A cigarette making machine equipped to manufacture two continuous cigarette rods simultaneously

A technology for simultaneously manufacturing and manufacturing machines, applied in the manufacture of cigarettes, tobacco, signal transmission systems, etc., can solve problems such as degradation and oppression of tobacco physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

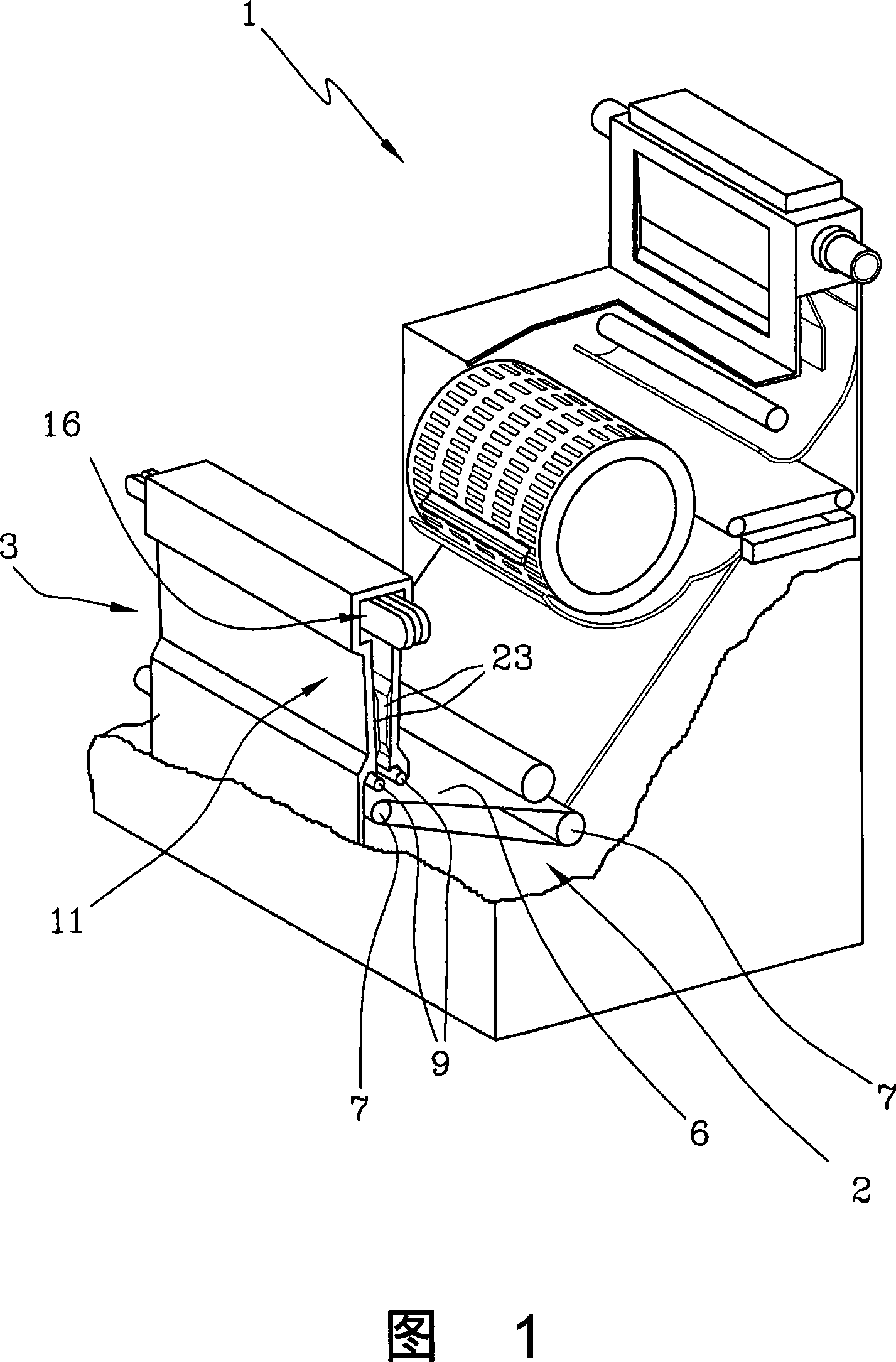

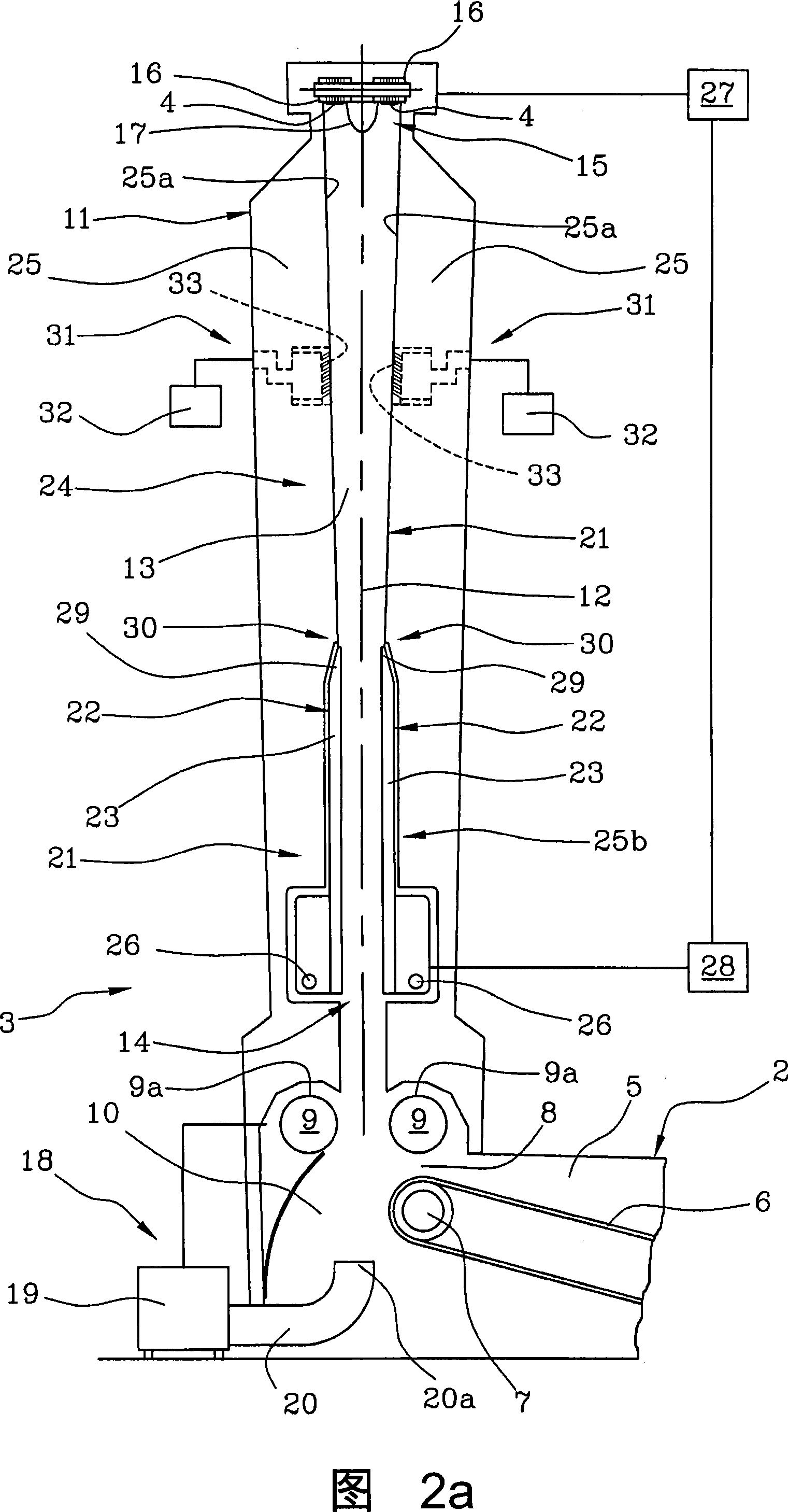

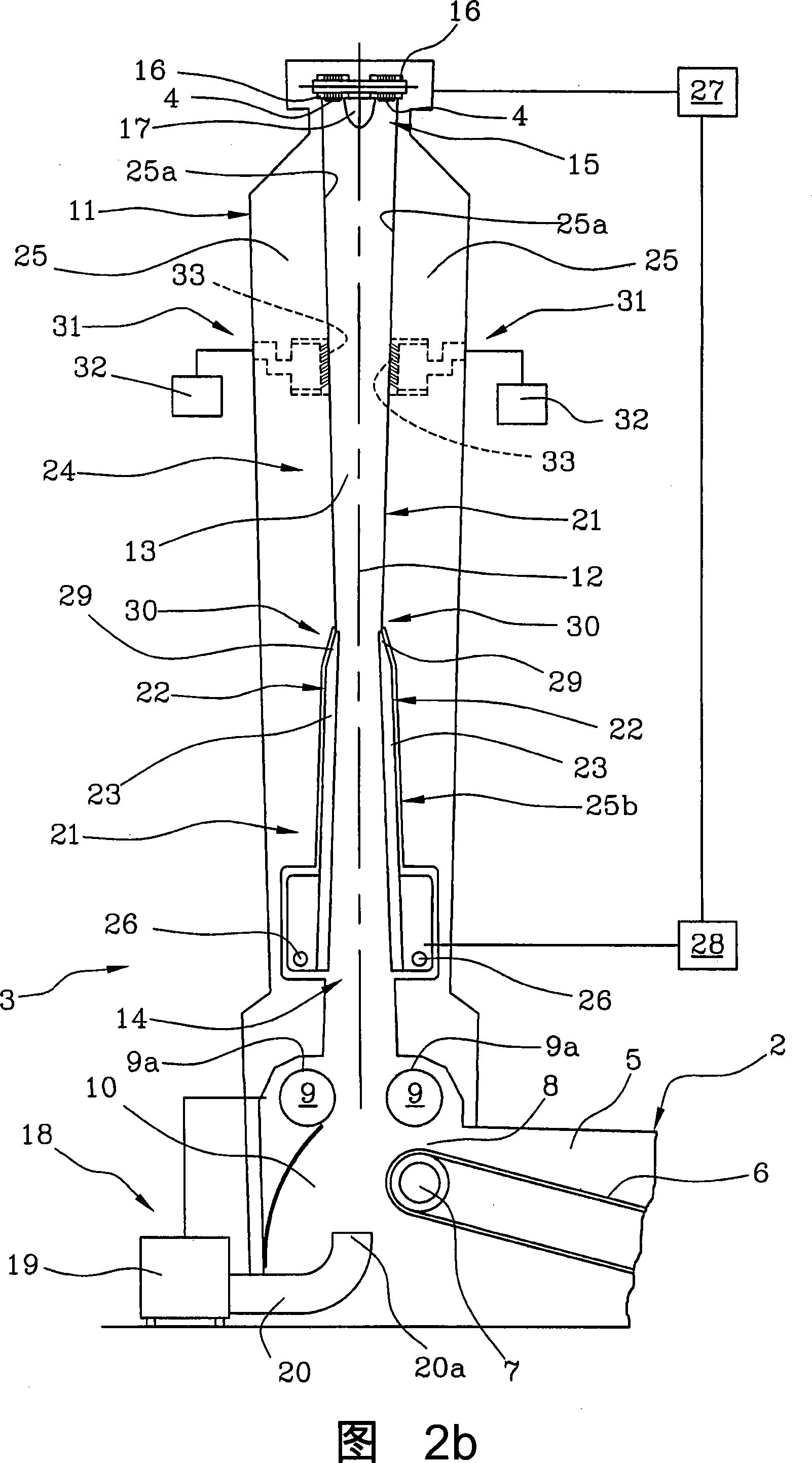

[0017] Referring to Figure 1, numeral 1 generally designates a machine equipped to manufacture two consecutive cigarette rods simultaneously.

[0018] The machine 1 has a first section, referenced 2, through which a continuous flow of chopped tobacco particles is fed to a second section, referenced 3; during their passage through the second section 3, the particles are distributed and Two continuous tobacco streams 4 are formed.

[0019] In particular, the first part 2 comprises a substantially horizontal inner duct 5 housing a power drive transmission belt 6 which circulates at opposite ends around two pulleys 7, only visible in FIG. One of the two pulleys 7. The top of the conveyor belt 6 is positioned such that a carding unit of the usual type (as shown in Figure 1) takes the shredded tobacco and conveys it over a downstream pulley 7 by means of two counter-rotating rollers 9 and 10 about parallel horizontal axes into the uppermost communicating feed chamber 8 with the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com