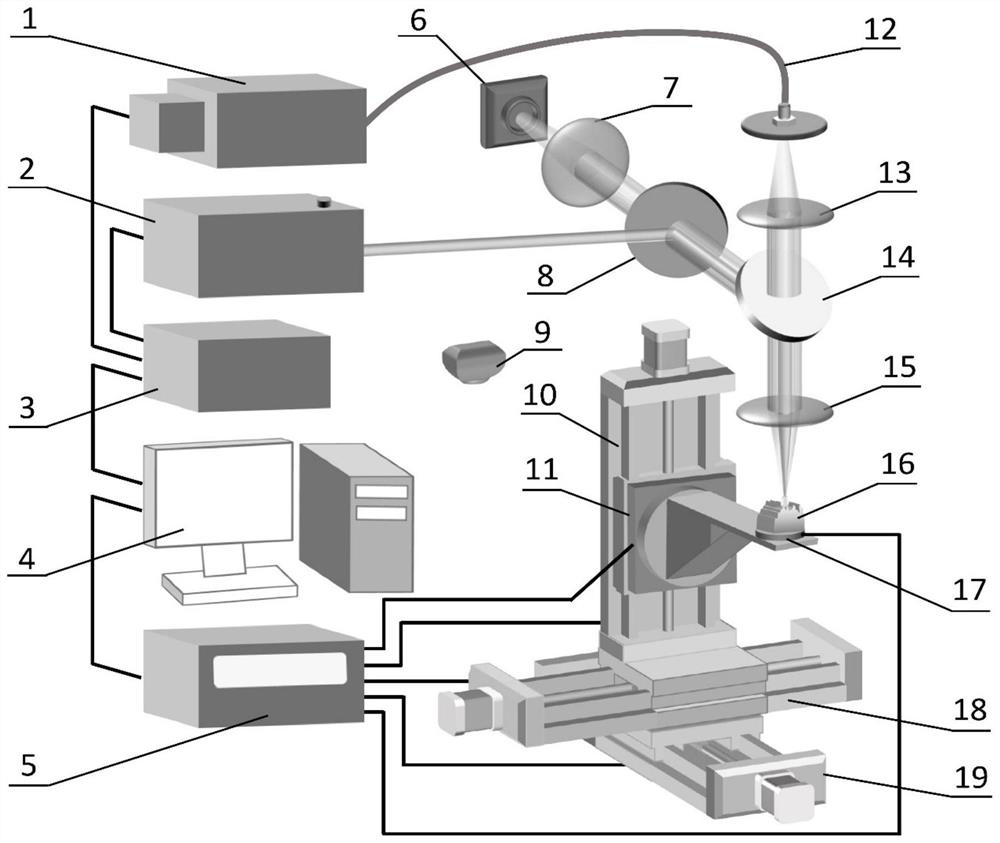

LIBS system capable of automatically aligning and focusing

An automatic alignment and focusing mirror technology, applied in the field of spectral detection, can solve the problem that the laser cannot focus vertically to ablate the surface of the sample, and achieve the effect of improving the analysis accuracy, signal quality, and experimental accuracy and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0061] Now take the automatic alignment and focusing of ore with uneven surface as an example to illustrate the use process of the LIBS automatic alignment and focusing detection device of the present invention. The specific operation steps are as follows:

[0062] Optical path correction of LIBS automatic alignment focusing detection device: adjust the position of the first focusing lens so that the laser focus point and the image of the surface of the sample to be tested in the area array CCD camera are most clearly at the same level.

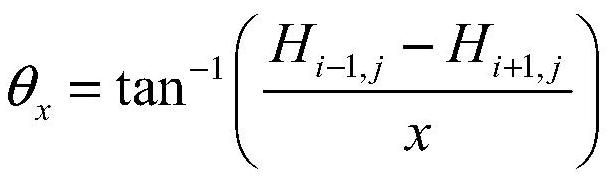

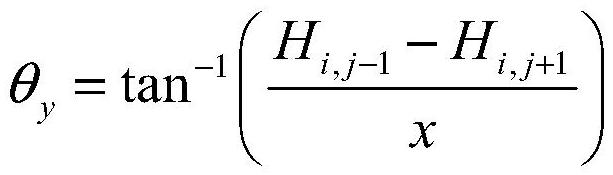

[0063] Obtain ore surface height information: first, place the ore sample on the stage, the computer drives the five-axis electric displacement system to make the ore sample be located directly below the laser ranging sensor, and the computer controls the five-axis electric displacement system to translate, so that the laser distance measurement The sensor collects the height information of a point every x=2μm on the ore sample surface. The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com