Novel wax plate conveyor

A conveyor, a new type of technology, used in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of wax plate pollution, inconvenient installation, maintenance, pollution of the machine head, etc., to reduce manufacturing costs and long service life. , the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

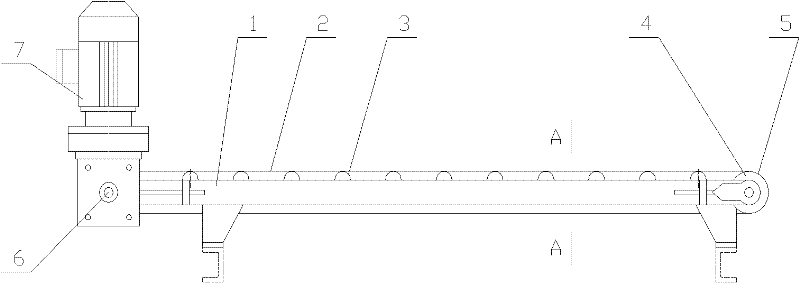

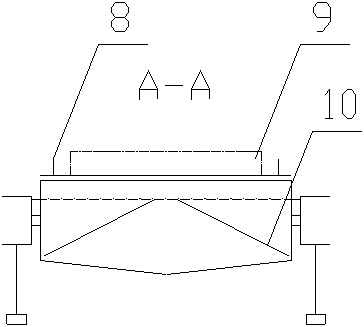

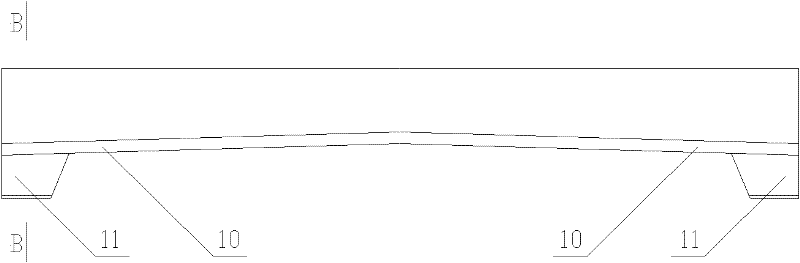

[0022] like figure 1 As shown, the new conveyor for wax plates is composed of frame 1, driving driving roller 6, passive driving roller 4, idler roller 3, micro variable speed motor 7, semi-closed endless belt 2 and wax chip recovery device. Frame 1 is a supporting body formed by steel plate technology, and is a basic supporting structure for installing other supporting components. The width of frame 1 is 58cm-60cm to meet the smooth transportation of wax plates, and its length is 280cm-300cm. Docking needs; the direction of the output wax plate can be changed arbitrarily on both sides of the machine head.

[0023] The active drive roller 6 and the passive drive roller 4 are respectively installed at the front and rear ends of the frame 1, and the distance between the active drive roller 6 and the passive drive roller 4 can be adjusted in time as required to control the tightness of the semi-closed endless belt 2; Between the active driving roller 6 and the passive driving ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com