Automatic cigarette maker

a cigarette maker and automatic technology, applied in the field of cigarette makers, can solve the problems of difficult control, inconvenient use of the above-mentioned machines, and not only a lot of time and work to make cigarettes,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

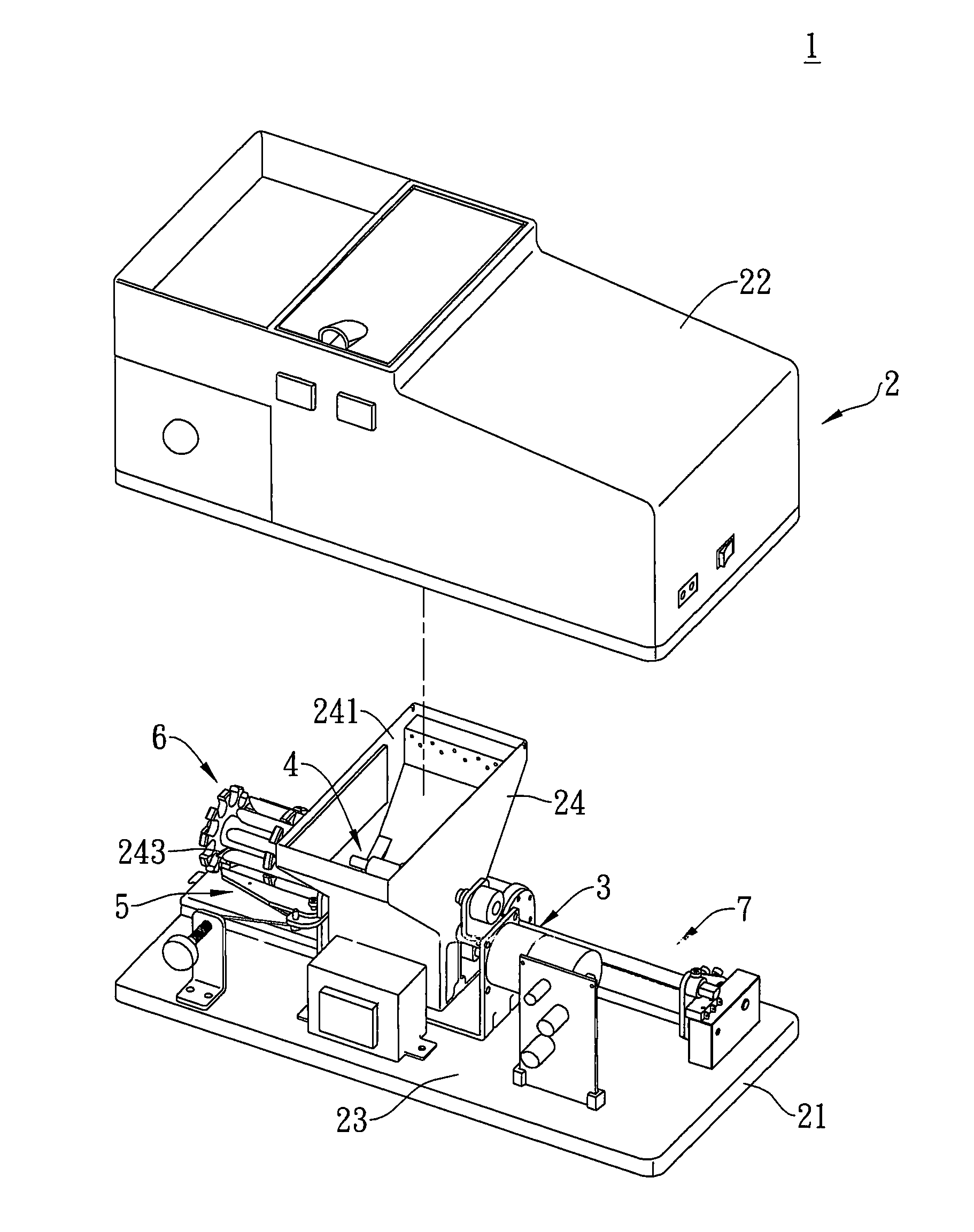

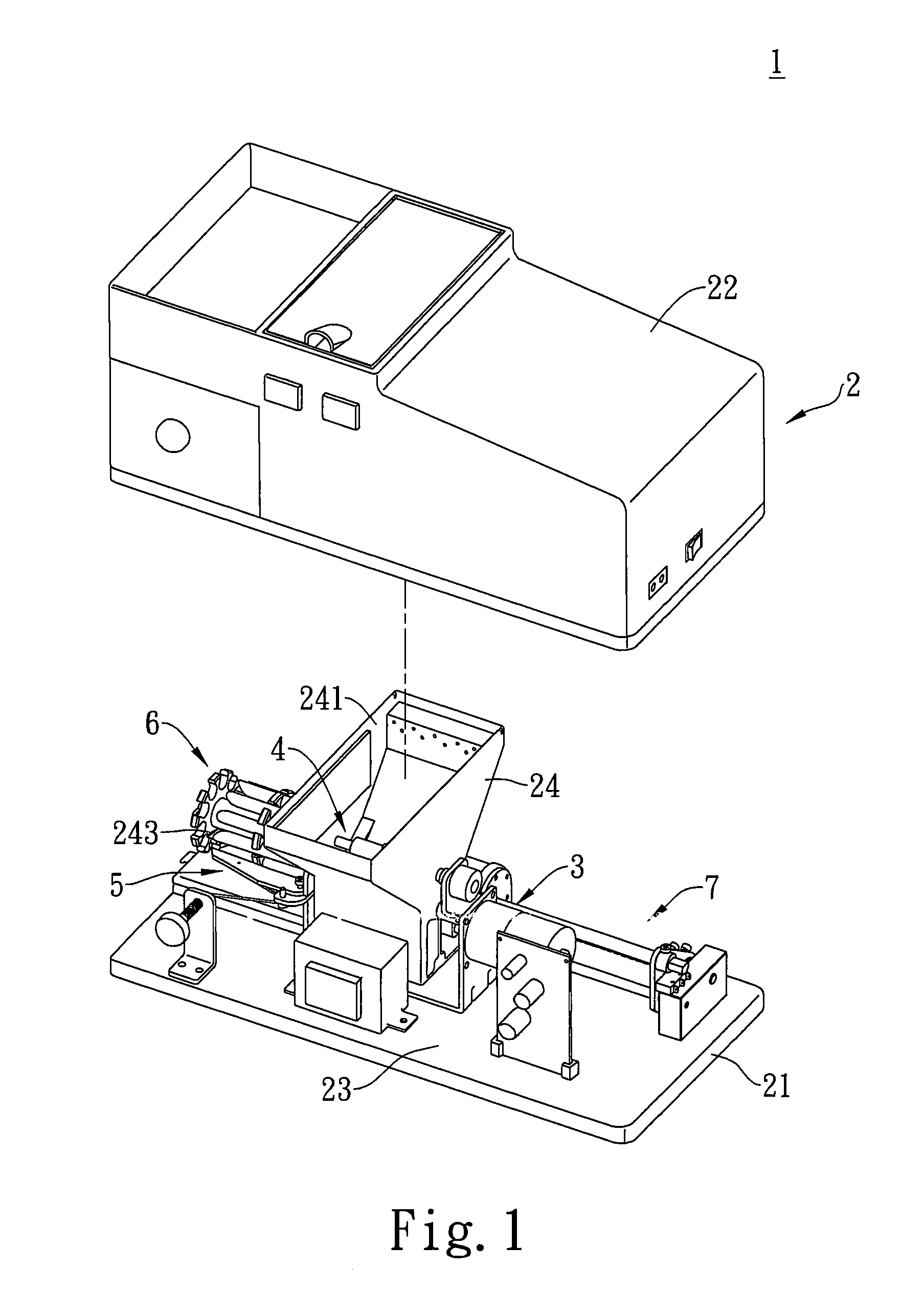

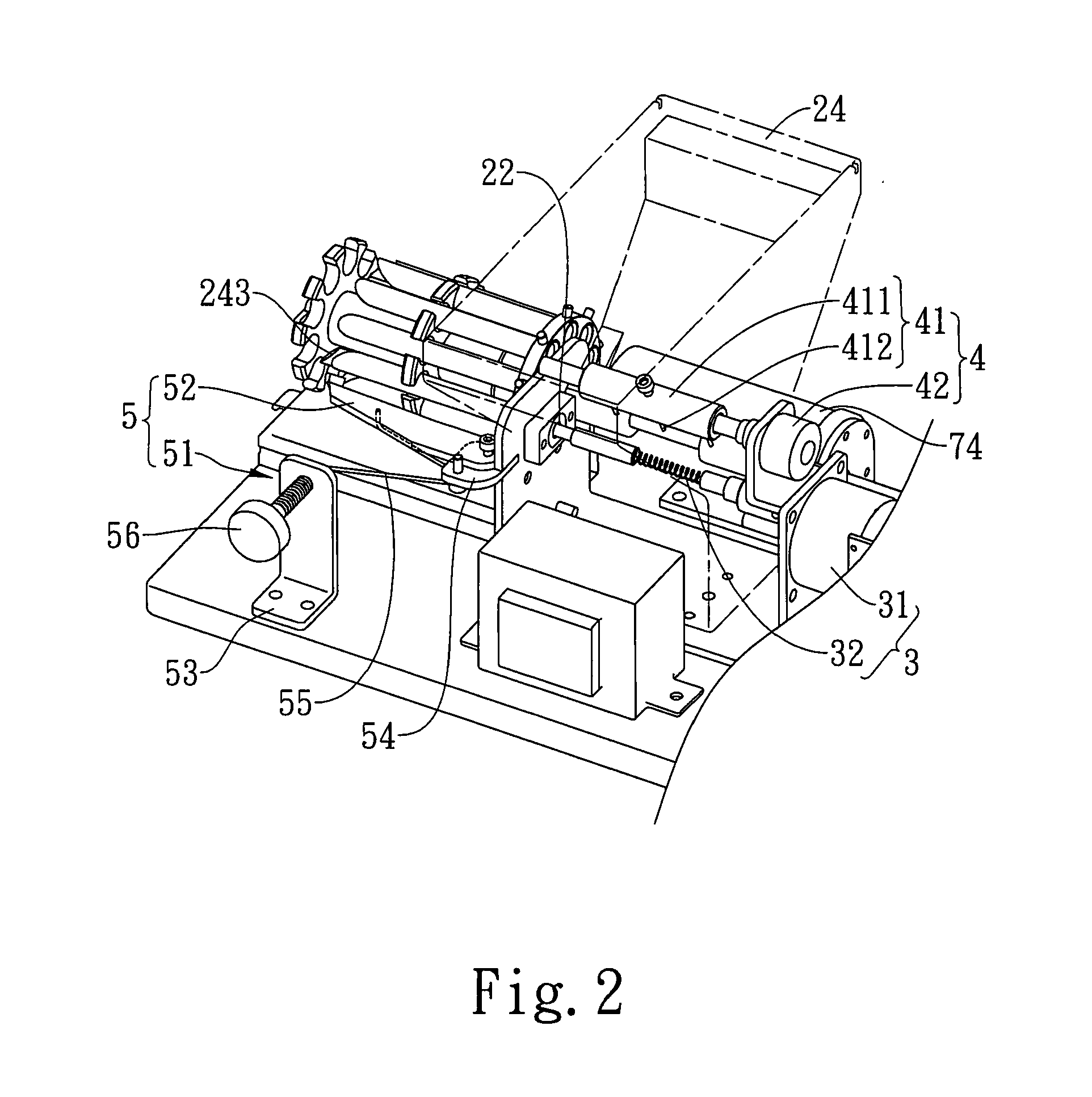

[0014]Please refer to FIG. 1 that shows an embodiment of an automatic cigarette maker according to the present invention. The automatic cigarette maker 1 comprises a case 2, a feeding module 3, an agitating module 4, a pressure regulator 5, a rotary disc 6, and a linkage arrangement 7. The case 2 is generally in rectangular shape and includes a seat 21 and a cover 22 covering the seat 21. Space 23 is formed between the seat 21 and the cover 22. A container 24 having an opening 241 provided at the top thereof is fixed in the space 23 for holding tobacco leaves. The front side of the container 24 is provided with an outlet 242 and the outlet 242 is in communication with a tobacco supply duct 243 provided at the front side of the container 24 (as shown in FIG. 2).

[0015]As shown in FIG. 2, the feeding module 3 includes a motor 31 and a propulsion shaft 32. The motor 31 is fixed at the rear side of the container 24. The propulsion shaft 32 is preferably a spiral shaft. The rear end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com