Negative pressure automatic regulating system for material-feeding and cigarette-rod-forming machine of cigarette maker

A technology of automatic adjustment and rod forming machine, which is used in tobacco, conveyors, cigarette manufacturing and other directions, and can solve the problems that the negative pressure valve cannot be automatically opened and the size of the negative pressure value is automatically adjusted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings of the invention.

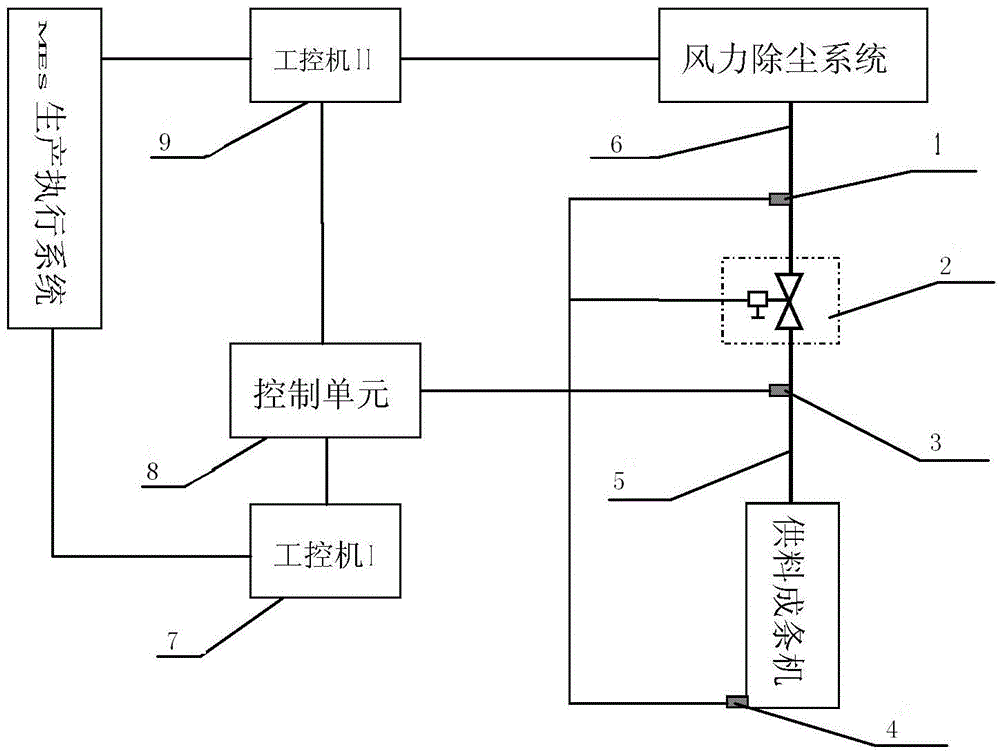

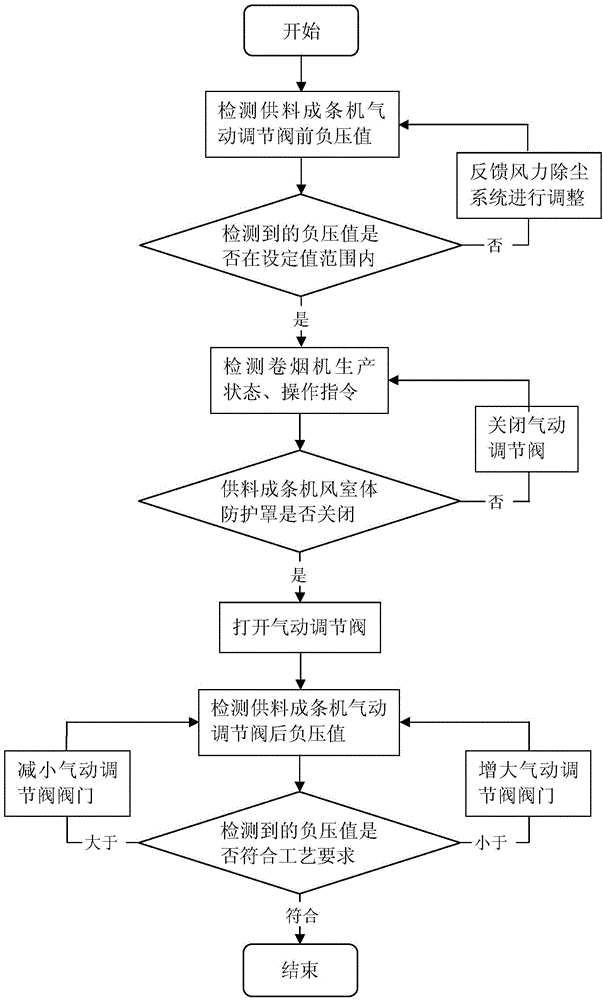

[0017] See attached figure 1 , the negative pressure automatic adjustment system of the cigarette machine feeding and forming machine, including a pneumatic regulating valve 2 installed on each group of cigarette machines, a negative pressure sensor 1 before the valve, a negative pressure sensor 3 behind the valve, a control unit 8, and a control unit 8 on the cigarette machine. An industrial computer I (7) installed and an industrial computer II (9) installed in the wind dust removal system. The pneumatic control valve 2 is installed on the negative pressure air pipe of the feeding strip machine, the negative pressure sensor 1 is installed in front of the negative pressure air pipe 6 of the pneumatic control valve 2, and the negative pressure air pipe 5 is installed behind the pneumatic control valve 2 The post-valve negative pressure senso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com