Device for offline and online screening of cut tobacco from removed stem slivers of cigarette maker

A technology of cigarette making machine and shredded tobacco, which is applied in the direction of separating solids from solids with airflow, application, tobacco, etc. It can solve the problems of rough process, inability to separate, and large footprint, and achieve convenient adjustment of valve position Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

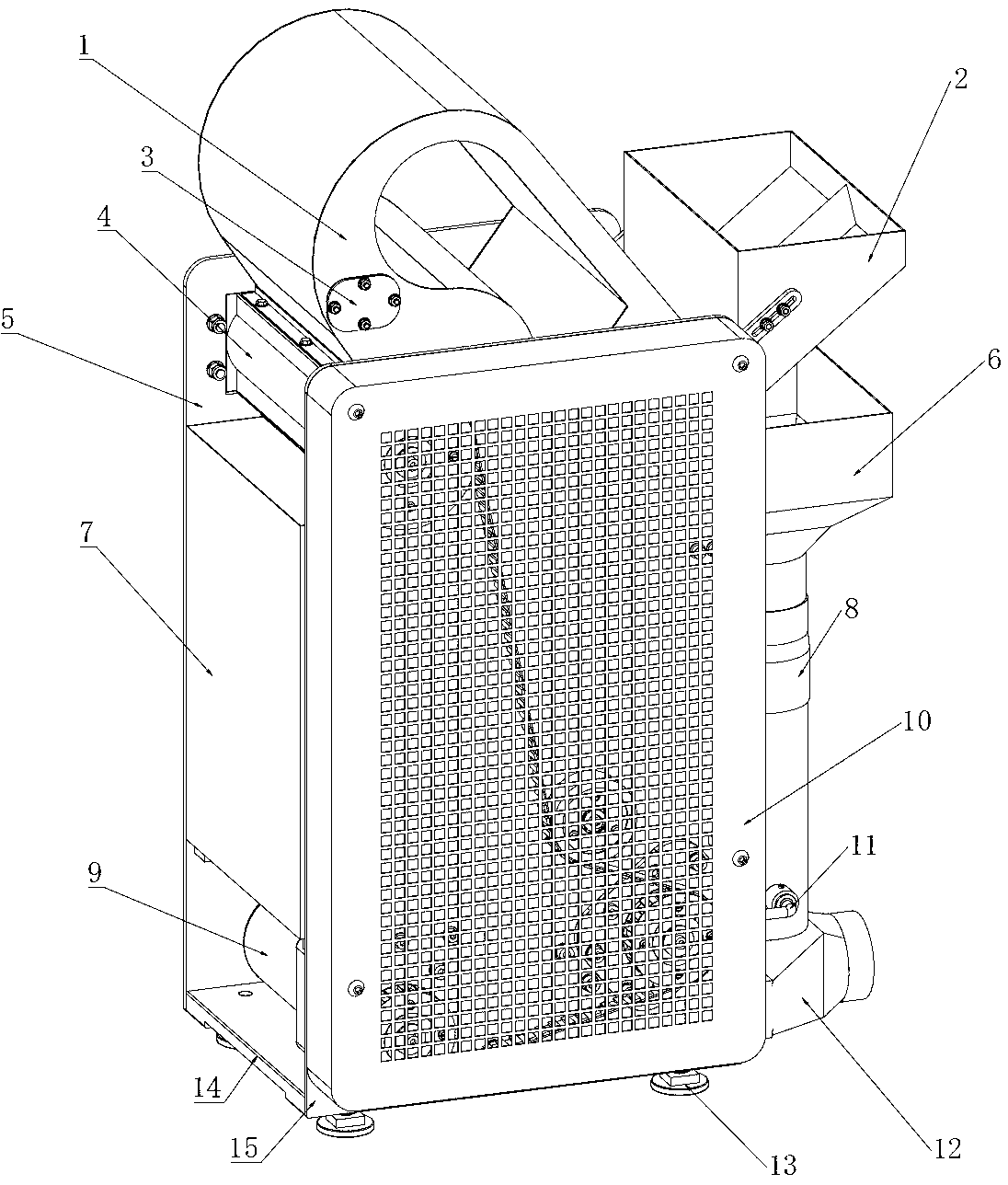

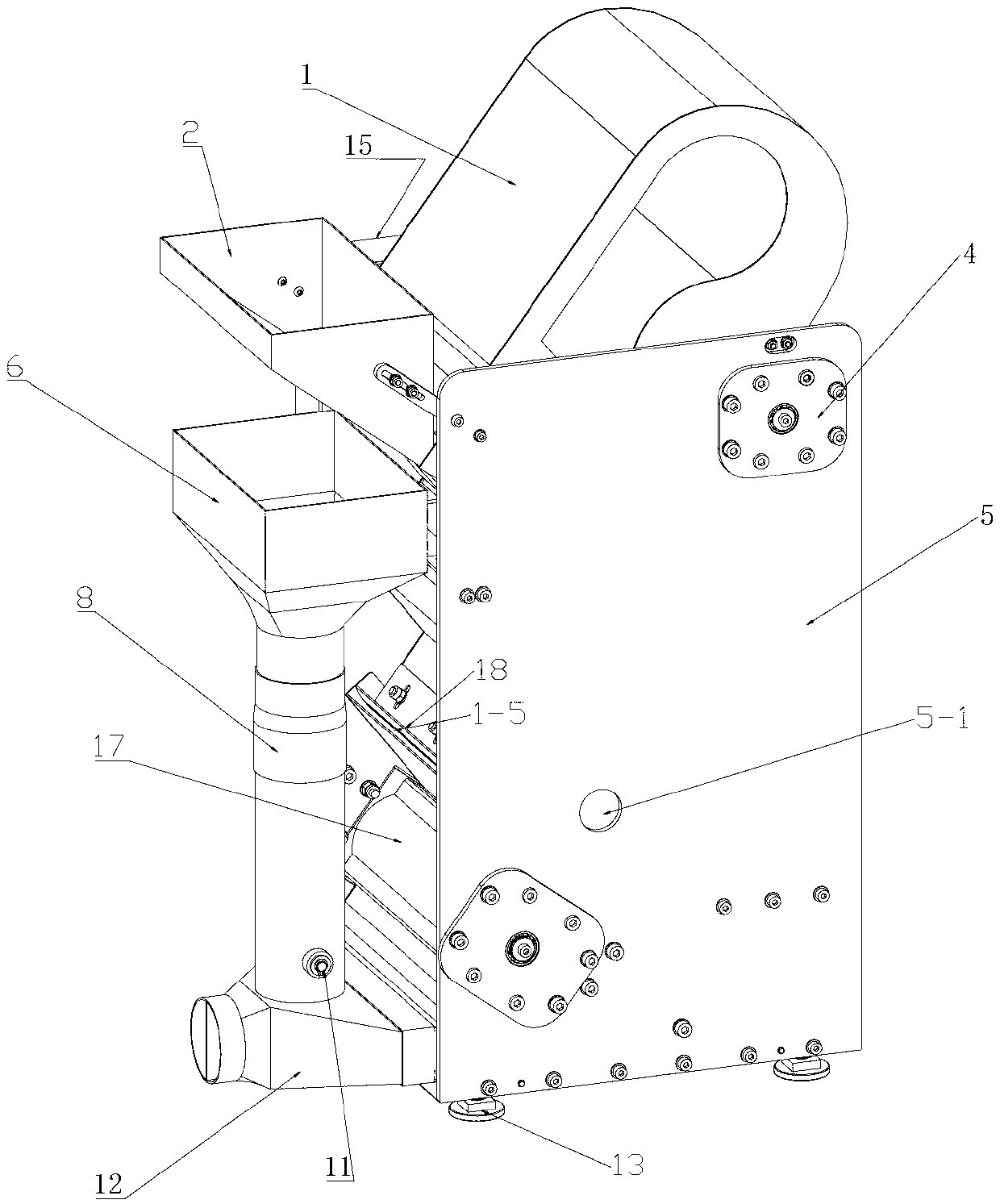

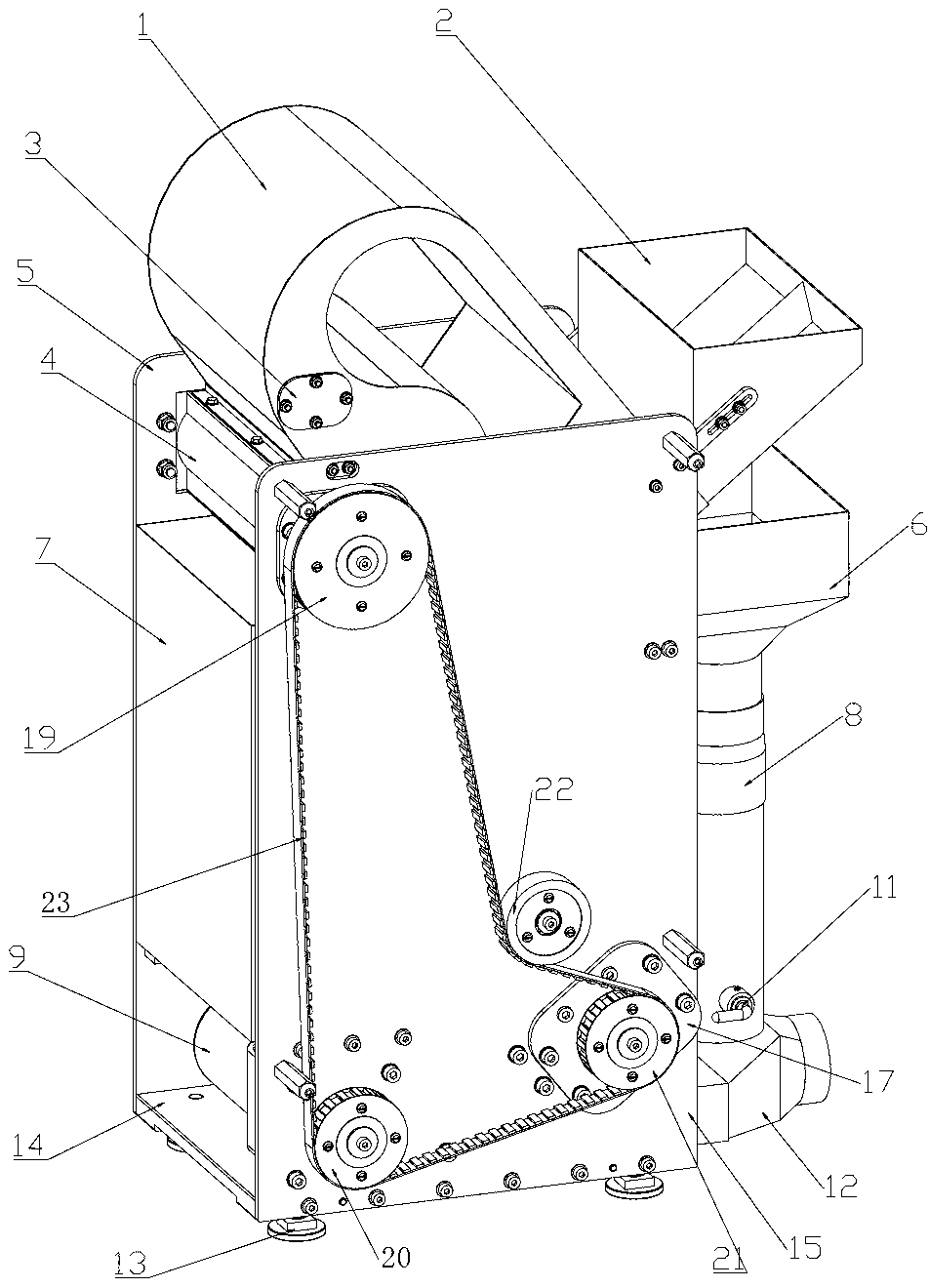

[0061] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0062]Hereinafter, the stem sticks that are mixed with or adhered to more shredded tobacco and removed through the shredded stem separation process during the operation of the cigarette machine are called "stem sticks containing shredded tobacco", and the "stem sticks containing shredded tobacco" that have been screened by this device Sign" is called "stalk sign".

[0063] Due to the low position of the discharge port of the shredded tobacco sticks of PROTOS70 and other models of cigarette machines, in order not to affect the equipment layout, the appearance of the device should be reduced as much as possible on the premise that all the shredded tobacco sticks can be removed when the screening equipment is produced at full speed. As far as possible, the device can be placed in the lower part of the air chamber of the cigarette machine, which contains th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com