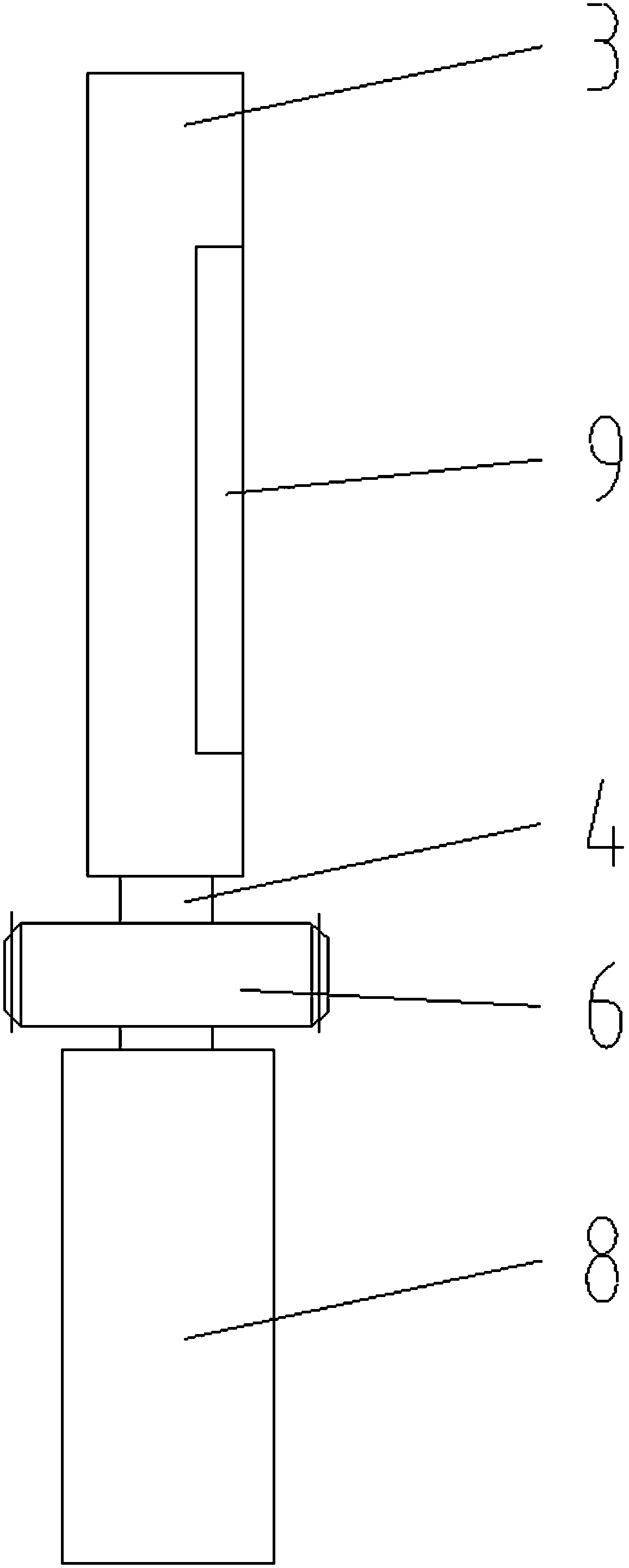

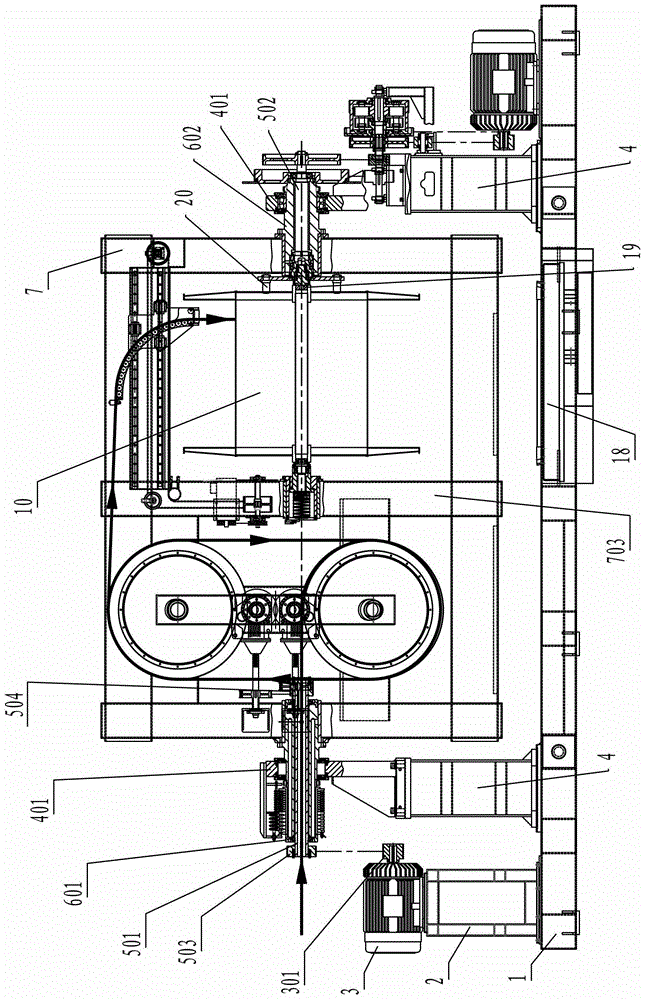

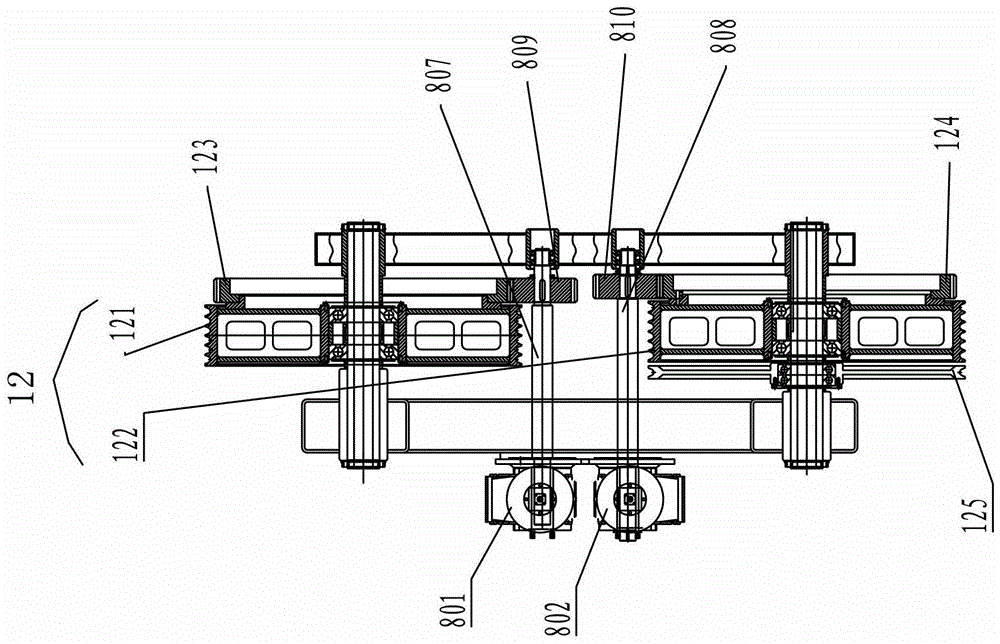

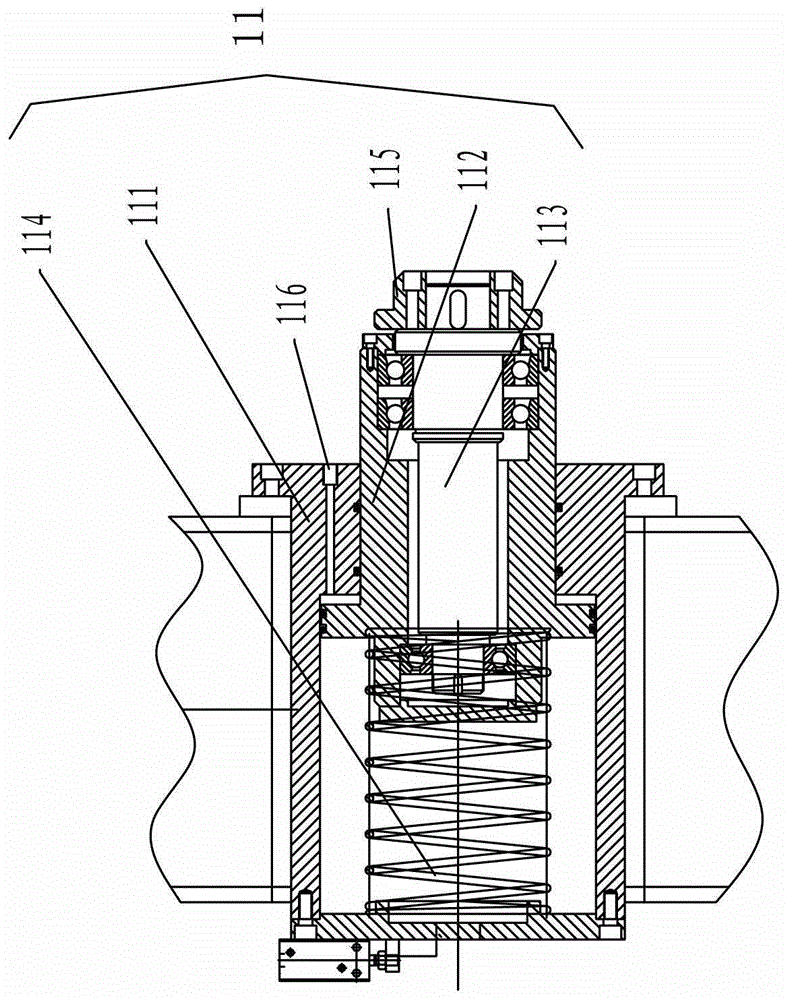

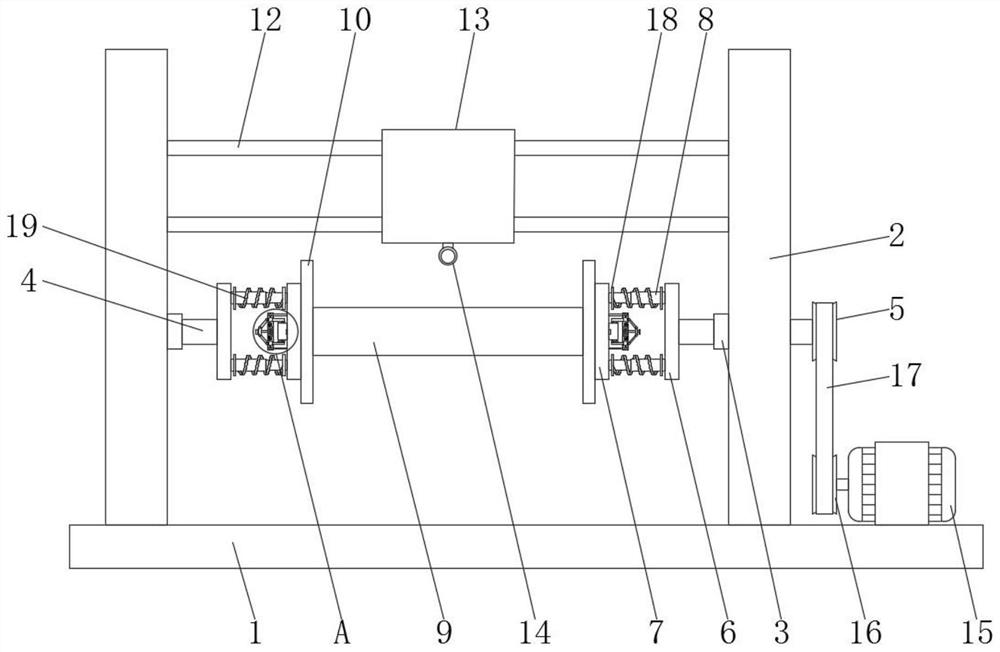

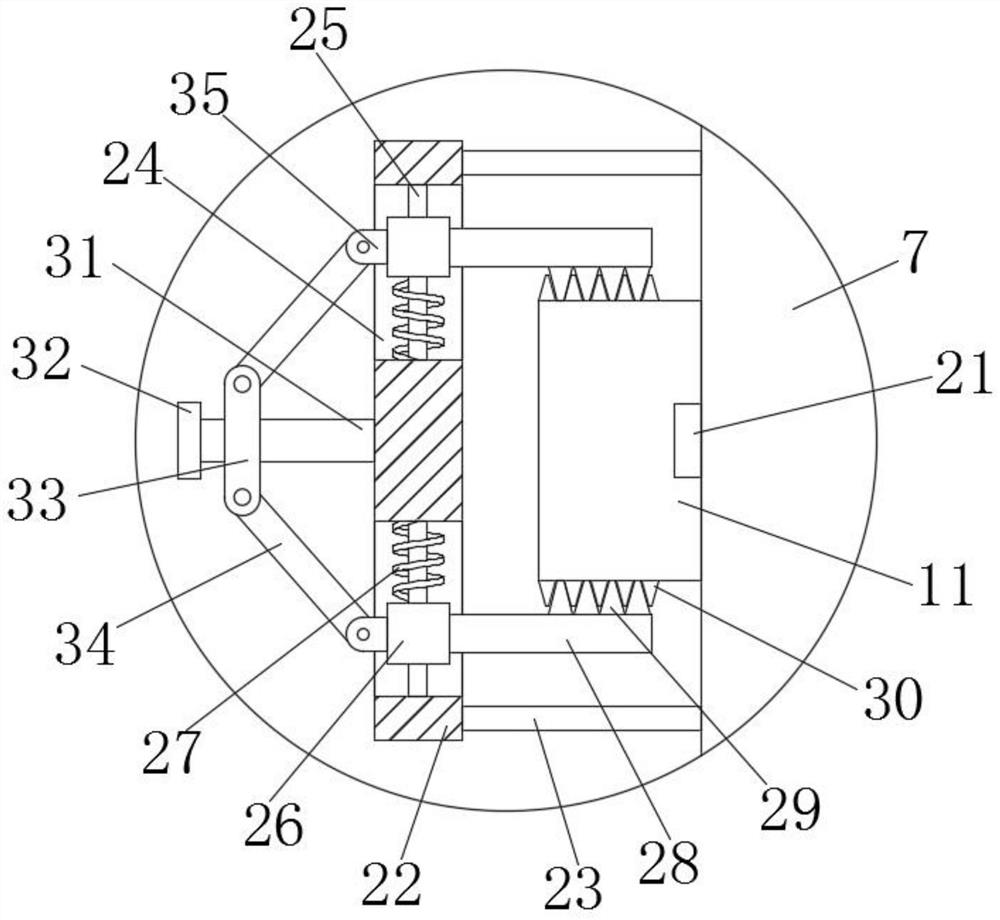

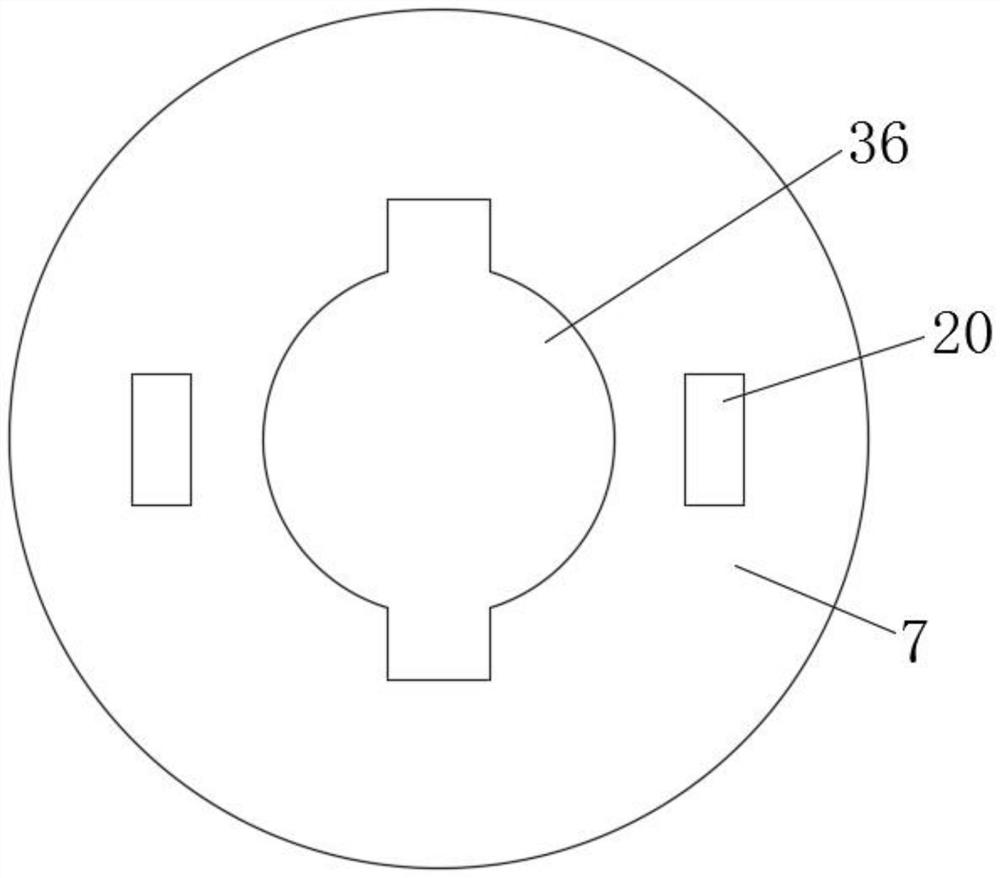

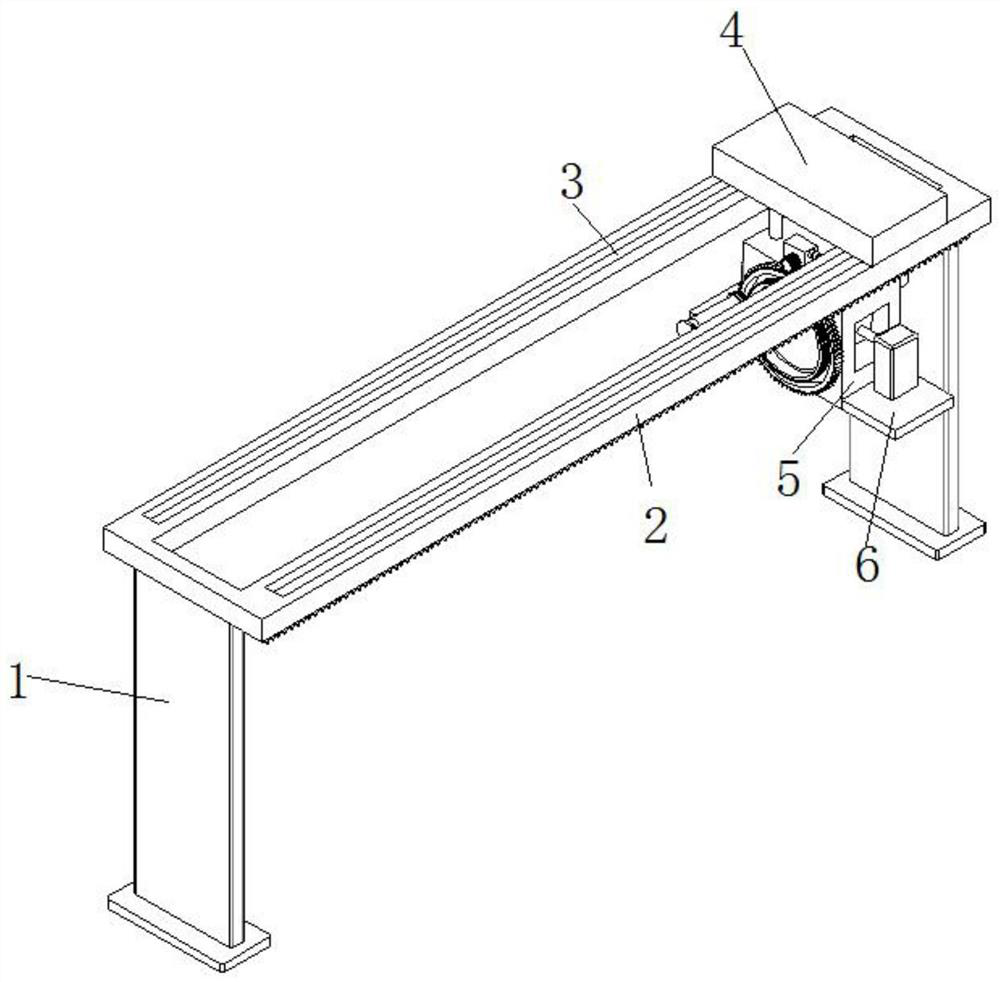

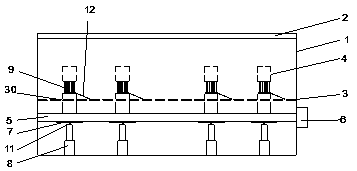

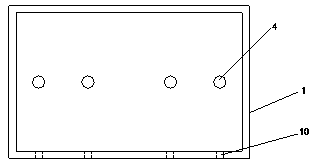

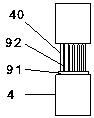

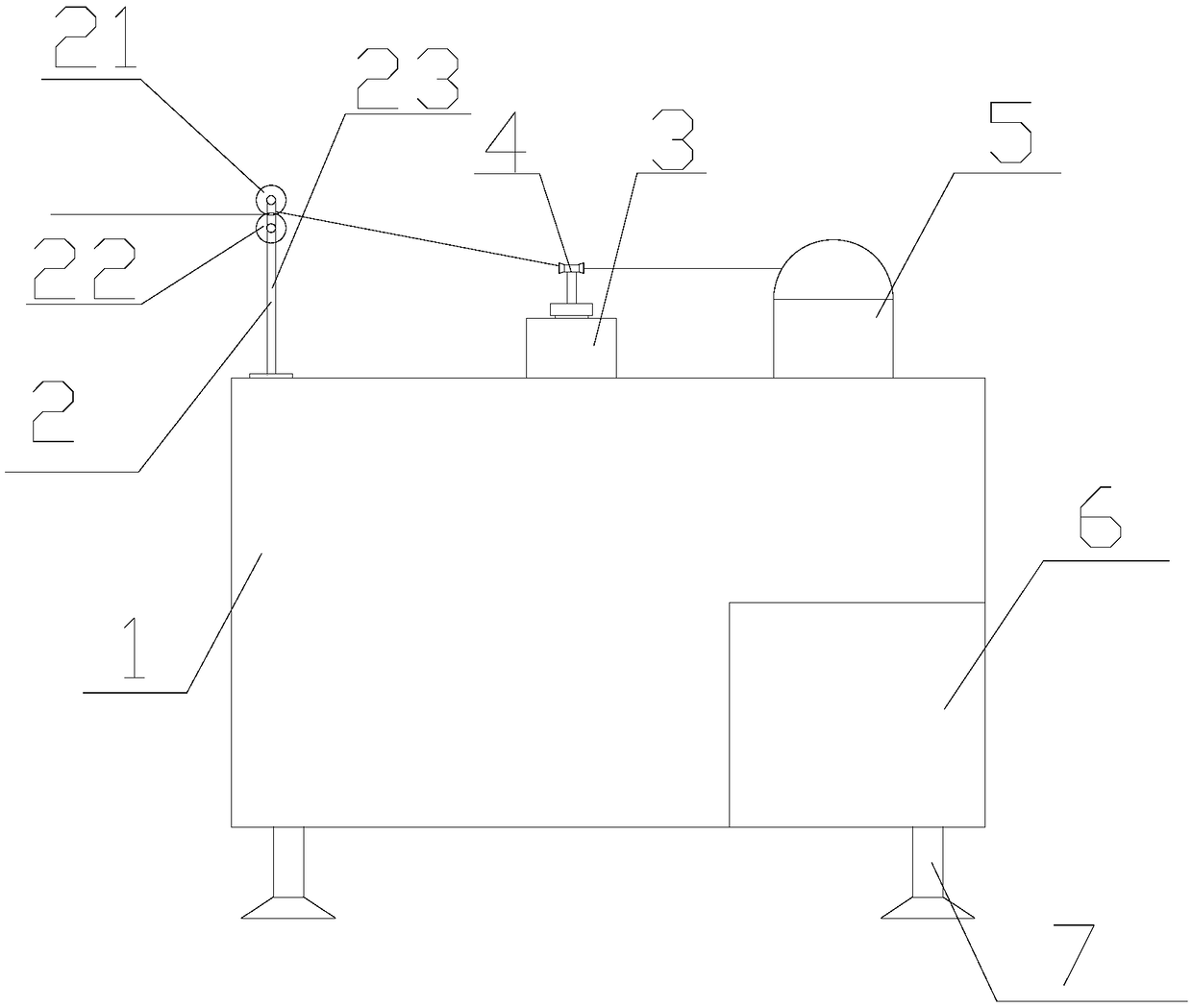

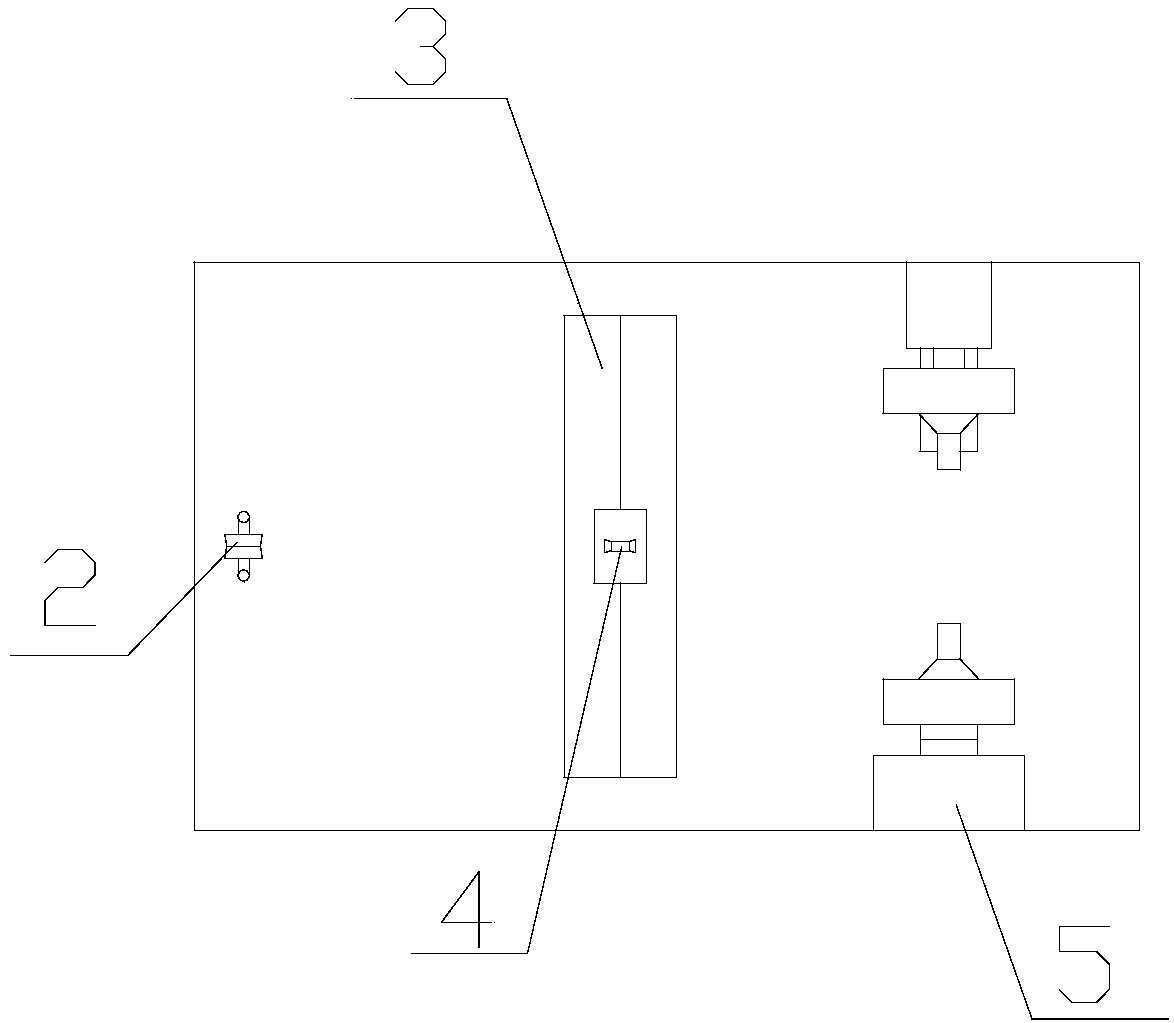

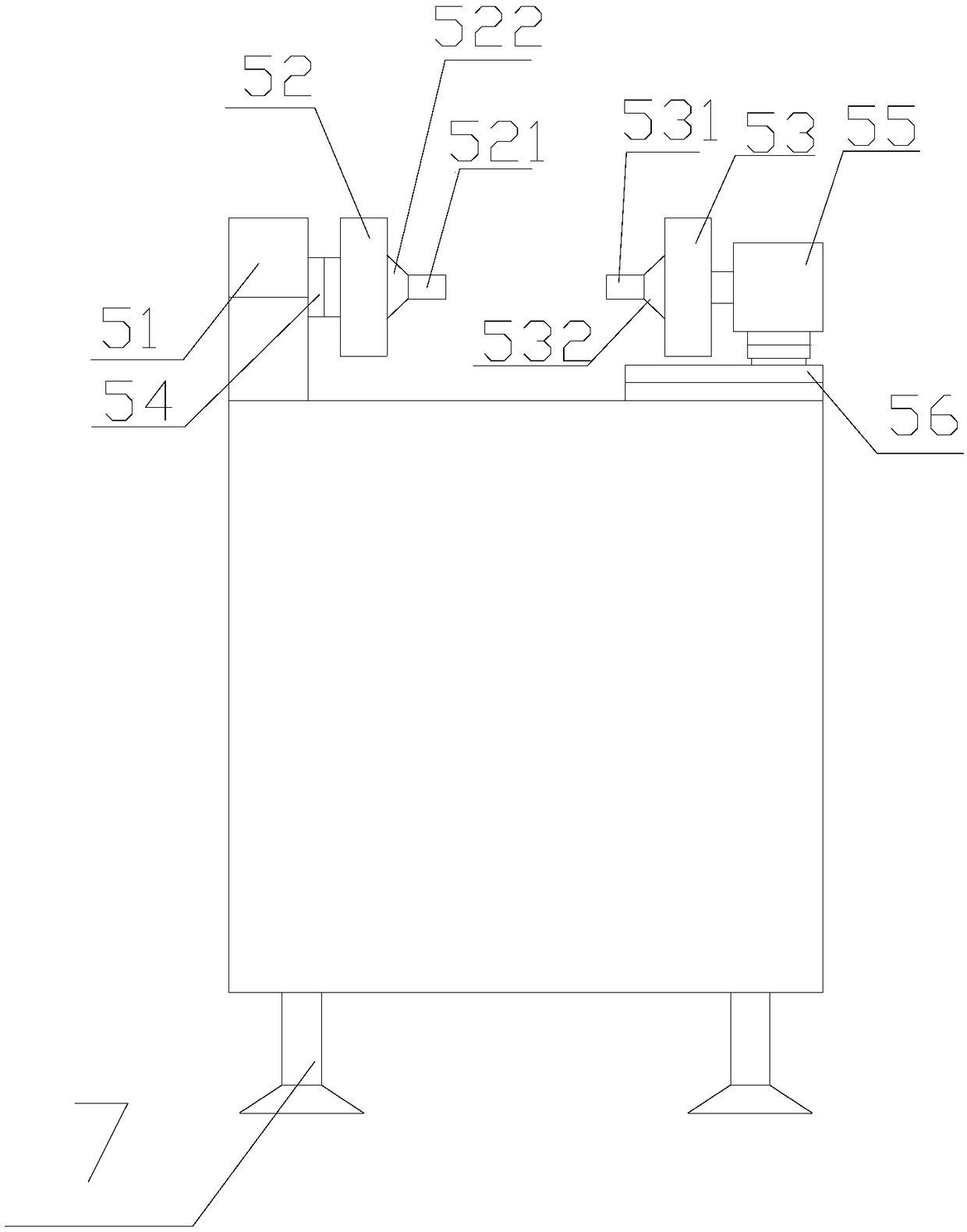

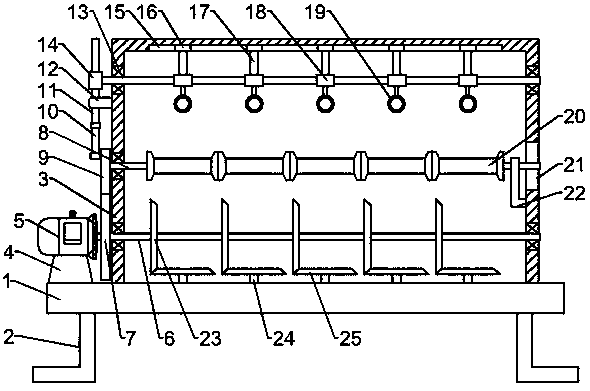

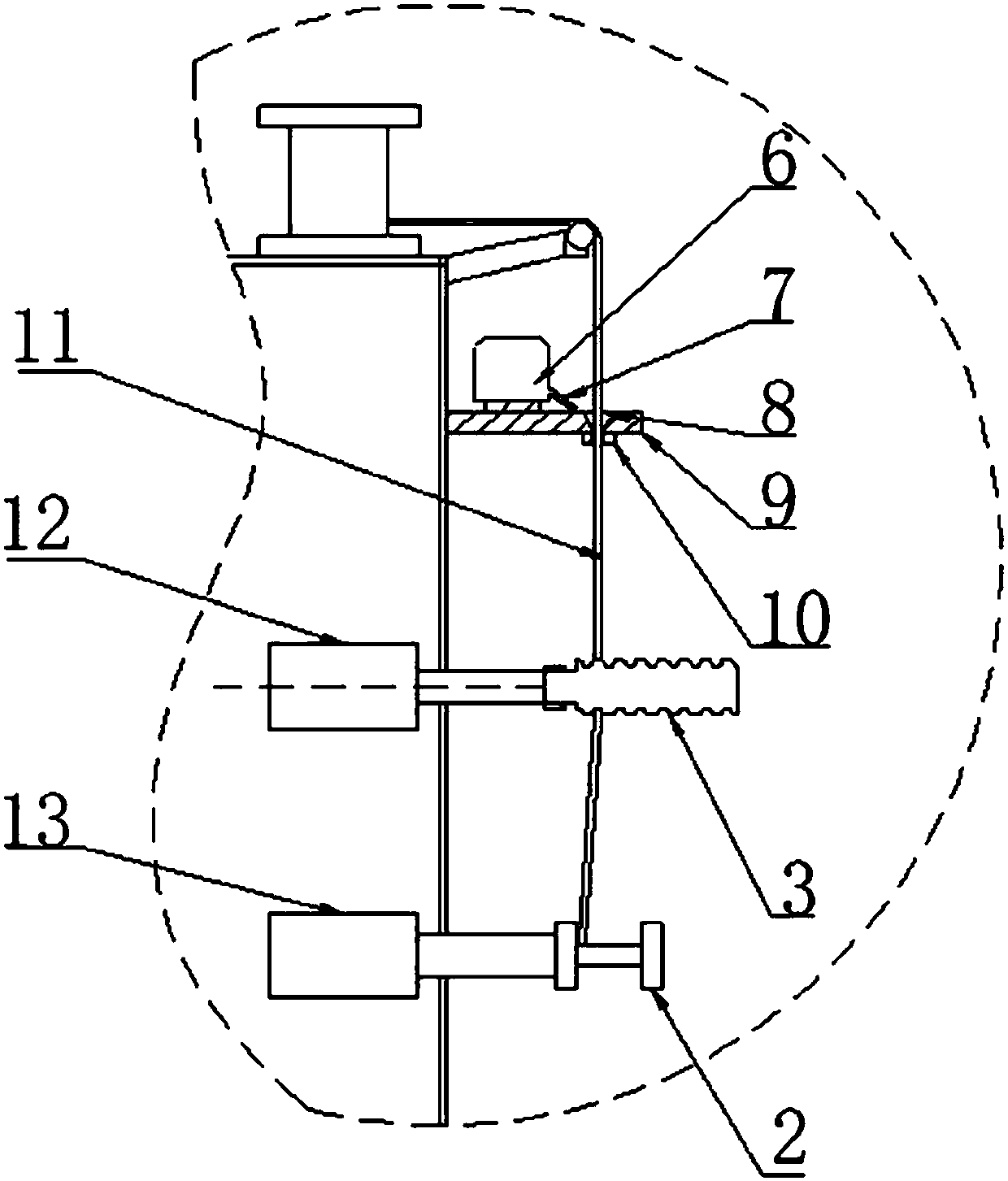

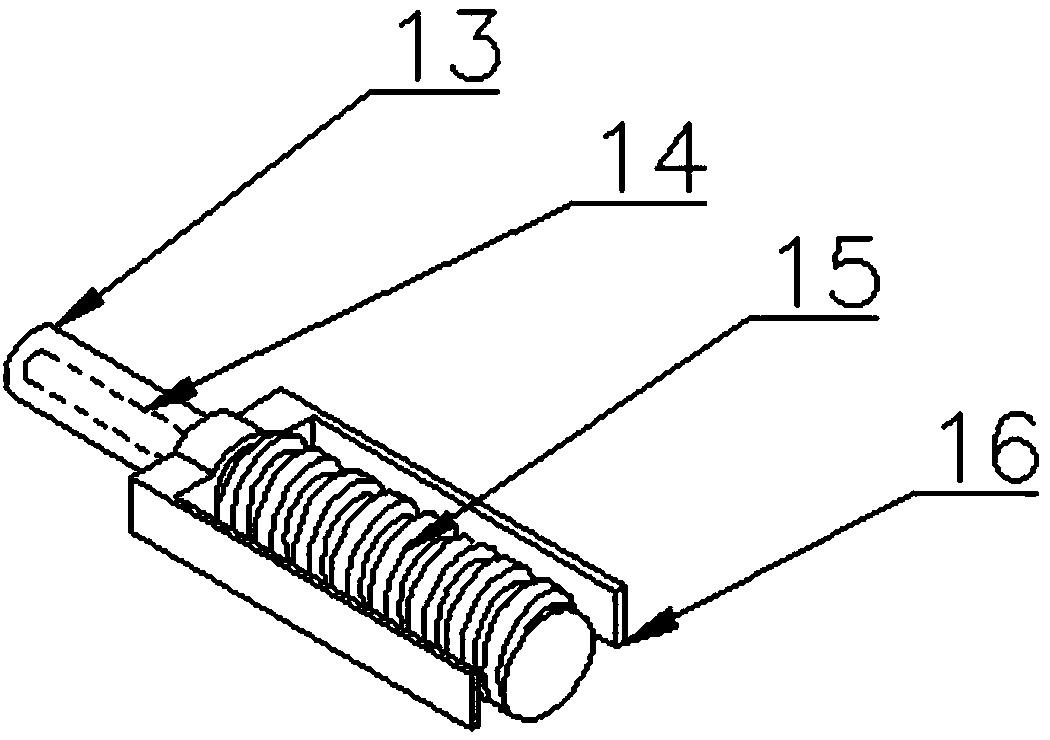

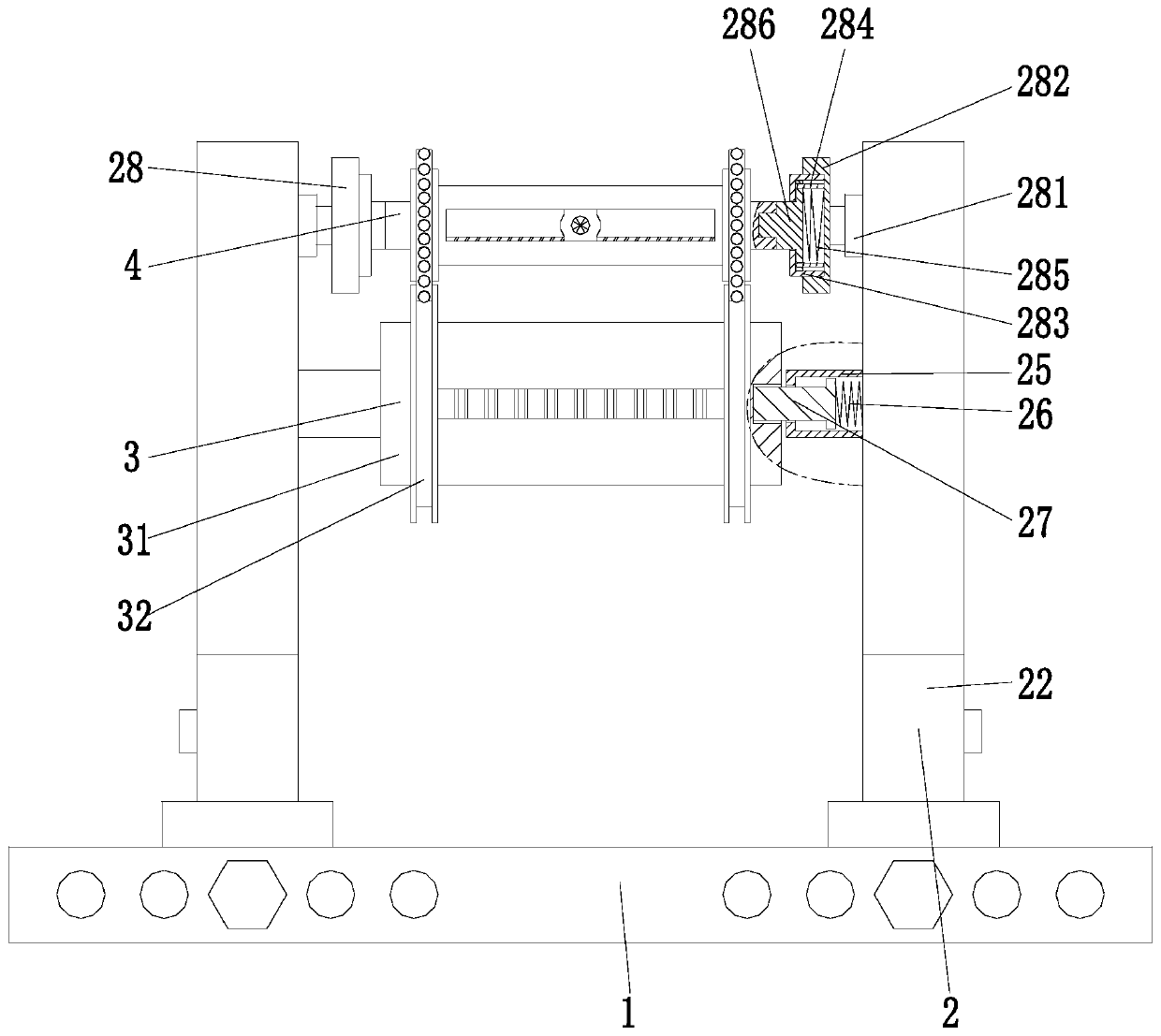

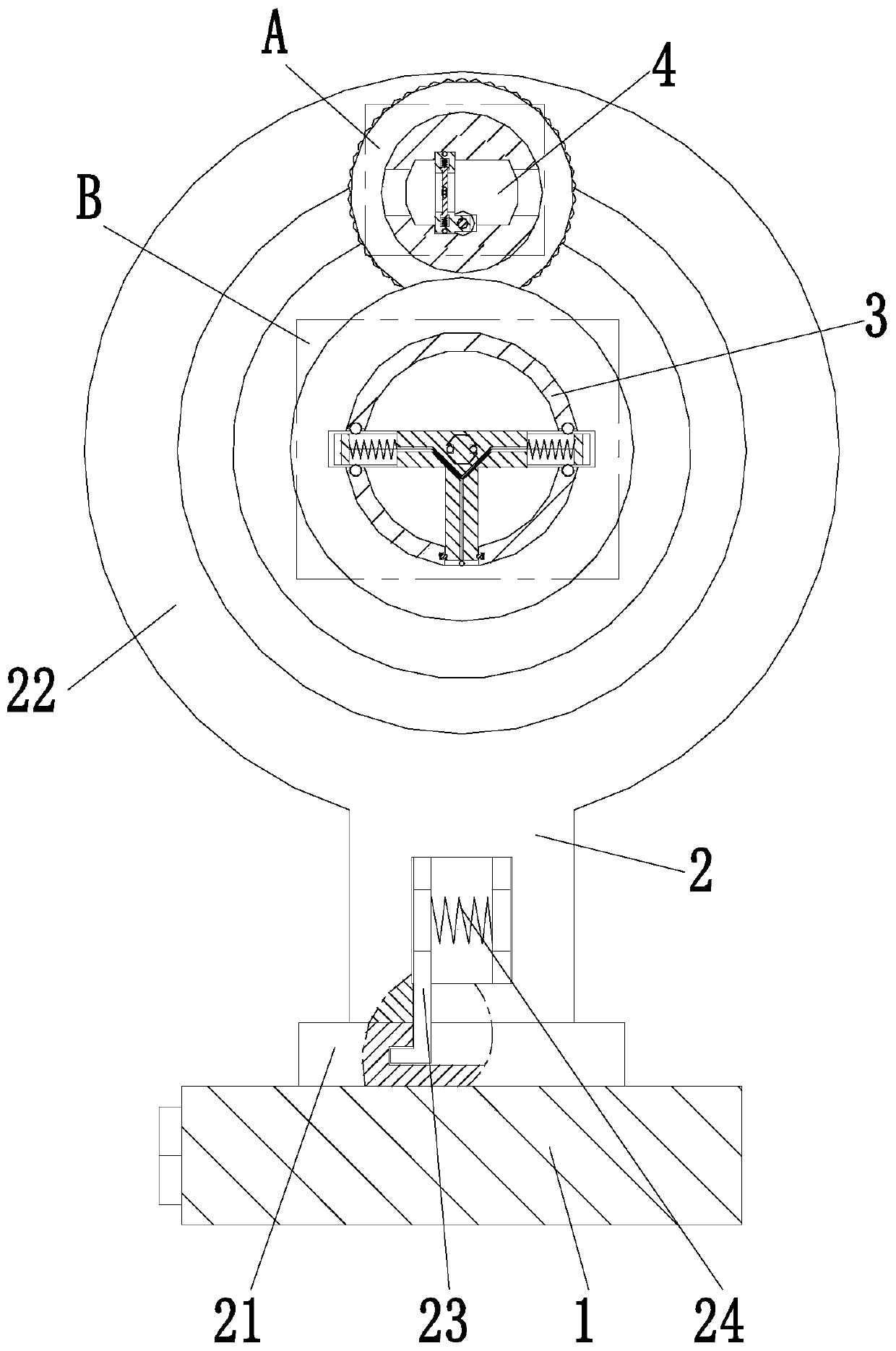

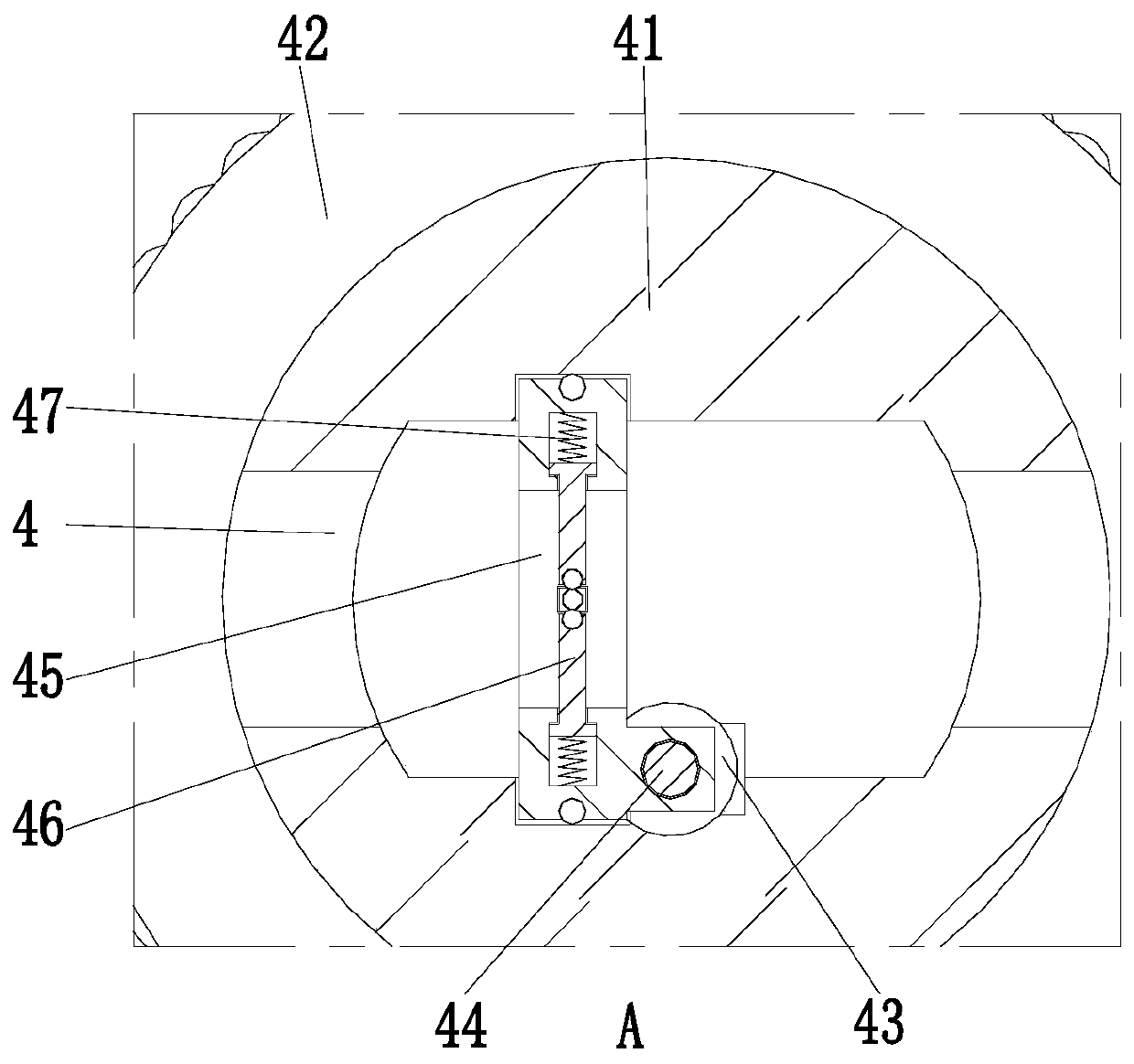

Frame-type single-stranding machine and working method thereof

ActiveCN103632773ALarge adjustment rangeRealize dockingCable/conductor manufactureLaser rangingSingle strand

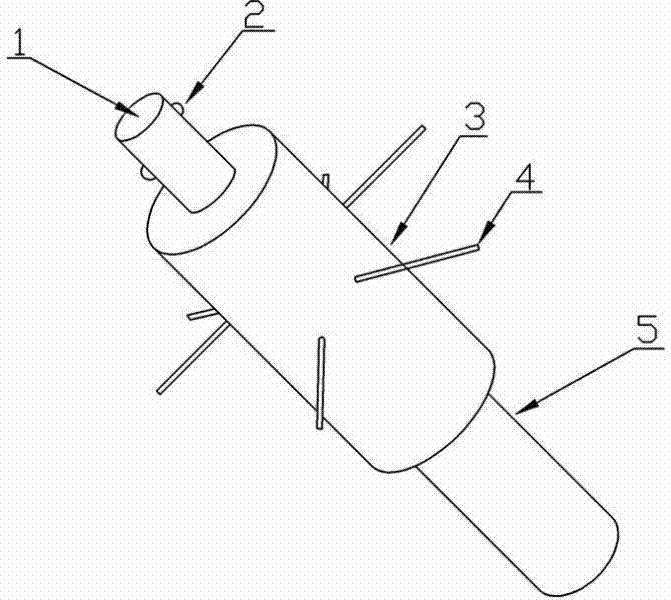

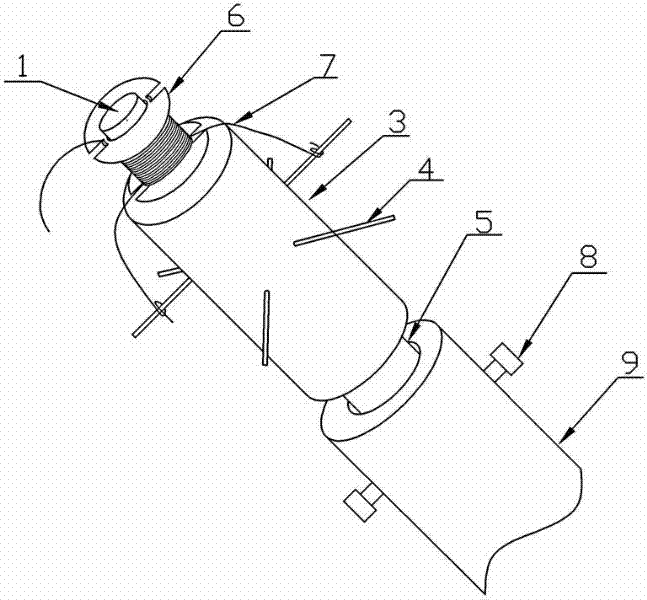

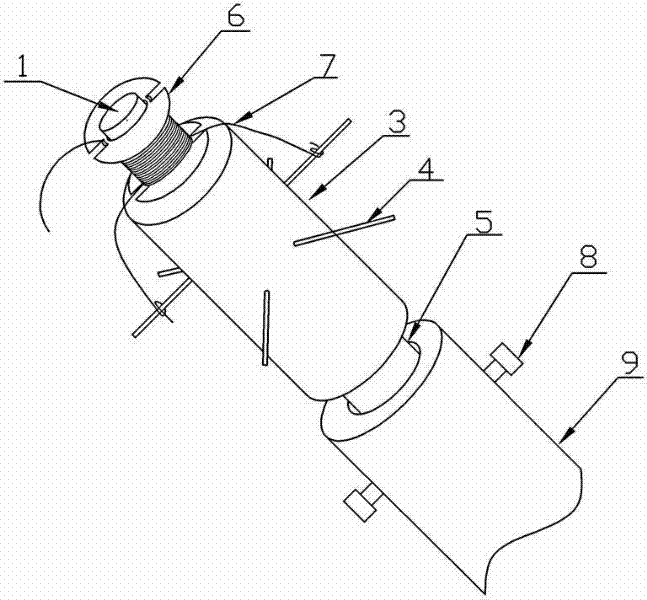

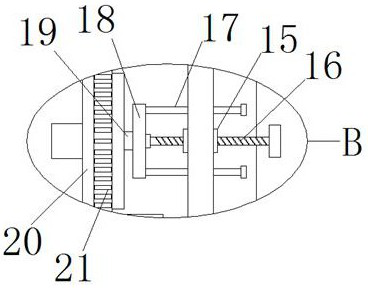

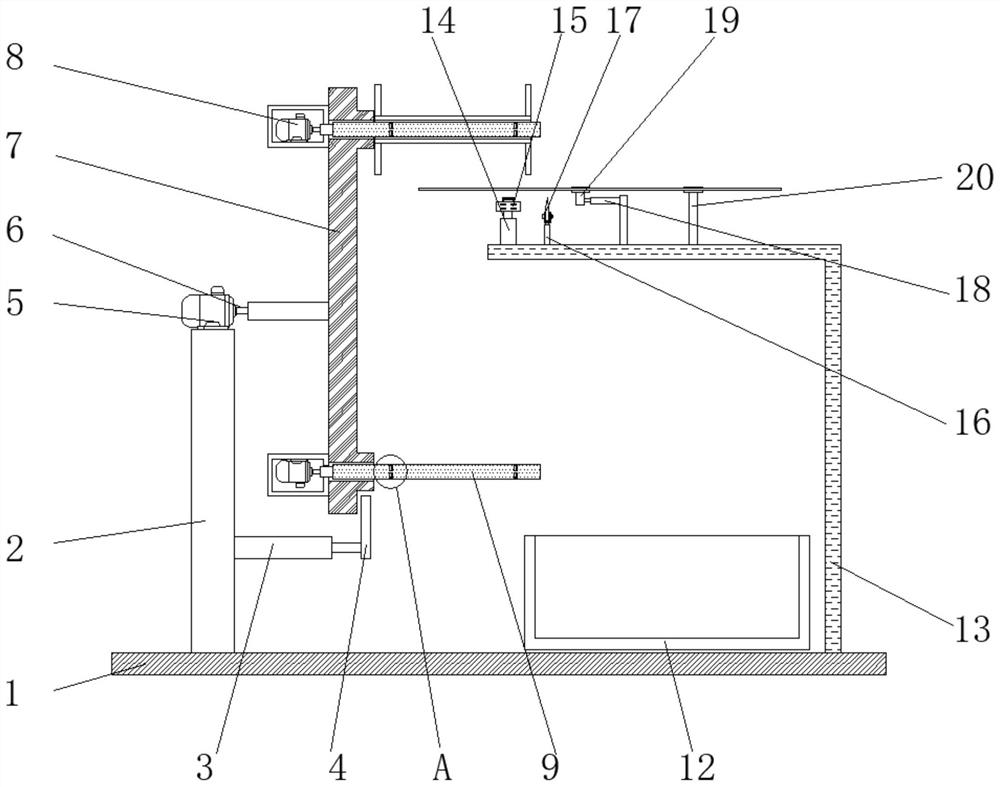

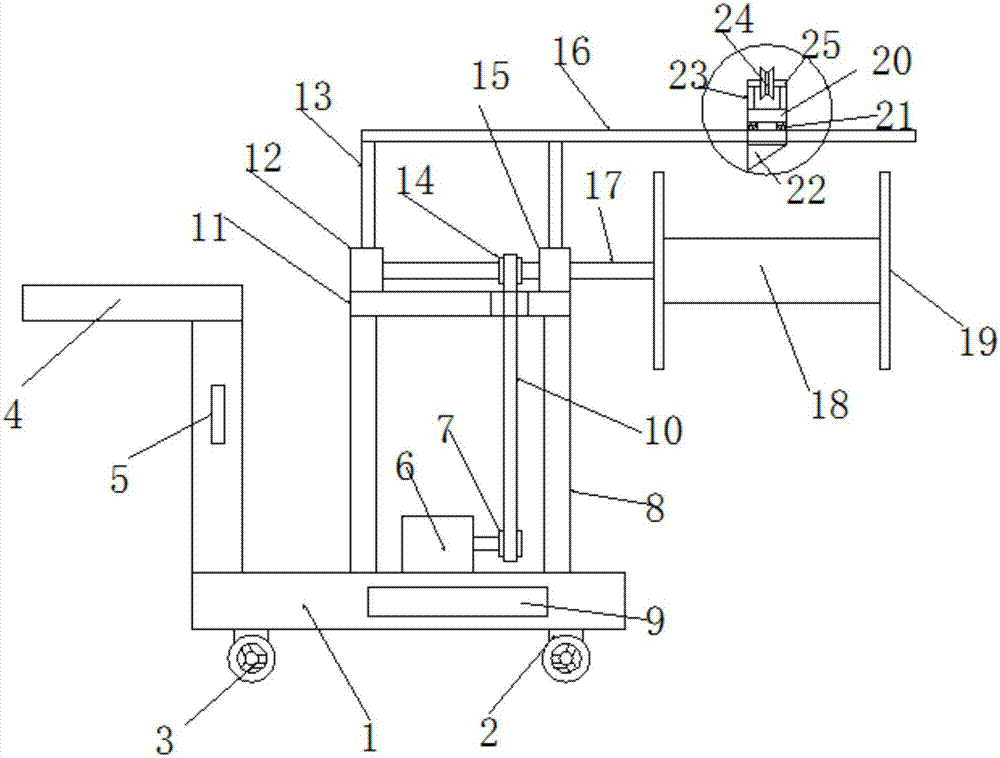

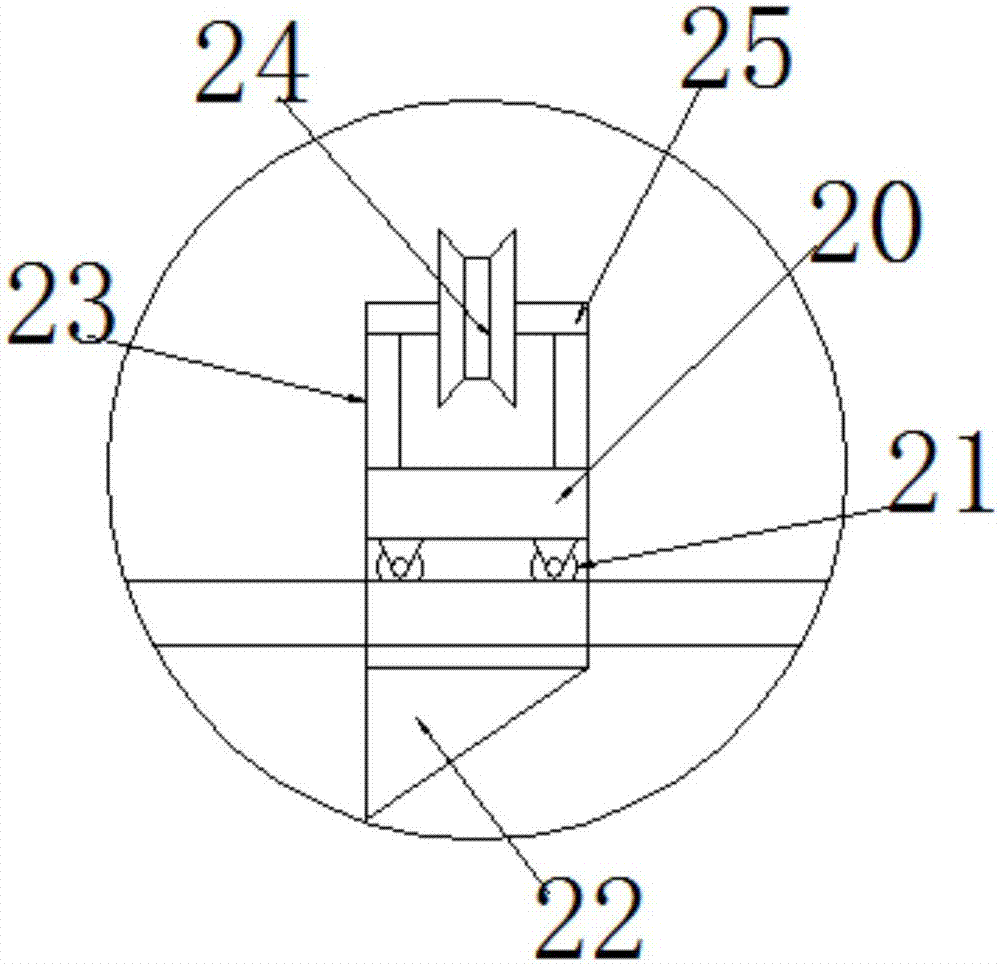

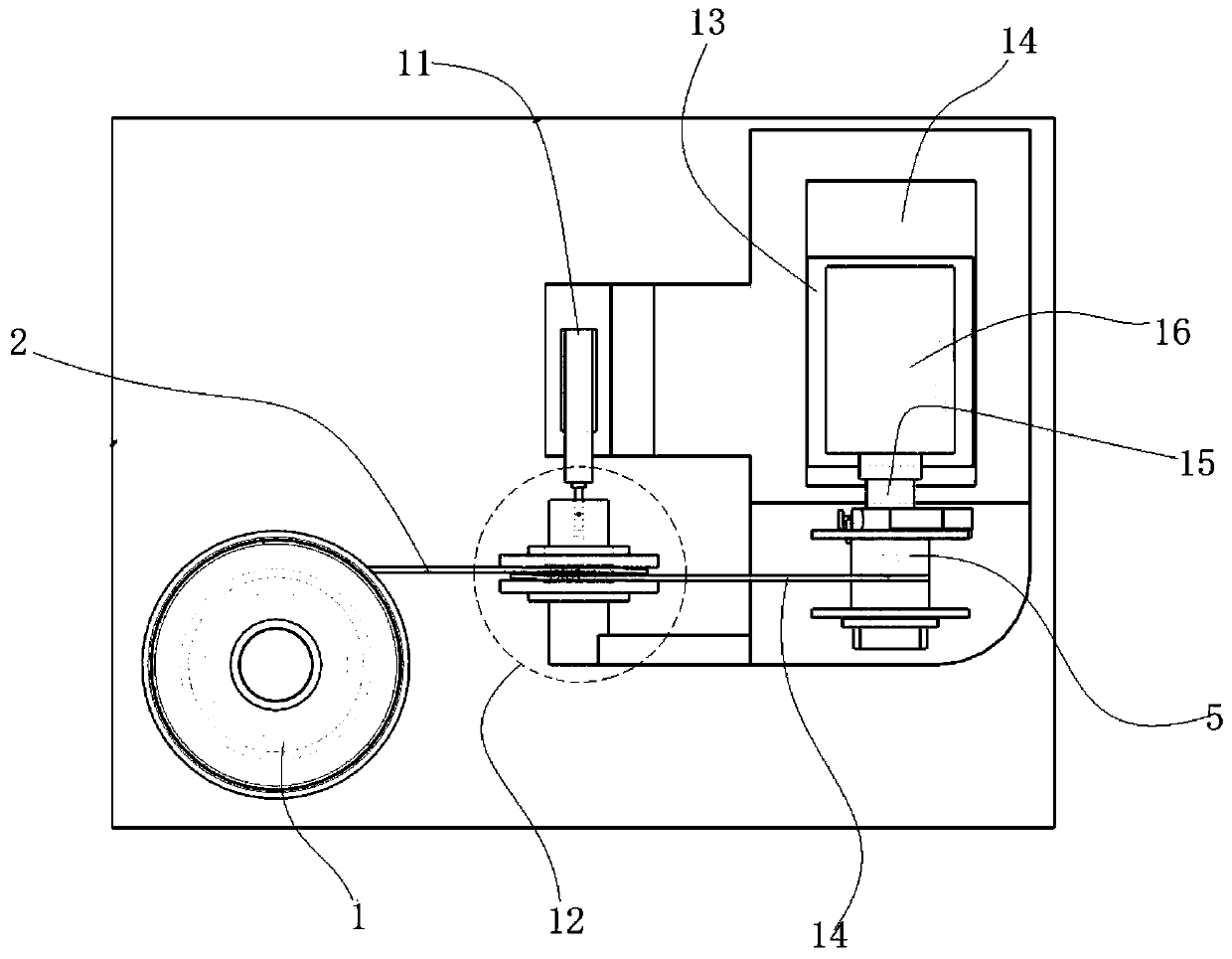

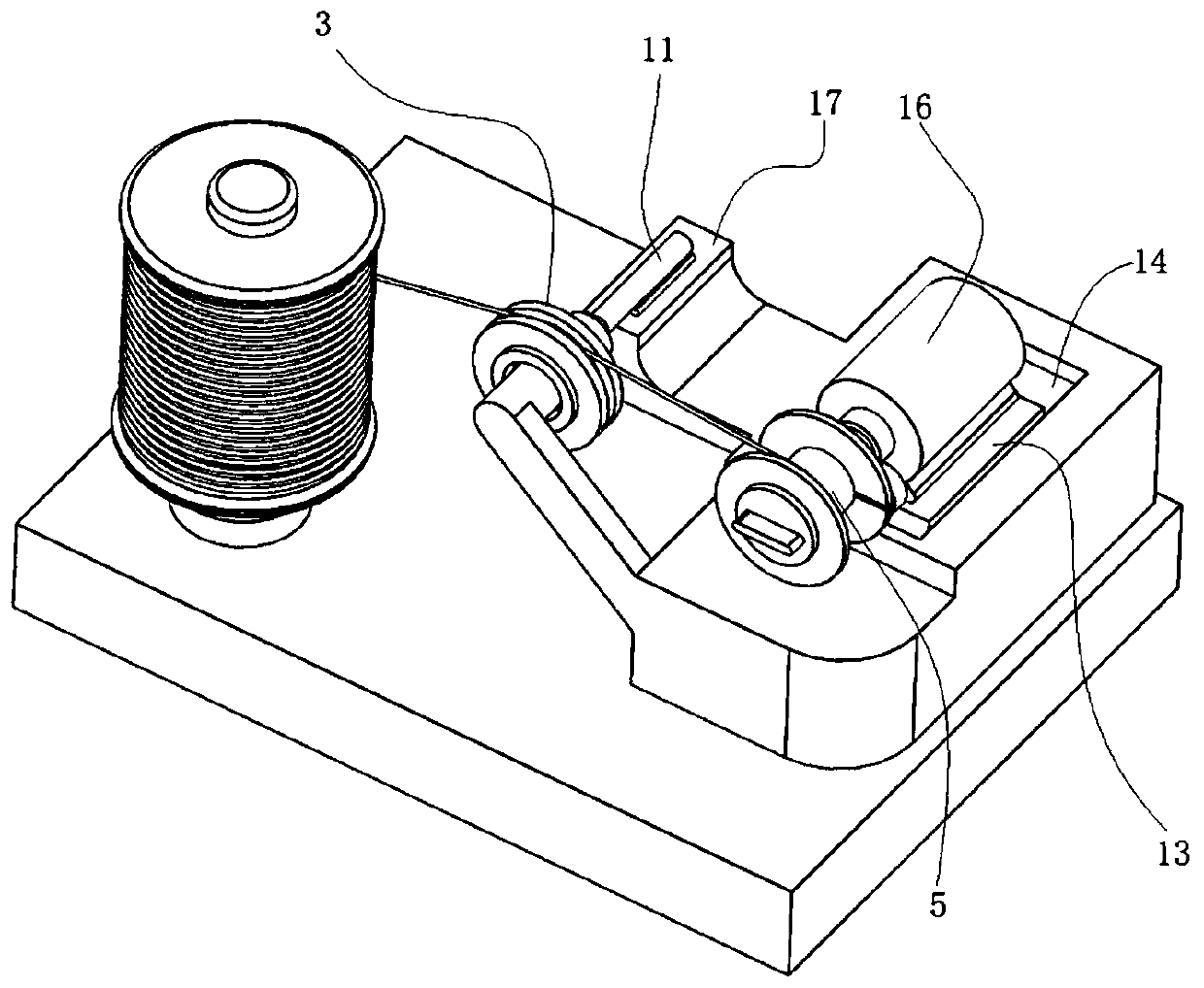

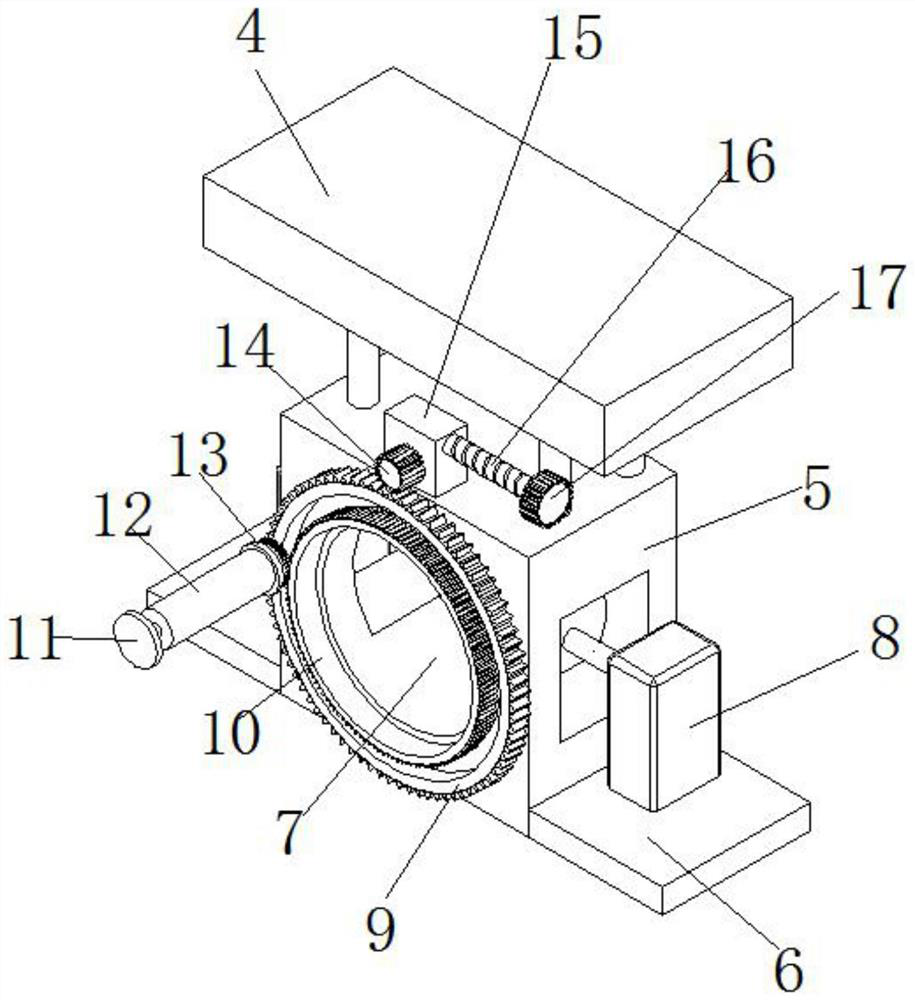

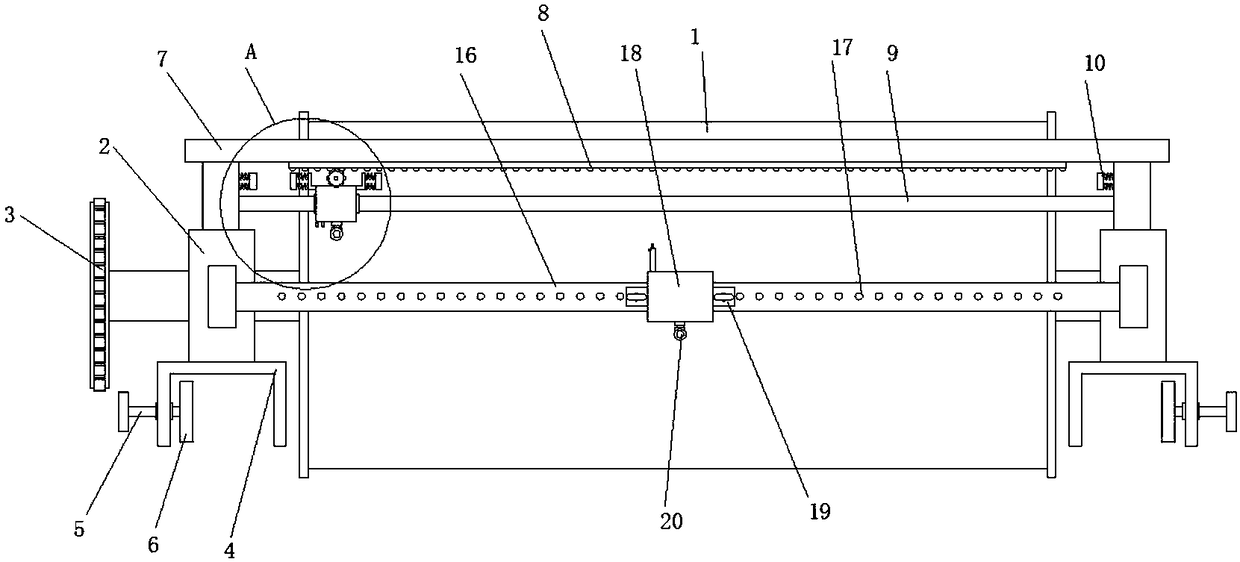

The invention relates to a frame-type single-stranding machine. A base is provided with a pair of supports Two, a motor One, a motor Two and a motor Three; a rectangular framework is arranged on the pair of supports Two in a bearing matching manner; each support Two is provided with a bearing seat One; the framework is arranged on the bearing seats One in a rotatable matching manner; wire-leading wheels are arranged in a left-side rectangular frame of the framework in a rotatable matching manner through a rotating shaft; the motor One drives the wire-leading wheels to rotate around the rotating shaft; and the outer circumference of each wire-leading wheel is provided with a plurality of wire slots. A wire coil is arranged in a right-side rectangular frame of the framework in a rotatable matching manner, and the central line of the wire coil is overlapped with the central line of the framework. A wire arranging mechanism used for uniformly winding cable wires on the wire coil is fixedly arranged above the wire coil in the right-side rectangular frame of the framework, the wire arranging mechanism is provided with a wire arranging frame, and the wire arranging frame is provided with a laser range finder One and a laser range finder Two. According to the frame-type single-stranding machine of the invention, the laser range finders are adopted to measure the thickness of wires wound on the wire coil; and through cooperation of the motors and a differential mechanism, precise matching between wire leading speed and wire winding speed can be ensured.

Owner:JIANGSU HANDING MACHINERY

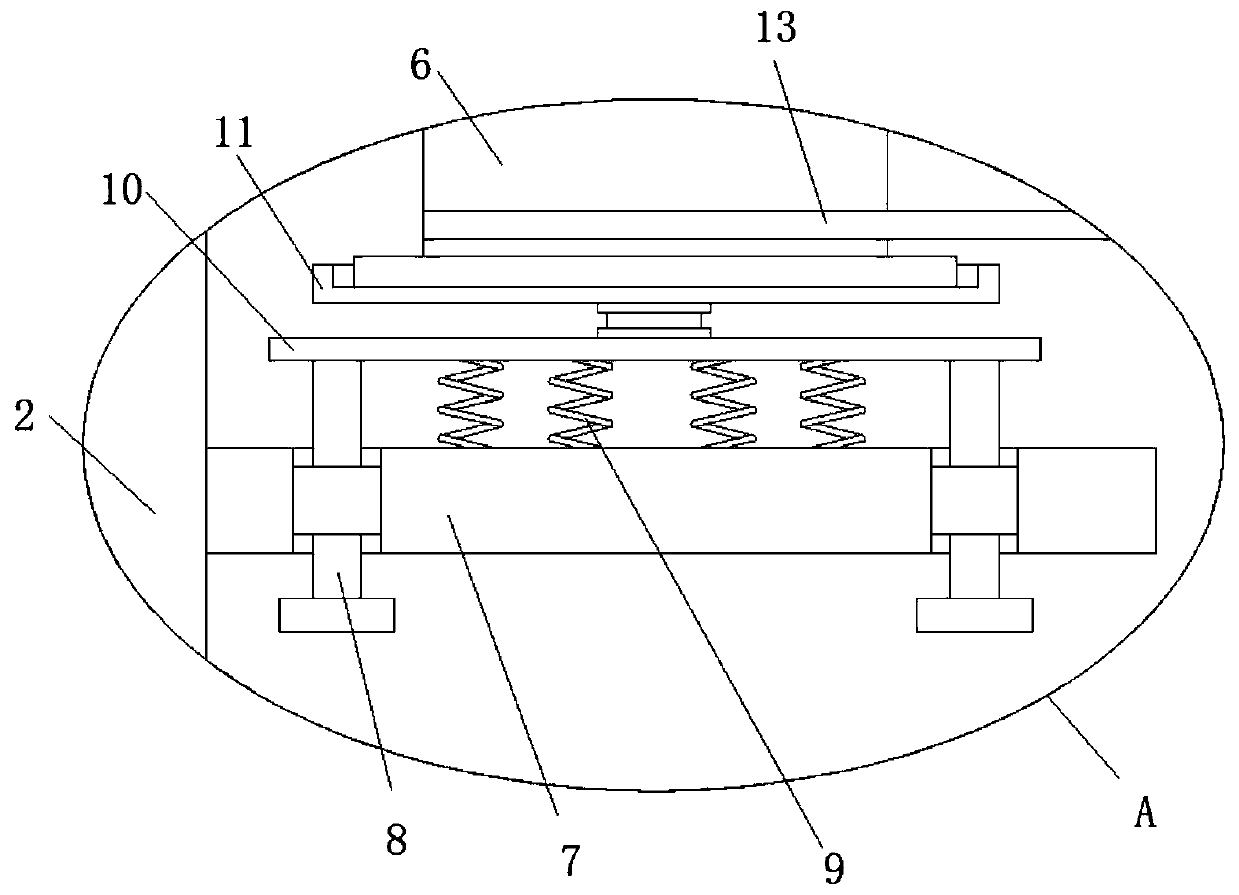

Device for evenly winding spinning yarn

The invention discloses a device for evenly winding spinning yarn. The device includes a base plate. A left vertical plate and a right vertical plate are vertically fixedly installed on the base plate, and top plates are vertically fixedly installed on the left vertical plate and the right vertical plate. The left side of the left vertical plate is provided with a driving motor, a driving shaft iscoaxially fixedly mounted on an output shaft of the driving motor, and a driving gear is coaxially fixedly mounted at the right end of the driving shaft. Returning springs are fixedly connected between the left vertical plate and a first fixed plate and between the left vertical plate and a second fixed plate respectively, the left end of each returning spring is fixed to the right side wall of the left vertical plate, and a pull rope extends rightwards horizontally and penetrates the right vertical plate. A limiting ring pulls the spinning yarn to move back and forth in the length directionof a winding roller, so that the spinning yarn can be evenly wound around the surface of the winding roller, which avoids the excessive concentration of the spinning yarn on a certain position on thewinding roller, achieves uniform winding of the spinning yarn and avoids the winding knotting of the spinning yarn. As a result, the winding quality is improved, the operation of the device can be achieved through the driving motor, and the device saves energy and is efficient.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

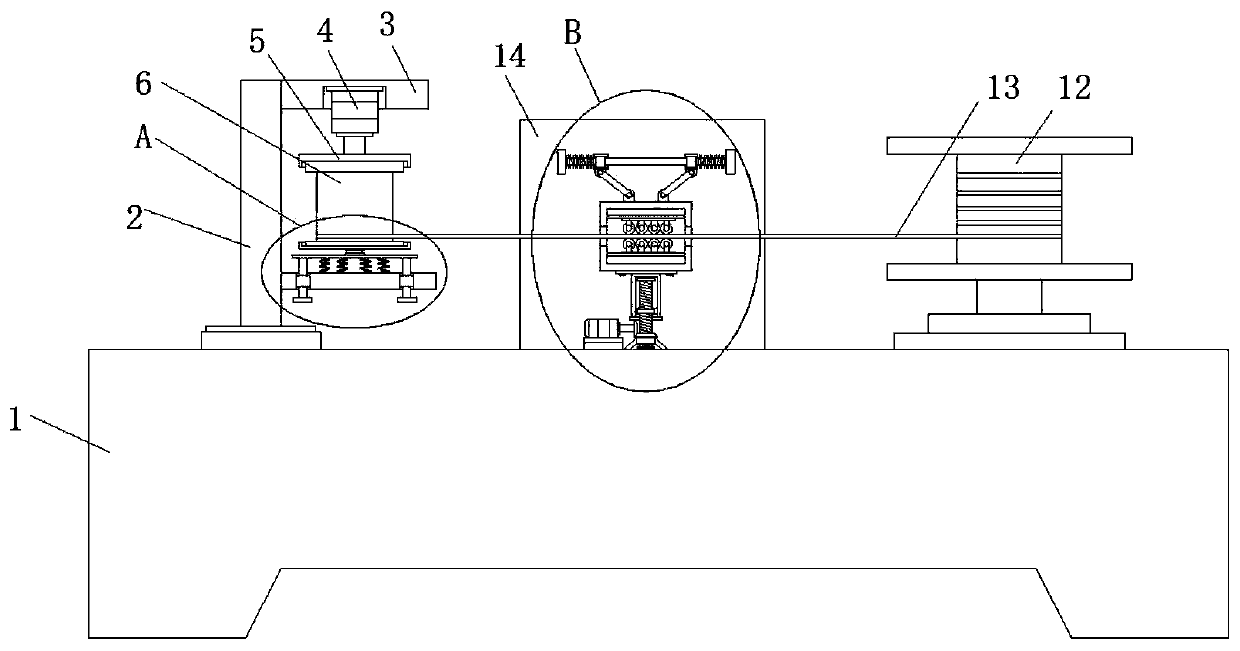

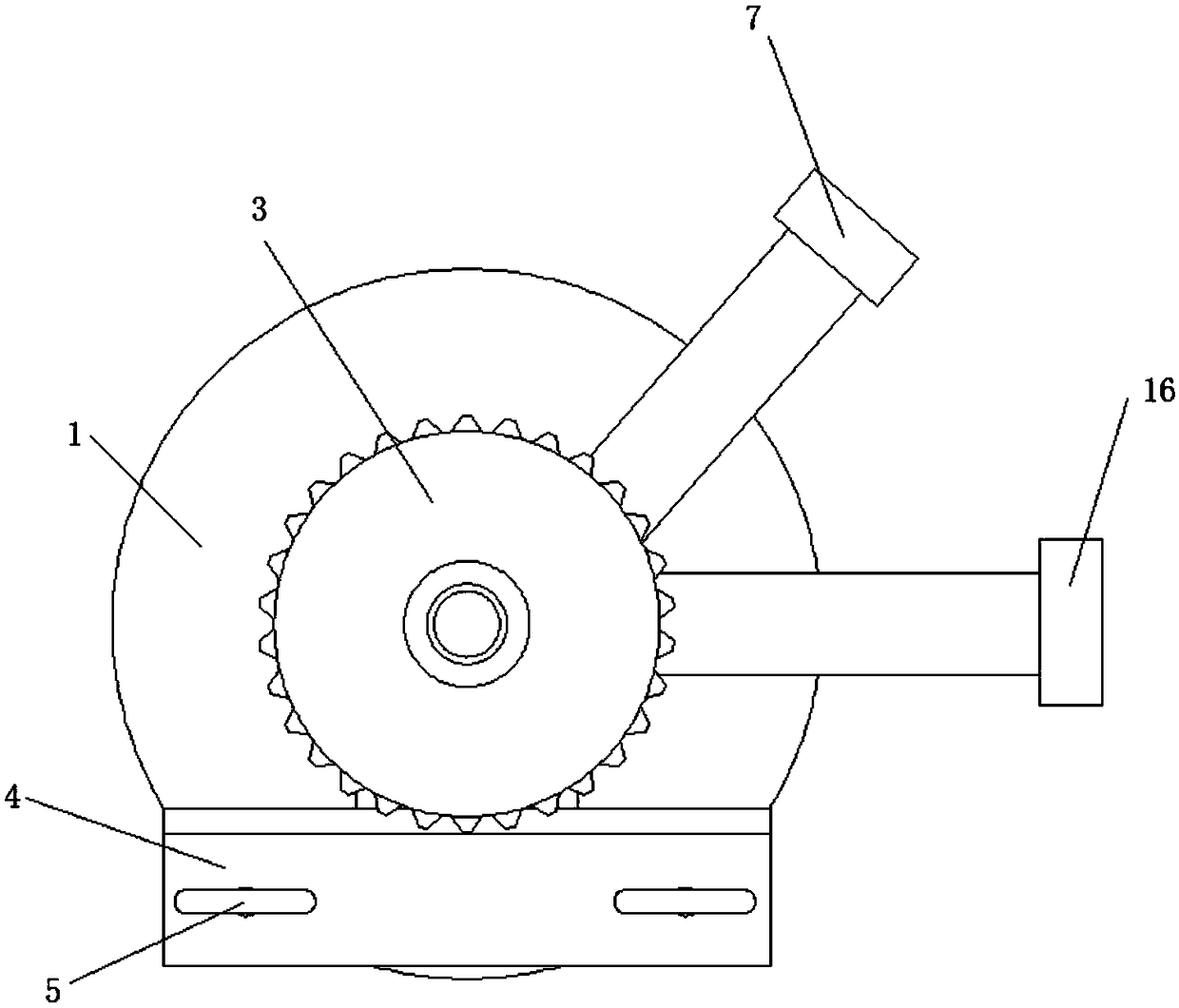

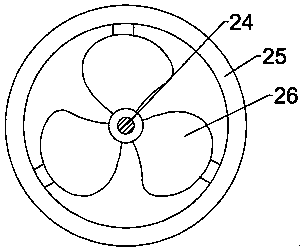

Wire adjusting mechanism of winding machine for winding fan housing

The invention discloses a wire adjusting mechanism of a winding machine for winding a fan housing. The mechanism comprises a rack, wherein the rack is provided with a straightening device for straightening a metal wire; the straightening device comprises a mounting block, a guide component and an adjusting component; the mounting block is arranged on the rack; the adjusting component is mounted on the mounting block and connected with the guide component; and the guide component is provided with a guide slot matched with the metal wire. The metal wire is straightened and output through the guide slot instead of manual straightening; the phenomenon of wire jump in the winding process is avoided, the metal wire is uniformly wound on the metal bracket, and the product quality is guaranteed; and moreover, the mechanism realizes automation, effectively improves the production efficiency, is safe and reliable, has wide application range, simplifies the production process and reduces the production cost.

Owner:吴兆超

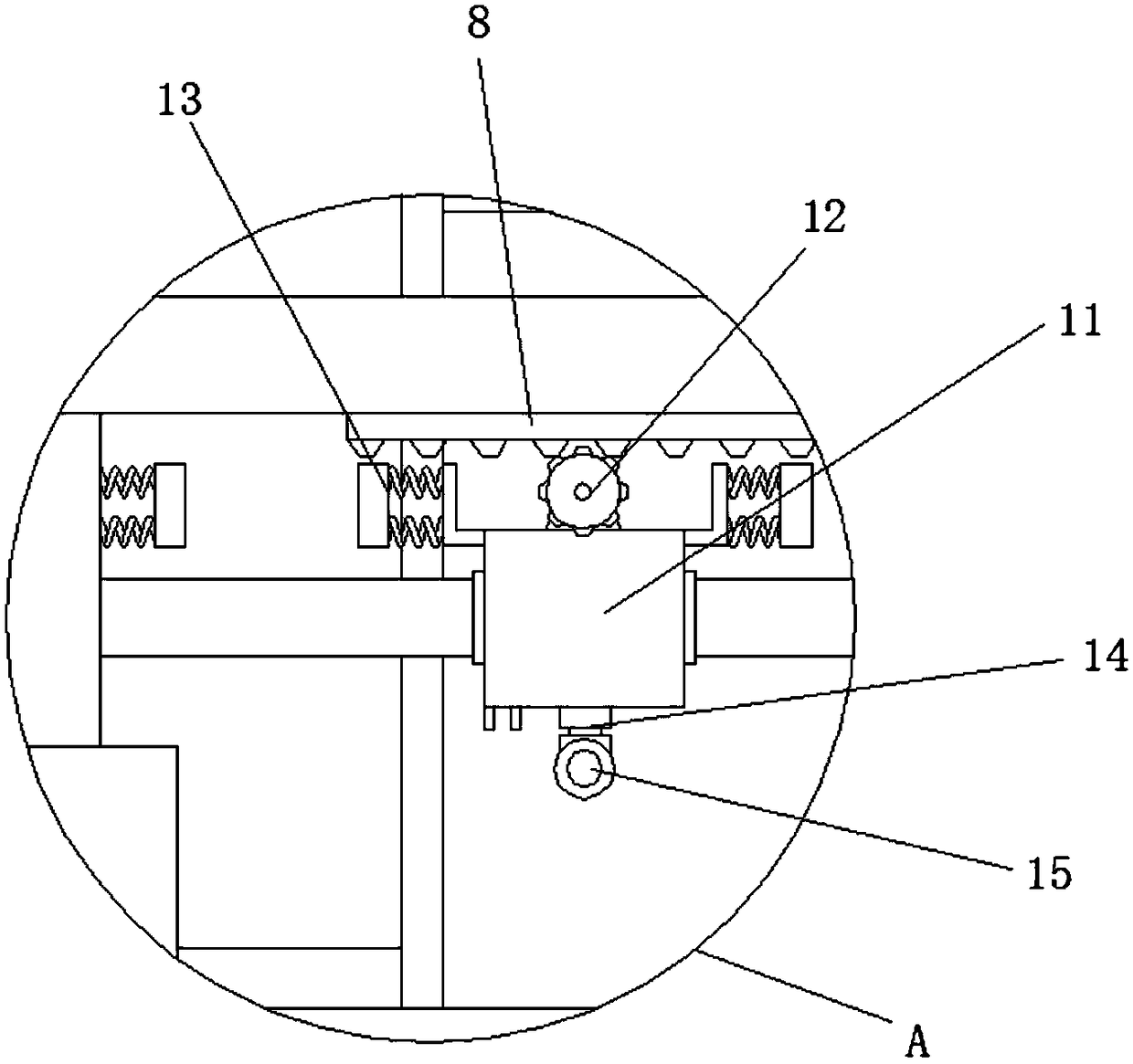

Winding device of square iron core inductor

The invention discloses a winding device of a square iron core inductor. The winding device comprises a workbench, wherein a support rod is fixedly arranged at the top of the workbench, a horizontal plate is fixedly arranged at the top of one side of the support rod, a driving motor is fixedly arranged at the bottom of the horizontal plate, an upper clamping seat is welded with an output shaft ofthe driving motor, an installation plate is fixedly arranged at one side of the support rod, two sliding rods are connected to the installation plate in a sliding way and are symmetrically arranged, tops of the two sliding rods extend to upper parts, opposite to each other, of the installation plate, and the same lifting plate is fixedly arranged at the tops of the two sliding rods. The winding device is simple in structure, and the inductor can be fixed by the upper clamping seat and a lower clamping seat; a coil can be slowly and uniformly wound around an outer side by the inductor under matching of the driving motor and a stepping motor, and artificial winding is not needed; and compared with traditional manual operation, the working efficiency is improved, more uniform winding is achieved, and the product yield is improved.

Owner:湖南俊宇电子科技有限公司

Auxiliary winding device for umbilical cord nursing gauze

The invention provides an auxiliary winding device for umbilical cord nursing gauze. The device comprises a bottom plate, a winding mechanism, supporting mechanisms and a fixing module, the winding mechanism is installed in the middle of the bottom plate, the supporting mechanisms are symmetrically arranged on front and back panels of the bottom plate, and the supporting mechanism located at the front end of the bottom plate is provided with the fixing module; the device can solve the main problems existing in the process of winding the gauze around the navel of an infant by a nurse that a, the newborn can be easily injured through too tight winding by the gauze, so that the newborn breathes difficultly; too loose winding by the gauze cannot achieve the binding effect; b, in the process ofwinding the gauze around the navel, the knotting and wrinkling phenomena can easily occur, so that the corners of the gauze are folded together, binding is uneven, and the binding effect is influenced; c, in the process of binding up the navel by the gauze, the newborn needs to be moved back and forth, bones of the newborn can easily fracture, and hidden safety dangers exist, and the device can achieve the function of automatically winding the umbilical cord gauze around the navel.

Owner:JILIN UNIV

Fixing device of coil framework of miniature transformer and method for winding coils

ActiveCN102420044ATightly coupledTightly woundTransformers/inductances coils/windings/connectionsCoils manufactureTransformerSteel ball

The invention relates to a fixing device of a coil framework of a miniature transformer and a method for winding coils. The fixing device of the coil framework consists of five parts, namely a framework fixing shaft, metal springs, steel balls, a tap fixing shaft, a tap fixing pin group and a connection shaft. A transformer framework is fixed and multi-winding taps are led out and fixed, the winding level of the miniature transformer is improved, and a method which is simple, high in efficiency, high in reliability and wide in application is provided for winding of the transformer. By adoption of the fixing device, the method for winding the coils is also improved. By performing the steps of installing a winding fixing device of the miniature transformer, installing the coil framework, winding the coils and fixing winding taps, the method has the advantages that: the winding efficiency of the miniature transformer is improved; the rate of finished products is improved from about 60 percent to above 95 percent, so that wasting is avoided; a transformer manufacturing process is simple and easy to operate; manufacturing efficiency is at least doubled; and the method is wide in application.

Owner:EAST CHINA INST OF OPTOELECTRONICS INTEGRATEDDEVICE

Winding device for transformer core

The invention belongs to the field of transformers, particularly relates to a winding device for a transformer iron core, and aims to solve the problems that in the iron core winding process of an existing winding device, firstly, an iron core cannot be conveniently fixed, and copper wires are easily distributed unevenly in the copper wire winding process, so that the quality problem of the produced iron core is easily caused, and the production cost is lowered. According to the technical scheme, the device comprises a base, a vertical plate is fixedly connected to the top of the base, a left side plate and a right side plate are fixedly connected to the vertical plate, the left side plate and the right side plate are provided with the same winding mechanism, a motor is fixedly installed on the vertical plate, and a worm is welded to an output shaft of the motor; when the device is used, an iron core can be simply and conveniently clamped and fixed, then the iron core is driven to rotate through clamping friction force, so that the purpose of winding a copper wire is achieved, the copper wire can be uniformly distributed on the iron core in the winding process, and the production quality is improved.

Owner:PENGLAI POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

High-automation-degree automatic reeling machine

PendingCN111960183AHigh degree of automationFirmly connectedFilament handlingElectric machineryMachine

The invention discloses a high-automation-degree automatic reeling machine. The high-automation-degree automatic reeling machine comprises a base and a motor, wherein a support is fixed to the left side of the upper end face of the base, a bearing frame is fixed to the right side of the upper end face of the base, a second electric telescopic column and a second electric telescopic rod are locatedon the left side and the right side of a third electric telescopic column correspondingly, a fixed sleeve is located on the right side of the second electric telescopic rod, and the left end of the second electric telescopic rod is connected with a movable sleeve. According to the high-automation-degree automatic reeling machine, after a silk thread penetrates through the movable sleeve and the fixed sleeve, a pasting device moves upwards, the head end of the silk thread can be conveniently and automatically pasted to a reel, after the pasting device moves downwards to the original position,the reel rotates along with rotation of a corresponding rotating rod, automatic reeling operation is facilitated, in the reeling process, the movable sleeve moves to the position below the reel firstand then moves left and right repeatedly below the reel, so that the silk thread can be evenly wound around the reel.

Owner:FUJIAN JINJIANG TECH

Improved communication cable coiling and uncoiling device

The invention discloses an improved communication cable coiling and uncoiling device, which comprises a base. Support legs are symmetrically arranged at two sides of the lower end of the base; rolling wheels are arranged on the lower ends of the support legs; a handrail is arranged at the left upper side of the base; an installation plate is horizontally arranged above the base; two sides of the lower end of the installation plate are connected and fixed with the based through support pillars; a No. 1 bearing seat and a No. 2 bearing seat are respectively arranged at two sides of the upper end of the installation plate; a rotary shaft is arranged on the No. 1 bearing seat and the No. 2 bearing seat in a penetrating way; a rope coiling roller is fixed to the right end of the rotary shaft; a driven pulley is arranged on the rotary shaft between the No. 1 bearing seat and the No. 2 bearing seat; a drive motor is fixed onto the base below the installation plate; a drive pulley is arranged at the output end of the drive motor; the drive pulley and the driven pulley are in transmission connection through a belt; a slide plate is arranged above the rope coiling roller. The improved communication cable coiling and uncoiling device provided by the invention is simple and reasonable in structure and convenient to transport, and a cable can be uniformly wound on the rope coiling roller from left to right, so that the utilization ratio of a rope coiling space of the rope coiling roller is maximized.

Owner:杭州宇飞电缆有限公司

Yarn bobbin device for textile machinery

The invention relates to the technical field of textile machinery, in particular to a bobbin device for textile machinery, which comprises a base and a worktable, a first vertical plate and a second vertical plate are vertically mounted on two sides of the top of the worktable respectively, a bobbin is horizontally and rotatably connected between the first vertical plate and the second vertical plate, and a driving mechanism is arranged on the side surface of the first vertical plate. A supporting structure is arranged in the second vertical plate, the two ends of the spool are sleeved with limiting discs, a moving mechanism is arranged in the spool, moving columns are vertically welded to the two sides of the bottom of the workbench, pulleys are installed at the bottoms of the two moving columns, and a reciprocating moving mechanism for driving the workbench to move left and right is arranged in the base. According to the device, the defects in the prior art are overcome, the bobbins can be adjusted through the moving mechanism, the driving mechanism and the reciprocating moving mechanism, the diameters of the bobbins are the same all the time, the tensioning force can be adjusted, and yarn can be evenly wound on the bobbins in a left-right back-and-forth rotating mode.

Owner:苏州绿杰纺织有限公司

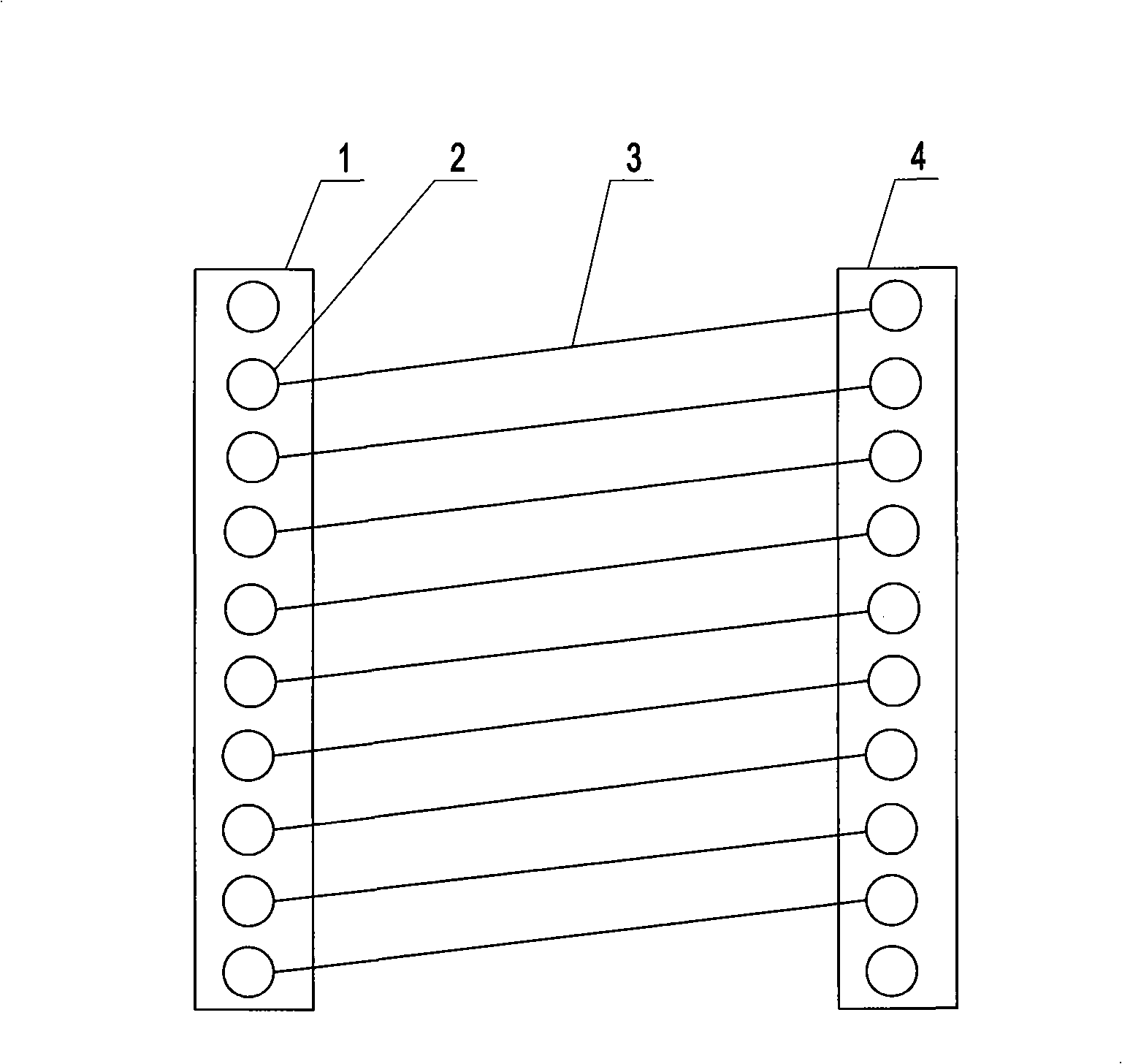

Current mutual inductor coil excitation characteristic test wire winding tool equipment

The invention discloses an excitation characteristic test coiling frock for a coil of a current mutual inductor. The coiling frock comprises two insulating boards and a plurality of conducting wires, both ends of which are fixed onto the two insulating boards. A locking device is arranged on the two insulating boards. After the two insulating boards are fastened, a plurality of conducting wires are connected end to end in sequence to form a loop. The interval and the length of the conducting wires are fixed, so the coil is coiled up by fastening the two insulating boards only. The test coiling frock has the advantages of even coiling, high working efficiency, small coiling radian and long service life. In addition, materials and labor are saved.

Owner:STATE GRID CORP OF CHINA +1

Inductor enameled wire winding process device and process thereof

InactiveCN110931246AControl the initial air pressureControl tightnessCoils manufactureBobbinElectric machine

The invention discloses an inductor enameled wire winding process device comprising an inductance coil framework of a to-be-wound guide coil, the inductance coil framework comprises a bobbin, an ironcore insertion hole coaxially penetrating through the bobbin is formed in the bobbin, and a first wire coil and a second wire coil are coaxially arranged at the two ends of the bobbin respectively; afirst wire passing groove and a second wire passing groove which extend in the radial direction are symmetrically formed in the two sides of the second wire coil in a hollowed-out mode. The device issimple in structure, the position of the first piston in a first piston channel can be controlled through the linear motor, so that the initial air pressure in the air pressure cavity is controlled, the magnitude of the upward air pressure borne by a second piston is controlled, the rotation resistance of a transition wire roller is adjusted, and the tightness degree of a second outgoing wire wound on the bobbin is controlled.

Owner:陆林娣

Winding device for textile thread processing

InactiveCN112537699AEasy winding handlingContinuous and efficient winding operationFilament handlingEngineeringStructural engineering

The invention discloses a winding device for textile thread processing. The winding device comprises a thread guiding mechanism, a locking mechanism, a rotating frame and a conveying belt device, a second sliding block is slidably connected into the rotating frame, a clamping plate is slidably connected into the second sliding rail, and the conveying belt device is rotatably connected between supporting plates. According to the winding device for textile thread processing, the front half part of the conveying belt device is used for conveying empty winding reels, and the rear half part of theconveying belt device is used for conveying the winding reels wound with threads; hook-and-loop fasteners are fixed to the surfaces of the outer sides of the winding reels, and after one ends of the textile threads manually penetrate through a thread guide barrel to adhere to one winding reel on the left side of the upper end face of a rotating table, the winding reel rotates so that the textile threads can be conveniently wound; after one reel of textile threads is wound, the rotating table horizontally rotates by 180 degrees, so that the textile threads adhere to the other winding reel; andafter the textile threads are cut off through shear knives, winding operation can be continued to be conducted by the other winding reel, and therefore the whole winding operation is continuous and efficient.

Owner:徐州银宇纺织有限公司

Efficient winding device for optical fiber gyroscope production

The invention discloses an efficient winding device for optical fiber gyroscope production, and relates to the technical field of optical fiber gyroscope winding devices. To enable the tightness of a wire rod to be conveniently regulated and controlled, the device specifically comprises a mounting table, a mounting frame is arranged on the outer wall of the top of the mounting table, a pay-off motor is arranged on the outer wall of one side of the mounting frame, the output end of the pay-off motor is rotationally connected with a pay-off wheel, and a wire is wound around the pay-off wheel; and a translation mechanism is arranged on the outer wall of the top of the mounting table, and a movable frame is movably connected into the translation mechanism. By arranging the pay-off wheel, a rotating cylinder, an optical fiber ring and other structures, when the acting force reaches a certain degree, the deformation of a movable tooth spring causes a movable tooth to slide into the next meshing tooth, so that a mounting disc rotates by the angle of one meshing tooth relative to the rotating cylinder, the tightening state of a wire is relieved, the borne tension is reduced, the phenomenon that the wire is pulled to be damaged is effectively avoided, the rotating speed of a winding motor and the rotating speed of the pay-off motor do not need to be accurately controlled, and reliability is improved.

Owner:青岛君戎汇通光电科技有限公司

Uniform cable reeling device for vertical shaft cable production

The invention discloses a uniform cable reeling device for vertical shaft cable production. The uniform cable reeling device for vertical shaft cable production comprises a transmission shaft and a driving motor. One end of the transmission shaft is sleeved with a driven gear disk and a first bevel gear from left to right in sequence. An output shaft of the driving motor is in transmission connection with a driving gear disk. The driving motor is in engaged transmission connection with the driven gear disk through the driving gear disk. The first bevel gear is in transmission connection with atransmission rod. According to the uniform cable reeling device for vertical shaft cable production, the driving motor is started to rotate, the first bevel gear is in engaged transmission connectionwith a second bevel gear to rotate, and then a limiting rod at one end of the transmission rod is made to slide in a sliding groove; as a sliding bar welded to one side of the sliding groove can onlyslide in the horizontal direction, the sliding bar does left-right reciprocating motion and is then is in linkage with clamping blocks on the top of the sliding bar to do left-right reciprocating motion; through cooperation with a cable reel on one side, a cable passes through the clamping blocks to be uniformly wound around the cable reel; and in this way, uniform winding of the cable is completed.

Owner:CRANE GRP OF HUNAN CABLE TECH

Cable insulation layer shrinkage processing device and process

InactiveCN111696729ANot prone to burrs, etc.Improve protectionFilament handlingInsulating conductors/cablesPolyesterInsulation layer

The invention relates to a cable insulation layer shrinkage processing device and process. The device comprises a cable supply mechanism, a film coating mechanism and a winding mechanism, wherein thecable supply mechanism is used for supplying cables, the film coating structure comprises a chassis, a box body fixedly connected with the chassis, a first working chamber formed in the box body and afilm coating assembly arranged in the first working chamber, the box body is provided with a wire inlet communicated with a first workshop, an upper surface of the box body is provided with a wire outlet, the coating assembly is used for coating a polyester film on a cable, and the winding mechanism is used for winding the coated cable. The device has the effect of preventing burrs from appearingon a cross section of a cable insulation layer.

Owner:北京朝阳隆华电线电缆有限公司

Take-up device for electric power

InactiveCN111847104AWon't relaxAvoid knotsFilament handlingApparatus for overhead lines/cablesElectric powerElectric wire

The invention discloses a take-up device for electric power. The take-up device comprises a base, wherein supporting frames are fixedly mounted on two sides of the base; a wire roller assembly is arranged between the two supporting frames; a take-up adjusting assembly is arranged on the base; the take-up adjusting assembly comprises slide blocks, a mounting plate, a roller and fixed plates; the two slide blocks are arranged on the base, and each of the two slide blocks is provided with a wire hole; the mounting plate is fixedly mounted above the slide blocks; the two fixed plates are symmetrically arranged at the lower end of the mounting plate; each fixed plate comprises a sleeve rod, a sleeve and a connecting spring; the sleeves are fixedly mounted on the mounting plate; each sleeve rodis movably arranged in the corresponding sleeve in a sleeving manner, and each connecting spring is arranged between the corresponding sleeve rod and the corresponding sleeve; the roller is rotatablymounted between the two sleeve rods; through arrangement of the take-up adjusting assembly, an electric wire on the wire roller assembly penetrates through the wire holes of the two slide blocks in atake-up process; and under the action of the connecting springs, the roller abuts against the electric wire all the time, so that the electric wire released from the wire holes is not loosened all thetime and is prevented from being knotted.

Owner:宋允华

Preparation method for marten hair-simulating shell fabric

The invention relates to a preparation method of a shell fabric, in particular to a preparation method for a marten hair-simulating shell fabric. The preparation method primarily solves the technicalproblems that existing marten hair-simulating shell fabrics in the prior art are relatively poor in thick and solid feeling, flexibility, fluffiness and smoothness and are quite different from true hairs in color and luster and hand feeling, and the whole processing course is relatively poor in degree of automation, the qualities are irregular and the like. The preparation method comprises the following steps: beaming velvet yarns and ground yarns on a beaming mechanism; then weaving the velvet yarns and the ground yarns by a warp knitting mechanism to obtain a gray fabric; feeding the gray fabric into a sizing mechanism to be sized and then luster-finishing the gray fabric; feeding the gray fabric into a dyeing and finishing mechanism to be dyed to form a patterned fabric, then steaming and color-fixing the pre-roasted fabric, and washing, dehydrating and drying the fabric after smooth treatment and flexible treatment; feeding the patterned fabric into a hair reduction mechanism for hair reduction, and successively carrying out hair brushing, luster finishing and shearing, pattern finishing, tailoring and sewing to finally obtain the marten hair-simulating shell fabric.

Owner:HANGZHOU ZHENGDA TEXTILE

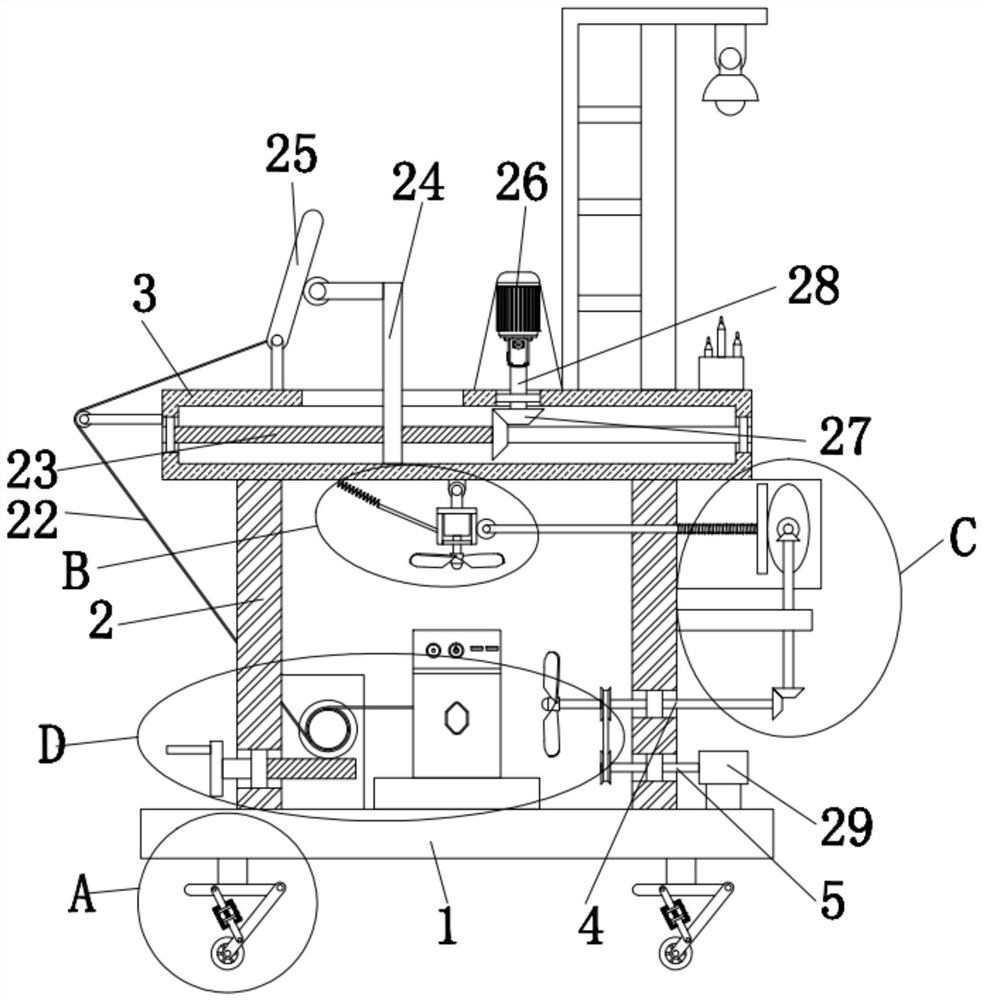

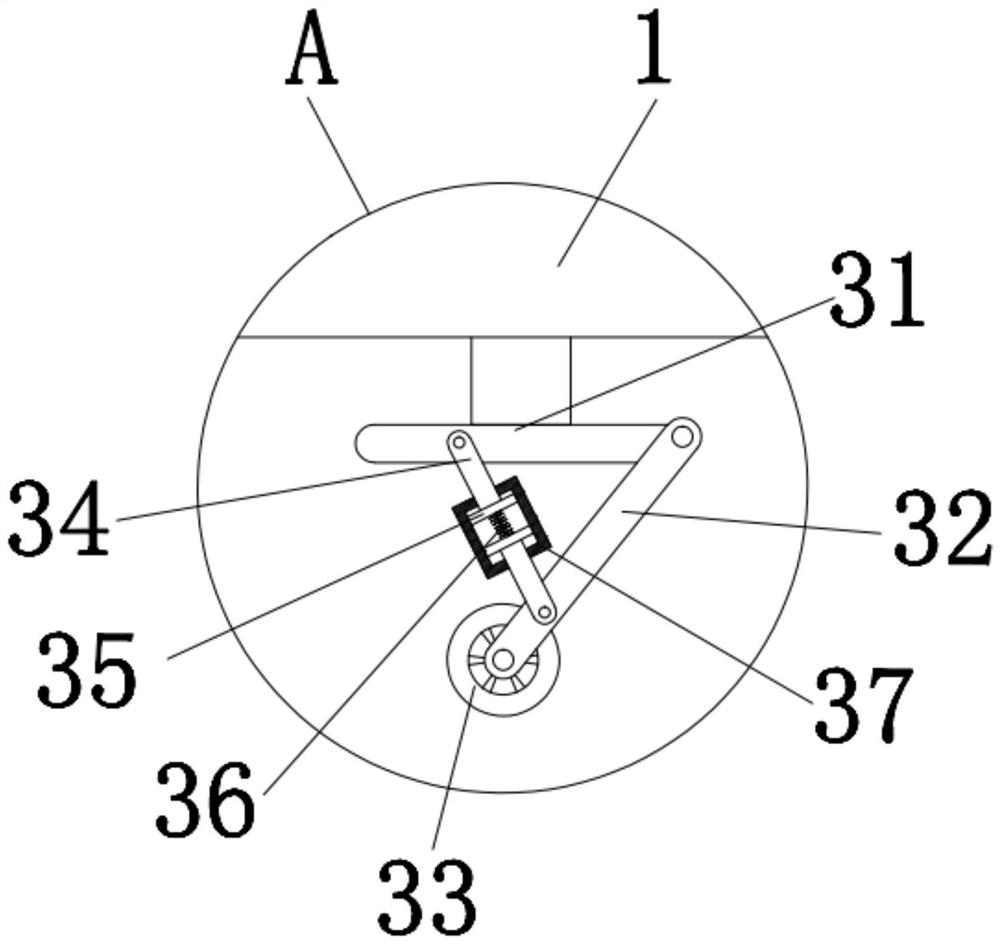

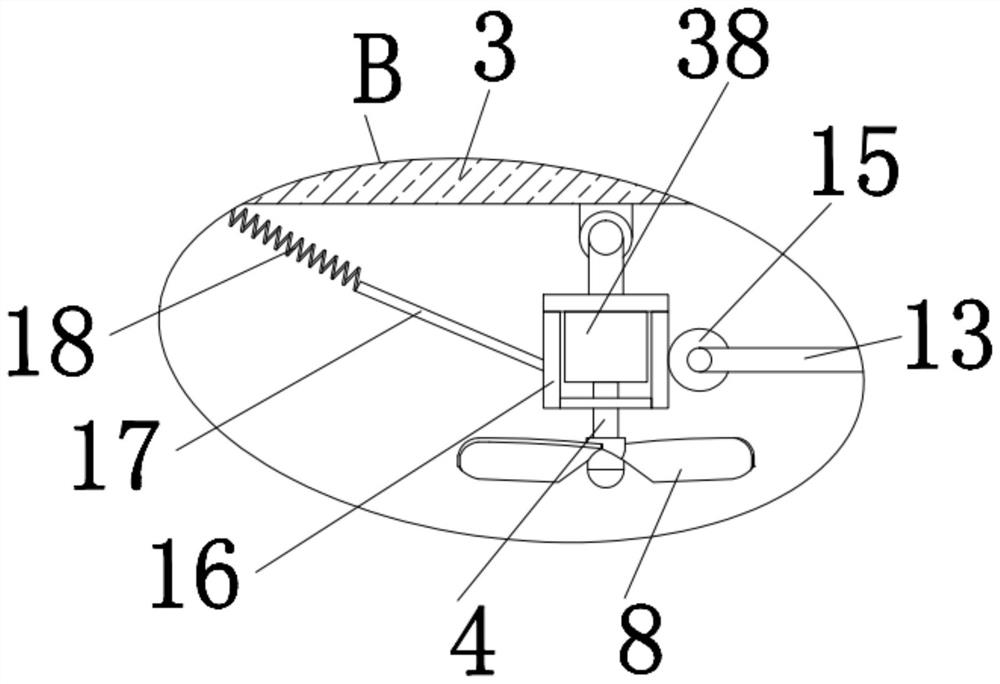

Big data interactive teaching practical training platform and use method thereof

InactiveCN112435511AReduce tanglingExpand the cooling rangeStands/trestlesElectrical appliancesEngineeringFan blade

The invention relates to the technical field of practical training platforms, and discloses a big data interactive teaching practical training platform and a using method thereof. The big data interactive teaching practical training platform comprises a base, two supporting plates are fixedly installed at the top of the base, the same platform is fixedly installed at the tops of the two supportingplates, a connecting shaft is rotatably mounted in one of the two supporting plates, a rotating box is rotatably mounted at the bottom of the platform, rotating shafts are rotatably mounted in the rotating box and in one of the two supporting plates, and fan blades are fixedly mounted at one ends of the two rotating shafts. The teaching platform is reasonable in design, the host body in the teaching platform can be subjected to heat dissipation treatment, so that the service life of the teaching platform is prolonged, the display screen can be adjusted through the arranged threaded rod, so that different use angles are obtained, the teaching platform can meet different users, and the flexibility is high.

Owner:周英锋

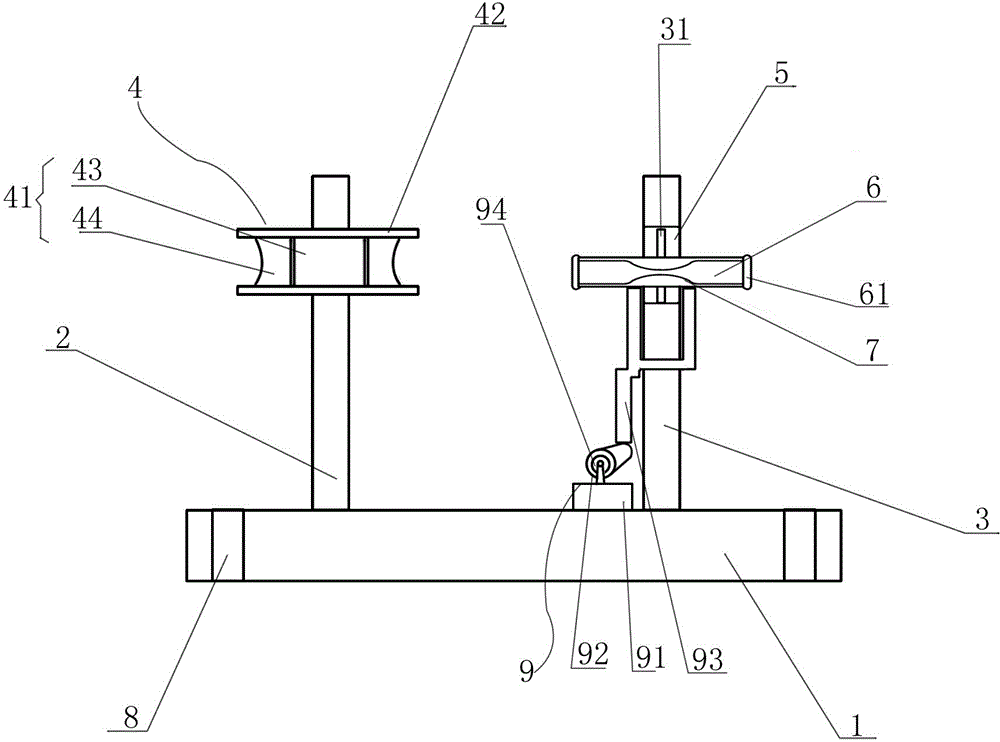

Entwist-prevented winder device for spinning

The invention discloses an entwist-prevented winder device for spinning; the entwist-prevented winder device for spinning comprises a base; the base is respectively provided with a first upright column and a second upright column which are used for installing a winder for winding and a yarn carding tube; the winder is used for winding yarns; and the yarn carding tube is used for carding the yarns; a strip-type through hole is arranged on the second upright column at the same height as the winder; slide rails arranged on bilateral sides of the strip-type through hole are used for being connected with the yarn carding tube; the yarn carding tube is able to move up and down along with the slide rails; a cam device on the base contacts with the yarn carding tube; under the effect of a motor, the cam device drives the yarn carding device to swing up and down, so as to uniformly wind the yarns on the winder; the occurrence of entwisting is effectively reduced. The entwist-prevented winder device for spinning has the advantages of simple in structure, convenient in use, low cost, and the like.

Owner:SONGLING BRANCH WUJIANG MINGMIN GARMENTS

A frame-type single twisting machine and its working method

ActiveCN103632773BLarge adjustment rangeRealize dockingCable/conductor manufactureLaser rangingElectric machinery

The invention relates to a frame-type single-stranding machine. A base is provided with a pair of supports Two, a motor One, a motor Two and a motor Three; a rectangular framework is arranged on the pair of supports Two in a bearing matching manner; each support Two is provided with a bearing seat One; the framework is arranged on the bearing seats One in a rotatable matching manner; wire-leading wheels are arranged in a left-side rectangular frame of the framework in a rotatable matching manner through a rotating shaft; the motor One drives the wire-leading wheels to rotate around the rotating shaft; and the outer circumference of each wire-leading wheel is provided with a plurality of wire slots. A wire coil is arranged in a right-side rectangular frame of the framework in a rotatable matching manner, and the central line of the wire coil is overlapped with the central line of the framework. A wire arranging mechanism used for uniformly winding cable wires on the wire coil is fixedly arranged above the wire coil in the right-side rectangular frame of the framework, the wire arranging mechanism is provided with a wire arranging frame, and the wire arranging frame is provided with a laser range finder One and a laser range finder Two. According to the frame-type single-stranding machine of the invention, the laser range finders are adopted to measure the thickness of wires wound on the wire coil; and through cooperation of the motors and a differential mechanism, precise matching between wire leading speed and wire winding speed can be ensured.

Owner:JIANGSU HANDING MACHINERY

Textile machinery wire anti-winding protection device

InactiveCN112299143AAvoid Surface Space WastePrecise positioningFilament handlingStructural engineeringTextile

The invention discloses a textile machinery wire anti-winding protection device, and particularly relates to the field of textile machinery, the textile machinery wire anti-winding protection device comprises a base, supporting plates are fixedly connected to the left and right sides of the top of the base, bearings are embedded in the bottoms of the opposite sides of the two supporting plates, and rotating shafts are fixedly connected to inner rings of the two bearings in a sleeving mode. The rotating shaft on the right side penetrates through the corresponding supporting plate and is fixedlyconnected with a driven wheel, and a driving mechanism used for driving the rotating shafts to rotate is arranged on the base. First connecting plates are fixedly connected to the opposite ends of the two rotating shafts. By arranging the first connecting plates, second connecting plates and telescopic rods, the two second connecting plates can be away from each other through stretching and retracting of the telescopic rods, positioning columns and clamping plates on two bundle plates can be in clamped connection with the two second connecting plates, then the two second connecting plates clamp the two bundle plates through elastic force of first springs, and thus a wire winding roller can be conveniently positioned.

Owner:江苏汤氏纺机集团有限公司

Hot runner zinc spraying device for power transmission line steel tube tower

PendingCN114015960AEvenly woundRealize isolation and storageMolten spray coatingWeb rotation wrappingHot runnerSlide plate

The invention provides a hot runner zinc spraying device for a power transmission line steel tube tower. The device comprises two vertical frames which are vertically arranged, steel tube clamping mechanisms are arranged on the upper portions of the sides, close to each other, of the two vertical frames, a rectangular frame is horizontally welded to the upper ends of the two vertical frames, a sliding plate is slidably arranged at one end of the upper portion of the rectangular frame, a moving seat is welded to the lower ends of four stand columns, zinc spraying assemblies are arranged on the two sides of the moving seat correspondingly, a rotating gear ring is rotationally arranged on the outer wall of one side of the moving seat around a passing opening by one circle, and a rotating roller is horizontally and rotationally arranged at the end, away from the moving seat, of the rotating gear ring. According to the invention, the isolation and storage of the surface of the steel tube tower after spraying zinc treatment are realized; different from traditional multiple procedures, the equipment saves procedures, is simple in structure, low in cost and more uniform in film winding, a film roll can be automatically released according to the pulling speed of a film, the situation that the film is broken midway due to the fact that the film is pulled out purely through pulling force is avoided, and the winding and laminating efficiency is improved.

Owner:JIANGSU HUADIAN STEEL TOWER MFG

Winding reel for textile machine

The invention discloses a winding reel for a textile machine. The winding reel comprises a winding reel body, supporting plates are connected to the two ends of the winding reel body through bearings,one end of the winding reel body is connected with a driving gear, U-shaped clamping blocks are arranged on the same sides of the two supporting plates, locking bolts are arranged on the side walls of the same sides of the two ends of the U-shaped clamping blocks, the ends, located in the U-shaped clamping blocks, of the locking bolts are fixedly connected with pressing discs, a moving beam is connected between the two supporting plates through a support, the moving beam is parallel to the winding reel body. The winding reel is novel in design, and rapid and convenient to use, the winding reel is connected with a mounting frame through the U-shaped clamping blocks, the locking bolts and the pressing discs, mounting is firm, detaching is rapid and convenient, when the winding reel carriesout winding, yarn can be evenly wound on the winding reel, the condition that the yarn is wound on the same portion all the time, and the yarn is knotted is avoided, rapid yarn discharging during yarnspinning operation can be facilitated, and work efficiency of the textile machine is improved.

Owner:苏州朦井纺织科技有限公司

Yarn winding machine

Provided is a yarn winding machine. The yarn winding machine is simple in structure, machining is convenient, and the work efficiency is improved. The yarn winding machine comprises a tank; a partition plate is arranged in the tank; a plurality of through holes are evenly formed in the partition plate; winding shafts are arranged in the through holes movably; a horizontally arranged worm is arranged in the position, below the partition plate, in the tank; a motor for driving the worm is arranged on the outer side of the tank; a worm wheel is arranged at the bottom of each winding shaft and engaged with the worm; lifting rods are arranged on the lower portions of the winding shafts; the winding shafts are provided with sliding grooves; flexible retainer rings are movably arranged in the sliding grooves; each flexible retainer ring comprises a ring and a plurality of supporting strips which are evenly connected to the ring in a circular mode; and a plurality of yarn holes corresponding to the winding shafts one by one are formed in the front wall of the tank. According to the yarn winding machine, machining is convenient, the work efficiency is improved, and time is saved.

Owner:湖州菱湖东方丝绸科技有限公司

Rapid winding device for nylon yarns

The invention discloses a rapid winding device for nylon yarns. The rapid winding device comprises a machine frame base, a wire passing wheel set, a first electric cylinder, a wire passing nozzle, a wire winding device and a control electric box, wherein the control electric box is arranged in the machine frame base, the wire passing wheel set is arranged at the upper end of the left side of the machine frame base, the wire passing wheel set is detachably connected with the machine frame base, the wire winding device is arranged at the upper end of the right side of the machine frame base, thefirst electric cylinder is arranged between the wire winding device and the wire passing wheel set, a motor drives a clamping disc to rotate to roll the nylon yarns, so that the winding speed is higher, and the efficiency is higher; the nylon yarns passes through the wire passing nozzle, and the wire passing nozzle is driven to transversely move through the electric cylinder, so that the windingof the nylon yarns is more uniform; and the nylon yarns are conveyed through the wire passing wheel set and the wire passing nozzle, so that the nylon yarns are prevented from being damaged in the conveying process, and compared with the prior art, the winding speed of the nylon yarns is increased, the efficiency is improved, the production cost is reduced, and the quality of the nylon winding ishigher.

Owner:ZHEJIANG YINAN FIBER TECH

Copper wire coiling device

The invention discloses a copper wire coiling device. The copper wire coiling device comprises a fixed bottom plate. A supporting frame is fixedly connected to the upper portion of the fixed bottom plate. A motor base is fixedly connected to the left side of the upper portion of the fixed bottom plate. A motor is fixedly connected to the upper portion of the motor base. The output end of the motoris fixedly connected with a first rotary shaft. The left end of the first rotary shaft is fixedly connected with a driving gear. A second rotary shaft is rotatably connected to the portion above thefirst rotary shaft. The second rotary shaft is rotatably connected with the supporting frame. The left end of the second rotary shaft is fixedly connected with a driven gear. The driven gear is engaged with the driving gear. A first driving rod is rotatably connected to the eccentric position of the upper portion of the left side of the driven gear. Compared with the prior art, the copper wire coilign device has the beneficial effects that the copper wire coiling device is simple in structure, convenient to use and capable of winding multiple copper wires simultaneously in the using process; meanwhile, the copper wire coiling device can effectively prevent the copper wires from pushing each other in the winding process and is uniform in winding and capable of cooling the copper wires in the winding process and avoiding heat accumulation.

Owner:中海宏祥铜业江苏有限公司

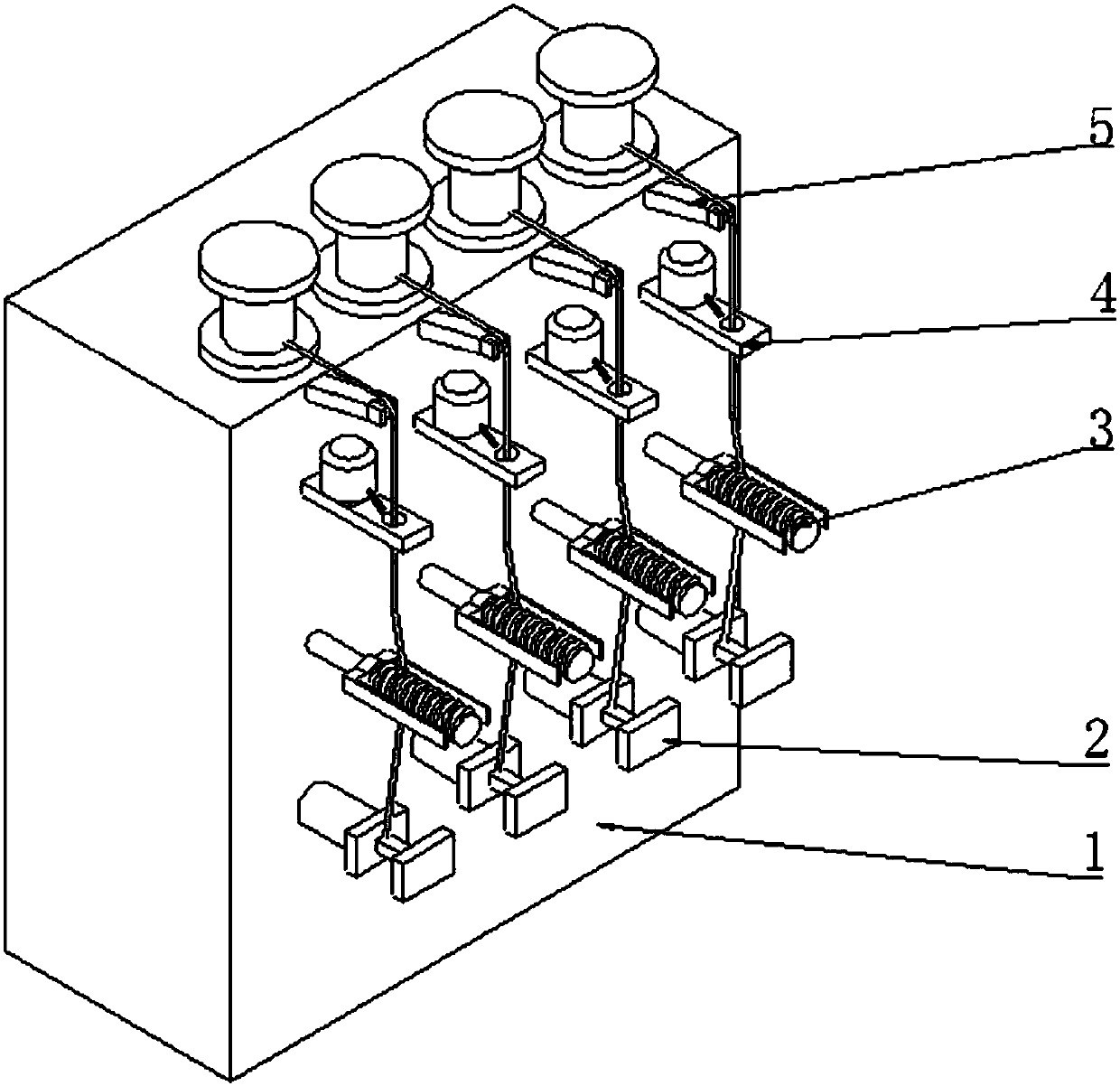

Wire winding device used for relay

ActiveCN107644783ASolve the problem of inaccurate circle dataSolve the problem of being easily bruisedRelaysSprayerEngineering

The invention discloses a wire winding device used for a relay. The wire winding device used for a relay comprises a machine body, a computer host, a display screen, wire arrangement mechanisms, wireguiding mechanisms, wire winding mechanisms and paint spraying mechanisms. The paint spraying mechanisms are arranged under the wire guiding mechanisms. The paint spraying mechanism comprises a paintbox, a guide groove, a support plate and a sprayer. The support plate is fixed on the machine body. The paint box is fixed on the support plate. An outlet of the paint box is communicated with the guide groove and the outlet of the guide groove is communicated with the sprayer. A through hole for an enameled wire to pass through is formed in the support plate. The sprayer is arranged on the bottomof the support plate. A nozzle of the sprayer faces the through hole. A pressure sensor is integrated on the wire guiding mechanism. The pressure sensor is in two-way electric signal connection withthe control host. The combined usage of the spraying mechanisms and the pressure sensors can commonly solve problems that the number of winding turns is not accurate and enameled wire is easy to suffer crush damages.

Owner:建德市桑迪电器有限公司

Improved spinning yarn coiling block

The invention provides an improved spinning yarn coiling block. A bottom plate, a supporting unit, a coiling block unit and a winding unit are included. The improved spinning yarn coiling block can solve the problems that yarn is different in kind, consequently, existing yarn is wound around a coiling block, the yarn is integrally loose, the yarn is likely to be twisted, the loose yarn is likely to be knotted, and when the existing yarn is wound around the coiling block, the yarn is likely to be accumulated at one position of the coiling block; and the thickness of the yarn at various positions of the coiling block is uneven, in the process that the coiling block around which the yarn is wound is moved, the yarn at the highest position on the coiling block is likely to be stirred to the low position, and the yarn gets loose; and usage of the yarn on the coiling block is influenced.

Owner:尹梦雅

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com