Cigarette making machine

A technology of cigarette maker and shredded tobacco, which is applied in the directions of tobacco, cigarette manufacturing, application, etc., can solve problems such as troublesome filling process of shredded tobacco, and achieve the effect of simple structure and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

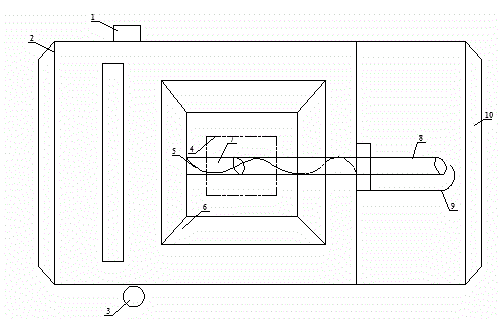

[0012] Such as figure 1 The shown cigarette maker includes a base, a cigarette maker body 2 is arranged on the base, a motor 4 is arranged in the cigarette maker body 2, a feed inlet 6 is arranged on the cigarette maker body 2, shredded tobacco is arranged in the feed inlet 6 The material tube 7 is provided with a push spring 5 outside the shredded tobacco material tube 7 , and the push spring 5 is set on the smoke sleeve 8 . Put the shredded tobacco into the feeding port 6, and roll the shredded tobacco into the cigarette casing 8 by pushing the spring 5. A power interface 1 is provided on one side of the cigarette maker body 2, and a cigarette tightness adjustment 3 is arranged on the other side of the cigarette maker body 2; Roll the shredded tobacco into the pipe by adjusting the tightness of the tobacco 3. Anti-slip lines 10 are provided at the bottom of the cigarette maker body 2 to play a fixing role.

[0013] Finally, it should be noted that the above embodiments ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com