New energy automobile control circuit board performance test method

A technology for controlling circuit boards and new energy vehicles. It is applied in electronic circuit testing, printed circuit testing, and electrical measurement. It can solve problems such as poor test results, waste of manpower and material resources, and inability to simulate dust accumulation on the surface of circuit boards. Achieve the effect of improving the accuracy of the experiment, reducing adverse effects, and optimizing the background of the test experiment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

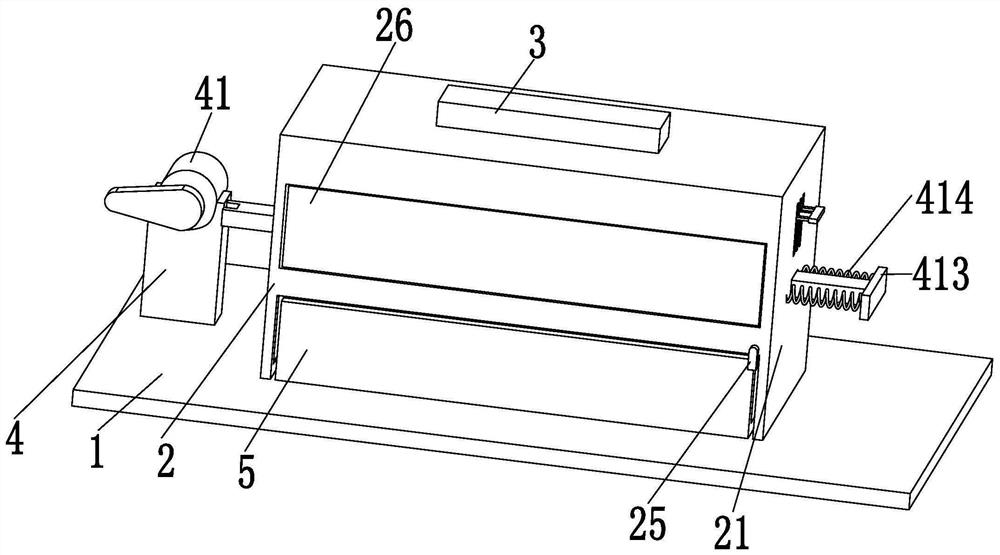

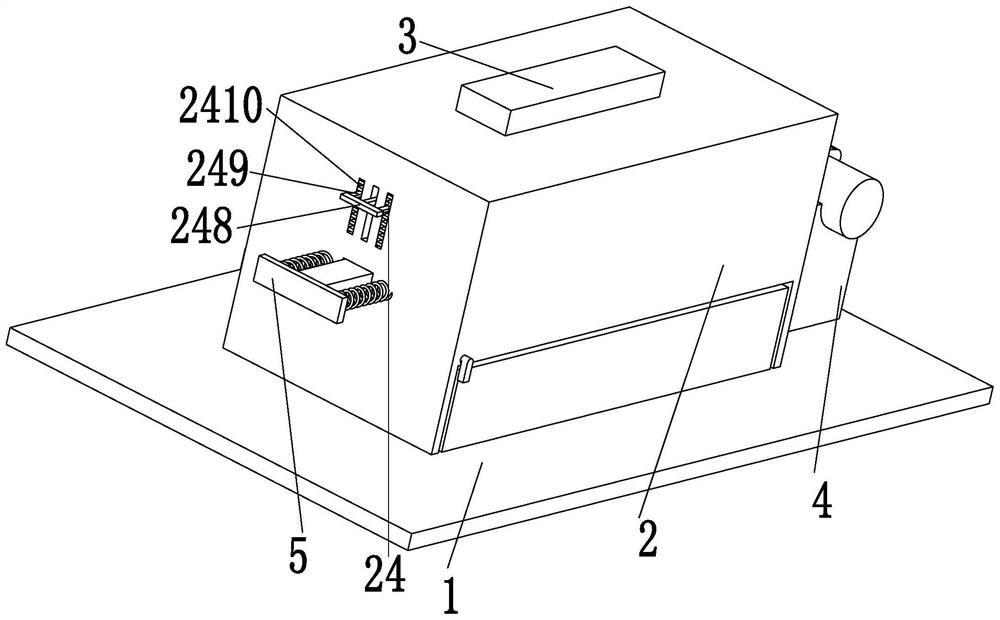

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

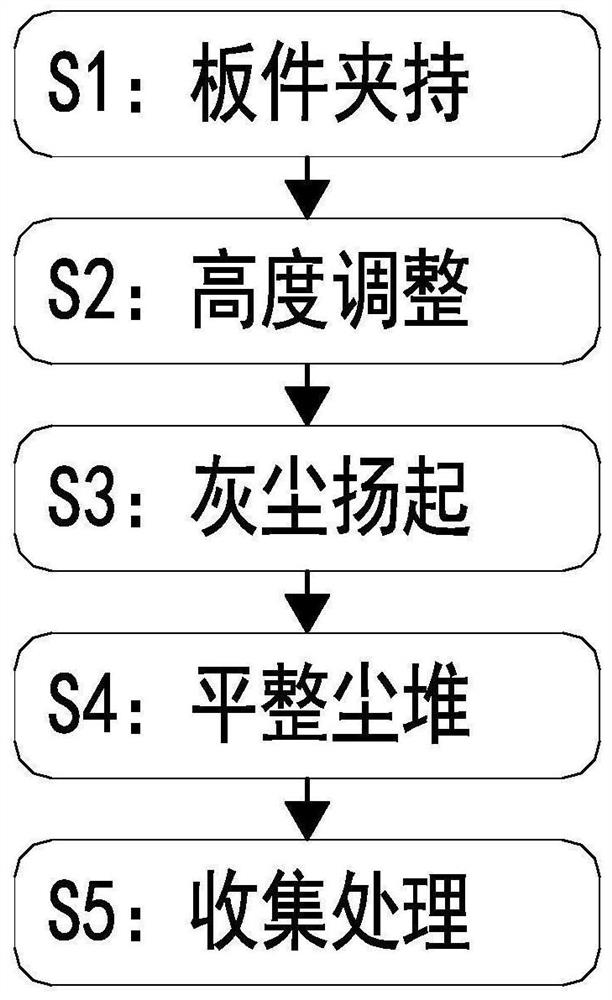

[0038] Such as Figure 1 to Figure 9 As shown, a new energy vehicle control circuit board performance test method mainly includes the following test steps:

[0039] S1. Plate clamping: rotate the moving plate 26 outward, put the circuit board into the clamping mechanism 45, and clamp it through the clamping mechanism 45;

[0040] S2. Height adjustment: the height of the dust falling on the circuit board is controlled by the height adjustment mechanism 24;

[0041] S3. Dust is raised: the dust is blown into the working frame 21 by the dust blower 3, and then sprinkled on the circuit board;

[0042] S4. Leveling the dust pile: the height adjustment mechanism 24 is driven to reciprocate on its plane by the reciprocating mechanism 41, and then the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com