Material feeding and strip forming machine of cigarette maker and operation method thereof

A technology for a rod forming machine and a cigarette making machine, which is applied to the operation field of the cigarette machine feeding rod forming machine and the cigarette machine feeding rod forming machine, can solve the problems of easy moisture loss of cut tobacco, broken tobacco, etc. Moisture loss, uniform density, effects of improved uniformity and looseness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

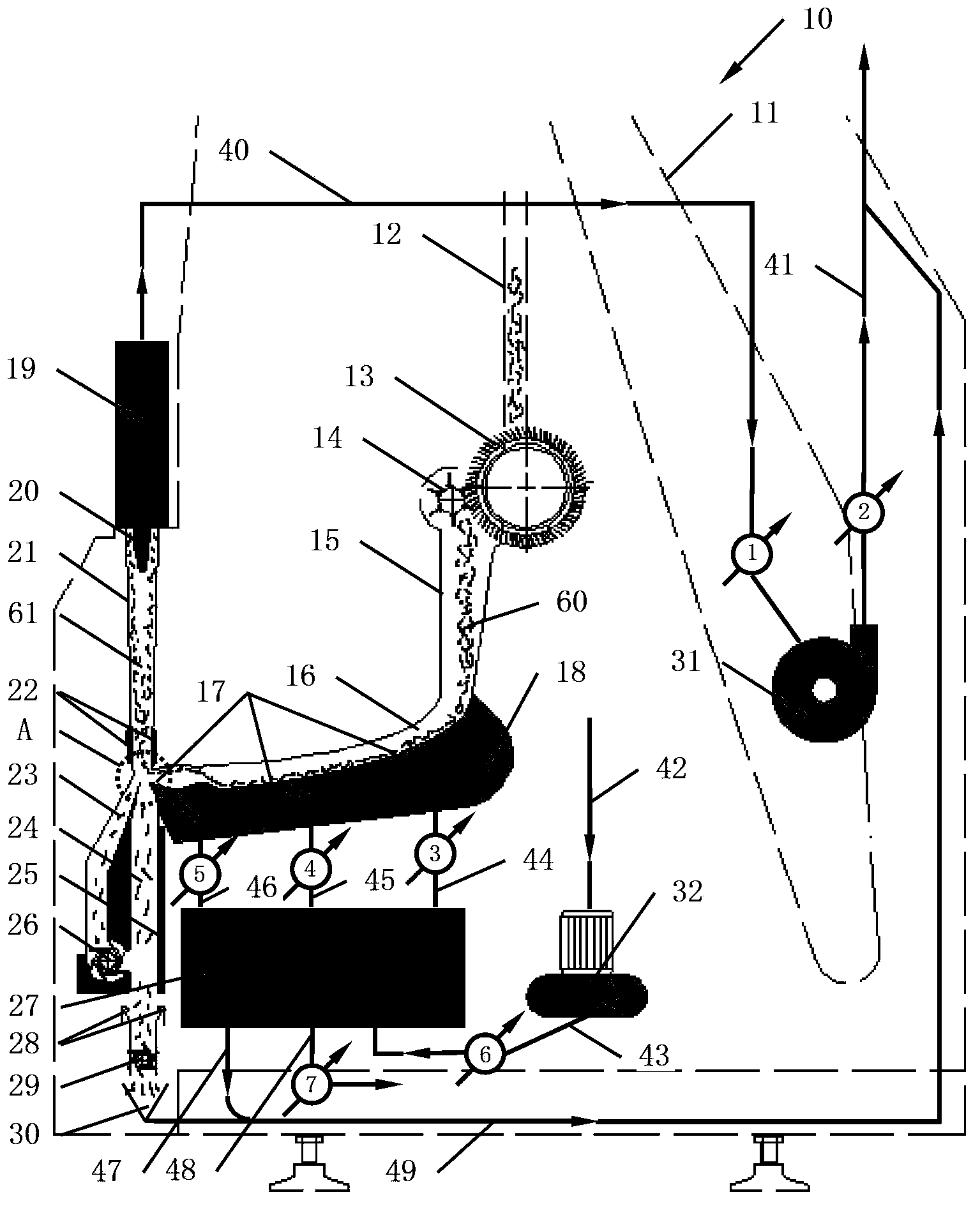

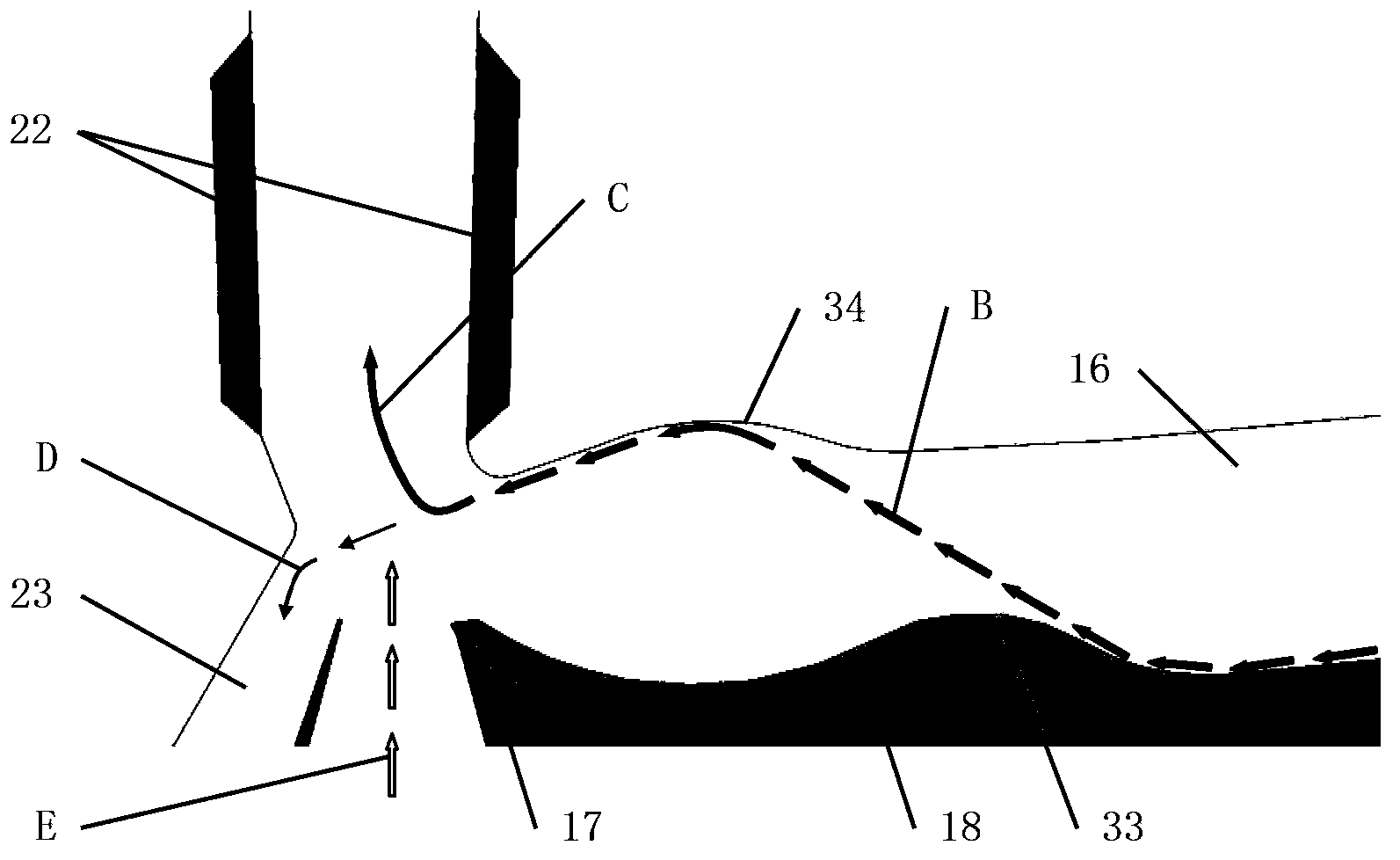

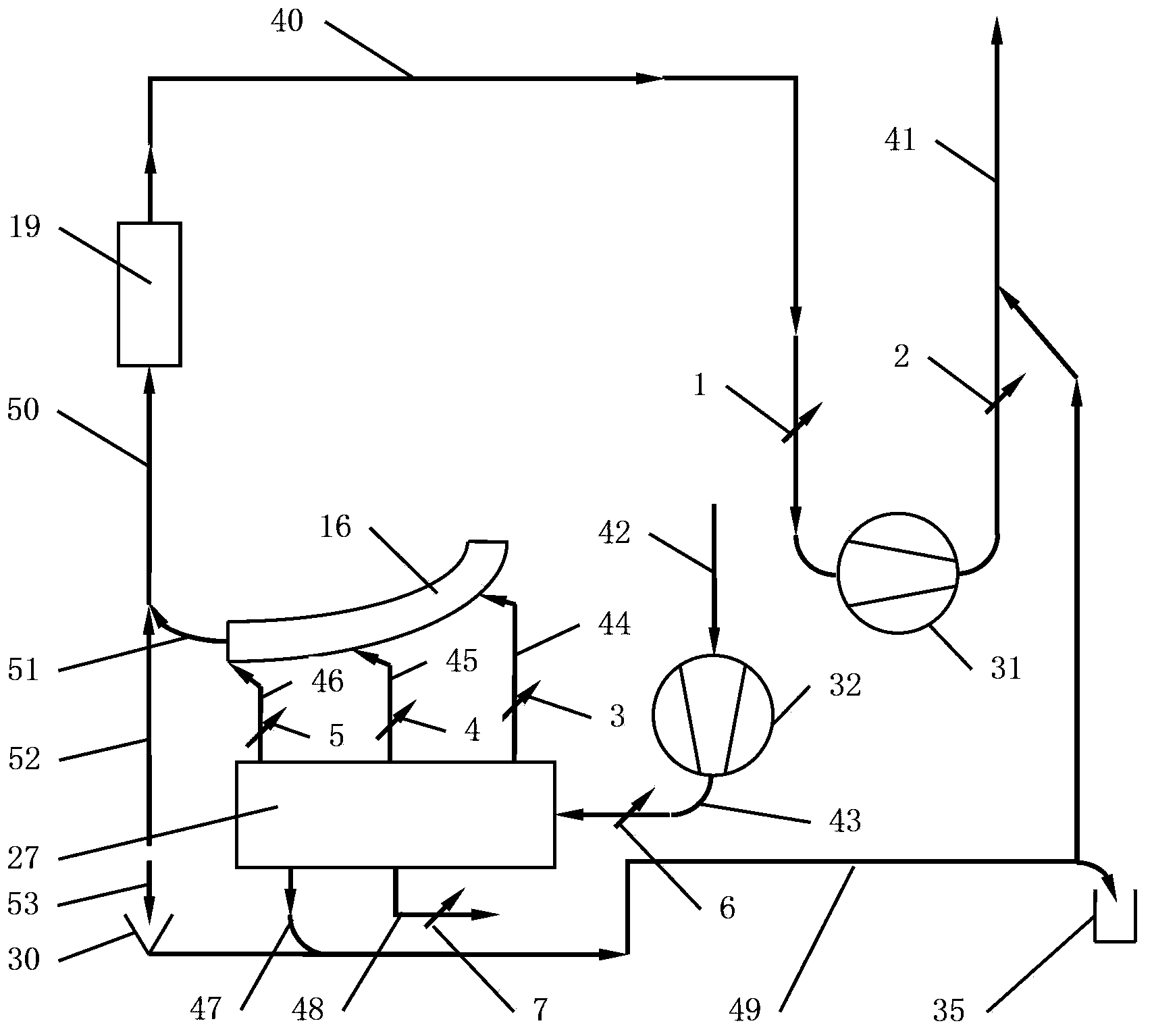

[0065] Such as figure 1 As shown, the cigarette machine feeding rod forming machine 10 of the present invention includes a steep-angle hoist 11, on which the steep-angle hoist 11 is uniformly equipped with tooth plates, and the upper turning of the steep-angle hoist 11 is an exit, and the teeth at the exit plate down;

[0066] The outlet of the steep angle hoist 11 is located above the top inlet of the metering chute 12, and the bottom outlet of the metering chute 12 is provided with a needle roller 13, which is used to quantitatively take out shredded tobacco from the metering chute 12; the metering chute 12 is vertical set up;

[0067] One side of the needle roller 13 is provided with an elastic wire reel 14, and the rotation direction of the elastic wire reel 14 is opposite to that of the needle roller 13; the elastic wire reel 14 is arranged at the top entrance of the doffing channel 15; the doffing channel 15 is arranged vertically;

[0068] The outlet at the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com