Patents

Literature

105 results about "Cigarette Makers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing a reduced ignition propensity smoking article

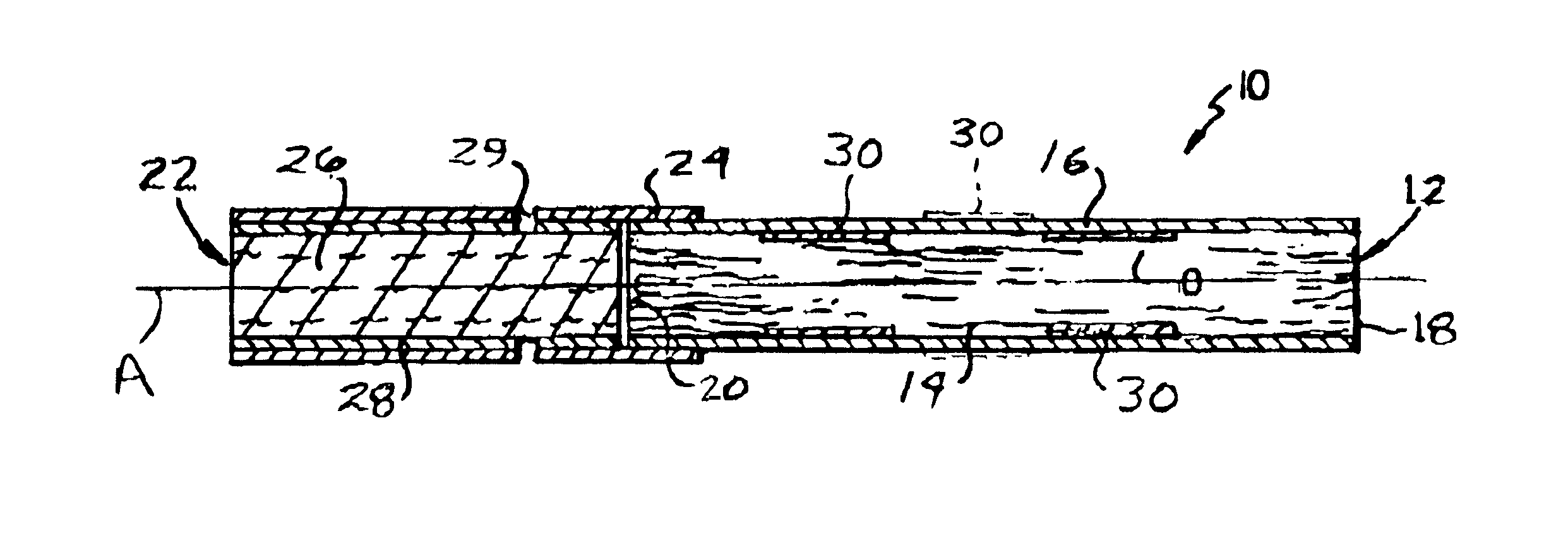

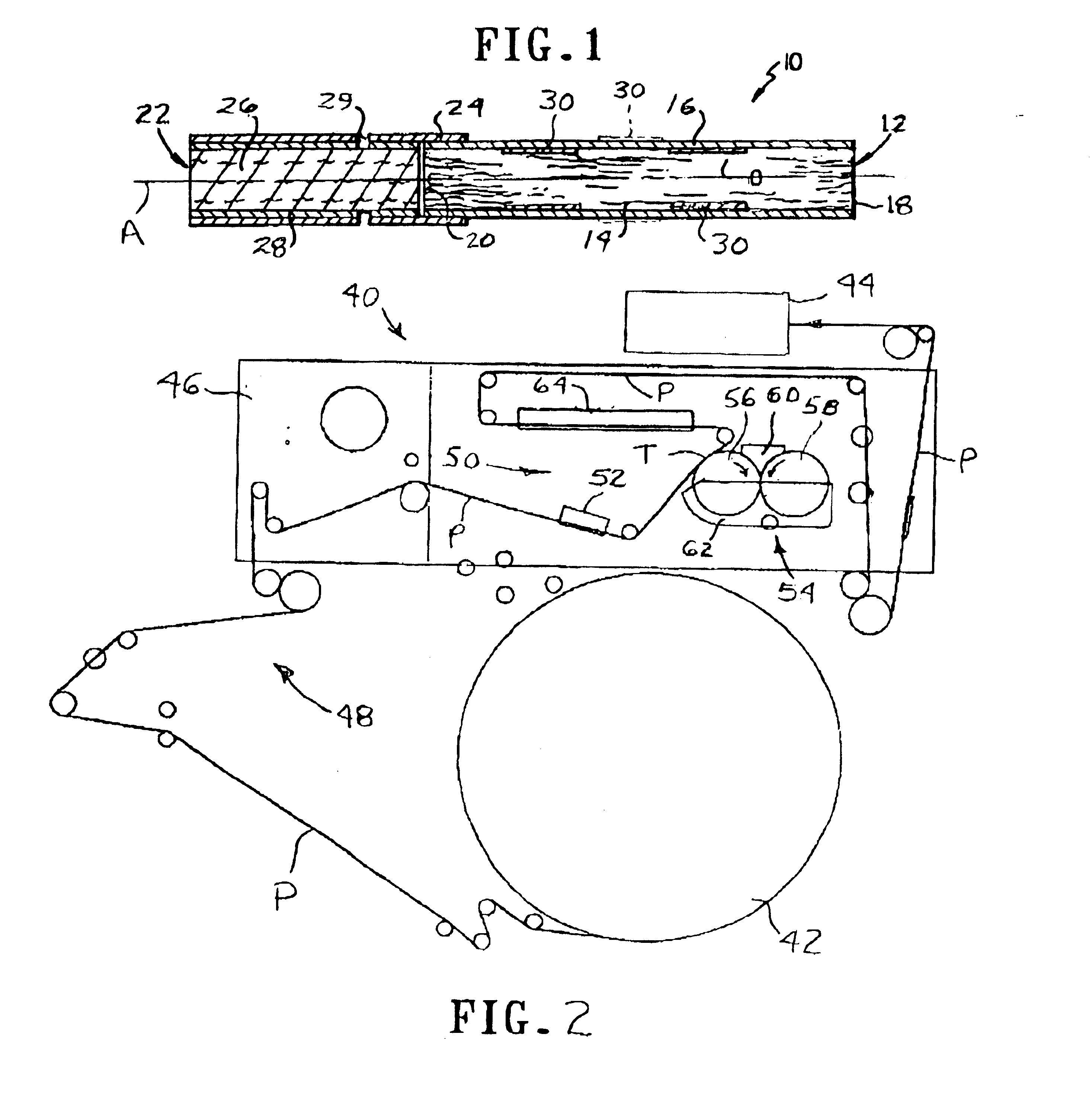

InactiveUS6854469B1Reduced ignition propensityLower and reduces permeabilityCigar manufactureCigarette manufactureCigarette MakersAdhesive belt

The present invention provides a smoking article having a reduced ignition propensity by reason of one or more cross-directional bands of an adhesive applied to the paper wrapper of the smoking article. The adhesive may be one of a cigarette seam adhesive, a filter plug wrap adhesive or a tipping paper adhesive conventionally used in the manufacture of cigarettes. A cigarette maker is modified to include the adhesive applicator apparatus of the invention which applies the adhesive bands to the paper wrapper in an in line process.

Owner:R J REYNOLDS TOBACCO COMPANY

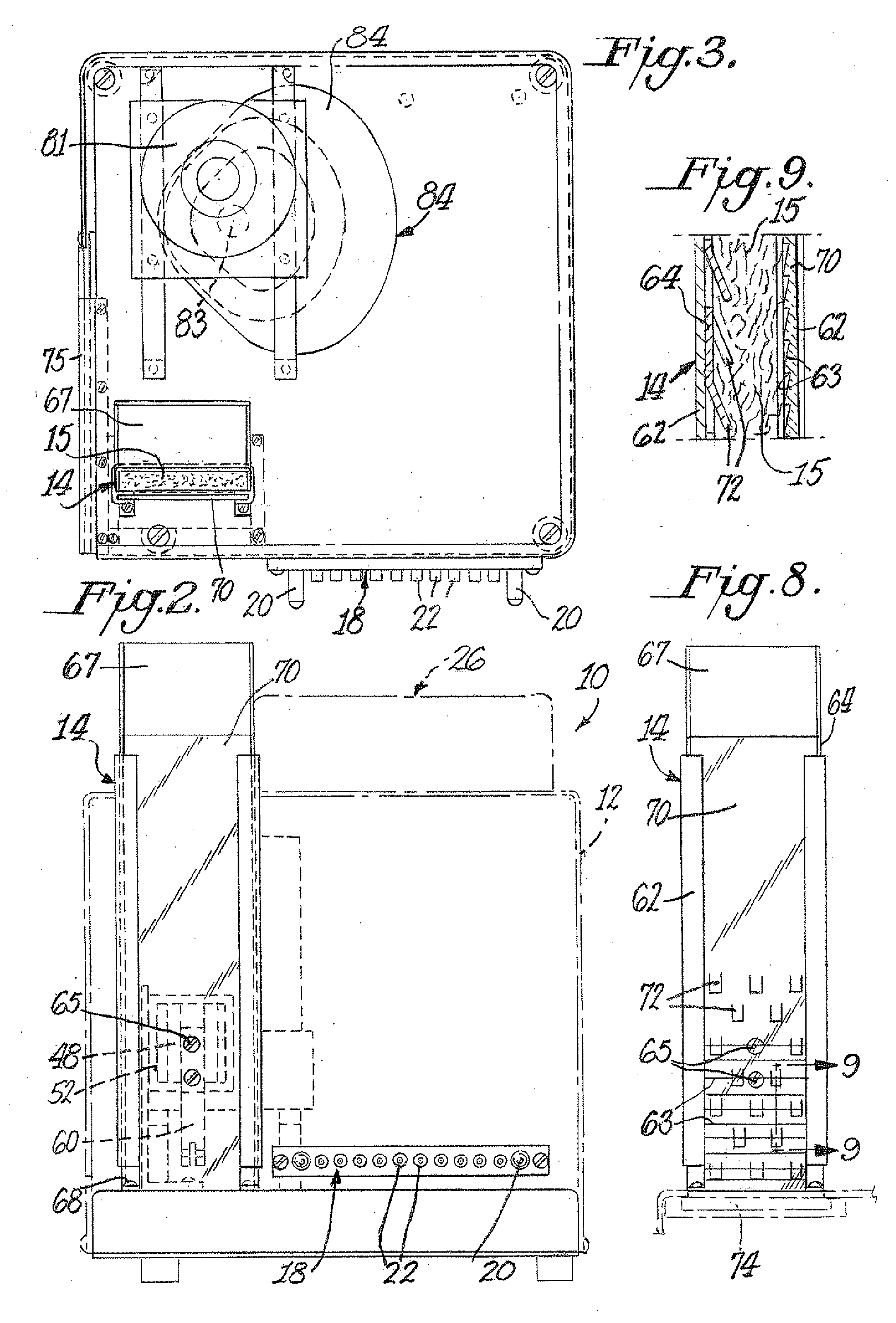

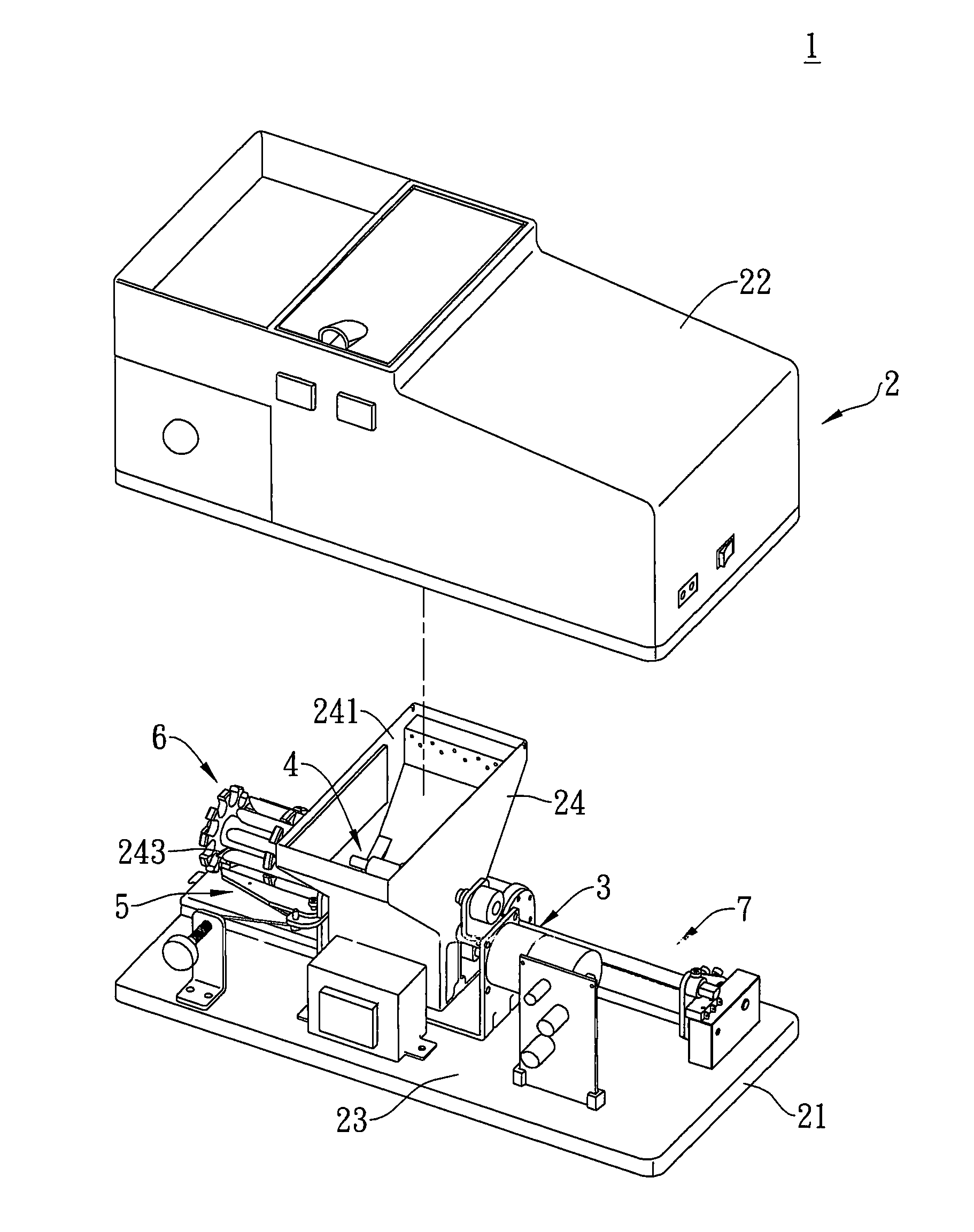

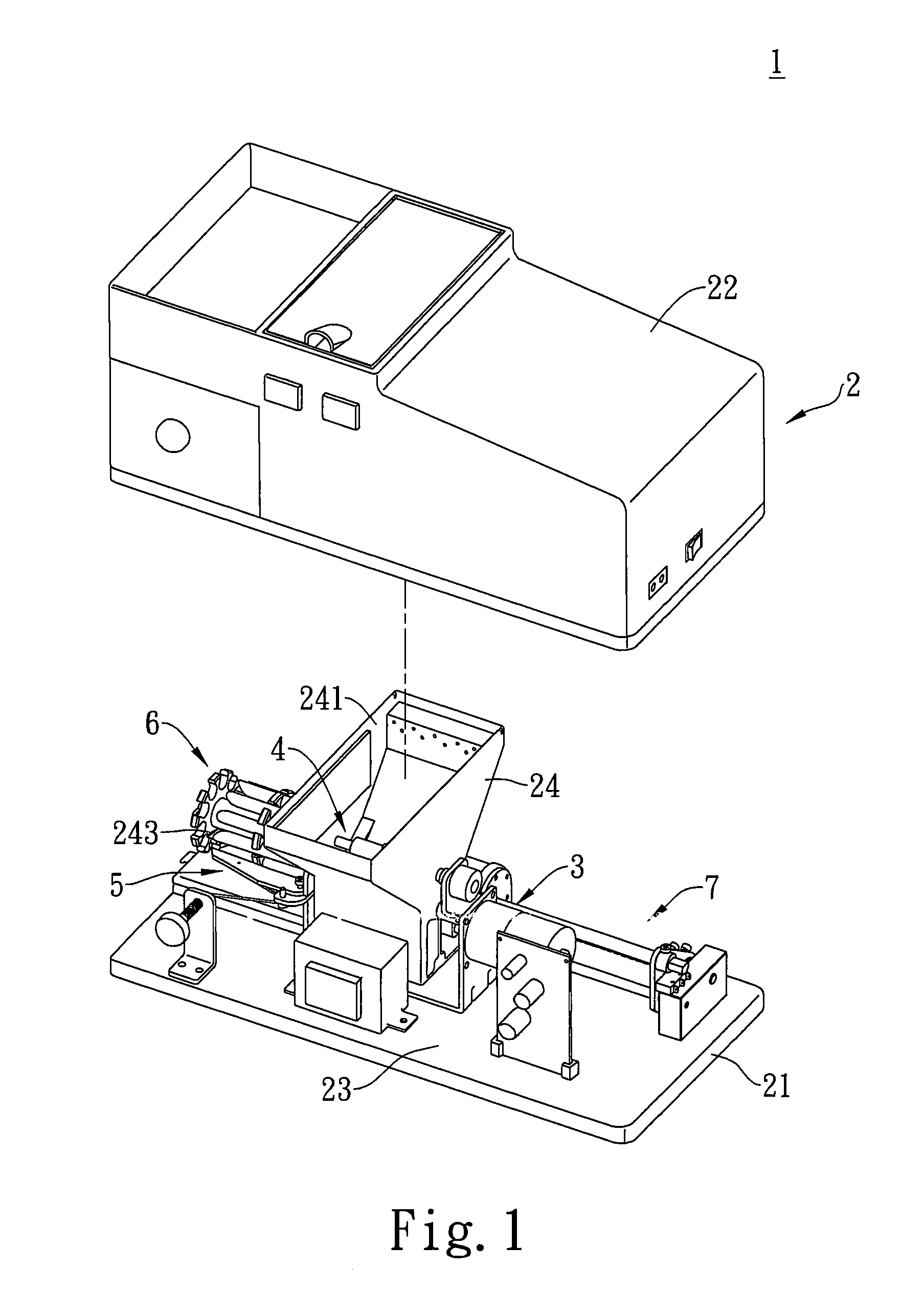

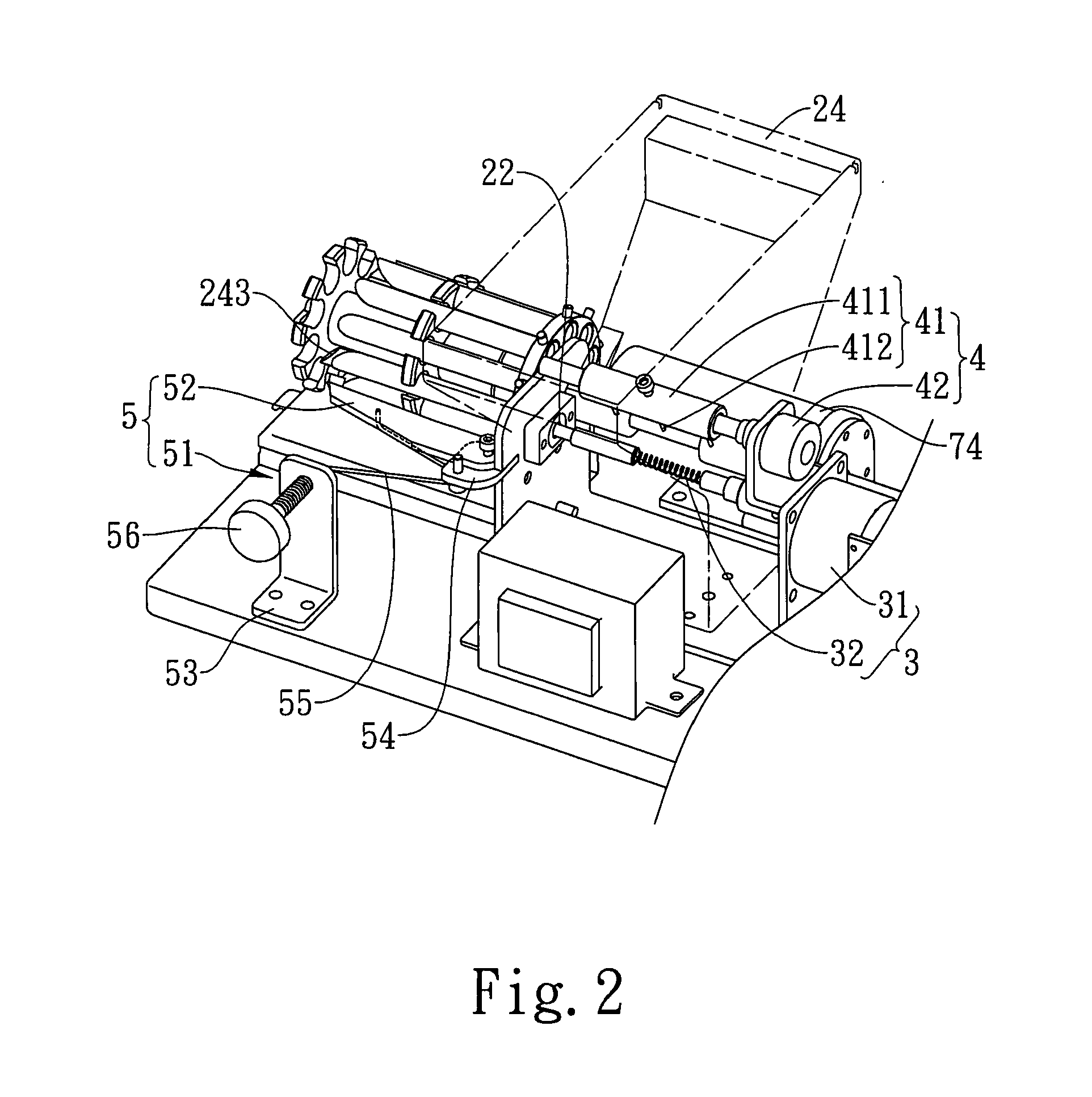

Tabletop cigarette maker

ActiveUS20070289601A1Save moneyReducing or eliminating trips to a storeCigarette manufactureCigarette MakersEngineering

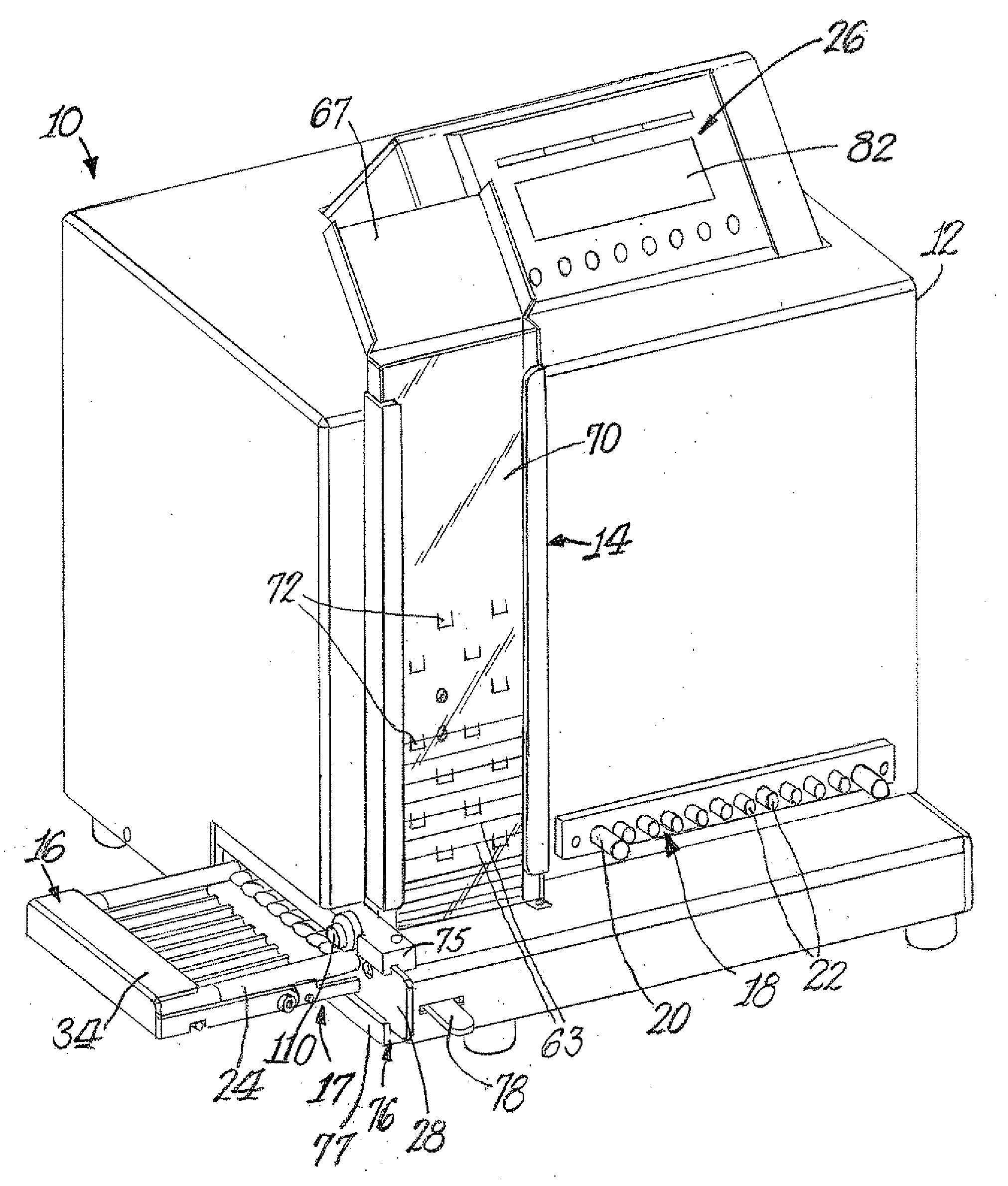

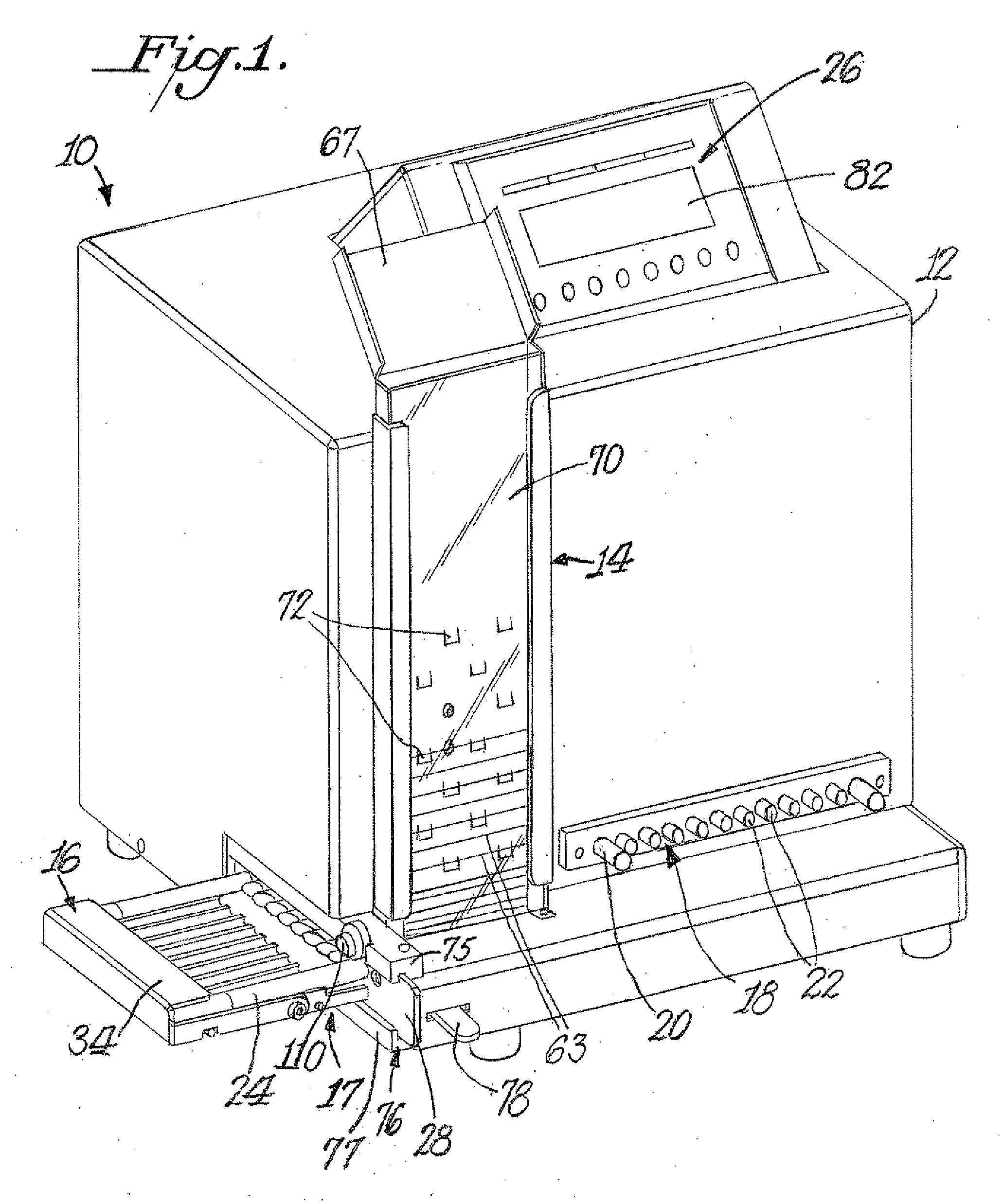

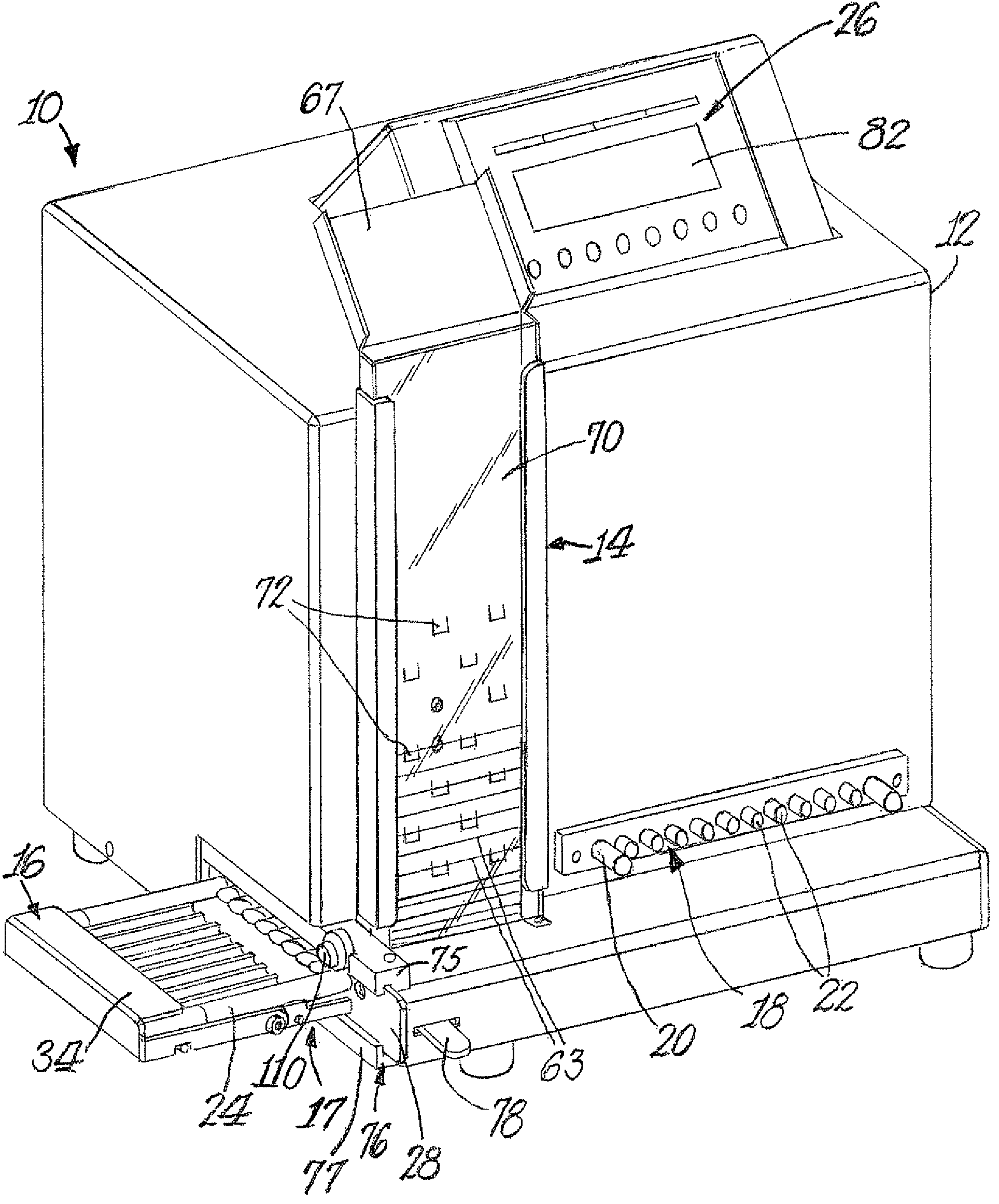

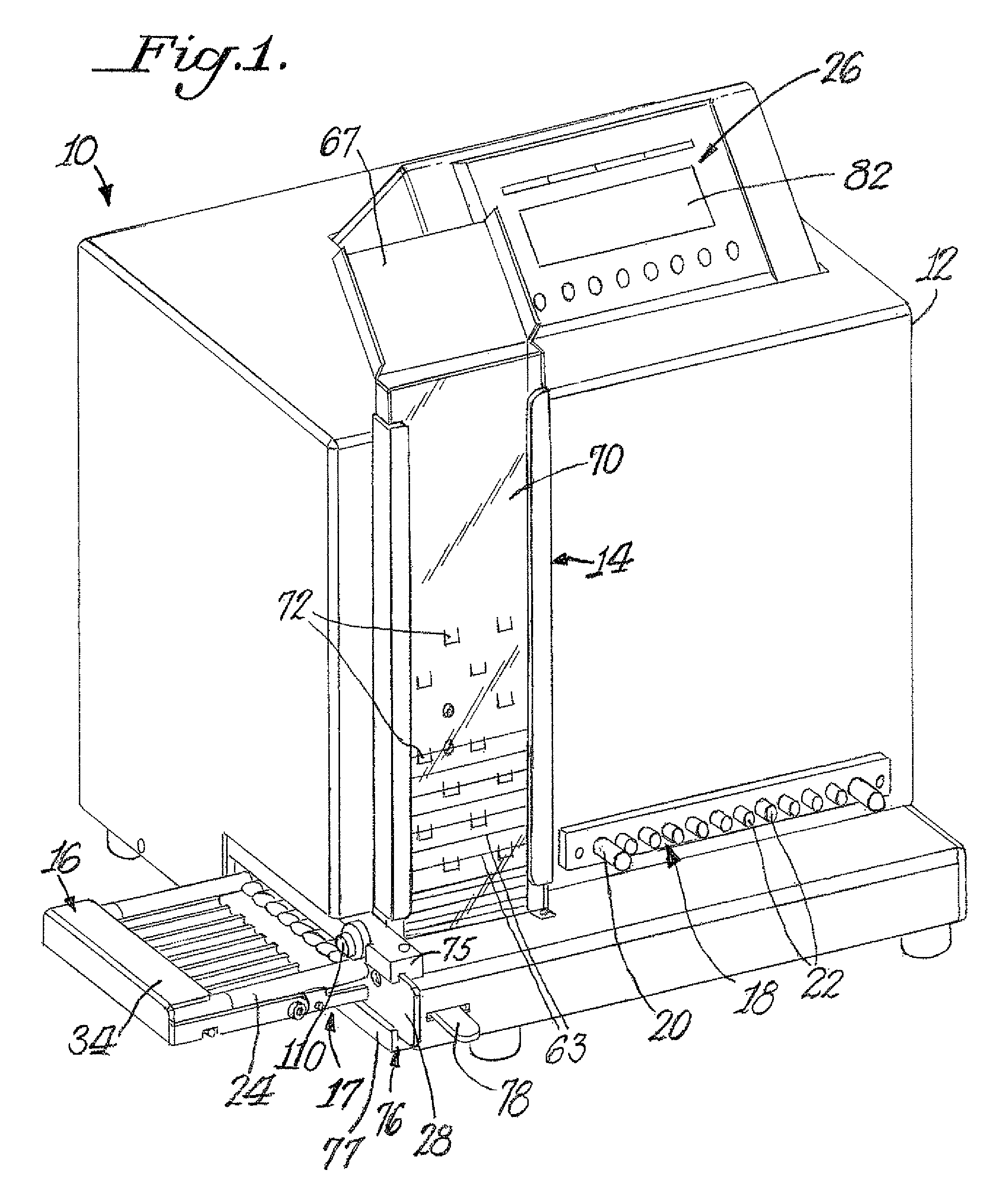

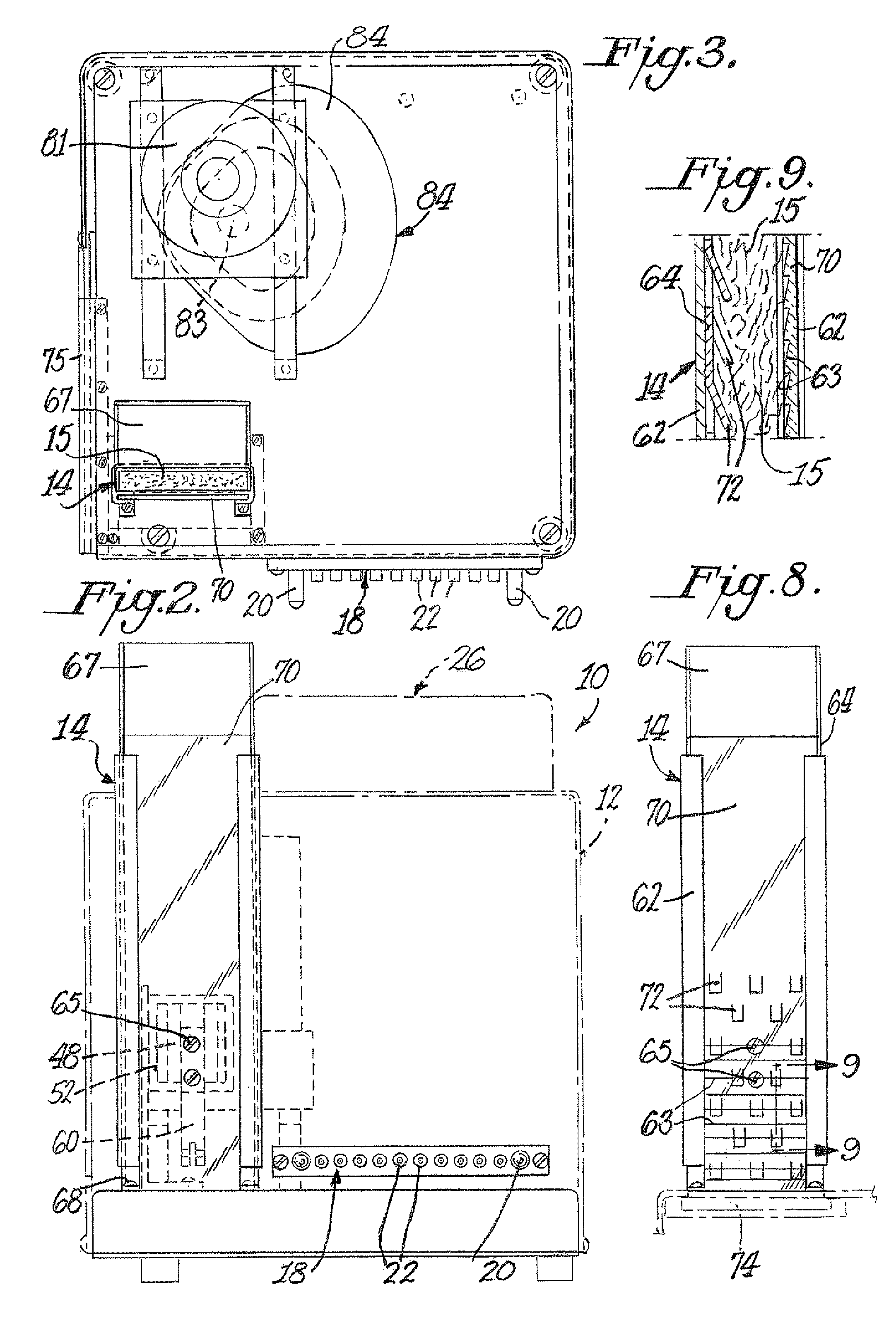

The present invention relates to the cigarette making apparatus 10 which may comprise a housing 12 with mechanical and electrical features. Cigarette apparatus 10 has a solenoid-assisted hopper 14 for accepting loose tobacco 15, a cigarette tube filling cassette 16 with nozzles 30 and a hinged lid 34 for assisting in maintaining cigarette tubes 24 in a predetermined alignment for loading tobacco 15, a filling area 17 with a indexing means for aligning cigarette tubes with a tobacco pushing means inside the apparatus, a cigarette tube loading and tobacco packing means 18 with guide pins 20 for guiding the cassette 16 in engagement with flattened tip pins 22 that compress tobacco 15 into cigarette tubes 24 after tobacco 15 has been inserted, and an electronic control area 26, which may include an electronic display for controlling the cigarette tube filling and packing apparatus

Owner:PHILIP MORRIS USA INC

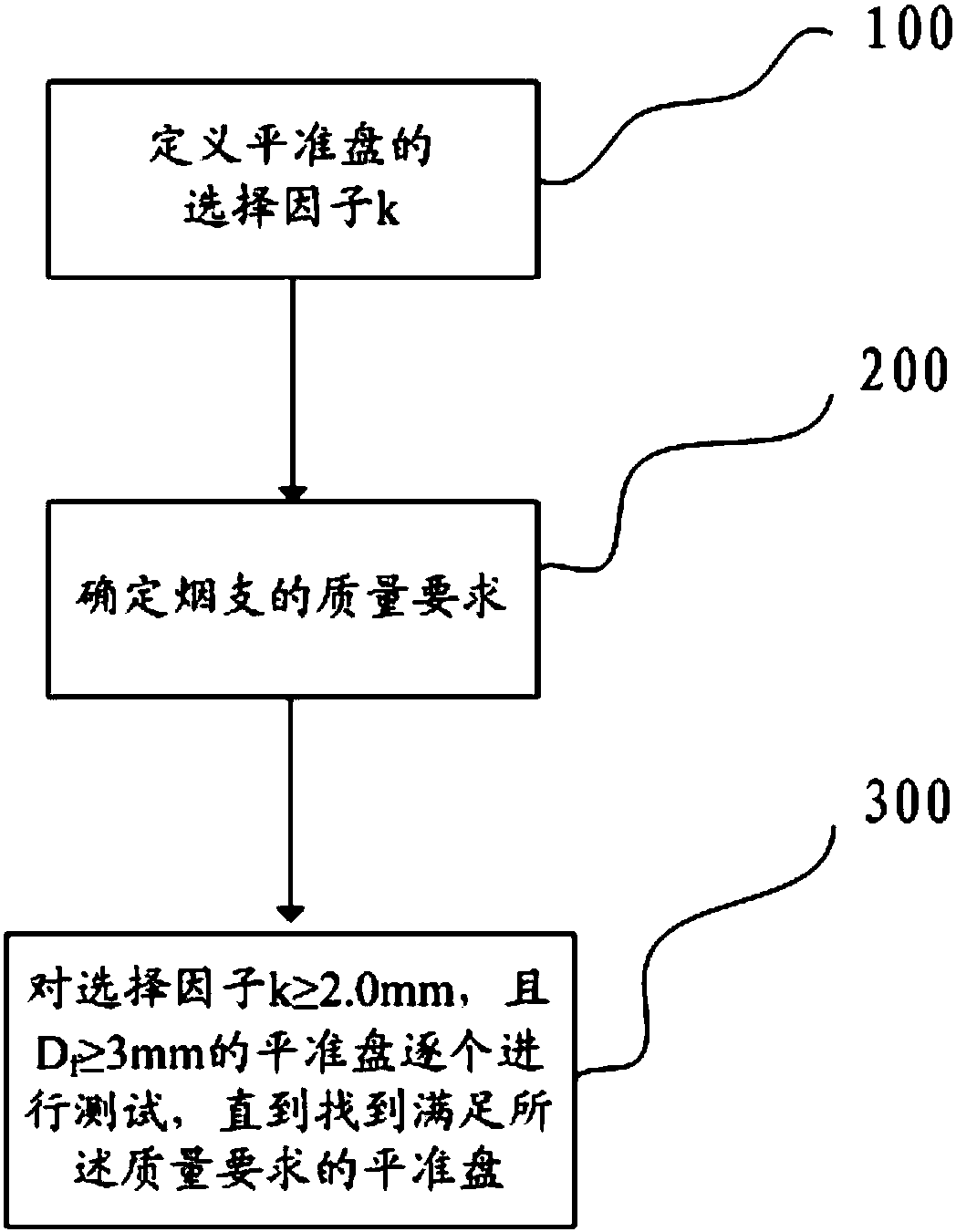

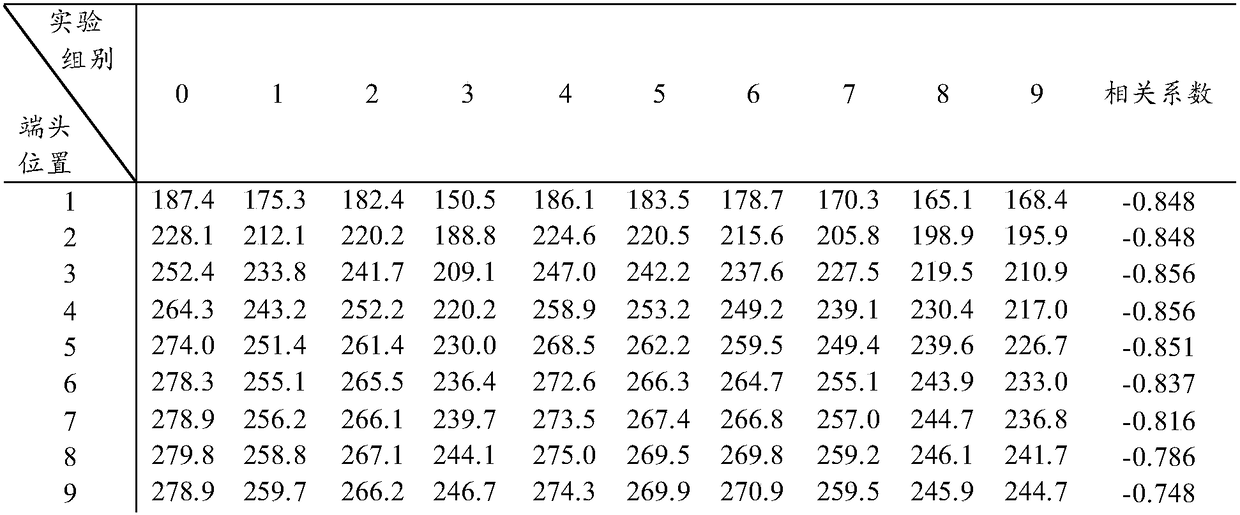

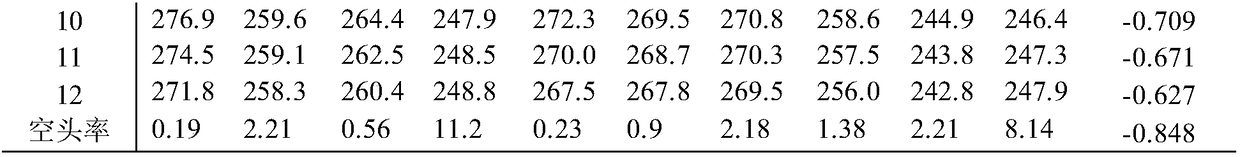

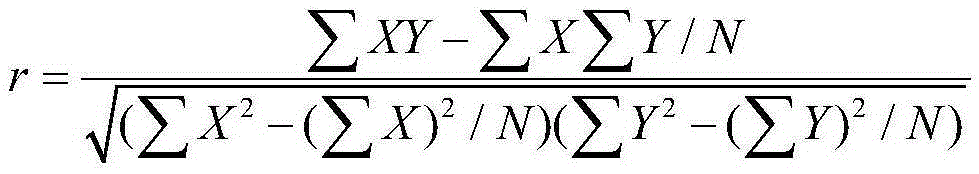

Method for selecting ecreteur disc of cigarette maker

ActiveCN108175124ATest RefinementReduce the number of testsMachine part testingCigarette manufactureCigarette MakersComputer science

Owner:CHONGQING CHINA TOBACCO IND CO LTD

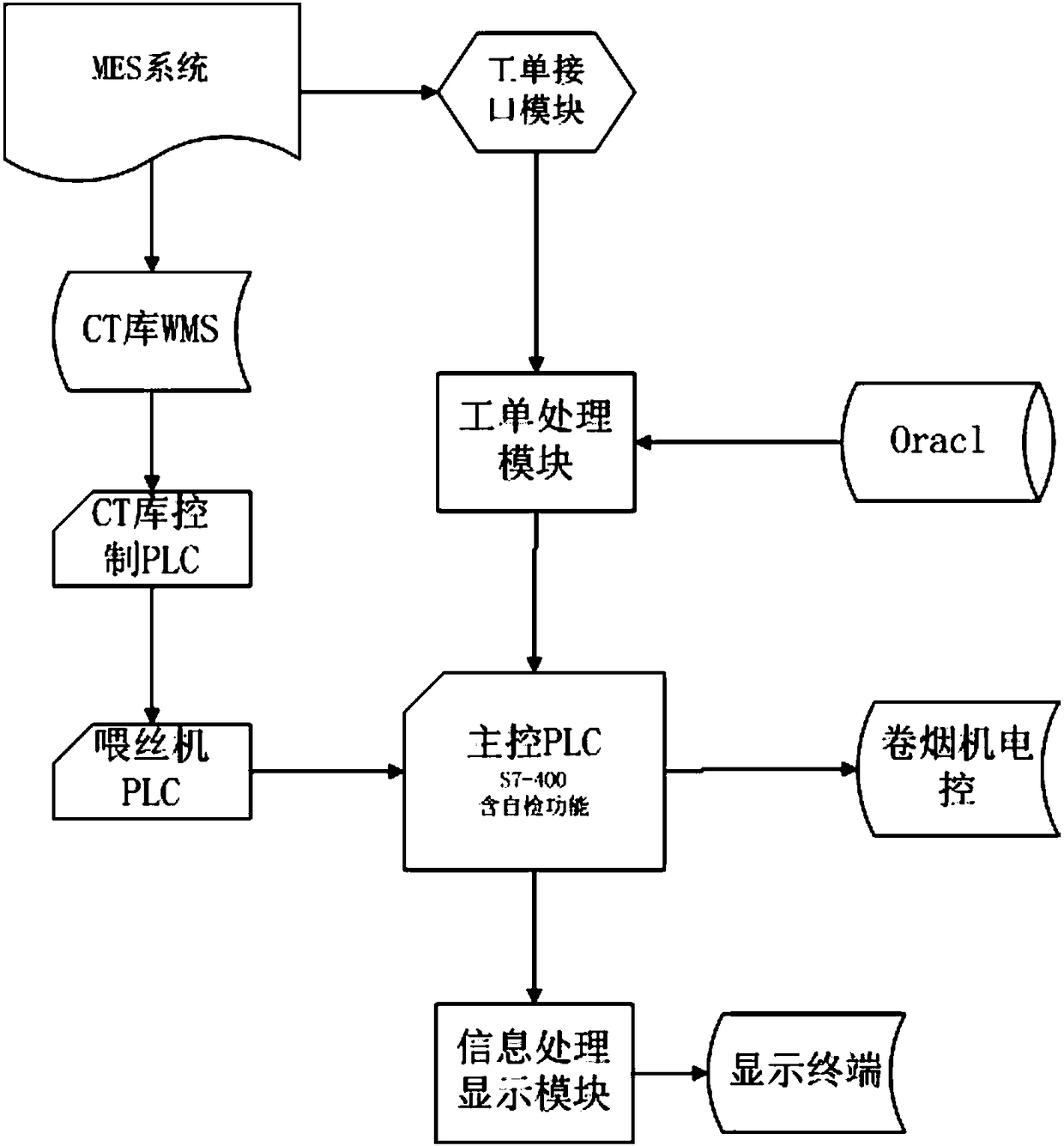

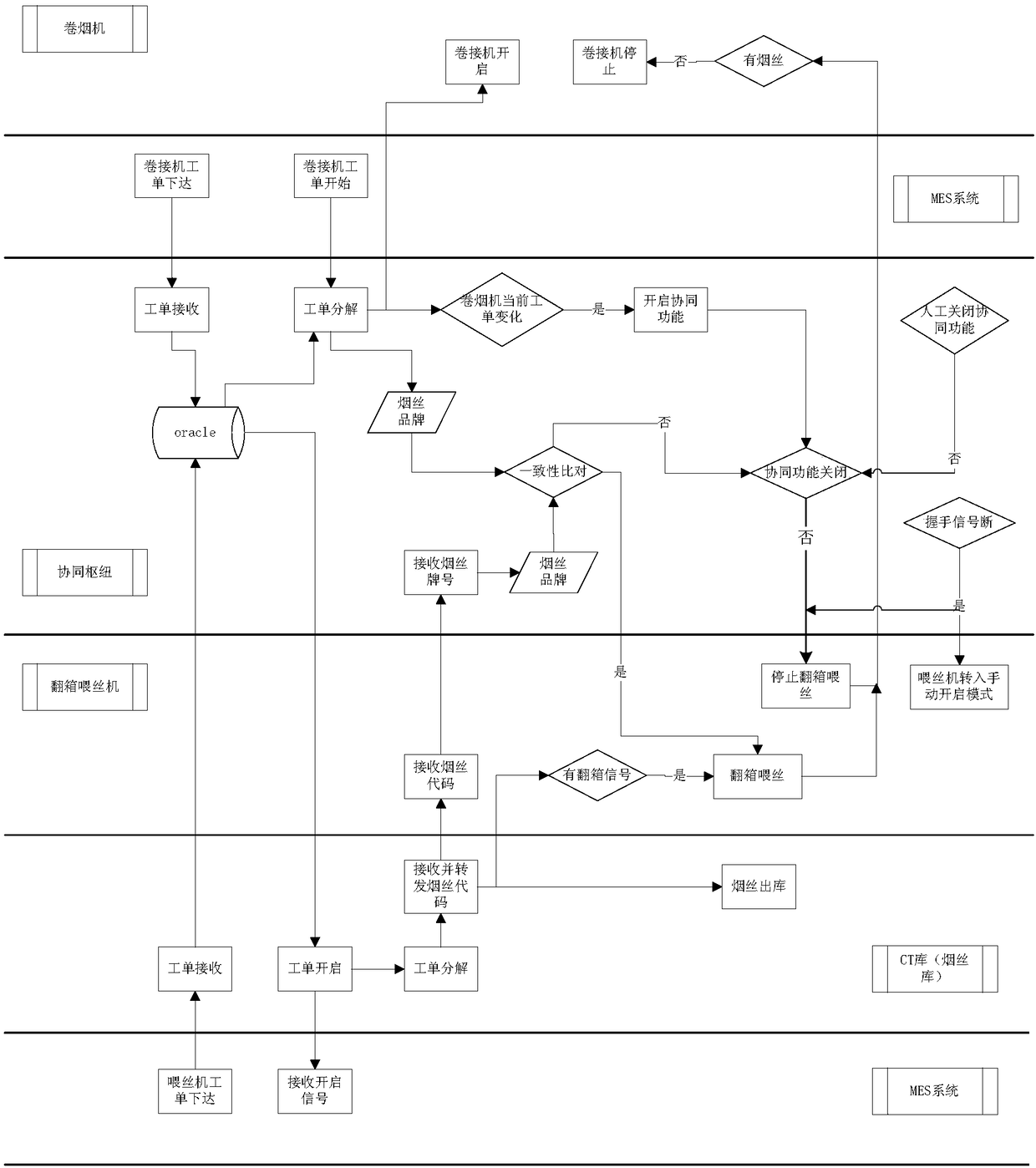

Cigarette maker and cut tobacco feeder production cooperative control method based on work orders

ActiveCN108244697ARealize automatic cooperative controlImprove efficiencyCigarette manufactureCigarette MakersProcess module

The invention discloses a cigarette maker and cut tobacco feeder production cooperative control method based on work orders; based on a cigarette maker production work order and a cut tobacco feeder production work order and a work order start signal issued by a MES system, a cooperative junction comprising a work order interface module, a work order processing module and a main control PLC is constructed; the work order interface module receives the cigarette maker work order and the start signal, the work order processing module decomposes a cut tobacco brand required by the cigarette maker,and sends the cut tobacco brand to the main control PLC, and the main control PLC controls the cigarette maker to start; a CT library WMS system receives the cut tobacco production work order and decomposes the cut tobacco production work order to obtain an outbound cut tobacco code, and sends the outbound cut tobacco code to the main control PLC, the main control PLC controls the cut tobacco feeder to turn for feeding cut tobacco; during the operation, the main control PLC can obtain the cut tobacco code of the cut tobacco feeder in real time, and the cut tobacco code is compared with a stored cigarette maker cut tobacco code. When the cut tobacco code is inconsistent with the stored cigarette maker cut tobacco code, a stop signal is sent to the cut tobacco feeder, the cut tobacco feederstops turning, the cigarette maker stops automatically when no cut tobacco is detected. The method effectively prevents the generation of mis-brand of the cut tobacco, and the cigarette making and cut tobacco feeding cooperative production can be fully automated.

Owner:CHINA TOBACCO ZHEJIANG IND

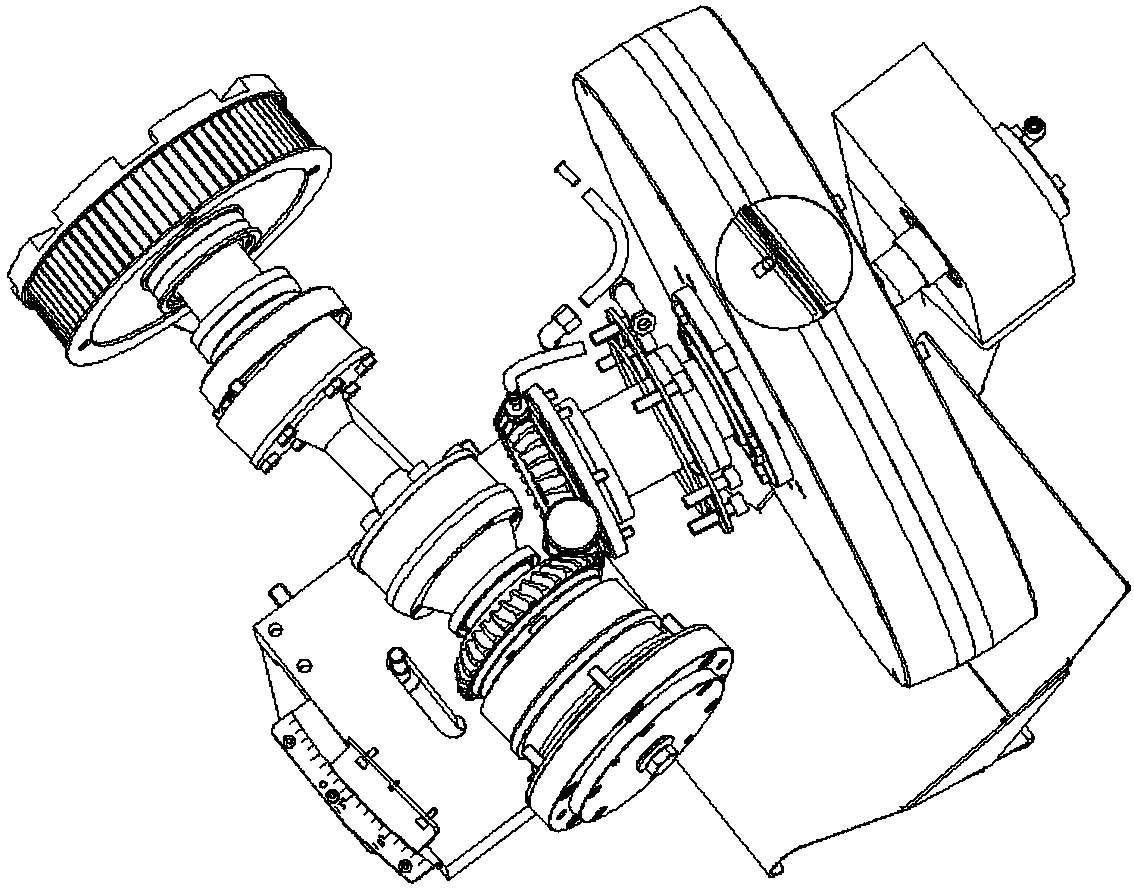

Leveling device of inclined disc type

InactiveCN102018281AReasonable designSimple structureCigarette manufactureCigarette MakersGear wheel

The invention discloses a leveling device of the inclined disc type, belonging to the technology field of cigarette machineries. In this invention, two level disks of the leveling device incline to two sides from the intermediate adjacent portion, and there is a tilt angle which is from 9.99 DEG to 10.01 DEG between the inner circle of the upper surface of the level disks and the horizontal plane. The angle between the cylindrical portion and the inner circle portion of the upper surface of the level disks is from 9.99 DEG to 10.01 DEG. The level disks are fixed on the top of level disk shafts, the level disk shafts are provided with helical gears, and the helical gears are engaged with long helical gears on long gear shafts. The helical gears and the level disk shafts are integrated, so do the long helical gears and the long gear shafts. The bearing arranged in a guide sleeve of the level disk shafts is a precision lathe bearing. The leveling device is characterized by reasonable design, simple structure and high automation degree. The leveling device can be applied to a present cigarette maker to provide reliable guarantee for the production quality.

Owner:HUBEI CHINA TOBACCO IND

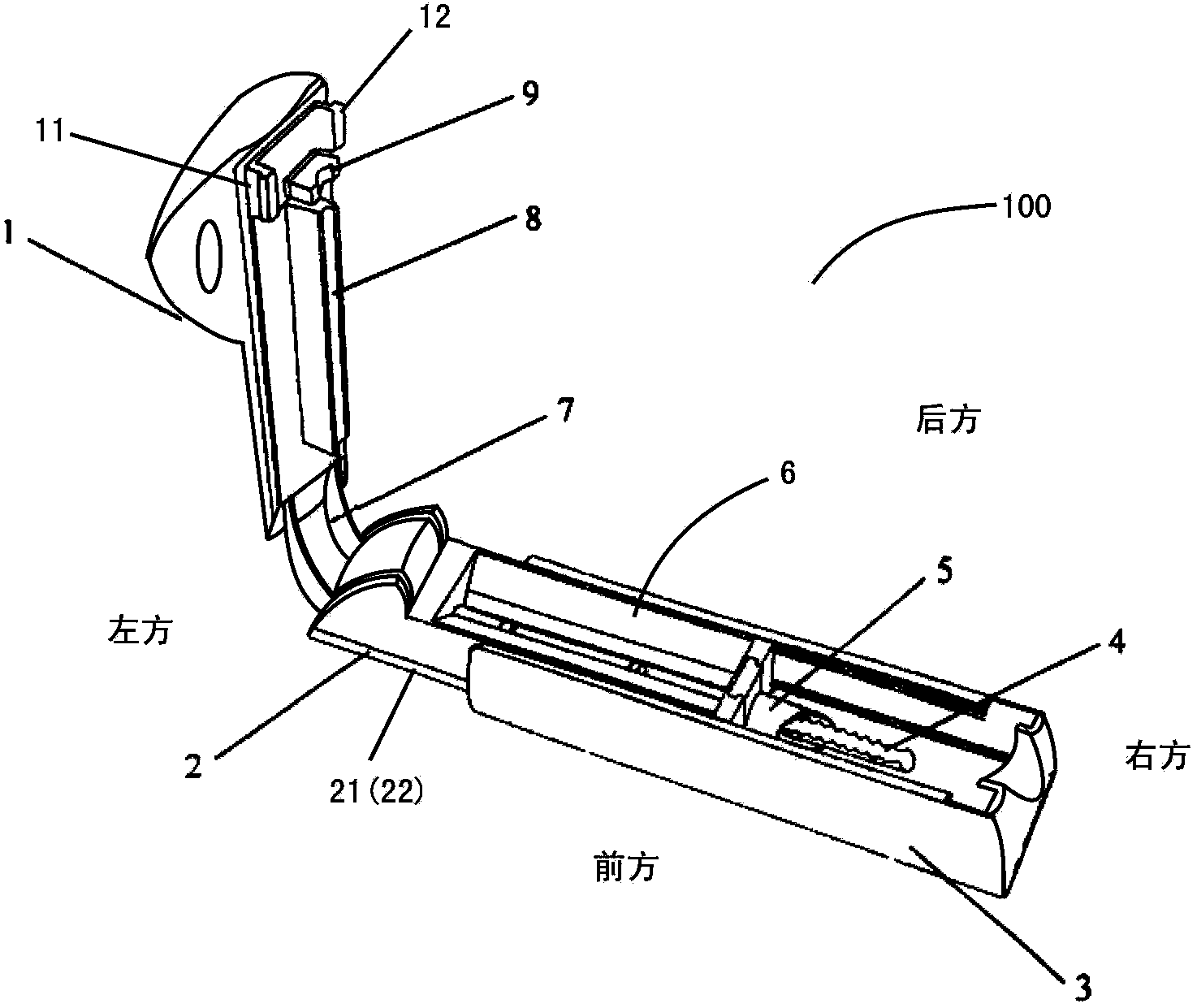

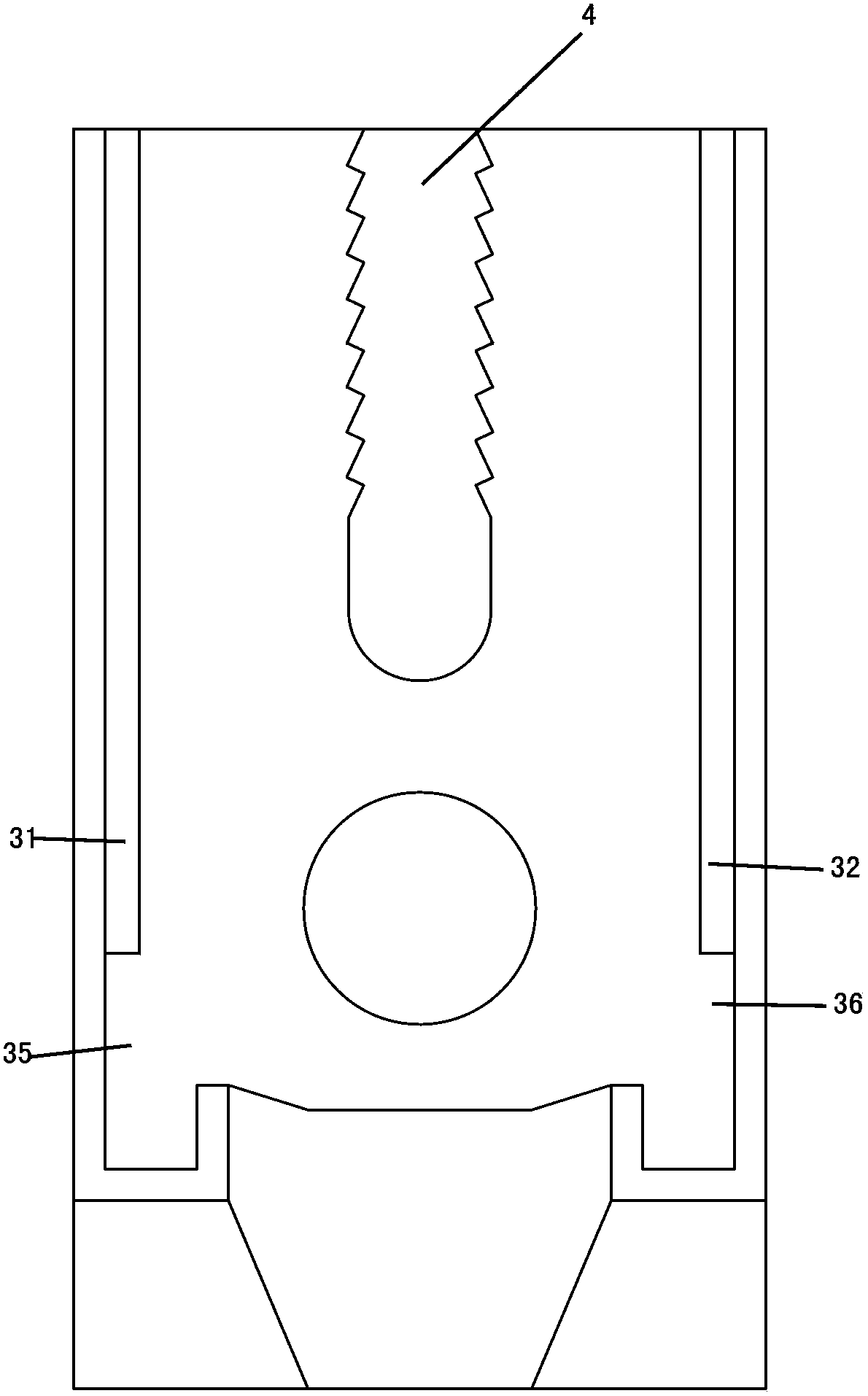

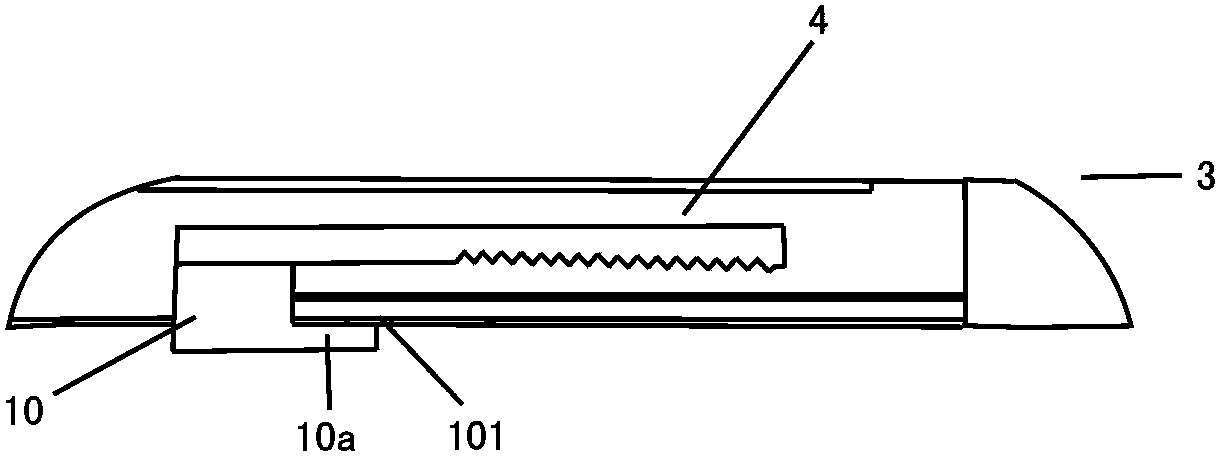

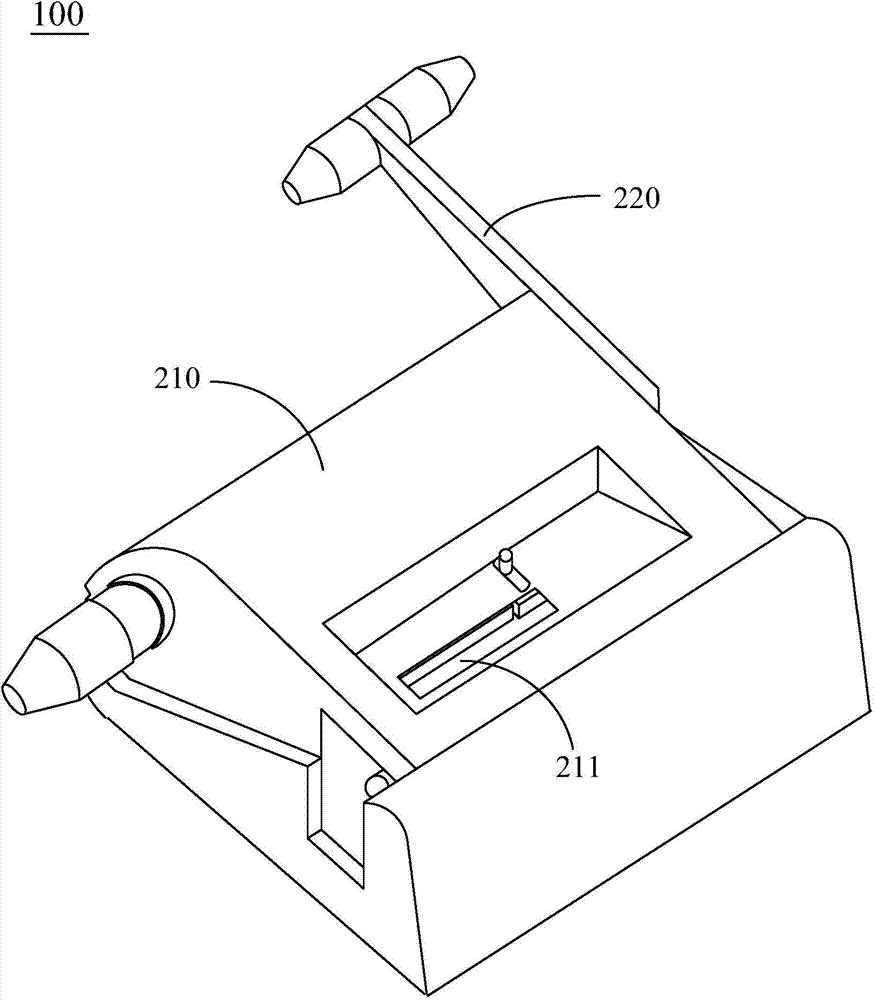

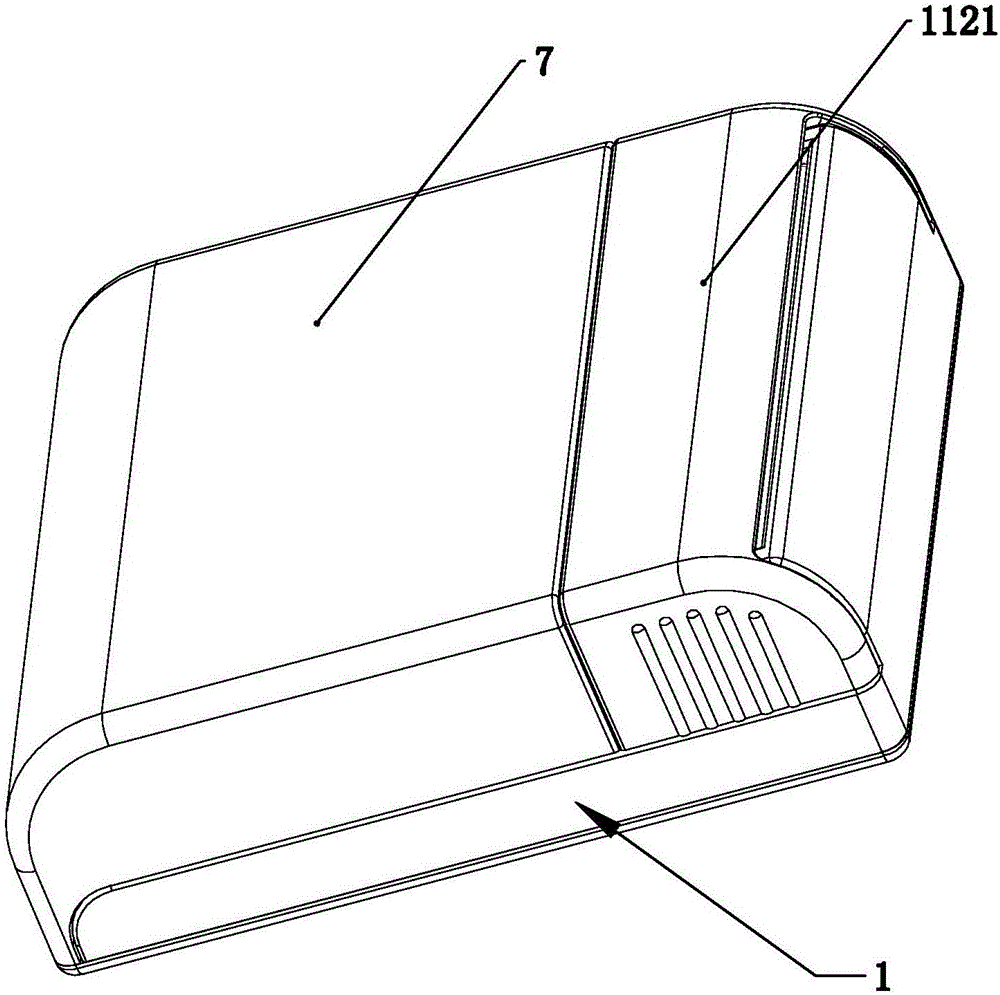

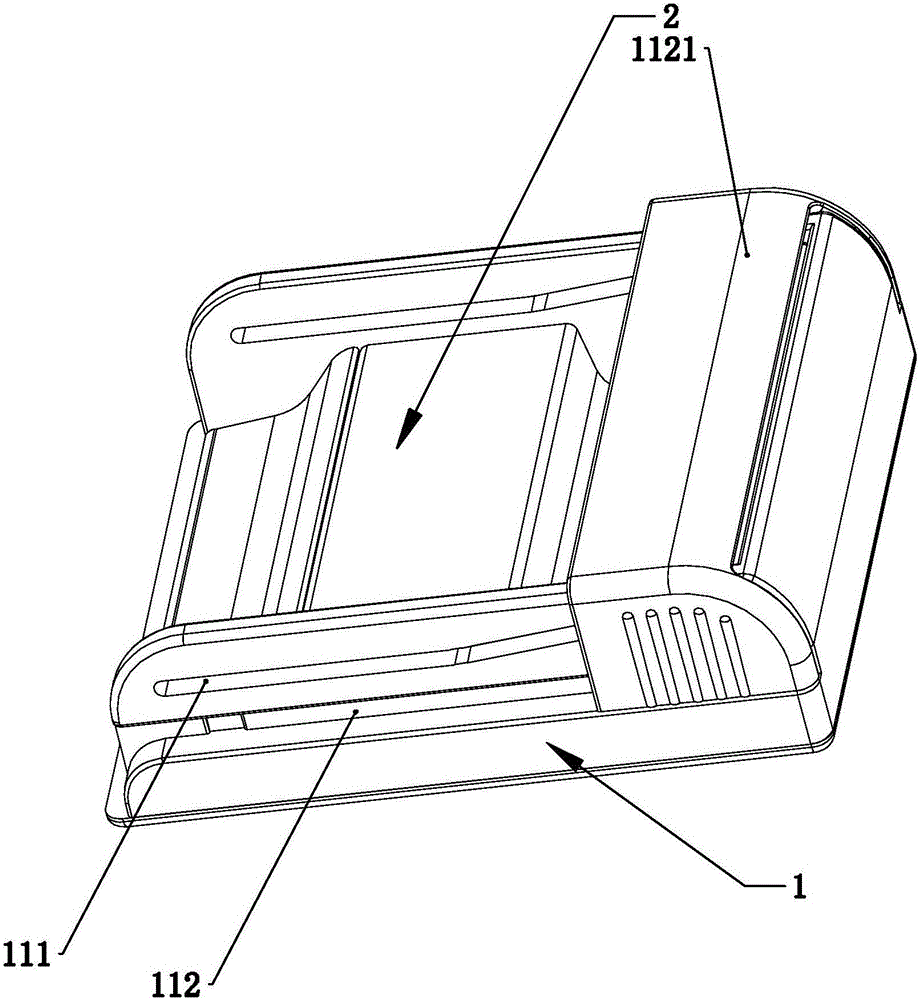

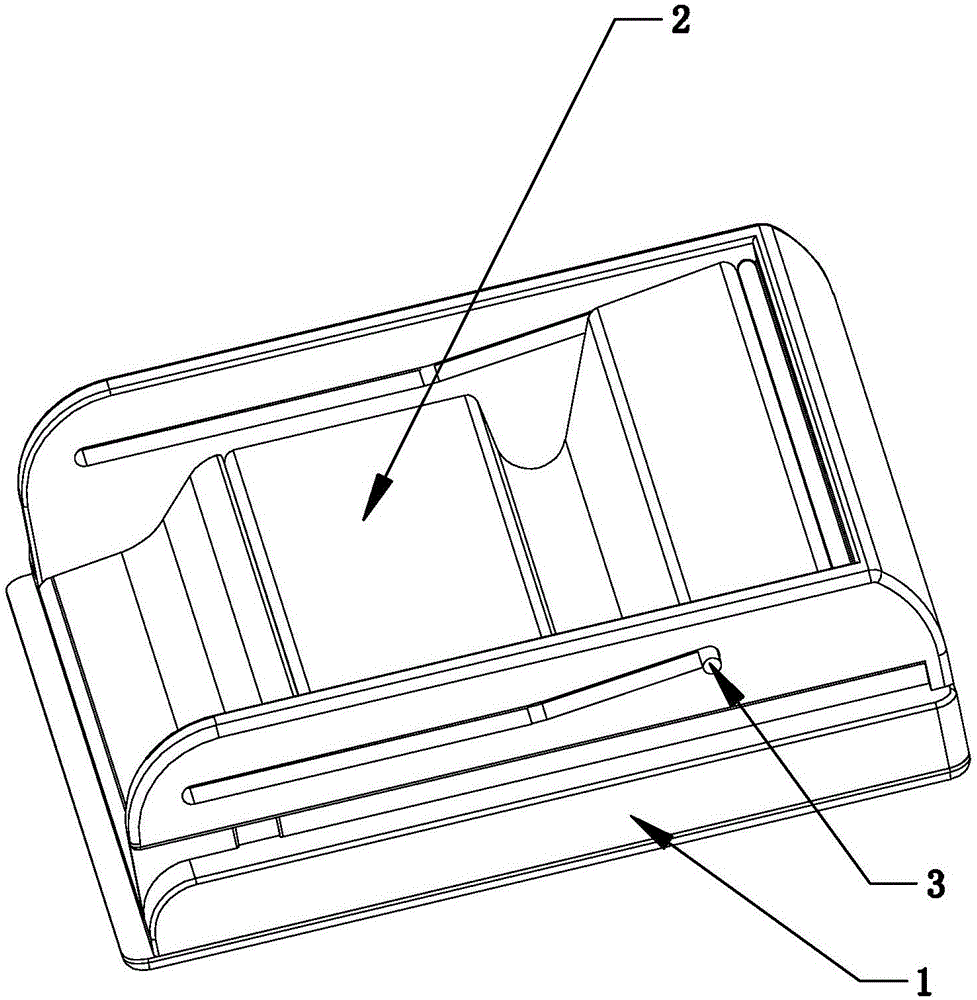

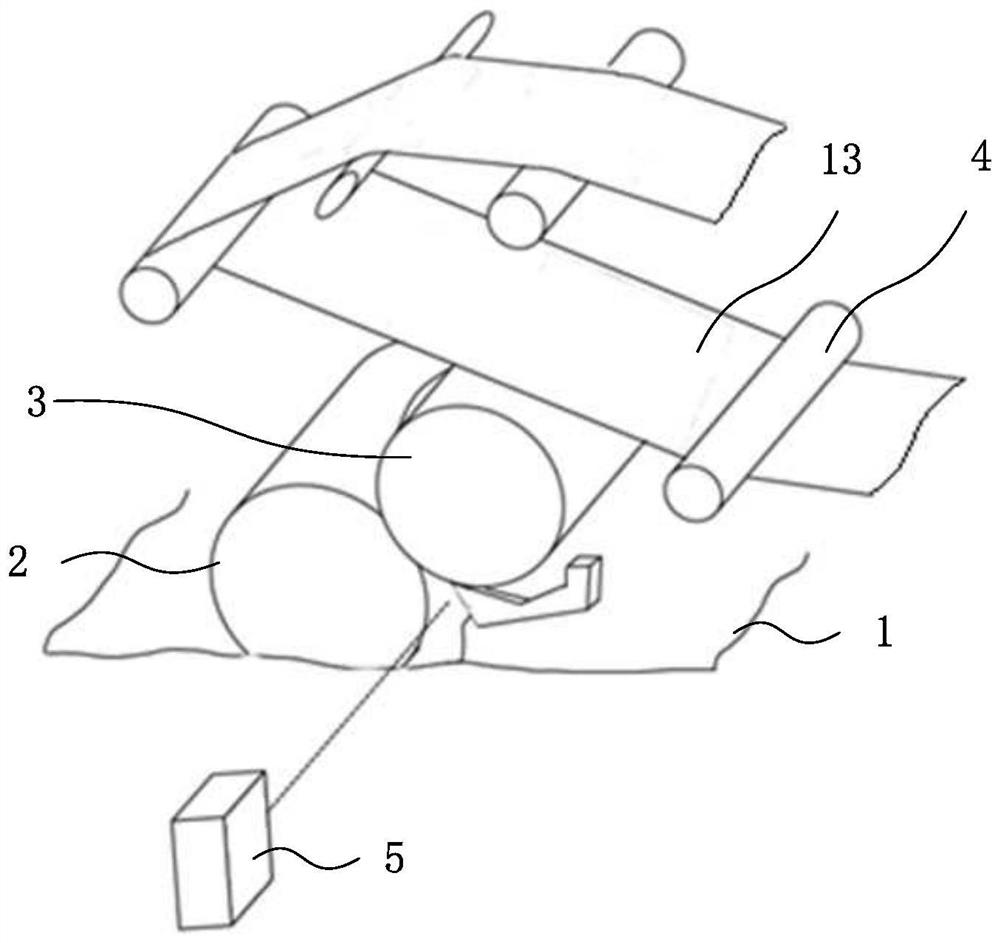

Pocket type household cigarette making apparatus

The invention provides a pocket type household cigarette making apparatus (100) which is provided with a base (3) and a push-and-pull base (2), wherein the push-and-pull base is arranged in the base in a sliding manner between a coincident position relative to the base and a staggered position relative to the base, an up-down through cut cigarette groove (6) is formed in the push-and-pull base, the base end of a cut cigarette spoon (4) is suspended and fixed at the left side of the base, the tail end of the cut cigarette spoon is arranged towards the right side in an extending manner, the cut cigarette spoon is arranged in the cut cigarette groove under the state that the push-and-pull base is coincident with the base, and the cut cigarette spoon is capable of penetrating through the push-and-pull base under the state that the push-and-pull base and the base slide relatively. The household cigarette making apparatus is also provided with a slippage regulating device. Therefore, the slippage of the push-and-pull base can be regulated, cut cigarette in the cut cigarette groove can be injected into a cigarette barrel in different quantities, and thus cigarettes of different sizes and lengths can be made.

Owner:REPUBLIC TOBACCO

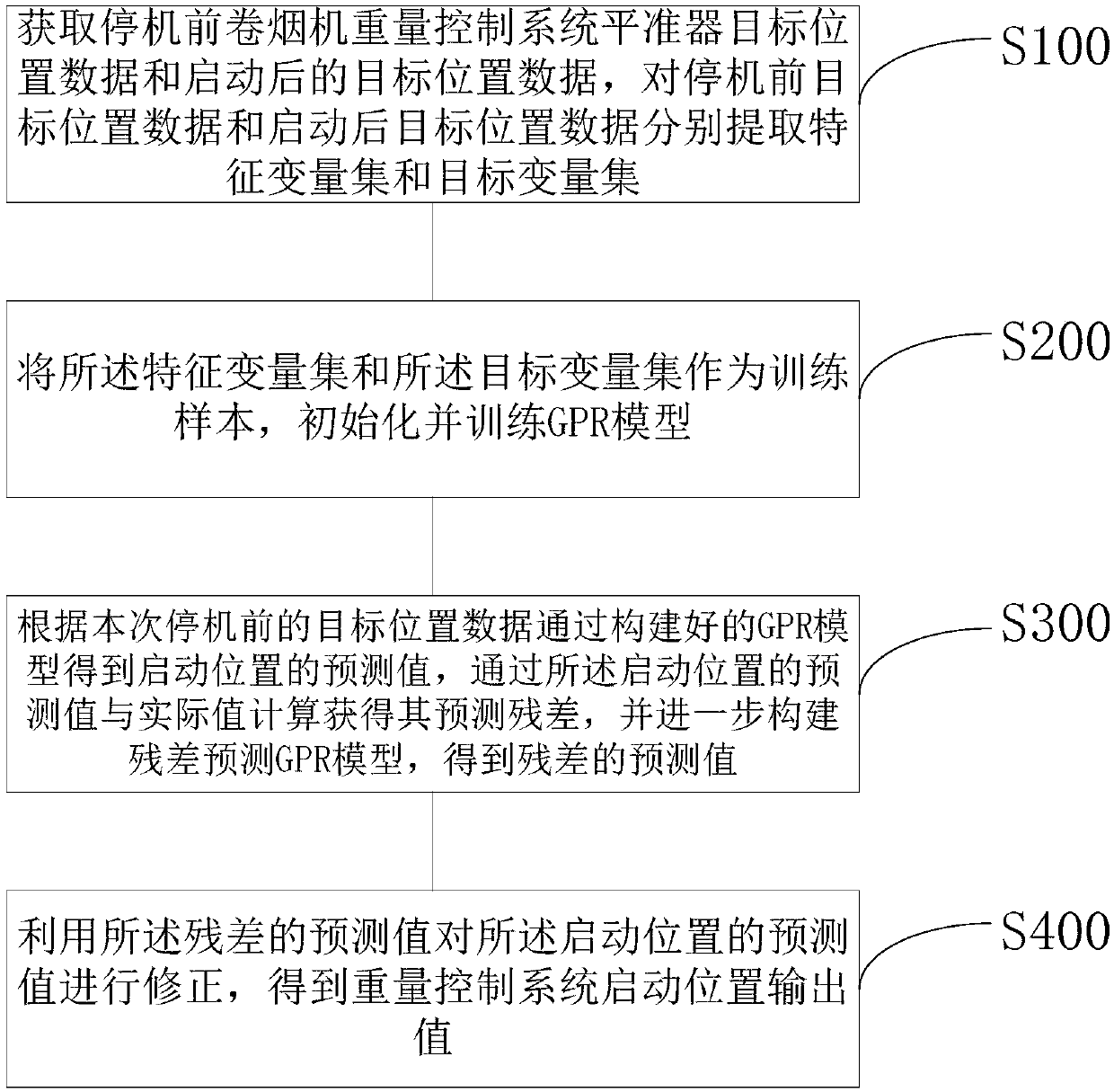

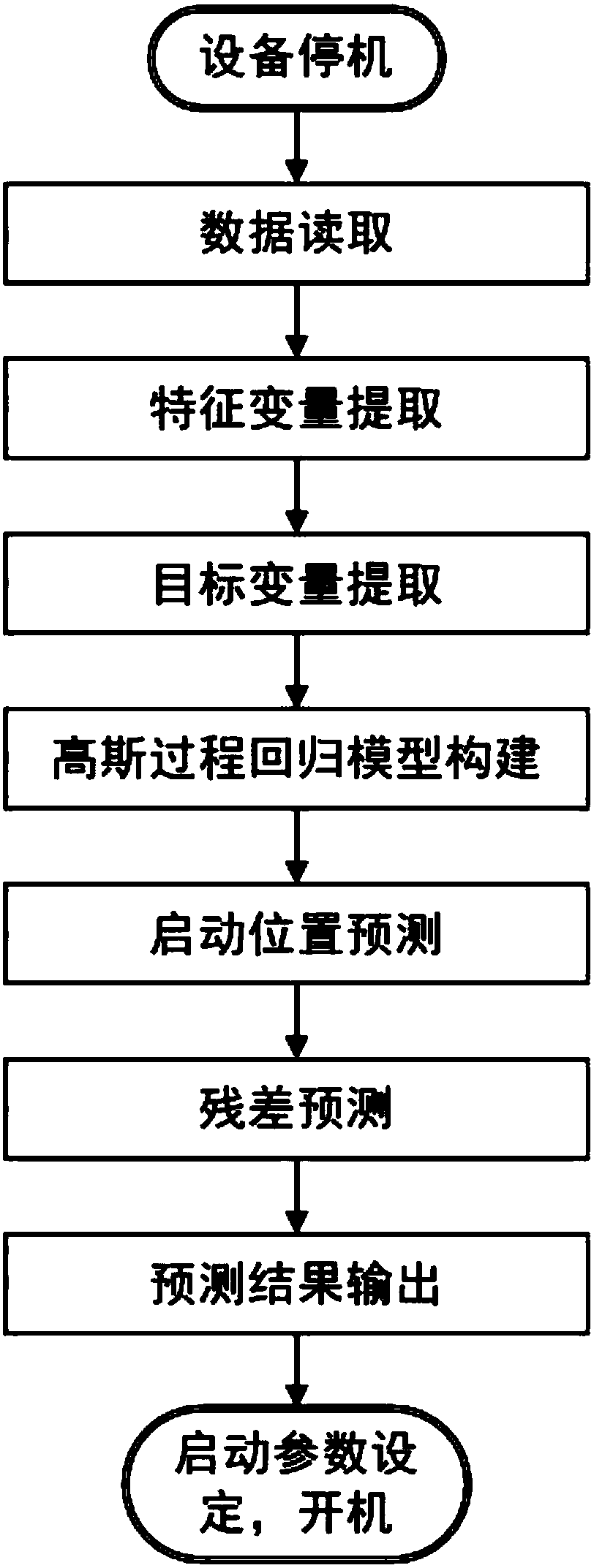

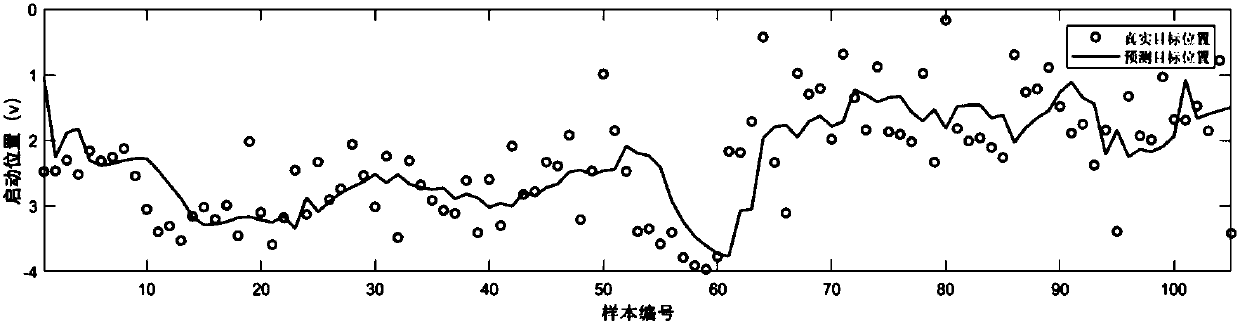

Cigarette weight control system starting position predicting method and system based on GPR model

ActiveCN108323797AGood technical effectReduce weight bias convergence timeCigarette manufactureCigarette MakersControl system

The invention discloses a cigarette weight control system starting position predicting method and a predicting system based on a GPR model. The predicting method comprises the following steps: acquiring target position data of a cigarette weight control system ecreteur of a cigarette maker before stopping as well as target position data after starting, and extracting characteristic variable sets and target variable sets of the target position data before stopping and the target position data after stopping; with the characteristic variable sets and the target variable sets as training samples,initializing and training the GPR model; in accordance with the target position data before stopping in the current time, obtaining a predicted value of a starting position via the constructed GPR model, calculating and obtaining a predicted residual via the predicted value of the starting position and an actual value, and further constructing a residual predicting GPR model, so that a residual predicted value is obtained; and correcting the predicted value of the starting position, so that an output value of the starting position of a weight control system is obtained. The method achieves relatively good robustness; and possible jump influence of sudden change of a production state in some time to an overall predicting result can be effectively prevented.

Owner:HANGZHOU ANMAISHENG INTELLIGENT TECH CO LTD

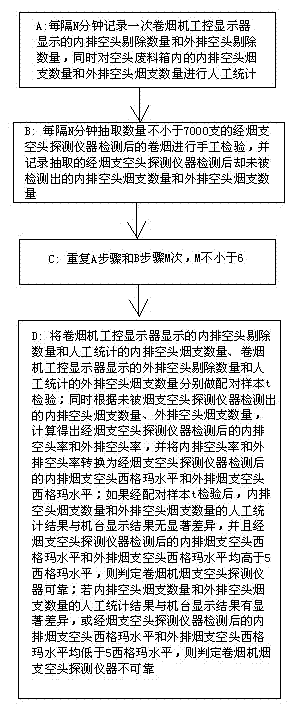

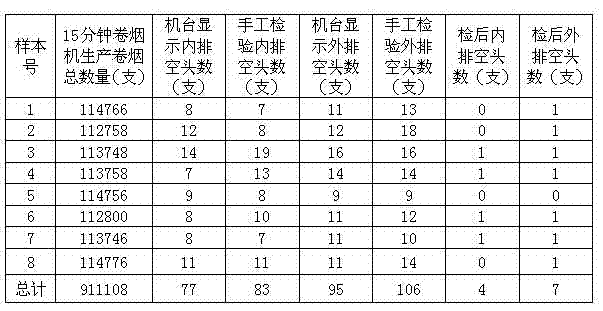

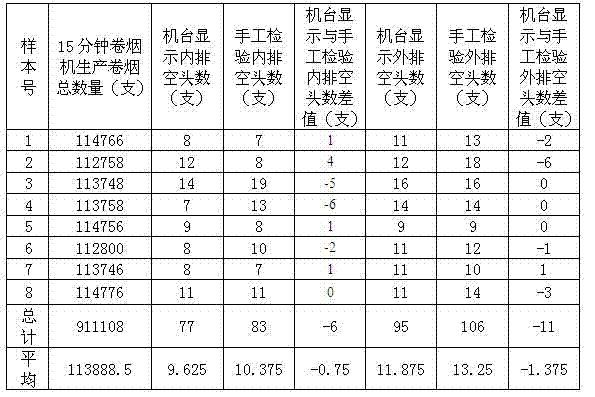

Method for determining reliability of cigarette maker cigarette loose end detector

ActiveCN102726833AAvoid economic lossNo destructive testing requiredCigarette manufacturePaired samplesCigarette Makers

The invention discloses a method for determining the reliability of a cigarette loose end detector that comes with a cigarette maker by hypothesis test and six sigma method, characterized by collecting an internally-discharged cigarette loose end rejecting amount and an externally-discharged cigarette loose end rejecting amount which are displayed by a cigarette maker industrial control display within the required time, simultaneously manually counting the amount of the internally-discharged cigarette loose ends and the amount of the externally-discharged cigarette loose ends in a cigarette loose waste tank, carrying out paired samples T test on the data; simultaneously according to the amounts of internally-discharged cigarette loose ends and externally-discharged cigarette loose ends which are not detected by the cigarette loose end detector, converting the internally-discharged cigarette loose end rate and externally-discharged cigarette loose end rate which are calculated by being detected by the cigarette loose end detector into a Sigma level. According to the invention, by means of hypothesis test and six sigma determination method, based on data analysis, the determination of the reliability and accuracy of the cigarette loose end detector that comes with the cigarette maker is realized accurately, objectively and effectively, thus the economic loss caused by shutdown detection is avoided.

Owner:CHINA TOBACCO HENAN IND

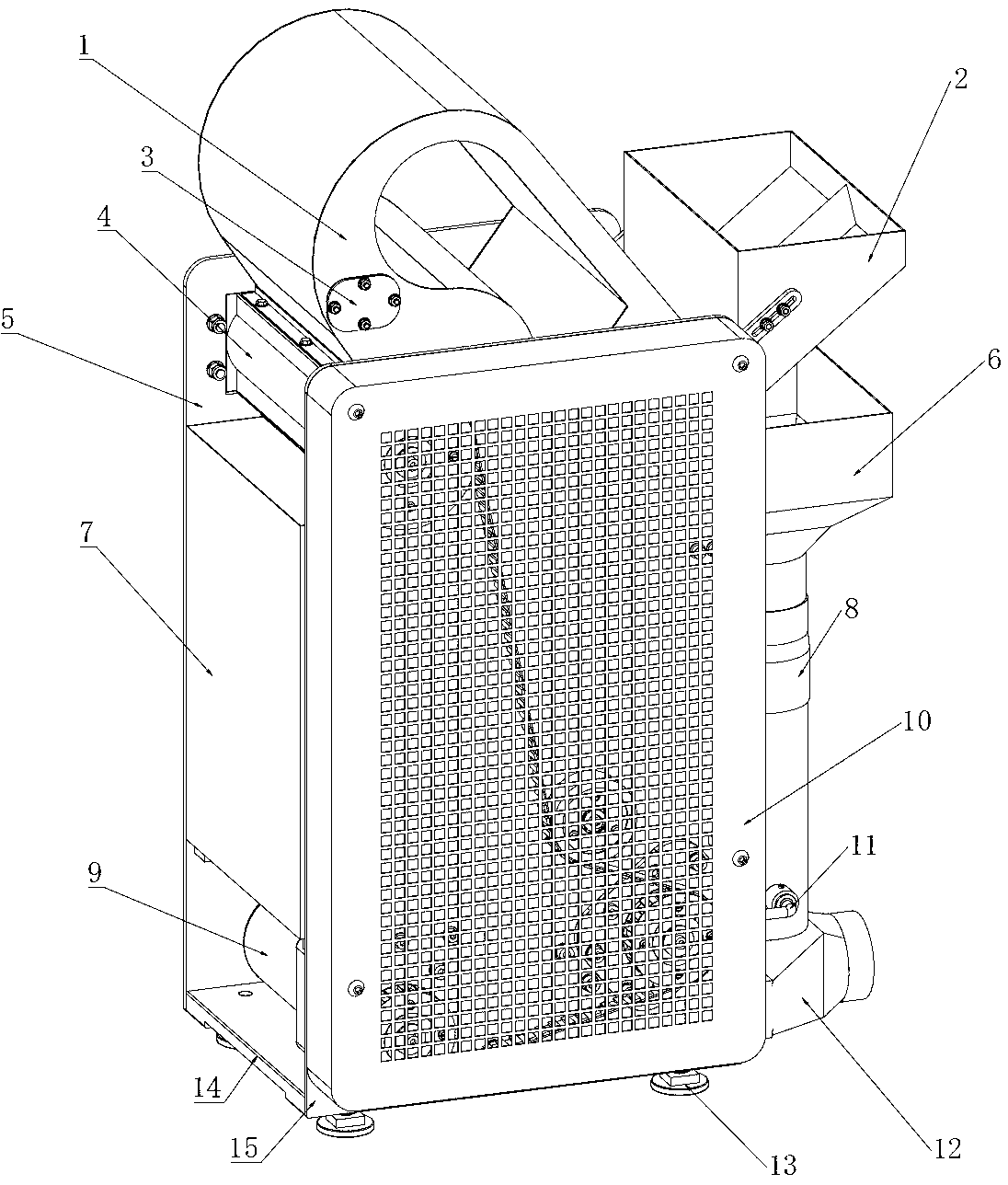

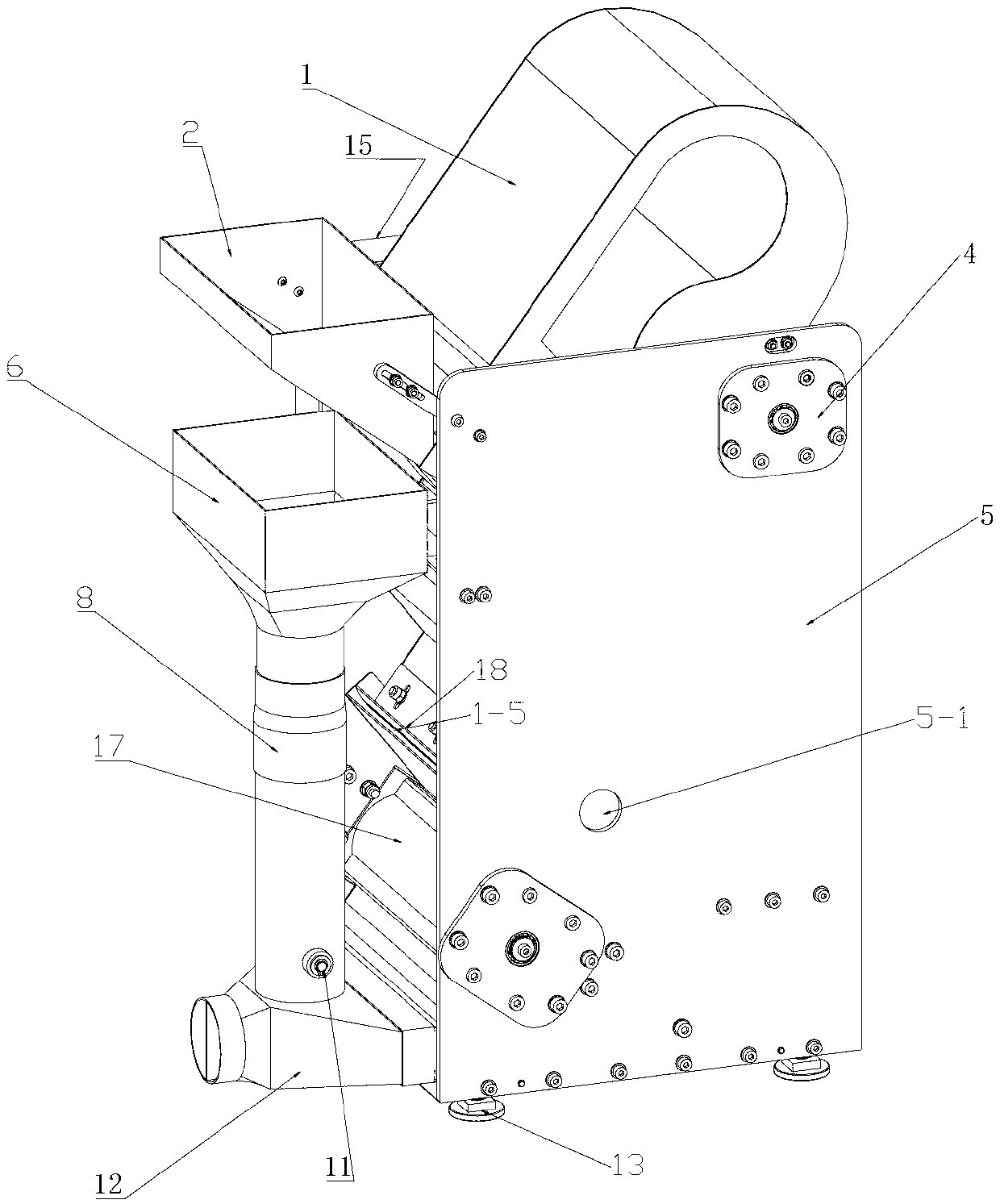

Device for offline and online screening of cut tobacco from removed stem slivers of cigarette maker

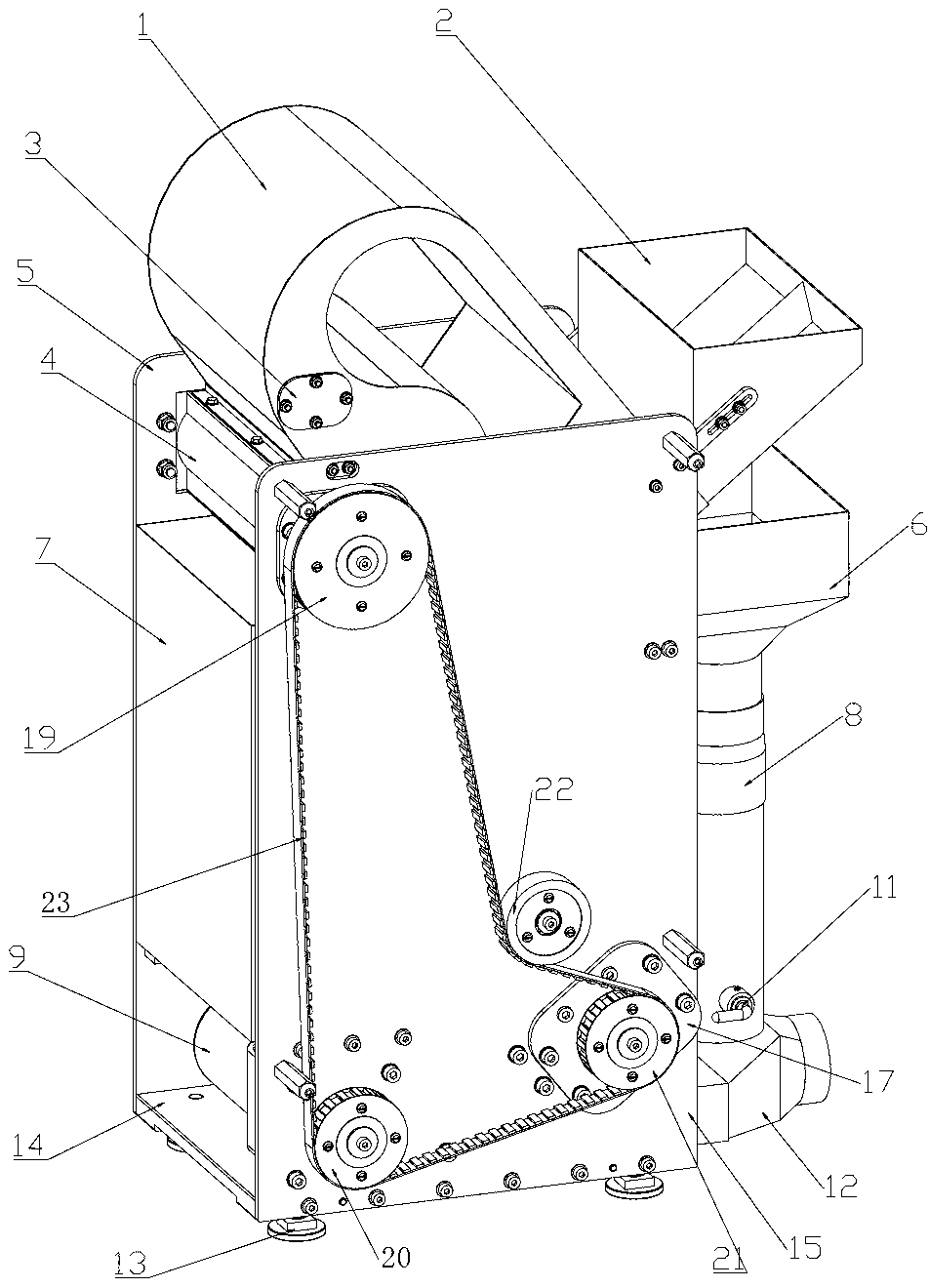

ActiveCN103126067AAdjustable sizeEasy to separateGas current separationCigarette manufactureCigarette MakersDrivetrain

The invention discloses a device for the offline and online screening of cut tobacco from removed stem slivers of a cigarette maker. The device a left side wallboard and a right side wallboard, the left and right side wallboards are fixed on a baseboard respectively, an airflow channel fixedly arranged on the baseboard is arranged among the left and right side wallboards and the baseboard, the airflow channel has a segment of a continuous Z-shaped separation channel, the side surface of the upper half portion of the continuous Z-shaped separation channel is provided with a funnel communicated with the continuous Z-shaped separation channel, and the side surface of the lower half portion of the continuous Z-shaped separation channel is provided with a gas inlet communicated with the continuous Z-shaped separation channel; the airflow channel is provided with a cut tobacco rotation air-valve and a stem sliver rotation air-valve, and the tail end of the airflow channel is connected with a tapered connecting pipeline; the lower portion of the cut tobacco rotation air-valve is correspondingly provided with a cut tobacco collection tank movably connected to the left and right side wallboards, the lower portion of the cut tobacco collection tank is provided with a power transmission system fixed on one of the left and right side wallboards, and the cut tobacco rotation air-valve and the stem sliver rotation air-valve are respectively connected with the power transmission system; and the cut tobacco rotation air-valve, the stem sliver rotation air-valve and the funnel are fixed on the left and right side wallboards respectively.

Owner:CHINA TOBACCO SHANDONG IND

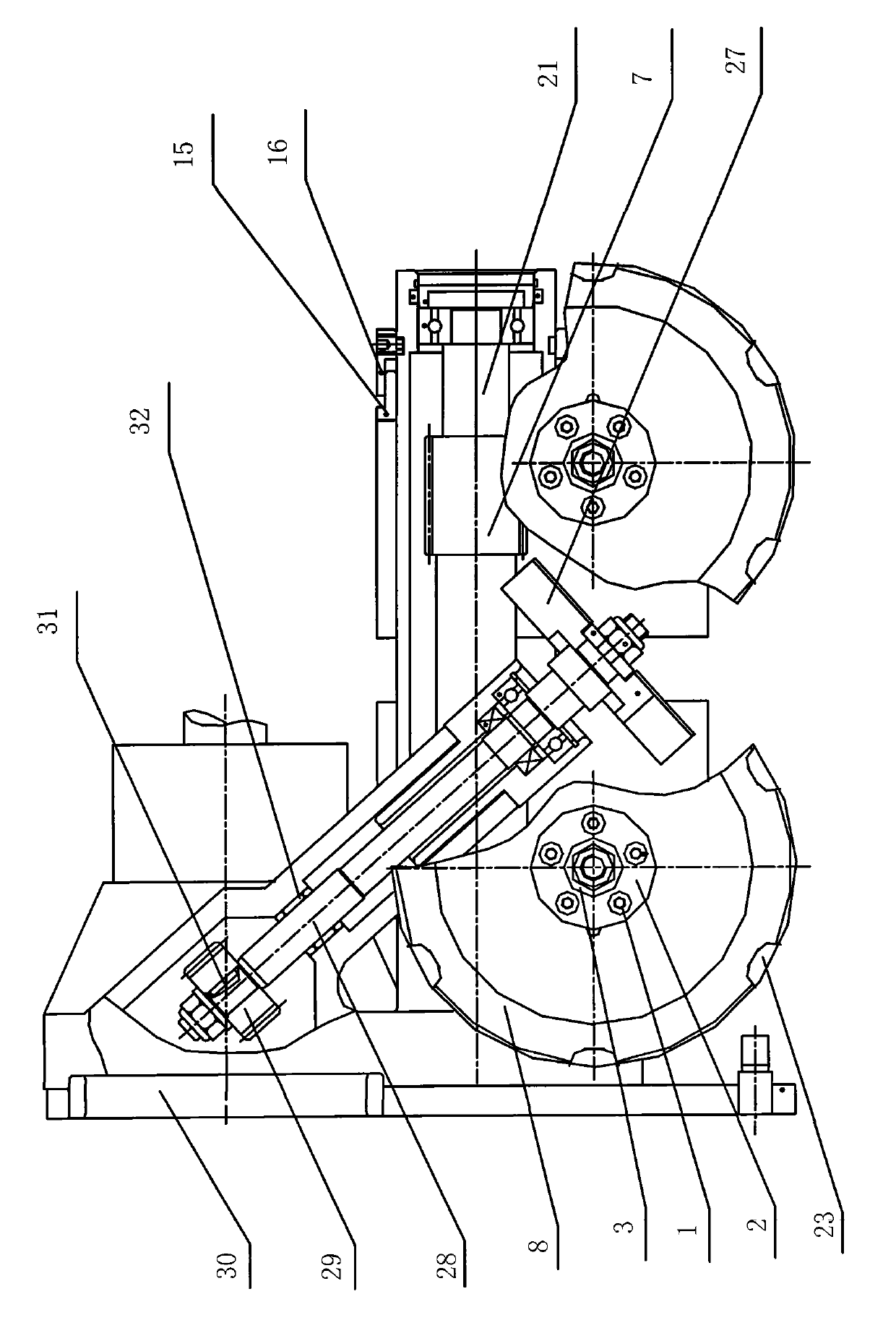

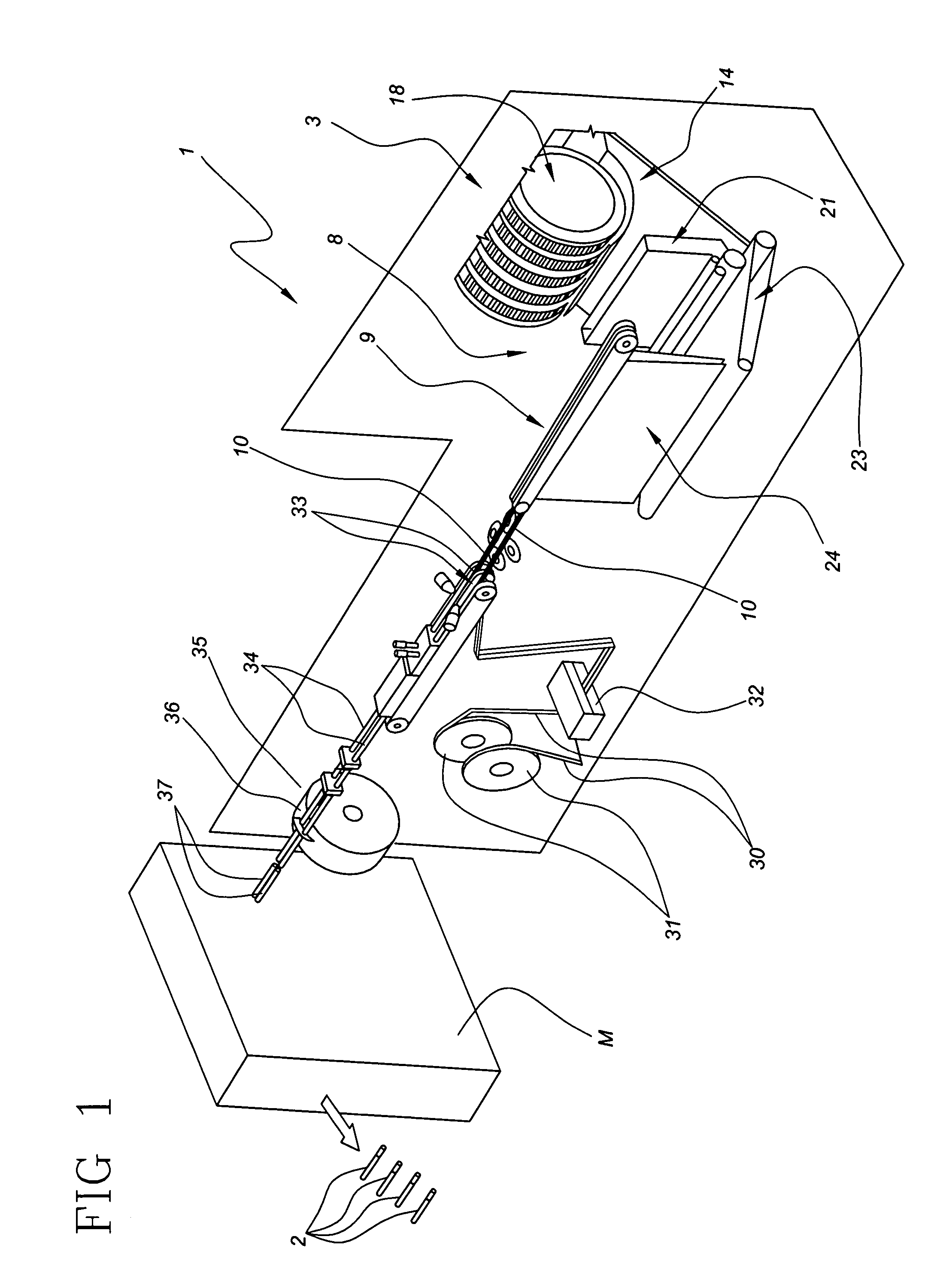

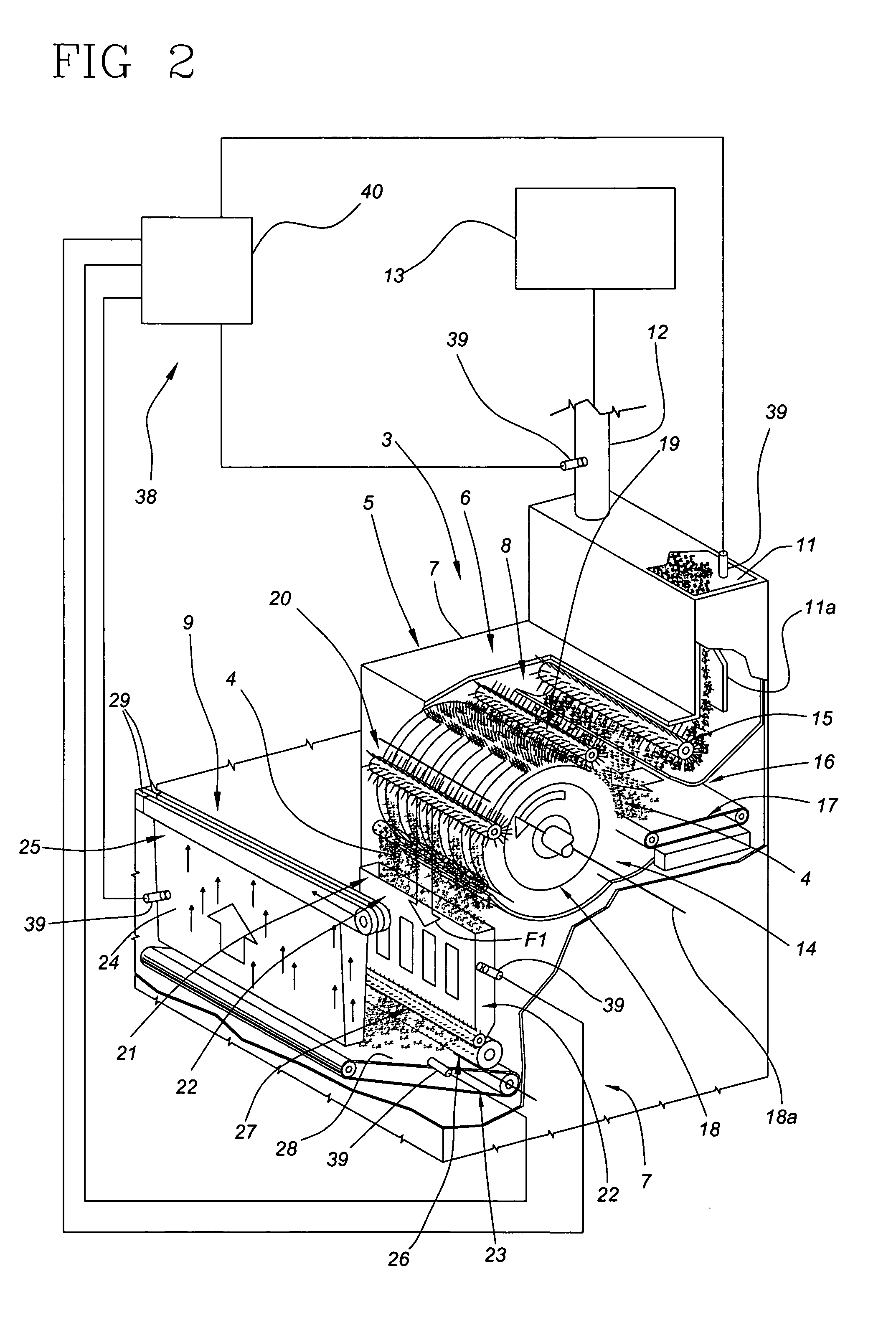

Automatic cigarette maker

InactiveUS20110023894A1Continuous fillingControl tightnessCigar manufactureCigarette manufactureCigarette MakersEngineering

An automatic cigarette maker comprises a case that is provided with a container therein. The container has an opening at the top thereof. The tobacco leaves in the container are pushed out of a tobacco supply duct by a feeding module. A rotary disc is connected with one end of a linkage arrangement and is provided with a plurality of tubes that are arranged in a form of circular array. Each tube is provided with a cigarette paper therein. Thereby, when the linkage arrangement moves the rotary disc backward relative to the container, a tube covers the tobacco supply duct for filling tobacco leaves. When the rotary disc is moved forward, a cigarette paper is fully filled with tobacco leaves. When being moved relative to the container forward and backward once, the rotary disc is rotated at a constant angle. Consequently, the tubes can cover the tobacco supply duct one after another and tobacco leaves can be filled into each cigarette paper in sequence.

Owner:LAING BAN INT

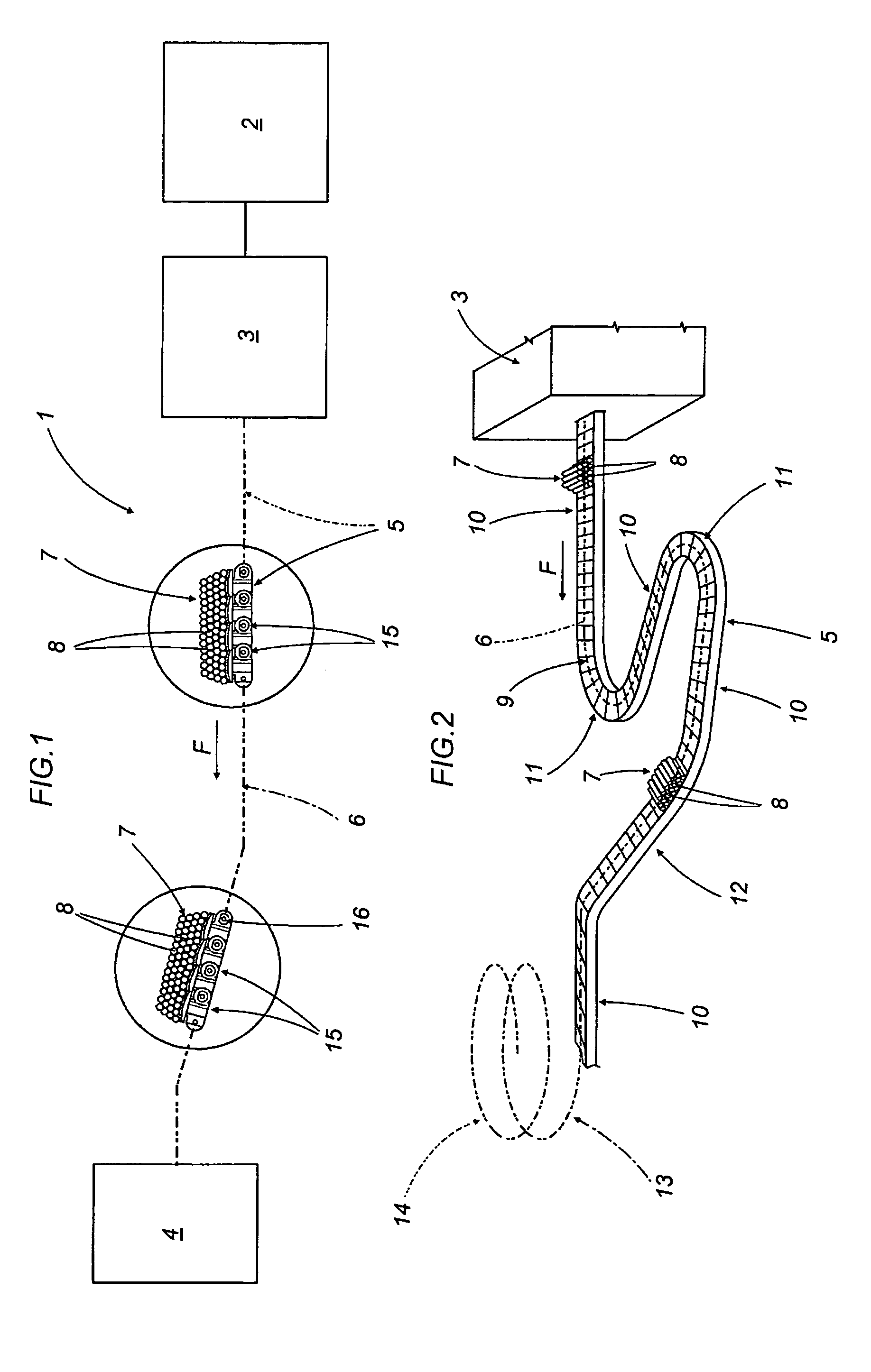

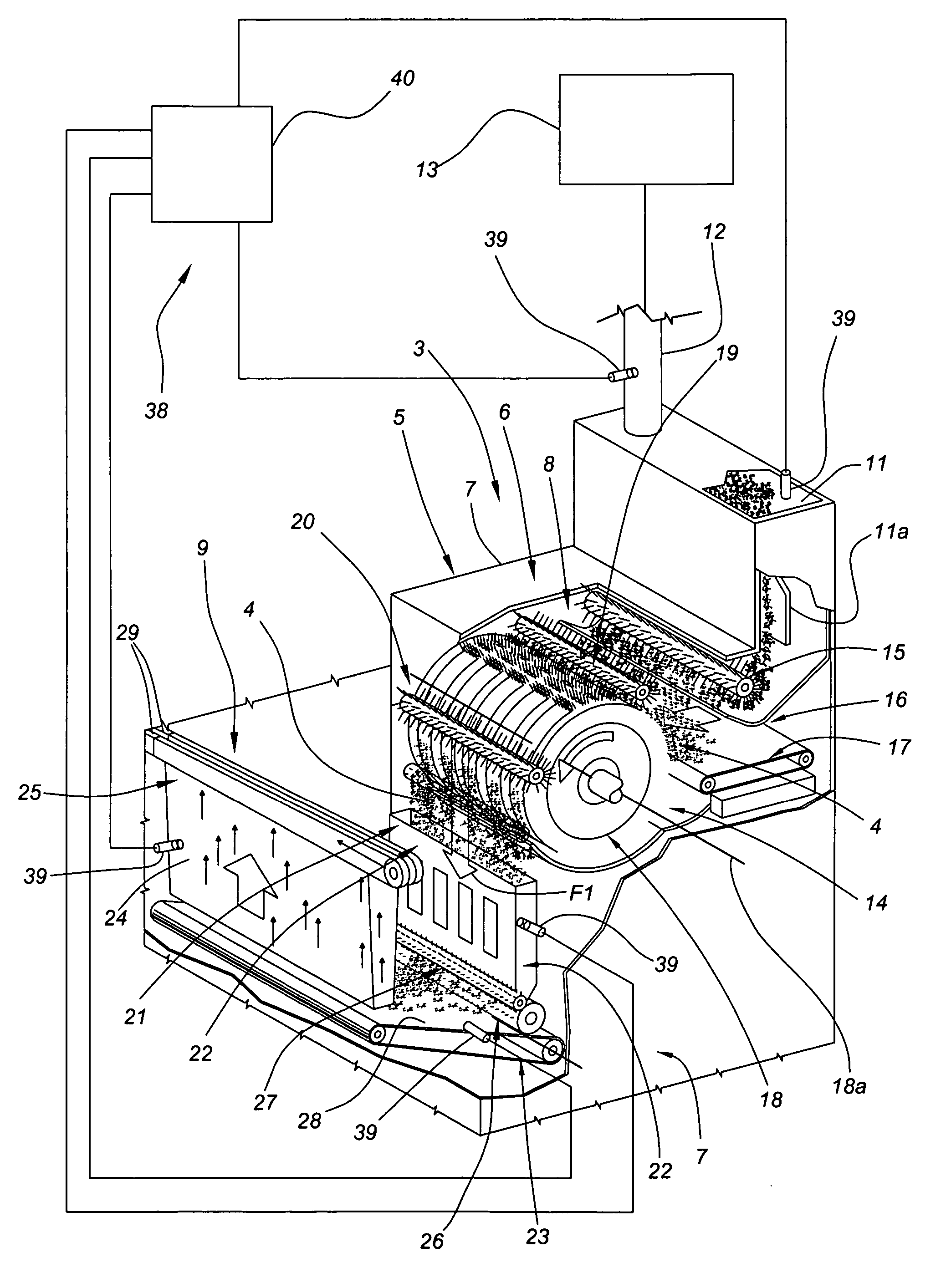

Transfer device in manufacturing systems for tobacco products

In a manufacturing system for tobacco products, a cigarette maker and a cigarette packer are linked by a transfer device consisting in a flat top chain conveyor that comprises a plurality of modular molded plastic elements connected one to the next by way of hinge elements and fashioned with respective tops combining to create a transport surface on which a layer of cigarettes advances en masse from one machine to the other; the flat tops of the single modular elements present a soft outer layer having a high coefficient of friction, which is co-molded with the relative modular element.

Owner:GD SPA

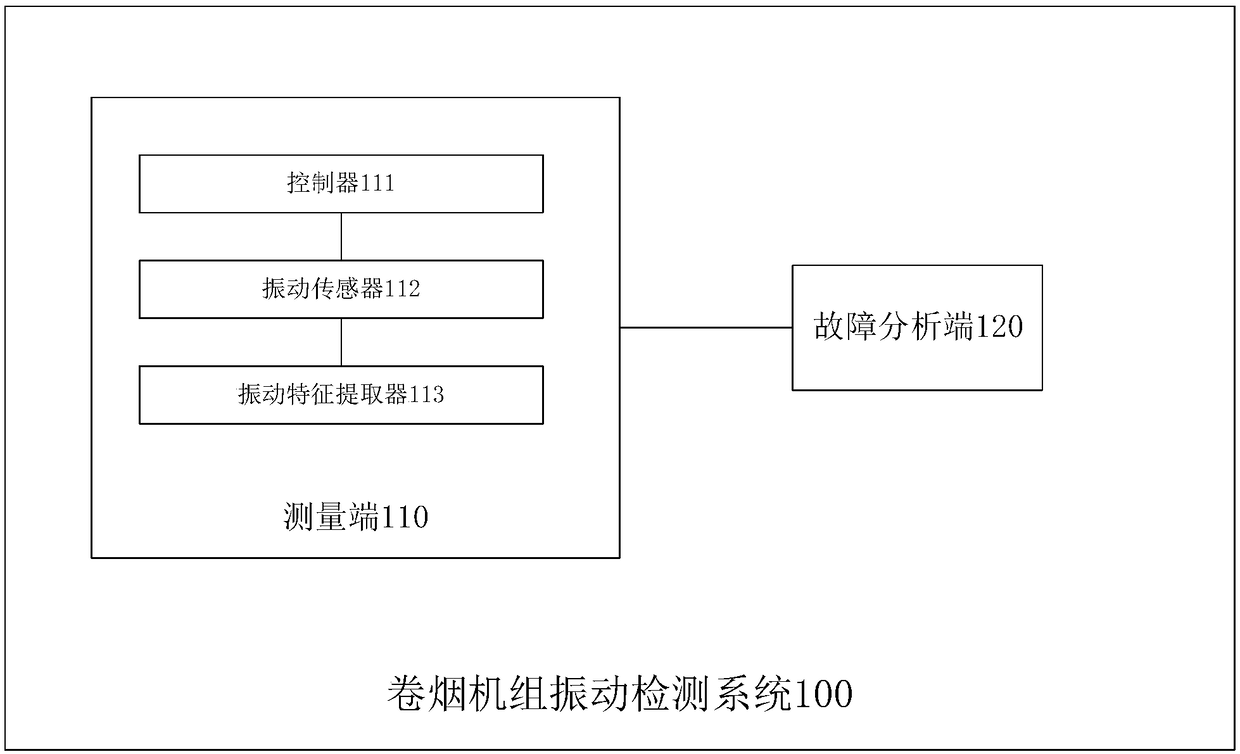

System and method for monitoring vibration of cigarette maker group

InactiveCN108344502ASubsonic/sonic/ultrasonic wave measurementStructural/machines measurementCigarette MakersInformation transmission

The invention provides a system for monitoring the vibration of a cigarette maker group, and the system comprises a measurement end and a fault analysis end. The measurement end comprises a controller, a vibration sensor disposed on the cigarette maker group, and a vibration feature extractor which is connected with the vibration sensor. The vibration sensor is used for collecting a vibration signal of the cigarette maker group at a preset position under the control of the controller in a preset mode. The vibration feature extractor is used for extracting a vibration characteristic quantity ofthe vibration signal under the control of the controller in the preset mode. The fault analysis end is used for obtaining a corresponding cigarette maker state through analysis according to the vibration characteristic quantity. Compared with the prior art that an original vibration signal needs to be transmitted to a fault analysis end, the system can reduce the information transmission quantityof a communication line. The invention provides a method for monitoring the vibration of the cigarette maker group, and the method is used for the above system. The method also has the above beneficial effects which are not described in details.

Owner:CHANGDE TOBACCO MACHINERY

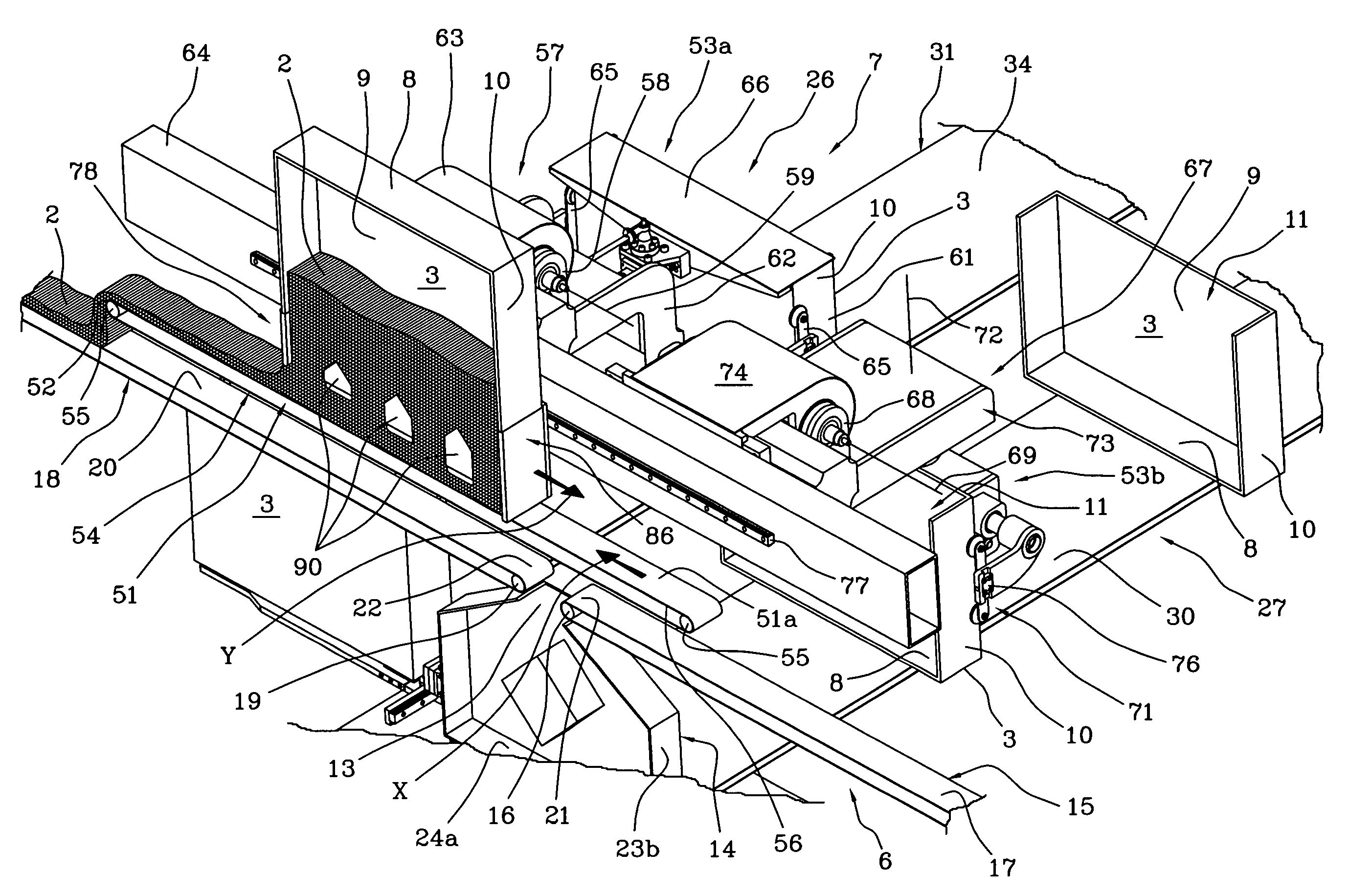

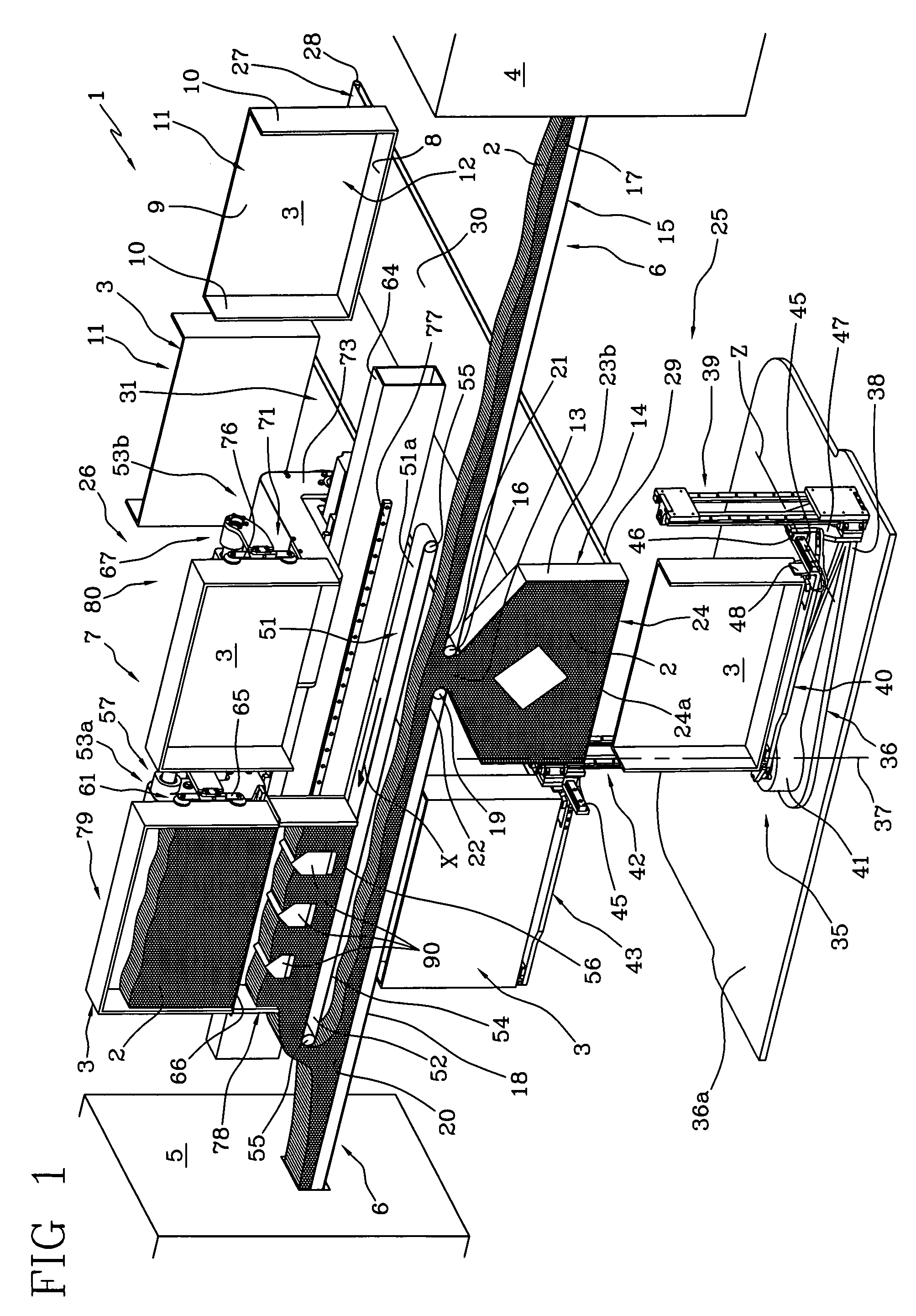

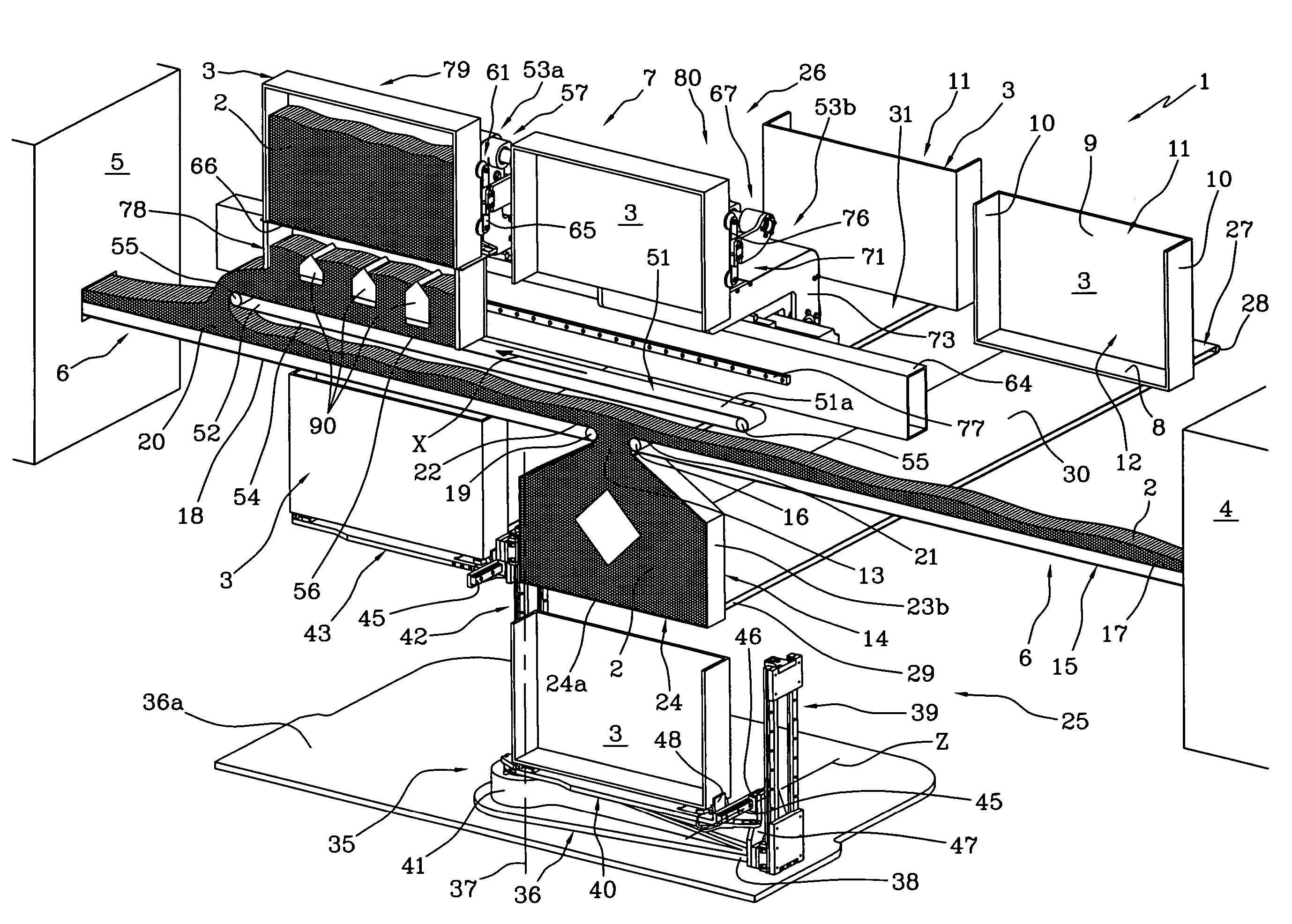

Method and equipment for batch handling and transfer of tobacco products

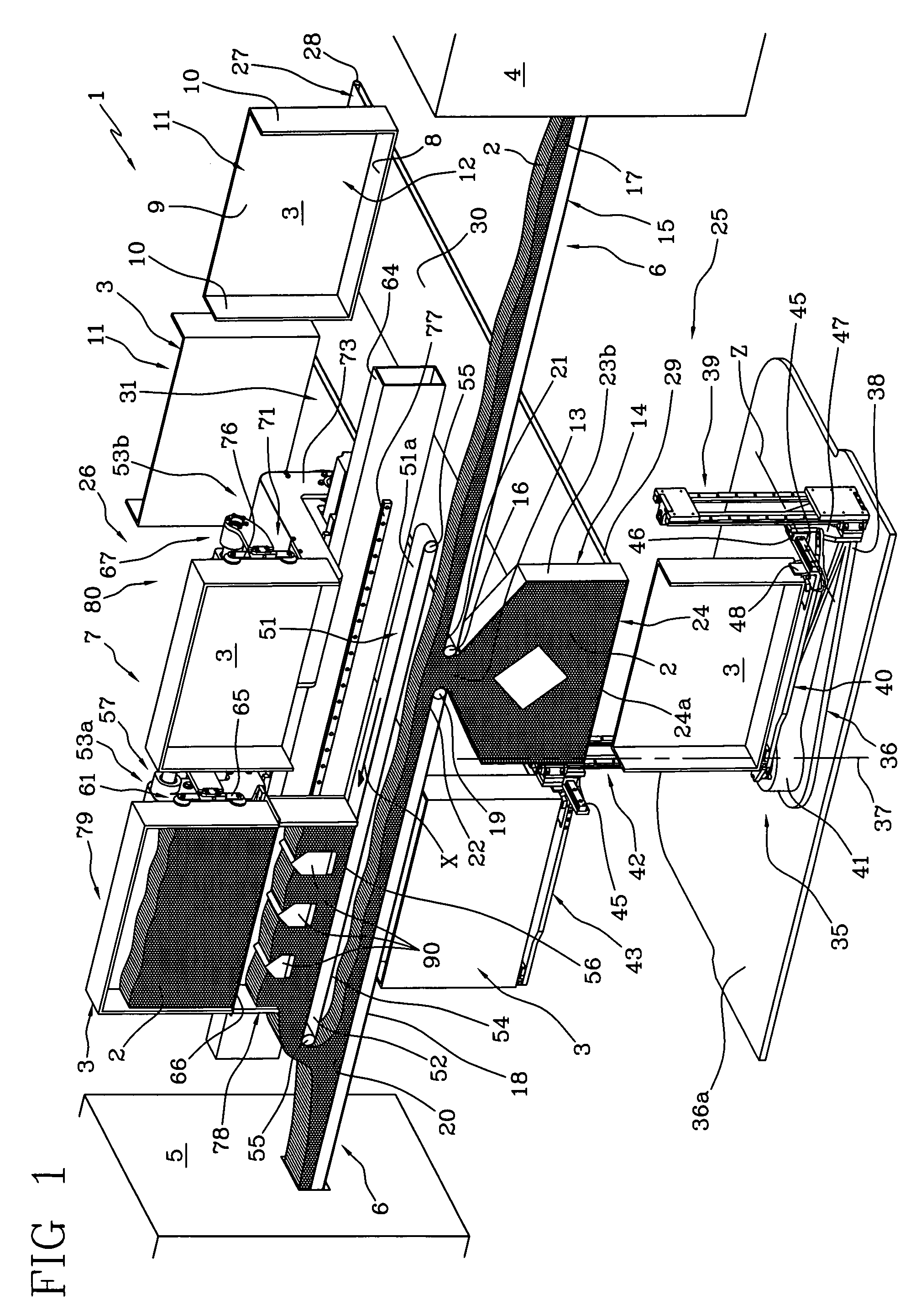

InactiveUS7621715B2Increase flow rateCigarette manufactureArticle unpackingCigarette MakersTobacco product

In a manufacturing system utilizing a cigarette maker linked to a packer, cigarettes temporarily surplus to requirements are stored in containers, each provided with an opening by way of which it can be filled and emptied. A full container is picked up by a first pivoting arm from a magazine and overturned above a bearing surface advancing along a feed direction parallel to this same surface, so as to direct the opening downwards and allow the cigarettes to drop onto the surface. During the step of unloading the cigarettes, the container rests on a hopper and is traversed from a first station toward a second station along a direction parallel and opposite to the feed direction of the bearing surface, so that the cigarettes can be released more quickly from the container. After being emptied, the container is picked up from the second station by a second pivoting arm and put into a magazine with other empty containers.

Owner:GD SPA

Nano silica-modified core-shell acetic acrylic emulsion flame-retardation high-speed cigarette nozzle connecting adhesive and preparation method thereof

InactiveCN107629736AReduce the temperatureImprove initial tack performanceMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesIsooctyl acrylatePolymer science

The invention discloses a nano silica-modified core-shell acetic acrylic emulsion flame-retardation high-speed cigarette nozzle connecting adhesive and a preparation method thereof. The method employsa core-shell emulsion polymerisation method, the butyl acrylate monomer and iso-octyl acrylate-modified acetic acrylic emulsion adhesive are synthesized, the emulsion particles have a core-shell structure having a hard core and a soft shell, persistent adhesivity of the adhesive is guaranteed, film forming temperature is obviously reduced, and primary viscosity is increased; iso-octyl acrylate induced in a shell layer substitutes partial butyl acrylate, the primary viscosity is further increased, and the emulsion viscosity is reduced; a fire retardant and nano silica are introduced into the polymerization process, compatibility with a polymer is increased, dispersion is uniform, so that the acetic acrylic emulsion has better water proofness, stain resistance, and solvent resistance, the prepared core-shell acetic acrylic emulsion is used as the nozzle connecting adhesive, through testing by a M5 cigarette maker, sealing degree of cigarette loading is high, bonding effect is good, andthe flame-retardation self-extinguishing character is obvious.

Owner:CHUZHOU GUANGWEI CHEM

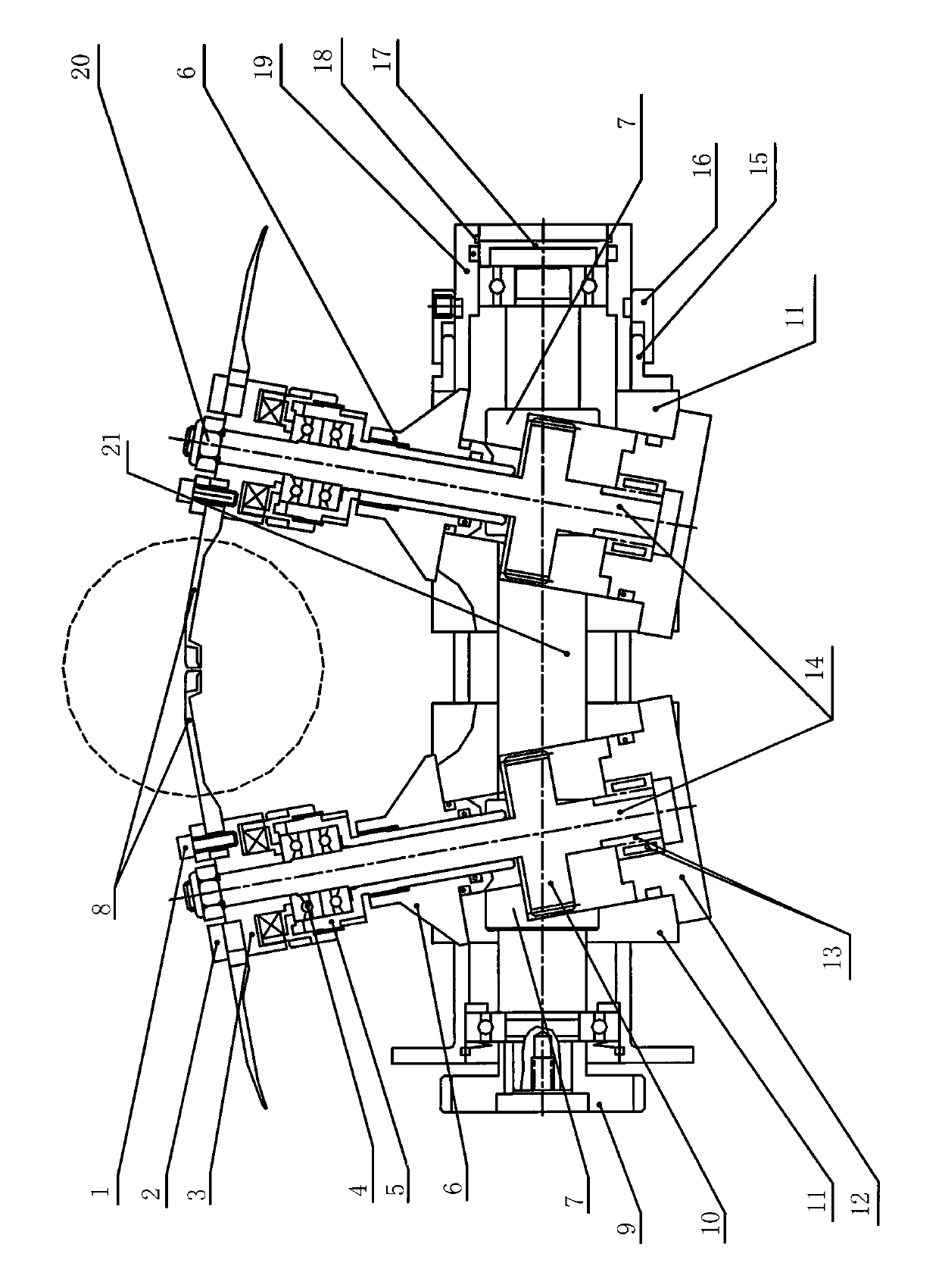

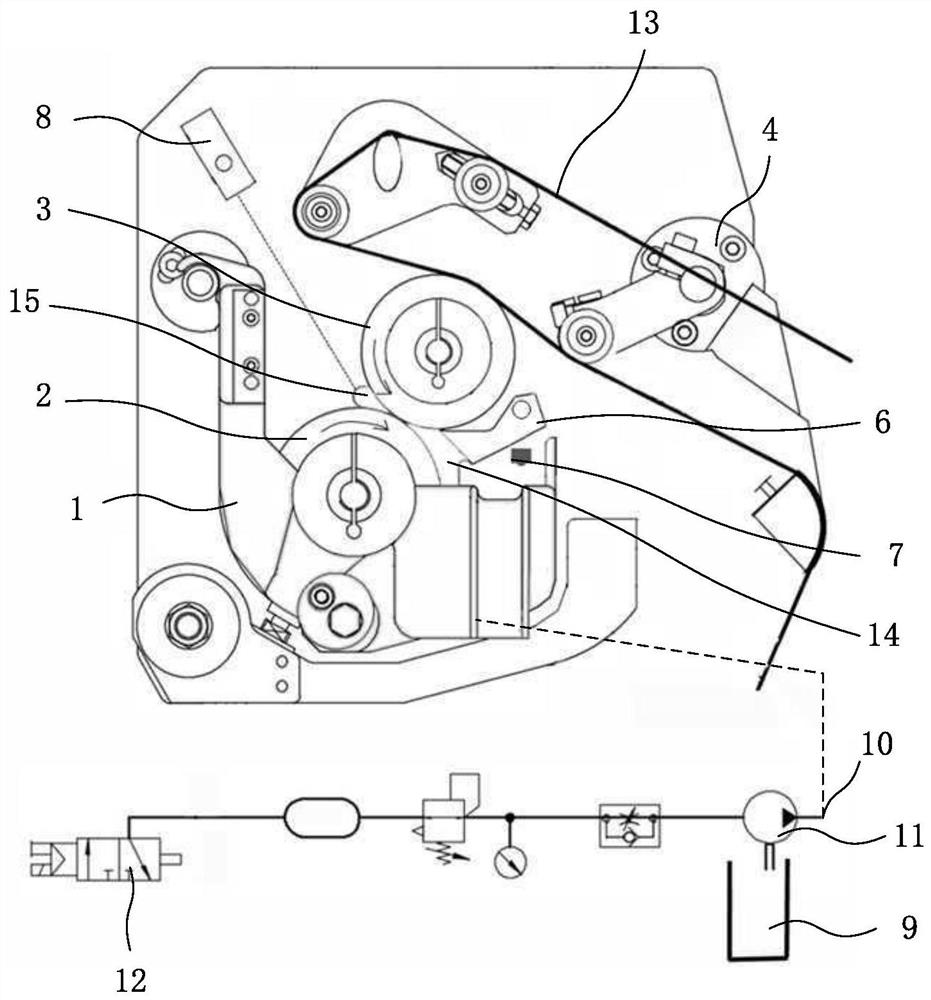

Material feeding and strip forming machine of cigarette maker and operation method thereof

ActiveCN104055220AReduce breakageDelay moisture lossCigarette manufactureCigarette MakersEngineering

The invention discloses a material feeding and strip forming machine of a cigarette maker. The material feeding and strip forming machine comprises a high-angle elevator; the outlet of the high-angle elevator is located above the top inlet of a metering hopper, and the bottom outlet of the metering hopper is provided with a needle roller; one side of the needle roller is provided with a tobacco shred flipping winch; the tobacco shred flipping winch is arranged at the top inlet of a tobacco shred falling channel; the bottom outlet of the tobacco shred falling channel is connected with the inlet of a transverse acceleration conveying channel; a plurality of nozzles are distributed in the transverse acceleration conveying channel; the outlet of the transverse acceleration conveying channel is connected with a primary sorting area; the primary sorting area is connected with the bottom inlet of a tobacco shred lifting channel; the primary sorting area is connected with the top inlet of a tobacco stem chamber, and one side of the tobacco stem chamber is provided with a secondary sorting chamber; and a vibration groove is arranged below the bottom inlet of the secondary sorting chamber. The material feeding and strip forming machine provided by the invention can reduce breakage and moisture loss of tobacco shreds and improve uniformity and the loose degree of tobacco shred flow. The invention further discloses an operation method for the material feeding and strip forming machine of the cigarette maker.

Owner:CHINA TOBACCO MACHINERY TECH CENT

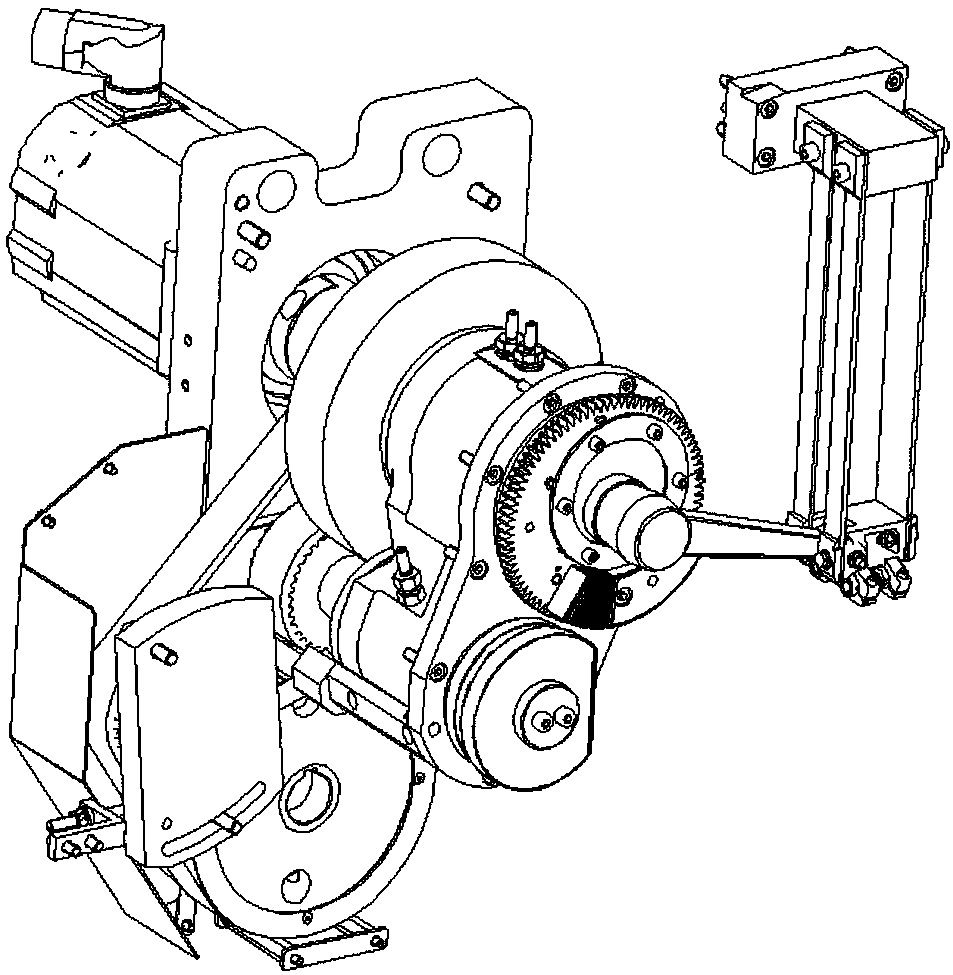

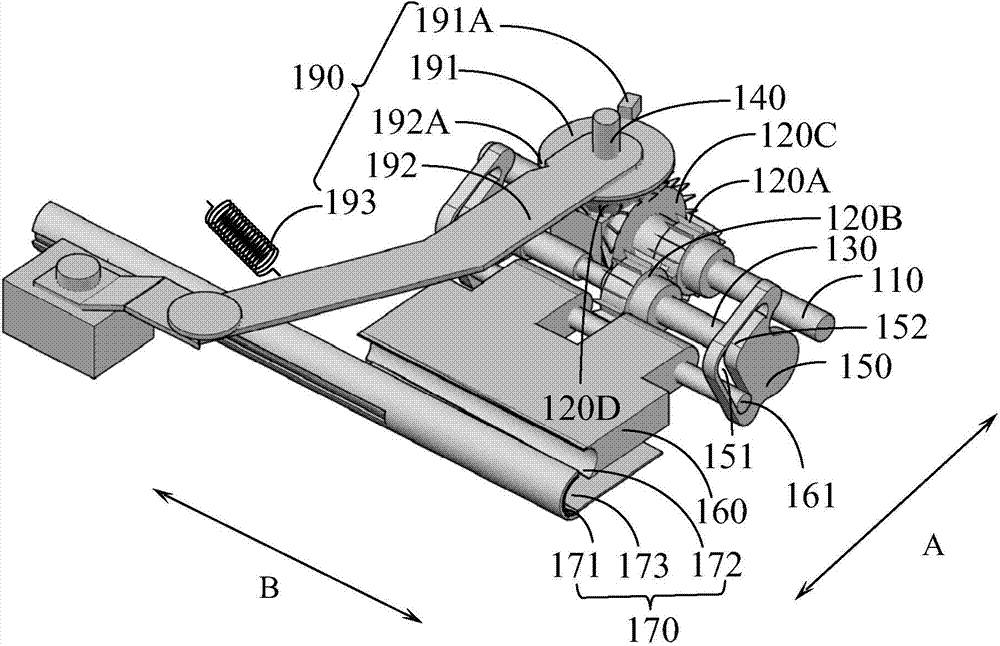

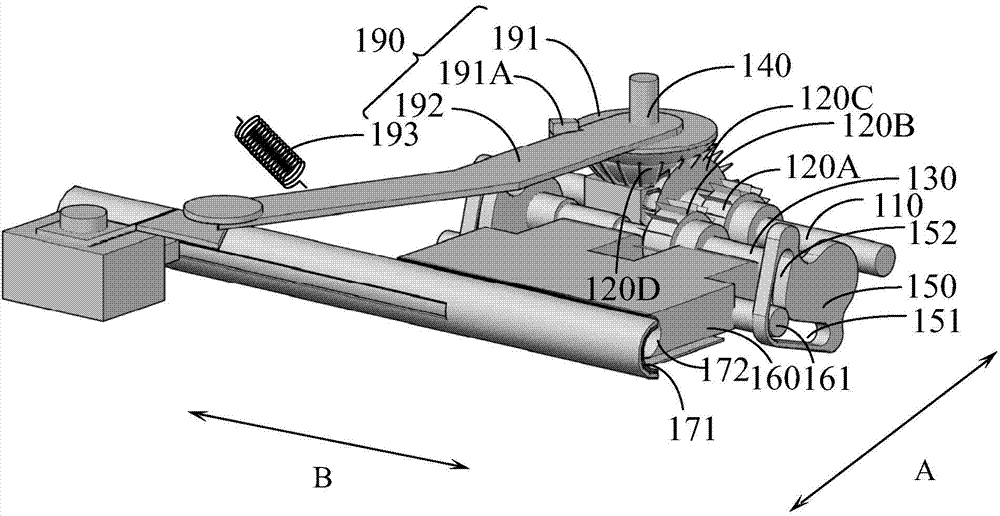

Cigarette maker

The invention provides a cigarette maker. The cigarette maker comprises a driving shaft, a first gear which is concentrically and fixedly arranged on the driving shaft, a first driven shaft which is arranged parallel to the driving shaft, a second gear which is concentrically and fixedly arranged on the first driven shaft and is engaged with the first gear, a first transmission piece which is fixedly arranged on the first driven shaft and rotates together with the first driven shaft, a compression piece and a compression cavity, wherein the first side of the compression piece is movably connected to the first transmission piece which is configured to convert rotation of the first driven shaft into reciprocating motion of the compression piece along a first direction, and the compression cavity comprises a first side wall and a second side wall which are oppositely arranged; a space for accommodating loose tobaccos is formed between the first side wall and the second side wall, the first side wall is fixedly arranged, and the second side wall is arranged on a second side, opposite to the first side, of the compression piece and is driven by the compression piece to reciprocate between an initial position and a compression position. The cigarette maker provided by the invention is simple to operate, high in stability and long in service life.

Owner:REPUBLIC TOBACCO

Tipping paper pre-rolling device of cigarette maker

ActiveCN104509968AWill not affect operationDoes not increase failure symptoms of fractureCigarette manufactureCigarette MakersPulp and paper industry

The invention provides a tipping paper pre-rolling device of a cigarette maker. The device comprises a first scraper device arranged on the paper delivery route of a cigarette maker, and a second scraper device arranged on the paper delivery route of the cigarette maker. The second scraper device comprises an installation seat and a scraper, which is fixedly arranged on the installation seat. The surface, which is used to fix the scarper, of the installation seat is a horizontal working plane, the cross section of the scraper is in a polygonal shape, all the edges of the scraper are working edges, one of the working edges faces the working plane, and a gap, which can allow the tipping paper to go through, is arranged between the working edge and the horizontal working plane. In the provided device, two scrapers can scrap and pre-roll the tipping paper at the same time, the effects of scraping and rolling are better, the quality of the rolled cigarettes is better, the delivery of the tipping paper is not affected, and the phenomenon that the tipping paper is broken is not increased.

Owner:CHINA TOBACCO GUIZHOU IND

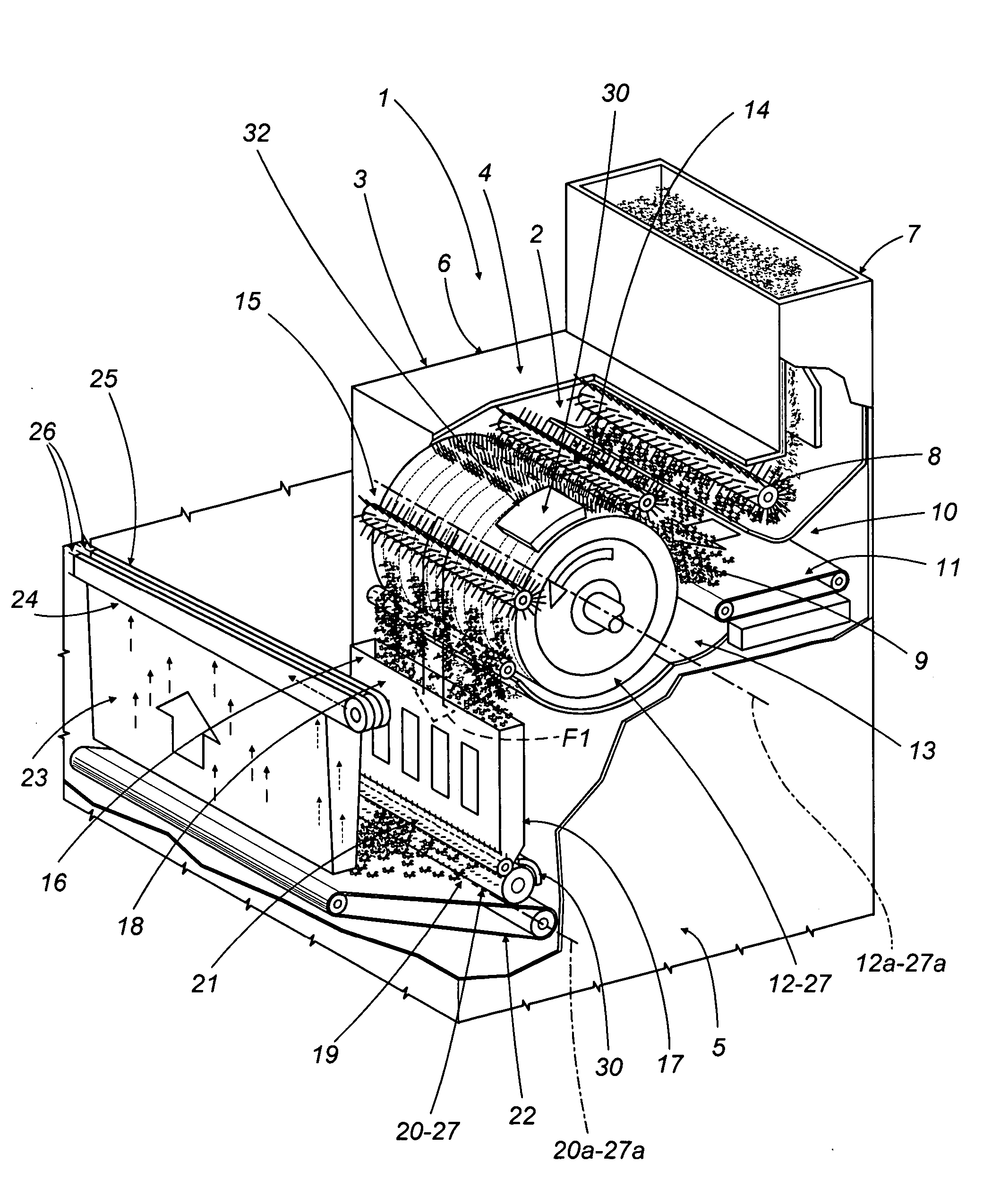

Unit and a method for feeding tobacco in a machine for manufacturing tobacco products

In a cigarette maker, shredded tobacco passes through a feed and transport section toward a unit by which divided particles of the tobacco are gathered into at least one stream providing the filler for cigarettes. By positioning one or more sensors either along the feed and transport section or at a point upstream, relative to the feed direction of the tobacco, it becomes possible to identify the type of tobacco being handled at any given moment, so that when production schedules include a changeover from one brand to another, supervisors can be certain that the right type of tobacco has been selected, and ensure that different types of tobacco will not mingle.

Owner:GD SPA

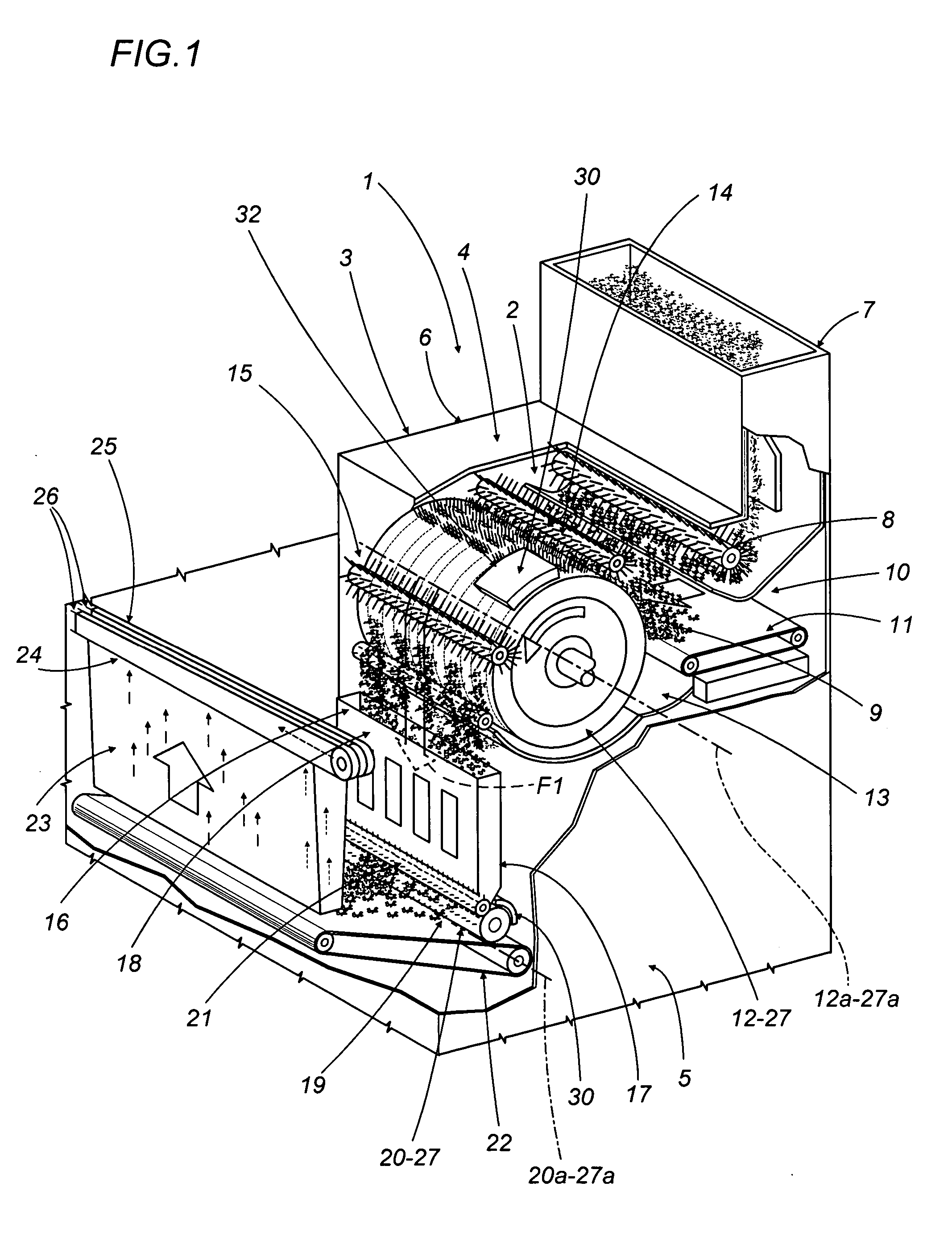

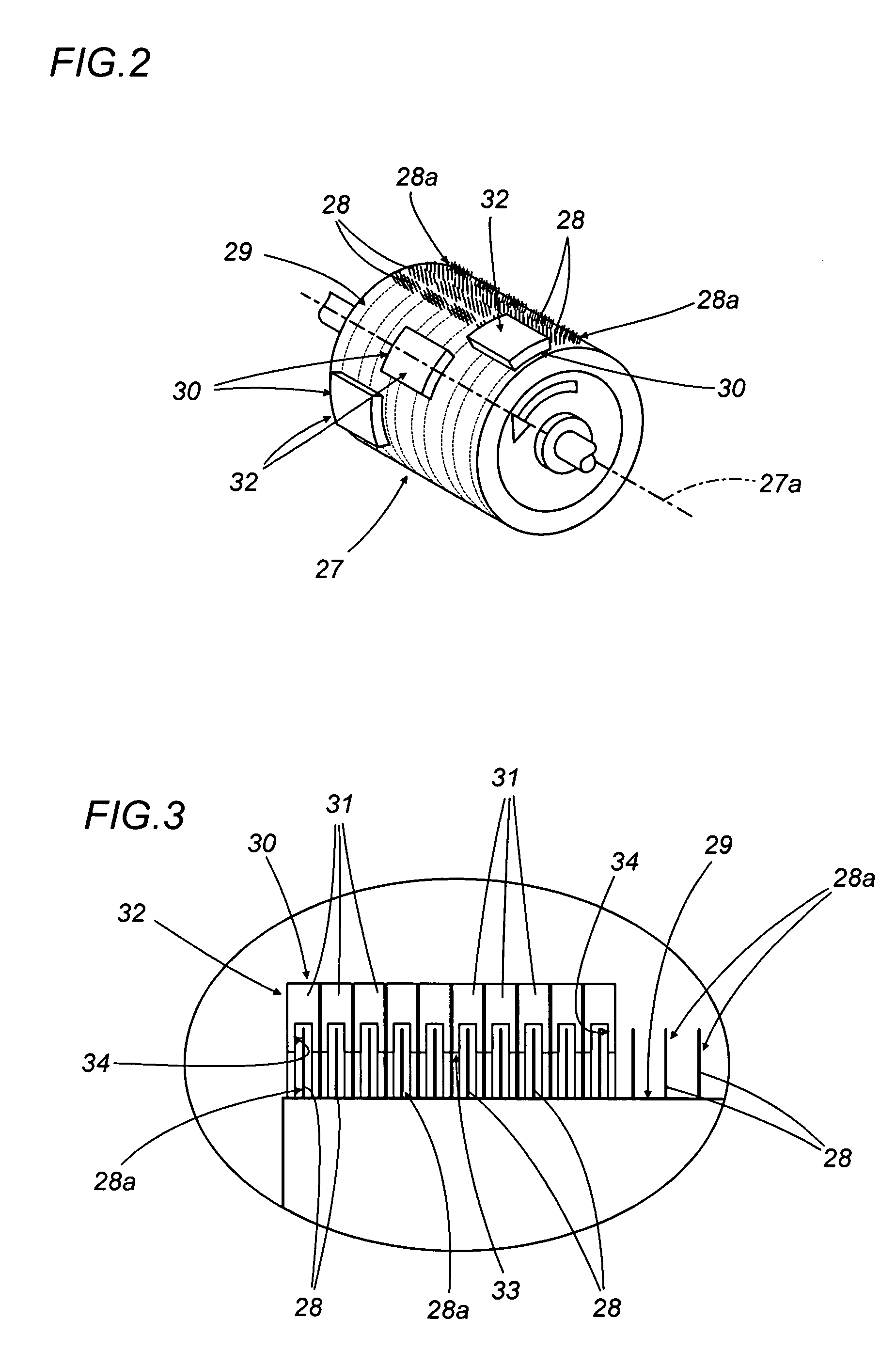

Tobacco feed and transport unit in a machine for manufacturing tobacco products

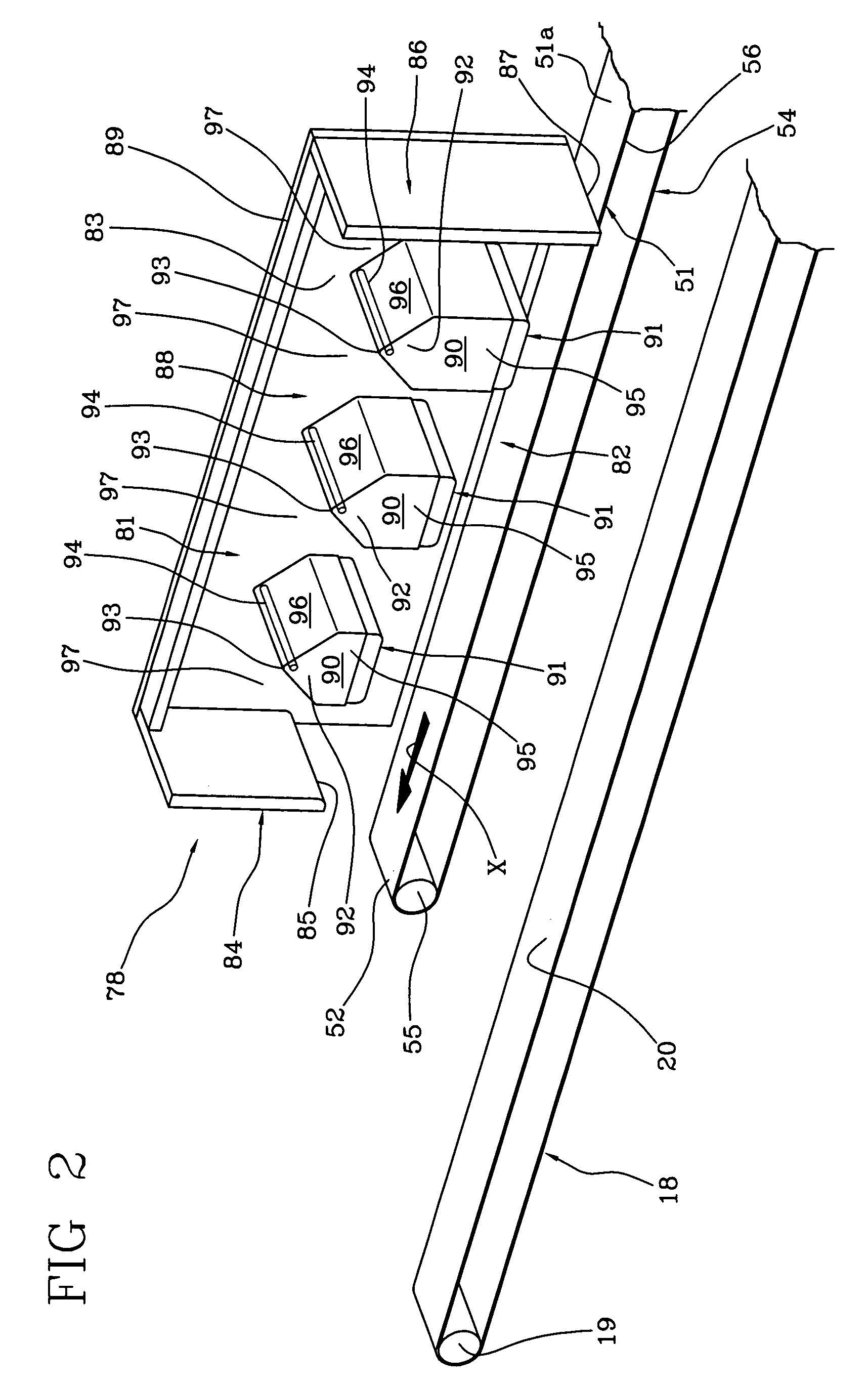

InactiveUS20050109354A1Located swiftly and easilyTobacco treatmentCigarette manufactureCigarette MakersEngineering

Shredded tobacco is fed into and transported through a cigarette maker by a unit that includes at least one transport roller, driven in rotation about a longitudinal axis and equipped with a plurality of radial pins projecting radially from a peripheral surface, by which the flow of tobacco is taken up and directed along a predetermined feed path toward a unit that forms it ultimately into at least one continuous stream; the feed and transport unit is also equipped with at least one sensing device, offered to the peripheral surface of the roller and serving to detect any points where pins may be missing or damaged.

Owner:GD SPA

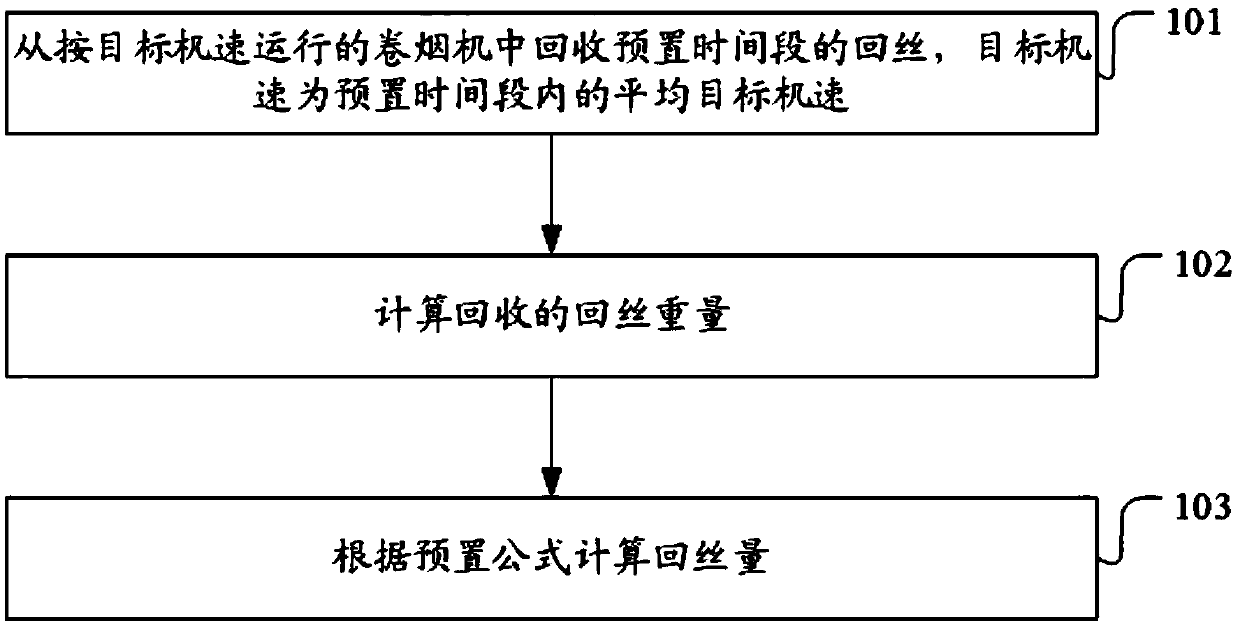

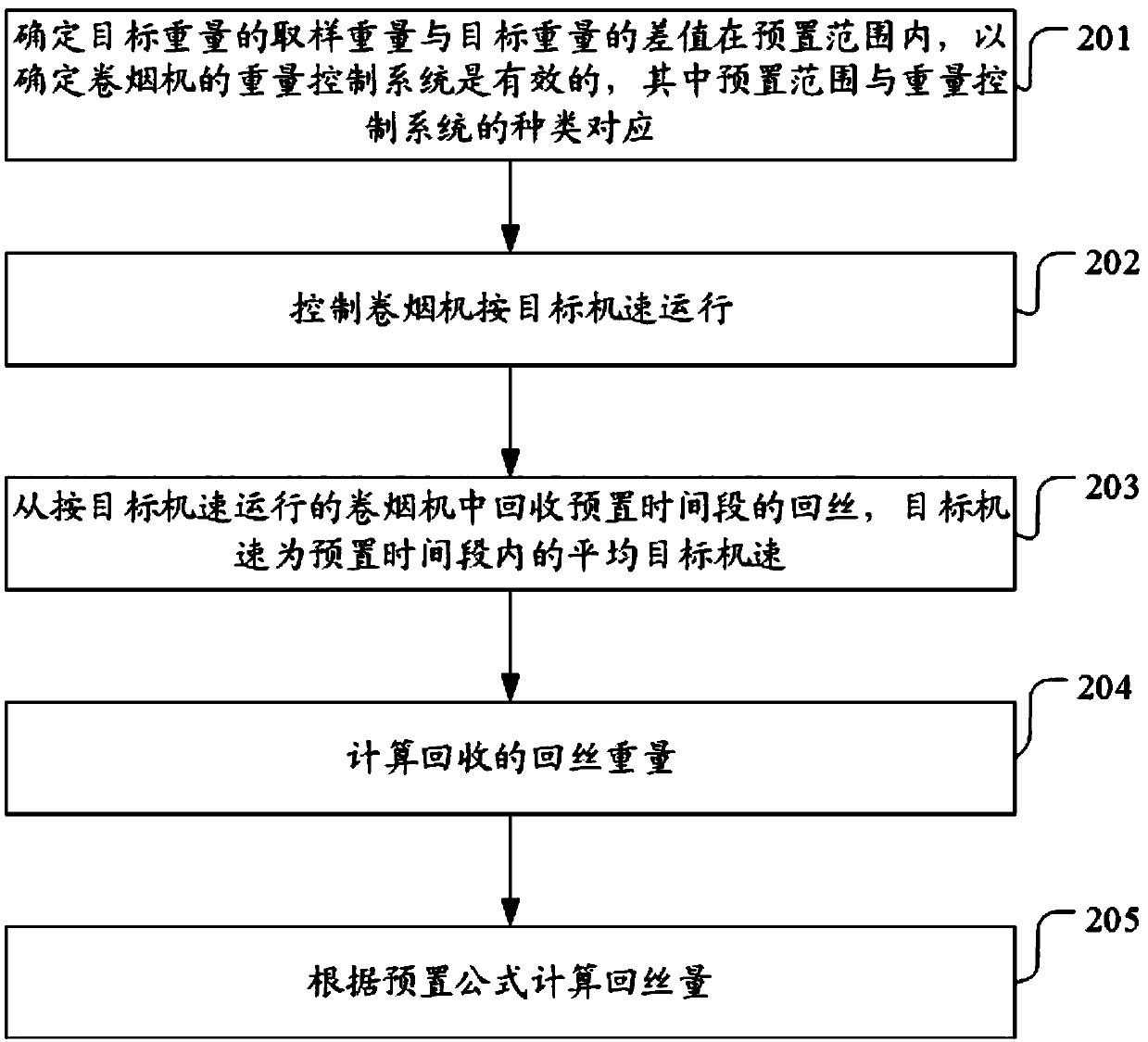

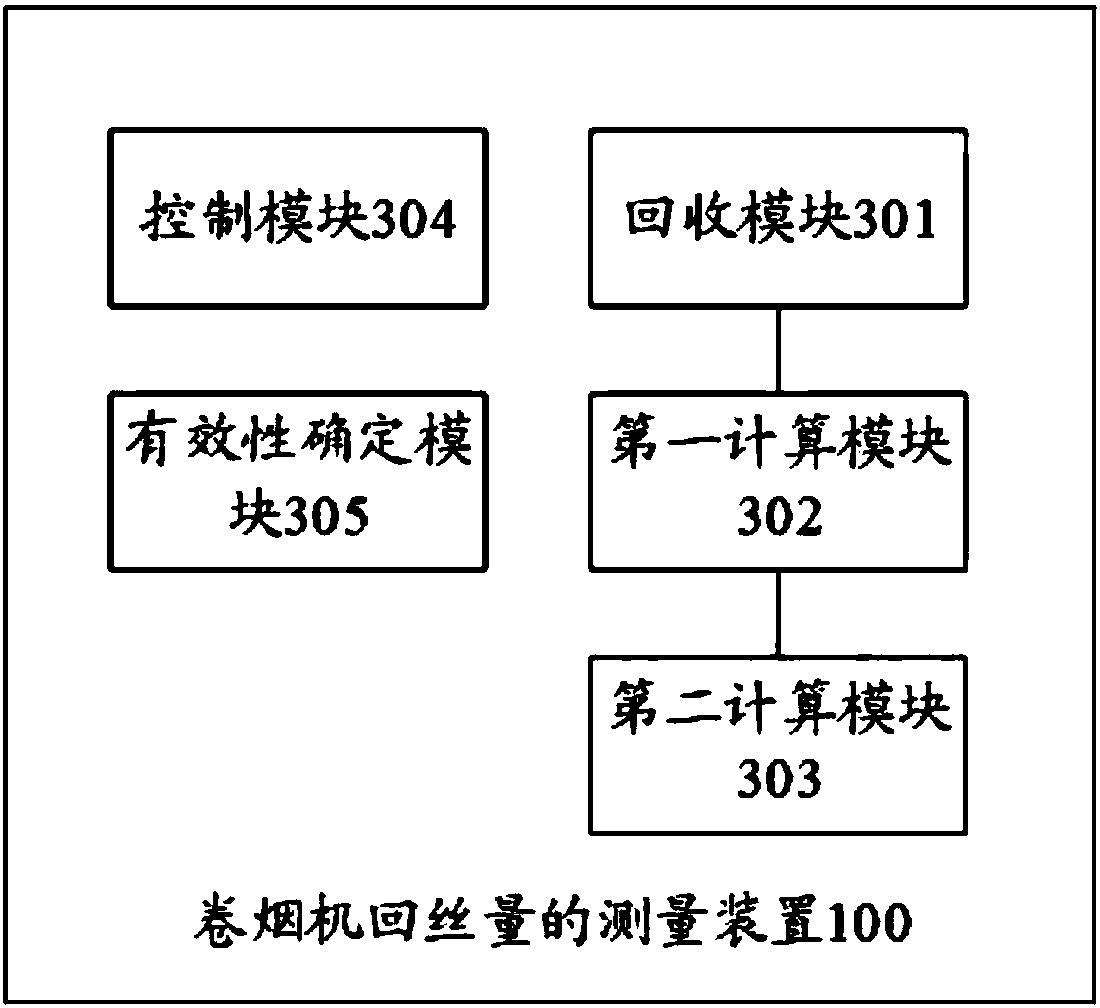

Method and device for measuring tobacco waste quantity of cigarette making machine, and cigarette making machine system

ActiveCN110384250AThe calculation result is accurateDoes not affect productivityCigarette manufactureCigarette MakersEngineering

The invention discloses a method and a device for measuring a tobacco waste quantity of a cigarette making machine, and a cigarette making machine system. The method comprises the following steps: recovering tobacco wastes in a preset time period from the cigarette making machine running at a target machine speed, wherein the target machine speed is an average target machine speed in the preset time period; calculating the weight of the recovered tobacco wastes; and calculating the tobacco waste quantity according to a preset formula. The technical problems that the tobacco waste quantity is calculated inaccurately, the machine must be stopped for measurement and a measurement result in stop is different from a measurement result in running of the cigarette maker in a traditional method are solved.

Owner:CHINA TOBACCO GUIZHOU IND

Cigarette making machine

InactiveCN105266193APlay a fixed roleSimple structureCigarette manufactureCigarette MakersElectric machinery

The invention discloses a cigarette making machine, and belongs to the technical field of an article for daily use, and in particular relates to a cigarette making machine. The cigarette making machine comprises a base, wherein a cigarette making machine main body is arranged on the base; a motor is arranged inside the cigarette making machine main body; a material inlet is arranged on the cigarette making machine main body; a tobacco shred charge pipe is arranged inside the material inlet; a propelling spring is arranged outside the tobacco shred charge pipe; and the propelling spring is arranged in a tobacco sleeve. According to the cigarette making machine disclosed by the invention, tobacco shreds are arranged inside the material inlet and are rolled in the tobacco sleeve by virtue of the propelling spring. The tobacco shreds are rolled in the tobacco sleeve by adjusting the tightness of the tobacco shreds. By virtue of anti-slip threads on the bottom of the cigarette making machine main body, the cigarette making machine can take an effect of fixing.

Owner:HENAN JINGSHENG COMP INFORMATION TECH

Method and equipment for batch handling and transfer of tobacco products

InactiveUS20070000215A1Increase flow rateCigarette manufactureArticle unpackingCigarette MakersEngineering

In a manufacturing system utilizing a cigarette maker linked to a packer, cigarettes temporarily surplus to requirements are stored in containers, each provided with an opening by way of which it can be filled and emptied. A full container is picked up by a first pivoting arm from a magazine and overturned above a bearing surface advancing along a feed direction parallel to this same surface, so as to direct the opening downwards and allow the cigarettes to drop onto the surface. During the step of unloading the cigarettes, the container rests on a hopper and is traversed from a first station toward a second station along a direction parallel and opposite to the feed direction of the bearing surface, so that the cigarettes can be released more quickly from the container. After being emptied, the container is picked up from the second station by a second pivoting arm and put into a magazine with other empty containers.

Owner:GD SPA

Manual cigarette making machine

InactiveCN105901763AProtect normal operationAlternate rotation flexibleCigarette manufactureCigarette MakersPulp and paper industry

The invention relates to a cigarette making machine, in particular to a cigarette making machine capable of making cigarettes in a manual mode. According to the adopted scheme, the manual cigarette making machine is characterized by comprising a base, soft leather and a push rod; the two ends of the soft leather are fixedly arranged on the base, the middle of the soft leather is arranged on the base in an interference shape after the two ends of the soft leather are fixed, and an opening is formed in the fixed position of the end, close to the soft leather, of the base in the width direction; a sliding chute or a sliding hole is formed in the position, on the upper side of a supporting face, of a convex edge, the push rod is located below the soft leather, the interference portion of the soft leather is arranged at the opening and sinks to form a containing space, cigarette paper and cut tobacco can be placed in the containing space, then the push rod is pushed to move towards one end of the supporting face, and the cigarette paper can wrap the cut tobacco to form the cigarettes after the soft leather is turned over. By means of the scheme, the novel manual cigarette making machine is compact in structure and convenient to use.

Owner:陈淑梅

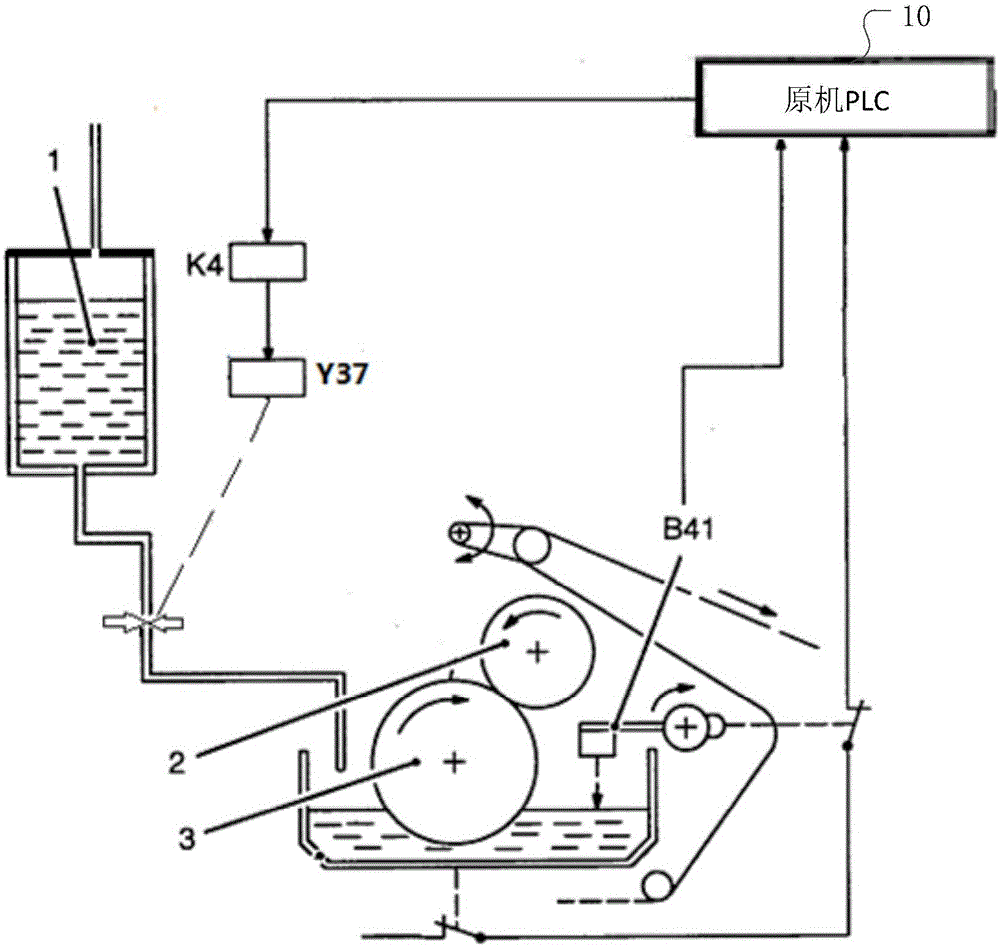

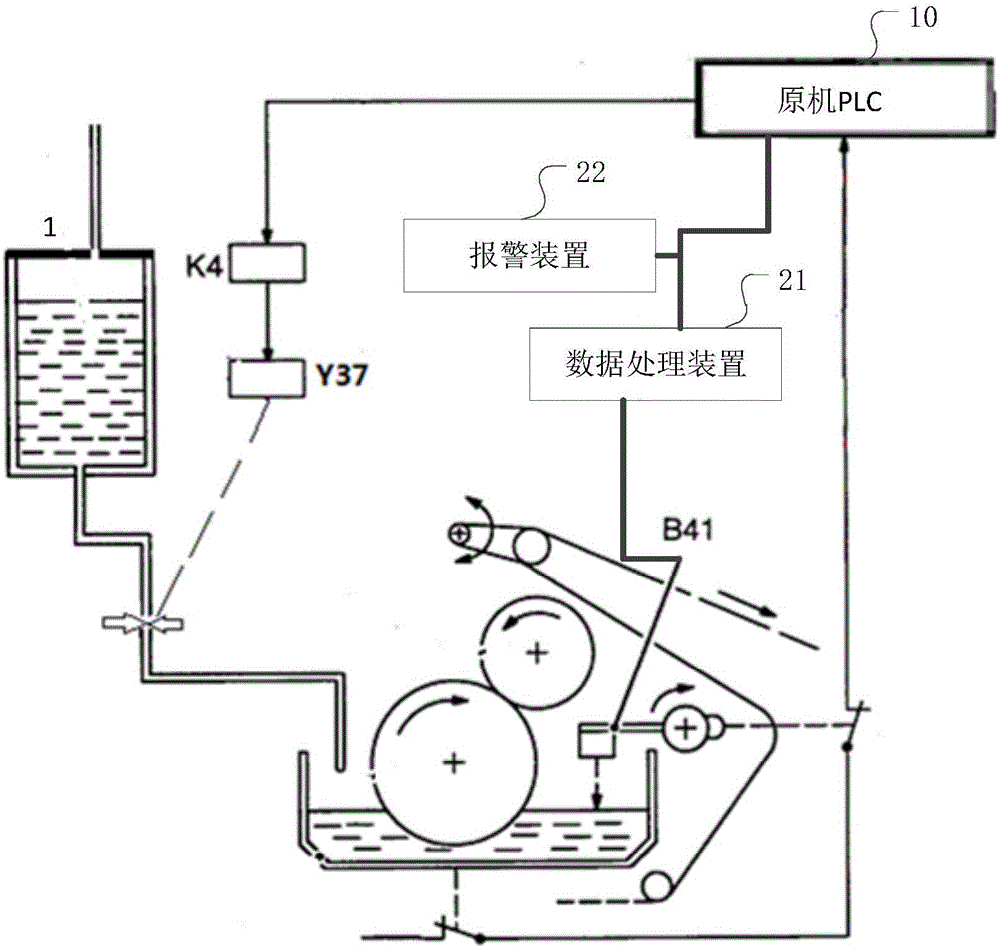

Cigarette maker glue supply control system with monitoring early warning

ActiveCN105068501AImprove reliabilityImprove stabilityProgramme control in sequence/logic controllersTime rangeCigarette Makers

The invention discloses a cigarette maker glue supply control system with monitoring early warning, and is applied to a ZJ17 cigarette maker. The system comprises a photoelectric switch and an original PLC, and further comprises a data processing apparatus for acquiring state signals of the indication lamp of the photoelectric switch in a corresponding glue injection time scope and determining whether the glue supply control system generates a fault according to the state signals, and an alarm apparatus for giving an alarm prompt when the data processing apparatus determines that the glue supply control system generates the fault, wherein the data processing apparatus is in communication connection with the photoelectric switch, the alarm apparatus is connected with the data processing apparatus. According to the system provided by the invention, the state signals of the indication lamp of the photoelectric switch in the corresponding glue injection time scope can be acquired through additional arrangement of the data processing apparatus, whether the glue supply control system generates the fault is determined according to the acquired state signals, and in case of the fault, the alarm apparatus gives the alarm prompt. Therefore, the system can monitor whether the glue supply control system generates the fault and further improves the reliability and the stability of the glue supply control system.

Owner:CHINA TOBACCO SICHUAN IND CO LTD

Tabletop cigarette maker

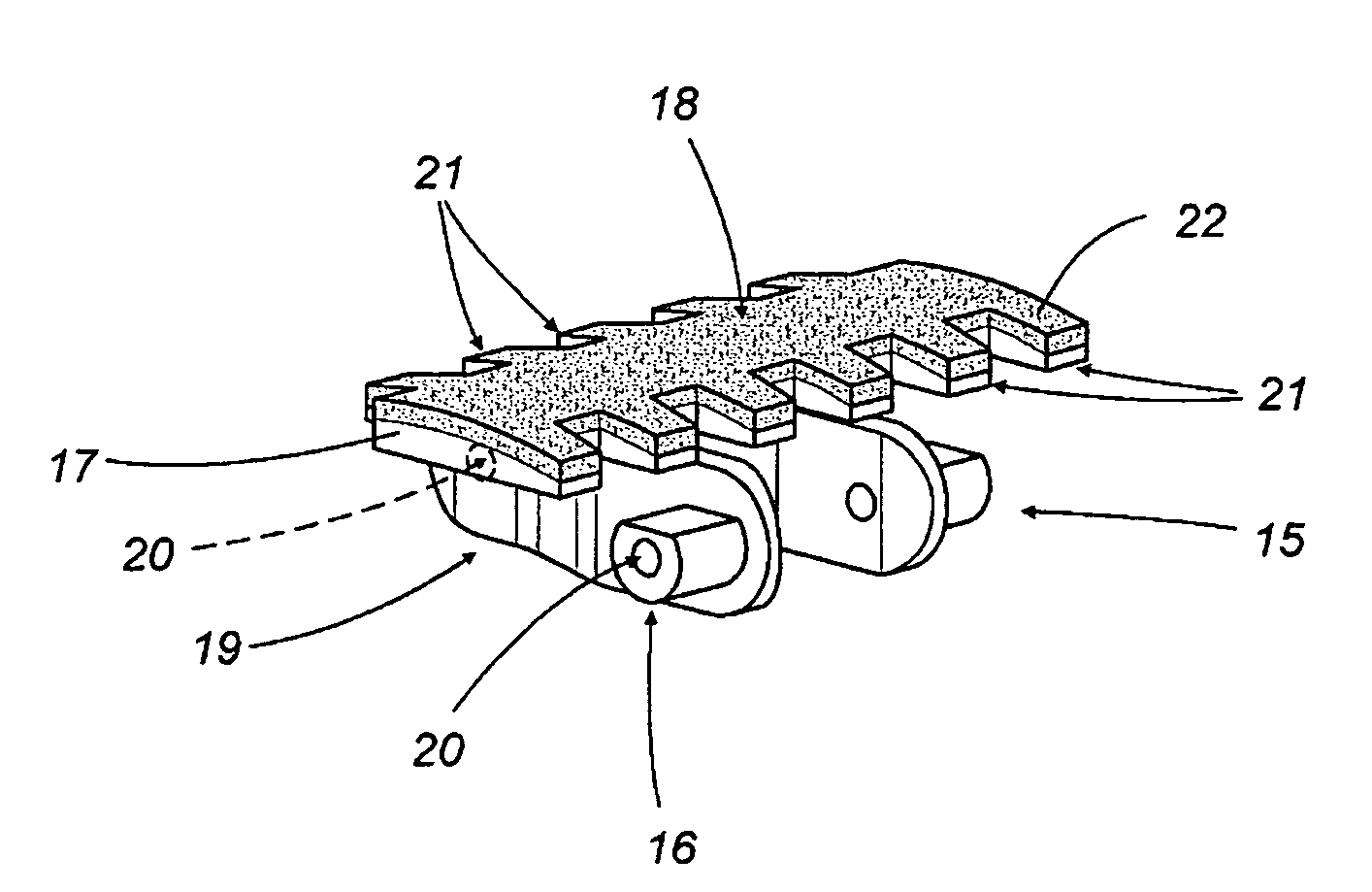

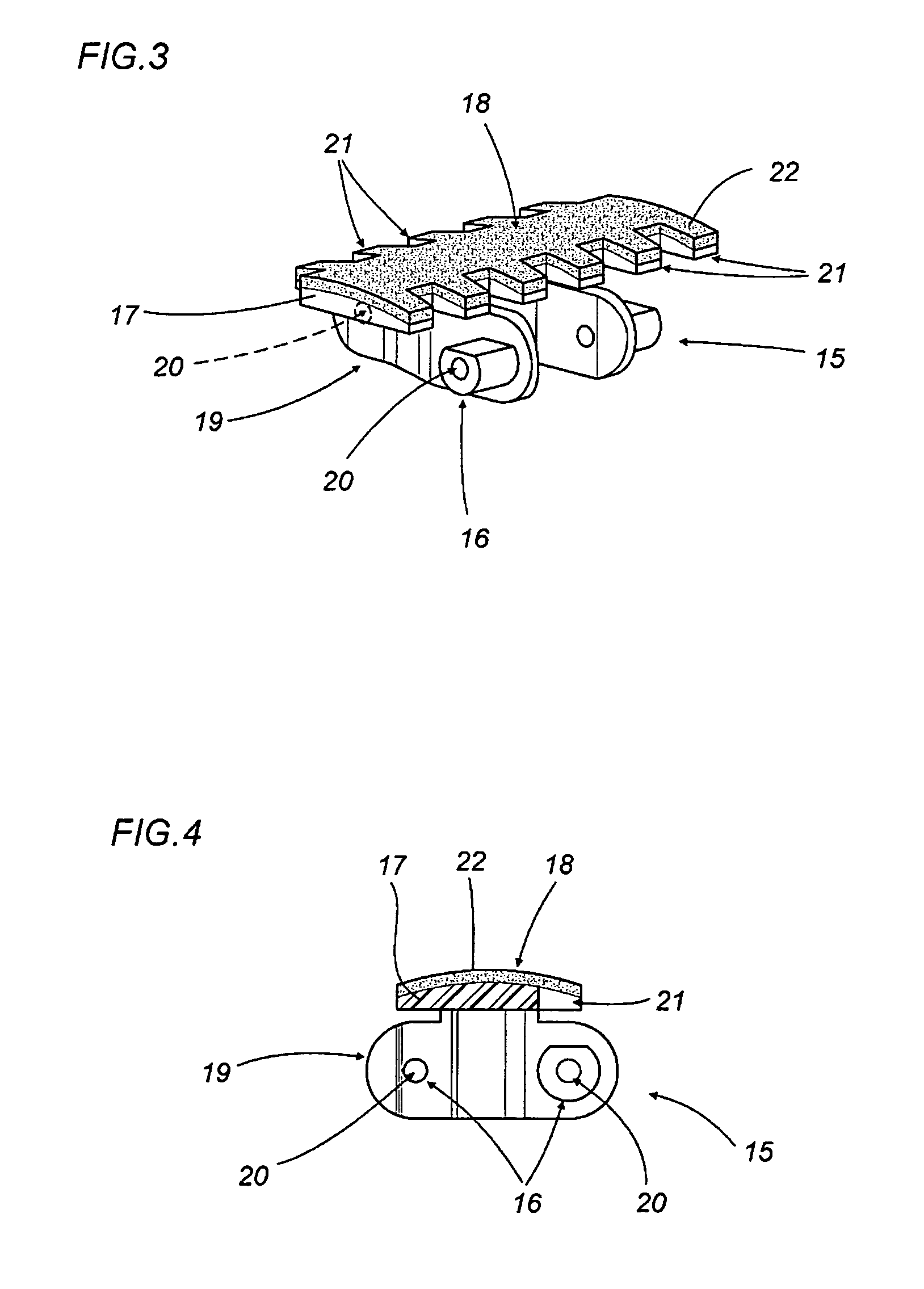

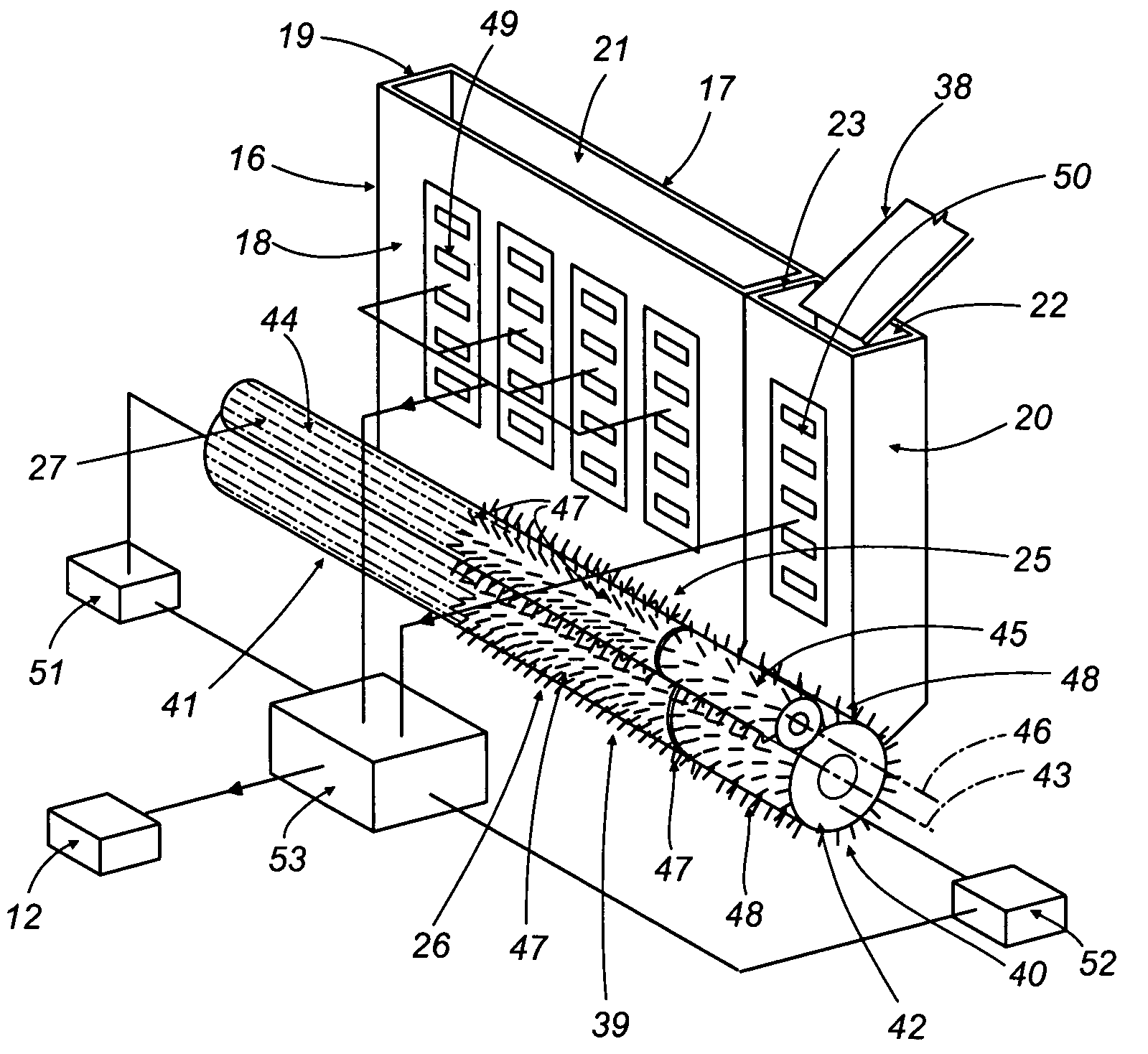

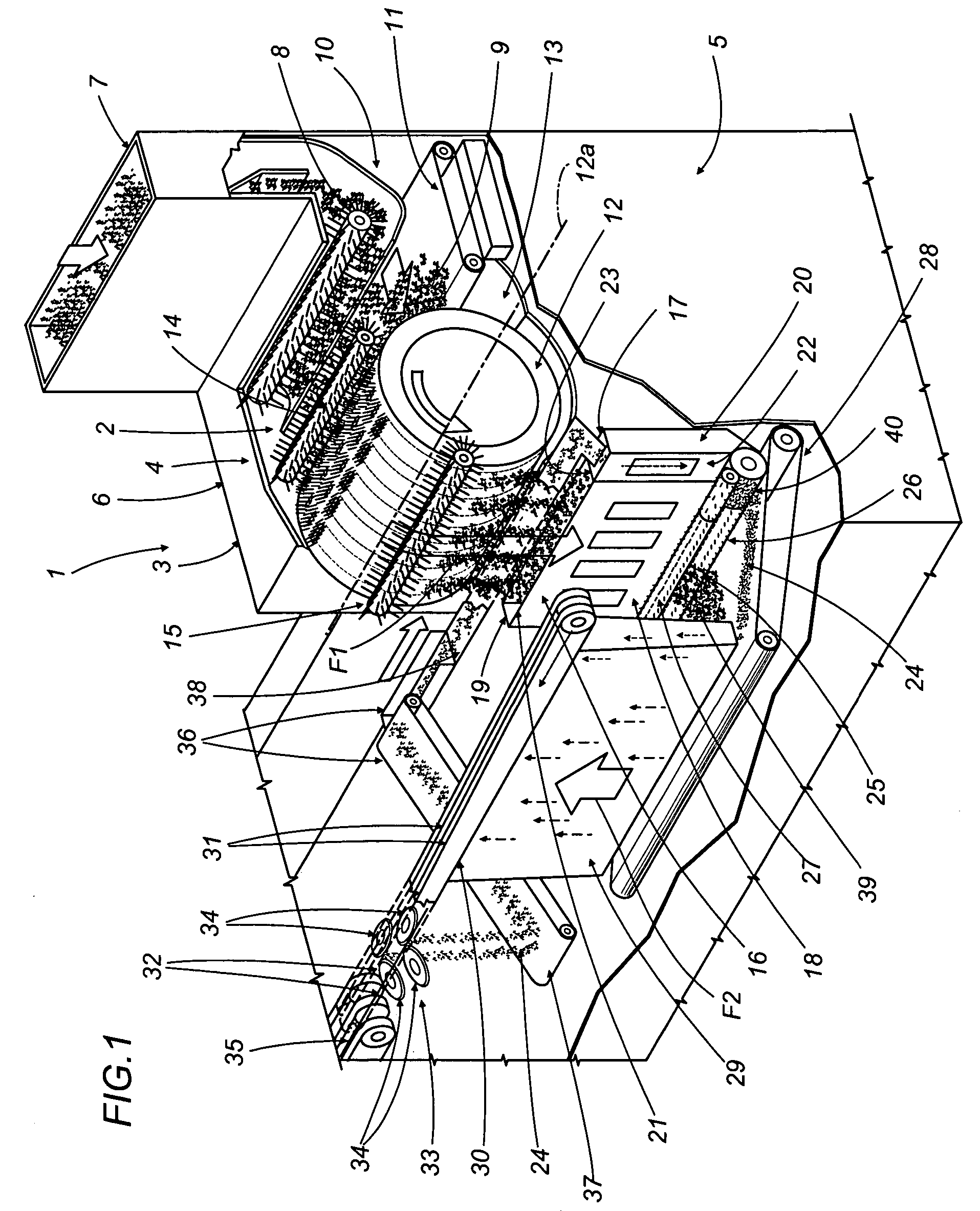

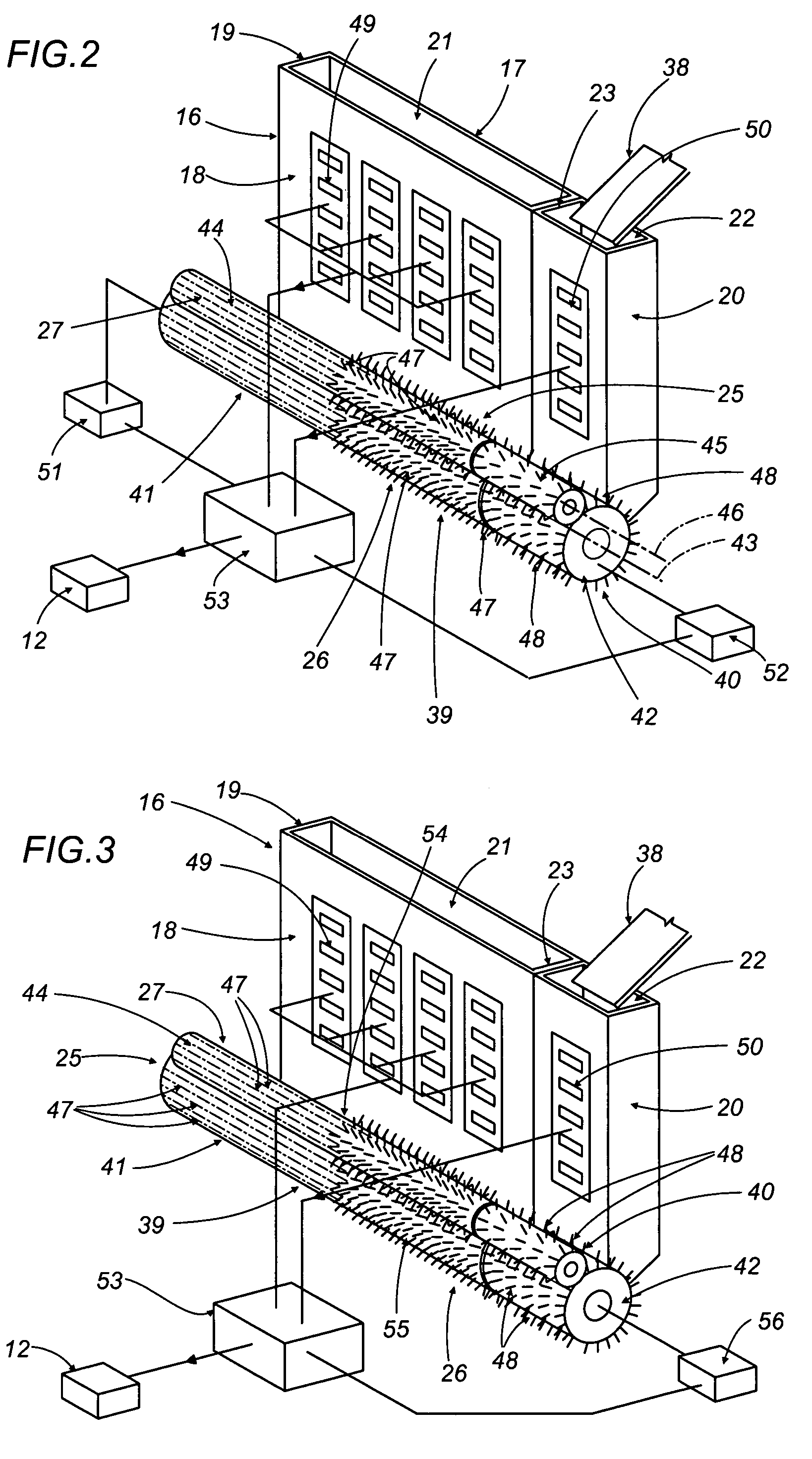

ActiveUS7789087B2Save moneyReducing or eliminating trips to a storeCigarette manufactureCigarette MakersEngineering

The present invention relates to the cigarette making apparatus 10 which may comprise a housing 12 with mechanical and electrical features. Cigarette apparatus 10 has a solenoid-assisted hopper 14 for accepting loose tobacco 15, a cigarette tube filling cassette 16 with nozzles 30 and a hinged lid 34 for assisting in maintaining cigarette tubes 24 in a predetermined alignment for loading tobacco 15, a filling area 17 with a indexing means for aligning cigarette tubes with a tobacco pushing means inside the apparatus, a cigarette tube loading and tobacco packing means 18 with guide pins 20 for guiding the cassette 16 in engagement with flattened tip pins 22 that compress tobacco 15 into cigarette tubes 24 after tobacco 15 has been inserted, and an electronic control area 26, which may include an electronic display for controlling the cigarette tube filling and packing apparatus.

Owner:PHILIP MORRIS USA INC

Verifying method of cigarette apparatus detection technology

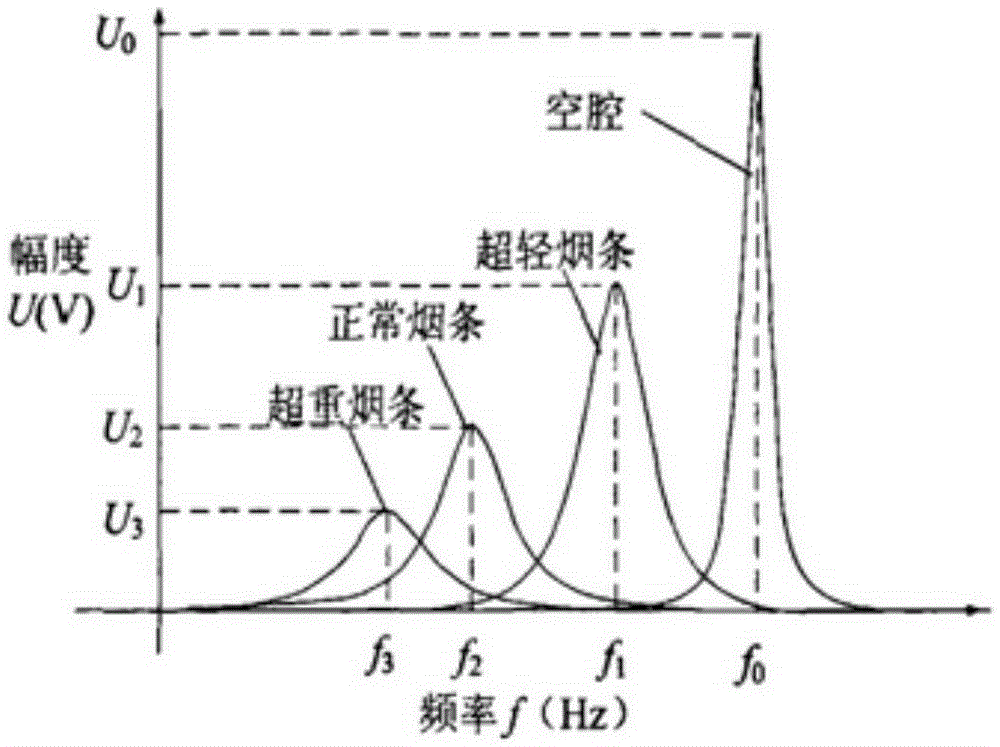

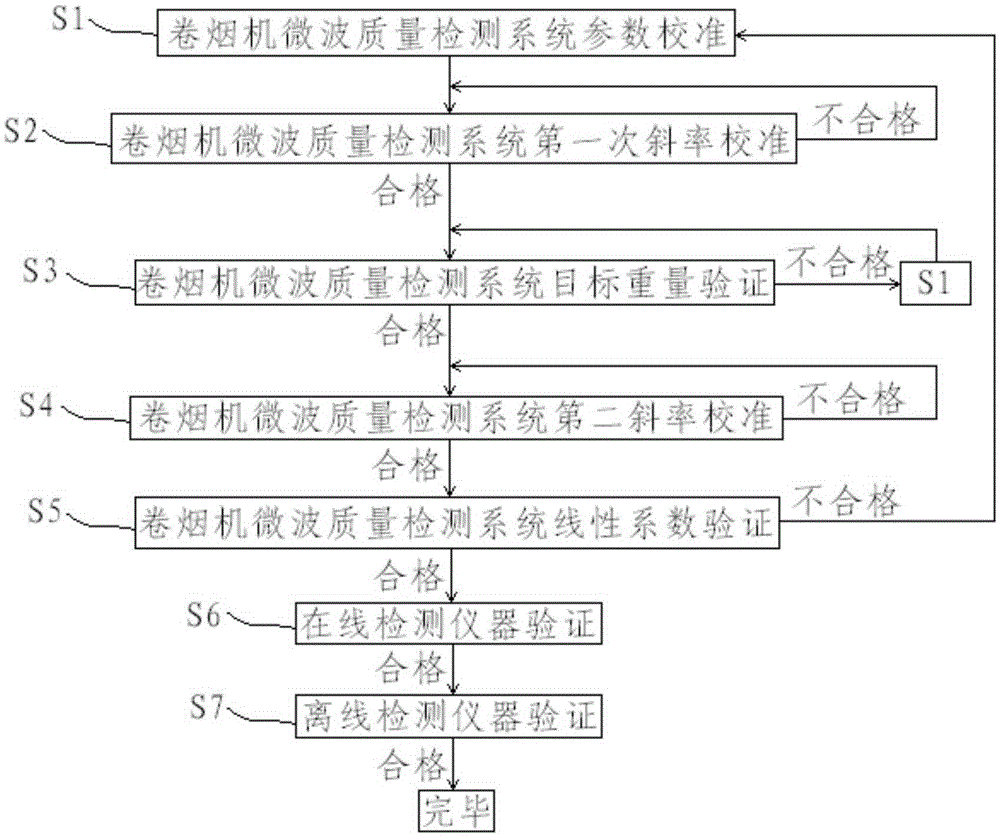

ActiveCN105388168AReliable test resultsMoisture content investigation using microwavesMicrowaveCigarette Makers

The invention relates to the technical field of cigarette manufacturing, and especially relates to a verifying method of a cigarette apparatus detection technology. The method comprises the following steps: 1, carrying out parameter calibration on a cigarette maker microwave quality detection system; 2, carrying out first gradient calibration on the cigarette maker microwave quality detection system; and 3, carrying out target weight verification on the cigarette maker microwave quality detection system: extracting a plurality of samples with a target weight, measuring the practical weights of the samples, calculating the mean deviation and the standard deviation of the practical weights and the target weight, judging that the target weight verification is qualified when the mean deviation is smaller than 5mg and the standard deviation is smaller than 8mg, and repeating step 1 and step 3 when the mean deviation is not smaller than 5mg and the standard deviation is not smaller than 8mg until the target weight verification is qualified. The accuracy of the cigarette maker microwave quality detection system is verified and parameters of the system are timely afresh calibrated through the target weight verification, so accuracy of the cigarette maker microwave quality detection system in the running process is ensured.

Owner:CHINA TOBACCO GUIZHOU IND

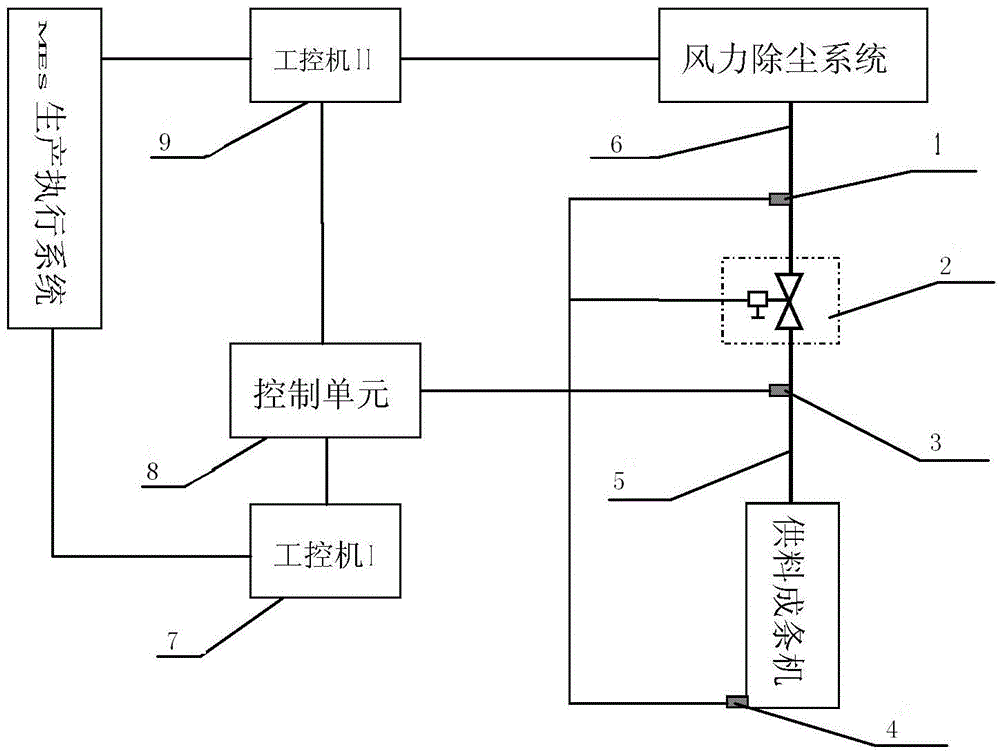

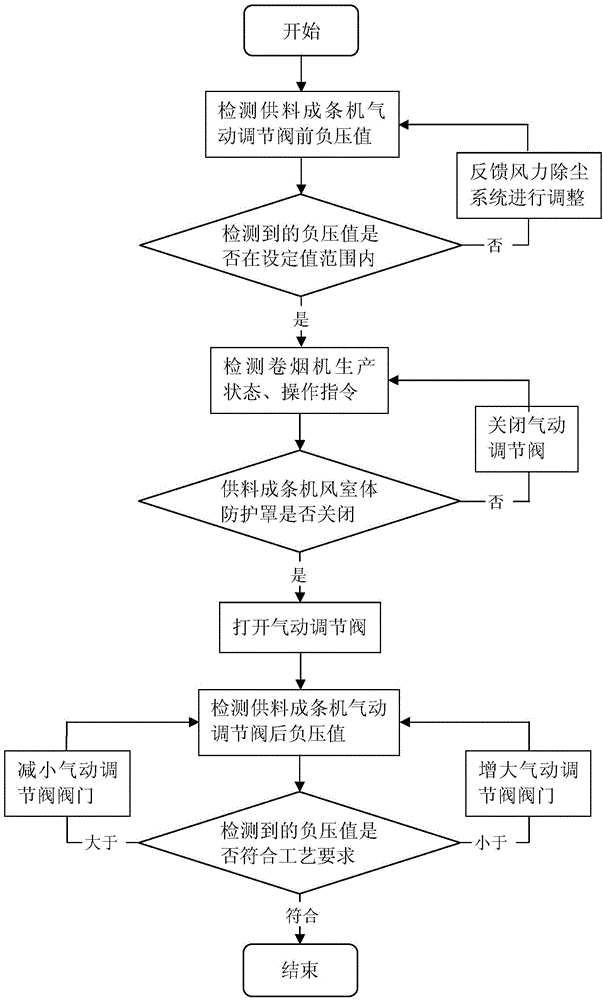

Negative pressure automatic regulating system for material-feeding and cigarette-rod-forming machine of cigarette maker

InactiveCN104856218ARealize remote managementEasy to controlCigarette manufactureBulk conveyorsCigarette MakersEngineering

The invention relates to a negative pressure automatic regulating system for a material-feeding and cigarette-rod-forming machine of a cigarette maker. The negative pressure automatic regulating system comprises a pneumatic control valve installed on each set of cigarette maker, two negative pressure sensors, a control unit, an industrial control computer mounted on the cigarette maker and another industrial control computer mounted on a wind dedusting system. The pneumatic control valve is installed on a negative pressure air duct of the material-feeding and cigarette-rod-forming machine and replaces an original hand-operated control valve; the two negative pressure sensors are respectively mounted on the negative pressure air duct at positions before and after the pneumatic control valve; and the signal of an interlock switch of an air compartment of the material-feeding and cigarette-rod-forming machine is connected to the control unit. The negative pressure automatic regulating system provided by the invention can realize automatic opening and closing of the negative pressure valves of the material-feeding and cigarette-rod-forming machine and automatic adjusting of the value of negative pressure so as to stabilize the negative pressure value of the material-feeding and cigarette-rod-forming machine, so the purposes of saving energy and improving tobacco rod quality are achieved and remote management and control of negative pressure of the cigarette maker are realized.

Owner:CHINA TOBACCO GUANGXI IND

Tipping paper gluing device and cigarette maker

ActiveCN112264253APrevent air leakageAvoid quality problemsLiquid surface applicatorsTobacco smoke filtersCigarette MakersMechanical engineering

Owner:LONGYAN CIGARETTE FACTORY

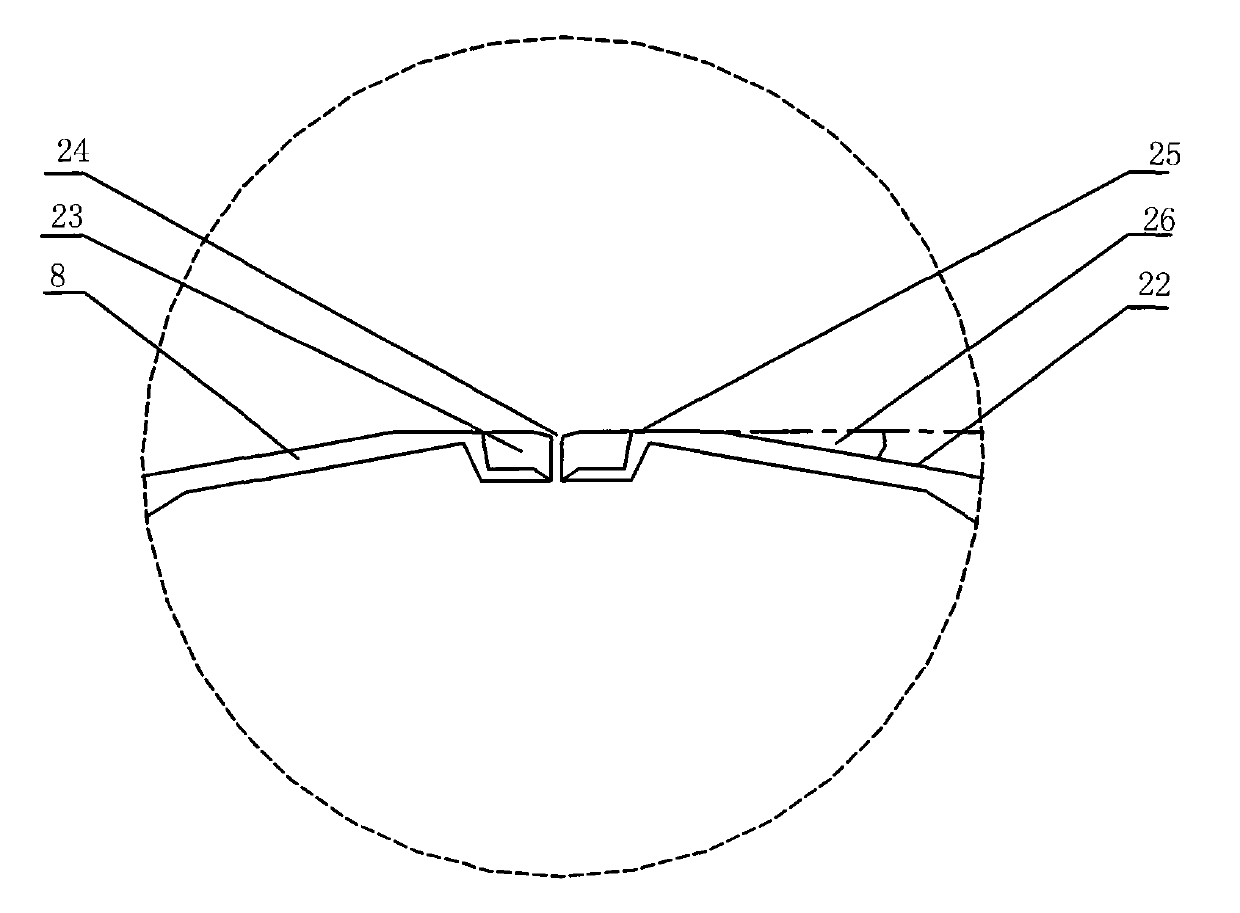

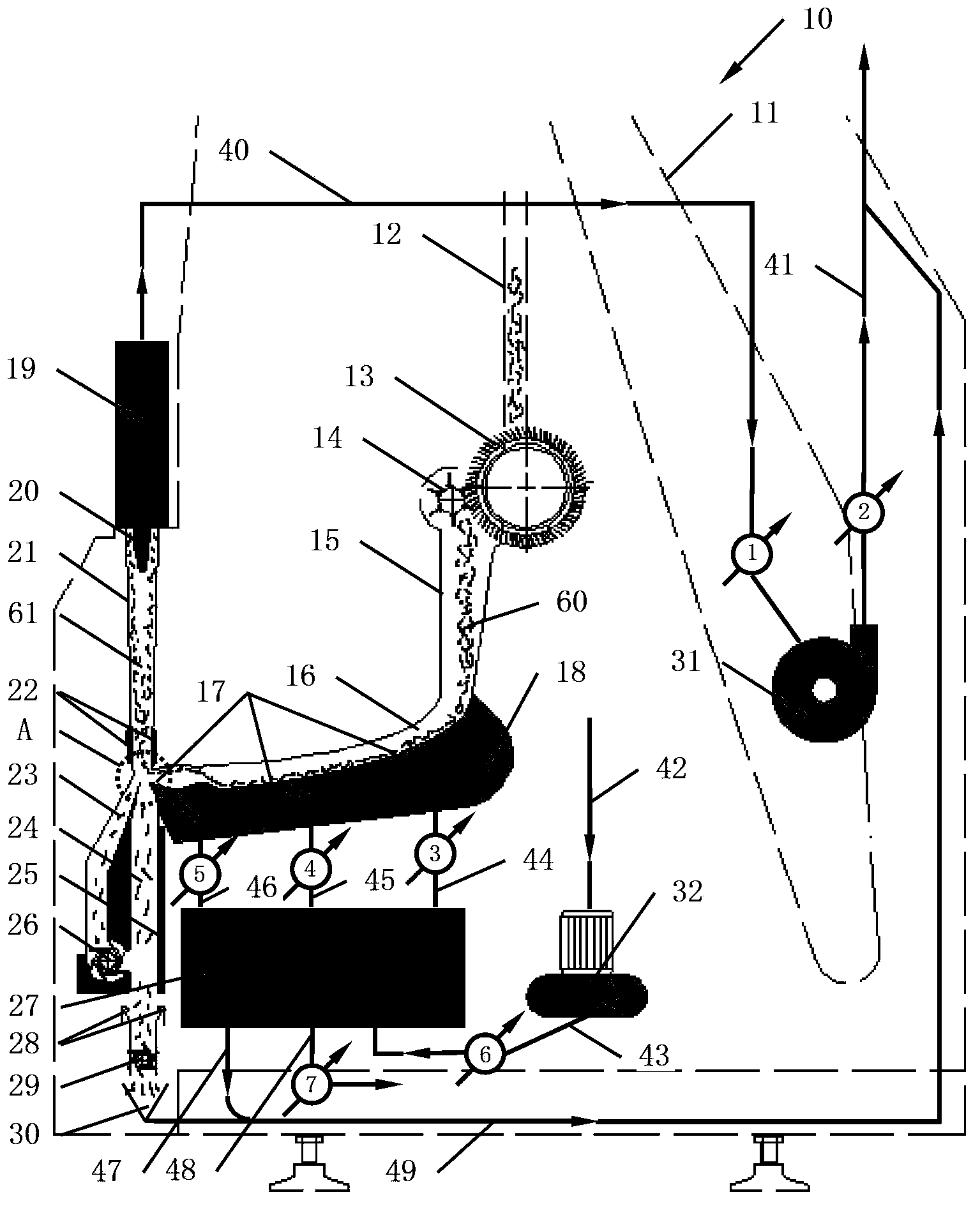

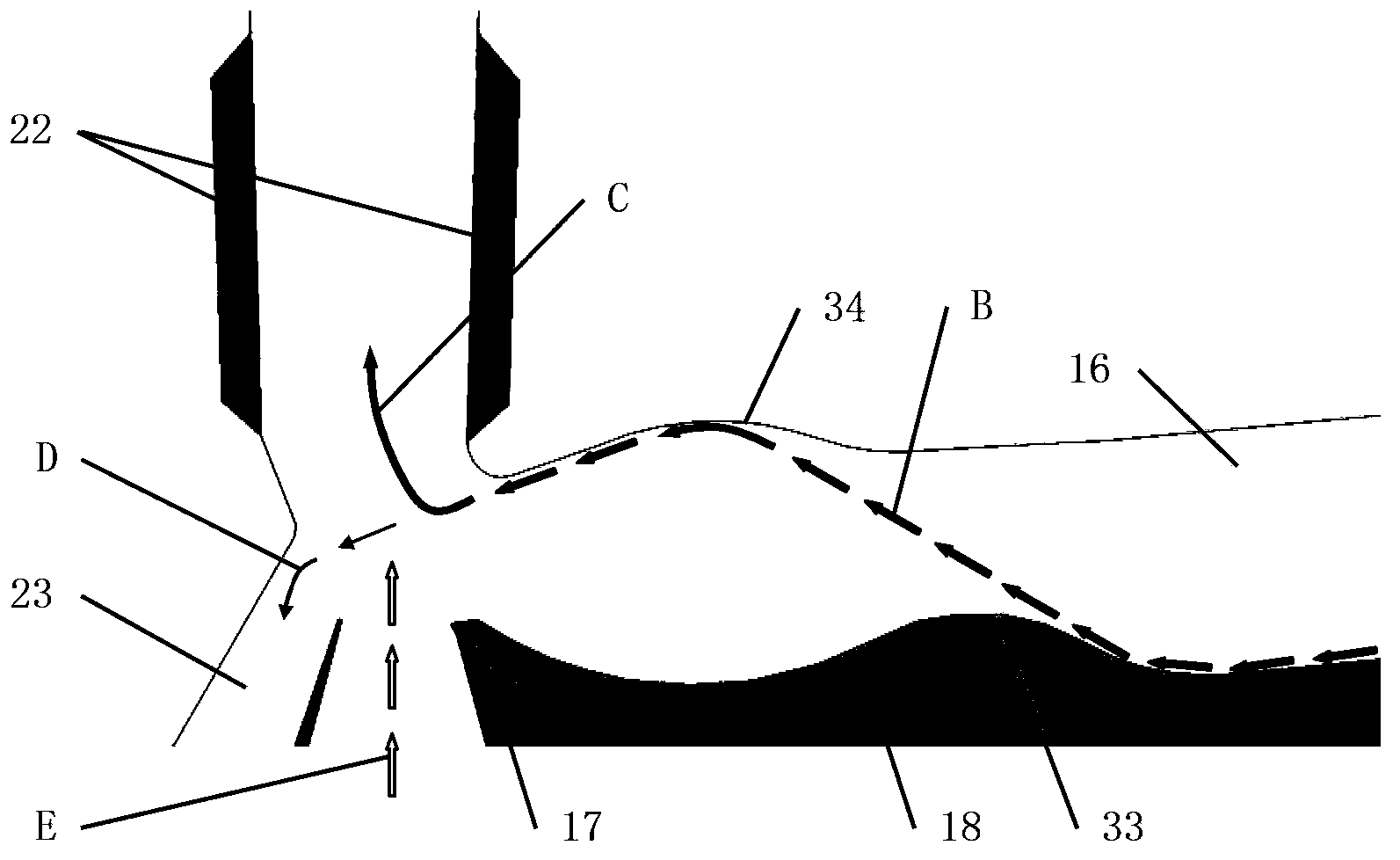

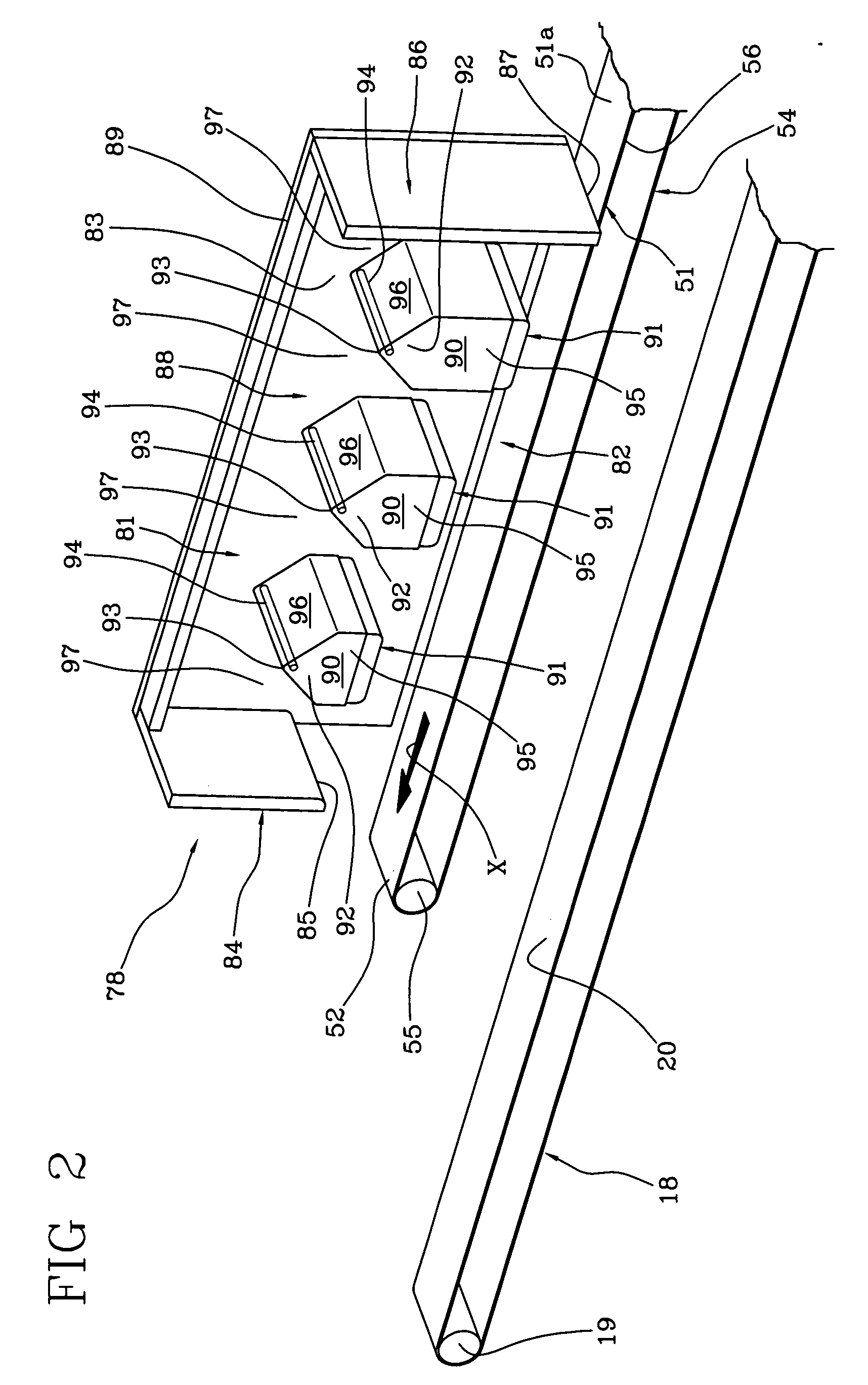

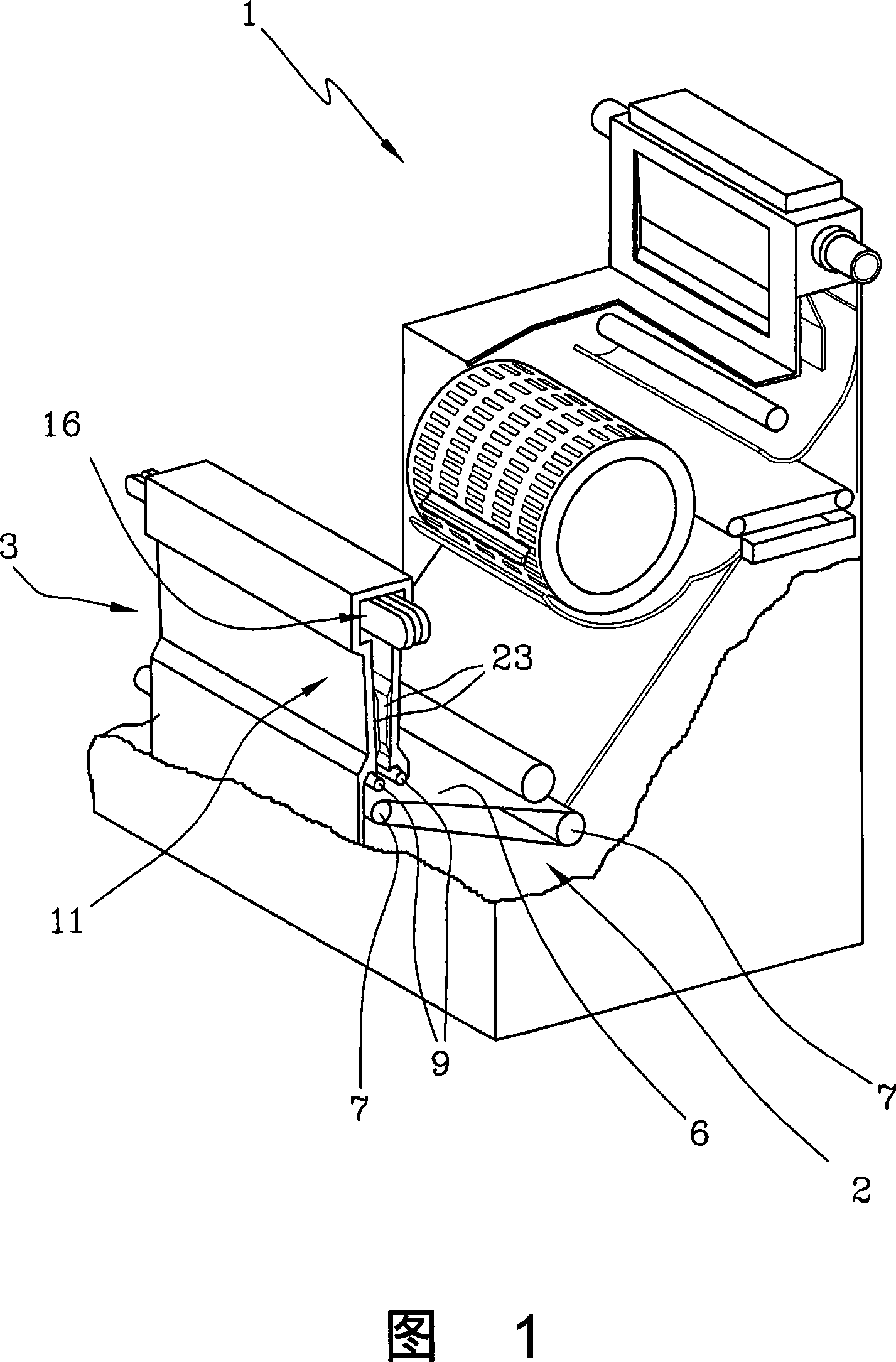

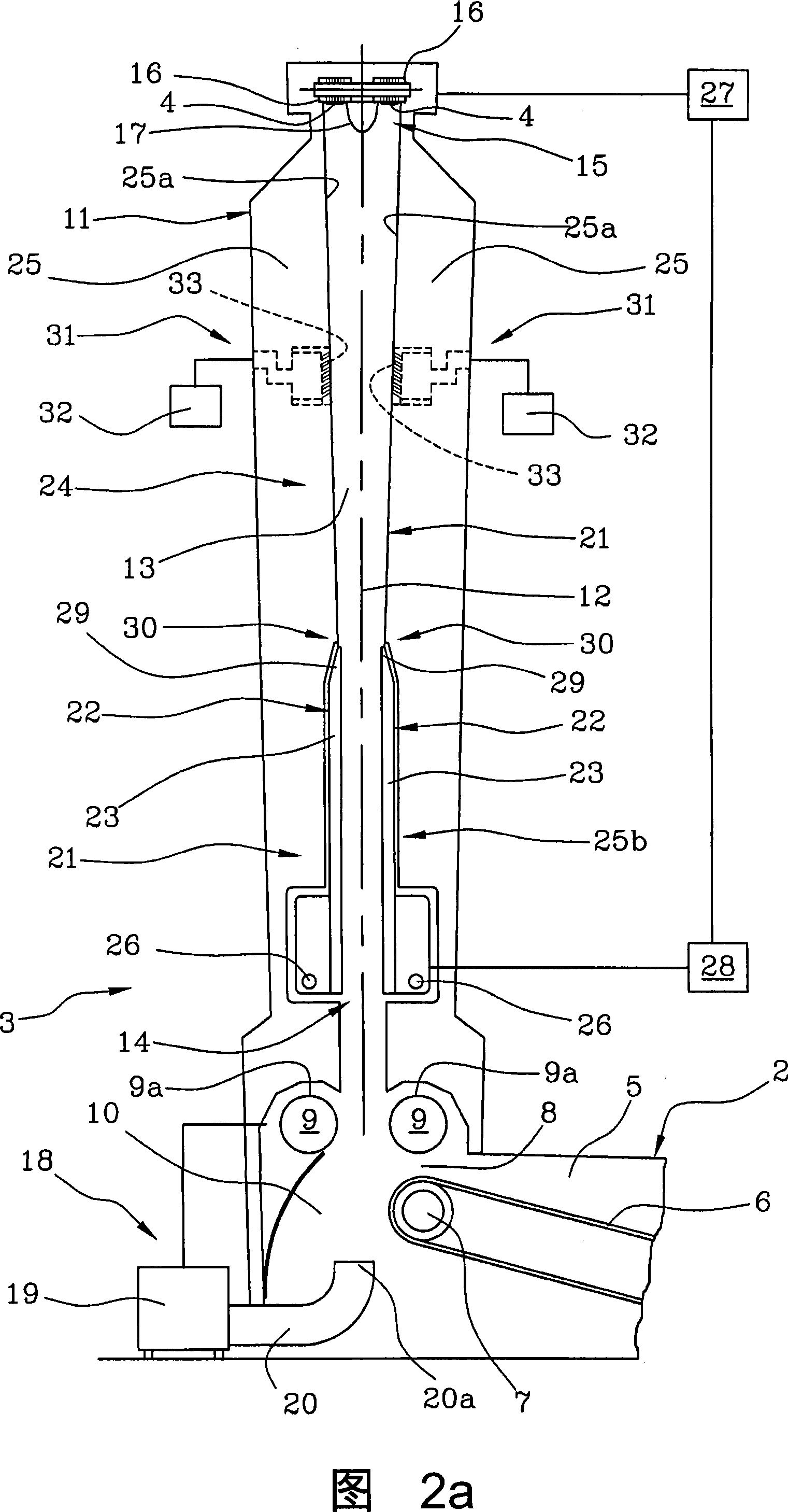

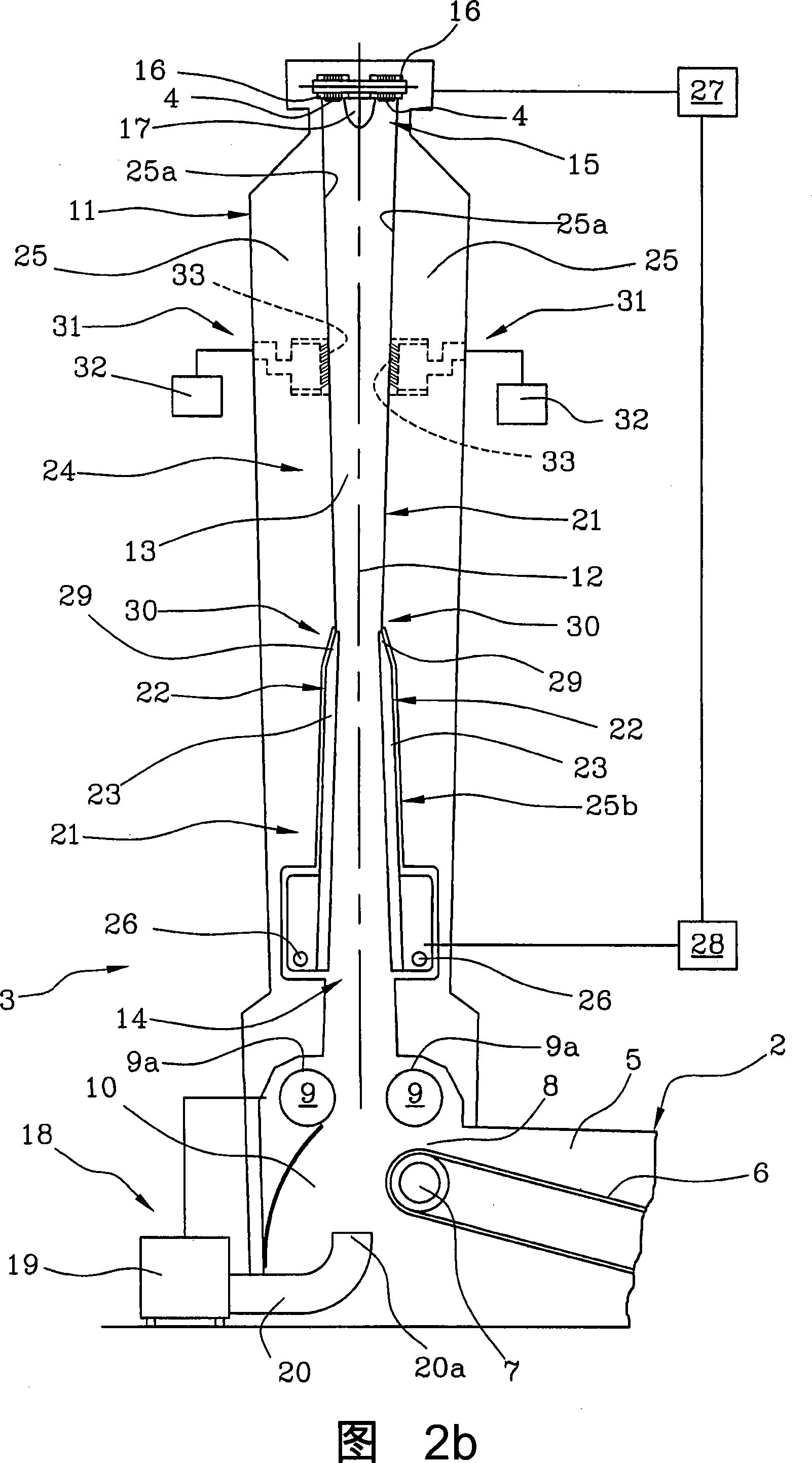

A cigarette making machine equipped to manufacture two continuous cigarette rods simultaneously

In a twin-track cigarette maker (1) designed to manufacture two continuous cigarette rods at once, shredded tobacco particles entrained in an air current are directed up a channel (11) aligned on a substantially vertical axis (12). The channel (11) forms part of a chimney (13) enclosed at the top end (15) by two aspirating conveyor belts (16) and presenting a lower segment (21) equipped with a mechanism (22) intended to counter a loss of upward momentum tending to occur naturally in the flow of tobacco particles; the mechanism (22) comprises at least two flaps (23) hinged at the bottom and located internally of the channel (11), which are adjustable between a position parallel one with another, and a position converging toward an upper segment (24) of the chimney.

Owner:GD SPA

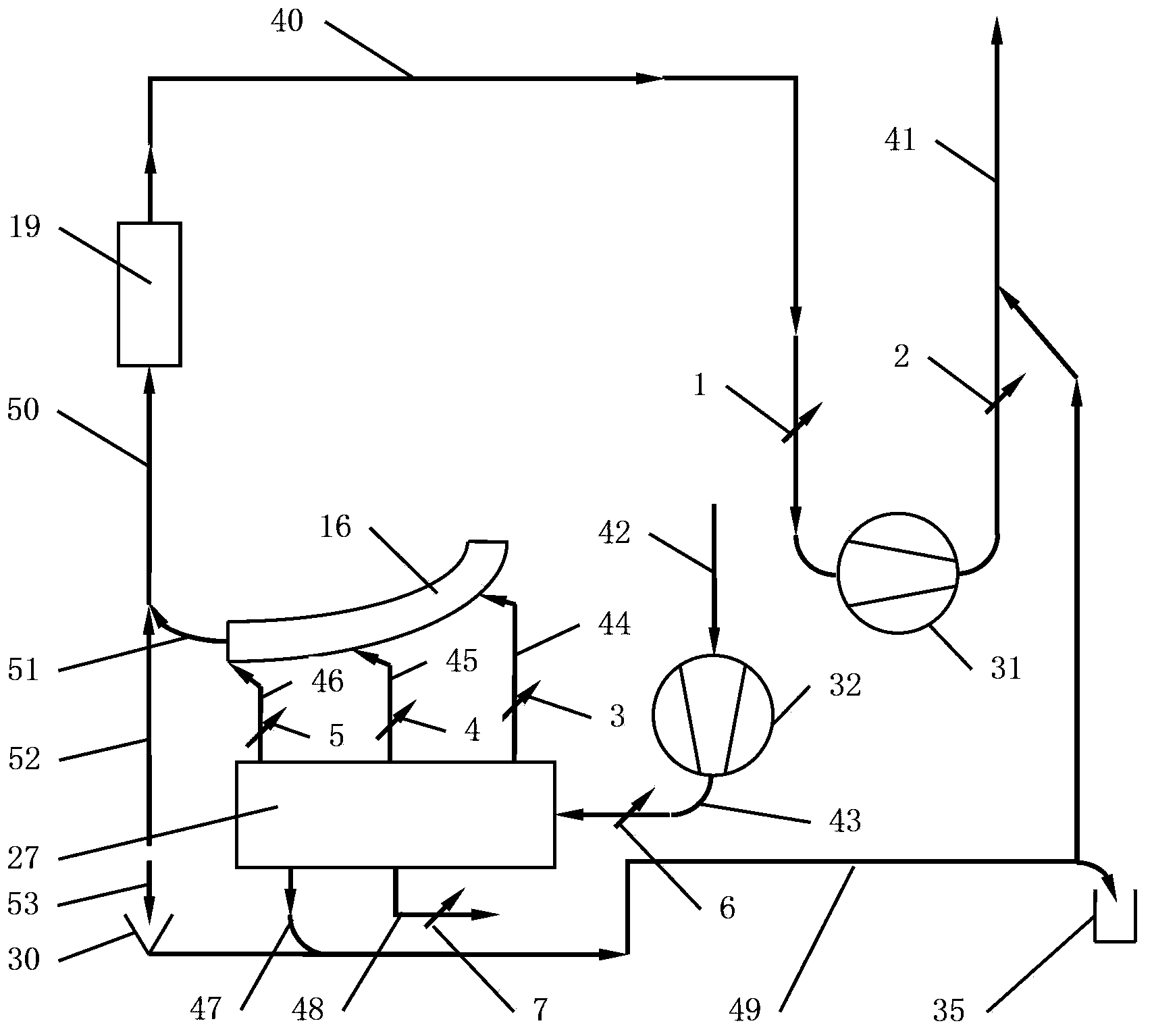

Cigarette maker

In a cigarette maker comprising a descent channel filled with shredded tobacco by a carding unit and with reclaimed tobacco by a conveyor, the shredded tobacco and the reclaimed tobacco are taken up and transferred by a toothed unit toward an ascent channel, from where both are attracted onto a belt by suction and formed into a continuous stream; the descent channel is split into two distinct portions serving respectively to admit the shredded tobacco and the reclaimed tobacco, whilst the toothed unit comprises a first and a second roller positioned to take up the shredded tobacco and reclaimed tobacco and operating in conjunction with respective impeller rollers.

Owner:GD SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com