Method for determining reliability of cigarette maker cigarette loose end detector

A detection instrument, cigarette machine technology, applied in the fields of tobacco, cigarette manufacturing, application, etc., can solve the problems of economic loss of enterprises, inability to make scientific judgments, substandard products, etc., to avoid economic losses, easy to grasp and promote the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

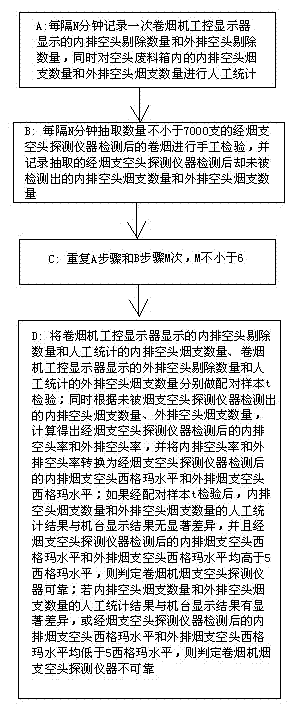

[0016] like figure 1 As shown, the method for judging the reliability of the cigarette machine cigarette empty end detection instrument according to the present invention comprises the following steps

[0017] A: Every N minutes, record the number of inner empty ends and outer empty ends removed displayed on the industrial control display of the cigarette machine, and at the same time manually count the number of inner empty end cigarettes and outer empty end cigarettes in the empty end waste box;

[0018] B: At intervals of N minutes, not less than 7,000 cigarettes that have been detected by the short-end detection instrument are selected for manual inspection, and the extracted cigarettes that have been detected by the short-end detection instrument but have not been detected are recorded. Quantity and number of empty cigarettes discharged outside;

[0019] C: Repeat step A and step B M times, M not less than 6;

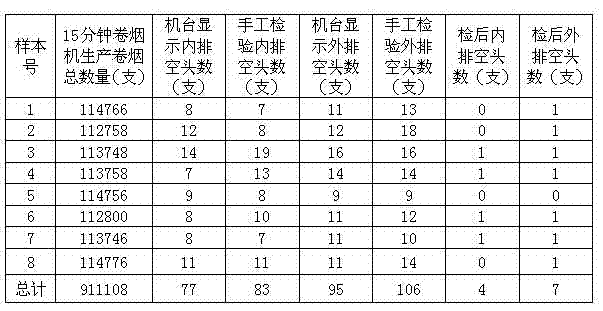

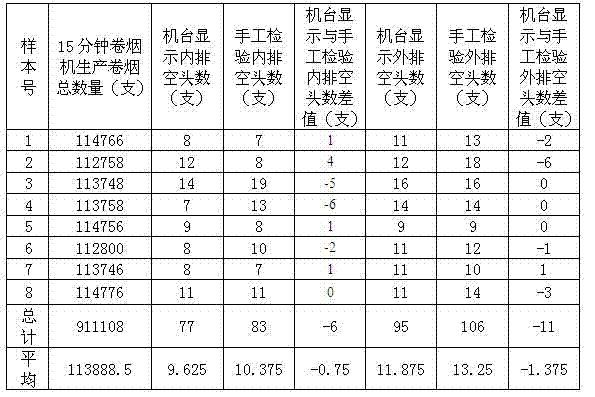

[0020] D: The number of empty ends removed from the inner e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com