High-precision cyclone separation filter

A cyclone separation and filter technology, applied in the direction of filtration separation, separation method, filtration loop, etc., can solve the problems of manpower and material resources, clean water consumption, water effluent, etc., to save floor space, reduce water inlet back pressure, improve The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

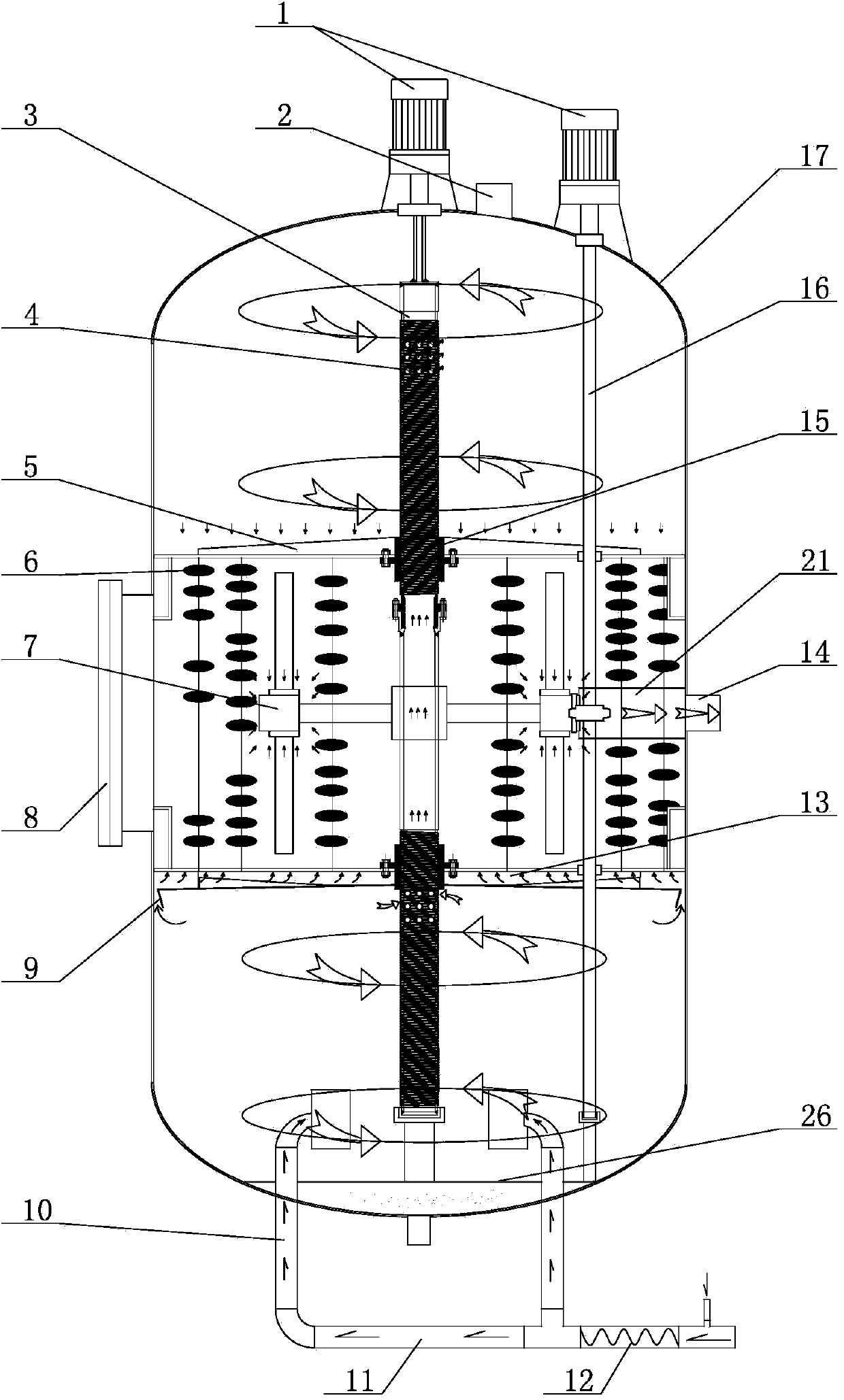

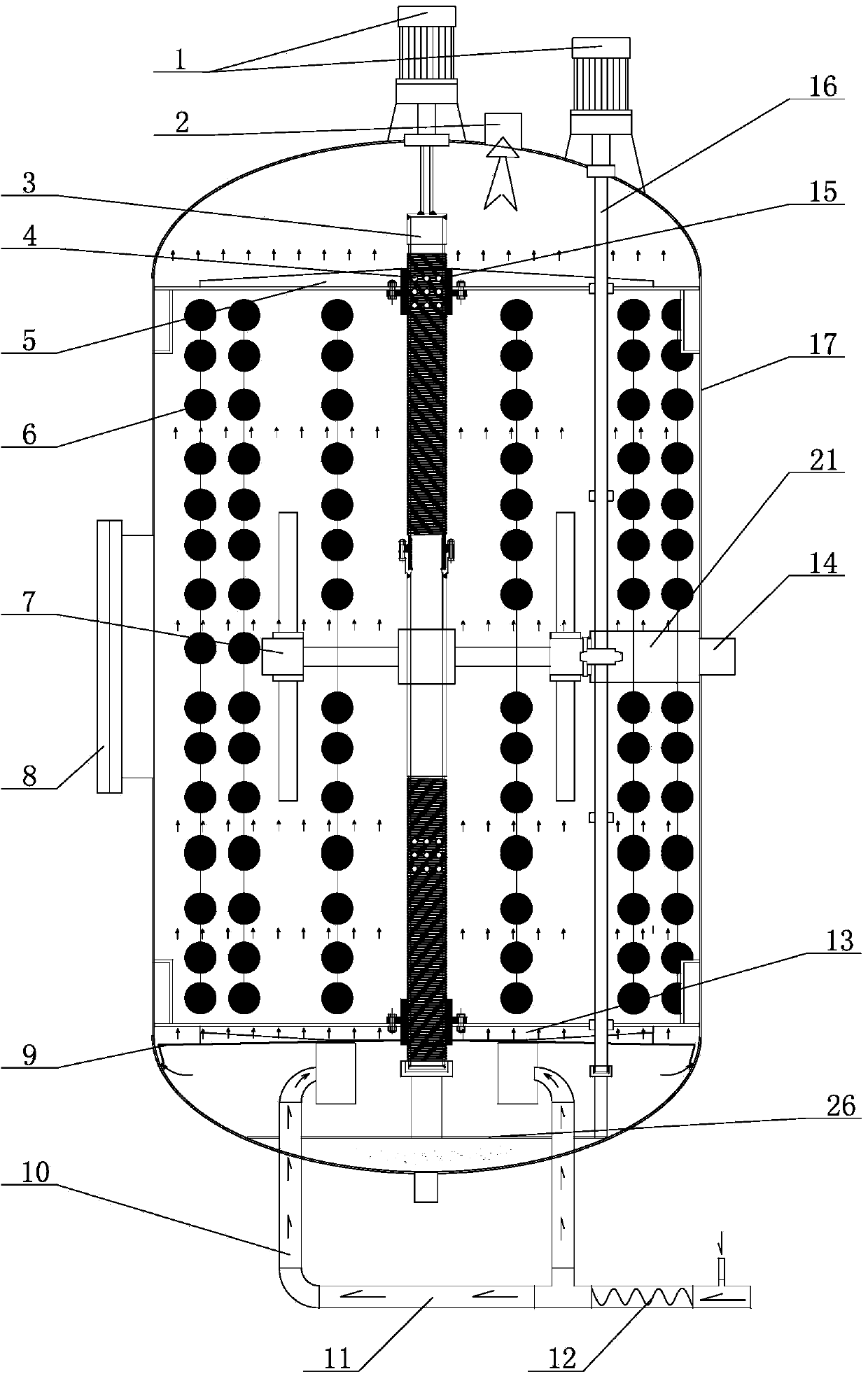

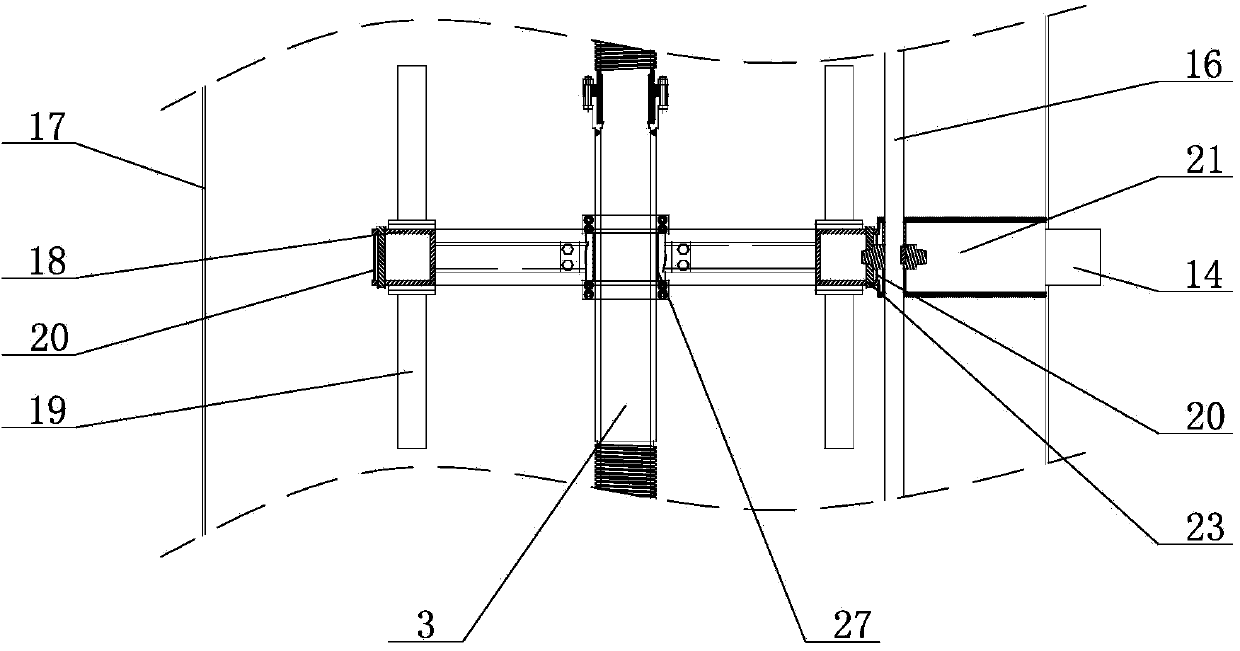

[0024] Such as Figure 1 to Figure 5 As shown, the high-precision cyclone separation filter of the present invention includes a cylinder body 17, an upper end pressure plate 5 and a lower end pressure plate 13 are arranged in the cylinder body 17, and filter material 6 is filled between the upper and lower end pressure plates. The hollow screw 3 runs through the lower end pressure plate, threaded sleeves 15 are provided at both ends of the screw rod 3, the upper and lower end pressure plates are respectively connected with the screw rod 3 through the threaded sleeves 15, and a splitter plate 9 is arranged below the lower end pressure plate 13, and the splitter plate 9 is fixed on the On the threaded sleeve connected to the lower pressure plate 13, the upper and lower parts of the screw 3 are respectively distributed with tangential water holes 4, the bottom of the cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com