Tobacco feed and transport unit in a machine for manufacturing tobacco products

a technology which is applied in the field of tobacco feed and transportation unit in a machine for manufacturing tobacco products, can solve the problems of affecting the quality of cigarettes, the pins are completely detached from the roller, and the quality of cigarettes is ultimately affected, so as to achieve the effect of rapid and easy placemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

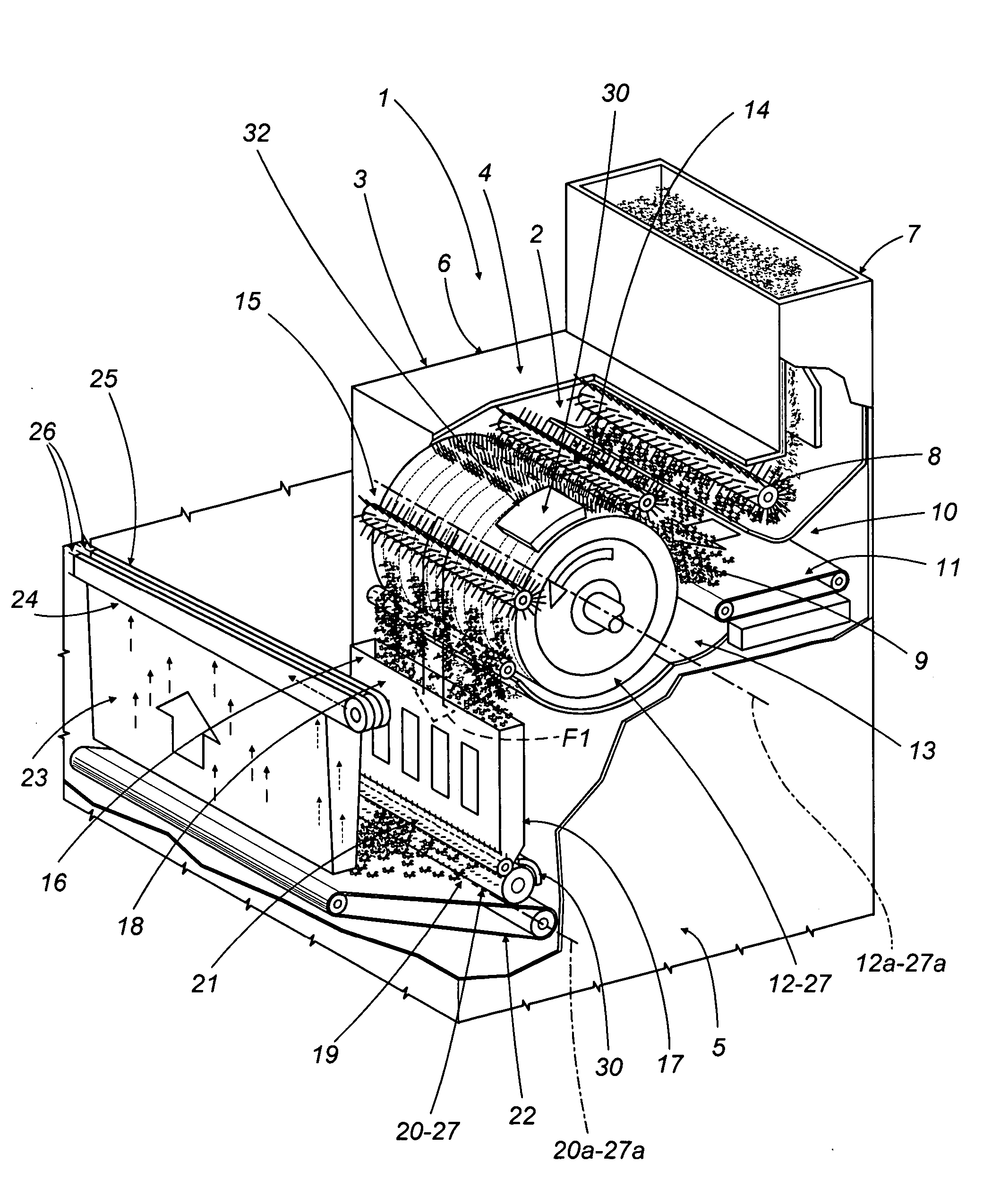

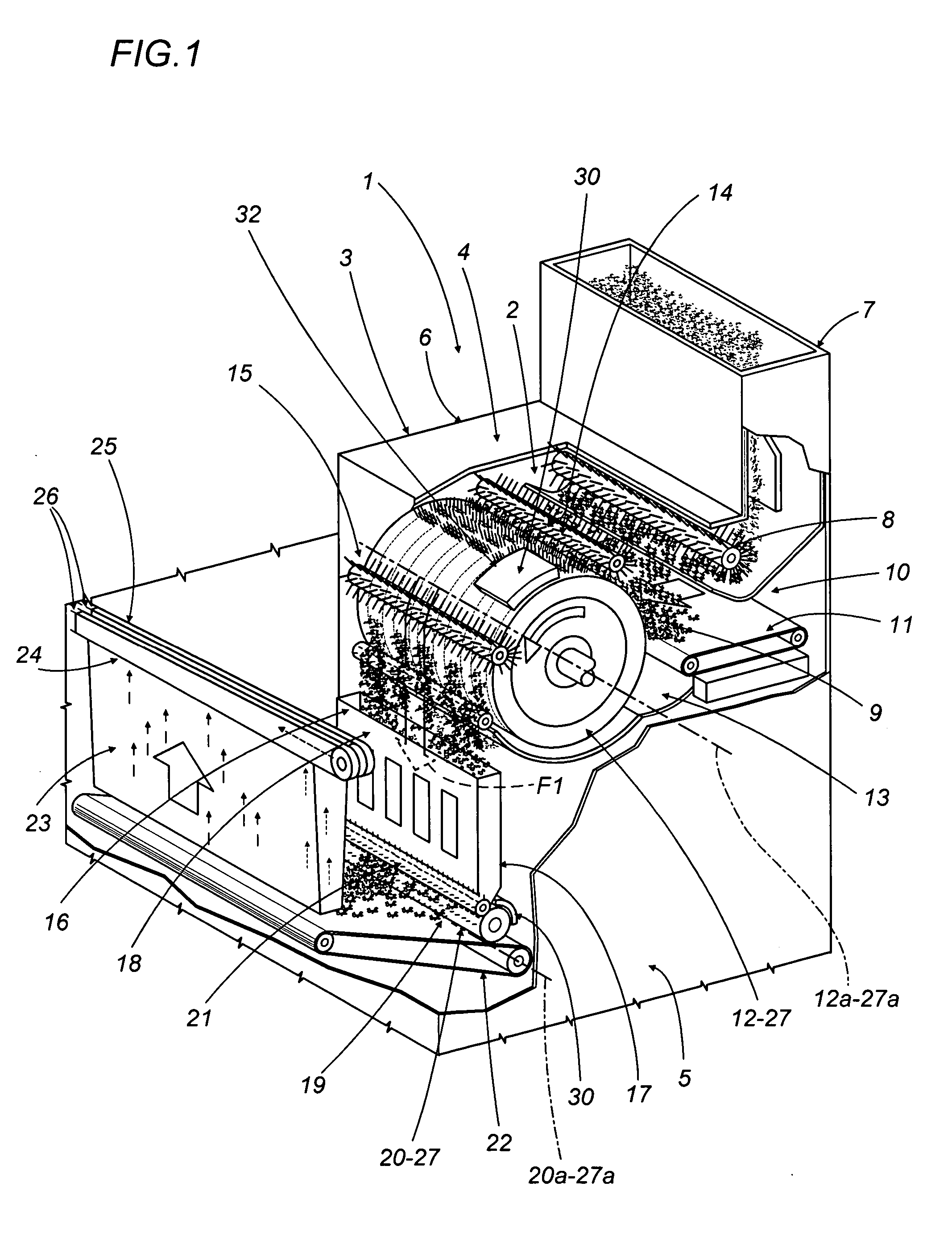

[0017] With reference to FIG. 1, which shows an infeed portion of a cigarette maker, the infeed portion is denoted 1 in its entirety and comprises a tobacco feed and transport unit 2 serving to transform a mass of shredded tobacco into a continuous flow of tobacco particles.

[0018] The components of the feed and transport unit 2 are housed in a vertically extending enclosure 3 delimited uppermost by a horizontal wall 4 and on either side by two vertical walls 5 and 6.

[0019] The infeed portion 1 presents an inlet duct 7 extending upward from the horizontal wall 4, and below the duct, internally of the enclosure 3, a power driven toothed roller 8 by which the shredded tobacco 9 is directed down into a lower chamber 10 delimited at the bottom by a conveyor belt 11.

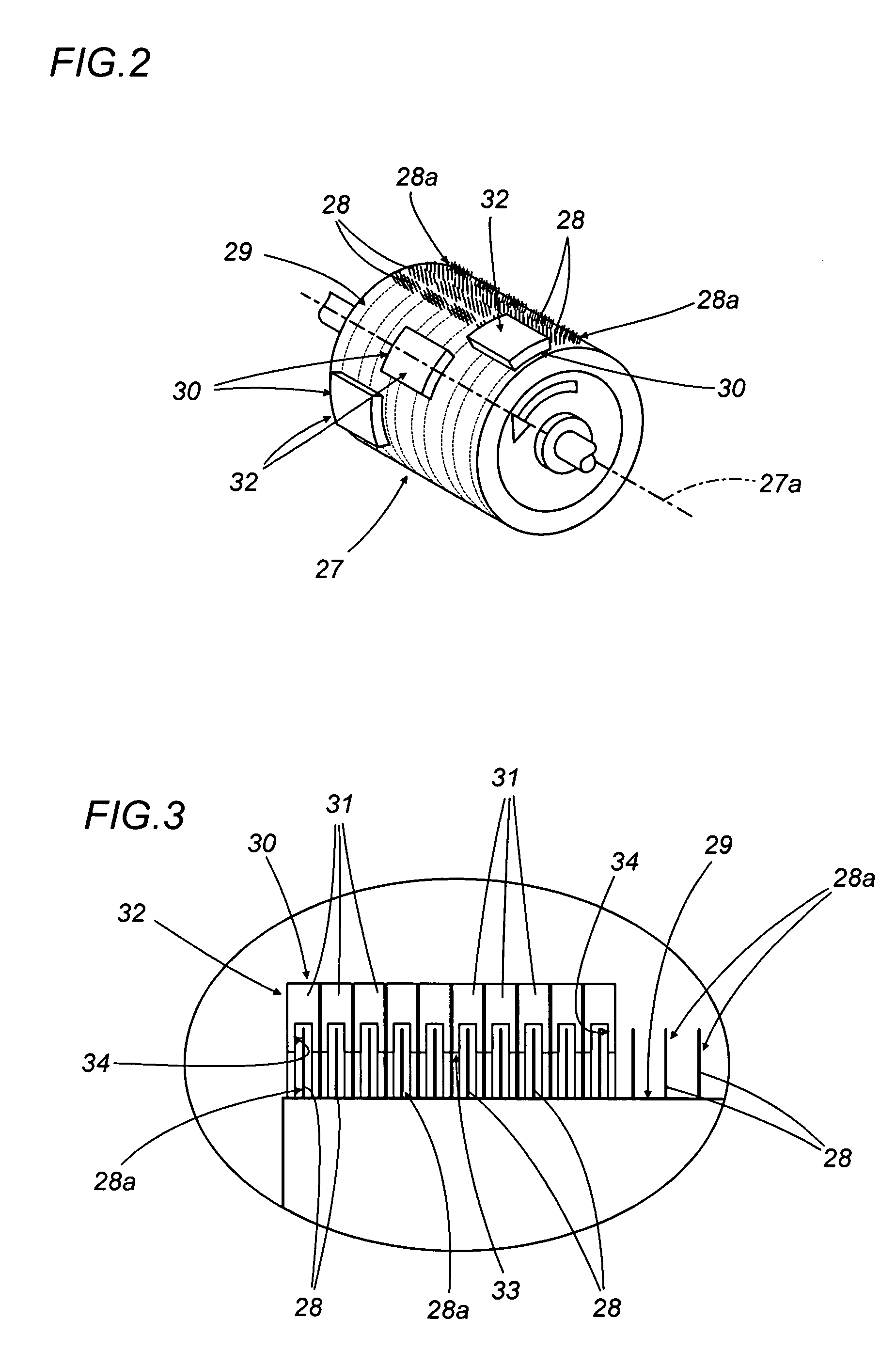

[0020] The chamber 10 accommodates a carding drum, or roller 12, rotatable about an axis 12a transverse to the two side walls 5 and 6, which forms part of a carding unit 13 and occupies a position adjacent to the downstream...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com