Device for inner and outer circle chamfering and end face opening flattening of two ends of metal ventilation pipe and application method of device

A technology of ventilation pipes and inner and outer circles, which is applied in the direction of grinding drive devices, metal processing equipment, and machine tools suitable for grinding workpiece edges, etc. It can solve the problems of low labor cost, high degree of automation, and inability to effectively remove burrs. , to achieve the effect of easy installation and saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

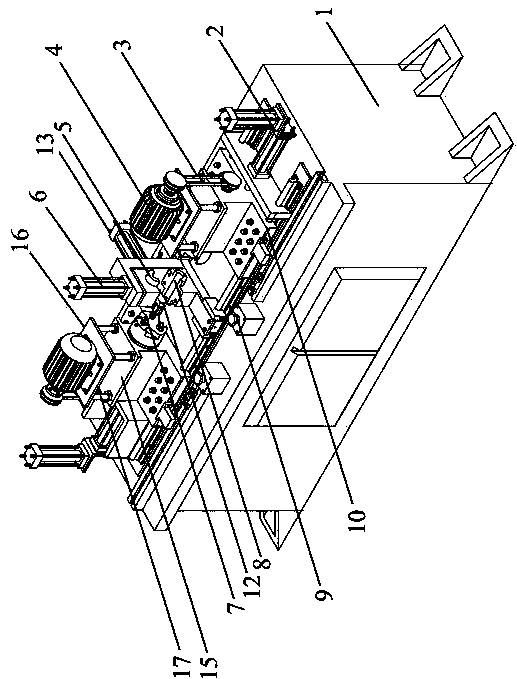

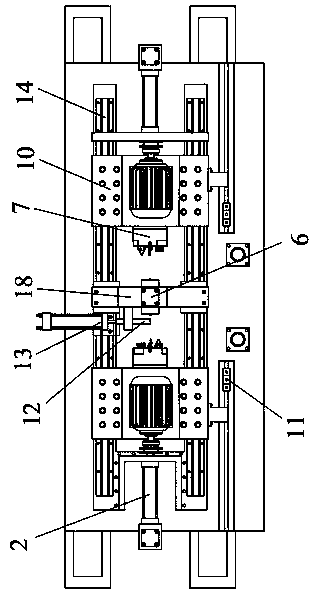

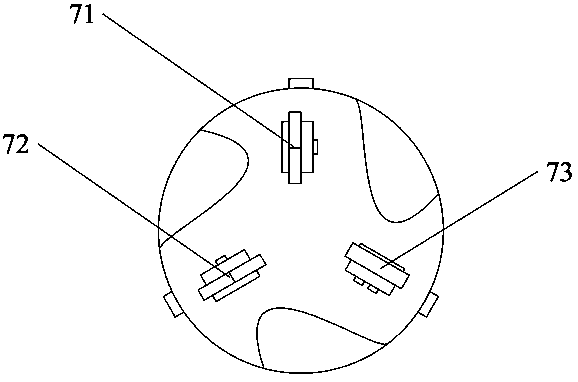

[0033] Such as figure 1 As shown, a metal ventilating pipe with internal and external chamfering at both ends and a flat mouth device includes a working platform 1, a fixed clamping device, a pressurized cylinder 2, a belt 3, a motor 4, a pipe fixing end cover 5, a cylinder 6, and a combination Tool turntable 7, coaxiality fine-tuning device 8, control button 9, mobile platform 10, limit block 11, stop block 12, cylinder two 13, guide rail 14.

[0034] The upper part of the working platform 1 is provided with a guide rail 14, two groups of mobile platforms 10, control buttons 9, and a fixed clamping device. The mobile platform 10 is connected to the working platform 10 through the fitting of the guide rail 14, and the guide rail 14 is connected to the working platform 10 through screws; fixed clamping The device is fixed in the middle of the working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com