Cigarette weight control system starting position predicting method and system based on GPR model

A technology for starting position and weight control, applied in tobacco, cigarette manufacturing, applications, etc., can solve the problems of poor model robustness, low prediction accuracy adaptability, unsatisfactory static model prediction performance, etc., to reduce convergence time, reduce wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

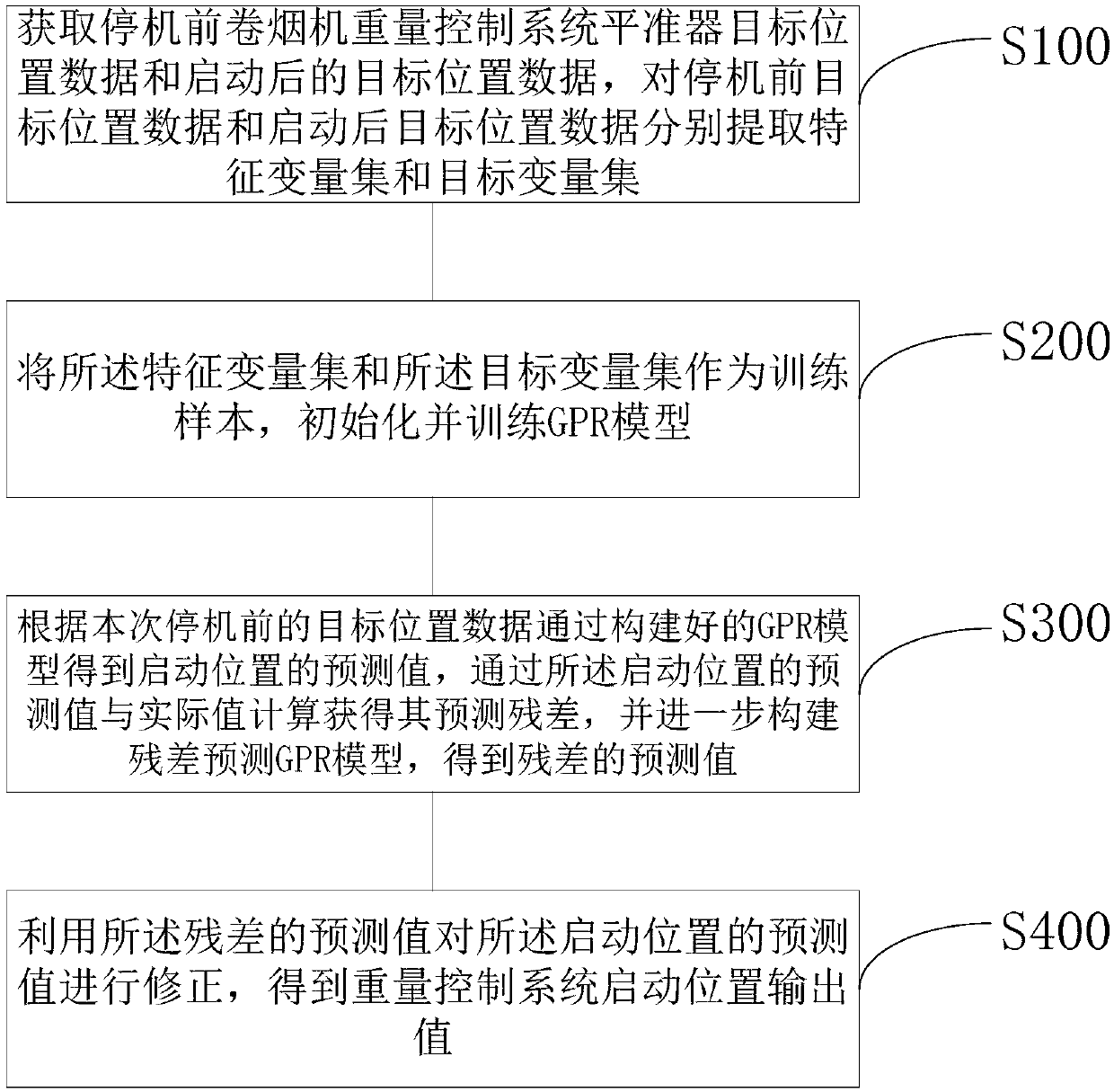

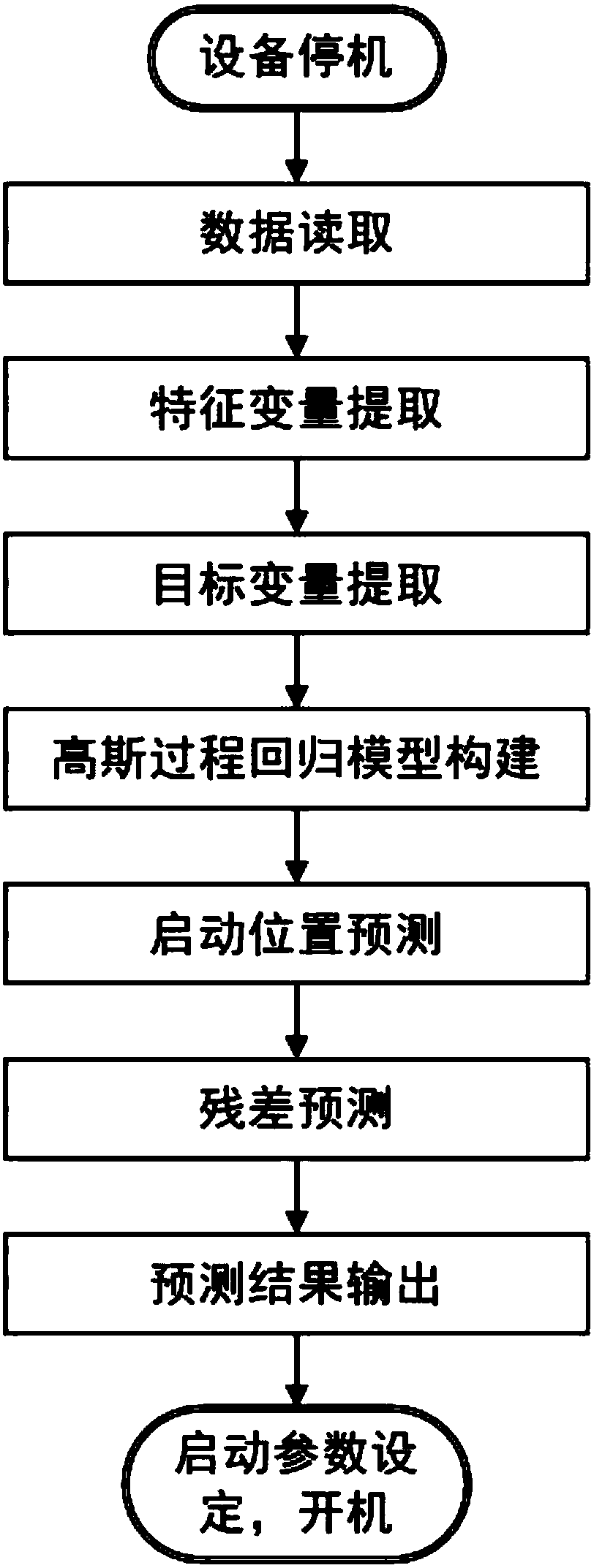

[0091] For the currently widely used ZJ112 coiling unit to combine the above methods for verification, such as figure 2 Shown is the flow chart of the starting position prediction of the cigarette weight control system based on the online learning GPR model provided by the present invention in this embodiment, including the specific implementation steps of the method applied in this embodiment:

[0092] After the cigarette machine stops, read the target position data of the collimator before stopping and the target position data after starting in the previous n=5 stop data;

[0093] Standardize the target position data of the collimator before the shutdown, intercept the data 3 minutes before the shutdown, use the previous data to make up for those less than 3 minutes, use the target position of the collimator before the shutdown to construct the target variable set T={T k |k=1,2,...,5};

[0094] Calculate the mean value of the target position in the first 3 seconds after st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com