Residue oil hydrogenation catalyst and preparation method thereof

A technology of residual oil hydrogenation and catalyst, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, hydrocarbon oil cracking, etc. It can solve the problems of reduced mechanical strength, failure of active metals to reach a high accumulation layer, and channel collapse. , to achieve the effect of reducing polarity and free energy, weakening capillary pressure, and improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

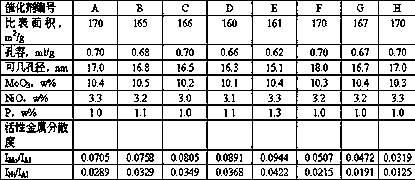

Embodiment 1

[0023] (1) Weigh 100g of industrially produced residual oil hydrodemetallization catalyst carrier alumina, spray with 100ml of Span-80 ethanol solution with a concentration of 0.5g / 100ml, and then vacuum-dry at 60°C for 5 hours;

[0024] (2) Preparation of impregnation solution: add ammonium molybdate, nickel nitrate and phosphoric acid into water to dissolve, then add sodium polyacrylate to obtain an impregnation solution, in which the content of molybdenum oxide is 25.7 g / 100ml, and the content of nickel oxide is 5.8g / 100ml , the content of phosphorus is 2.1g / 100ml, and the content of sodium polyacrylate is 0.5 g / 100ml. The prepared impregnating solution was used to impregnate the above-mentioned dried catalyst carrier for 2 hours, then dried at 120° C. for 5 hours, and then calcined at 500° C. for 4 hours to obtain residual oil hydrogenation catalyst A.

Embodiment 2

[0026] Same as Example 1, except that when spraying with ethanol solution containing Span-80, the concentration of Span-80 used is the ethanol solution of 1.0g / 100ml, vacuum-dried at 60°C for 5 hours, and then use the ethanol solution of Example 1 The impregnation solution in 1 impregnates the dried support to obtain residue hydrogenation catalyst B.

Embodiment 3

[0028] Same as Example 1, except that the content of sodium polyacrylate in the prepared impregnation solution is 1.0g / 100ml, the impregnation time is 3 hours, then dried at 120°C for 5 hours, and roasted at 500°C for 4 hours to obtain Residue Hydrogenation Catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com