Method and device for measuring tobacco waste quantity of cigarette making machine, and cigarette making machine system

A measuring method and measuring device technology, which is applied in the fields of tobacco, paper cigarette manufacturing, application, etc., can solve the problems of difference and inaccurate calculation of the amount of recycled silk, and achieve the effect of accurate calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

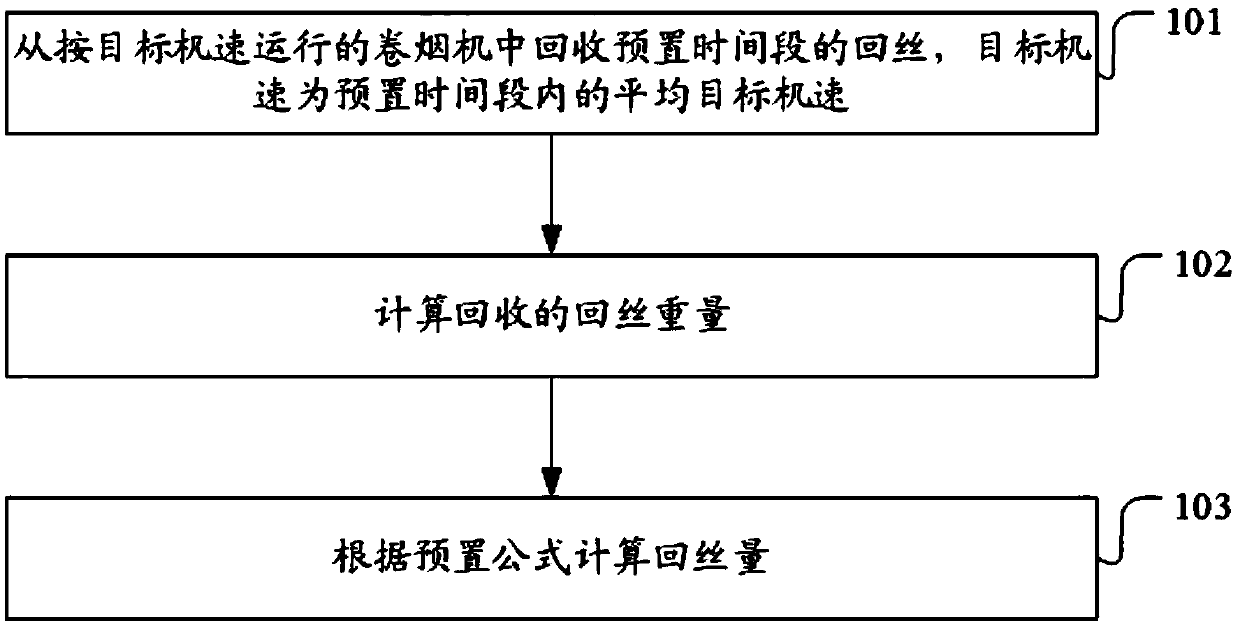

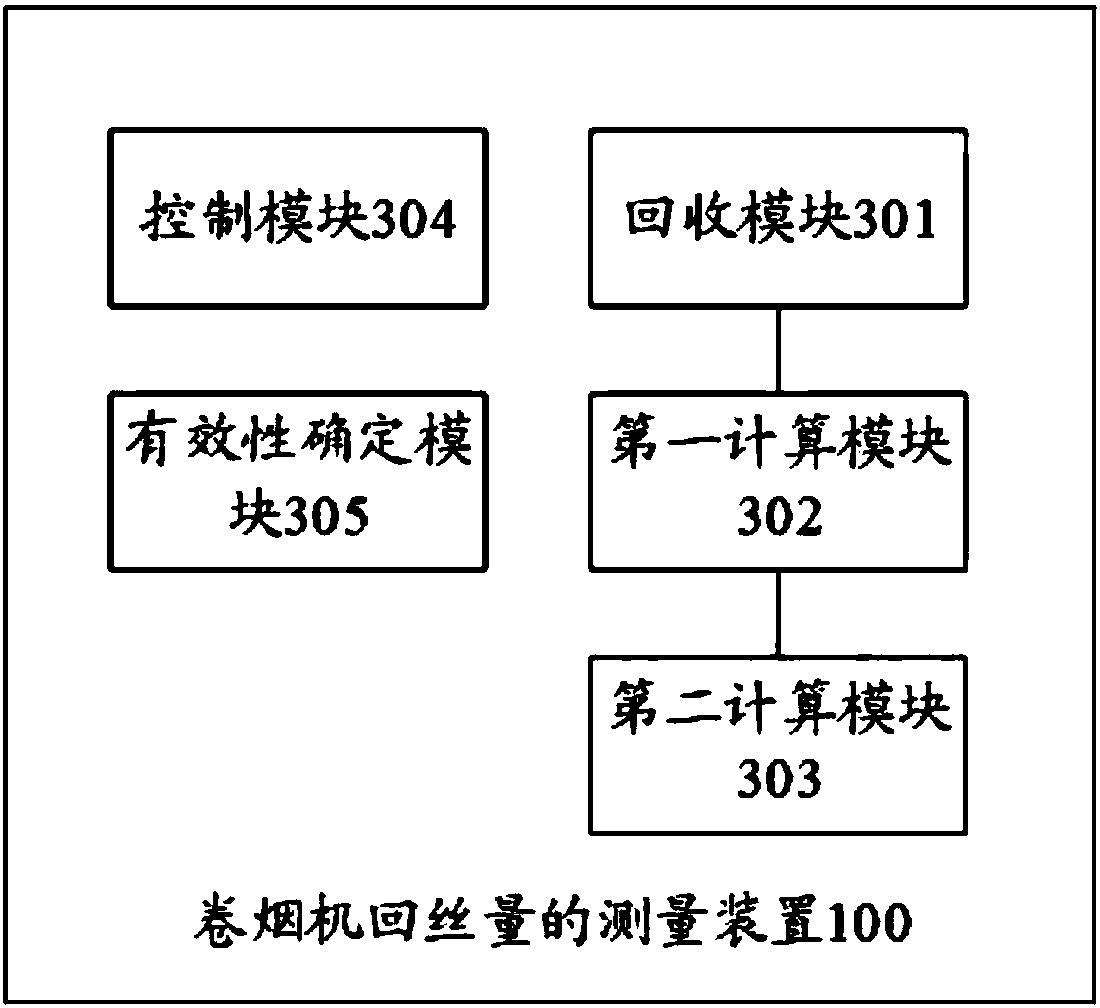

[0046] The present invention provides a first embodiment of a method for measuring the amount of waste wire in a cigarette machine, including:

[0047] 101. Recover the waste silk for a preset time period from the cigarette making machine running at the target machine speed, where the target machine speed is an average target machine speed within the preset time period.

[0048] It should be noted that, in this embodiment, the preset time period can be adjusted according to actual needs, and the target machine speed is generally calculated in minutes. For example, the target machine speed can be target machine speed=4300 cigarettes / min, correspondingly , and the preset time period is one minute, which will not be described in detail below.

[0049] 102. Calculate the weight of recycled silk.

[0050] 103. Calculate the amount of returned wire according to the preset formula, where the preset formula is

[0051]

[0052] It should be noted that the target weight of a singl...

no. 2 example

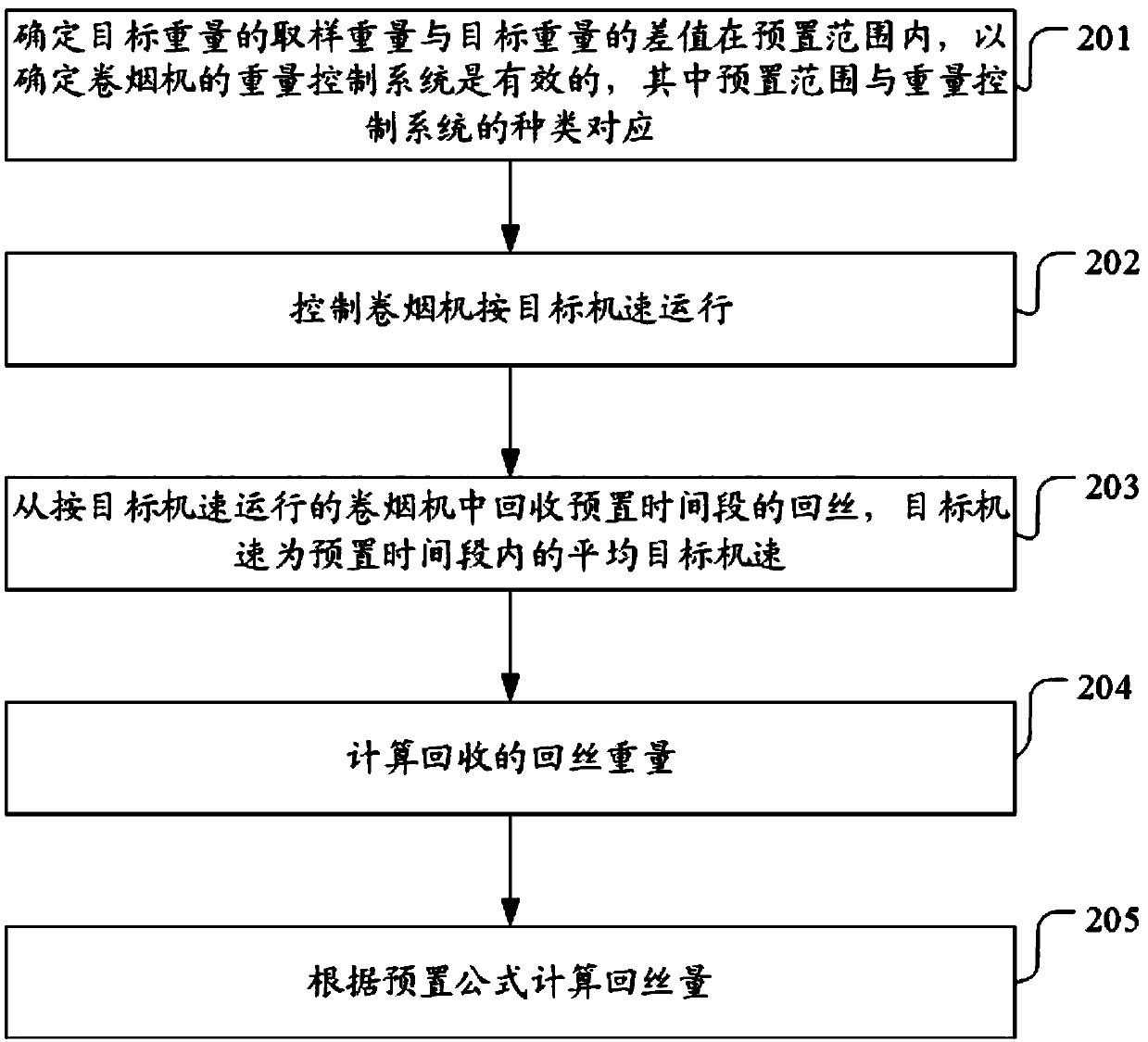

[0055] The present invention provides a second embodiment of a method for measuring the amount of wire waste in a cigarette machine, including:

[0056] 201. Determine that the difference between the sampling weight of the target weight and the target weight is within a preset range to determine that the weight control system of the cigarette machine is effective, wherein the preset range corresponds to the type of the weight control system.

[0057] It can be understood that a target weight can be determined first, and then the target weight can be actually sampled, and the actual sampled weight can be used as the sample weight of the target weight.

[0058] In this embodiment, step 201 can well ensure the accuracy of the calculation of the amount of recycled wire.

[0059] Different weight control systems correspond to different preset ranges. For example, in weight control systems, the preset range of nuclear scanners is generally -5mg to +5mg, while the preset range of mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com