A beer keg filling cleaning valve

A technology of beer kegs and cleaning valves, which is applied in the direction of keg/cask filling, packaging, valve lift, etc., which can solve the problems of inability to realize continuous filling of beer kegs, inability to clean beer kegs, low filling efficiency, etc., and achieve functional Complete, improve the taste, reduce the effect of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below through specific examples.

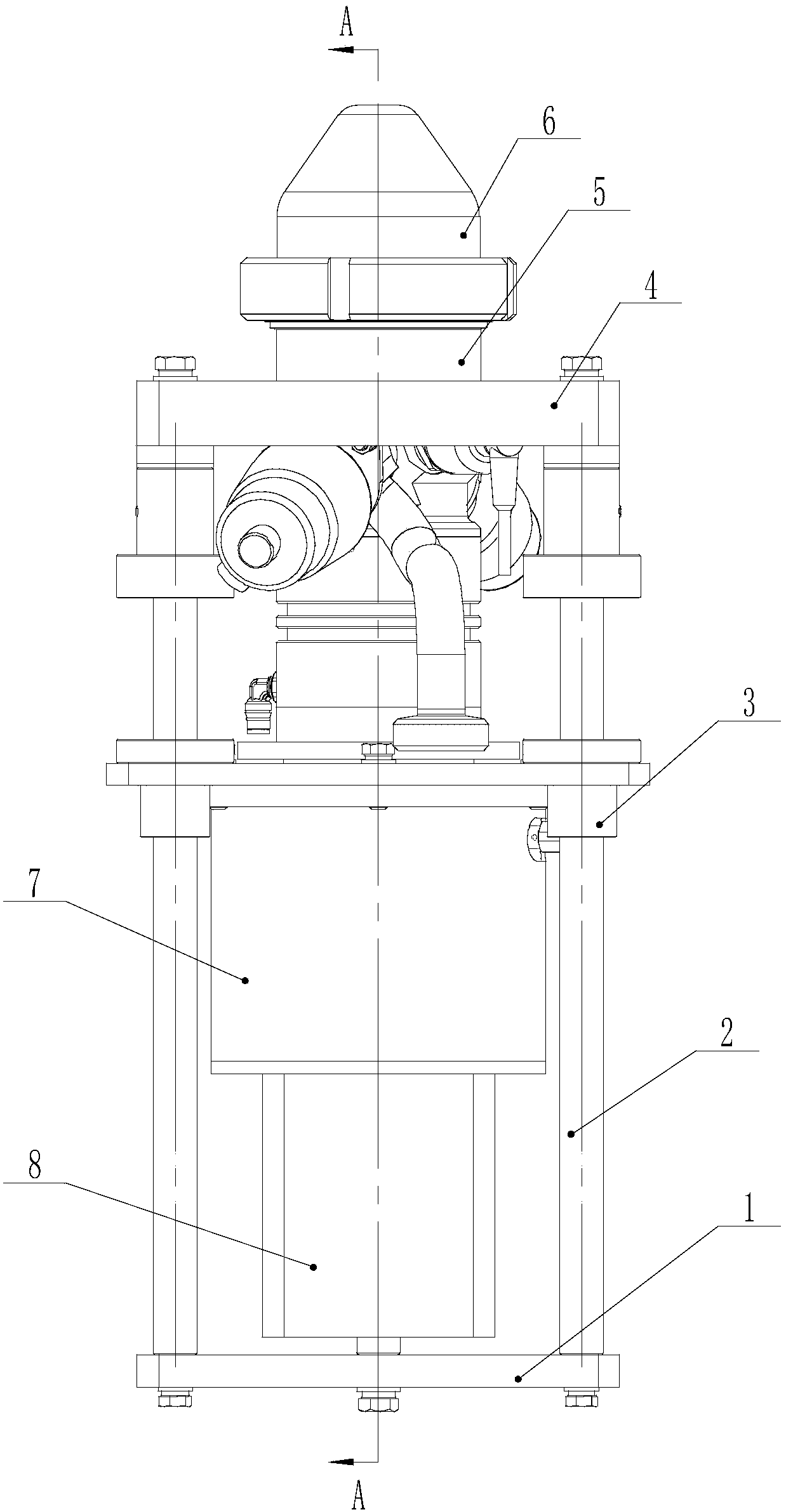

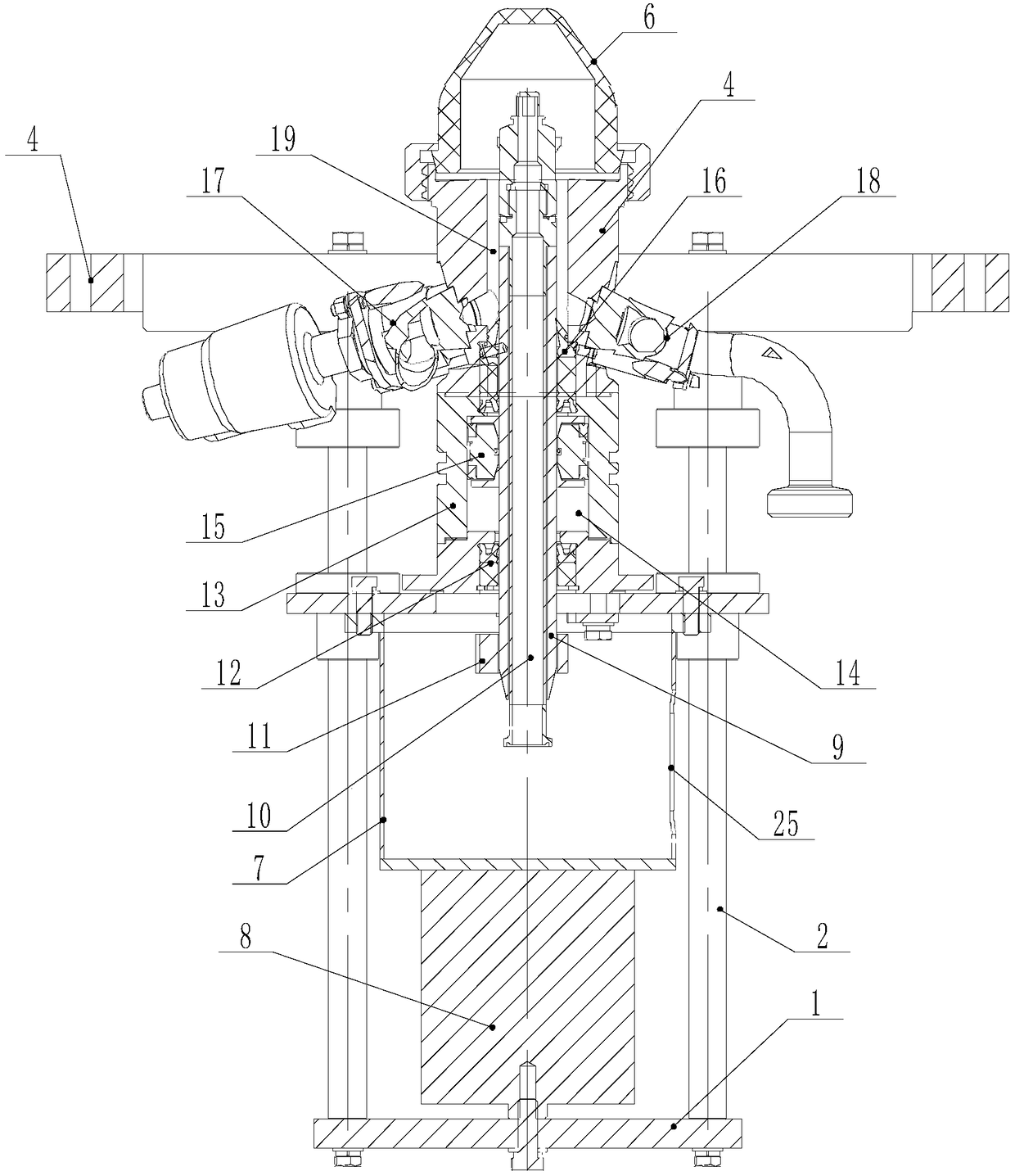

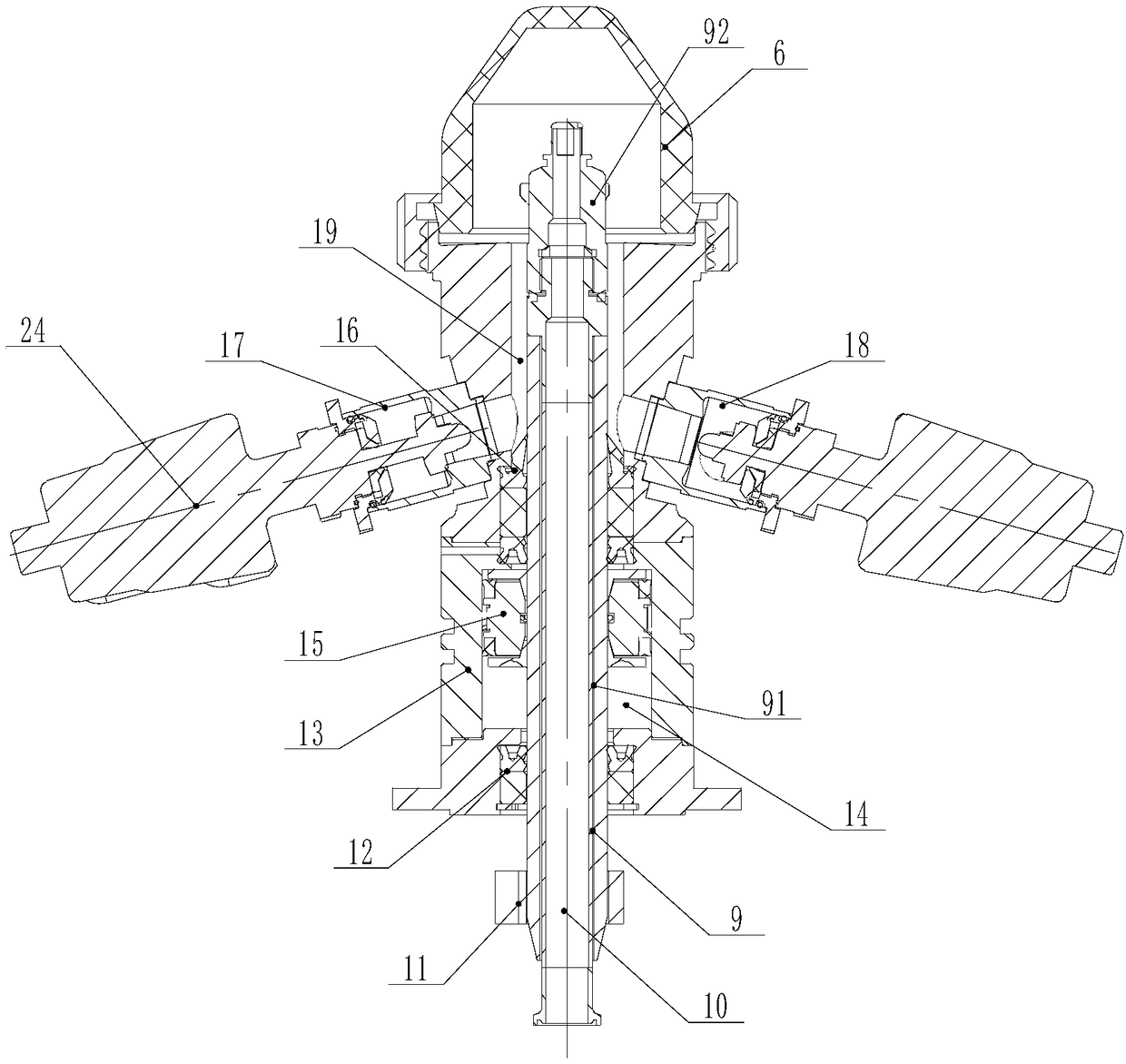

[0027] Such as Figure 1 to Figure 5 As shown, a beer keg filling and cleaning valve includes a valve body 5 and a valve stem 9. The valve stem 9 is axially slidably installed in the valve body 5, and the orientation is determined by the actual working state of the filling and cleaning valve. The valve stem 9 is axially and vertically slidably mounted on the valve body 5, and the valve body 5 is provided with a beer flow passage 19 outside the valve stem 9, and the beer flow passage 19 is used for the flow space of beer during filling , the upper end of the beer flow channel 19 runs through the upper end of the valve body 5, when the top of the valve stem 9 pushes away the wine spear, the beer flow channel 19 communicates with the beer keg inner cavity, the valve body 5 and the valve body The first sealing ring 16 at the lower end of the beer flow channel 19 is installed betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com