Device and method for measuring axial diffusion coefficient of gas in porous medium

A technology of axial diffusion and multi-porosity, applied in the direction of measuring devices, suspension and porous material analysis, instruments, etc., can solve the problems of lack of gas chromatography, destruction of diffusion balance, large experimental errors, etc., to achieve accurate calculation results and avoid fluid Expansion loss, the effect of improving the accuracy of the experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

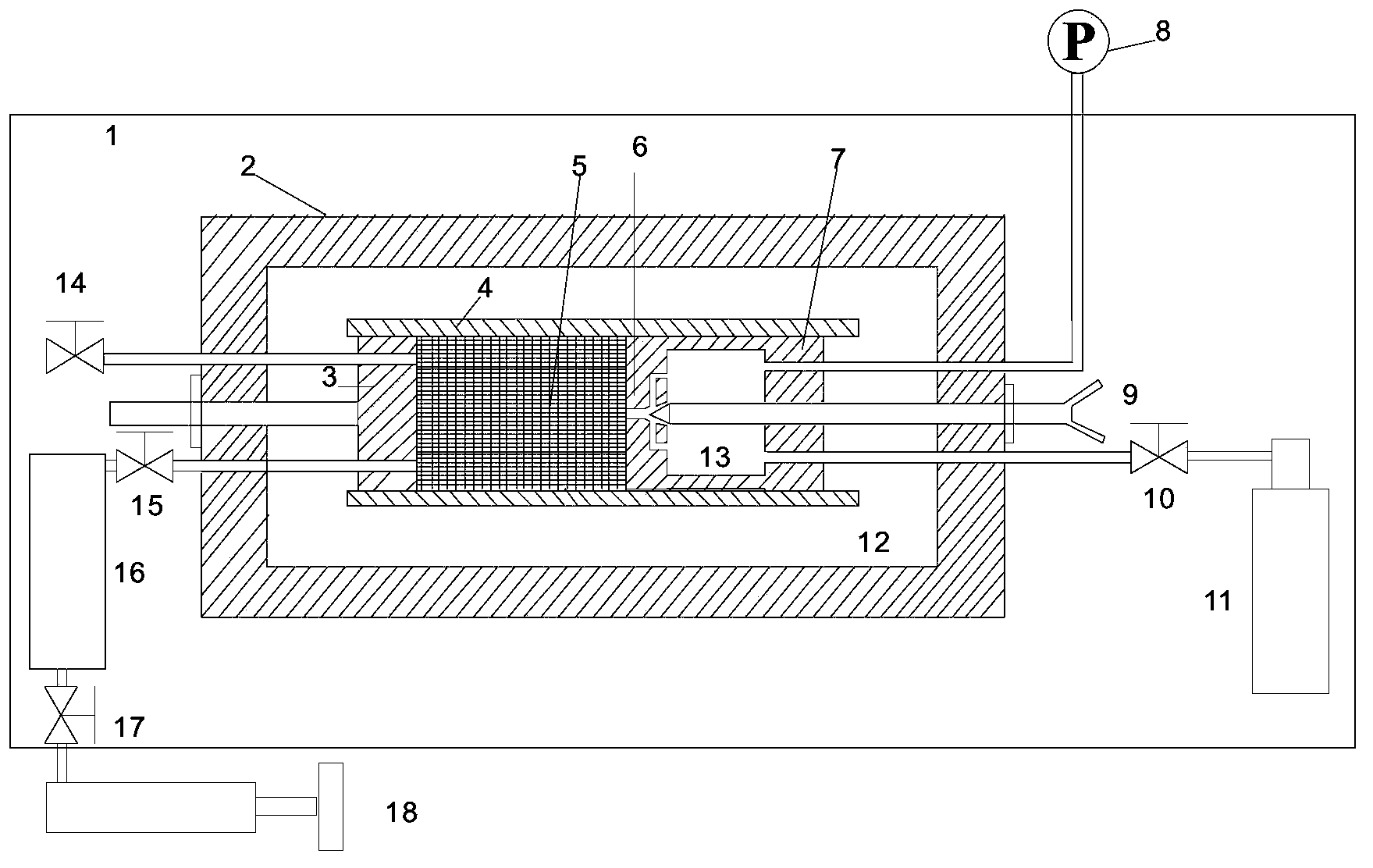

[0047] Below in conjunction with accompanying drawing, the present invention is described in further detail:

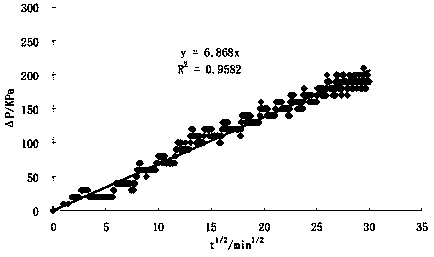

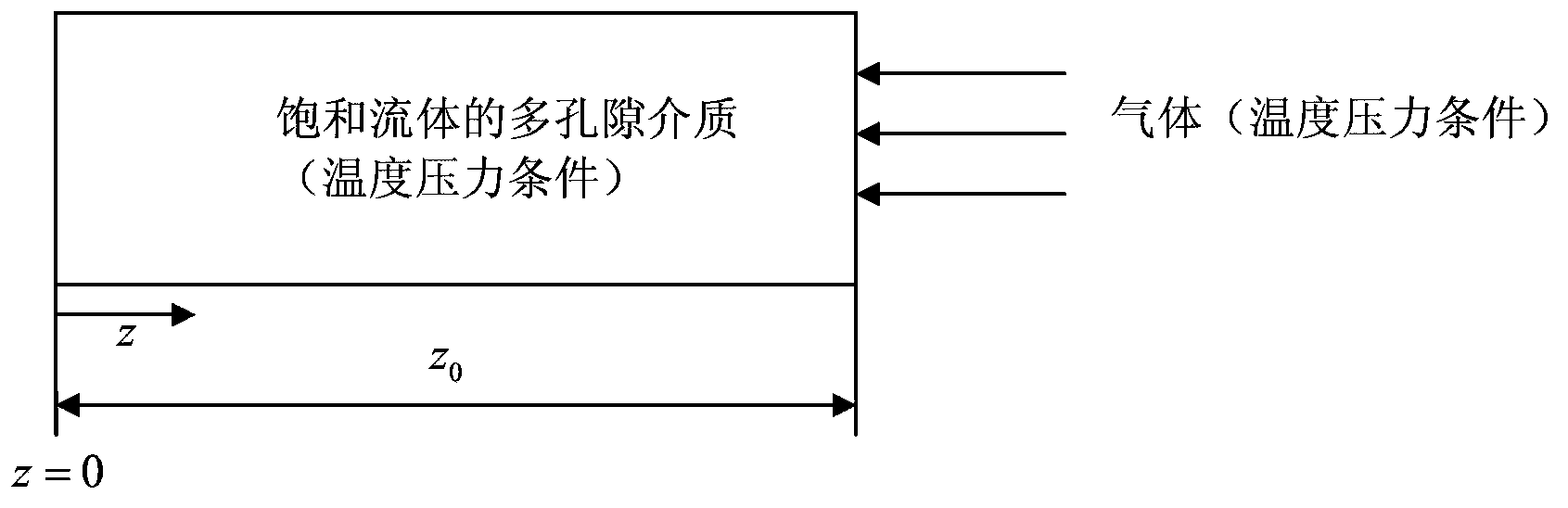

[0048] The present invention is a device and method for measuring the axial diffusion coefficient of gas in a porous medium saturated with fluid. The device measures the axial diffusion coefficient of gas in a porous medium saturated with fluid under the condition of temperature and pressure. Coefficients can provide data support for reservoir numerical simulation. The invention is divided into the following two parts: the first part, under the condition of temperature and pressure, the process of porous medium saturated fluid; the second part, under the condition of temperature and pressure, the process of gas diffusion, the whole invention realizes the in-situ connection of the process of fluid saturation and gas diffusion , the axial diffusion mode is closer to the formation conditions of the reservoir, and the pressure-time data recording method adopted is simple ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com