Wine distillation and filling production system

A production system and wine technology, applied in the field of wine distillation and filling production system, can solve problems such as dead corners that cannot be dried, uneven drying, affecting wine quality, etc. The effect of liquor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

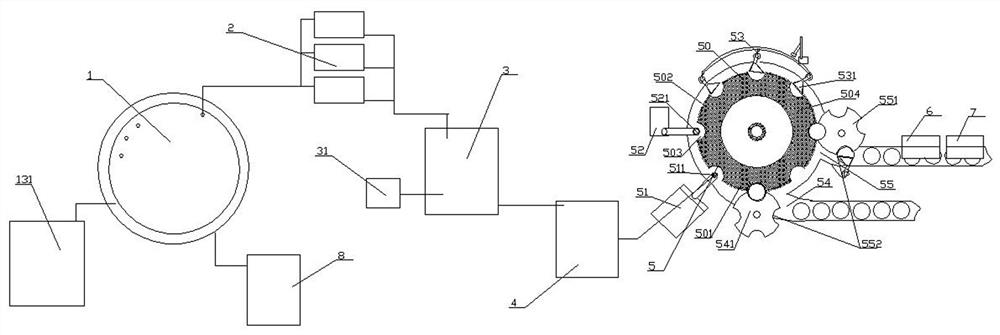

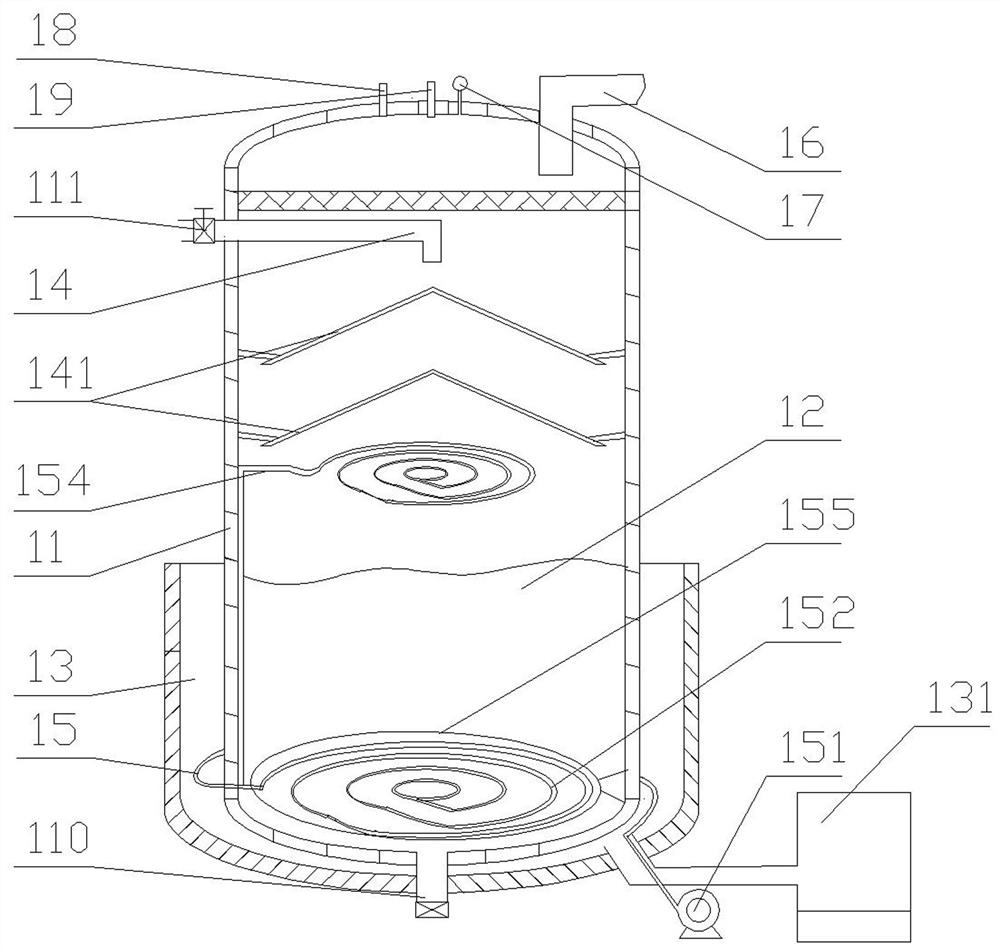

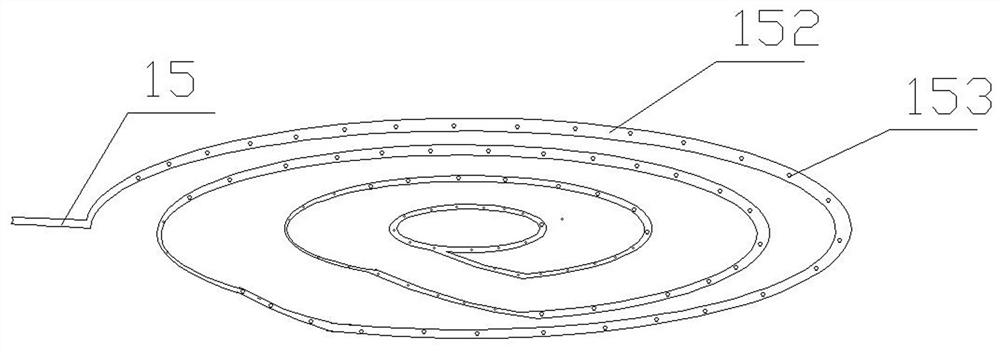

[0034] Example 1, refer to figure 1 , figure 2 , image 3 , Figure 4 , a wine distillation and filling production system, including a distillation device 1, a finished product condenser 2, a semi-finished product buffer tank 3, a finished product storage tank 4, a filling and pressing drying system 5, a rubber cap compressor 6 and a sticker connected in sequence. Standard machine 7, the distillation apparatus 1 includes a casing 11, a liquid storage cavity 12 is provided at the bottom of the casing 11, and a steam heating jacket 13 is provided on the outer wall of the casing 11 corresponding to the liquid storage cavity 12. The upper part of the casing 11 is provided with a feeding pipe port 14 that communicates with the outside world, and the liquid storage cavity 12 is provided with an air duct 15. One end of the air duct 15 is connected to the air outlet of the fan 151 arranged outside the casing 11, and the other end Protruding into the steam heating jacket 13 and coi...

Embodiment 2

[0046] Example 2, refer to Figure 5 , as a further optimized design of implementation 1, the outer side of the bottle feeding dial 541 and the outer side of the transmission dial 501 are located between the filling head 511 and the bottle feeding dial 541, and a brush 505 for drying the bottle is also provided. Before the stopper is installed, the wine bottle needs to be rinsed and dusted, and the remaining water droplets are difficult to remove through the general drying process, thus affecting the quality of the labeling. Dry provides convenience.

[0047] The grooves of the conveying dial 501, the bottle discharging dial 551, and the bottle feeding dial 541 are lined with elastic rubber pads to prevent the bottle body from being damaged due to collision when in contact with the wine bottle, and can increase the groove and the bottle body The friction between them can prevent relative sliding. The drive mechanism of the transmission dial 501, the bottle-out dial 551, the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com