Automatic unwrinkling and edge sealing veneer material receiving device

A material receiving device and veneer technology, which is applied to wood processing appliances, household components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

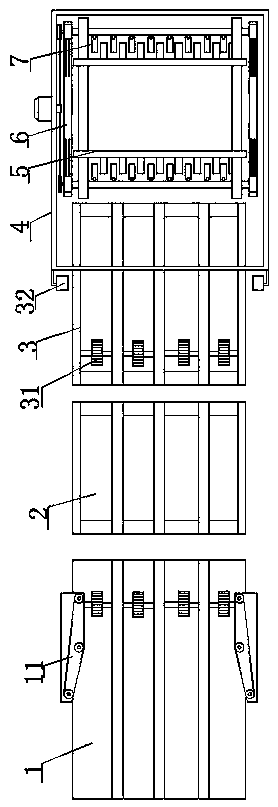

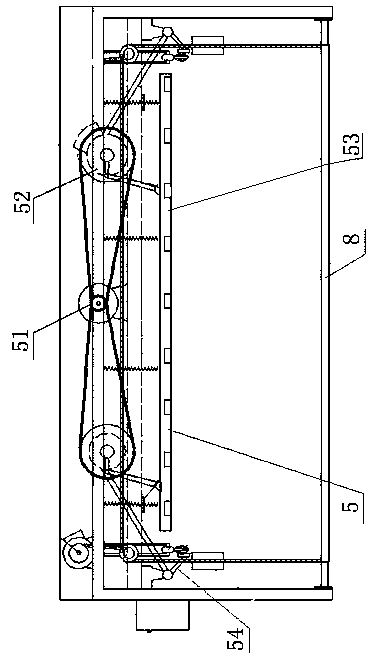

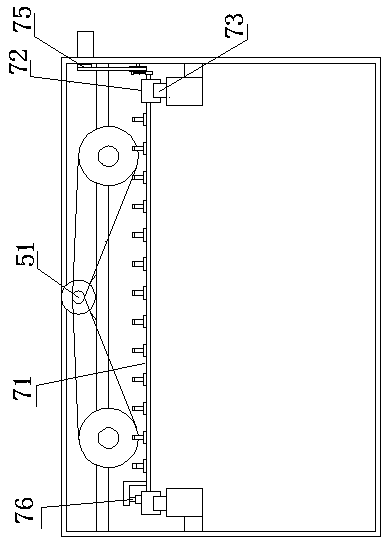

[0022] Such as Figure 1 to Figure 6 As shown, the present invention provides a veneer material receiving device for automatic folding and edge sealing, comprising a horizontal conveyor belt 1 connected horizontally to the outlet of the skin turning machine, and a skin grafting machine 4 is provided at the rear of the horizontal conveyor belt. Both sides of the frame are provided with pressure rails 54 that can be opened to both sides. The pressure rails crimp the veneer and transfer it to the top of the skin receiving plate. Drive its pressing plate rocker arm device 52 and pressing plate drive motor 51 that move up and down, and pressing plate is arranged on the position before and after the skin grafting machine respectively, is used for whole veneer is pressed down.

[0023] The improvement of the present application is that it also includes a transmission part, the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com