Inductor enameled wire winding process device and process thereof

A process device and technology of enameled wire, which is applied in the field of inductors, can solve problems such as the inability to adjust the tightness of wire winding and affect the quality of coil winding, and achieve the effect of simple structure, realizing resistance, and realizing tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

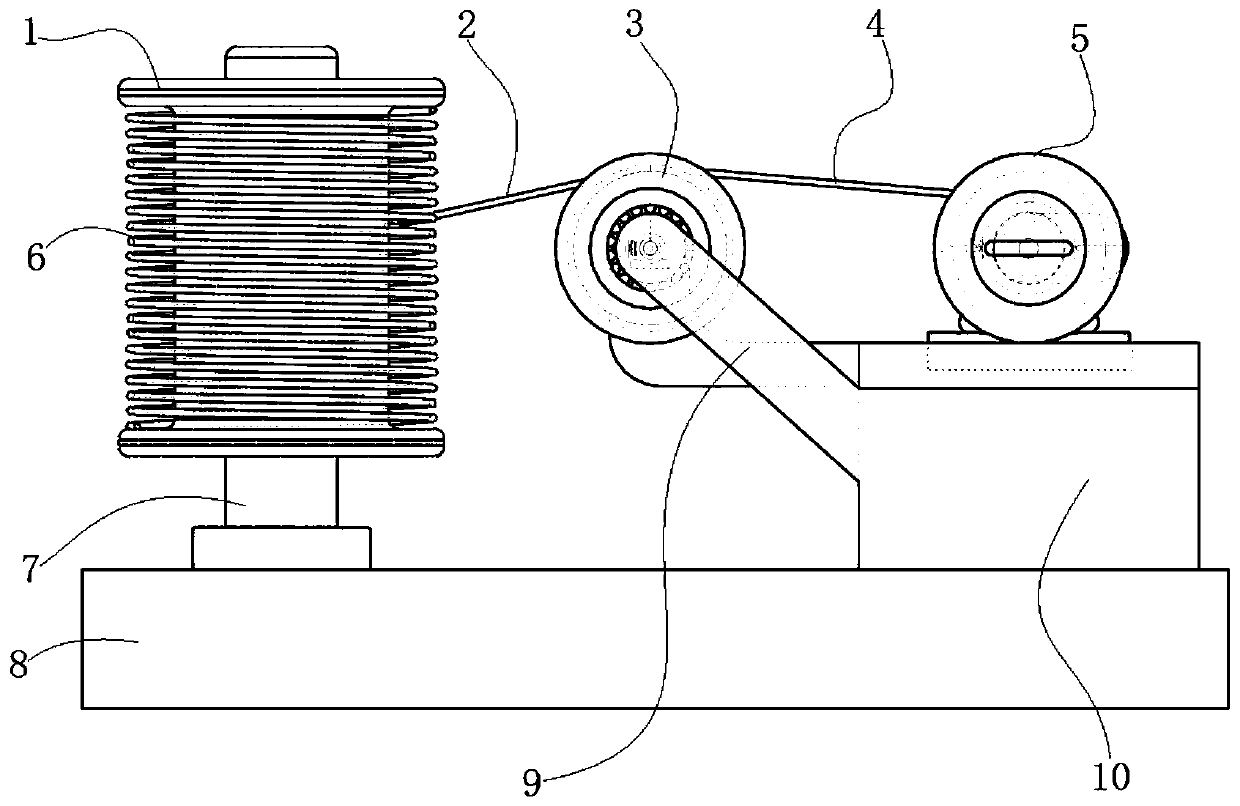

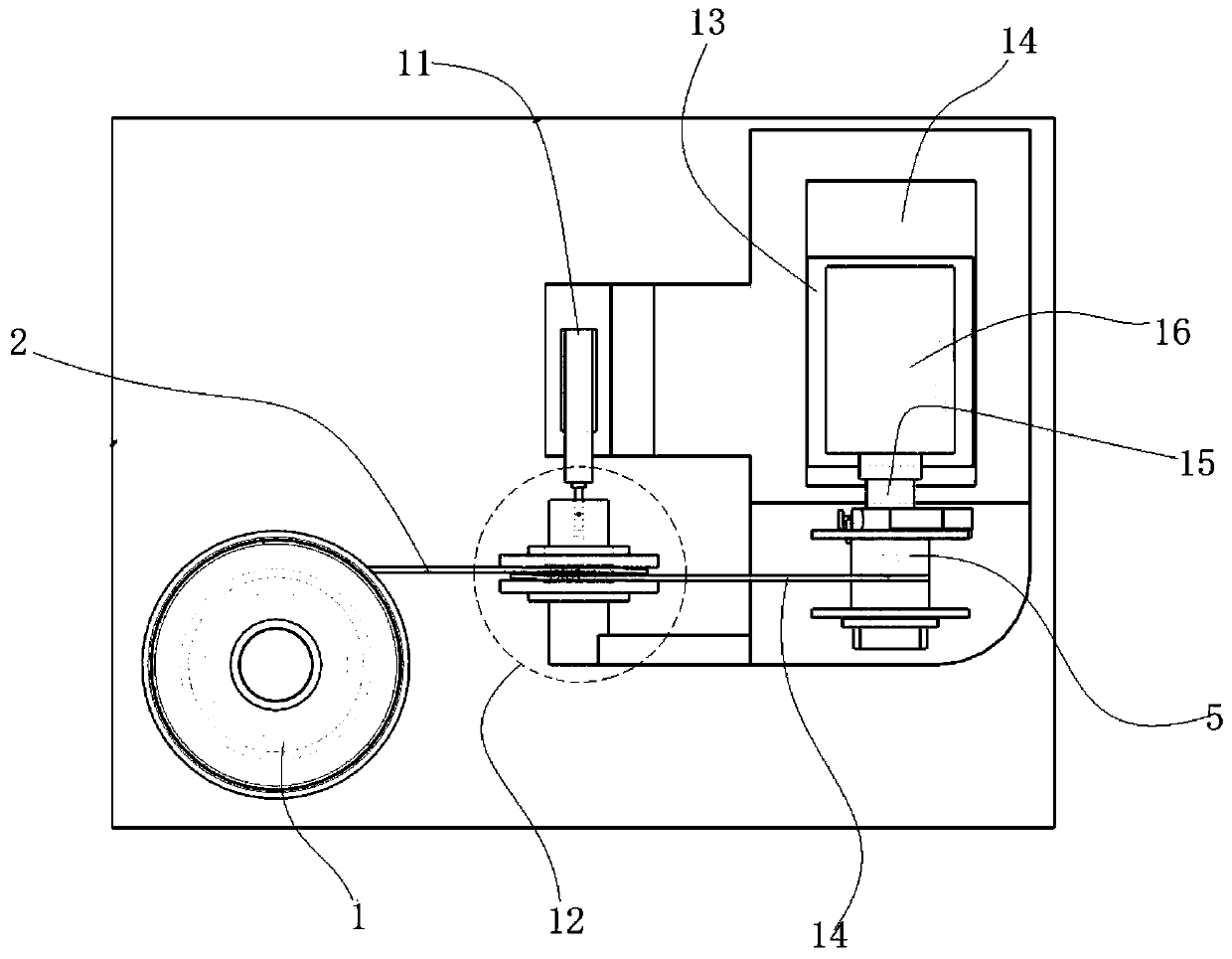

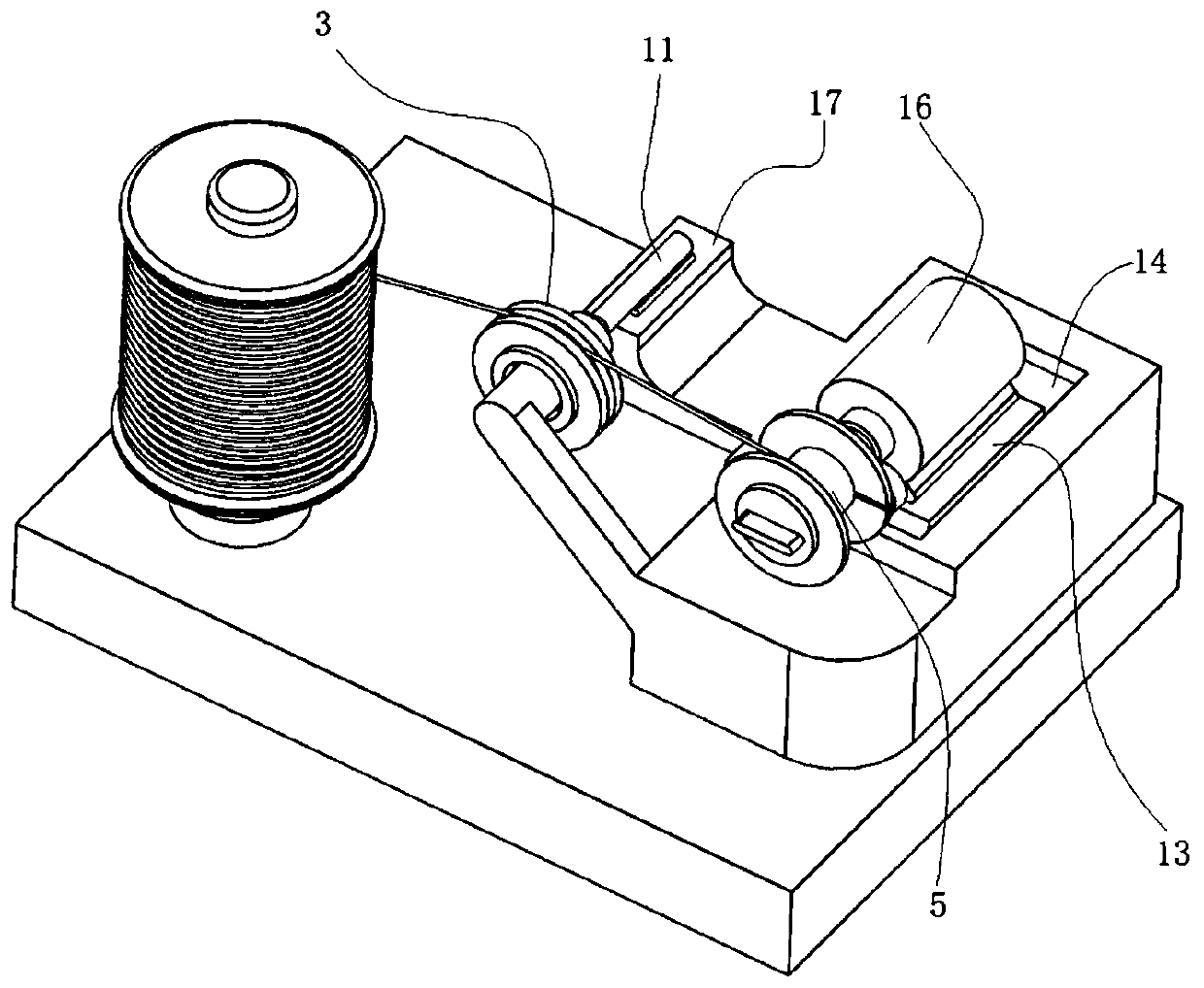

[0045] as attached Figures 1 to 13 The shown inductor enameled wire winding process device includes an inductor bobbin 5 to be wound into a conductive coil, the inductor bobbin 5 includes a wire barrel 29, and the inside of the wire barrel 29 is a coaxial core that penetrates through the core. Insert the hole 100, the two ends of the wire barrel 29 are respectively coaxially provided with a first wire reel 21 and a second wire reel 23; the two sides of the second wire reel 23 are symmetrically hollowed out with first Wire slot 22 and the second wire slot 28;

[0046] It also includes a coil bobbin installation station, the inductance coil bobbin 5 is detachably installed and fixed on the coil bobbin installation station, and the coil bobbin installation station can drive the inductance coil bobbin 5 to rotate along its own axis;

[0047] The bobbin installation stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com