Leveling device of inclined disc type

A technology of leveler and swash plate, applied in the field of leveler, can solve the problems of low precision of cigarette weight control, high waste rate of empty cigarettes, and high waste rate, and achieve simple structure, high degree of automation, and production quality assurance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

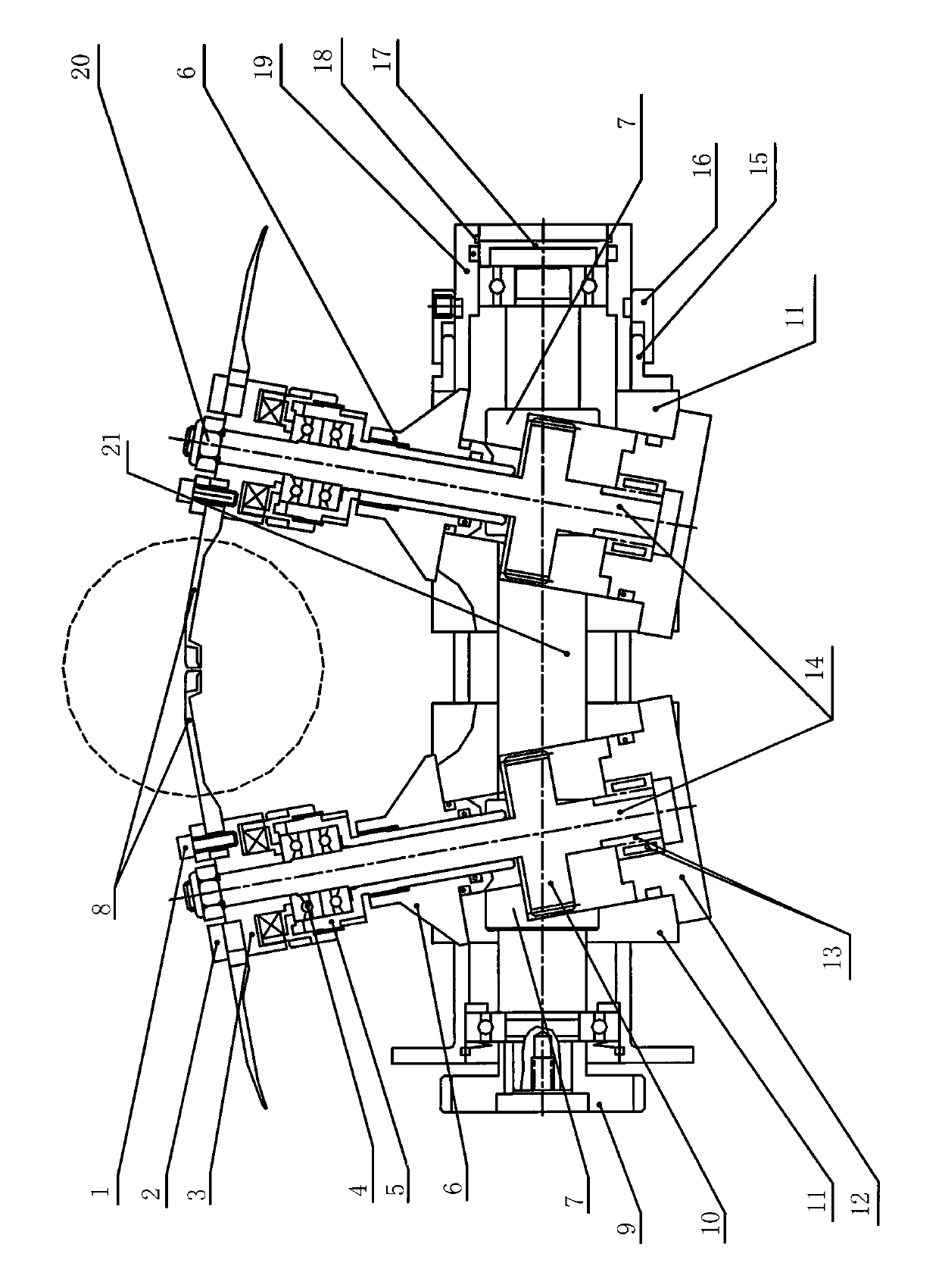

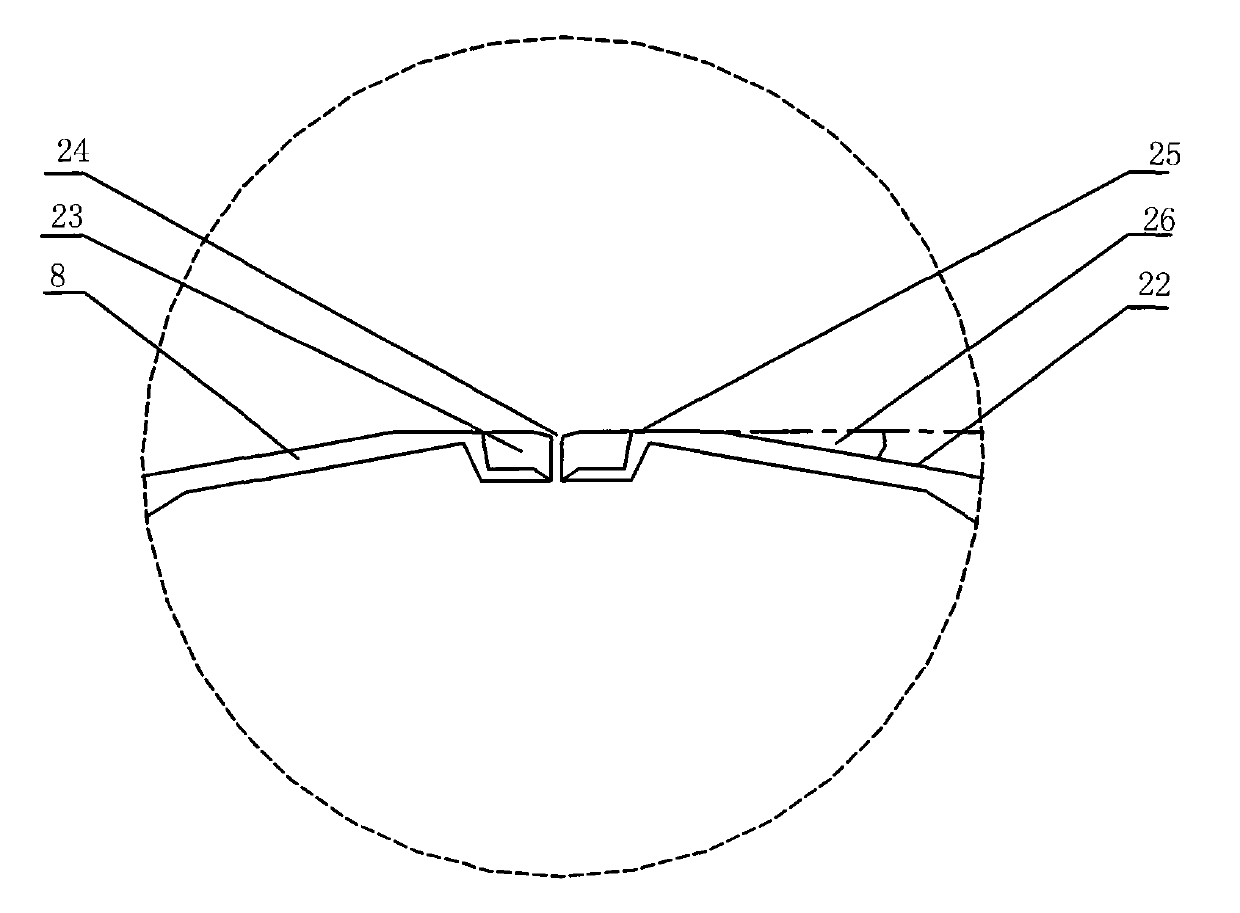

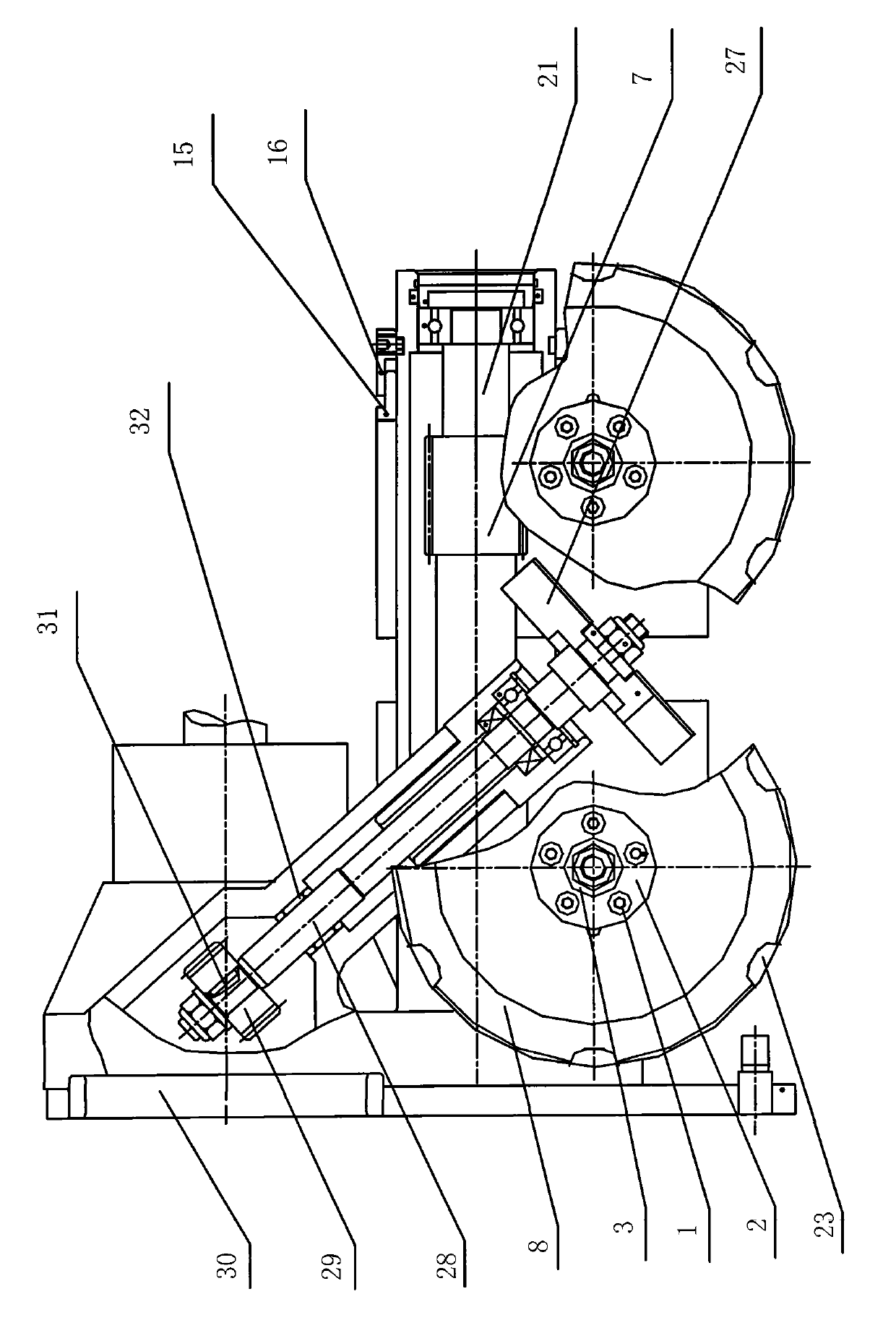

[0013] The specific implementation manners and related technical problems of the present invention will be further described in detail below in conjunction with the accompanying drawings. Since the advent of the cigarette machine, the continuous rolling of cigarettes has been carried out according to the following principle: first, the shredded tobacco is made into a continuous shredded tobacco bundle, and then rolled into continuous tobacco rods longitudinally along the shredded tobacco bundle by a continuously running cigarette paper belt, and then The continuous tobacco rod is cut into equal length cigarettes. The shredded tobacco in each equal-length cigarette is uneven, with more shredded tobacco at the two ends and a tighter structure, and less shredded tobacco in the middle with a looser structure. So the shredded tobacco in the continuous tobacco rod is also uneven, showing a tight and loose structure, and the continuous shredded tobacco bundle also needs to form a str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com