Novel large-capacity medicine subpackaging machine

A large-capacity, filling machine technology, applied in the direction of packaging, etc., can solve the problems that cannot meet the production needs of enterprises, is not suitable for large-capacity drug packaging, and has low packaging efficiency. It achieves simple structure, improved filling efficiency, and low cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

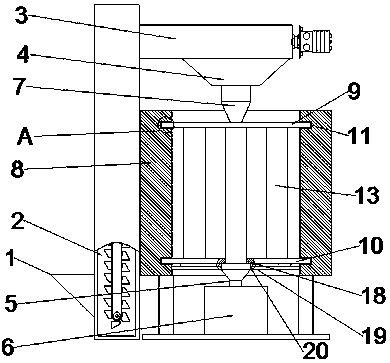

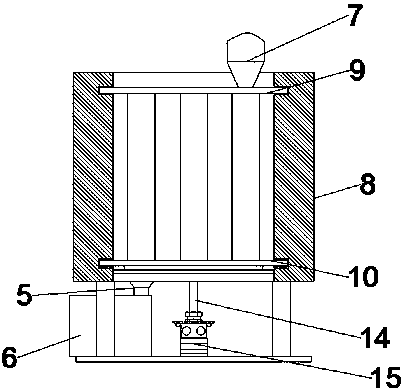

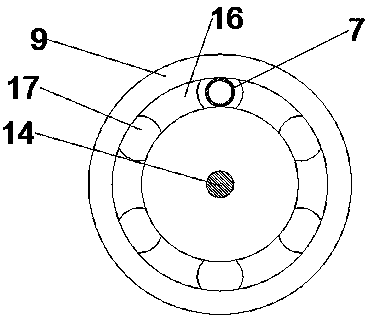

[0023] see Figure 1-Figure 5 , a new type of large-capacity medicine dispensing machine, including a feed hopper 1, an elevator 2, a conveying auger 3, a drop hopper 4, a discharge pipe 5 and a container 6, and the feed hopper 1 is bolted to the elevator 2, the top right bolt of the hoist 2 is equipped with the conveying auger 3, the bolt below the conveying auger 3 is fixed with the dropping hopper 4, and the lower part of the dropping hopper 4 is provided with the A discharge pipe 5, the container 6 is placed below the discharge pipe 5; a discharge pipe 7 is fixed below the discharge hopper 4, and a reset mechanism 21 is arranged on the discharge pipe 7, and the discharge pipe 7 is provided with an upper support plate 9, the upper end surface of the upper support plate 9 is provided with a sliding groove 16, and the bottom end of the falling tube 7 is slidingly clamped in the sliding groove 16, and the sliding groove 16 is provided with a A plurality of blanking holes 17, ...

Embodiment 2

[0025] see Figure 5 In this embodiment, on the basis of Embodiment 1, the reset mechanism 21 includes a fixed tube 22, a sliding tube 23 and an elastic element 24, the fixed tube 22 is welded and fixed to the falling hopper 4, and the sliding tube 23 slides Set on the outside of the fixed tube 22, the elastic element 24 is connected between the fixed tube 22 and the sliding tube 23; During the inner sliding process, when the discharge pipe 7 moves to the position of the discharge hole 17, the discharge pipe 7 protrudes downward under the action of the elastic element 24, and starts to fill the medicine into the sub-package bin 13. When the filling is completed, , along with the rotation of the upper support plate 9, the blanking tube 7 will continue to slide in the sliding groove 16, and in the process of separating the blanking tube 7 from the blanking hole 17, the blanking tube 7 will be squeezed and retracted, so that It can realize the elongation of the blanking tube 7 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com