Patents

Literature

239results about How to "Control tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

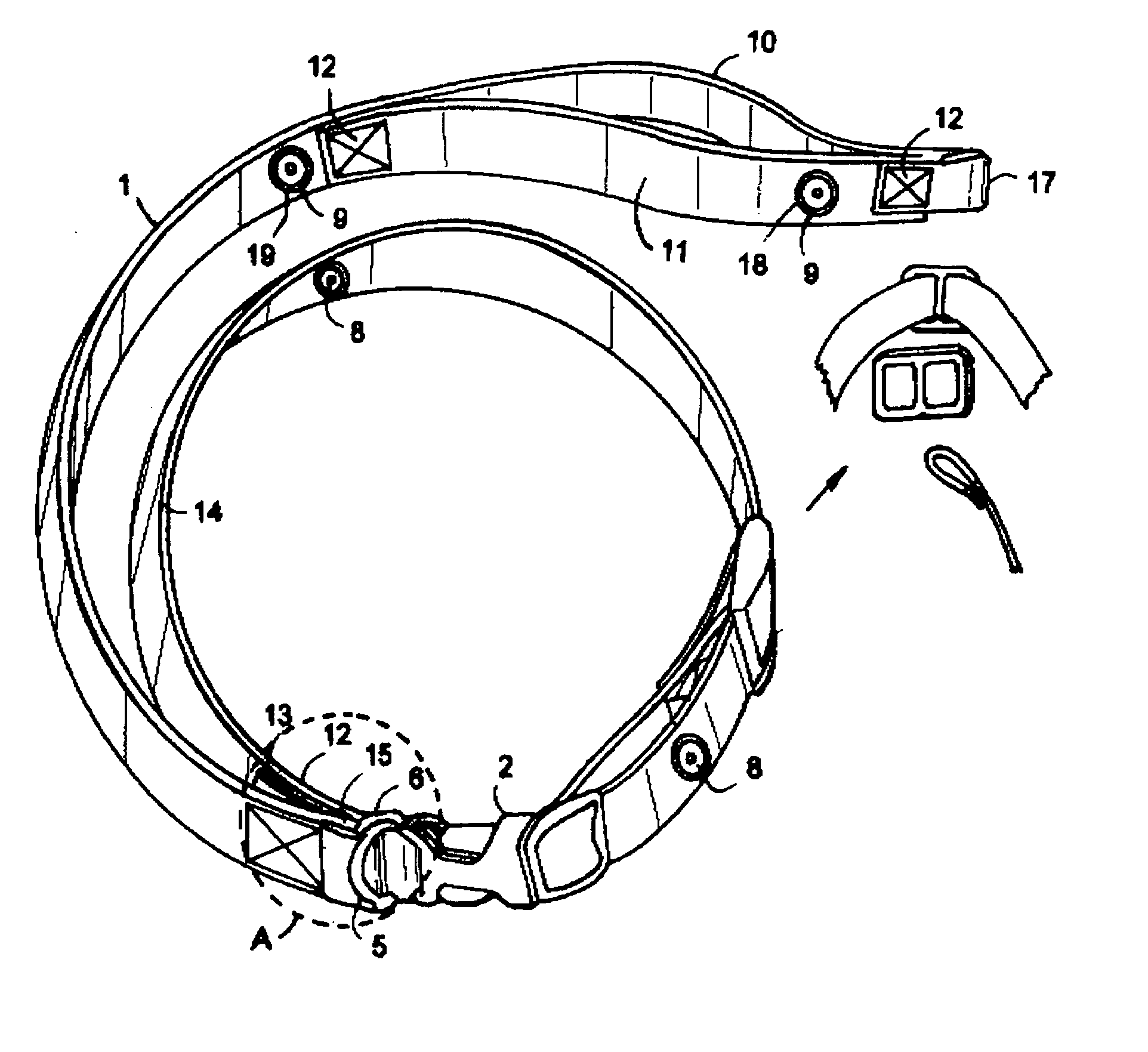

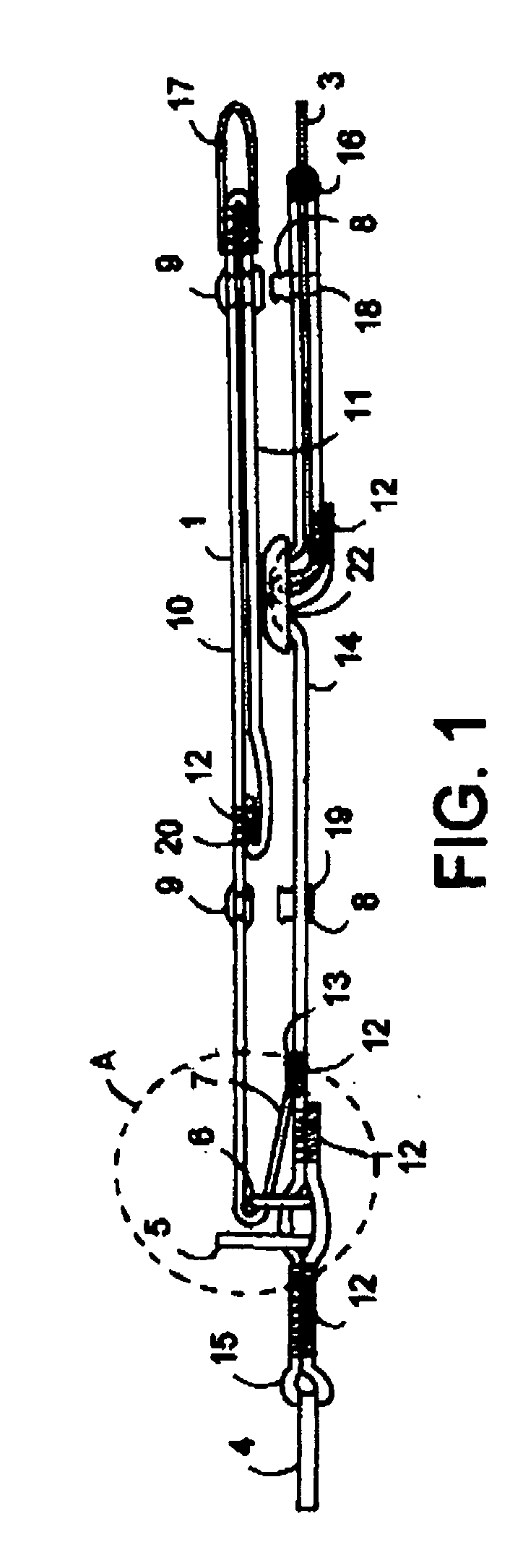

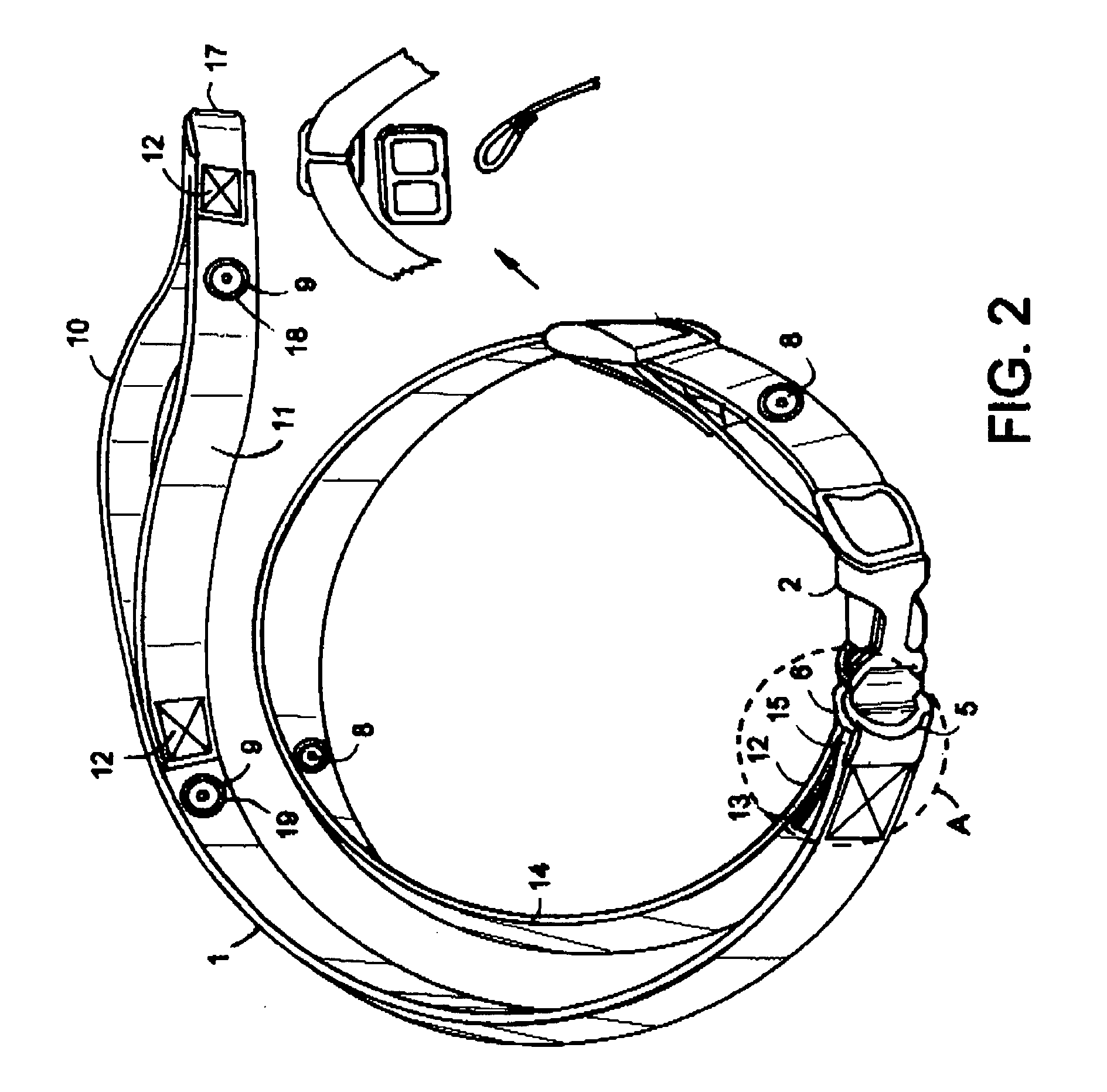

Animal safety collar with automatic tension control copyright

Owner:SANDBERG MICHAEL JOHN

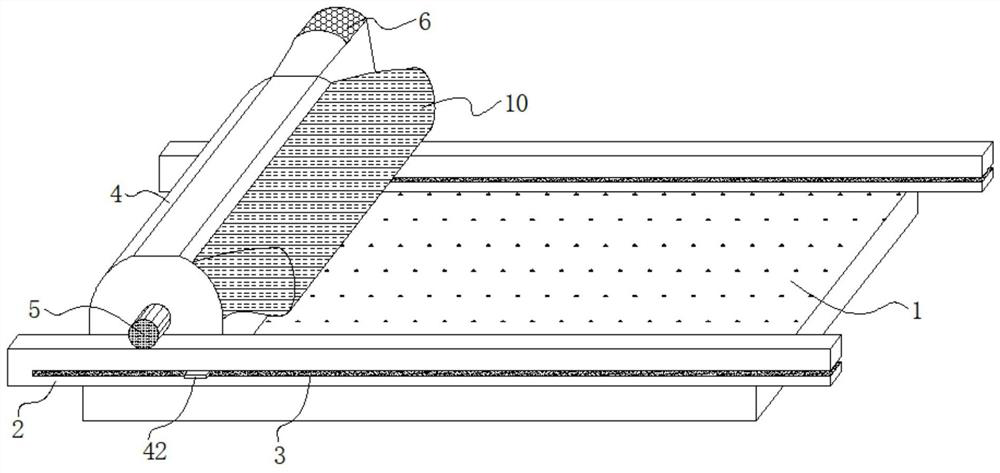

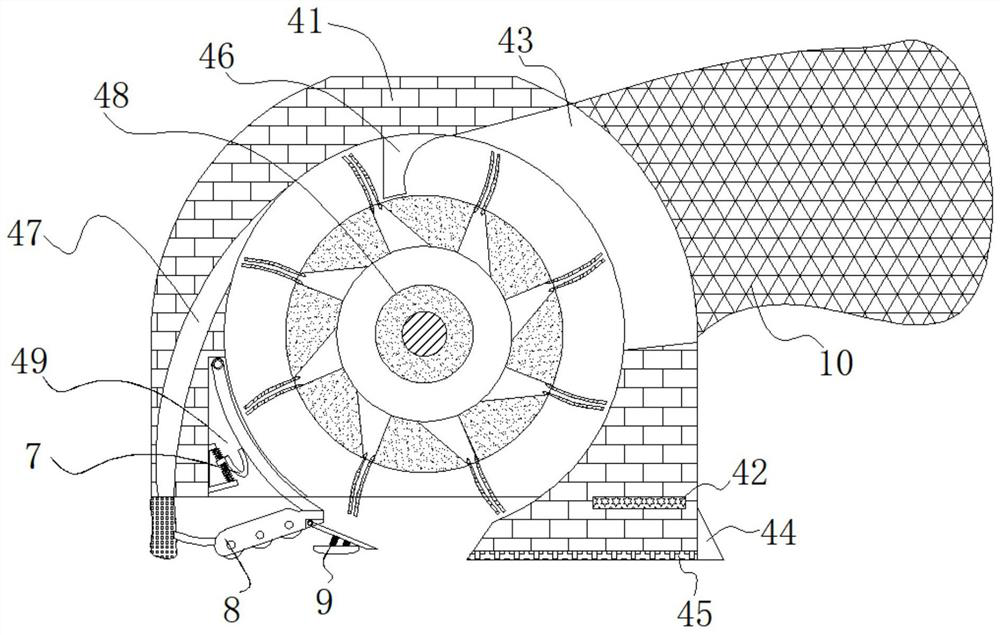

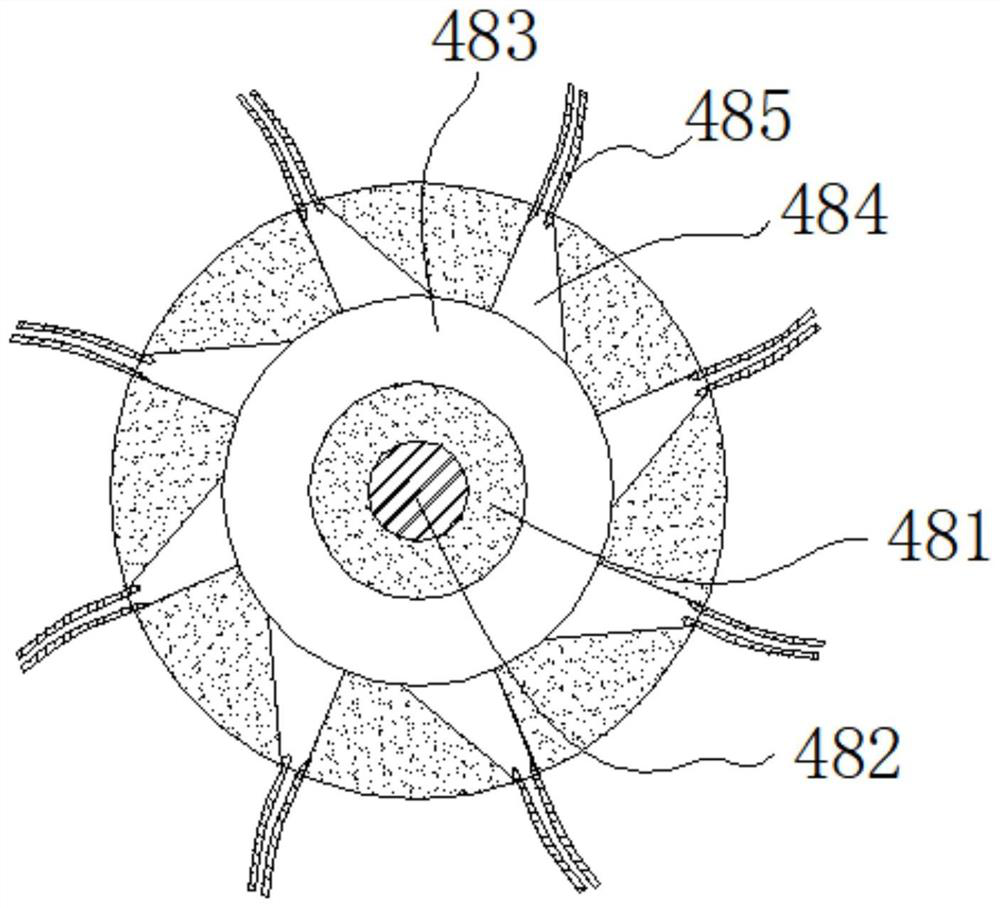

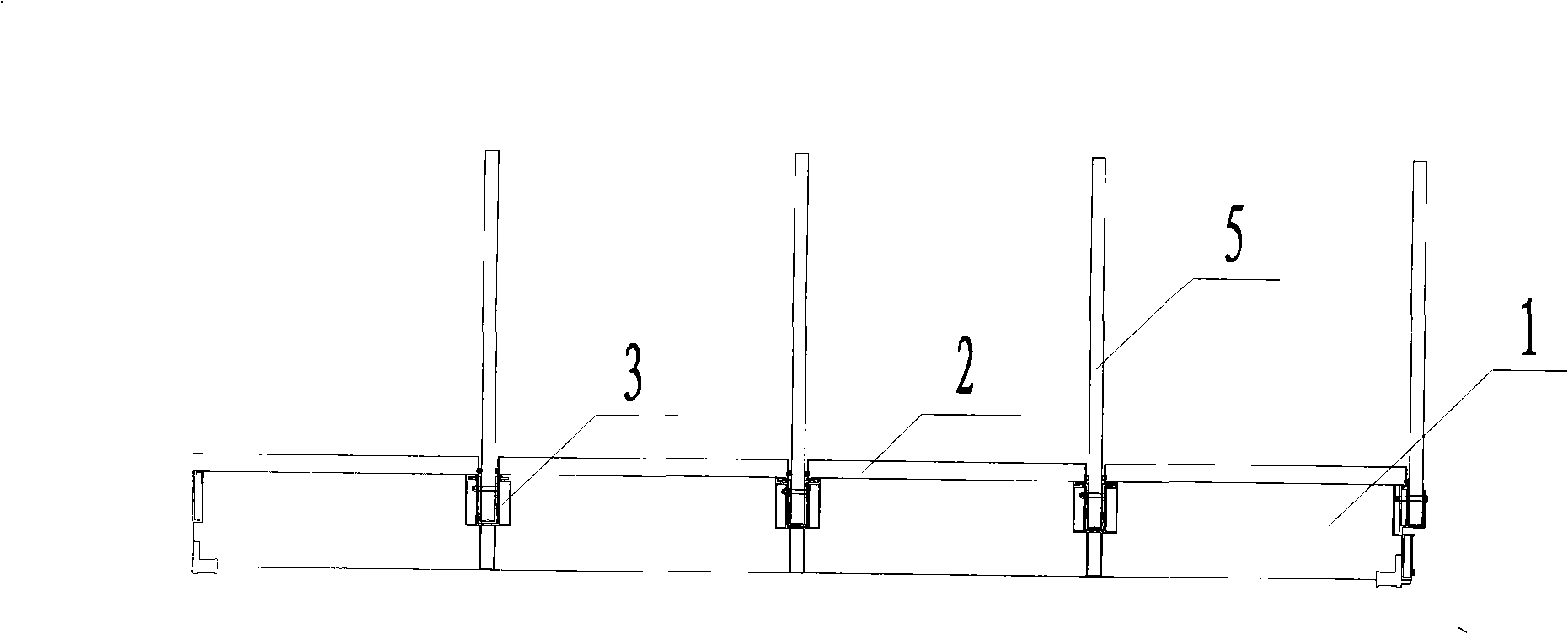

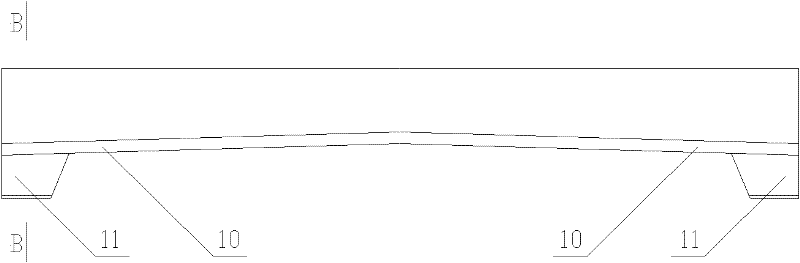

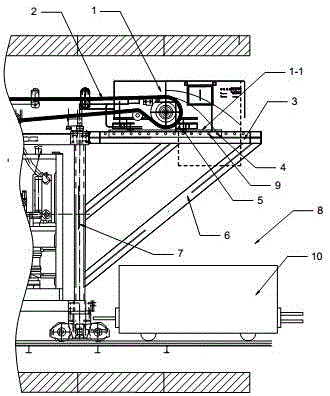

Dryer used for non-woven fabric

InactiveCN105318684ASmall temperature differenceImprove drying efficiencyDrying machines with progressive movementsWater vaporPulp and paper industry

The invention relates to a dryer used for non-woven fabric. The dryer comprises a machine frame. A drying barrel is arranged at the front end of the machine frame, two ends of the drying barrel are fixed to the machine frame through a barrel frame, a pressing and attaching device used for squeezing the non-woven fabric at the bottom of the drying barrel is arranged on the machine frame below the drying barrel, and a lifting device is arranged between the lower end of the pressing and attaching device and the machine frame. The non-woven fabric is pressed and attached to the drying barrel through a heat assisting blanket of the pressing and attaching device so that the temperature difference of two sides of the wet non-woven fabric can be small, water vapor in the non-woven fabric is forms convection, and accordingly the drying efficiency is improved.

Owner:孔令胜

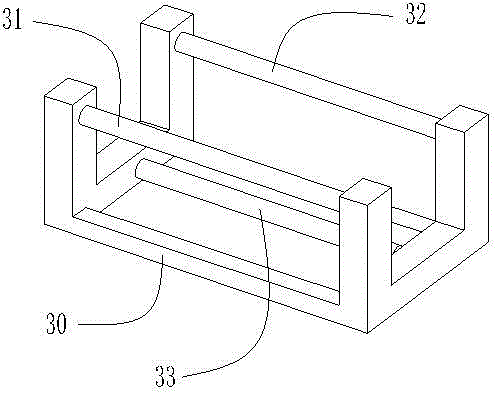

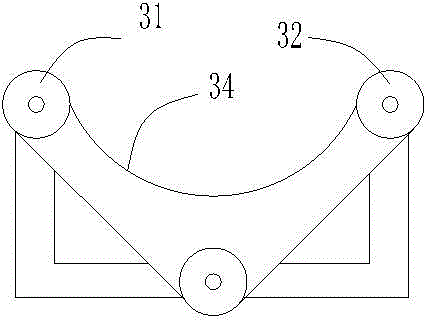

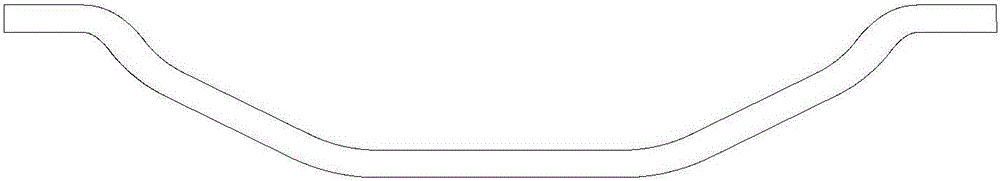

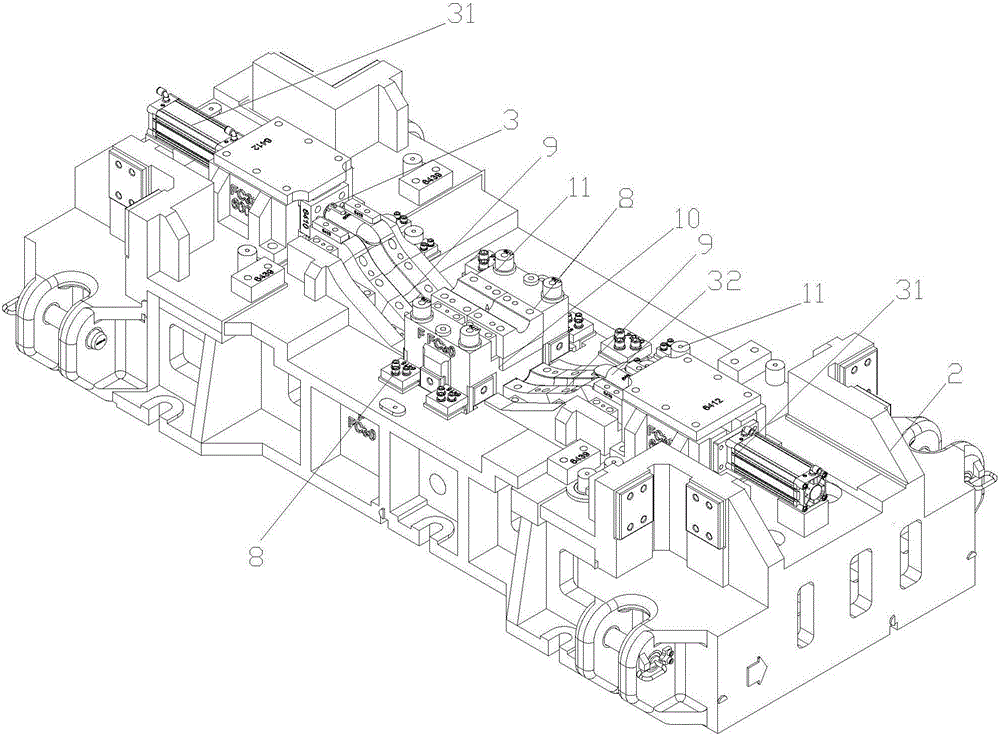

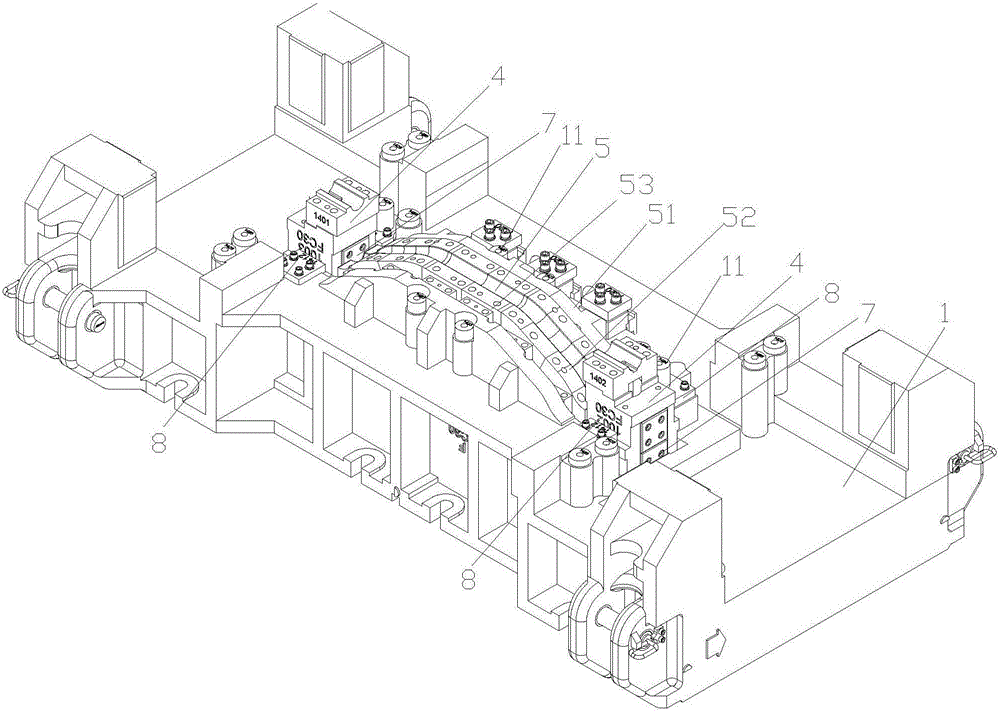

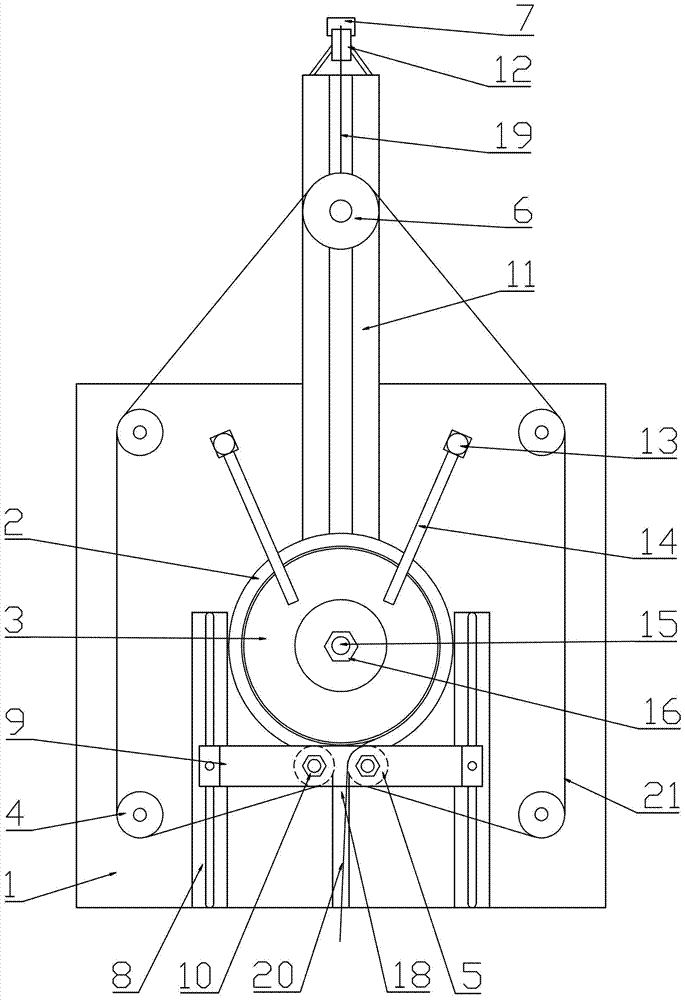

Stamping molding die for automobile front beam tube

The invention discloses a stamping molding die for an automobile front beam tube. The stamping molding die comprises an upper die base and a lower die base. An upper molding die assembly is arranged on the upper mold base. A lower molding die assembly is arranged on the lower die base. The two ends of the lower molding die assembly on the lower die base are each provided with a core rod assembly. The upper molding die assembly comprises upper end modules and an upper middle module, wherein the upper end modules are arranged at the two ends and can move up and down, and the upper middle module is fixedly arranged on the upper die base. Nitrogen springs are arranged between the upper end modules and the upper die base. The lower molding die assembly comprises a lower end module and a lower middle module, wherein the two ends of the lower end module are arranged on the lower die base, and the lower middle module is movably arranged in the lower die base and can be driven by an ejector rod of a stamping machine to move up and down. The motion stroke of the lower middle module is the distance between the axis of the molded middle section of a pipe and the axis of the pipe end section. Each core rod assembly comprises a core rod air cylinder arranged on the lower die base. The piston rod end of each core rod air cylinder is connected with a core rod. According to the stamping molding die, the automobile front beam tube can be stamped and molded at a time.

Owner:苏州金鸿顺汽车部件股份有限公司

Bag outputting mechanism of automatic plastic bag selling machine

The invention relates to a bag outputting mechanism of an automatic plastic bag selling machine. The bag outputting mechanism comprises a machine frame, a driving bag feeding roller, a driven bag feeding roller and a reel, wherein two inner sides of the machine frame are respectively provided with a base, each base is provided with a vertical guide groove, the two ends of the reel are connected in the vertical guide grooves respectively, two sides of the lower side of the reel are provided with the driving bag feeding roller and the driven bag feeding roller respectively, the driving bag feeding roller is driven by a motor, the driven bag feeding roller is located on one side of the driving bag feeding roller, and the two axial ends of the driving bag feeding roller and the two axial ends of the driven bag feeding roller are connected with the bases through bearing blocks. A support is arranged above each base, at least one leading-out roller set is arranged between the tops of the supports on two sides and composed of a driven outlet guide roller and a driving outlet guide roller, the driven outlet guide roller and the driving outlet guide roller are oppositely arranged in an upper and lower mode, one radial side of the leading-out roller set between the supports on the two sides is provided with a guide roller set composed of a driven guide roller and a driving guide roller, and the driven guide roller and the driving guide roller are oppositely arranged in an upper and lower mode.

Owner:HANGZHOU JIEKONG TECH

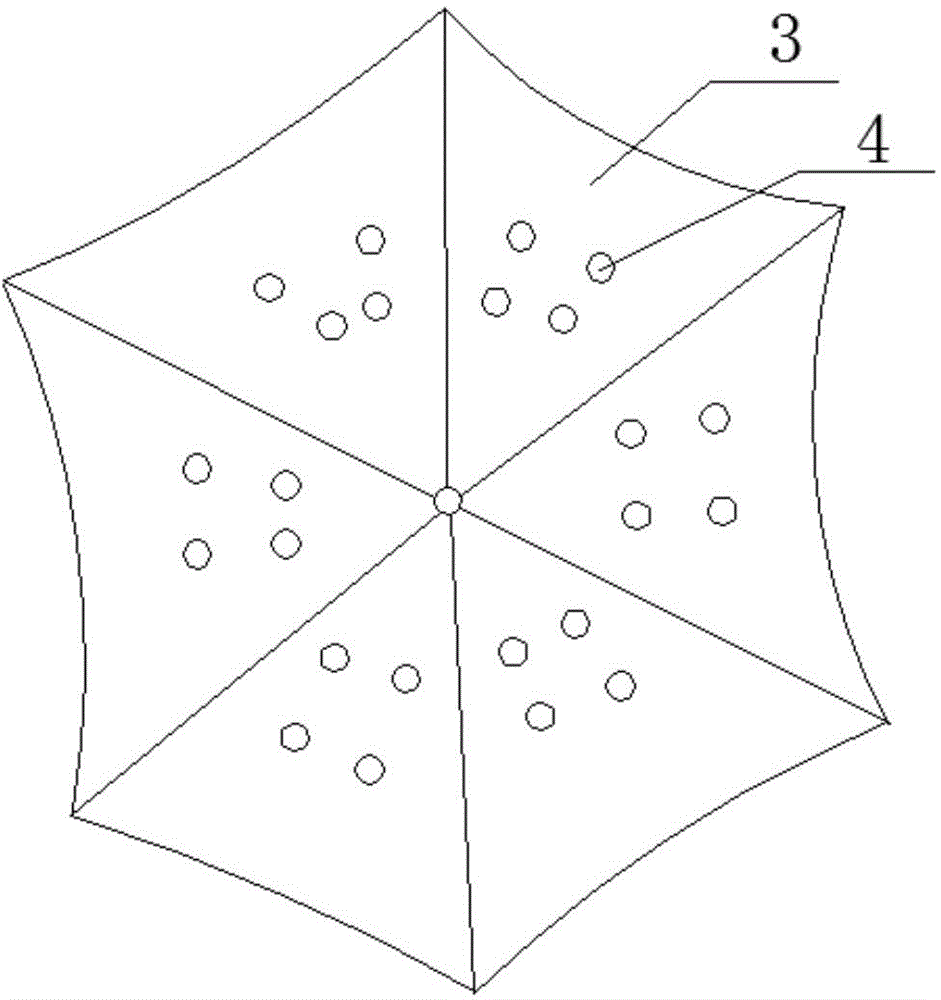

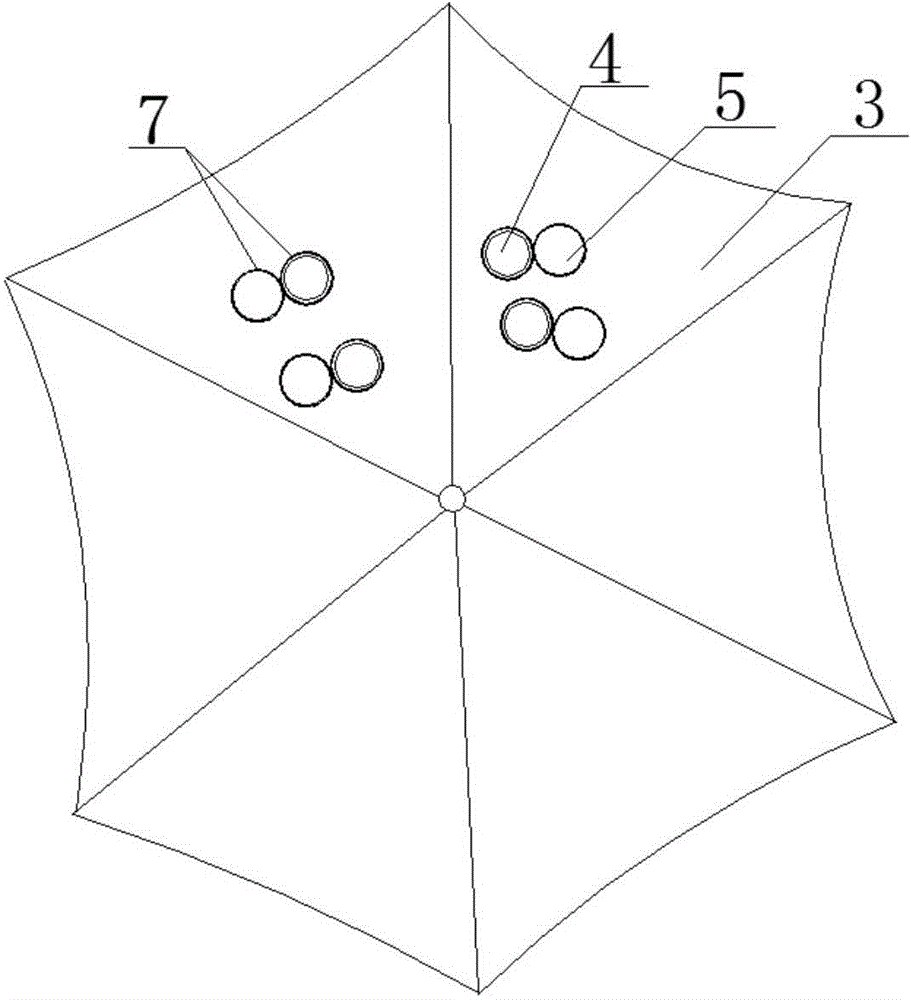

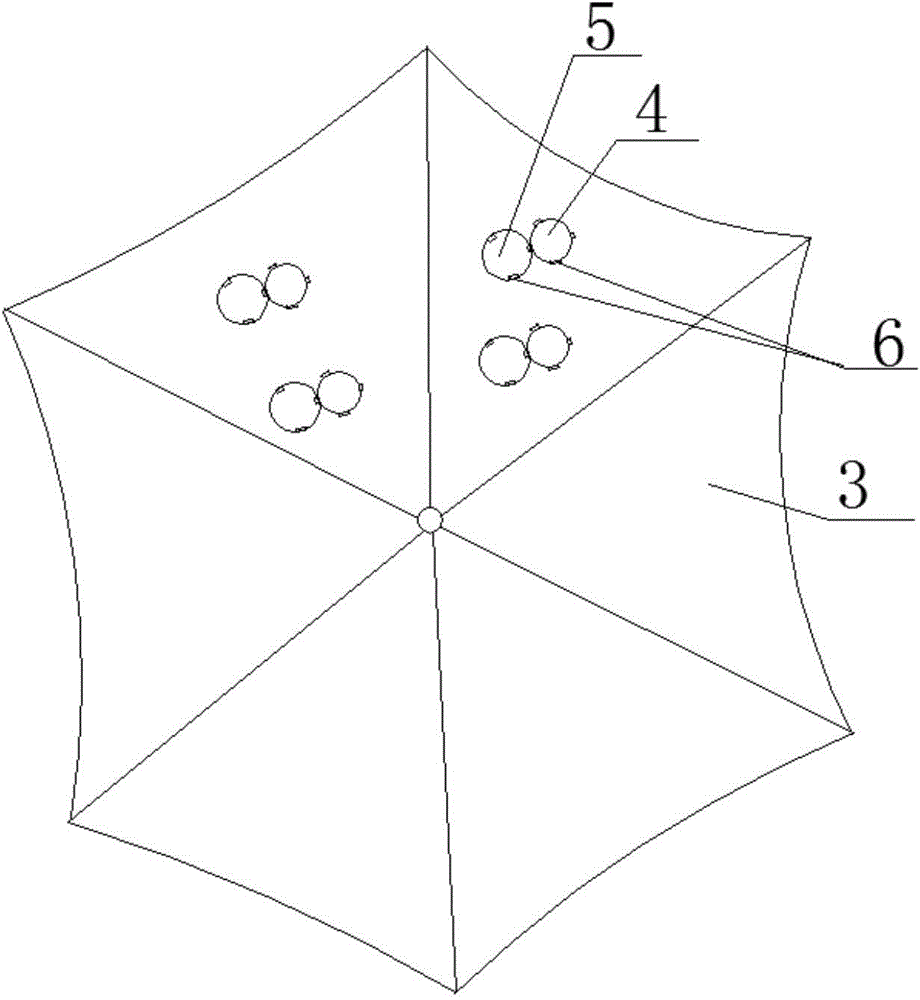

Multifunctional umbrella structure with holes

The invention relates to a multifunctional umbrella structure with holes. The multifunctional umbrella structure comprises ribs, an umbrella rod and an umbrella cover. The ribs are connected to the umbrella rod. The umbrella cover is connected to the ribs and provided with the through holes. The through holes are formed in the umbrella cover; when the wind is strong, the umbrella cover is not prone to being lifted up; when the multifunctional umbrella structure is used in the sun, part of sunshine can enter the multifunctional umbrella structure, a small amount of sunshine can be received while the sun-resistant effect is achieved, and the body immunity can be improved.

Owner:浙江巨力宝纺织科技有限公司

Antenna platform device

The invention discloses an antenna platform device which comprises an antenna platform body, a plurality of threading holes connected to the body, a thread clamping sheet with two sheets connected each other, a thread clamping sheet adjusting knob for adjusting a gap between the two sheets, and a ram used for connecting the threading holes, wherein a spring is arranged between the ram and the body, a trigger mechanism is arranged at the tail end of the ram, a knot tying claw is arranged on the routing track of a yarn, a certain gap is left between the knot tying claw and the body, and the knot tying claw is connected with the trigger mechanism. The antenna platform device has the beneficial effects that the yarn tension and slub size can be controlled, and when the yarn is broken, the device alarms and quits working, thereby preventing inferior cloth from occurring, reducing the yarn waste and protecting the economic benefit of customers.

Owner:NINGBO CIXING

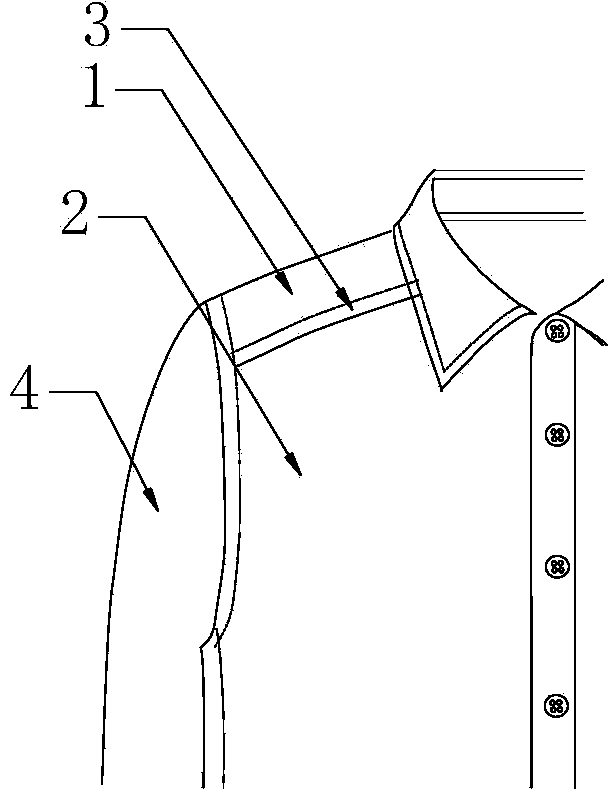

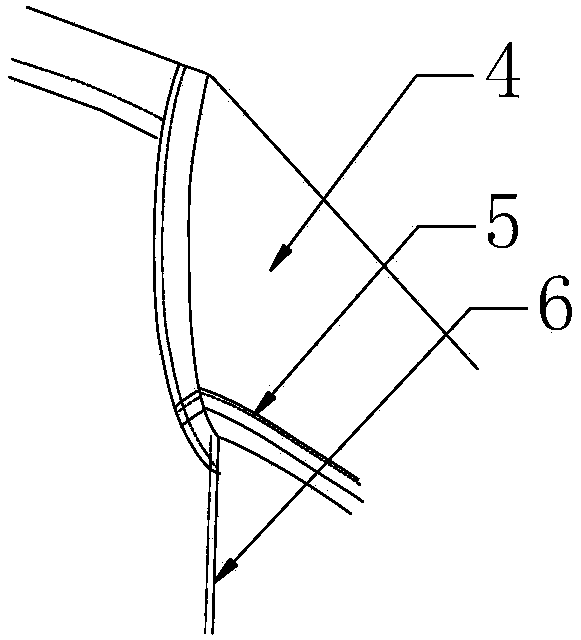

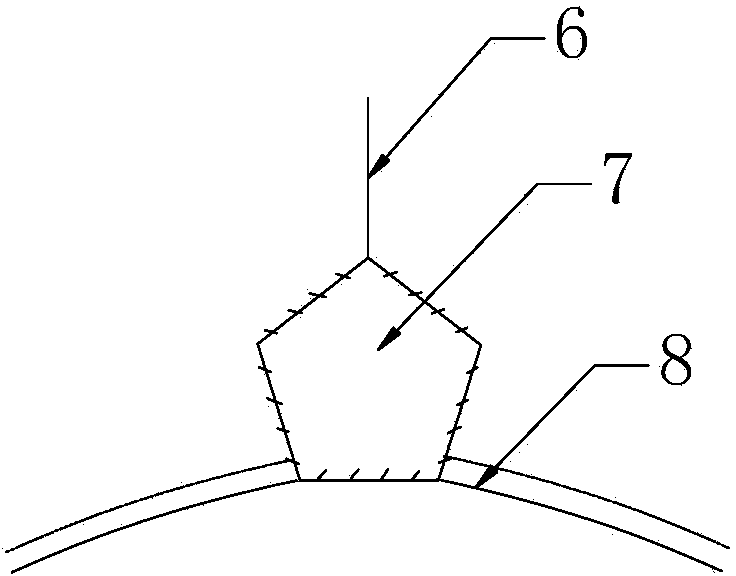

Semi-hand-sewing method for shirt

The invention relates to a semi-hand-sewing method for a shirt. The method includes the first step of cutting out a front shirt piece, a back shirt piece, yokes, sleeve pieces, cuffs and a collar of the shirt, the second step of sewing side seams of the front shirt piece and the back shirt piece, sewing the yokes and back shoulder portions of a shirt body and sewing the sleeve seams and side seams of the sleeve pieces, and carrying out processing on the sleeve pieces and the cuffs in a machine processing mode, the third step of carrying out sewing processing on the yokes of the shirt with the shift body in a hand sewing mode, the fourth step of carrying out sewing processing on shirt sleeves with the processed shirt body in a hand sewing mode, the fifth step of sewing pentagonal attached cloth on joints between the front shirt piece and the back shirt piece of the shift body, and the sixth step of sewing shirt buttons on the front fly portion of the shirt body in a hand sewing mode. According to the method, hand processing and machine processing are combined, the production efficiency of the shirts is guaranteed, and the processing quality is improved.

Owner:青岛酷特智能股份有限公司

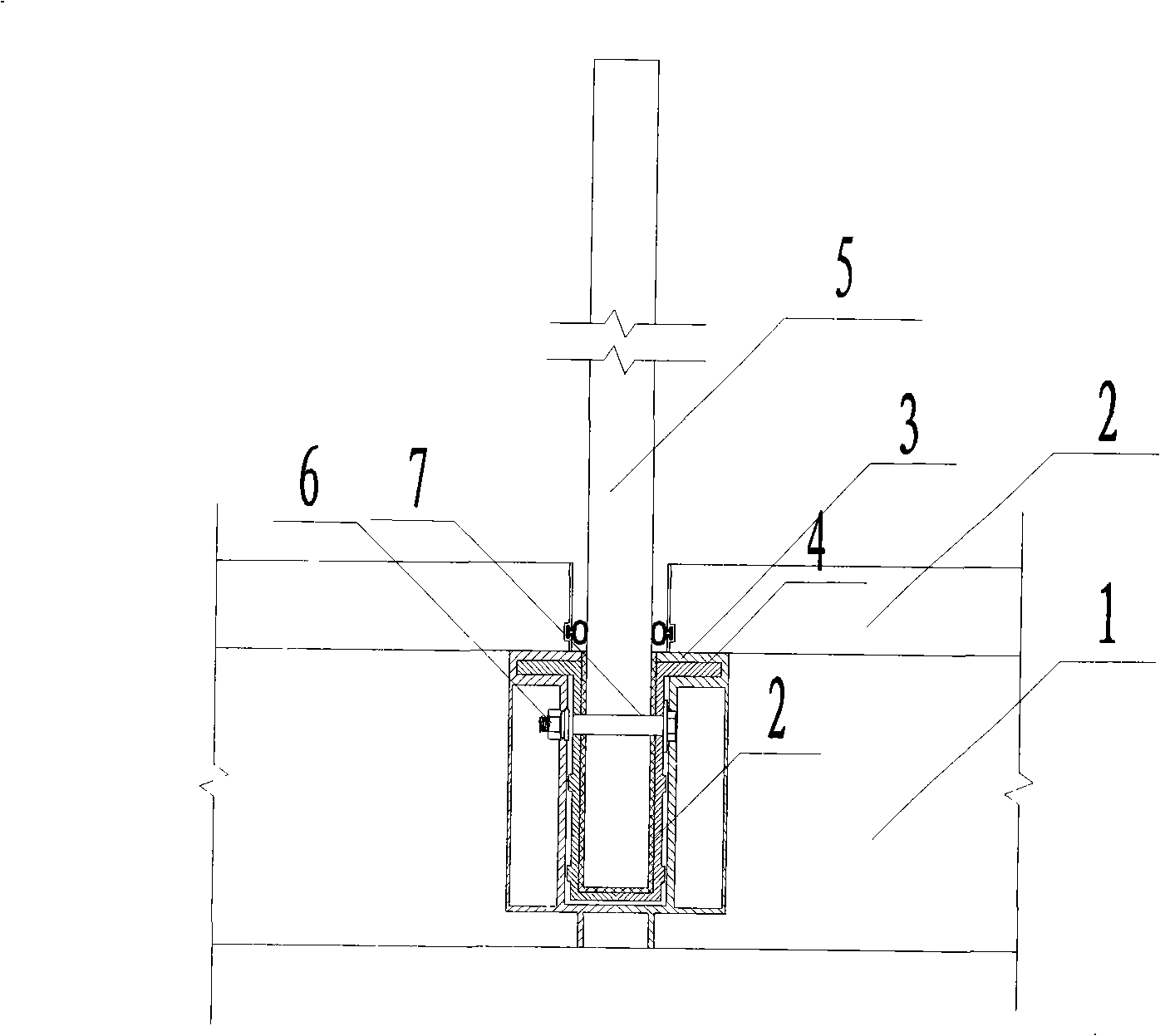

Sealing structure for sealing box

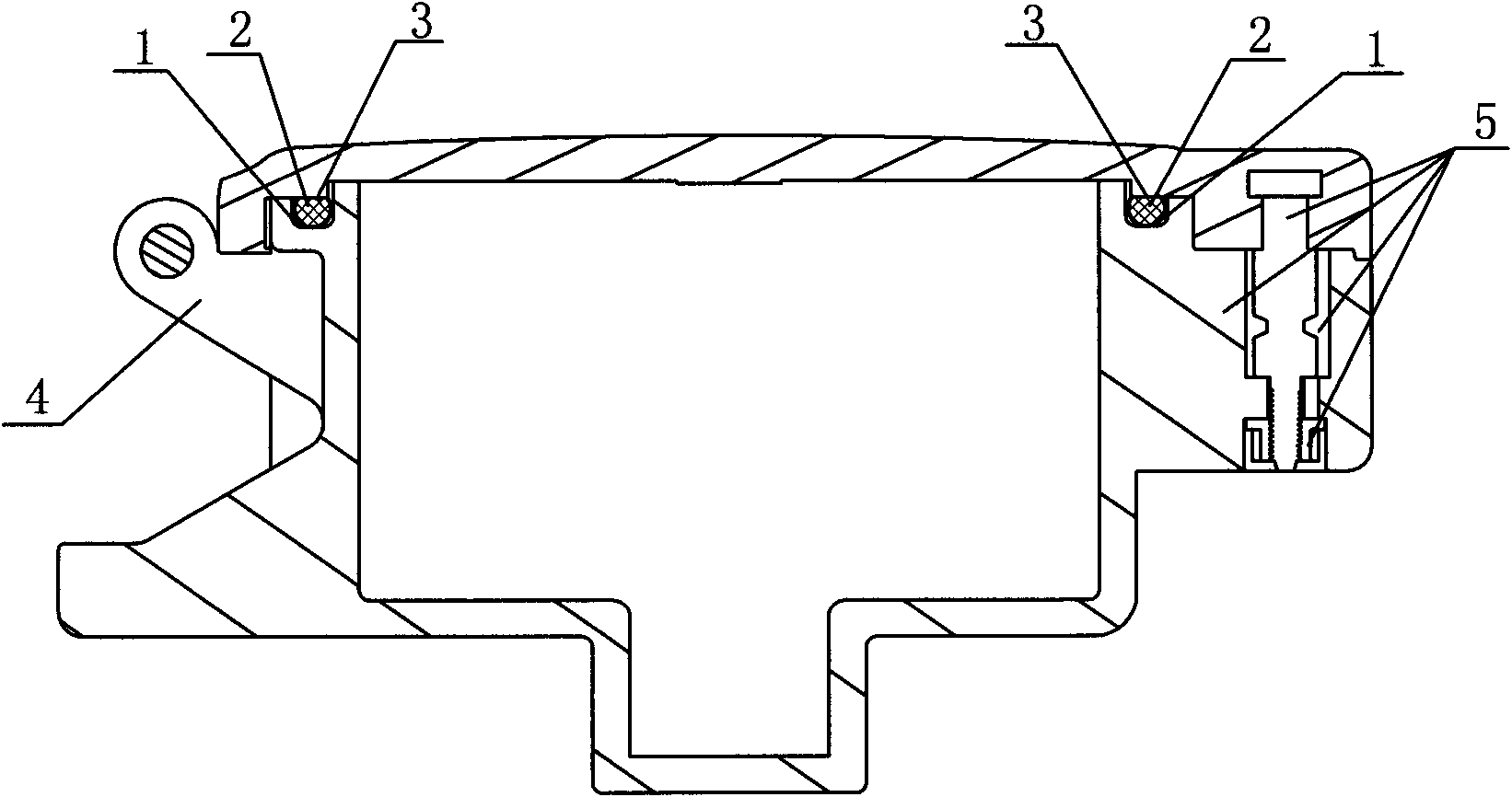

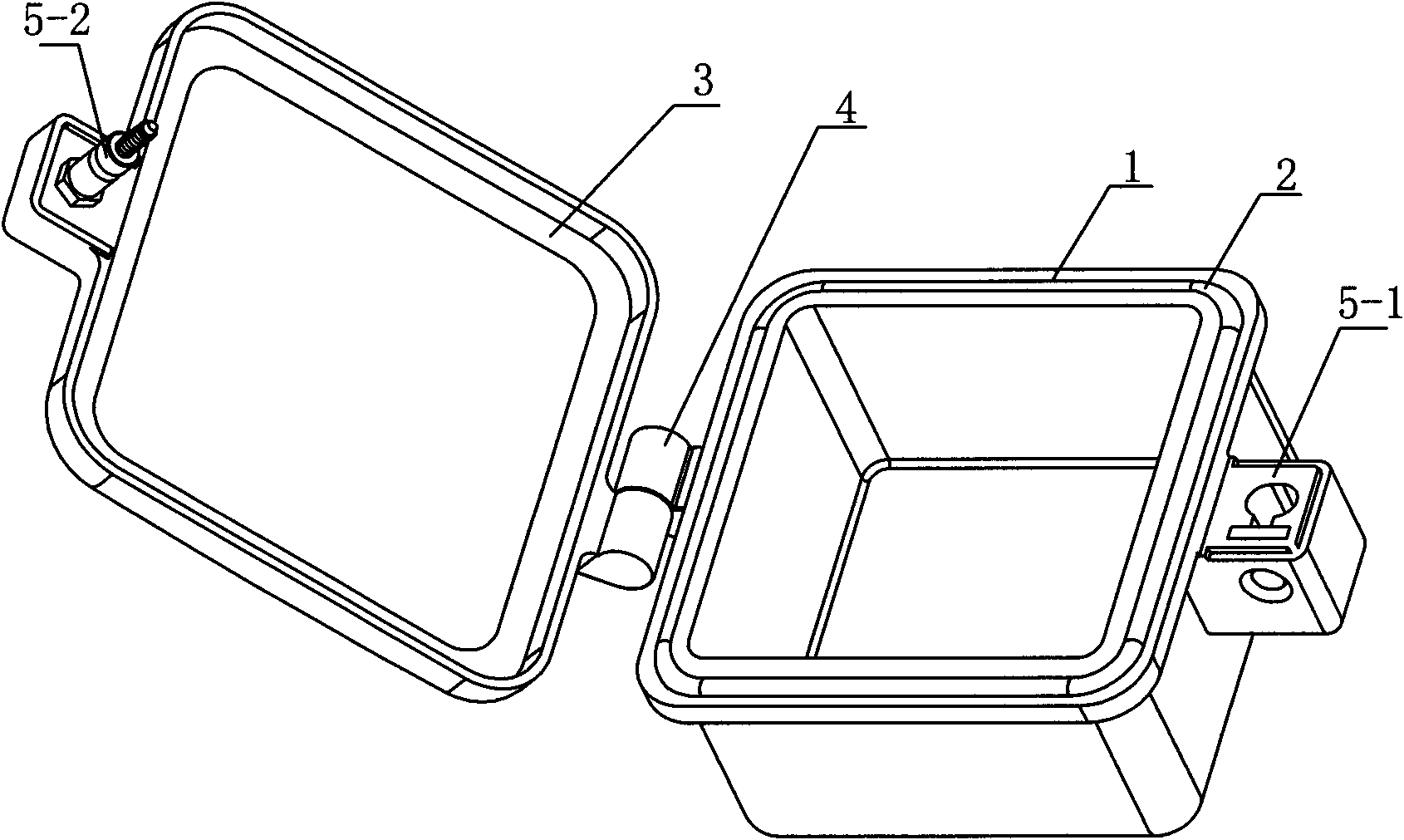

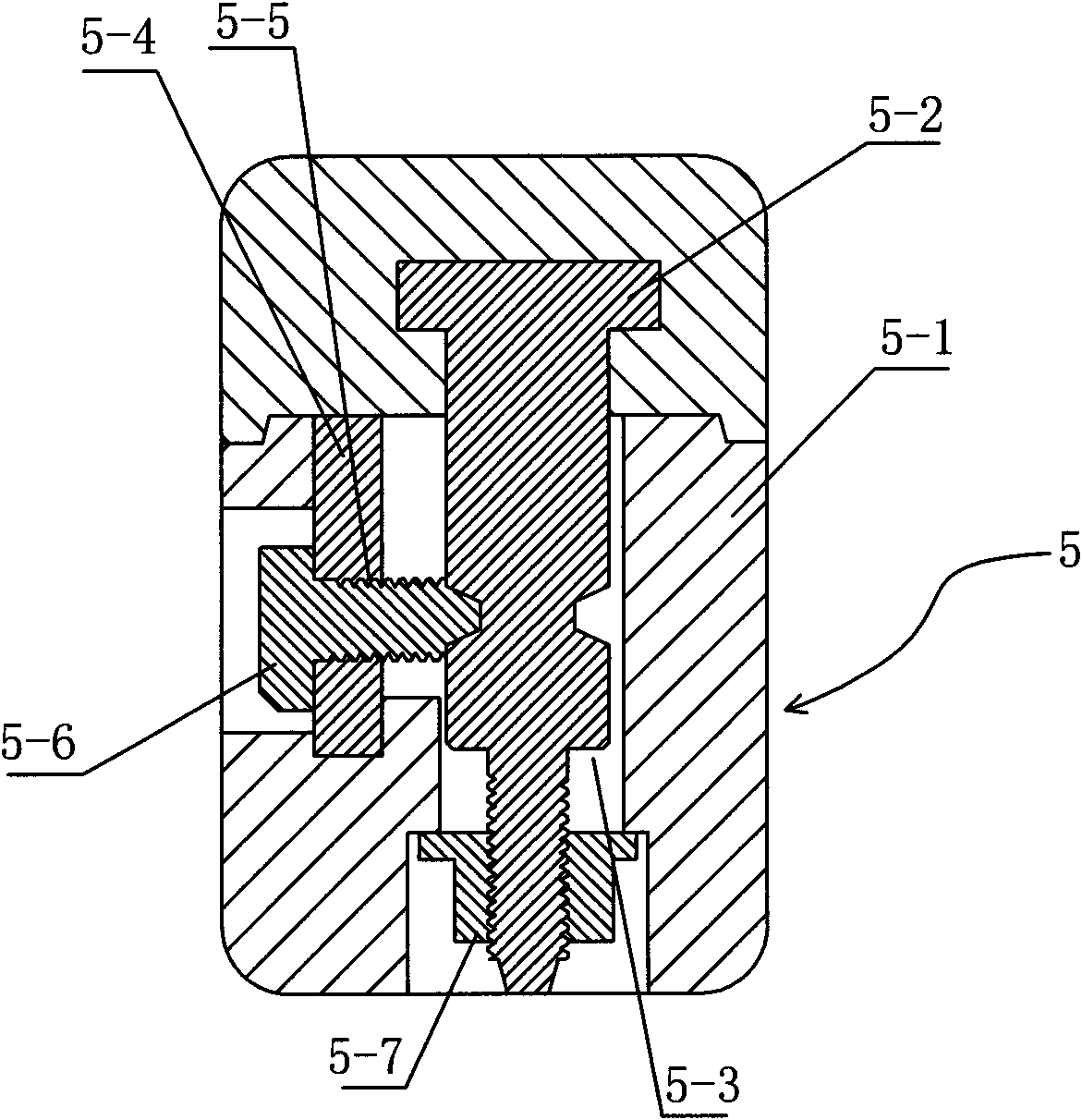

InactiveCN102182825AConsistent compressionNot easy to ageEngine sealsNutsEngineeringMechanical engineering

The invention discloses a sealing structure for a sealing box. The sealing structure comprises an annular accommodating groove (1) positioned on an upper edge of a box body, an annular elastic sealing piece (2) accommodated in the accommodating groove (1), and a pressing plate (3) which is arranged on a box cover and is used for pressing against the elastic sealing piece (2), wherein a contact surface between the pressing plate (3) and the elastic sealing piece (2) is a plane; the elastic sealing piece (2) and the pressing plate (3) are pressed against each other through a pressing device arranged on the box body and the box cover; the elastic sealing piece (2) has the hardness of 45-50 degrees and the compression of 1-1.5mm; and the pressing plate (3) has the surface flatness of not more than 0.4. The sealing structure for the sealing box is good in sealing effect and high in insulating level, and has a protection level of IP67.

Owner:NINGBO HUAYUAN FRP ELECTRICAL APPLIANCE MFR

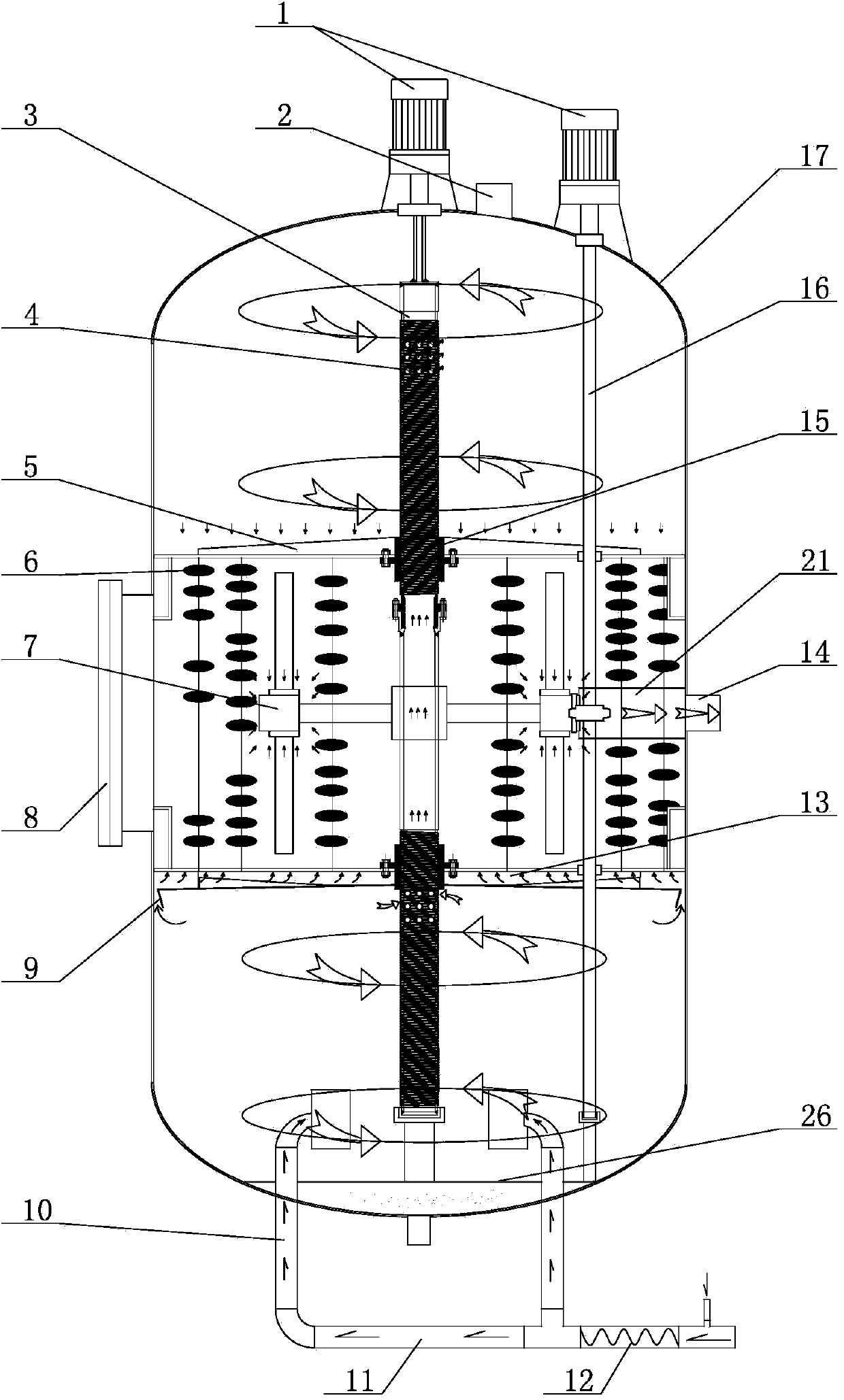

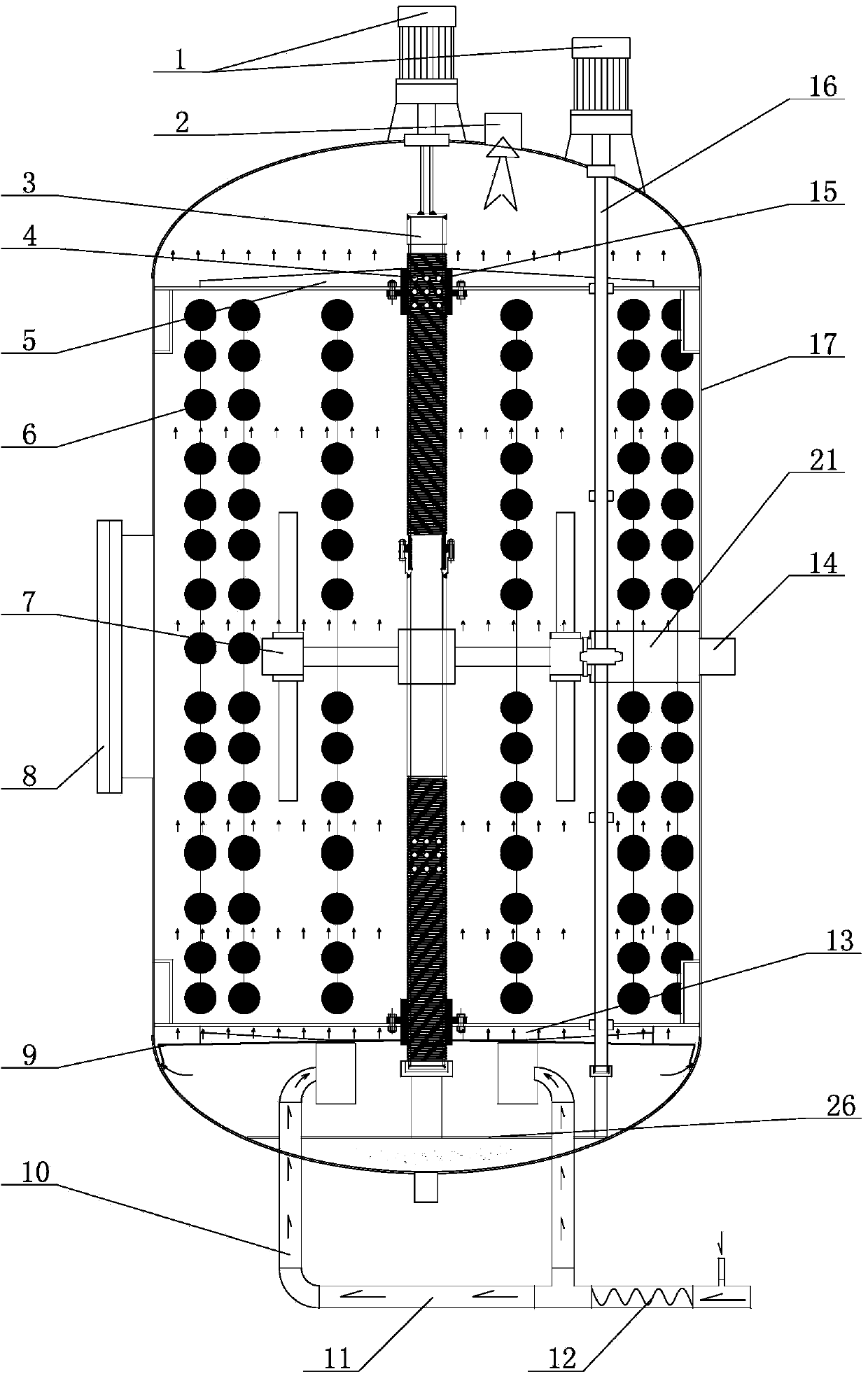

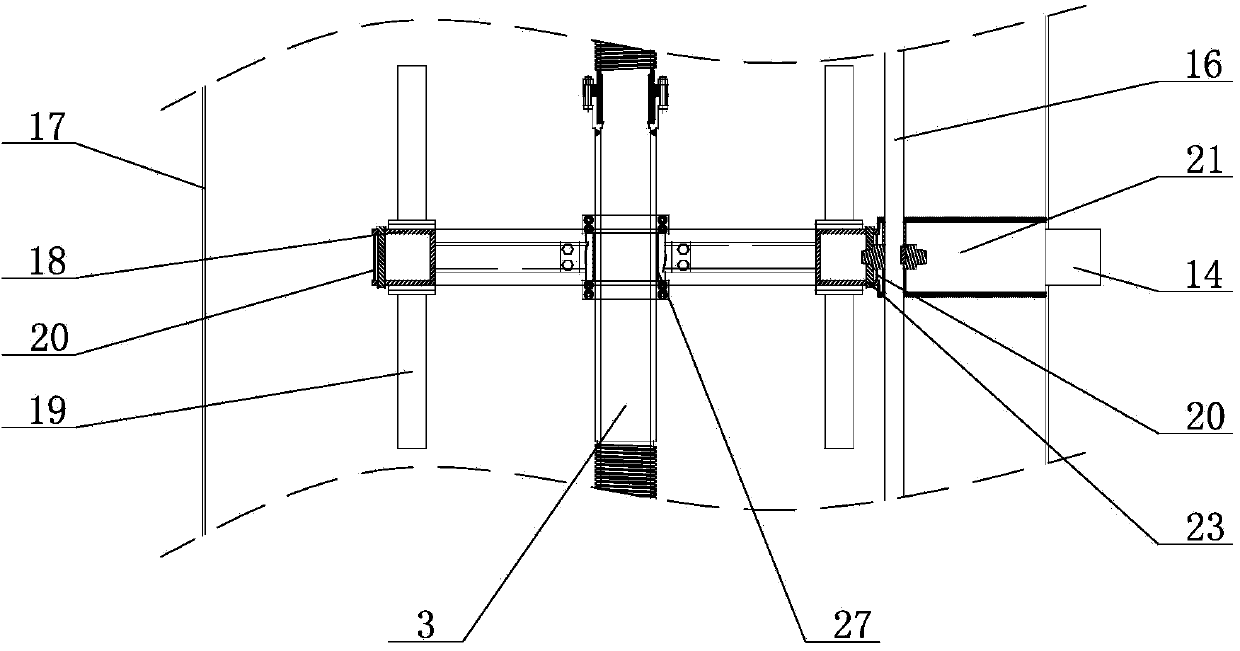

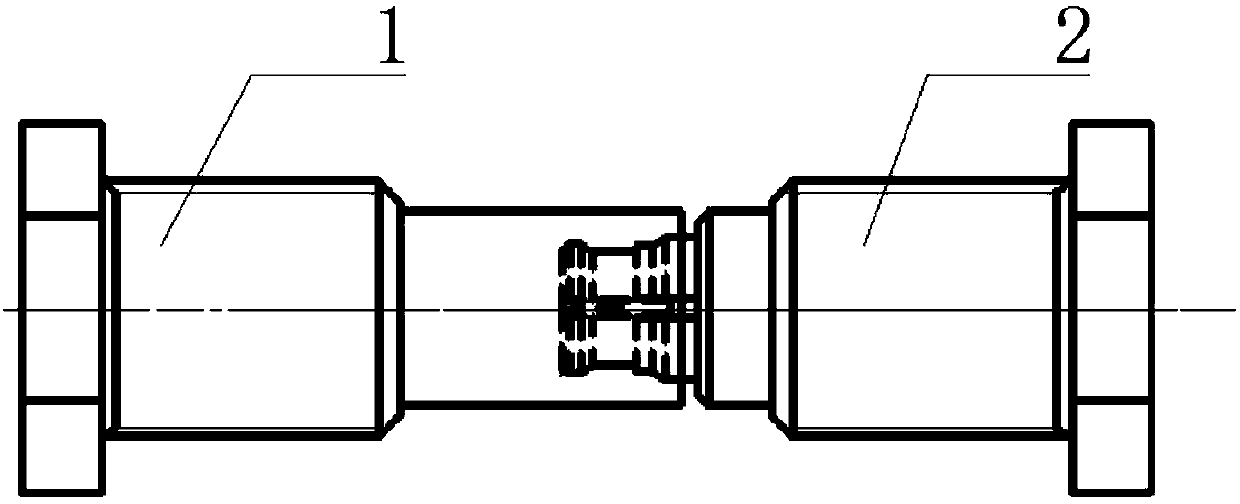

High-precision cyclone separation filter

ActiveCN104190154AImprove processing efficiencyExtend your lifeFiltration circuitsCyclonePulp and paper industry

The invention belongs to the field of water treatment filter equipment, and in particular relates to a high-precision cyclone separation filter. The high-precision cyclone separation filter comprises a cylinder, wherein an upper-end pressure plate and a lower-end pressure plate are arranged in the cylinder body; a filter material is filled between the upper-end pressure plate and the lower-end pressure plate; a hollow screw rod penetrates through a space between the upper-end pressure plate and the lower-end pressure plate; threaded sleeves are arranged at the two ends of the screw rod; the upper-end pressure plate and the lower-end pressure plate are respectively connected with the screw rod through the threaded sleeves; a flow division plate is arranged below the lower-end pressure plate and is arranged on the threaded sleeve which is connected with the lower-end pressure plate, in a sleeving manner; tangent water passage holes are respectively distributed in the upper part and the lower part of the screw rod; a water inlet cyclone device and a sedimentation screen plate are arranged on the bottom of the cylinder body; a backwash water outlet is formed in the top of the cylinder body; the top of the screw rod is connected with a motor; the middle part of the screw rod is connected with a water collecting device; the water collecting device is connected with a water outlet through a water delivery pipe; the water outlet is formed in one side of the cylinder body; a manhole is formed in the other side of the cylinder body. According to the high-precision cyclone separation filter, a backwash pump is not arranged, the number of combination tanks is not required, the high-precision cyclone separation filter can be adjusted and compressed, the filter area is large, the treatment precision is high, the water treatment amount is large, and the occupied area is small.

Owner:山东海钻节能环保科技有限公司

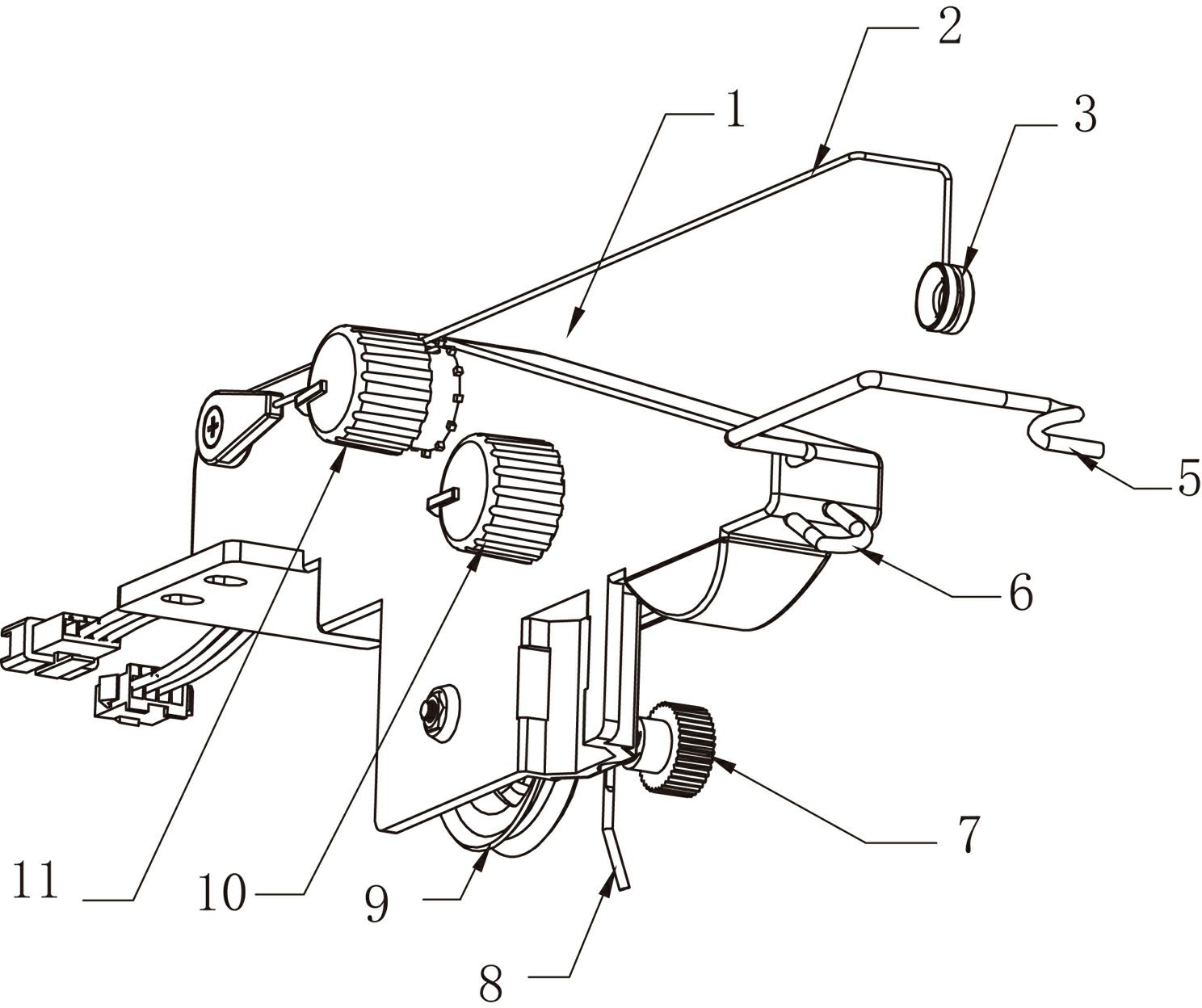

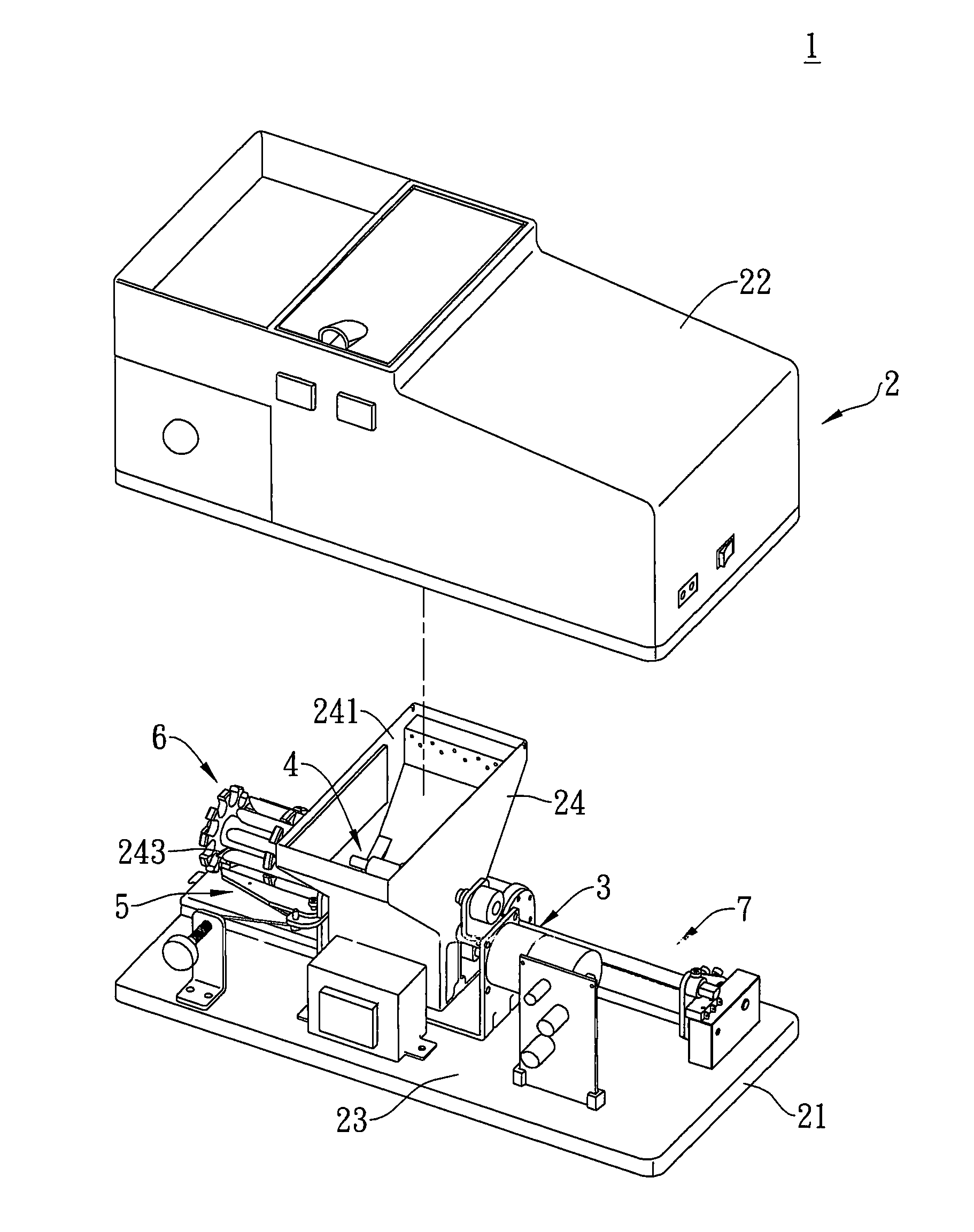

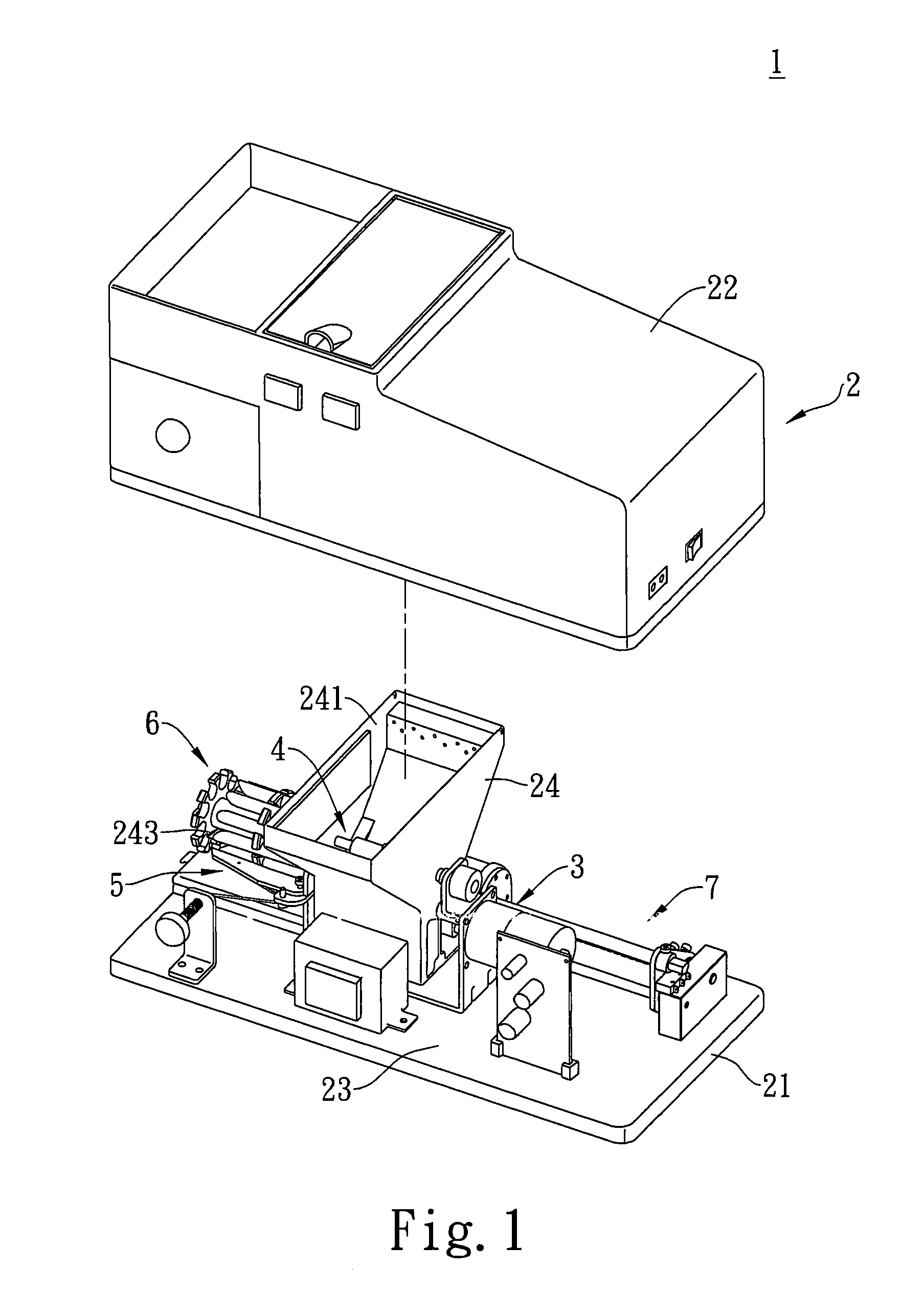

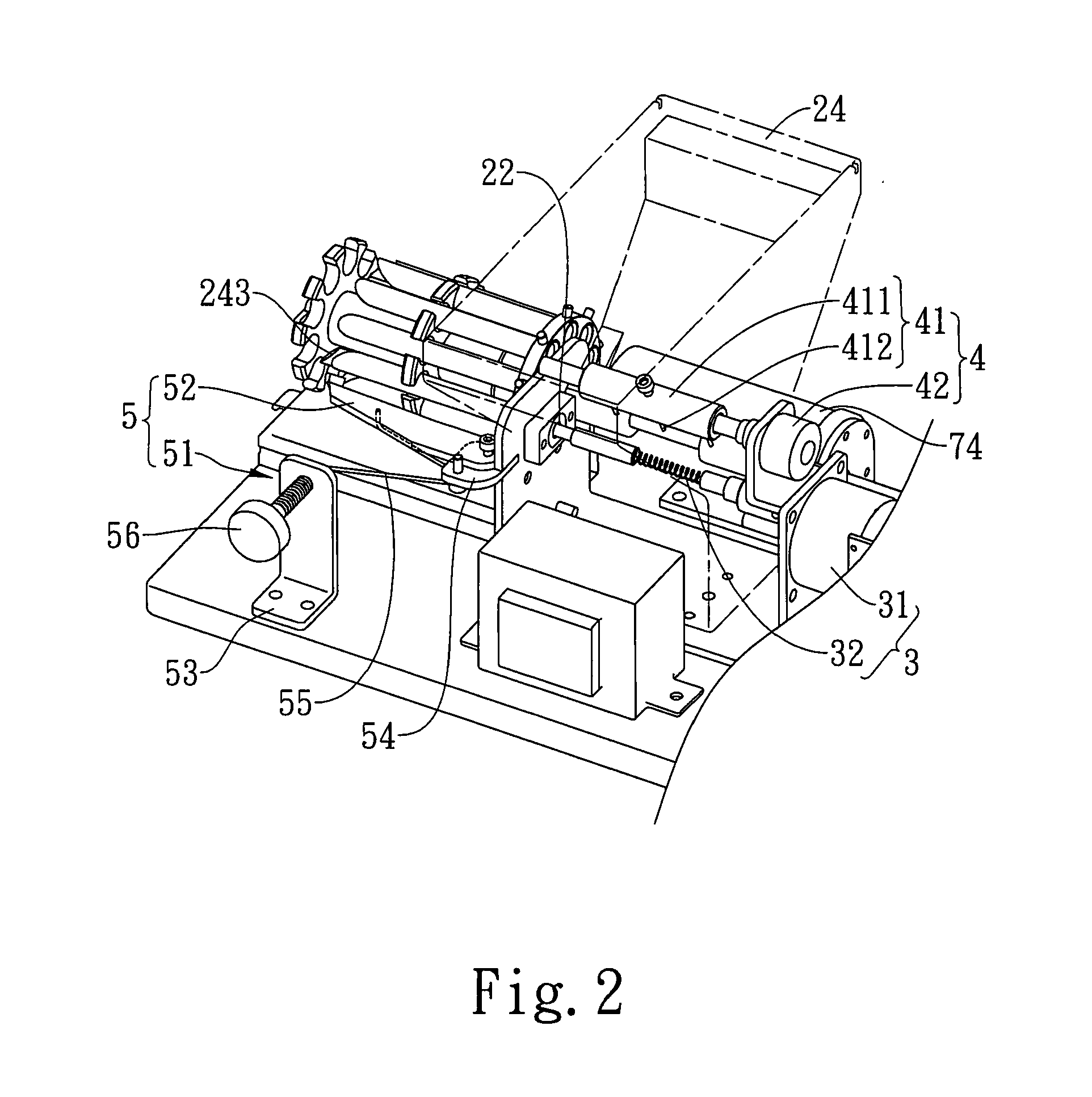

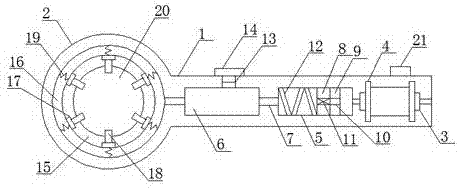

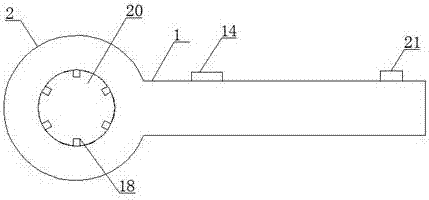

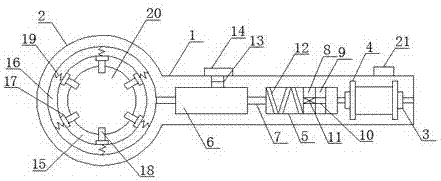

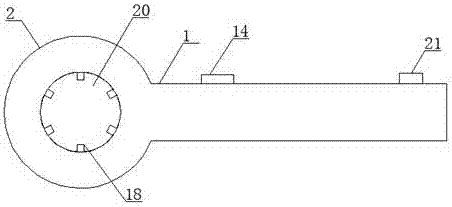

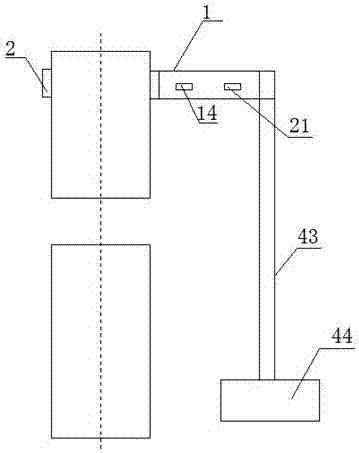

Automatic cigarette maker

InactiveUS20110023894A1Continuous fillingControl tightnessCigar manufactureCigarette manufactureCigarette MakersEngineering

An automatic cigarette maker comprises a case that is provided with a container therein. The container has an opening at the top thereof. The tobacco leaves in the container are pushed out of a tobacco supply duct by a feeding module. A rotary disc is connected with one end of a linkage arrangement and is provided with a plurality of tubes that are arranged in a form of circular array. Each tube is provided with a cigarette paper therein. Thereby, when the linkage arrangement moves the rotary disc backward relative to the container, a tube covers the tobacco supply duct for filling tobacco leaves. When the rotary disc is moved forward, a cigarette paper is fully filled with tobacco leaves. When being moved relative to the container forward and backward once, the rotary disc is rotated at a constant angle. Consequently, the tubes can cover the tobacco supply duct one after another and tobacco leaves can be filled into each cigarette paper in sequence.

Owner:LAING BAN INT

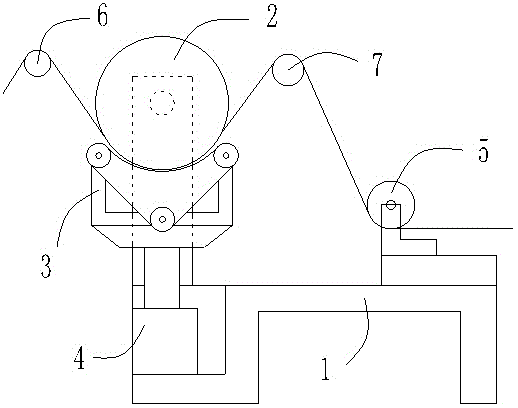

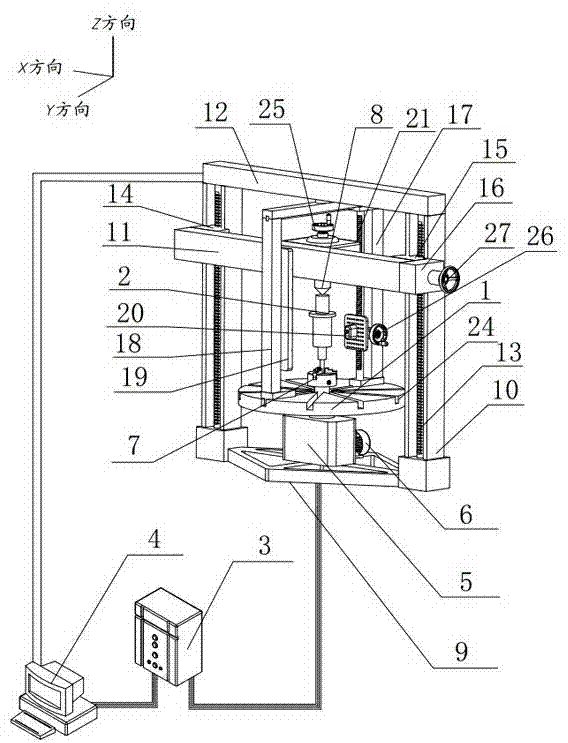

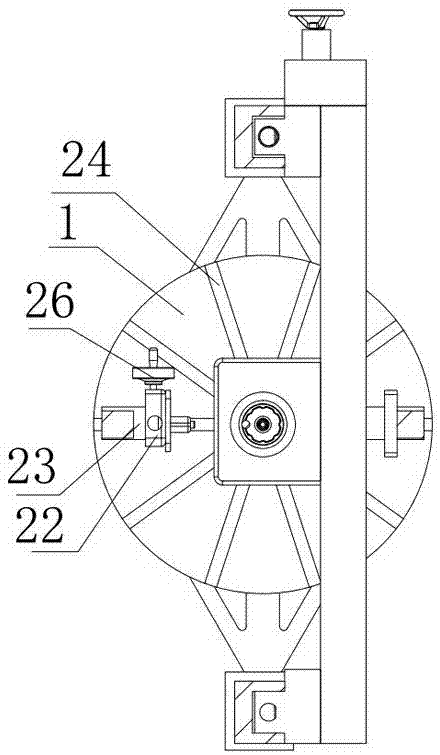

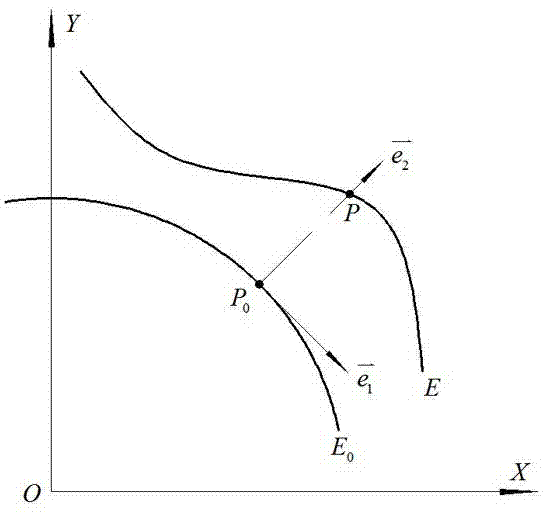

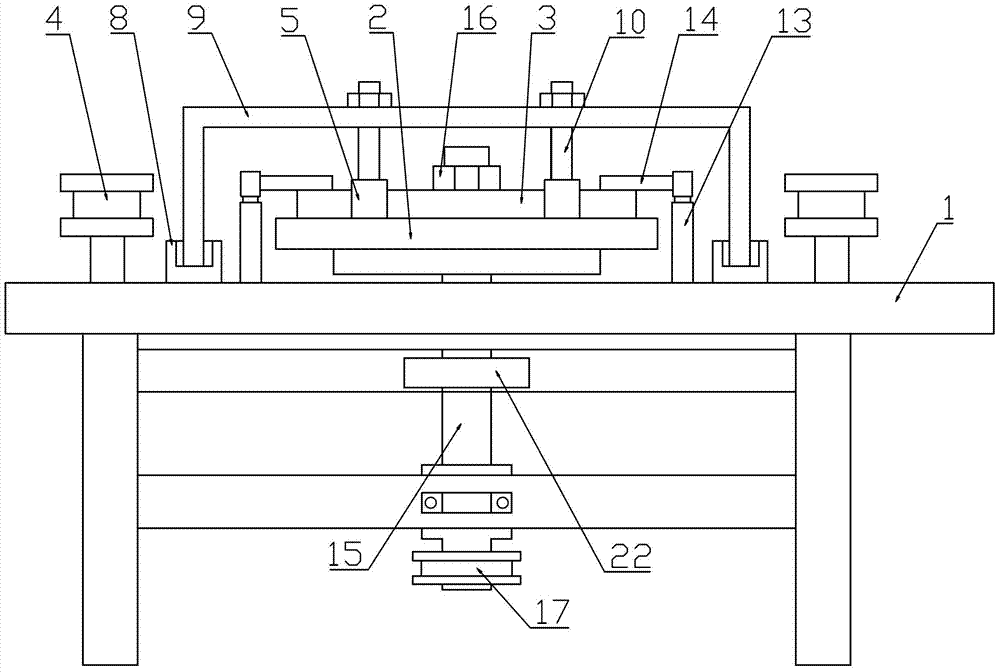

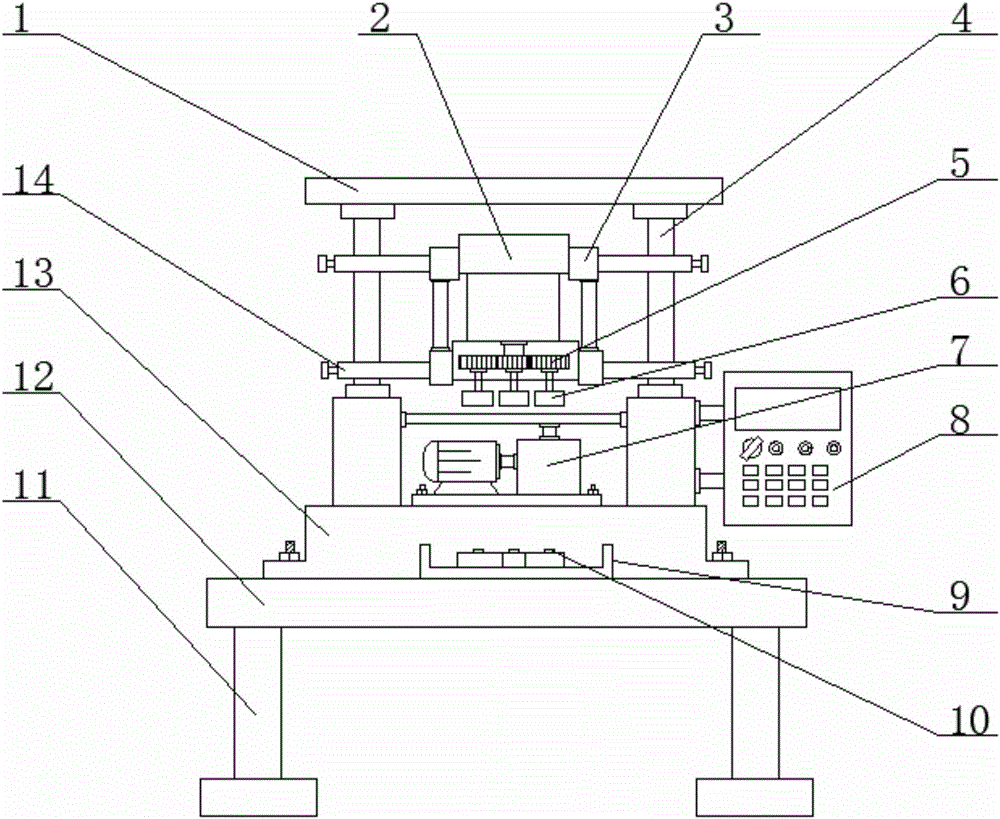

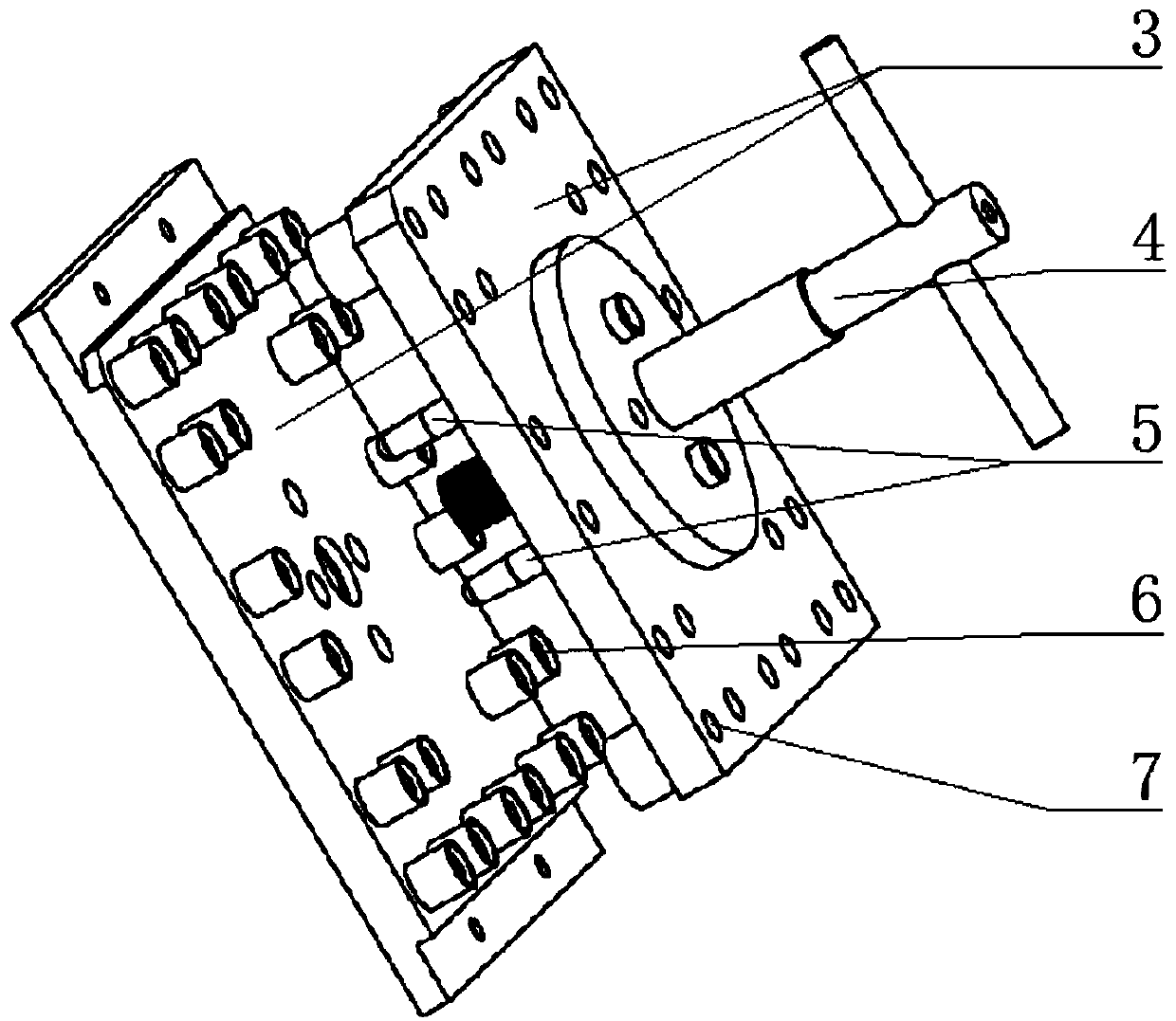

Non-contact type rotation part shape error precision detection device and detection method

The invention relates to the field of mechanical manufacturing, in particular to a non-contact type rotation part shape error precision detection device and a detection method. The detection device comprises a worktable (1), a clamping device, an obtaining device, an adjusting device, a controller (3) and a computer (4), wherein the clamping device is arranged on the worktable (1) and used for fixing a workpiece (2) to be detected and driving the workpiece (2) to be detected to rotate axially in the Z direction, the obtaining device is arranged on the worktable (1), can be adjusted in the Y direction and the Z direction and is used for obtaining the shape information of the workpiece (2) to be detected, and the adjusting device is used for loosening and clamping the clamping device. The clamping device, the information obtaining device and the adjusting device are respectively and electrically connected with the controller (3). The controller (3) and the information obtaining device are electrically connected with the computer (4). The detection device is low in price, easy to operate, low in requirement on environment and high in detection efficiency, and the detection method is good in detection effect.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Solar photovoltaic panel dust removal device for sand and dust land

InactiveCN112620205AAvoid sand lossAvoid damageDispersed particle filtrationPhotovoltaicsEngineeringAtmospheric sciences

The invention discloses a solar photovoltaic panel dust removal device for sand and dust land, and relates to the technical field of power generation facilities. The solar photovoltaic panel dust removal device for the sand and dust land comprises a photovoltaic panel and a sand and dust removal device, wherein sliding frames are arranged at the front end and the rear end of the upper surface of the photovoltaic panel; sliding ways are formed in the front faces of the sliding frames; and the upper surface of the photovoltaic panel is in lap joint with the bottom of the sand and dust removal device. According to the solar photovoltaic panel dust removal device for the sand and dust land, a cleaning device is arranged on the sand and dust removal device, an air blower conveys strong wind power to the cavity of a rotary drum, the wind power is focused and blown into a dust removal box through air gathering holes, sand on the upper surface of the corresponding photovoltaic panel in the dust removal box can be blown up under the action of the strong wind power, the rotary drum is driven to rotate anticlockwise under the action of a motor, and sand and dust in the dust removal box are blown into a sand storage bag along with the wind direction, so that the sand and dust on the photovoltaic panel are cleaned and collected without coming into contact with the photovoltaic panel, and damage to the photovoltaic panel is avoided.

Owner:苏州波粒新能源科技有限公司

Glass curtain wall with glass rib unit and manufacturing method thereof

InactiveCN101255724AReduce manufacturing costImprove assembly accuracy and qualityWallsSurface plateArchitectural engineering

A glass rib unit type glass curtain wall comprises a unit frame and a panel glass. A principal vertical support is supported between the upper and the lower frames of the unit frame. The principal vertical support is connected with the auxiliary vertical support, and the glass rib is fixed in the auxiliary vertical support. The method for preparing the curtain wall comprises the following steps: baiting, manufacturing the sectional material, assembling the frame, installing the glass rib vertical support and auxiliary support, installing the panel glass and installing the glass rib. The invention provides a technique of the unit type glass curtain wall which is provided with a glass rib.

Owner:ZHEJIANG BAOYE CONSTR GROUP CO LTD +1

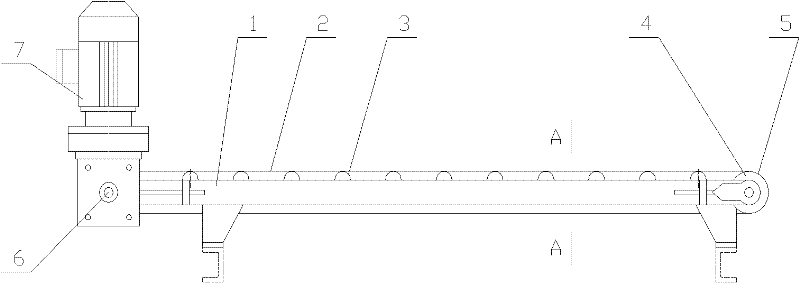

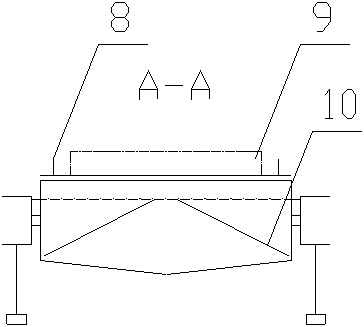

Novel wax plate conveyor

The invention discloses a novel wax plate conveyor, and a framework is a foundation support architecture which is formed through steel plate process and equipped with other mating parts; a driving transmission roller and a driven transmission roller are respectively mounted at the front end and the back end of the framework, and a supporting roller is mounted at the middle part of the framework; a semi-closed annular belt provided with blocking edges on the two sides bypasses the upper surfaces of the driving transmission roller, the driven transmission roller and the supporting roller; a micro-variable speed motor is mounted at the front end of the framework and coaxial with the driving transmission roller; and a wax crumb recovery device comprising a wax crumb sliding plate in the inverted V-shaped cross section, a wax crumb collecting groove which is in the shape of inverted V in the longitudinal direction and a wax crumb recovery funnel is mounted below the supporting roller and on a lower beam of the framework. The novel wax plate conveyor has the advantages that the semi-closed annular belt can prevent deviation, blockage and damages to wax plates; the wax crumb recovery device can prevent wax crumbs from scattering and enable the wax crumbs to automatically flow into the wax crumb recovery funnel, thereby preventing the wax plates from being polluted, being conductive to environmental protection and recovery of the wax crumbs and reducing the cost; the mounting is simple and convenient and the service life is long; and the manufacturing cost is reduced by about 20%.

Owner:大连天禄机电设备制造有限公司

New energy automobile charging gun head locking device

ActiveCN106992402APrevent looseningThe charging process is stableVehicle connectorsCharging stationsEngineeringControllability

The invention discloses a new energy automobile charging gun head locking device. The device comprises a side rod fixed to a charging pile and a fixing portion fixedly connected to the side rod. The fixing portion is coaxial with a charging port arranged on the charging pile. An iron column, a slide chamber and a hollow chamber are arranged in the side rod, wherein a circular wire sleeves an external portion of the iron column. An internal portion of the side rod is provided with a through groove connecting an external portion and the slide chamber and a through groove connecting the slide chamber and the hollow chamber. A side surface of the side rod is provided with an operation and control machine. One end inside the slide chamber, which is near the iron column, is provided with a magnetic block. One end surface of the magnetic block is fixedly provided with, a slide plate. A core of the slide plate and the magnetic block is a first through groove. In the invention, a charging gun head can be effectively fixed, the charging gun head can be prevented from loosening and a charging process is guaranteed to be stable. In addition, the device uses electromagnetism to control so that controllability is possessed. And according to a current size, the device can control a degree of tightness of fixation of the charging gun head and a suitable range is wide.

Owner:中诚鑫锐电力科技有限公司

Preparation method of heat-resisting seal microcapsule with sensitive pressure

ActiveCN103285794AControl mechanical strengthControl tightnessMicroballoon preparationMicrocapsule preparationPolymer scienceRepair material

The invention discloses a preparation method of a heat-resisting seal microcapsule with sensitive pressure. The preparation method comprises the steps of: firstly, preparing a microcapsule wall material, controlling the temperature to be within 20-80 DEG C, preparing epoxy rein and a core material curing agent equivalent to 0.50-0.85 time that of the epoxy resin into a prepolymer; then dissolving a prepolymer wall material in a solvent to form a solution; controlling the temperature of the solution to be within 20-80 DEG C, dropping a core material in the solution by using a needle hole until the microcapsule wall is cured and formed; filtering, washing and drying to obtain the heat-resisting seal microcapsule with the sensitive pressure. The preparation method is simple in process and equipment; meanwhile, a water phase is not introduced and the limitation to the water solubility or oil solubility of the microcapsule core material is not caused; through controlling the proportion and a system degree of functionality between the epoxy resin and the curing agent, the mechanical strength, the sealing property and the heat resistance of the microcapsule can be effectively controlled. The microcapsule is used as a micro-container, and can be used in fields of self-repairing materials, latent adhesives or other core materials needing release control or isolation.

Owner:JURONG NINGWU SCI & TECH DEV

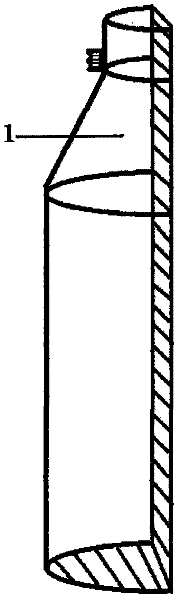

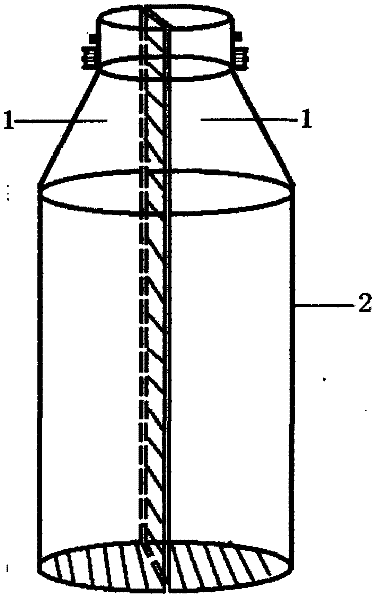

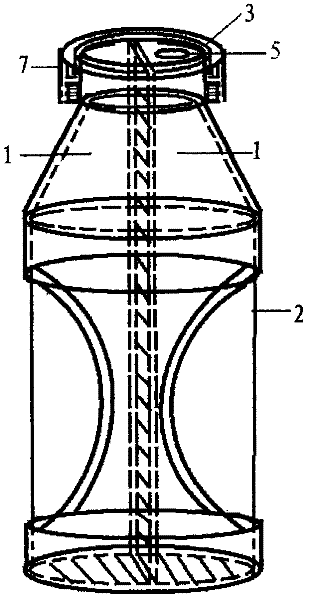

Multi-chamber combined bottle

The invention discloses a multi-chamber combined bottle, which is formed by combining a plurality of single chambers. A selective liquid trickling bottle cap is capped on the multi-chamber combined bottle and refers to a single movable cap or a combination of a movable cap and a fixed cap, and the movable cap is capable of freely rotating. The selective liquid trickling bottle cap is provided with liquid trickling holes, and positions of the liquid trickling holes are adjusted by rotating the movable cap so that the liquid trickling holes correspond to outlets of the chambers in a multi-chamber combined bottle body in position, and further, one or more types of liquids in a plurality of types of liquids in the multi-chamber combined bottle body can be poured out. Parts of components of the multi-chamber combined bottle or the bottle cap can be of an integrally formed structure or can be separately assembled, therefore, the components can be guaranteed to be freely movable and can be detachably cleaned when necessary so as to be kept clean.

Owner:连斌

Fixing device for welding

ActiveCN106914726AEasy to weldEffectively fixedWelding/cutting auxillary devicesAuxillary welding devicesMagnetEngineering

The invention discloses a fixing device for welding. The fixing device comprises a fixing rod and a fixing ring which is integrated with the fixing rod to form a whole, wherein the fixing ring is used for fixing a pipe fitting; the right end of the fixing rod is fixedly arranged at the top of a lifting rod driven by a motor; a base is arranged at the bottom of the lifting rod; an iron block, a sliding cavity and a storage cavity are arranged in the fixing rod, and a thread loop is arranged at the outer part of the iron block in a sleeving manner; a channel connected with outside and the sliding cavity, and a channel connected with the sliding cavity and the storage cavity are formed in the fixing rod; a controller is arranged on a lateral side of the fixing rod; a magnet is arranged in the sliding cavity, located at one end of the iron block; a sliding plate is fixed to one end surface of the magnet; and an internal channel is formed in the middle of the sliding plate and the magnet. Through the adoption of the fixing device disclosed by the invention, the pipe fitting can be effectively fixed, so that two pipe fittings can be conveniently welded; in addition, electromagnetism is utilized for control, so that the fixing device has controllability; and besides, the degree of tightness for fixing the pipe fitting can be controlled according to the magnitude of electric current, so that different demands can be met.

Owner:盐城市九洲汽车配件有限公司

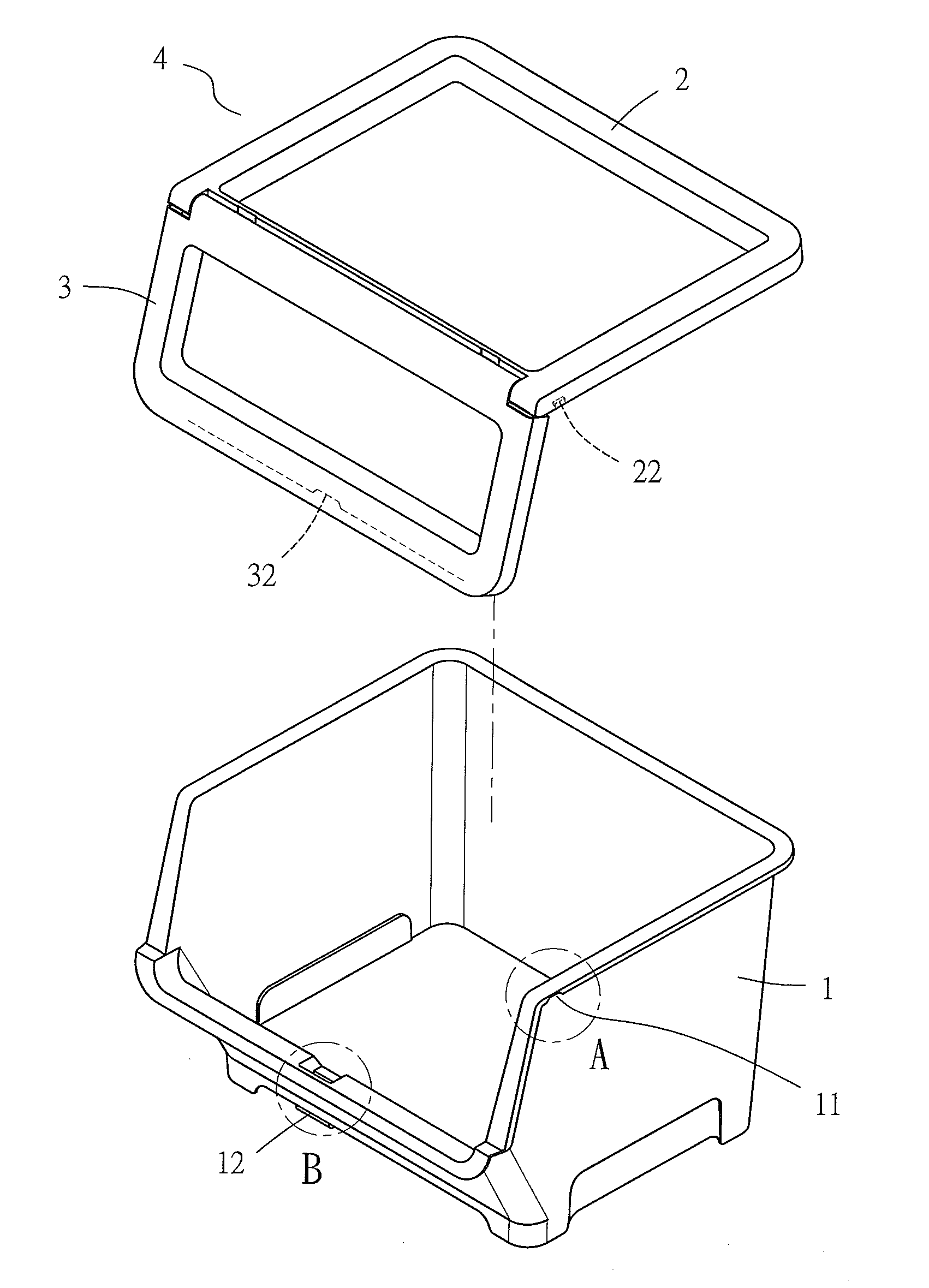

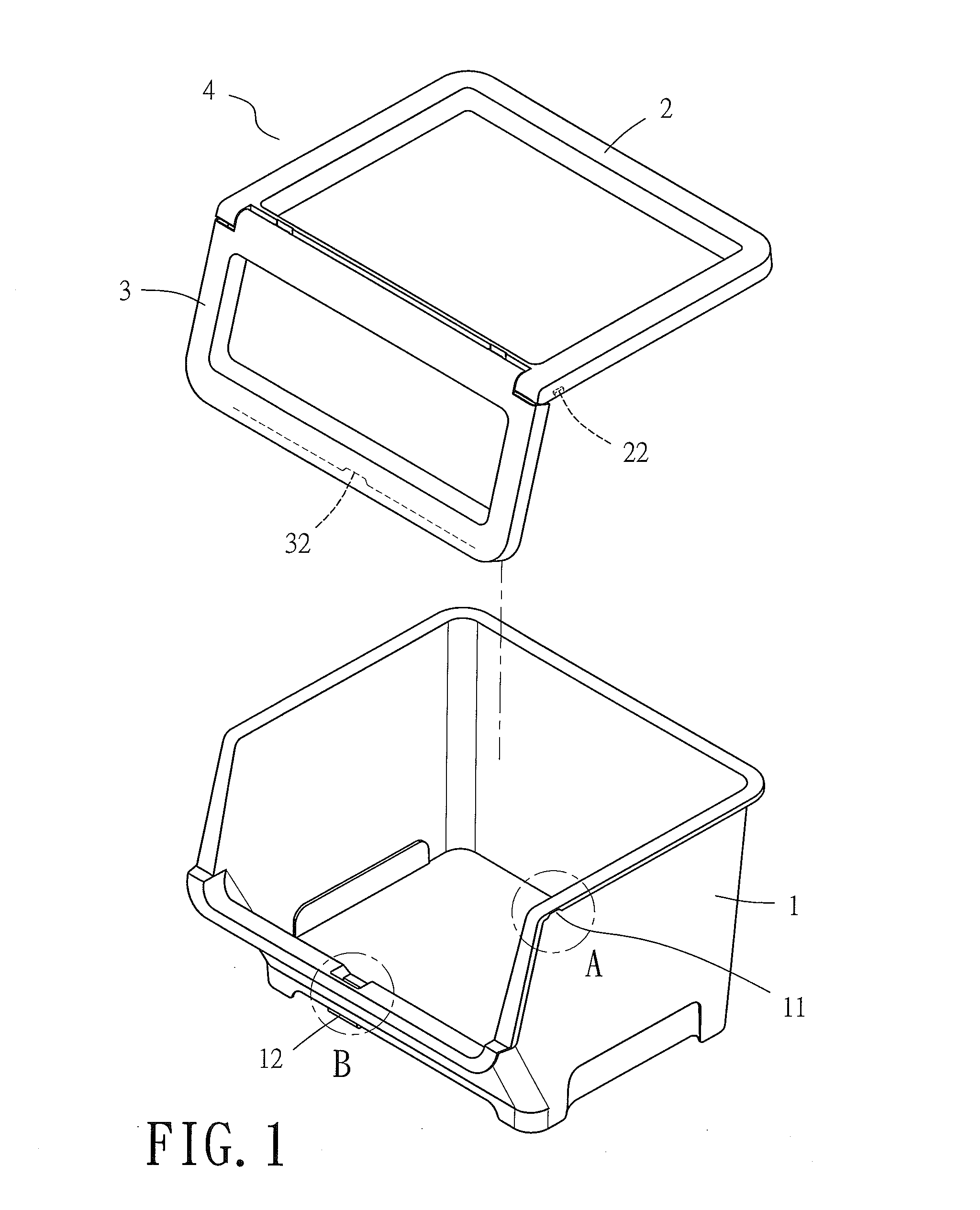

Containing Box Structure

A containing box structure includes a containing box and a lid body. The lid body includes top and front lids. Concave portions are concavely disposed at the edge of a top opening of the containing box. An engaging portion with an S-shaped cross section is disposed at the edge of the front of the containing box. The edge of the top lid extends by a length to form abutting portions which straddle at the upper edge of the containing box, such that hook portions of the top lid are inserted into the concave portions, thereby effectuating precise engagement between the top lid and the containing box. A protruding portion extends from the lower edge of the front lid to engage with the engaging portion of the containing box. Therefore, the containing box is covered, and thus is in precise positional engagement, with the top lid and the front lid.

Owner:L & F PLASTICS

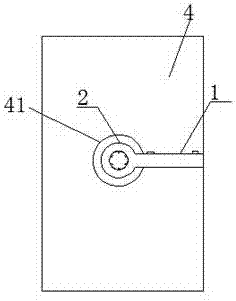

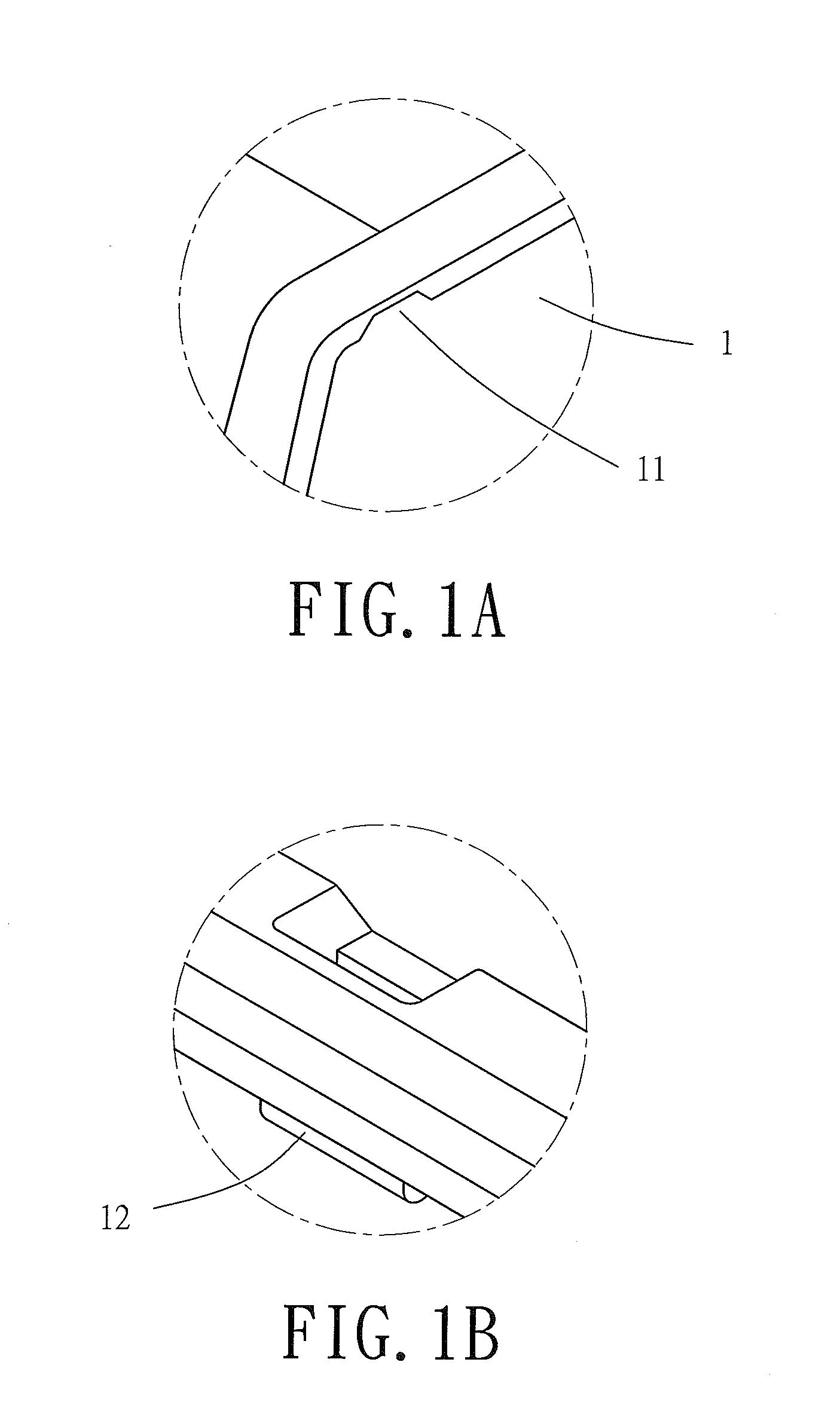

Secondary battery winding pin and battery winding method employing the winding pin

InactiveCN1992414AEasy to pull outReduce volumeFinal product manufactureSecondary cells manufactureEngineeringConductor Coil

This invention relates to a secondary battery volume needle, which primarily has the first component and the second component, in particular, the said first component and the second component connecting to form the two joints folder, the periphery of the folder being cylinder-shape. Using the said secondary battery volume needle winding method, especially assemble the folder to the motor; insert the anode slide head into the one joint of the folder, and clamping, and starting the motor; when the anode slide around the folder surrounding half, shutting down the motor, and inserting and positioning the cathode slide with two sides having separated film; continuing to activate the motor until the anode and cathode slide all volumes to stop motor; finally, pulling out the folder. The secondary battery volume needle is applicable to improving the secondary battery winding effect, and the battery winding method using the structure volume needle can extend battery using life, and save the battery raw materials.

Owner:BYD CO LTD

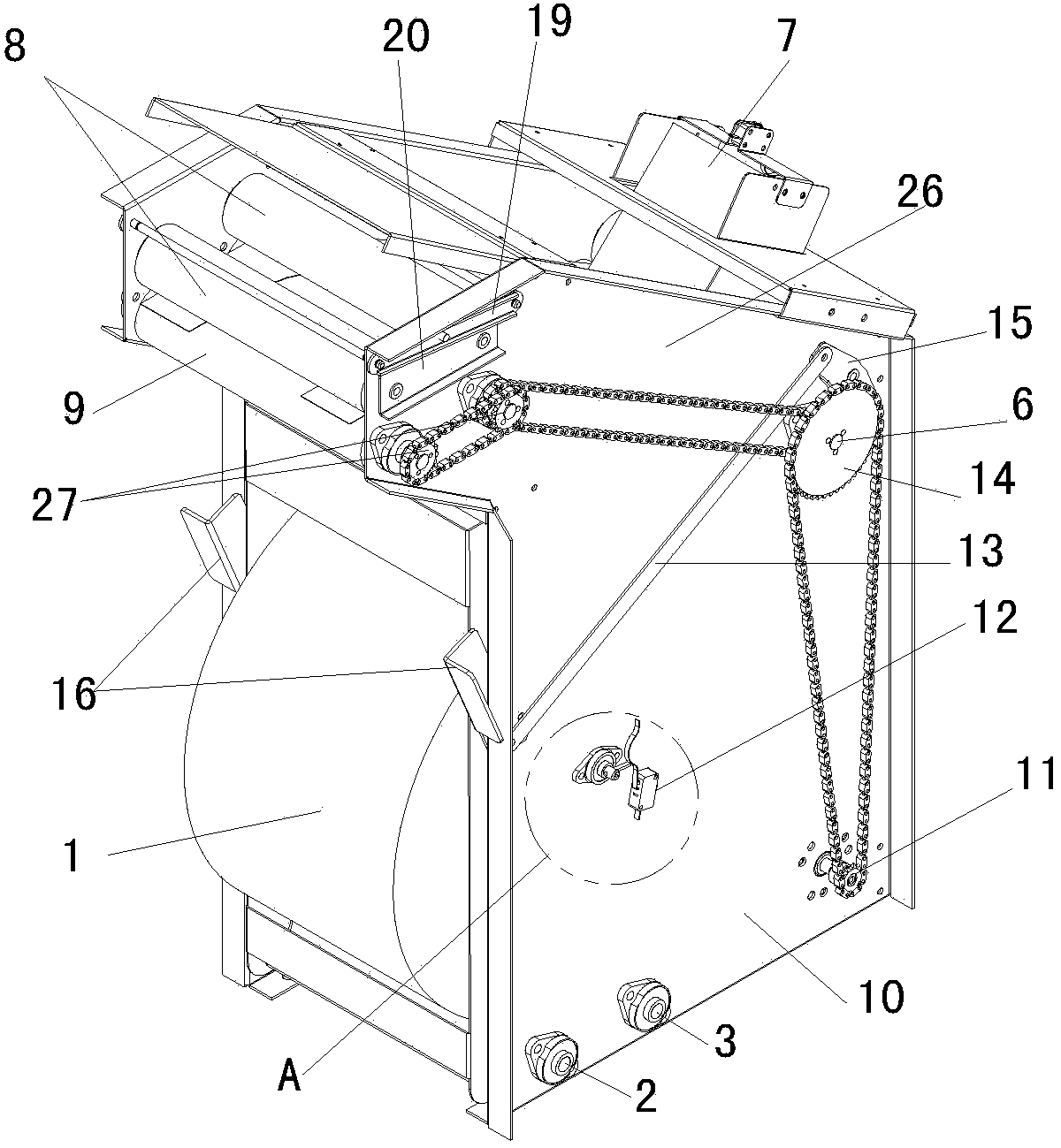

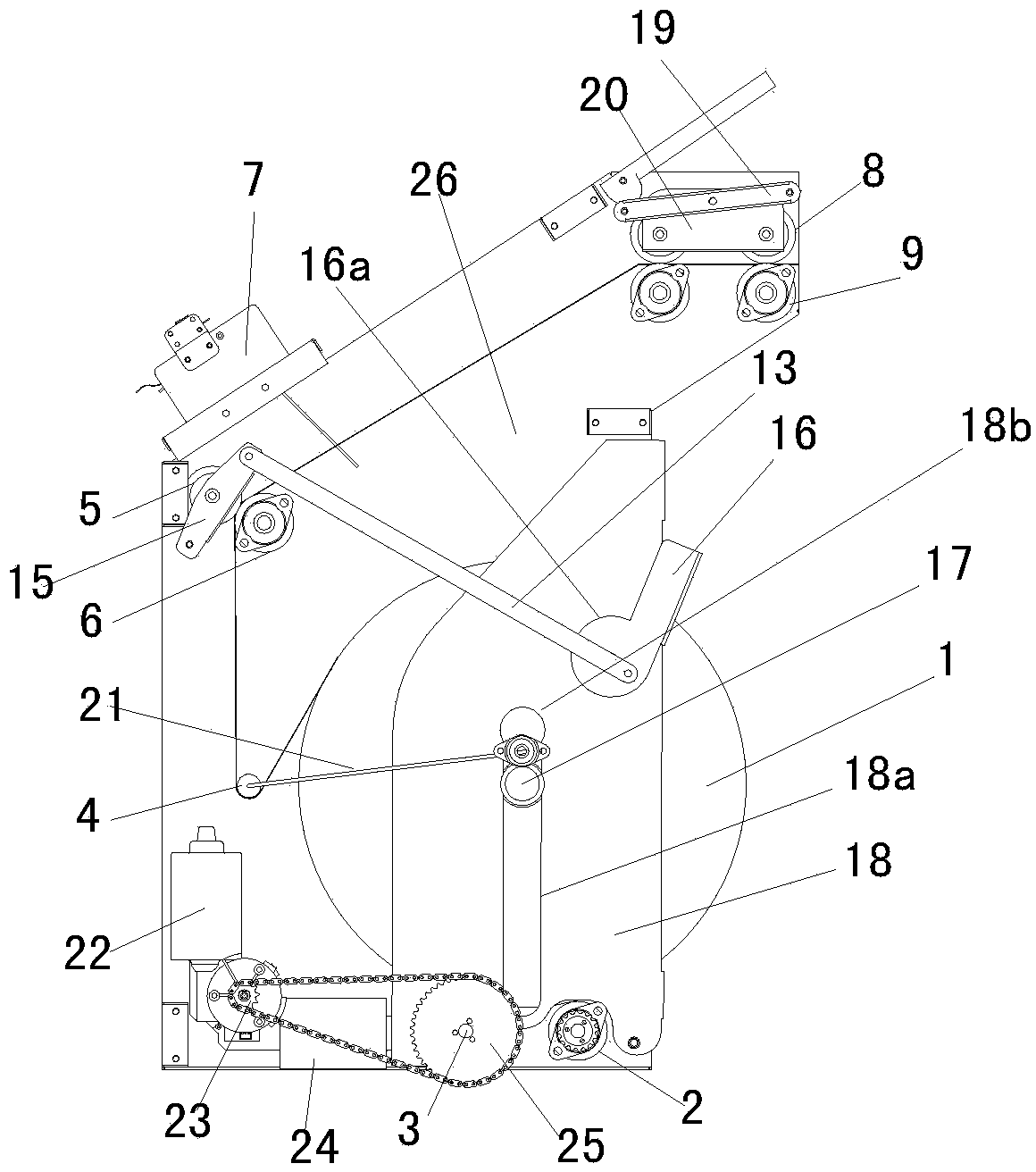

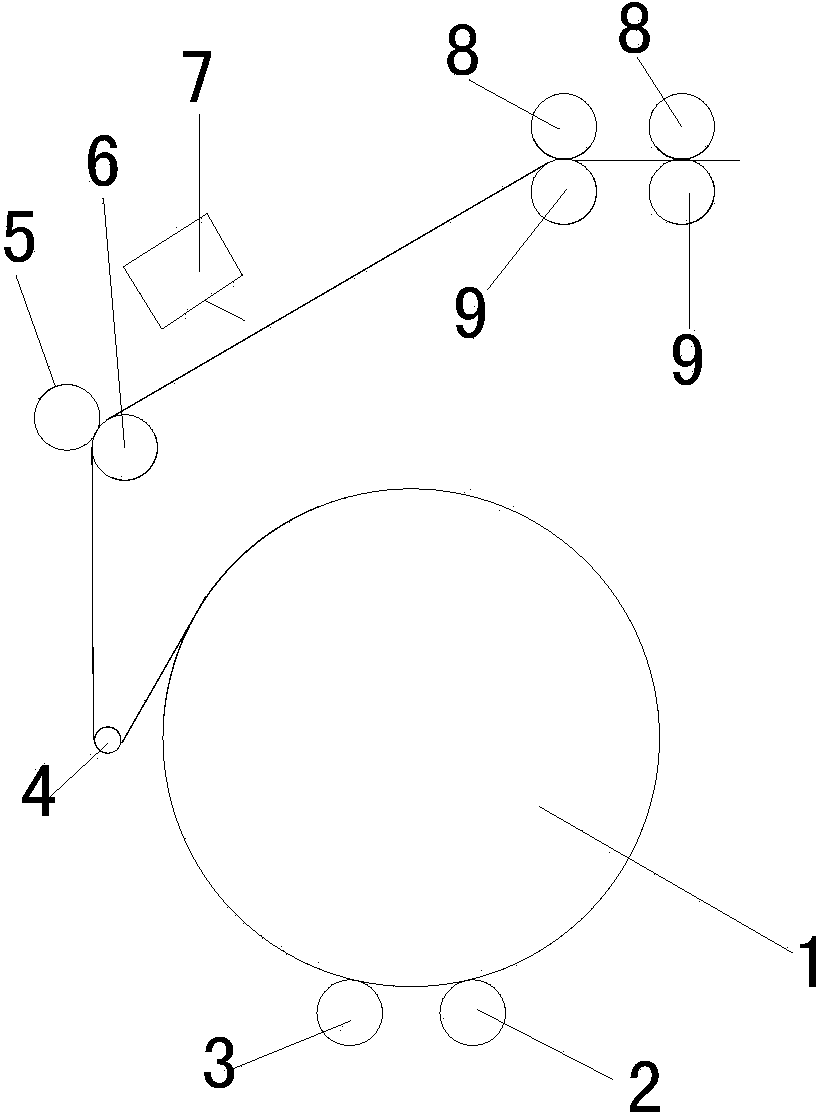

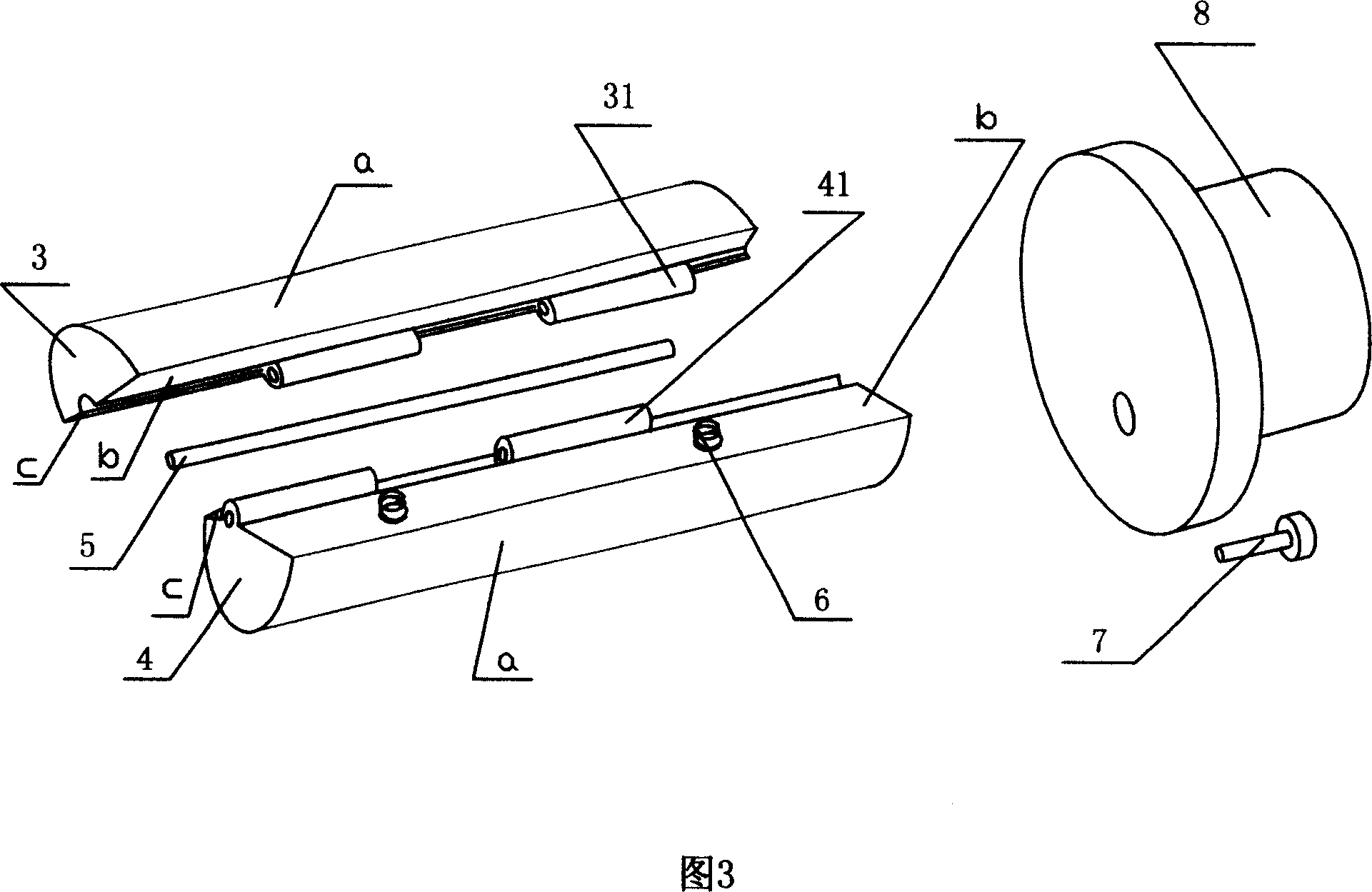

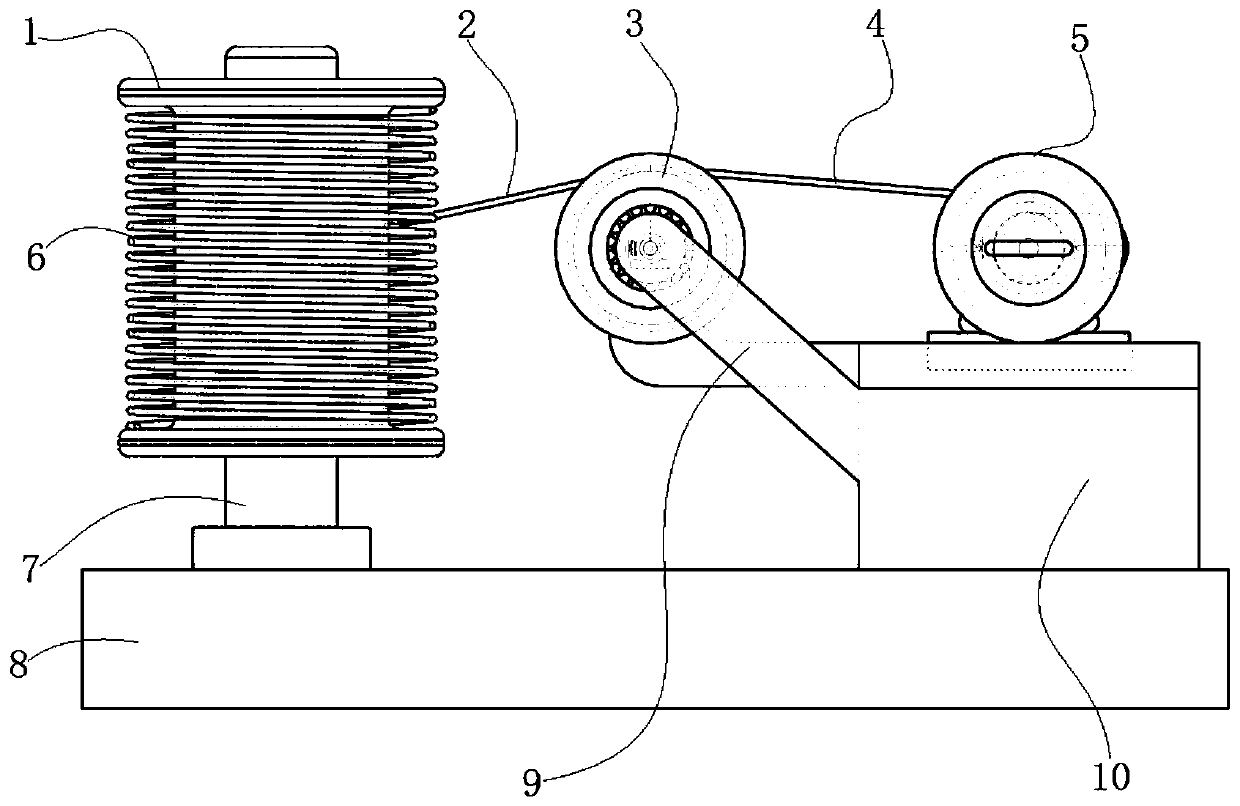

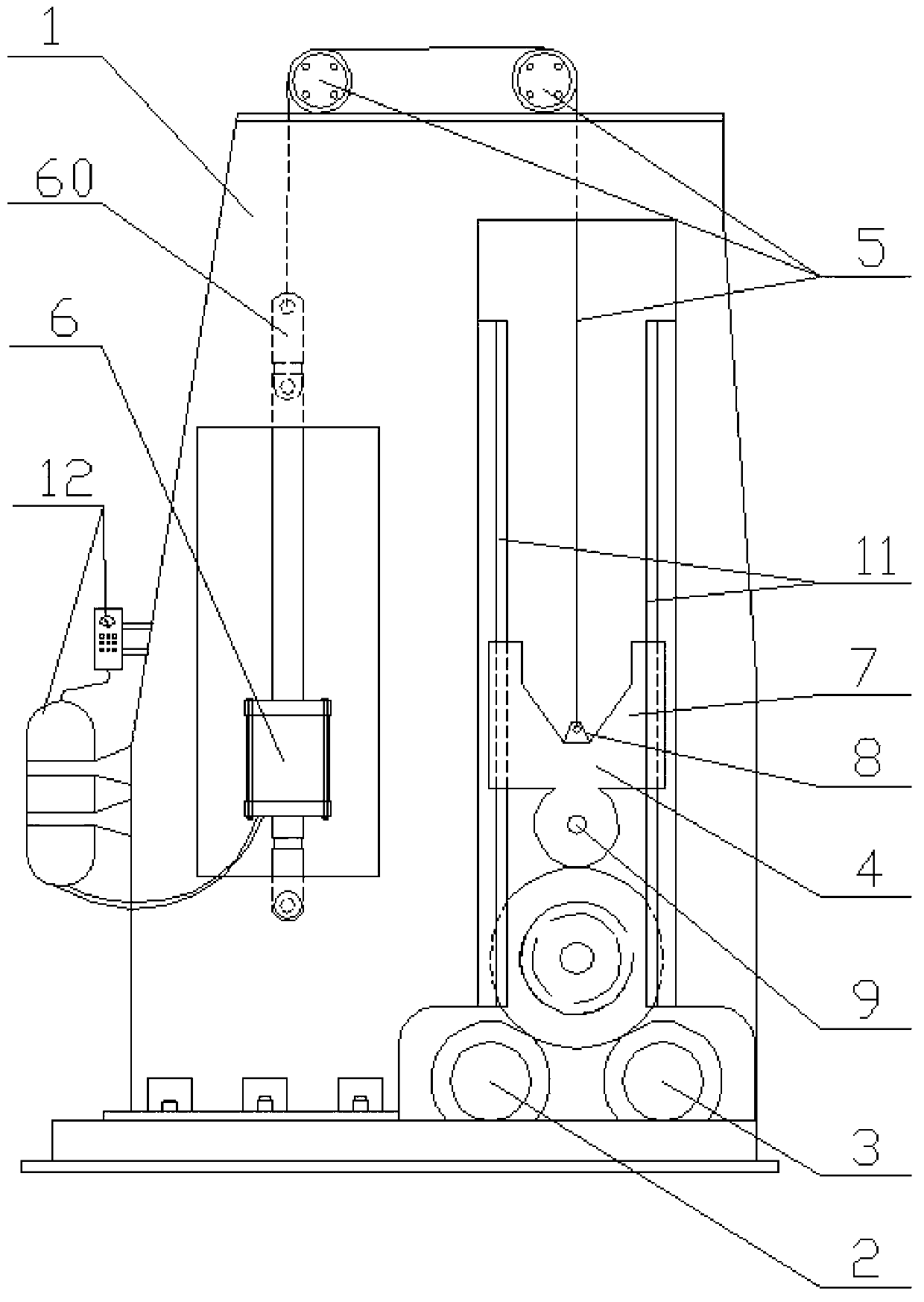

Large automatic winding machine for amorphous and ultrafine-crystalline thin strips

InactiveCN103325561AGuaranteed flatnessImprove product qualityInductances/transformers/magnets manufactureWinding machineEngineering

The invention relates to an automatic winding machine for enabling amorphous and ultrafine-crystalline thin strips to be wound into disk strips or large magnetic rings. The winding machine comprises a machine frame, the machine frame is provided with a rotating disk, the rotating disk is provided with a rotating inner core for winding a wound strip, the rotating inner core is in linkage with the rotating disk, at least two fixed wheels are fixedly arranged on the machine frame, and the machine frame is further provided with a pulley and a tensioning wheel which both can move. The pulley, the tensioning wheel and the fixed wheels are connected through a belt, the pulley is externally tangent with the rotating inner core, and the tensioning wheel is connected with a gravity balance block through a pull line. The automatic winding machine has the advantages that the pulley and the tensioning wheel can move along with increase of the external diameter of a winding product, and the pulley is tangent with the winding product, so that the tightness of the wound strip can be controlled by changing the weight of the gravity balance block according to the product production requirements; a rotating rod is added on the wound strip and abuts against the wound strip, product flatness in winding can be guaranteed, and product quality is improved.

Owner:ZHEJIANG ZHENGNUO COMPOSITE MATERIAL

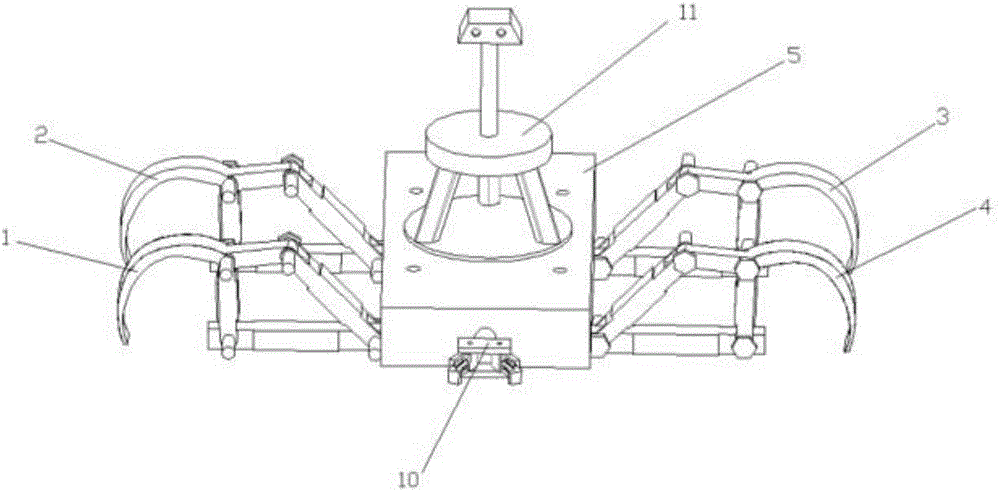

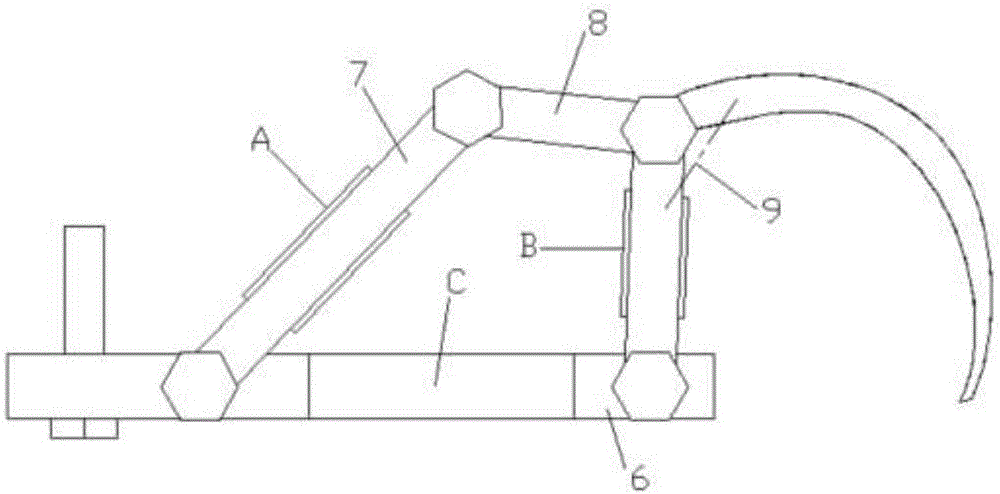

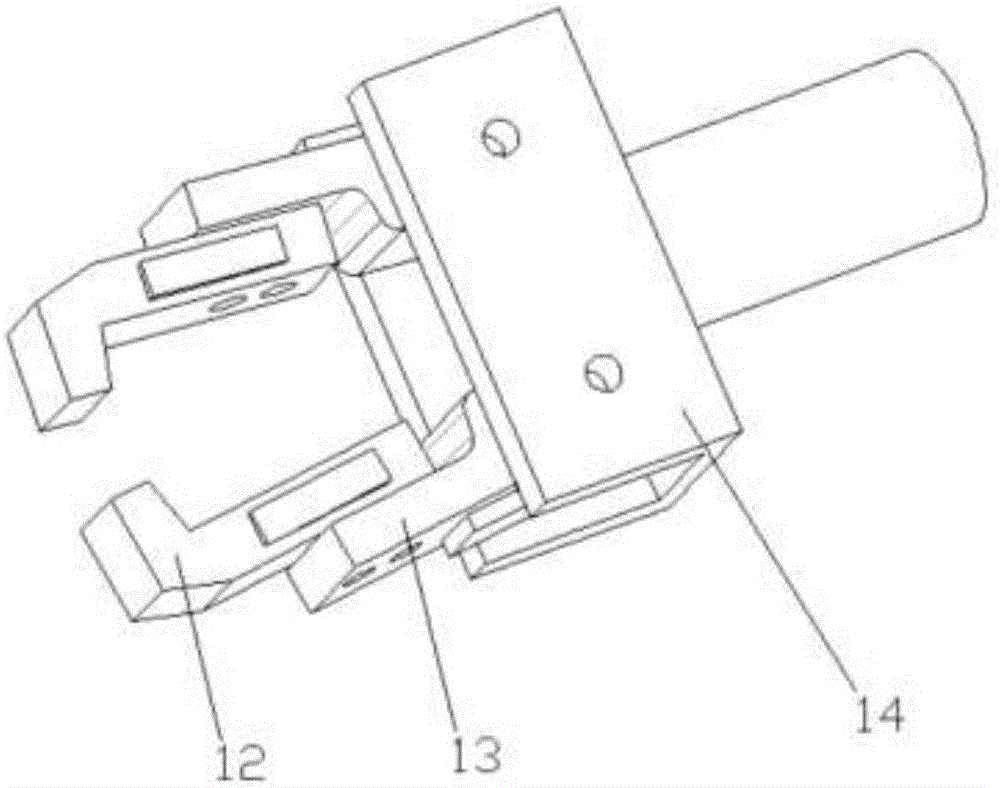

Bionic quadruped spider robot

ActiveCN106542017AWide field of visionFlexible movementVehicle componentsVehiclesEngineeringAdhesion force

A bionic quadruped spider robot comprises a body used as a trunk; two pairs of symmetrically-arranged leg crawling mechanisms are arranged on two sides of the body; a mouth clamping device is arranged on the front side of the body; a camera module is arranged in the middle of the body; the leg crawling mechanisms and the mouth clamping device are driven by corresponding piezoelectric patches to move; and piezoelectric patch groups of the leg crawling mechanisms, a vertical piezoelectric patch and a horizontal piezoelectric patch of the mouth clamping device and the camera module are connected with a control module. The leg crawling mechanisms of the robot have the higher adhesion force and the higher obstacle climbing ability with the ground, so that the robot can be used for carrying an object; the object can be grabbed by the mouth clamping device and can be carried to a destination along a set path, the clamping device has four degrees of freedom, the tightness for clamping the object can be controlled, the acting point for clamping the object can be adjusted through vertical rotation, and the robot has the higher flexibility and sensitivity; and the camera module at the top can rotate, and thus the bionic spider robot can capture a wider field of vision.

Owner:NINGBO UNIV

Quick preparation method for aerobic granular sludge

PendingCN109942079AHigh activityEase of industrial applicationSludge treatment by de-watering/drying/thickeningSustainable biological treatmentGranularitySludge

The invention relates to a quick preparation method for aerobic granular sludge. The quick preparation method comprises the following steps of dehydrating, spirally conveying, extruding, slicing and forming and spherically forming sludge successively. The prepared aerobic granular sludge can be input to an aerating pond as inoculating sludge and is used in a reactor suitable for culturing the aerobic granular sludge in a matched manner. Compared with the prior art, the aerobic granular sludge prepared by the method has the advantages of being low in processing cost, quick to discharge, high inactivity, high in granularity and the like.

Owner:SHANGHAI JIAO TONG UNIV

Split starting shield tunneling machine and temporary deslagging system

ActiveCN105673034AContinuous and fast slag dischargeSmooth slag dischargeTunnelsWork performanceSlag

The invention discloses a split starting shield tunneling machine and a temporary deslagging system and belongs to the technical field of split shield tunneling machine tunnel construction auxiliary equipment. The split starting shield tunneling machine mainly comprises a belt conveyor and a slag transporting car, the belt conveyor is detachably arranged behind the last segment of trolley of the split starting shield tunneling machine, the feeding direction of a belt of the belt conveyor is in the longitudinal direction of a tunnel, and slag is conveyed to the slag transporting car below the belt conveyor through the belt. The split starting shield tunneling machine and the temporary deslagging system can solve the problem that a split starting shield tunneling machine cannot complete deslagging operation normally and has the advantages of being easy to machine, refit, assemble and disassemble, convenient to use and stable in working performance, improving work efficiency greatly and the like.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

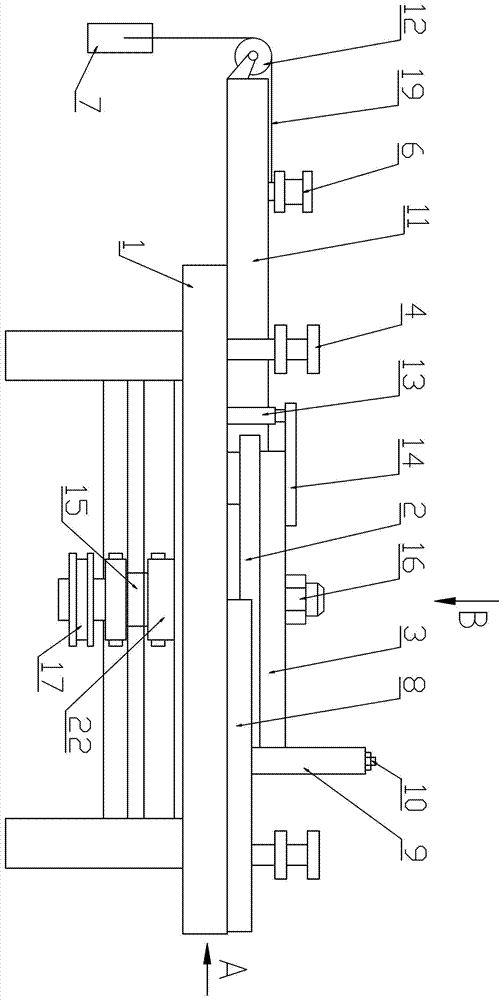

Device for inner and outer circle chamfering and end face opening flattening of two ends of metal ventilation pipe and application method of device

InactiveCN110103096AEasy to installSolve the problem of rough end faceEdge grinding machinesGrinding drivesWork periodEngineering

The invention relates to the field of cutting machining equipment, in particular to a device for inner and outer circle chamfering and end face opening flattening of the two ends of a metal ventilation pipe and an application method of the device. The upper portion of a work platform is provided with a guide rail, movable platforms and a fixed clamping device. The fixed clamping device is locatedin the middle position of the work platform and has the main effect of conducting positioning clamping on the metal pipe. The two movable platforms are located on the two sides of the fixed clamping device and are symmetrically distributed, and the two movable platforms are opposite along the guide rail and have the main effect of driving a combined tool rotating table to move so as to conduct thechamfering and opening flattening processes on the metal ventilation pipe of a dust collector. Inner and outer circle chamfering and opening flattening polishing are combined together, the problem ofend face roughness is solved in one process, subsequent workpiece installation is facilitated, operation of the two end faces of the metal pipe is conducted at the same time, and the work time is greatly saved. A coaxiality fine adjustment device is used for solving the problem of coaxiality deviation caused by long-time work, the work time is saved, the work efficiency is improved, and great market prospects and promotional value are achieved.

Owner:常熟市雷得双金属复合管业有限公司 +1

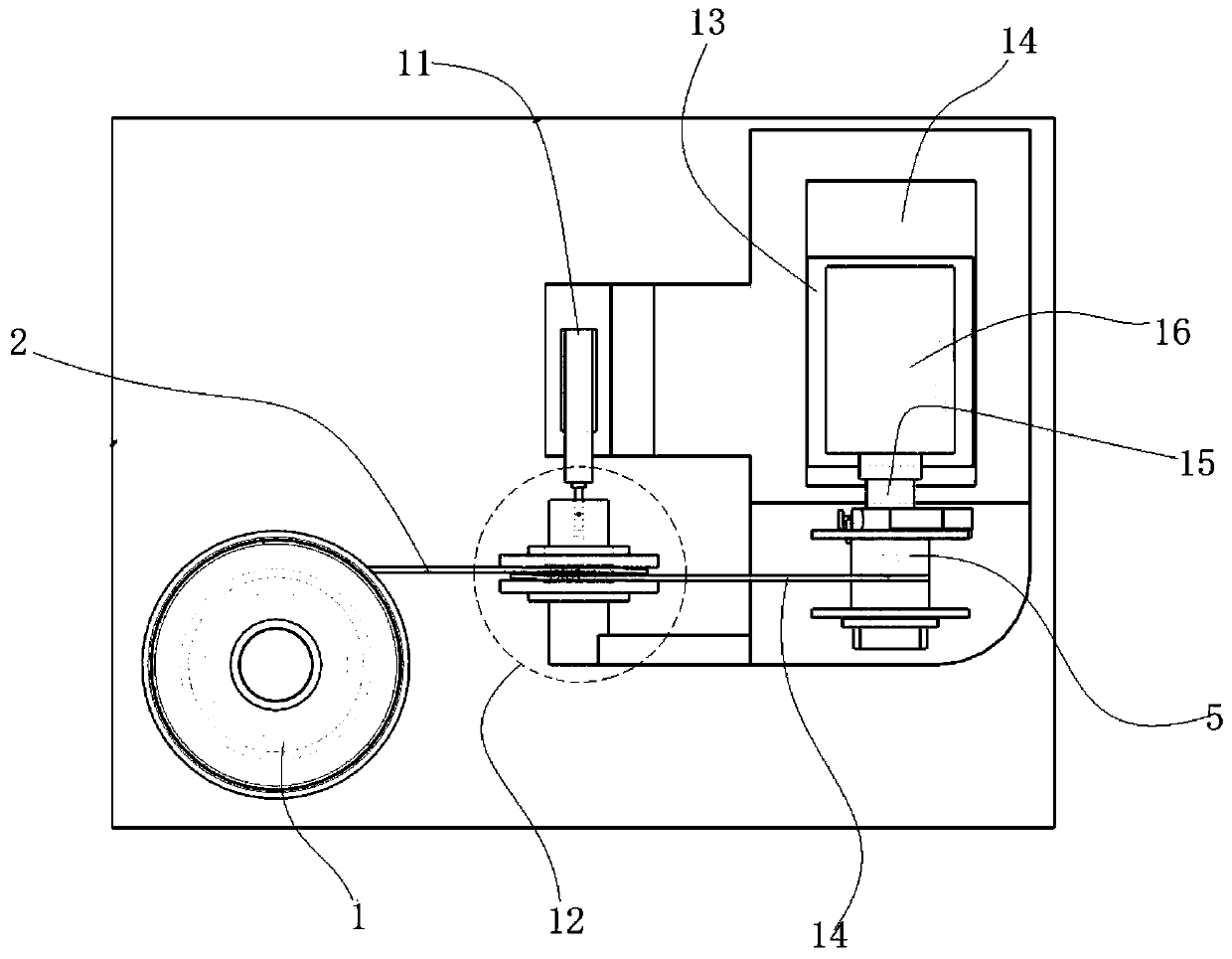

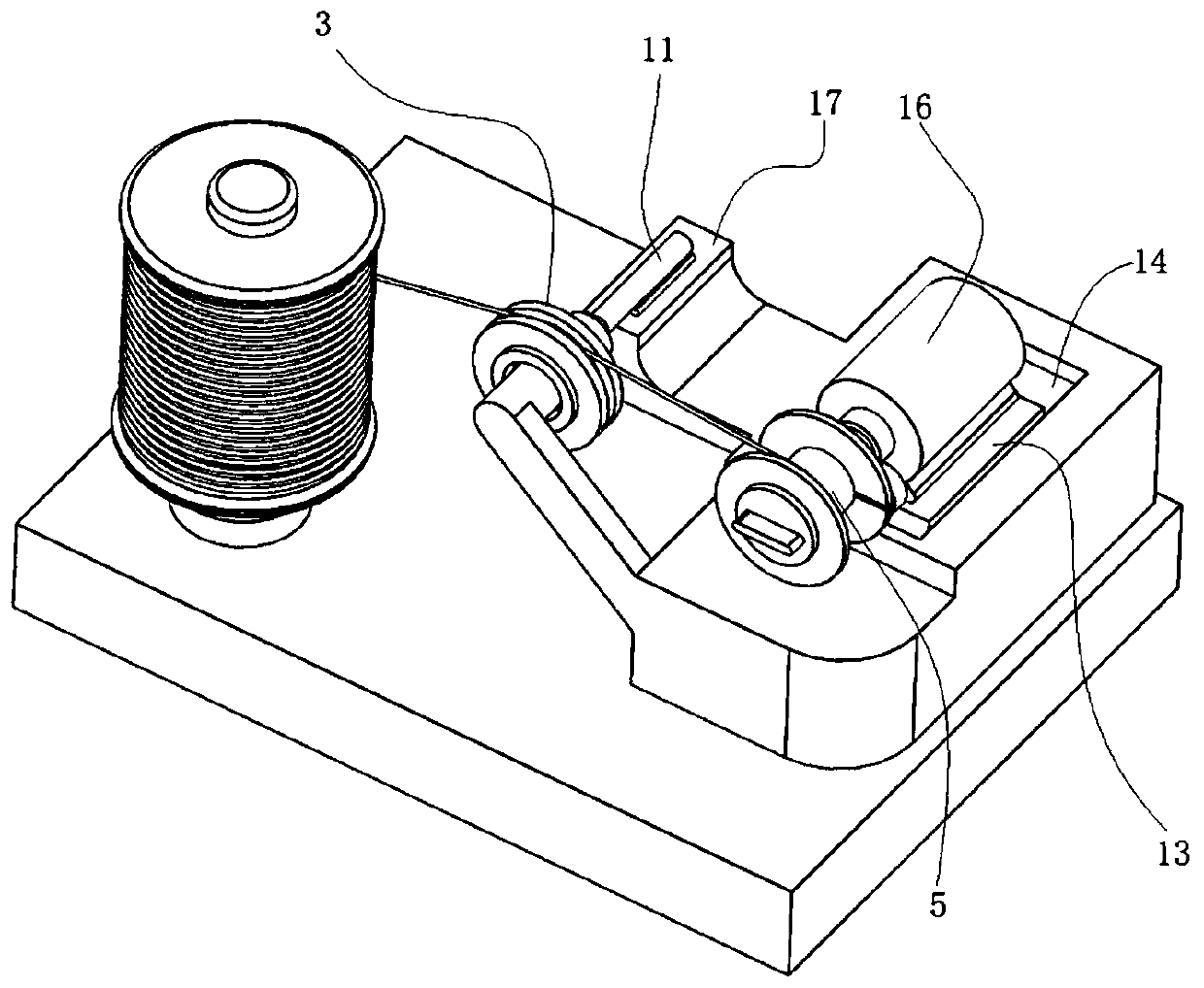

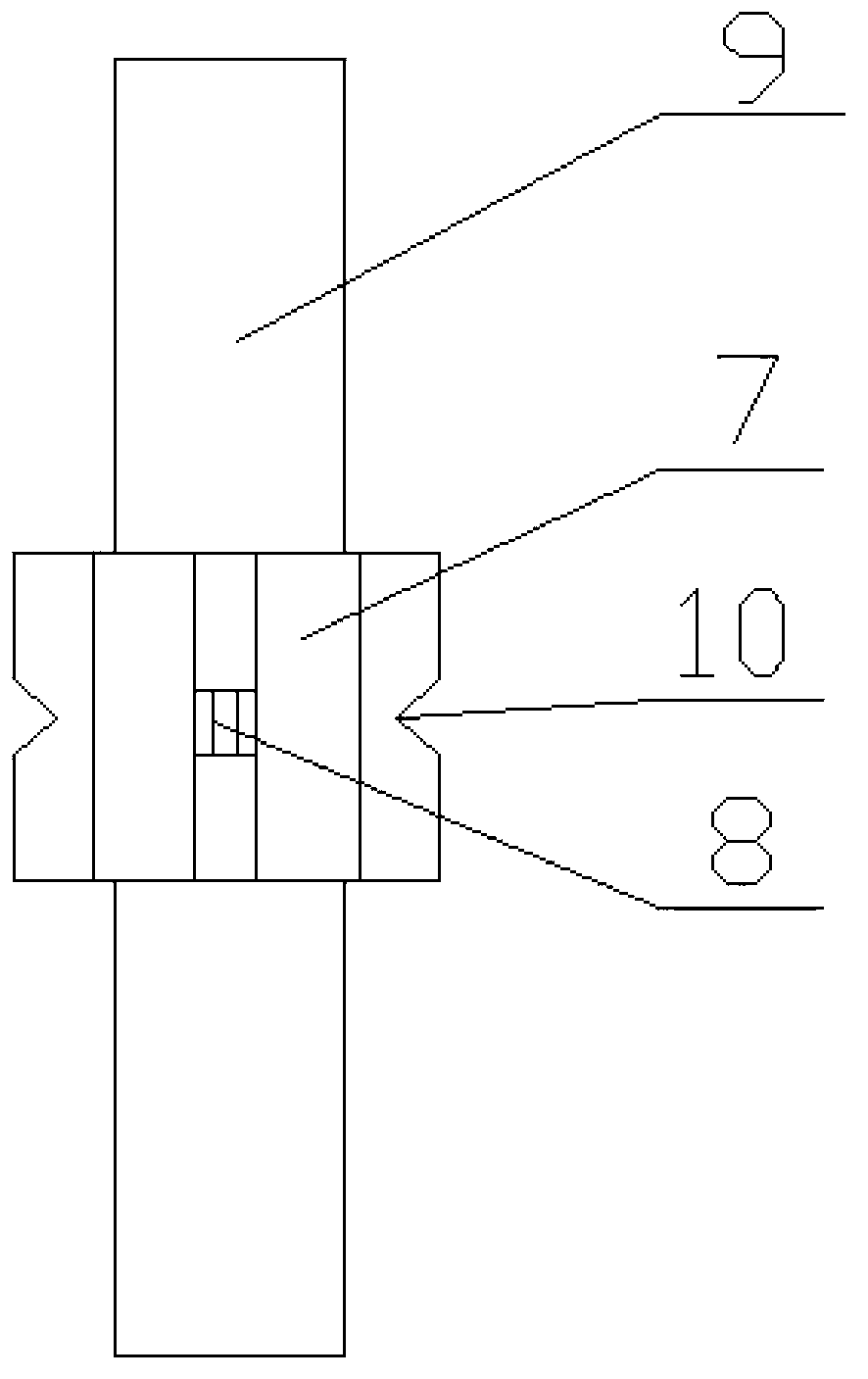

Inductor enameled wire winding process device and process thereof

InactiveCN110931246AControl the initial air pressureControl tightnessCoils manufactureBobbinElectric machine

The invention discloses an inductor enameled wire winding process device comprising an inductance coil framework of a to-be-wound guide coil, the inductance coil framework comprises a bobbin, an ironcore insertion hole coaxially penetrating through the bobbin is formed in the bobbin, and a first wire coil and a second wire coil are coaxially arranged at the two ends of the bobbin respectively; afirst wire passing groove and a second wire passing groove which extend in the radial direction are symmetrically formed in the two sides of the second wire coil in a hollowed-out mode. The device issimple in structure, the position of the first piston in a first piston channel can be controlled through the linear motor, so that the initial air pressure in the air pressure cavity is controlled, the magnitude of the upward air pressure borne by a second piston is controlled, the rotation resistance of a transition wire roller is adjusted, and the tightness degree of a second outgoing wire wound on the bobbin is controlled.

Owner:陆林娣

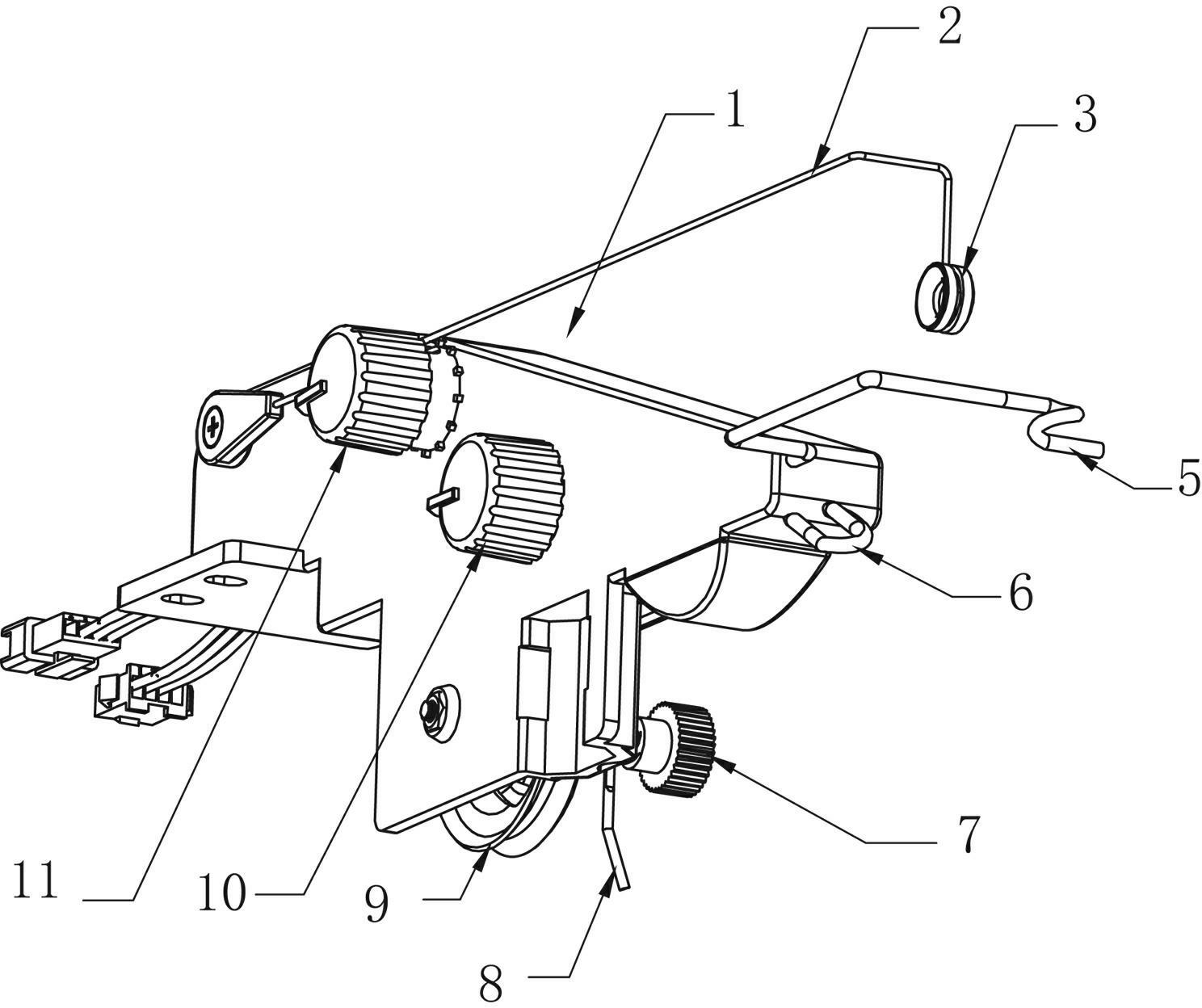

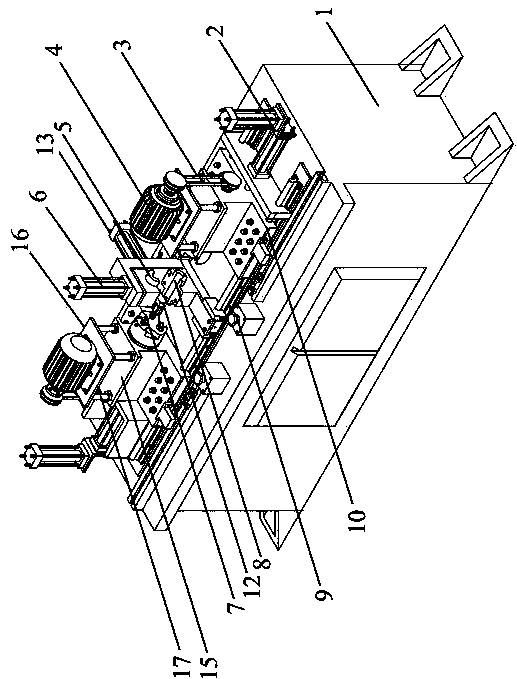

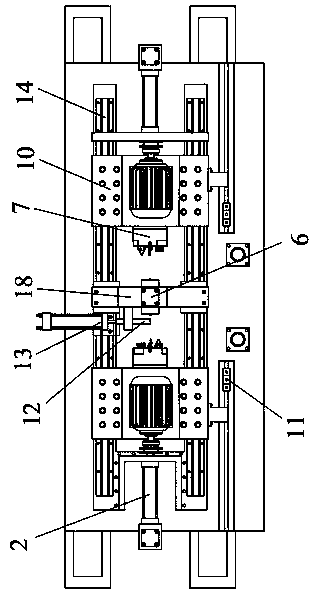

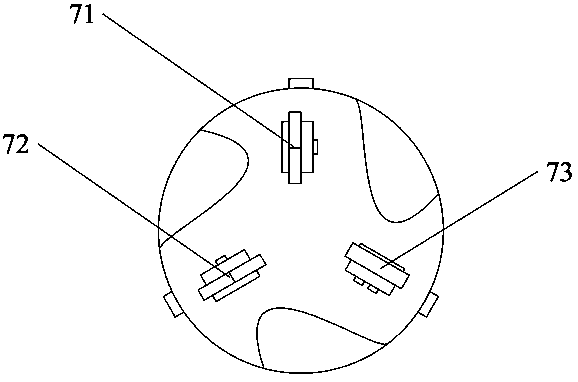

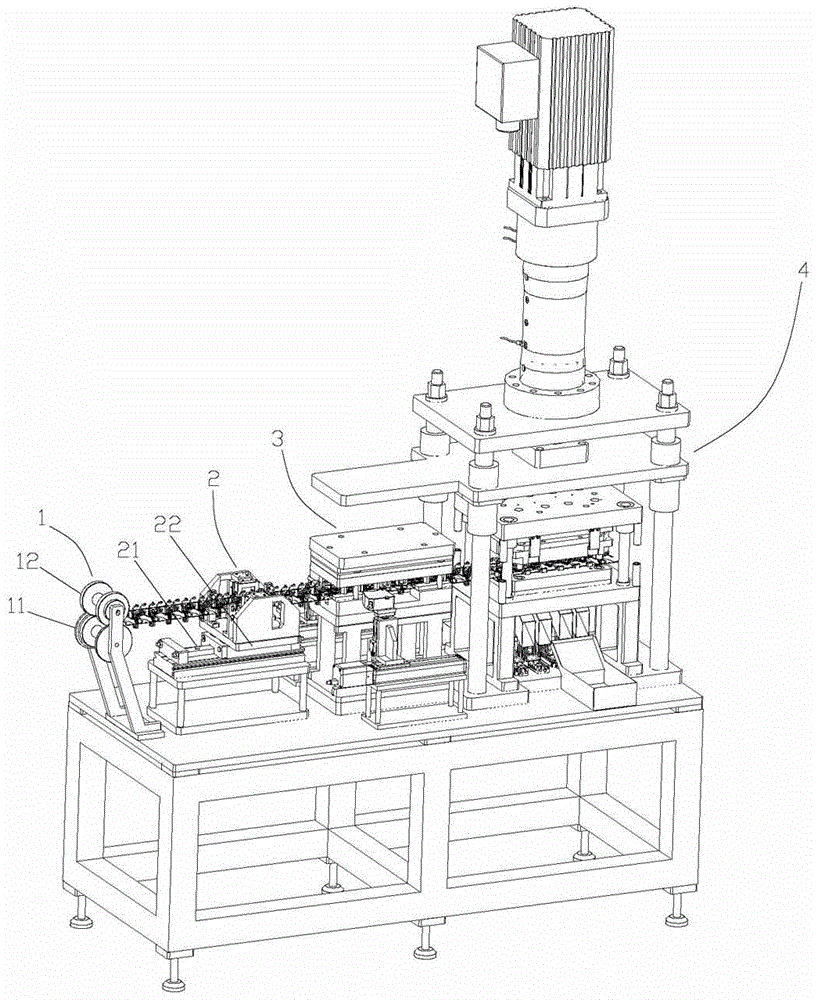

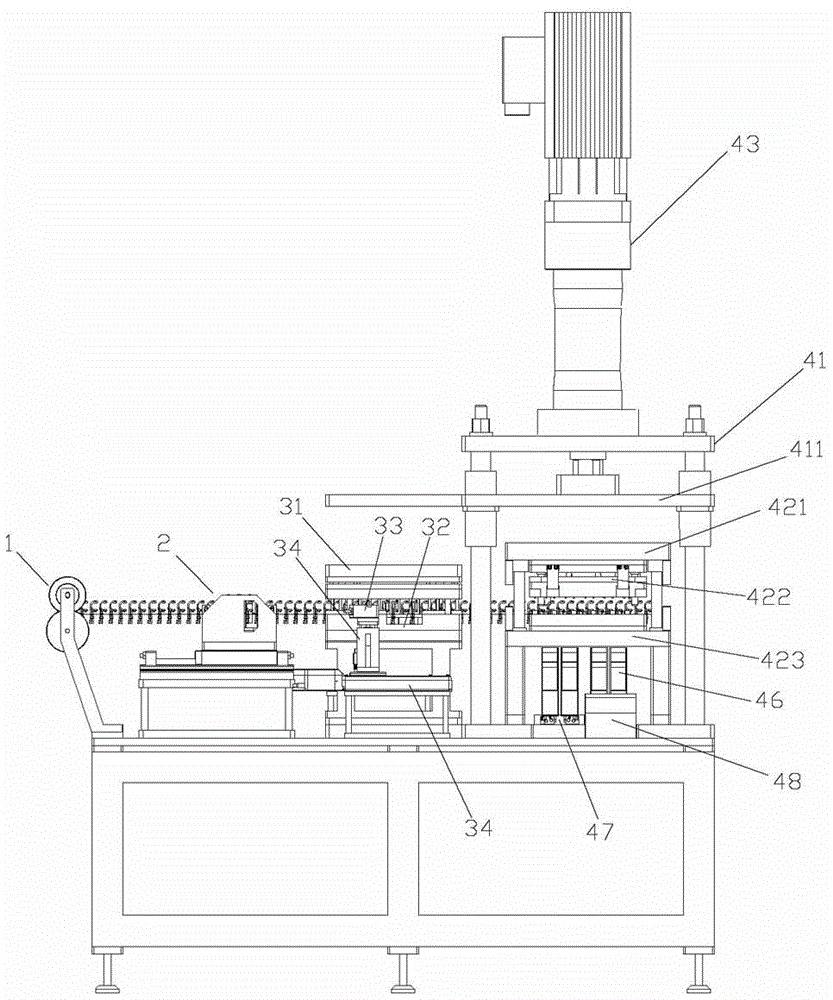

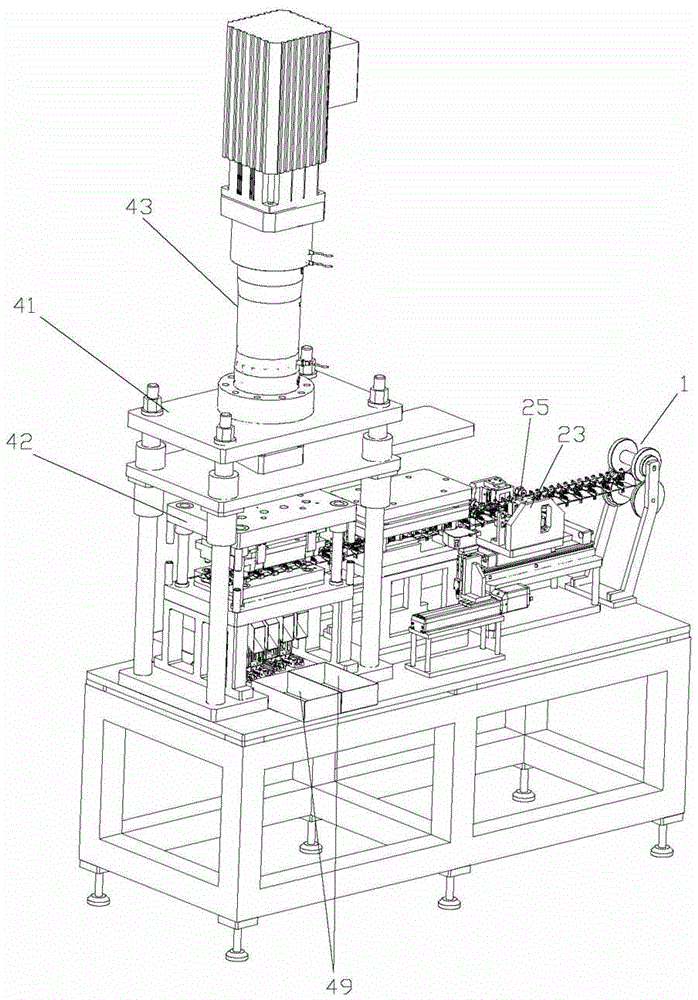

Online detection forming and distributing device of electronic elements

ActiveCN105478372AControl tightnessPlay the role of feedingSortingMetal working apparatusManufacturing engineeringElectron

The invention relates to an online detection forming and distributing device of electronic elements. Important procedures of punching, forming, detecting, packaging and the like are integrated so that full-automatic production can be achieved, and qualified products and defective products are collected in a classified manner; in this way, waste of labor, production places and transfer is greatly saved, quality of products flowing to the customer side can be guaranteed, high cost caused by customer complaints and return of products is reduced, and meanwhile the overall image of a company in hearts of customers is improved.

Owner:TAIZHOU ZHONGRUI ELECTRONICS

Efficient table type hoisin sauce cap screwing machine special for marine product processing

InactiveCN106044671AScientific and reasonable structureSafe to useThreaded caps applicationProduct processingMachining time

The invention discloses an efficient table type hoisin sauce cap screwing machine special for marine product processing. The efficient table type hoisin sauce cap screwing machine comprises a transmission servo motor, weight sensors and a working table. Supporting stand columns are arranged below the working table. A sauce bottle containing base is arranged at the middle position on the upper portion of the working table. The weight sensors are installed at the middle position of the sauce bottle containing base. A drive fixed installation base is arranged on the portion, close to the sauce bottle containing base, of the upper portion on the working table. A hydraulic pump is arranged at the middle position of the upper portion of the drive fixed installation base. The efficient table type hoisin sauce cap screwing machine is scientific and reasonable in structure and safe and convenient to use. The tightness degree of bottle caps can be effectively controlled through the transmission servo motor, the problem that the bottle caps are broken due to the too large strength or the caps are not tightly screwed due to the too small strength is solved, the three bottle caps can be rotated at the same time through three cap screwing boxes, the processing time is saved, the processing efficiency is improved, and the weight of sauce bottles is conveniently detected through the weight sensors.

Owner:上海虹联(东台)食品有限公司

Automatic rising-lowering rewinder of paper pressing roller

The invention discloses an automatic rising-lowering rewinder of a paper pressing roller. The automatic rising-lowering rewinder comprises a rack, wherein a front bottom roller and a rear bottom roller are arranged on the bottom of the rack, the paper pressing roller is arranged above the front bottom roller and the rear bottom roller, the paper pressing roller is connected with one end of a pulley block, the other end of the pulley block is connected with a lifting cylinder, the lifting cylinder is fixed on the rack, and the height of the paper pressing roller is adjusted up and down along with rising and falling of the lifting cylinder. Compared with a rewinder with the paper pressing roller being regulated manually before, the automatic rising-lowering rewinder of the paper pressing roller adjusts rising and falling of the paper pressing roller through an air-actuated control system by using the lifting cylinder, and the compactness of a scroll can be better controlled.

Owner:ZHEJIANG RONGSHENG PAPER IND HLDG

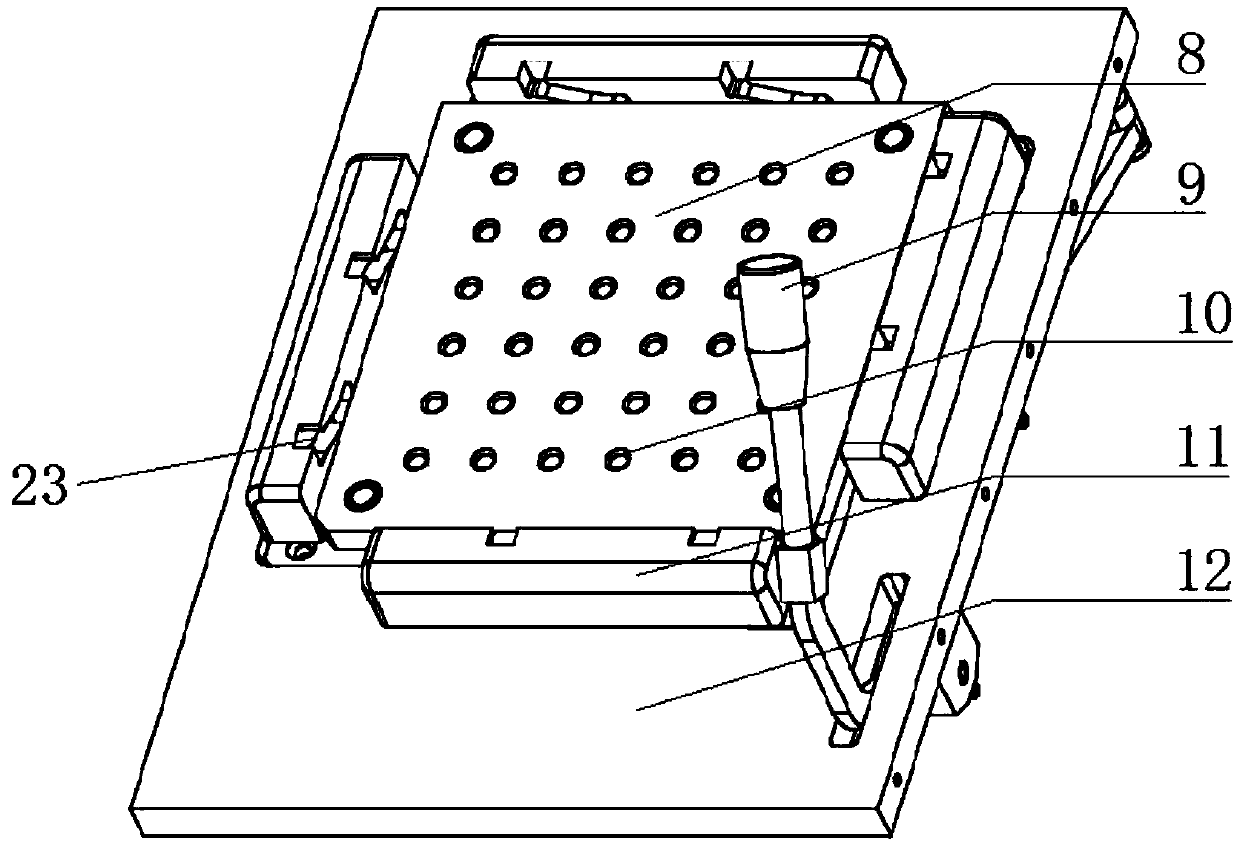

Quick insertion device for SMP connectors

ActiveCN108281847AReasonable distanceReduce mistakesCoupling device detailsTesting/measuring connectorsDevice PanelRadio frequency signal

The invention discloses a quick insertion device for SMP connectors. The quick insertion device comprises a device panel, an upper insertion panel, a lower insertion panel and a connecting-rod drive mechanism; the upper insertion panel and the lower insertion panel are arranged on the drive panel, radio-frequency line mounting holes are correspondingly formed in the upper insertion panel and the lower insertion panel; locking blocks and sliders which are mutually connected are respectively arranged on upper and lower surfaces of the device panel, the sliders are connected with the connecting-rod drive mechanism, and the locking blocks are movably connected with the upper insertion panel and drive the same to move vertically. More radio-frequency lines can be installed on the same quick insertion device, a safe, reliable, rapid and efficient way of locking is achieved, tightness in docking of the radio-frequency lines and radio-frequency heads can be well controlled, error of radio-frequency signals is lowered, and service life of the quick insertion device is prolonged; locking is performed by pushing a handle, and working efficiency of working personnel is improved.

Owner:ACETEC SEMICON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com