Glass curtain wall with glass rib unit and manufacturing method thereof

A glass curtain wall and glass rib technology, which is applied in the direction of walls, buildings, and building components, can solve the problems that glass curtain wall units cannot be installed with glass ribs, achieve low cost, improve assembly accuracy and quality, and install tightly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

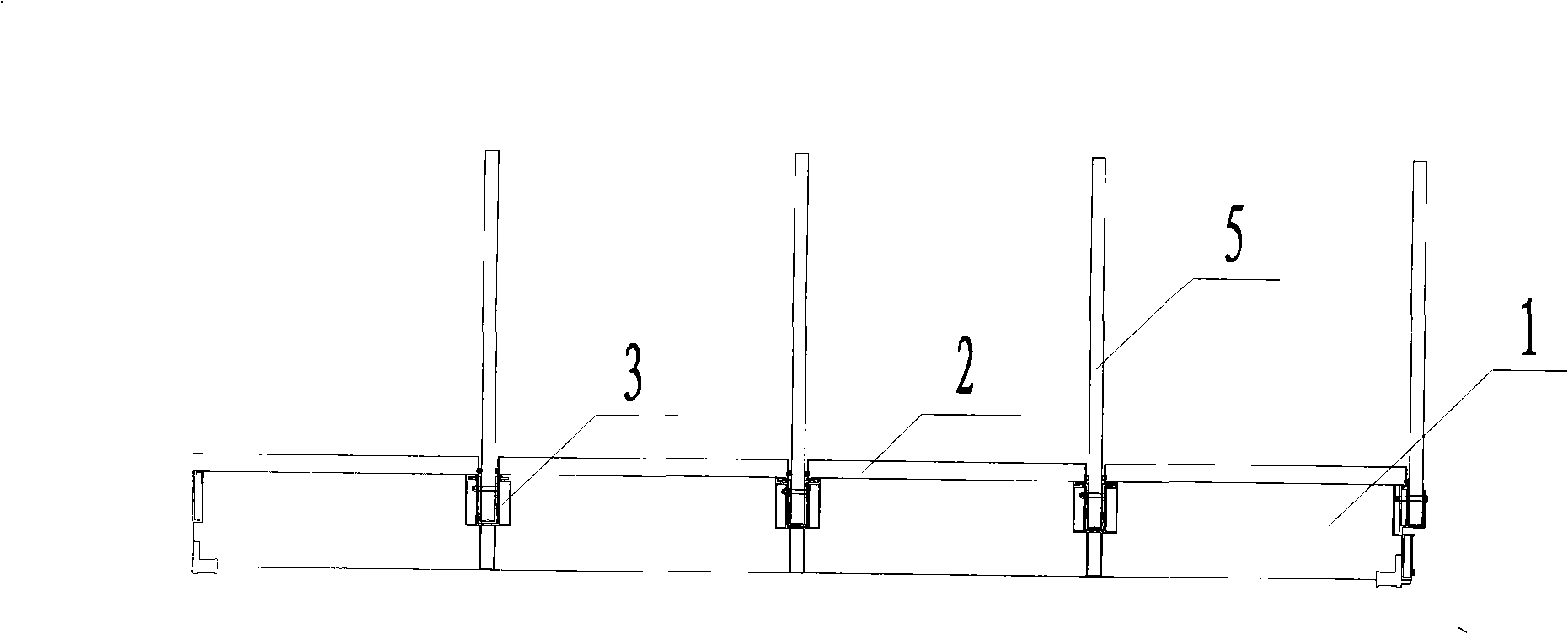

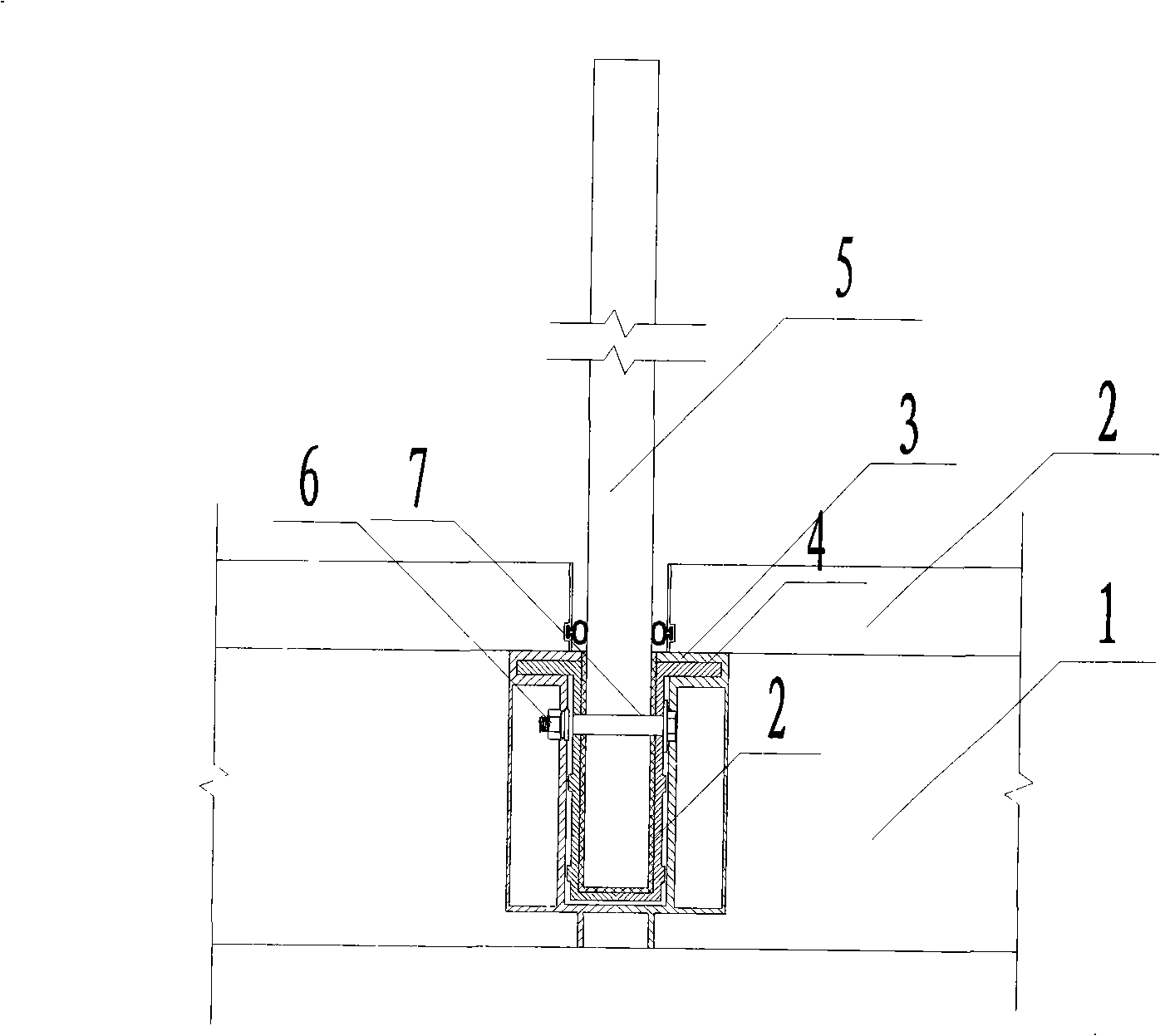

[0027] The unitized glass curtain wall with glass ribs of the present invention comprises a unit frame 1 and a panel glass 2, the main upright 3 is installed between the upper and lower frames of the unit frame 1 along the vertical direction, and the main upright 3 is connected with the auxiliary upright 4 , The glass rib 5 is fixed in the attached stand 4.

[0028] The main uprights 3 are provided with axial grooves, and a plurality of auxiliary uprights 4 are connected in the grooves. distributed. Bolt holes 7 are provided on the main stand 3, the attached stand 4 and the glass rib 5, and the connecting bolt 6 passes through the bolt hole 7 to connect the stand 3, the attached stand 4 and the glass rib 5.

[0029] Attach upright 4 and the contact surface of glass rib 5 that glue pad is housed.

[0030] The method for making the unitized glass curtain wall with glass ribs of the present invention comprises the following steps:

[0031] (1) Unloading, cutting and blanking a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com