Patents

Literature

40results about How to "Play the role of feeding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

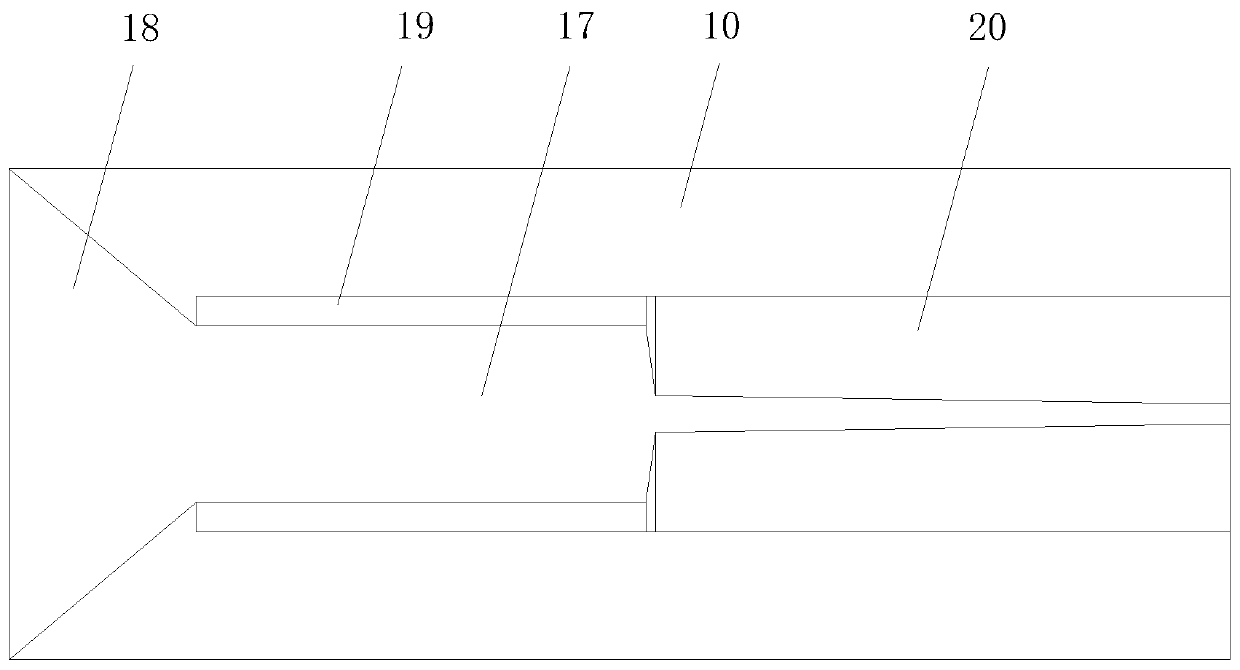

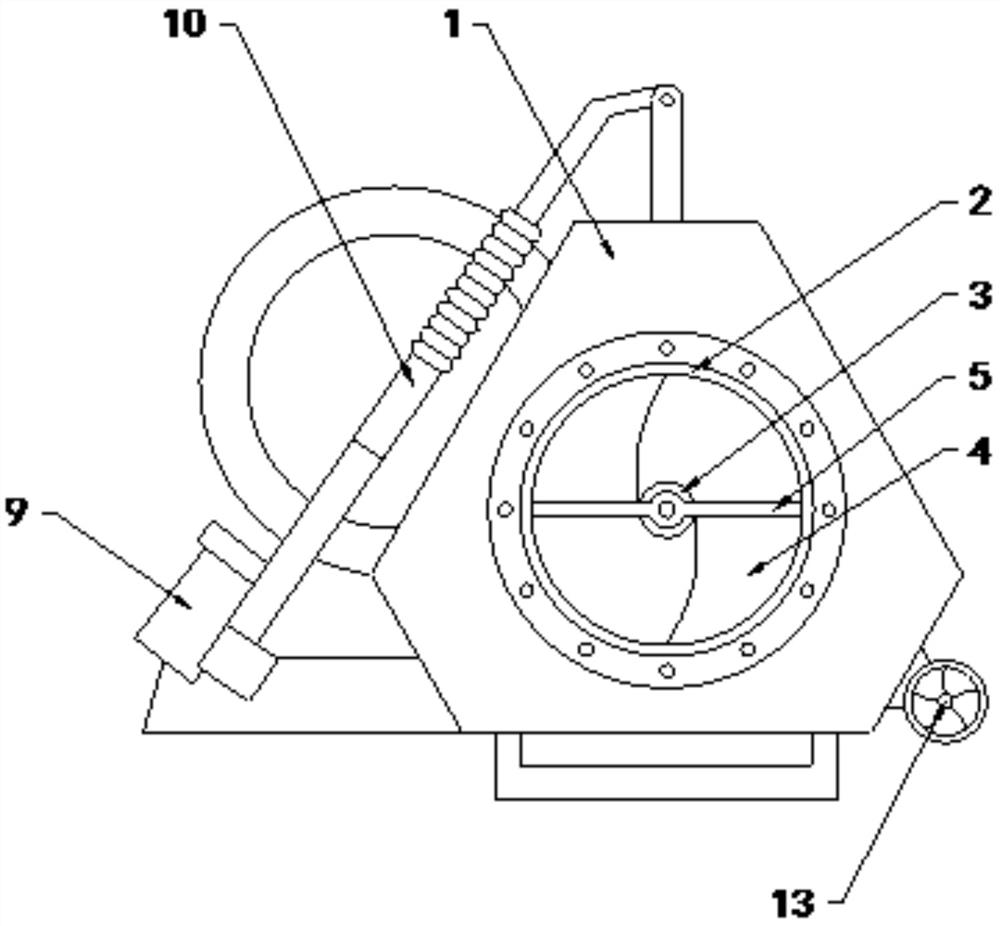

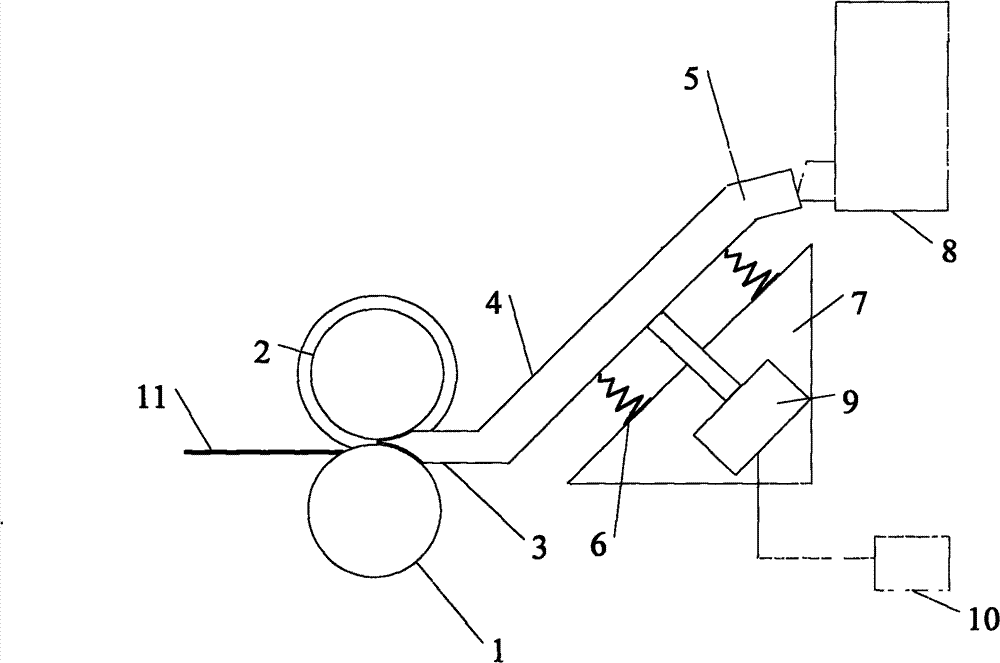

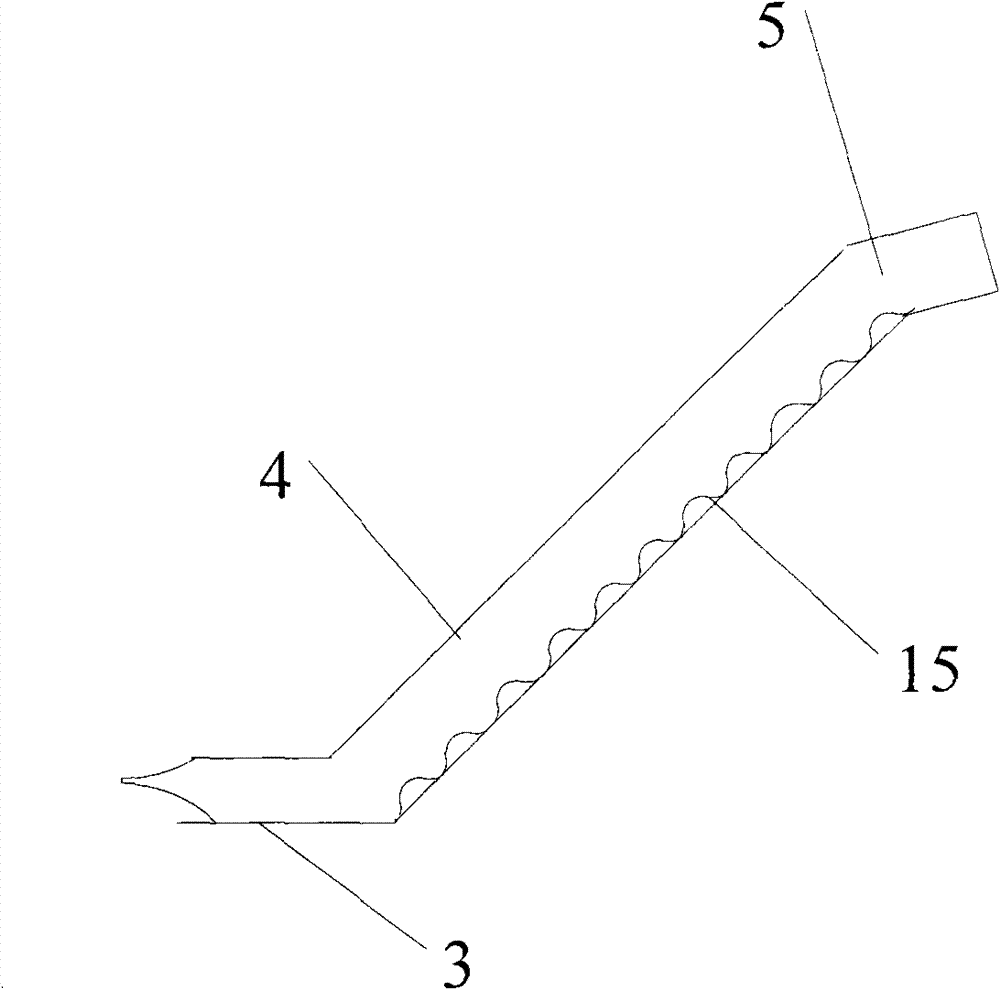

Continuous rheomolding device for manufacturing metal plate strips

InactiveCN101890431AIncreased speed of continuous rheological formingGood formabilityMetal rolling arrangementsEngineeringAlloy

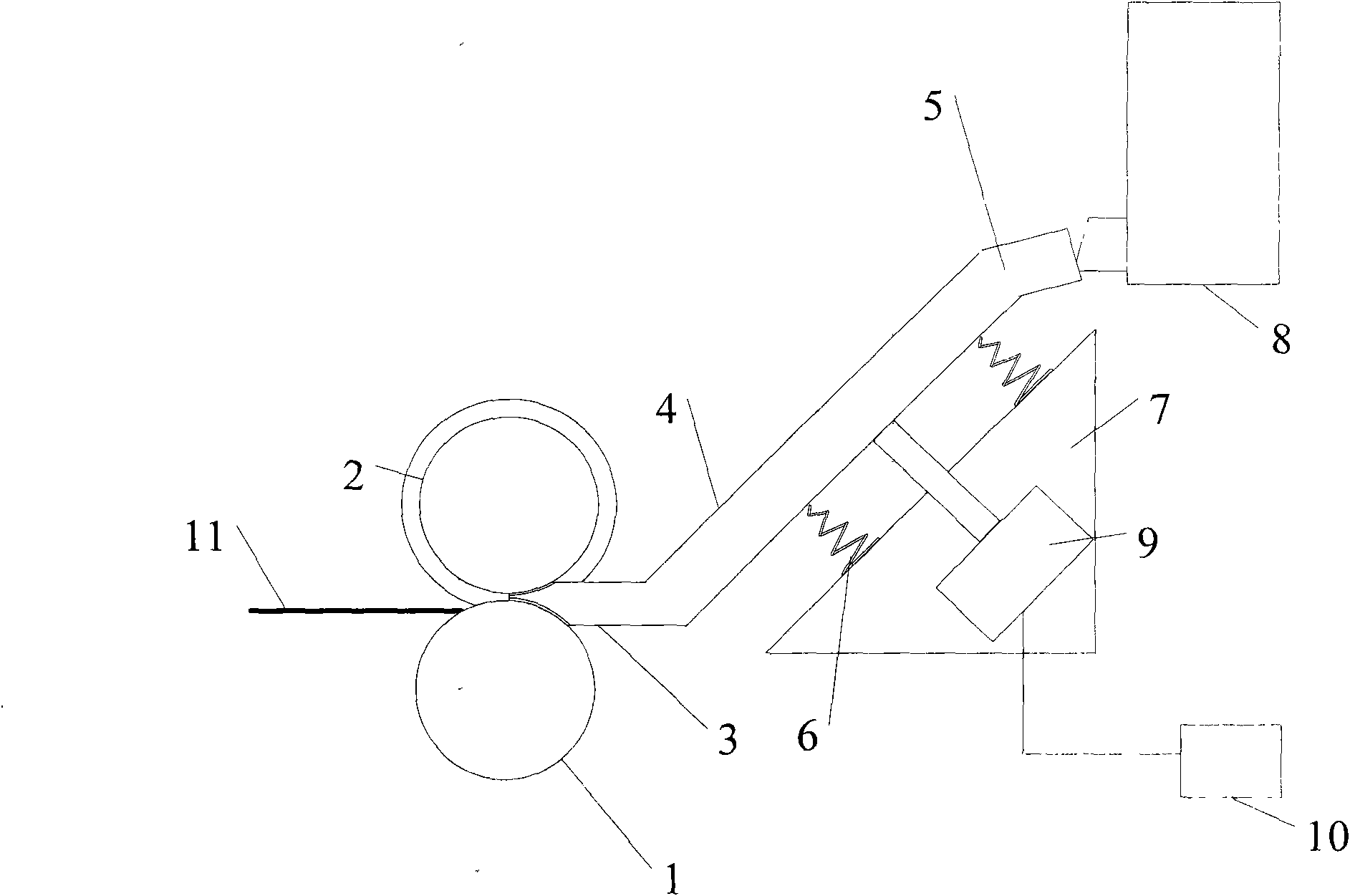

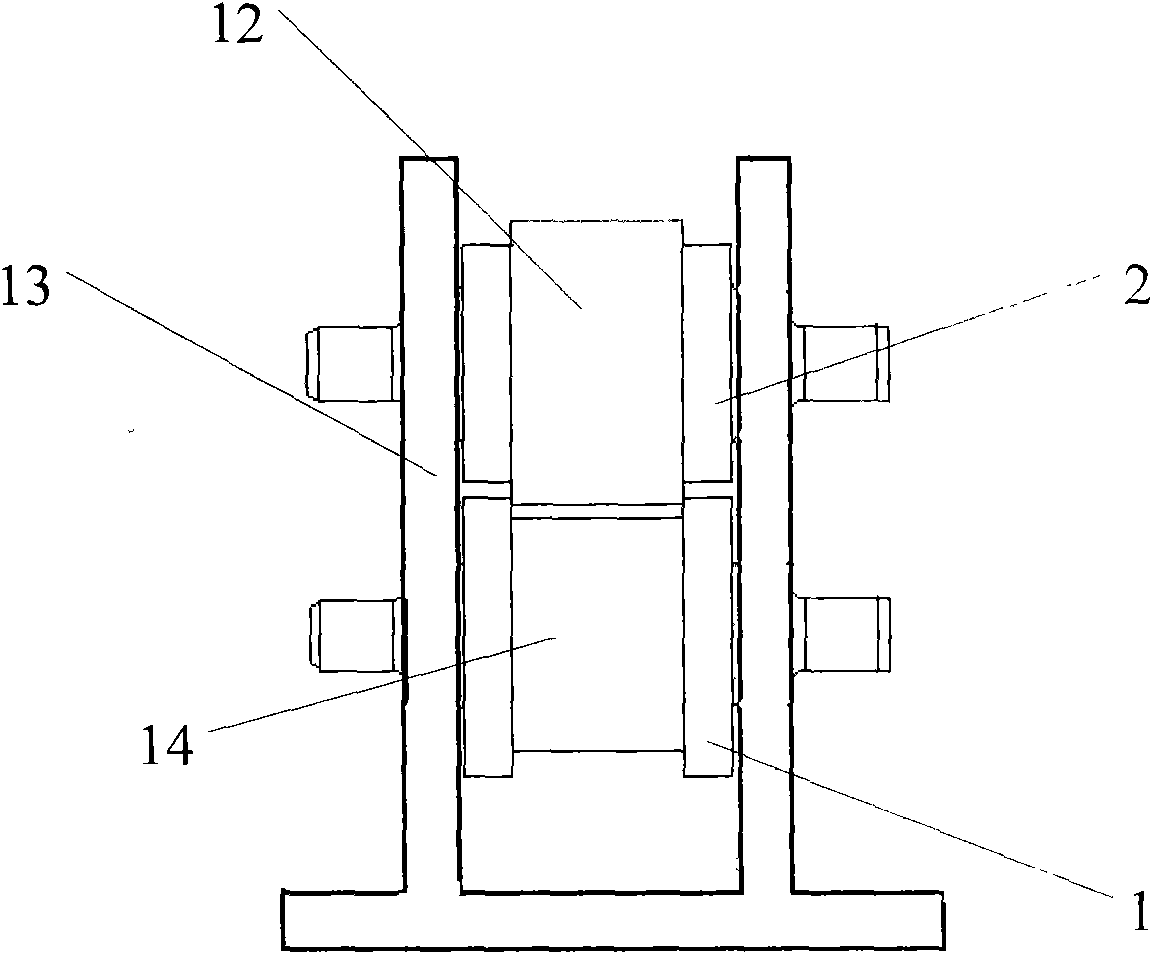

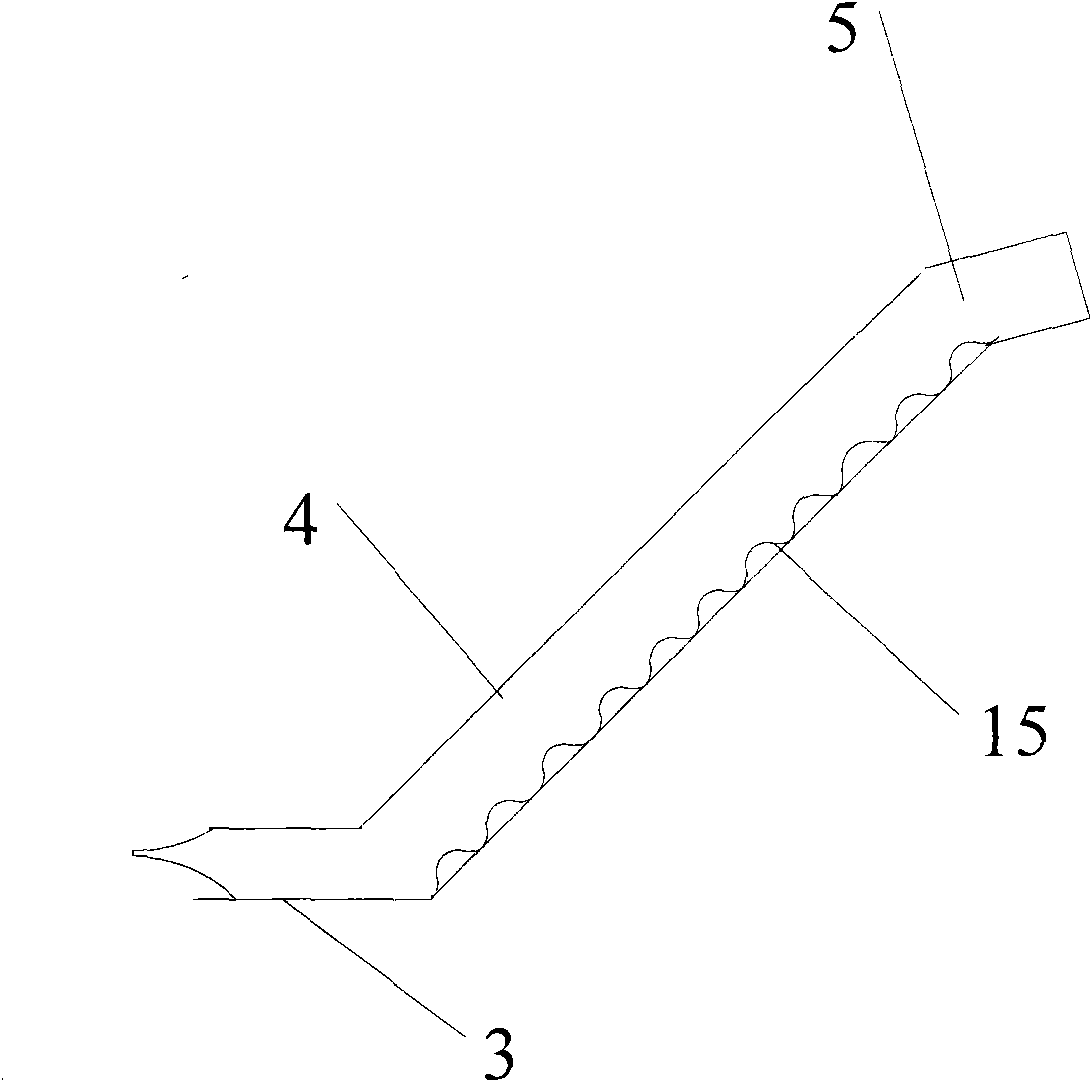

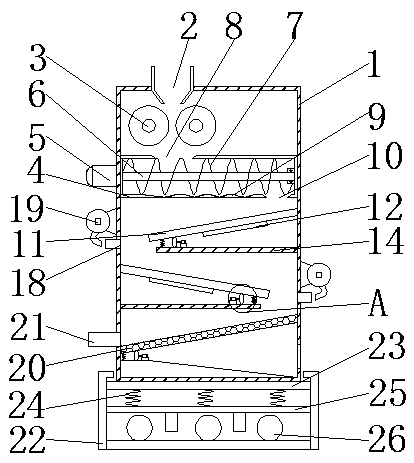

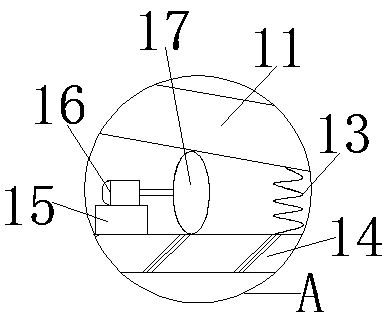

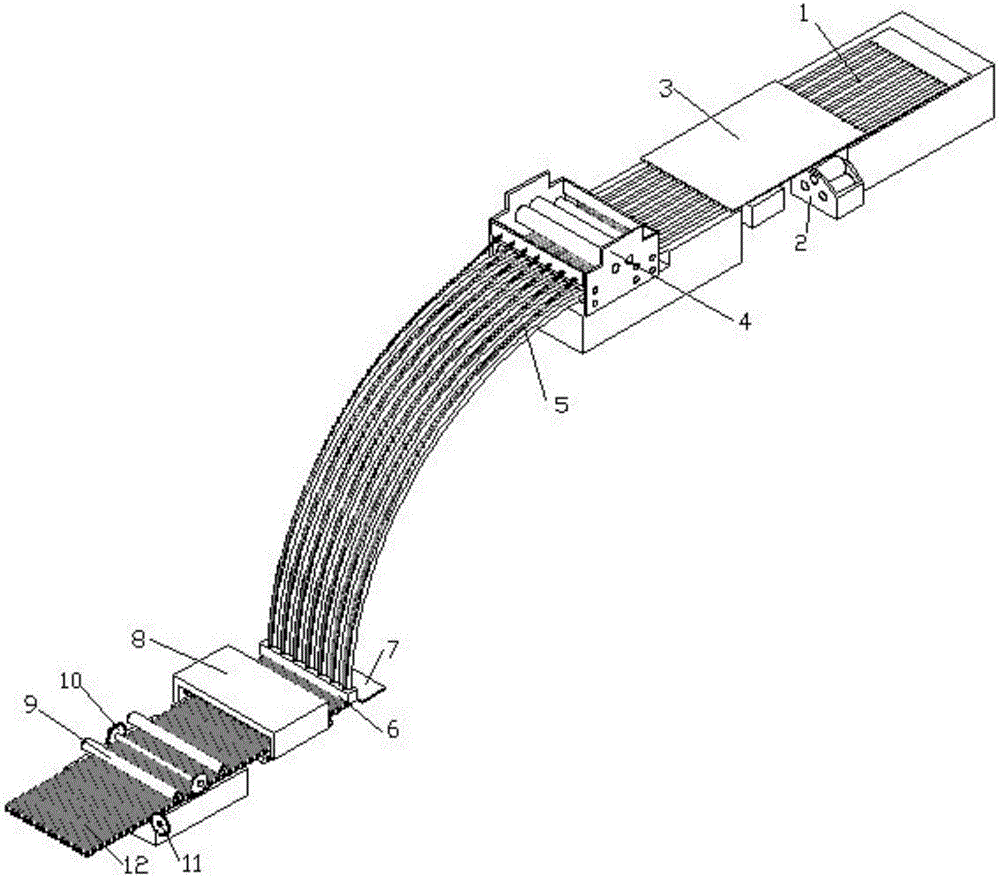

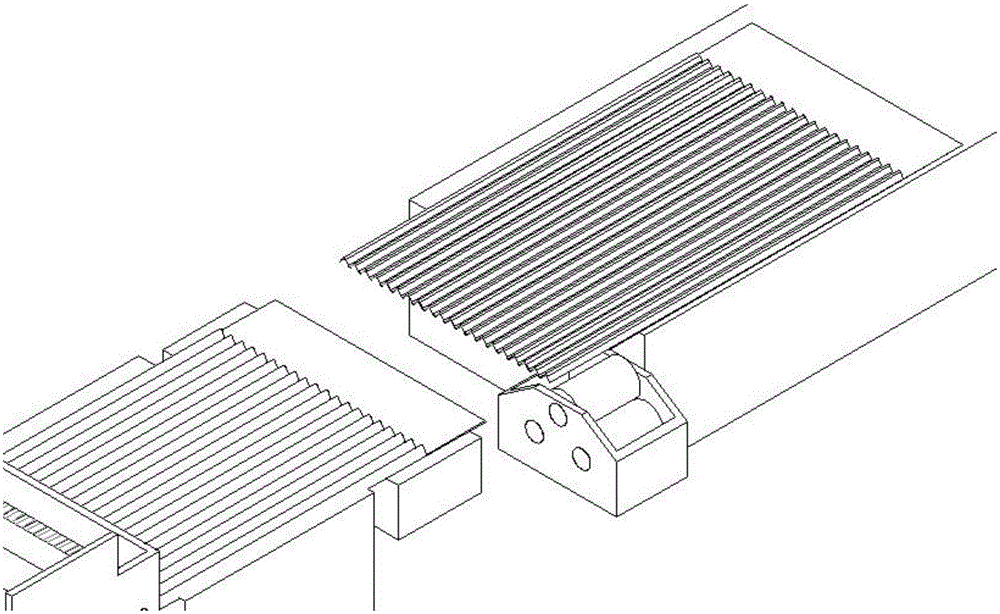

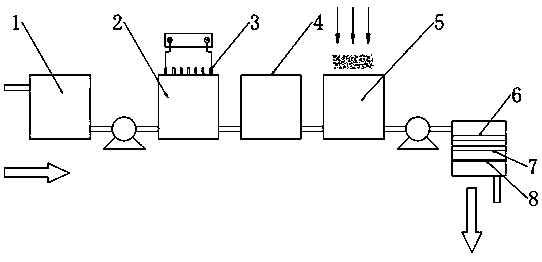

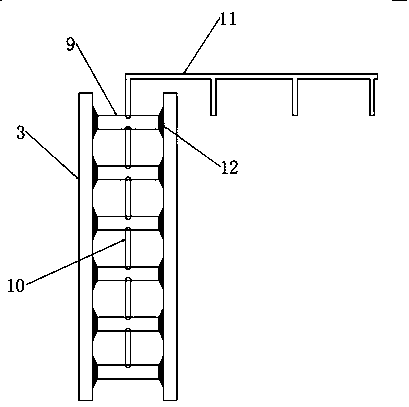

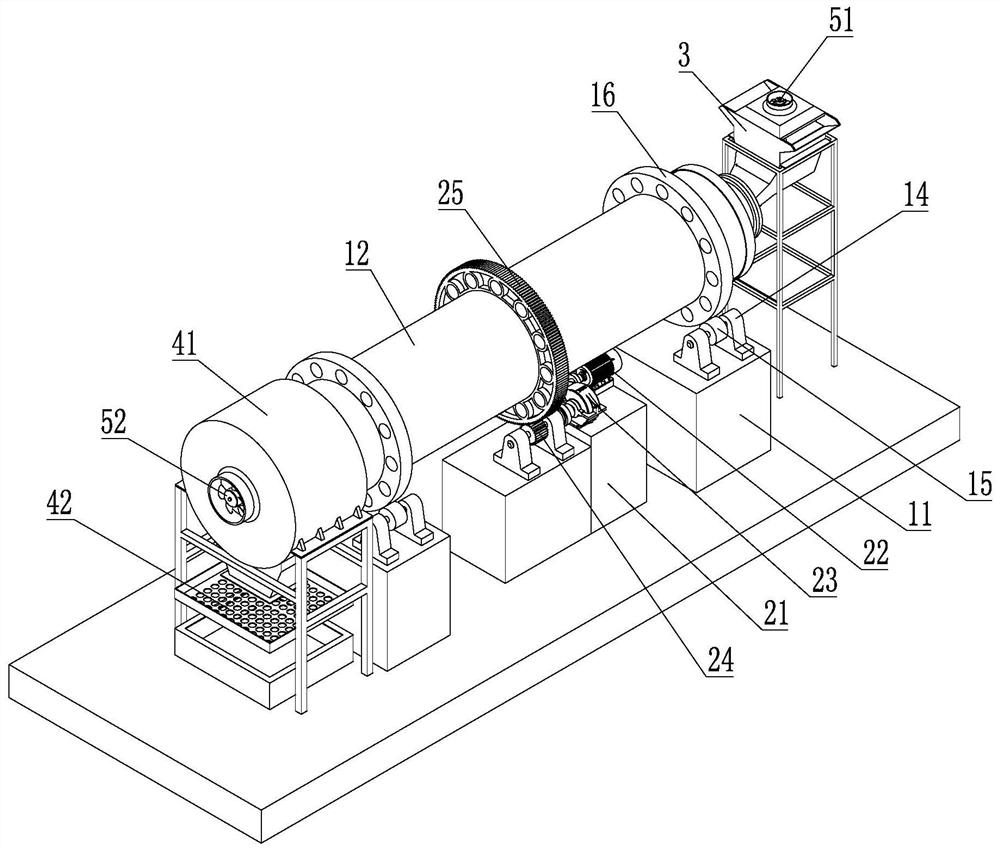

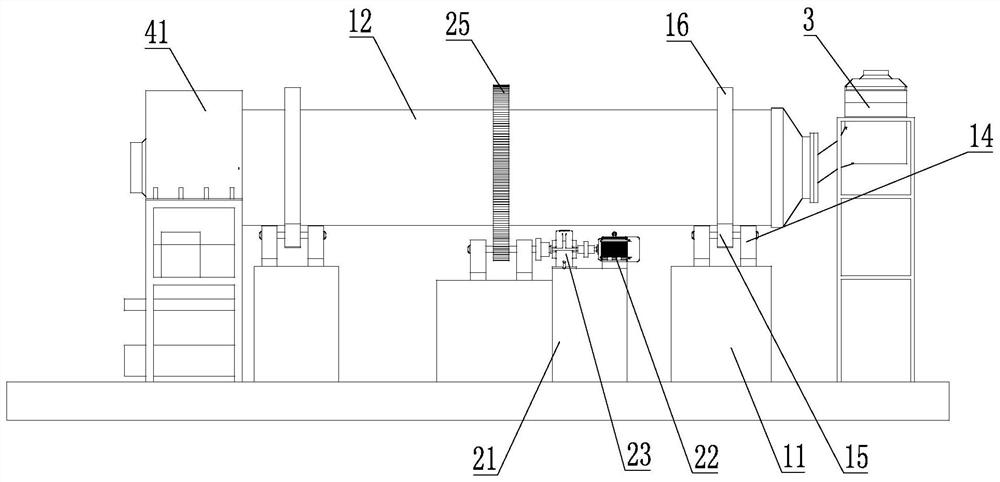

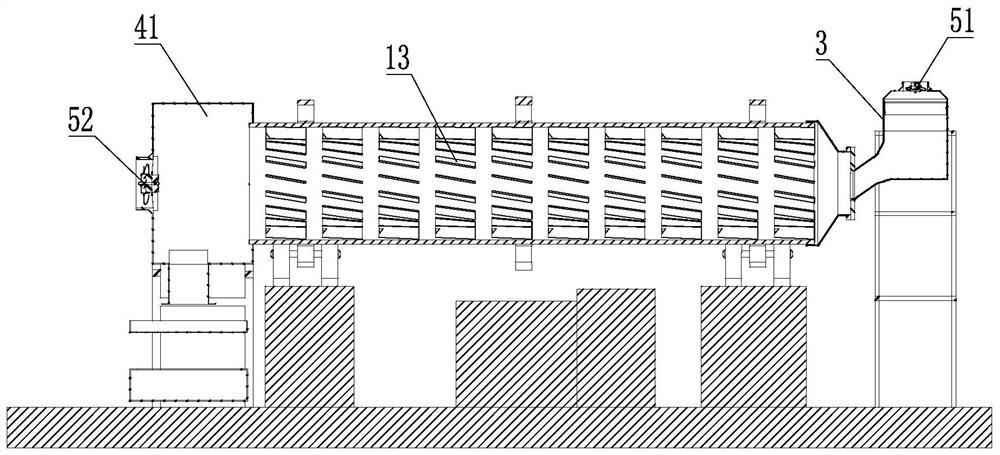

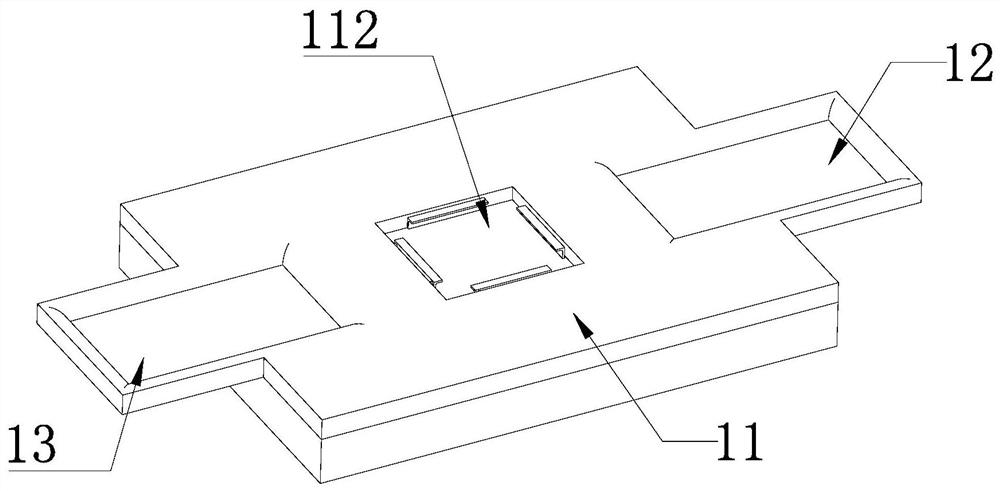

The invention provides a continuous rheomolding device for manufacturing metal plate strips. The device comprises an inclined plate, a base, an electromagnetic vibration exciter and a double-roller rolling mill and is characterized by also comprising the double-roller rolling mill, wherein the inclined plate is formed by connecting a feeding section, a pulping section and a discharging section in turn; the lower side of a bottom plate of the pulping section is connected with the upper end of a spring; the lower end of the spring is fixed on the base; one end of the electromagnetic vibration exciter is fixed on the base, and the other end of the electromagnetic vibration exciter is connected with the lower side of the bottom plate of the pulping section; and gaps are formed between the bottom plate and two side plates of the discharging section and the roll surfaces of upper and lower rollers of the double-roller rolling mill. The range of vibration frequency which can be provided by the electromagnetic vibration exciter adopted by the device is expanded greatly and the vibration frequency is adjusted so that an alloy structure can be improved more effectively and molten metal is prevented from crusting on the surface of the inclined plate.

Owner:NORTHEASTERN UNIV

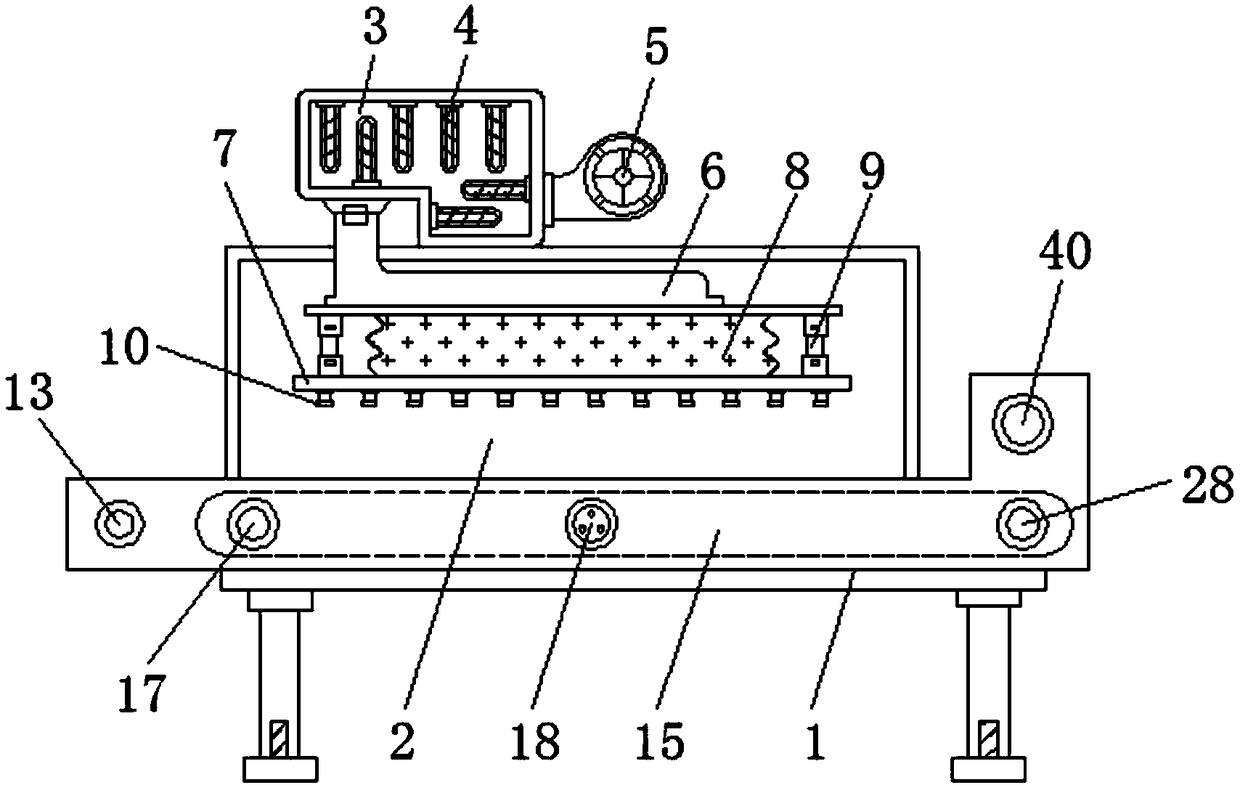

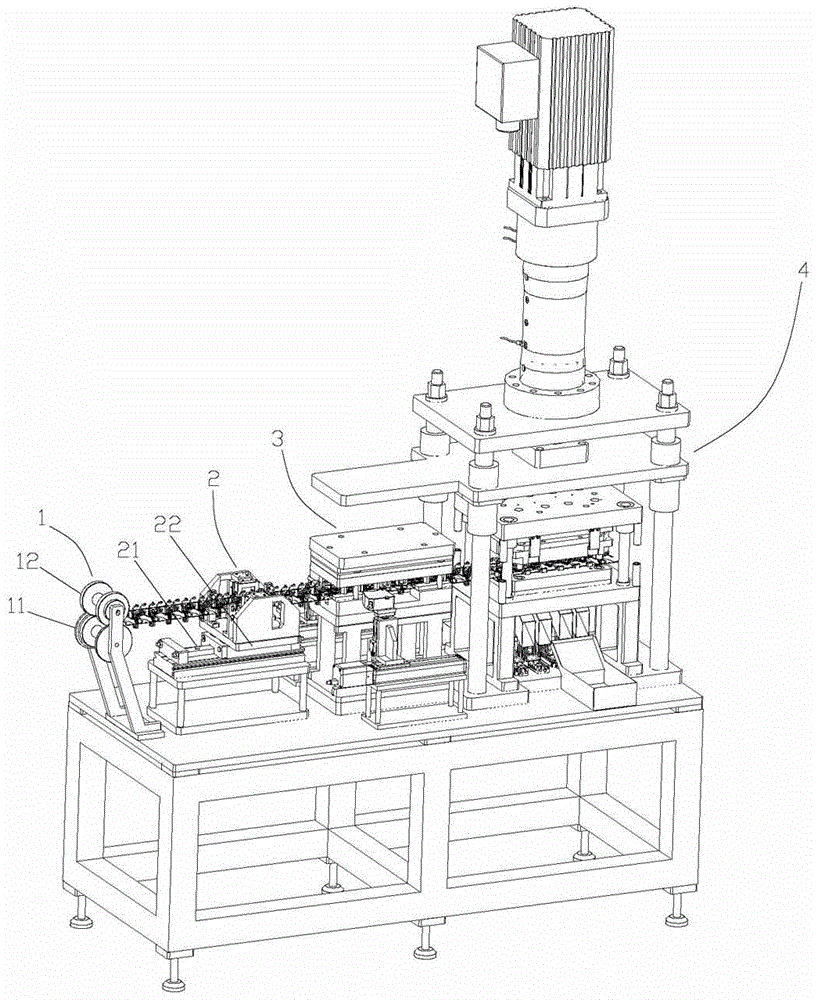

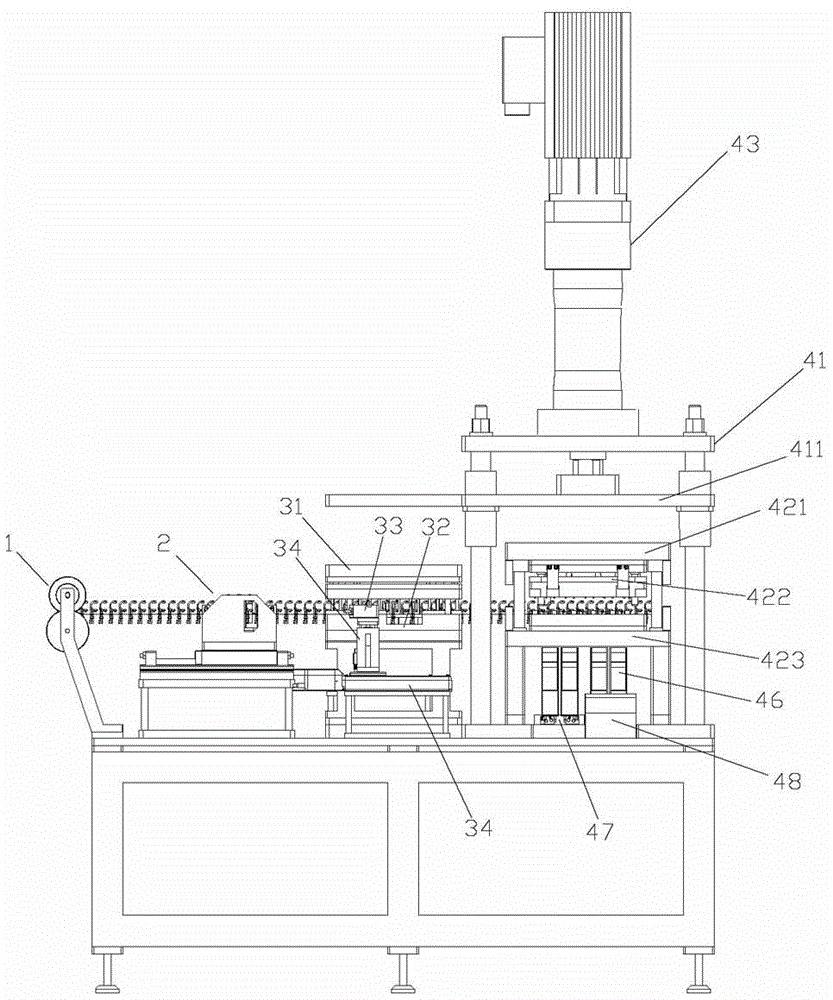

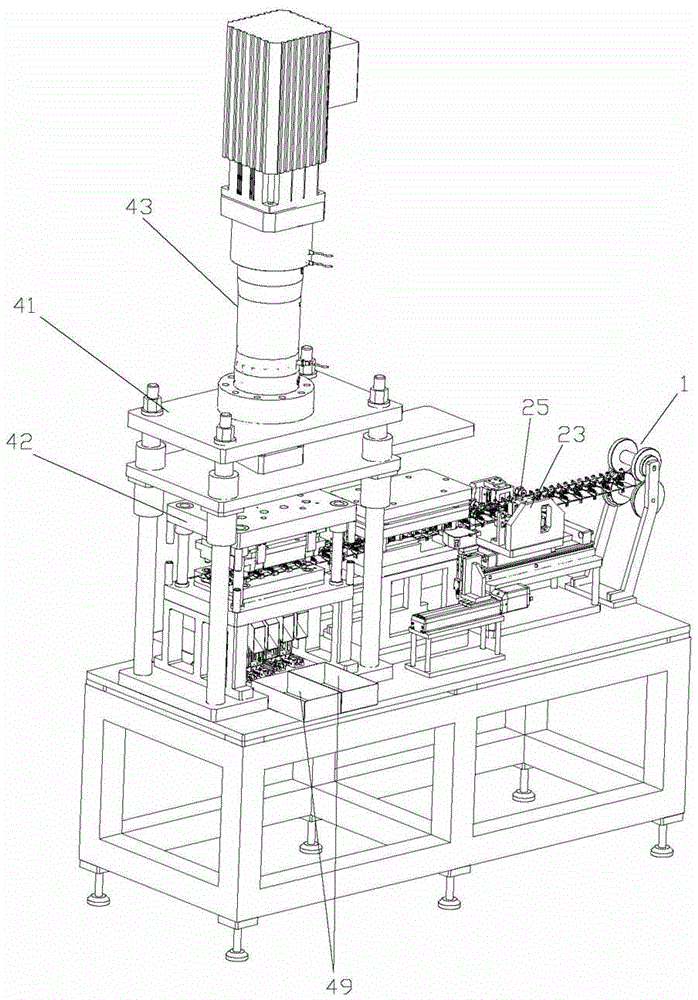

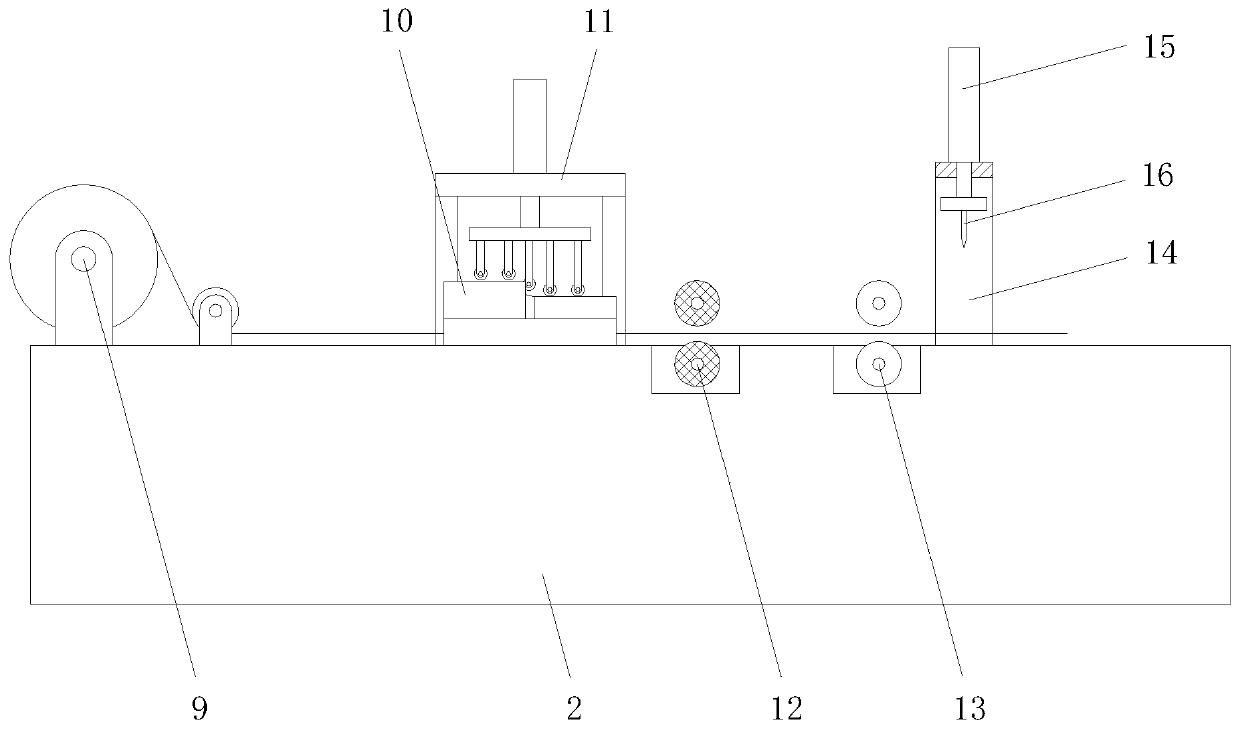

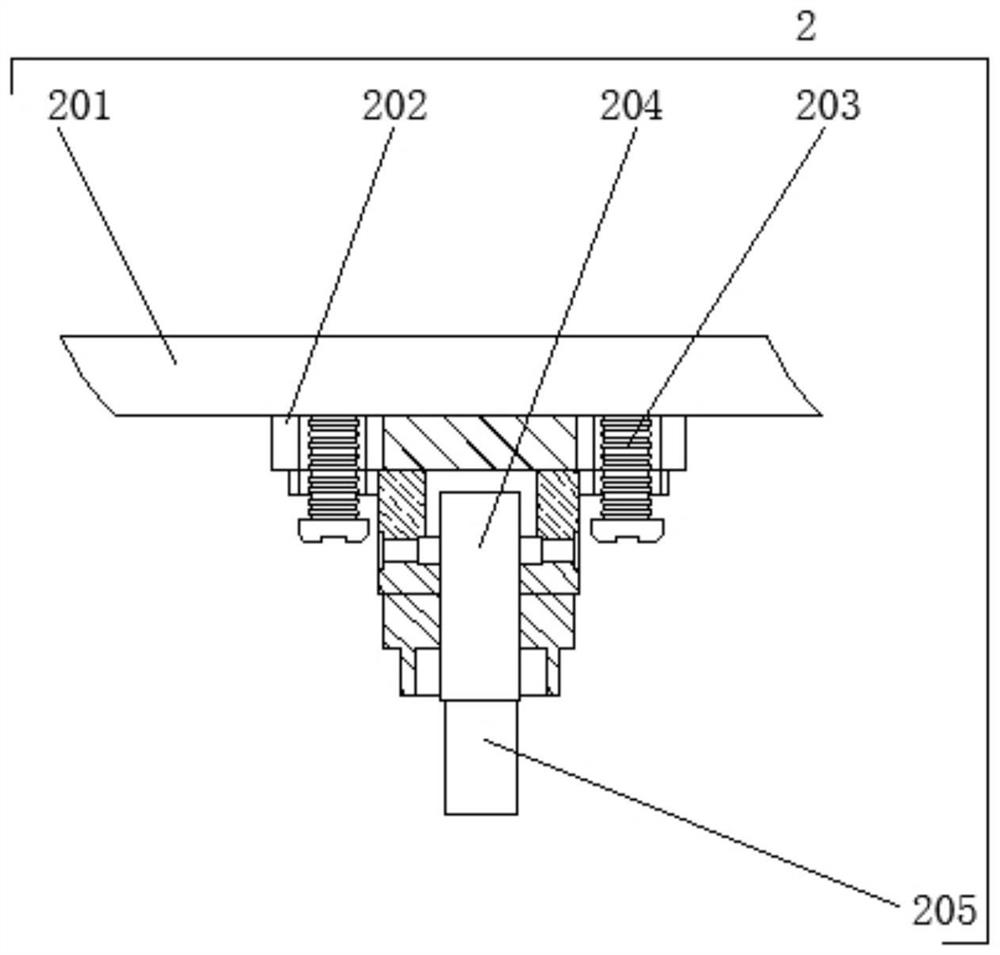

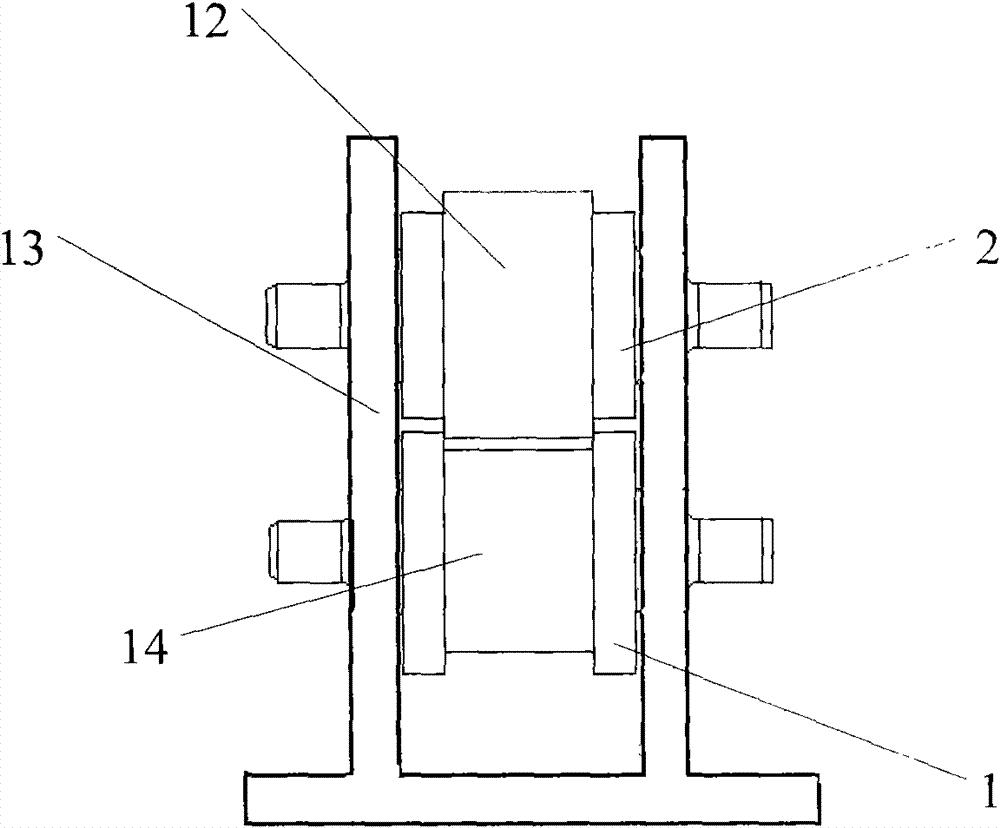

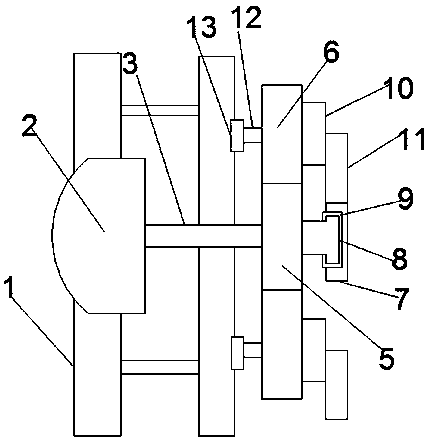

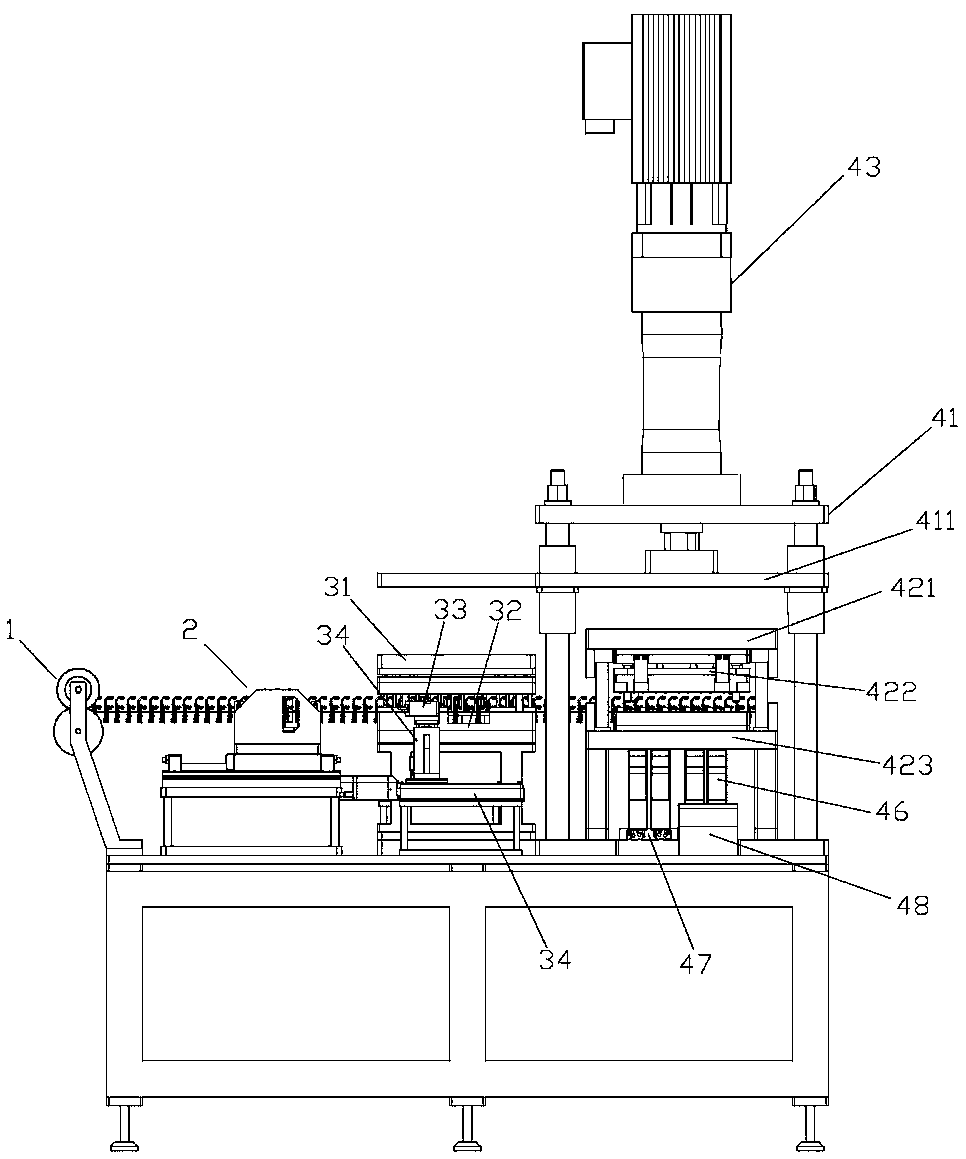

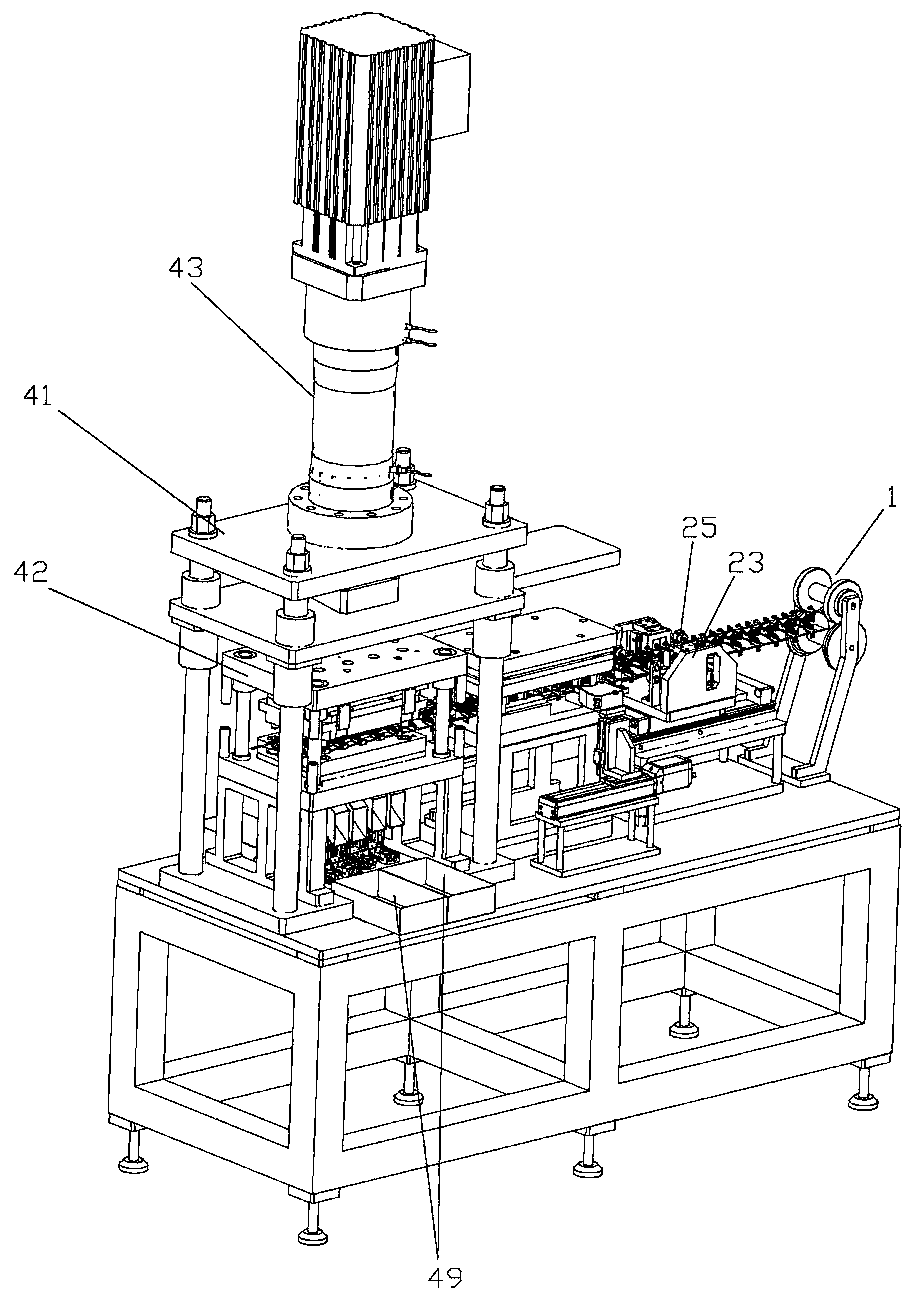

Continuous stamping device for brake shrapnel

InactiveCN108435862AAccurate feedingHigh degree of automationMetal-working feeding devicesStripping-off devicesFixed frameEngineering

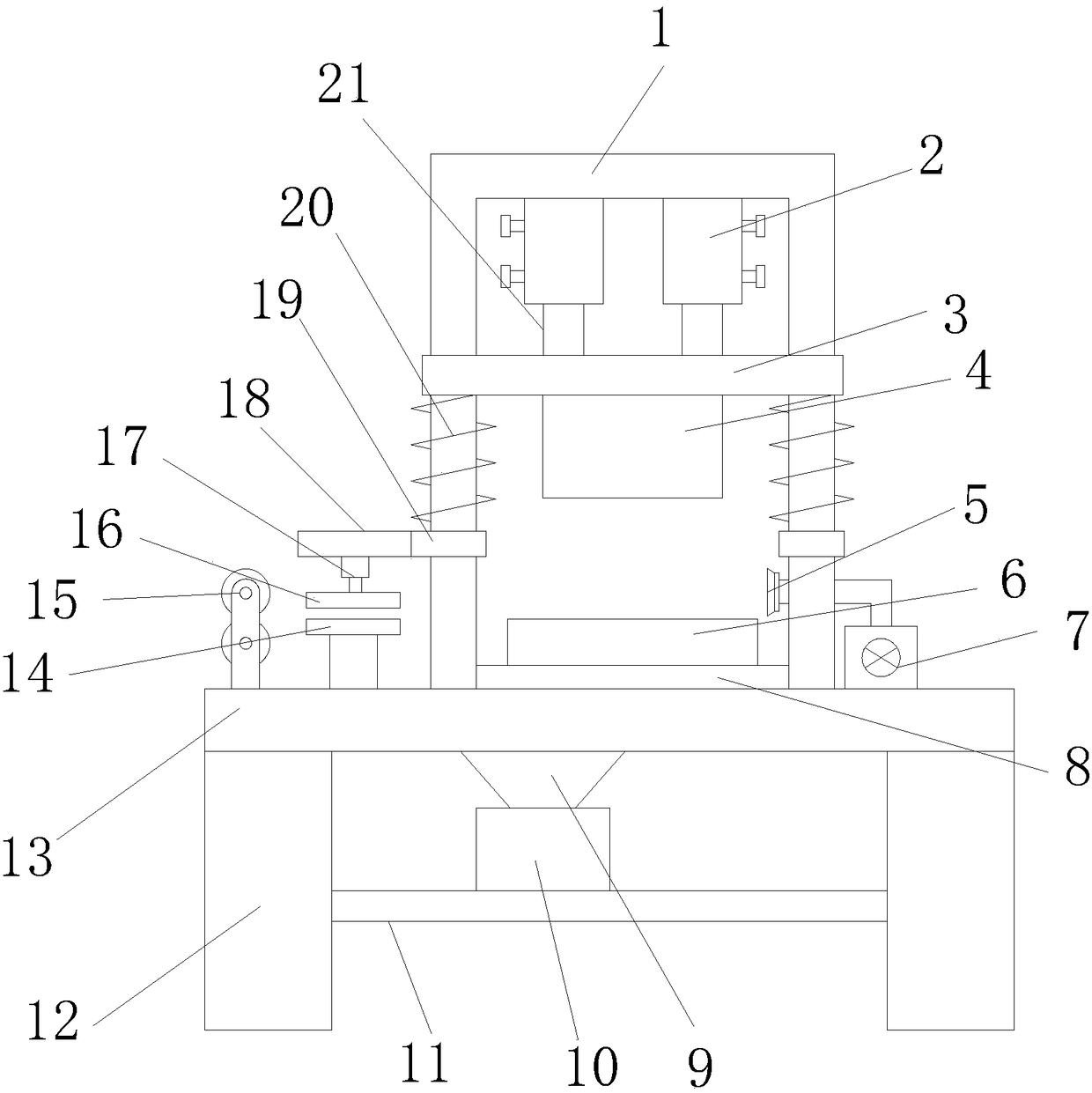

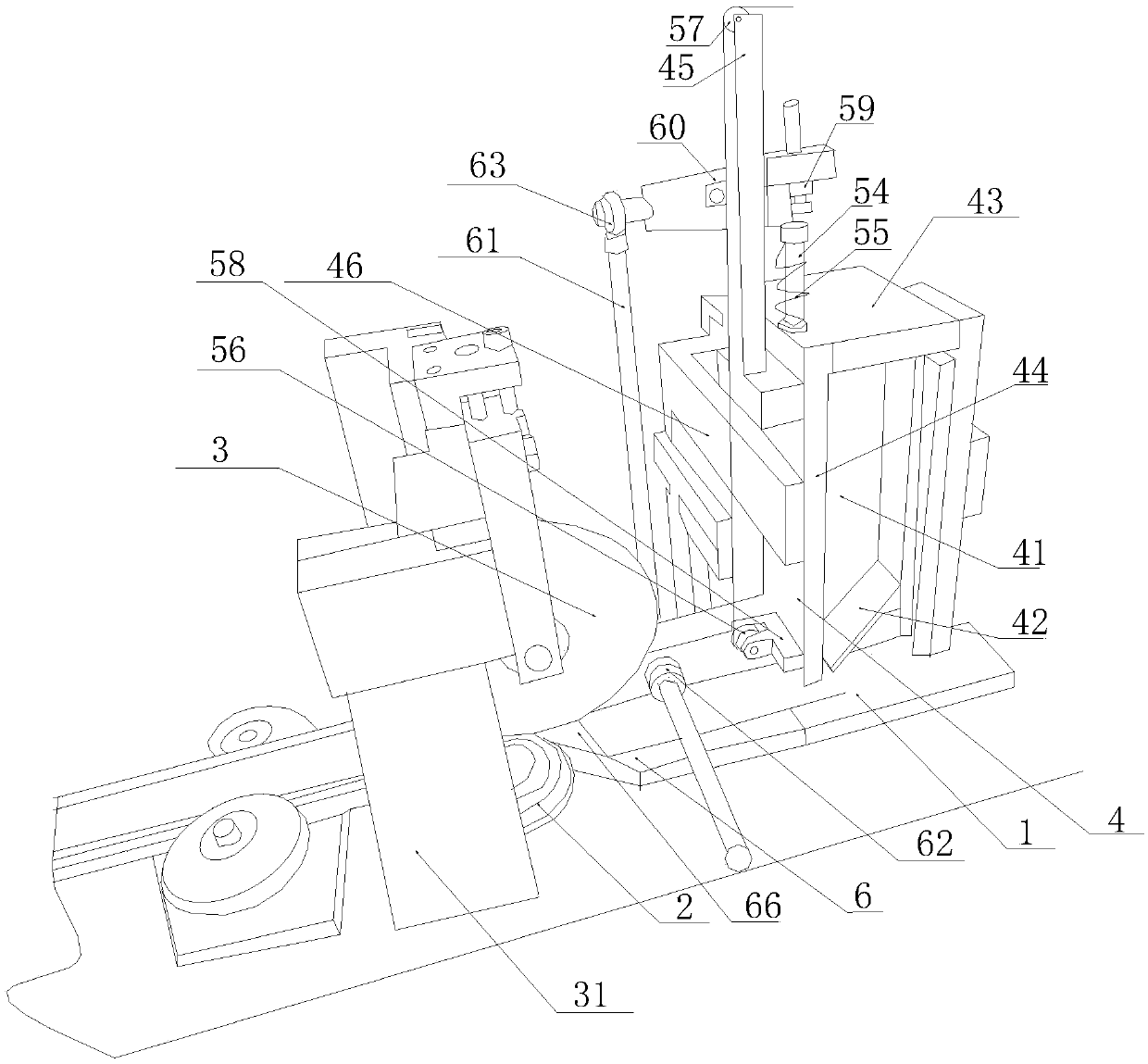

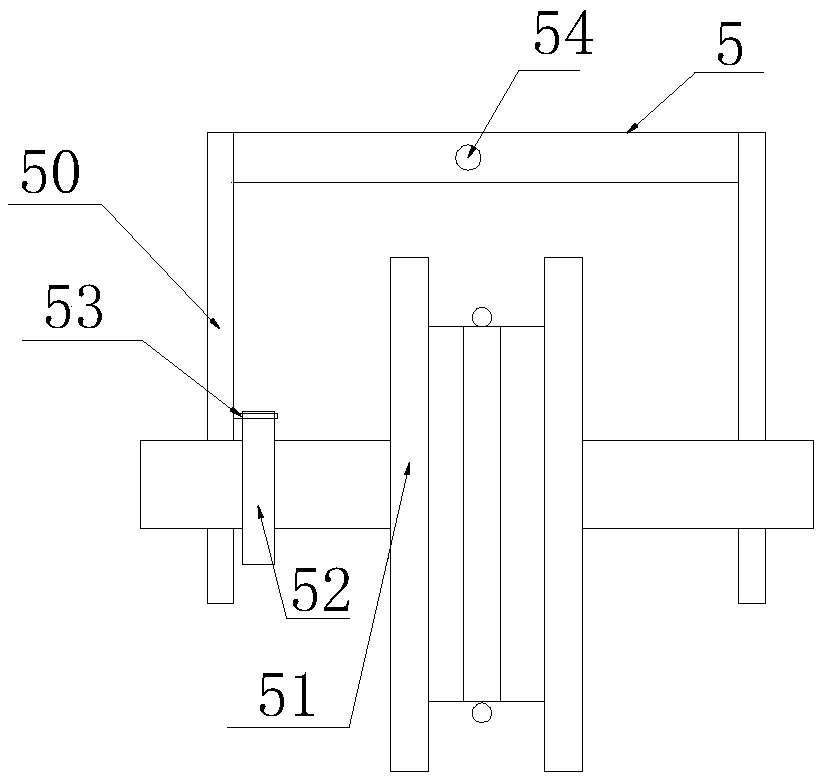

The invention discloses a continuous stamping device for brake shrapnel. The continuous stamping device comprises a workbench and a fixing frame, wherein a plurality of feeding rollers are fixedly arranged at the left end above the workbench, a material pressing device is arranged on the right side of each feeding roller, the fixing frame is arranged on the right side of each material pressing device, the fixing frame is fixedly connected with the right side of the upper end of each material pressing device, and the fixing frame is fixedly arranged in the middle of the upper surface of the workbench. A lower fixing plate is arranged below the inside of the fixing frame, a lower die seat is fixedly arranged in the middle above the lower fixing plate, an upper fixing plate is arranged in themiddle of the fixing frame, and the fixing frame is in sliding connection with the two ends of the upper fixing plate . Springs are arranged in the middle of the two sides of the fixing frame in a sleeving mode, limit blocks are fixedly connected with the lower ends of the springs, and the limit blocks are fixedly installed below the left and right sides of the fixing frame. The continuous stamping device has the advantages of simple structure, diverse kinetic energy, high practicability, high safety, high degree of automation, fast production efficiency and favorable popularization.

Owner:广德盛源电器有限公司

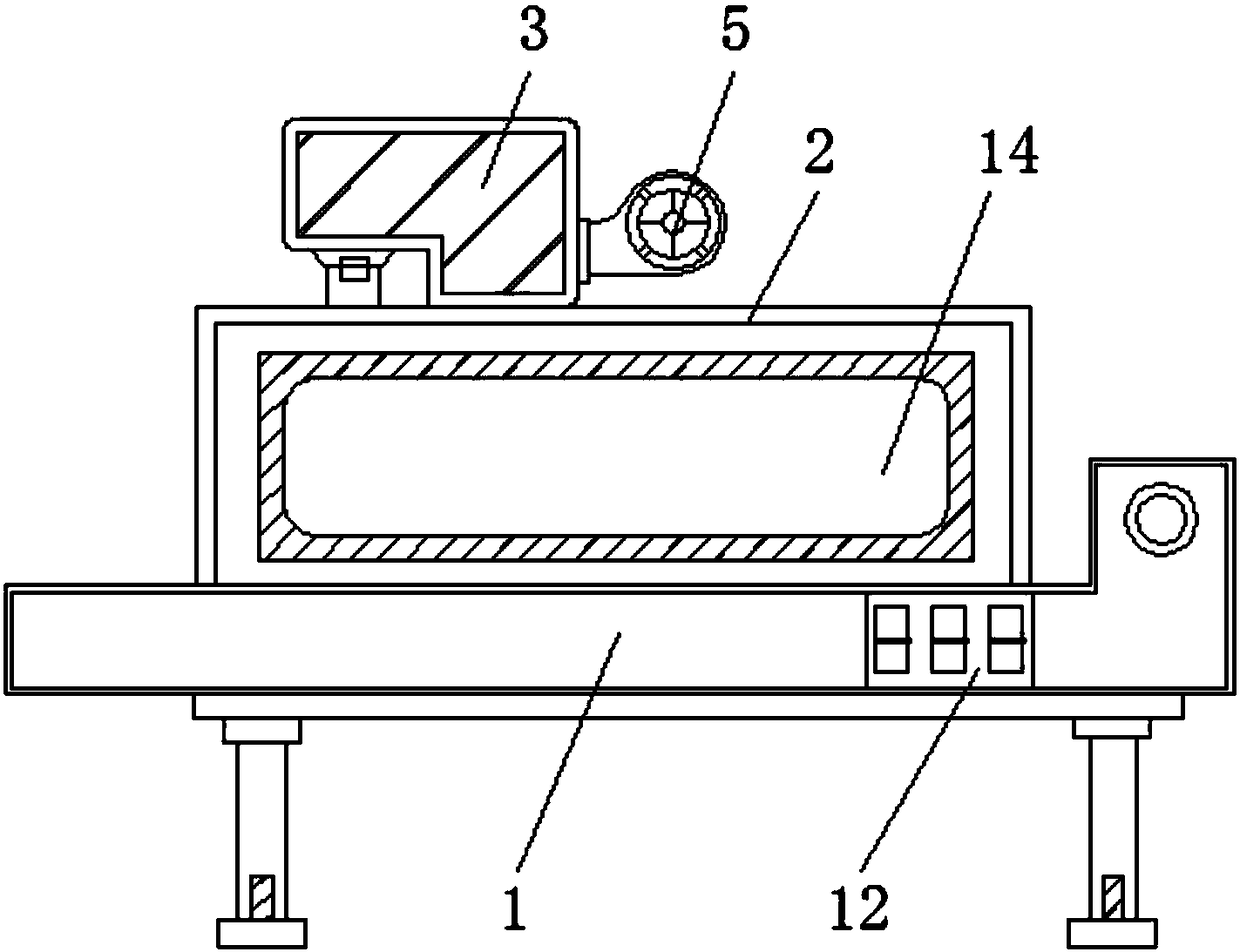

Spinning oven with anti-wrinkling function

ActiveCN108387091AWith anti-wrinkle functionAvoid damageDrying gas arrangementsDrying machines with progressive movementsDrive wheelEngineering

The invention discloses a spinning oven with an anti-wrinkling function. The oven comprises a frame, a fixed frame, a cloth guide roller, a conveying belt, a cloth winding roller, a cleaning brush, afixed sleeve and a cloth collecting roller; a box is fixed above the frame; the right side of a heating cylinder is connected with a fan; an exhaust nozzle is mounted below the fixed frame; a motor ismounted in front of the frame; the cloth guide roller is positioned on the inner side of the frame; an observation window is mounted on the surface of the box; an output wheel is connected with a fixed slide block through a connecting piece on the right side; and the cloth collecting roller is positioned on the left side of a driving wheel. The spinning oven with the anti-wrinkling function can change the cloth tension by changing the height of a pressing roller to facilitate reduction of drapes on cloth; meanwhile, the cleaning brush is convenient to clean impurities and dust on the cloth; and the surfaces of the pressing roller and the cloth winding roller are of thread structures to achieve a two-way traction effect on the cloth, so that the drapes on the surface of the cloth are reduced, and the levelness of the cloth is improved.

Owner:浙江威臣纺织股份有限公司

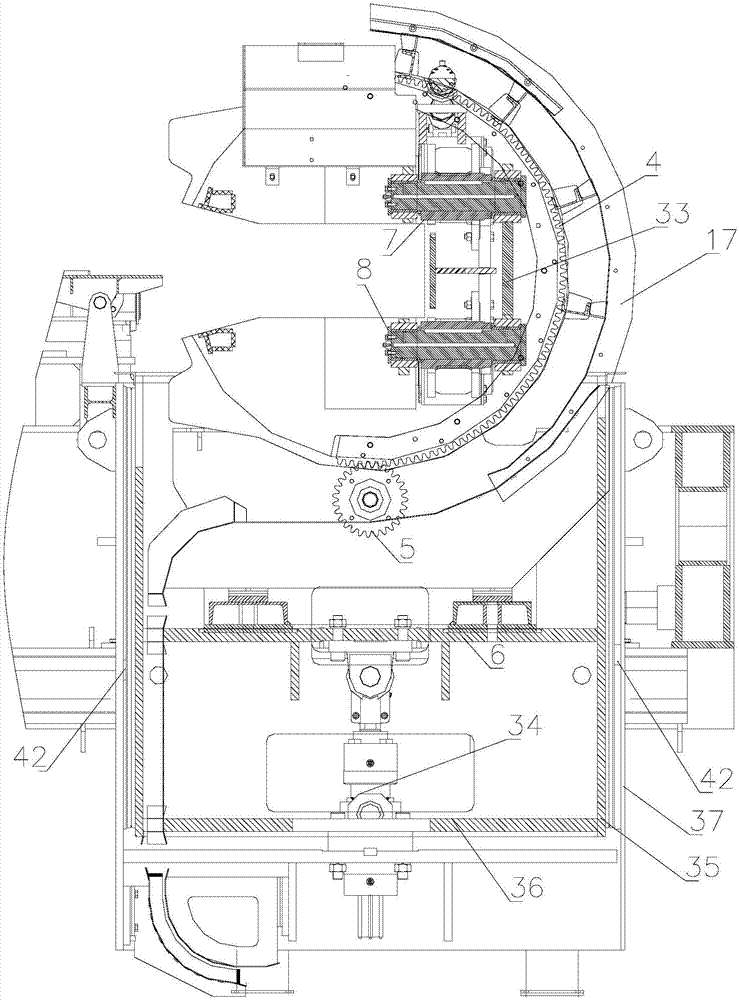

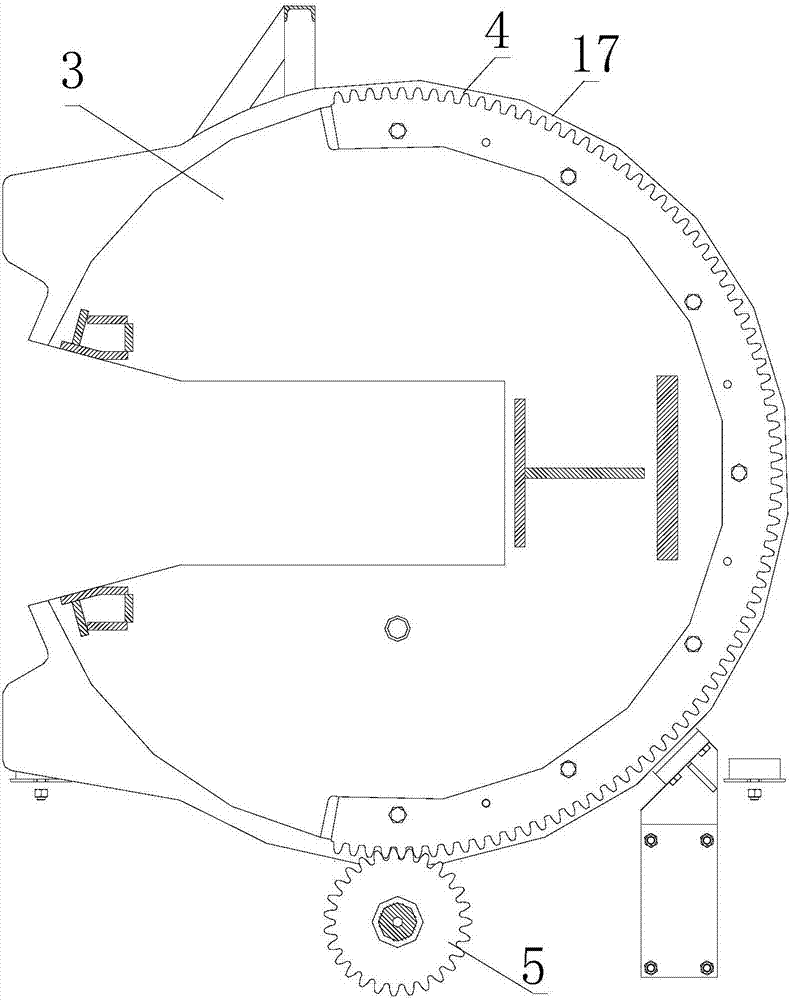

Tilting head and tong-type tilting machine

Owner:KEHE IND EQUIP TECH SHANGHAI

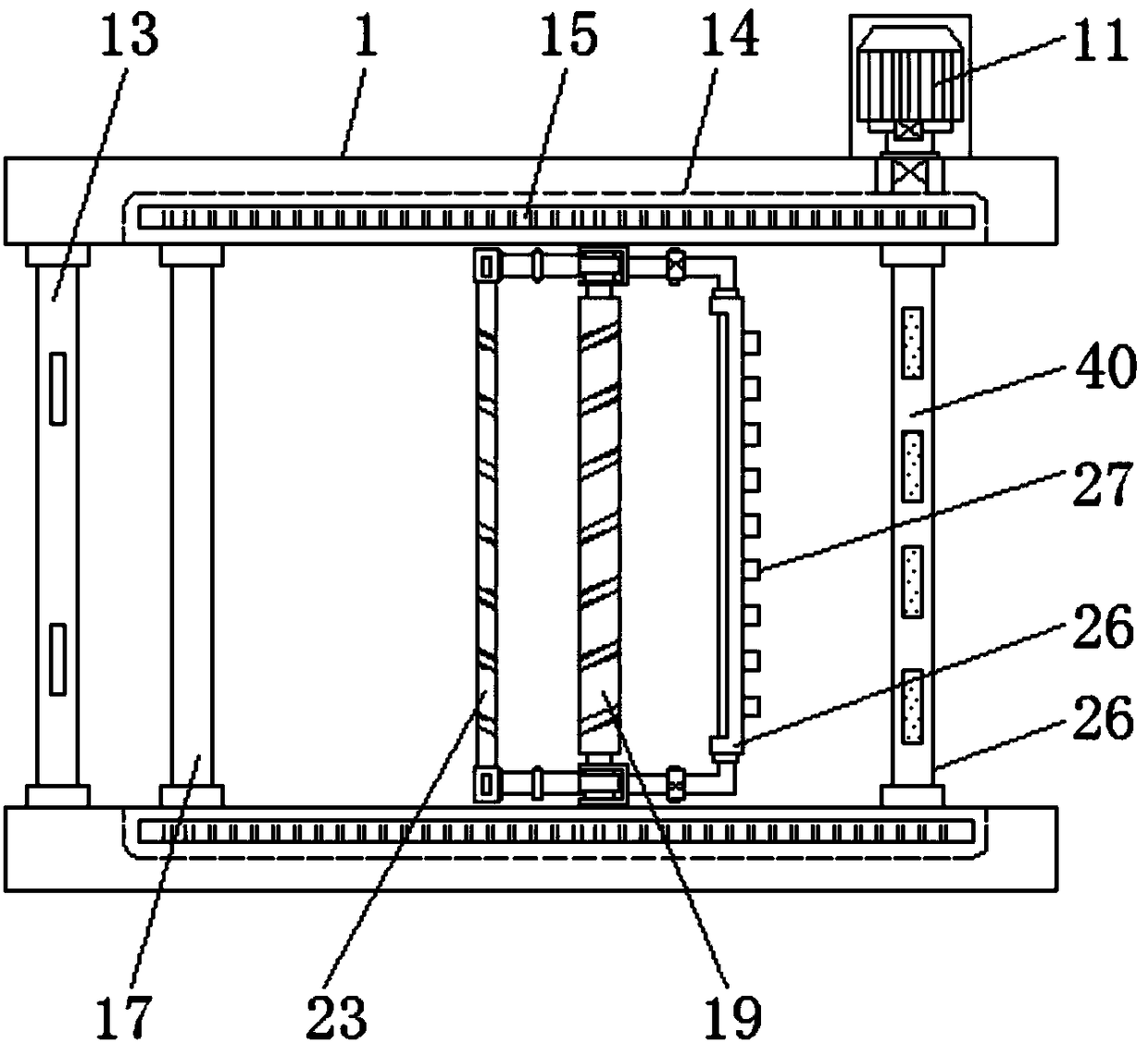

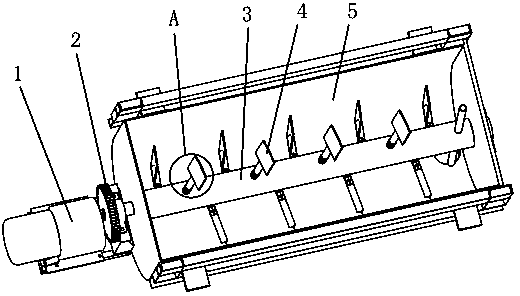

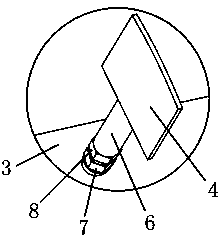

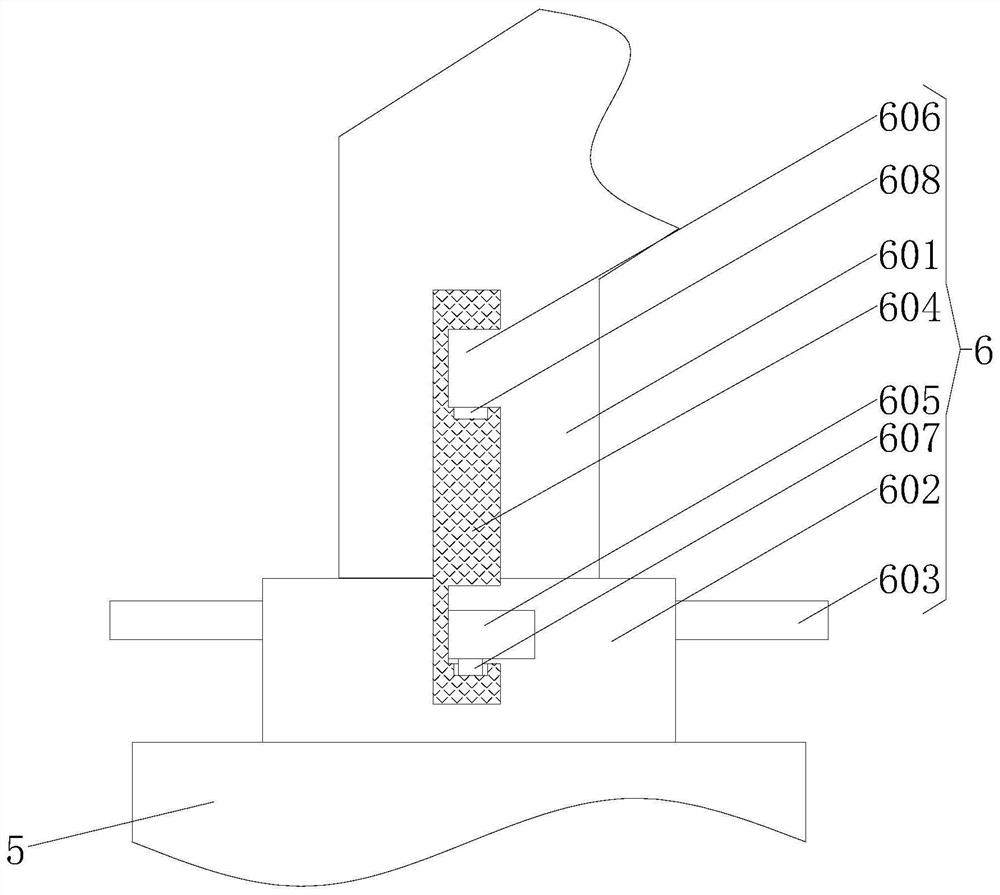

Peeling device for grain processing

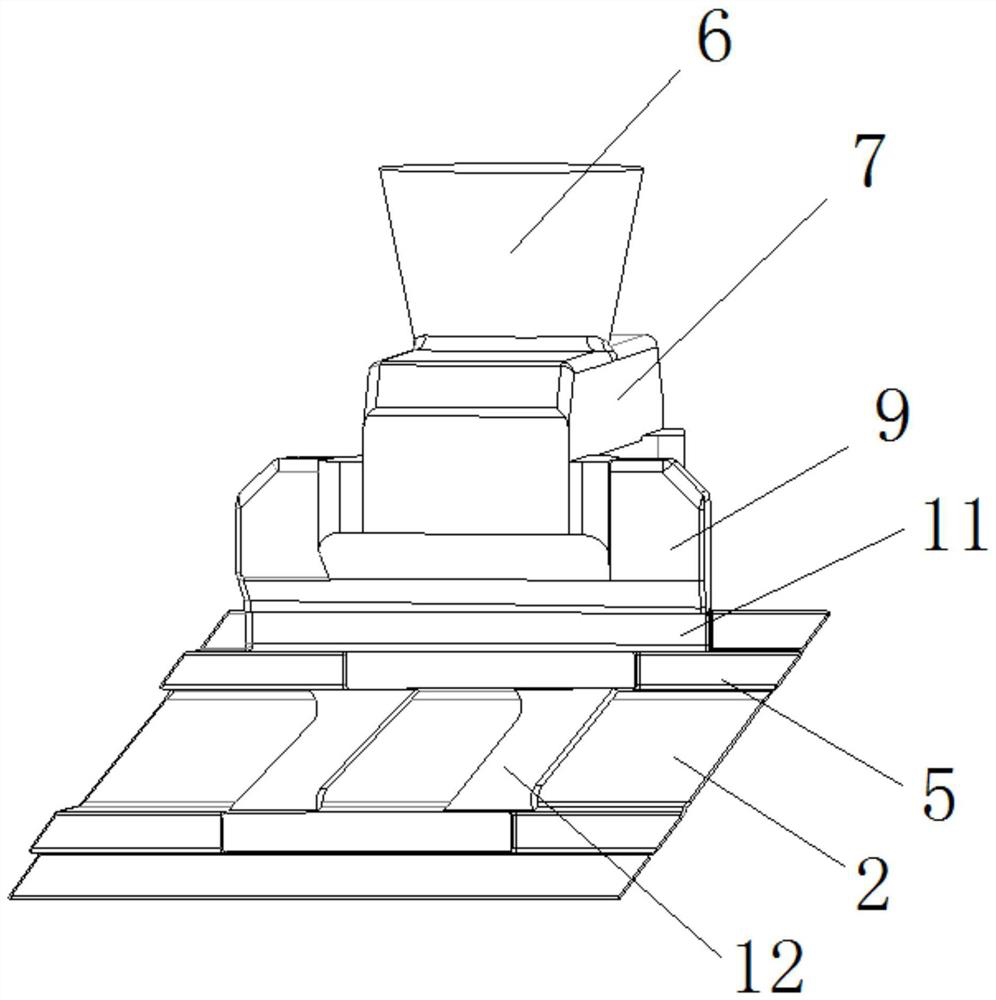

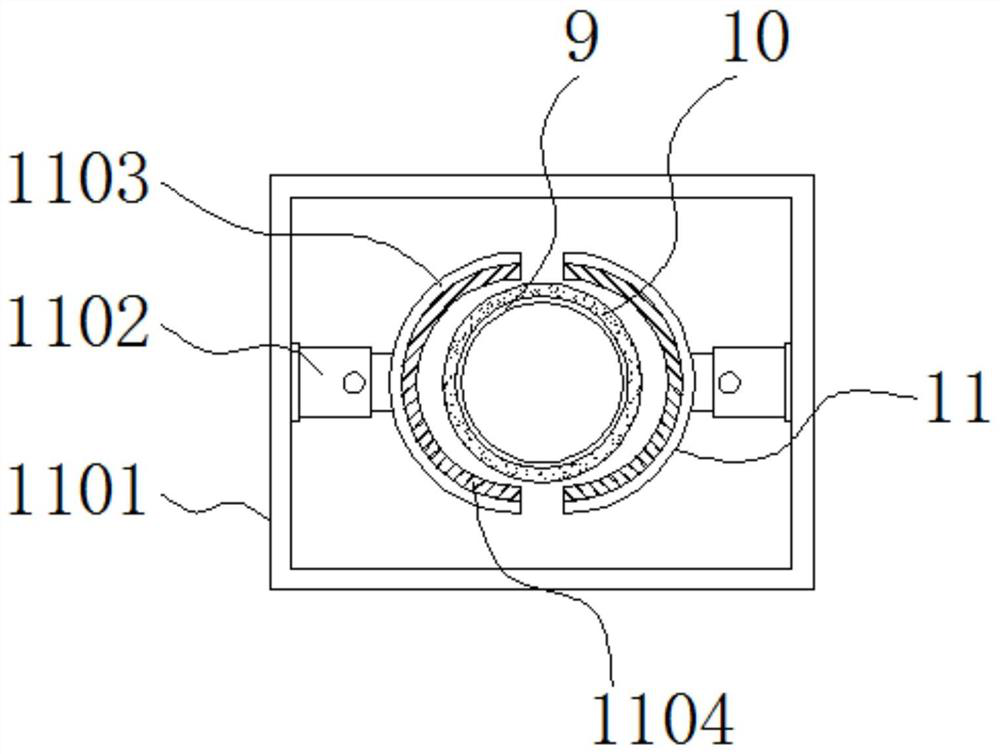

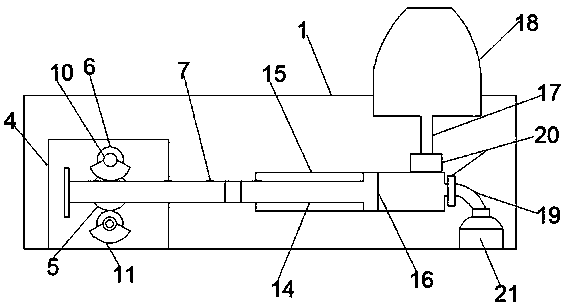

PendingCN108421585APlay peelingPlay the role of feedingGrain huskingGrain polishingSpiral bladeEngineering

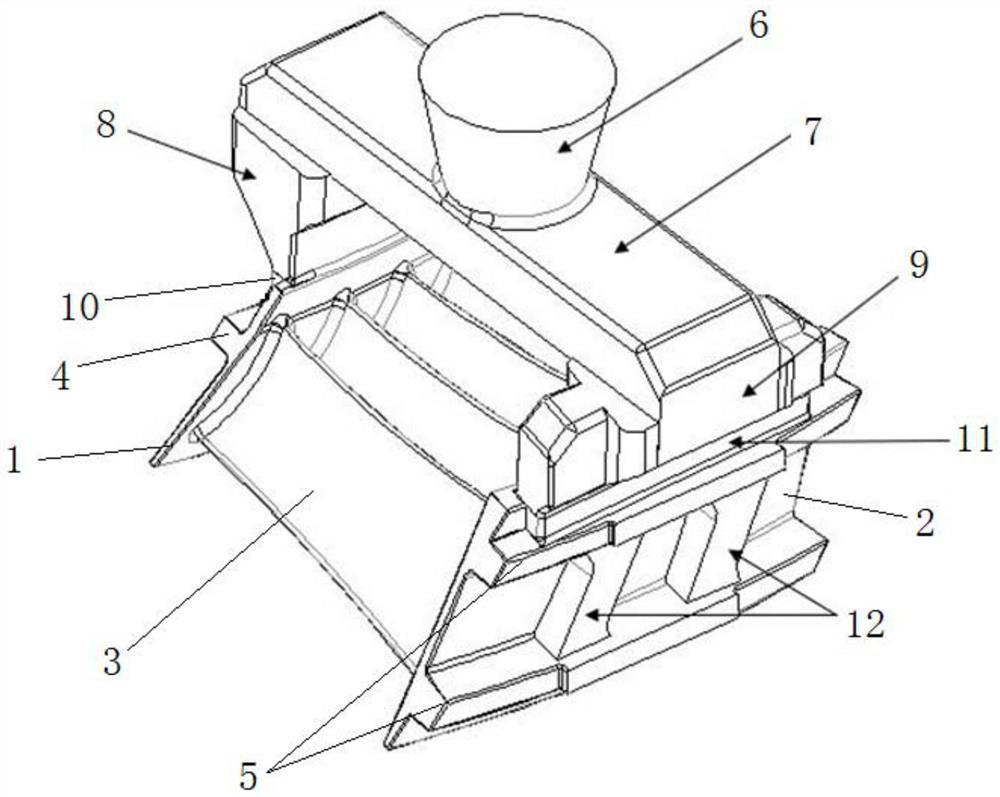

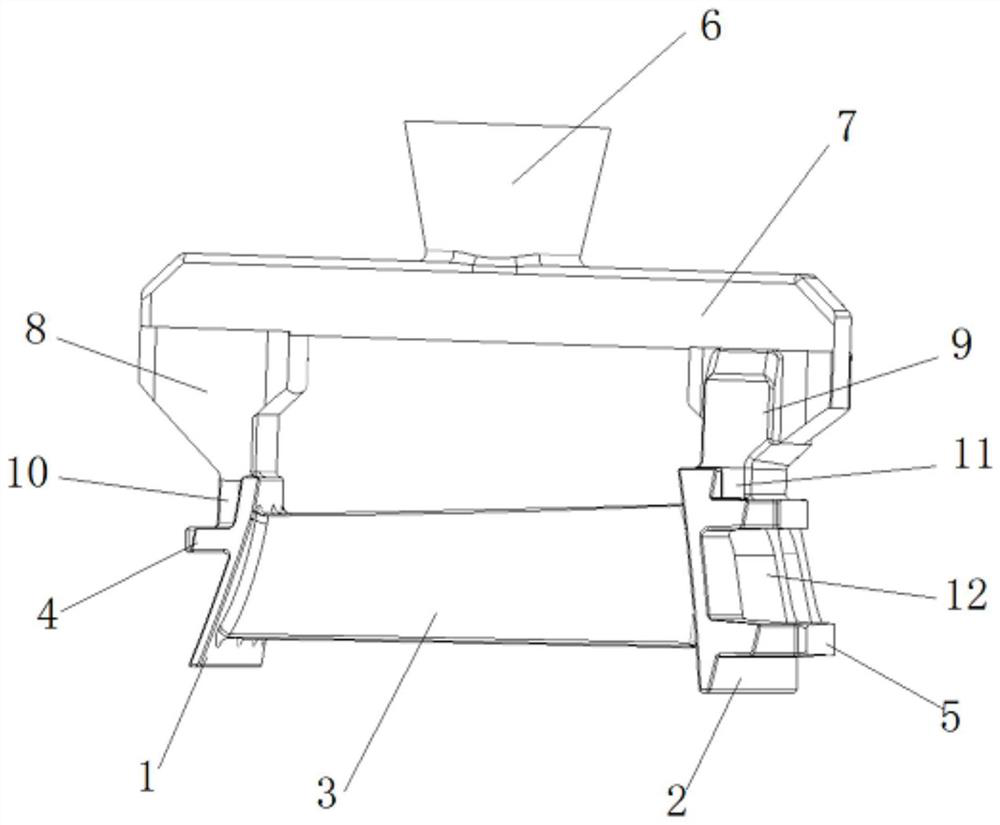

The invention relates to the technical field of grain processing machines and discloses a peeling device for grain processing. The peeling device for grain processing comprises a shell. A feed hopperis arranged at the top of the shell, rotating rollers are arranged at the bottom of the feed hopper, the inner walls of both sides of the shell are fixedly connected with the outer surfaces of both sides of a conveying box, a motor is arranged at one side of the shell, and the output end of the motor is fixedly connected with a rotating shaft; and one end of the rotating shaft penetrates and extends into the conveying box, a spiral blade is fixedly connected to the outer surface of the rotating shaft, a feed inlet is formed in the top of the conveying box, and separating plates fixedly connected to the inner wall of the shell are arranged at the bottom of the conveying box. According to the peeling device, materials can be peeled and fed through the rotating rollers, the motor, the rotating shaft, the spiral blade and protrusions, so that the feeding is uniform while the peeling effect is ensured, the cleaning effect can be improved, and the materials can be peeled more fully; and thespiral blade can prevent excessive materials from accumulating on the separating plates and is beneficial to improving the cleaning effect.

Owner:刘丽娜

Manufacturing device and method for novel corrugated paperboard

ActiveCN106273676AAny width can be cutAdjustable thicknessMechanical working/deformationLaminationCardboardEngineering

The invention discloses a manufacturing device and method for a novel corrugated paperboard. The device comprises a gluing mechanism which is connected with a staggered composite paperboard, a glue roller mechanism which is used for gluing a composite paperboard bonded with the staggered composite paperboard, a shearing, superposing and bonding mechanism used for shearing and superposing the composite paperboard; and the gluing mechanism, the glue roller mechanism and the shearing, superposing and bonding mechanism are sequentially arranged. The manufacturing method comprises the steps of rolling the staggered composite paperboard, gluing the staggered composite paperboard, shearing the staggered composite paperboard and the like. According to the manufacturing device and method disclosed by the invention, fully-automatic processing can be realized, labor force and labor intensity of manpower can be saved, the yield is increased, process in the production process is simpler, product quality is further improved, products can be arbitrarily processed according to dimension requirements, the yield is increased, and the labor intensity of workers is greatly reduced. The manufacturing device and method is mainly used for automobile interior-trim lining blocks, wood-imitation furniture lining blocks, home-decoration soundproof and heat-insulating lining blocks, is widely applied in a novel composite material, and is low in cost.

Owner:何光耀

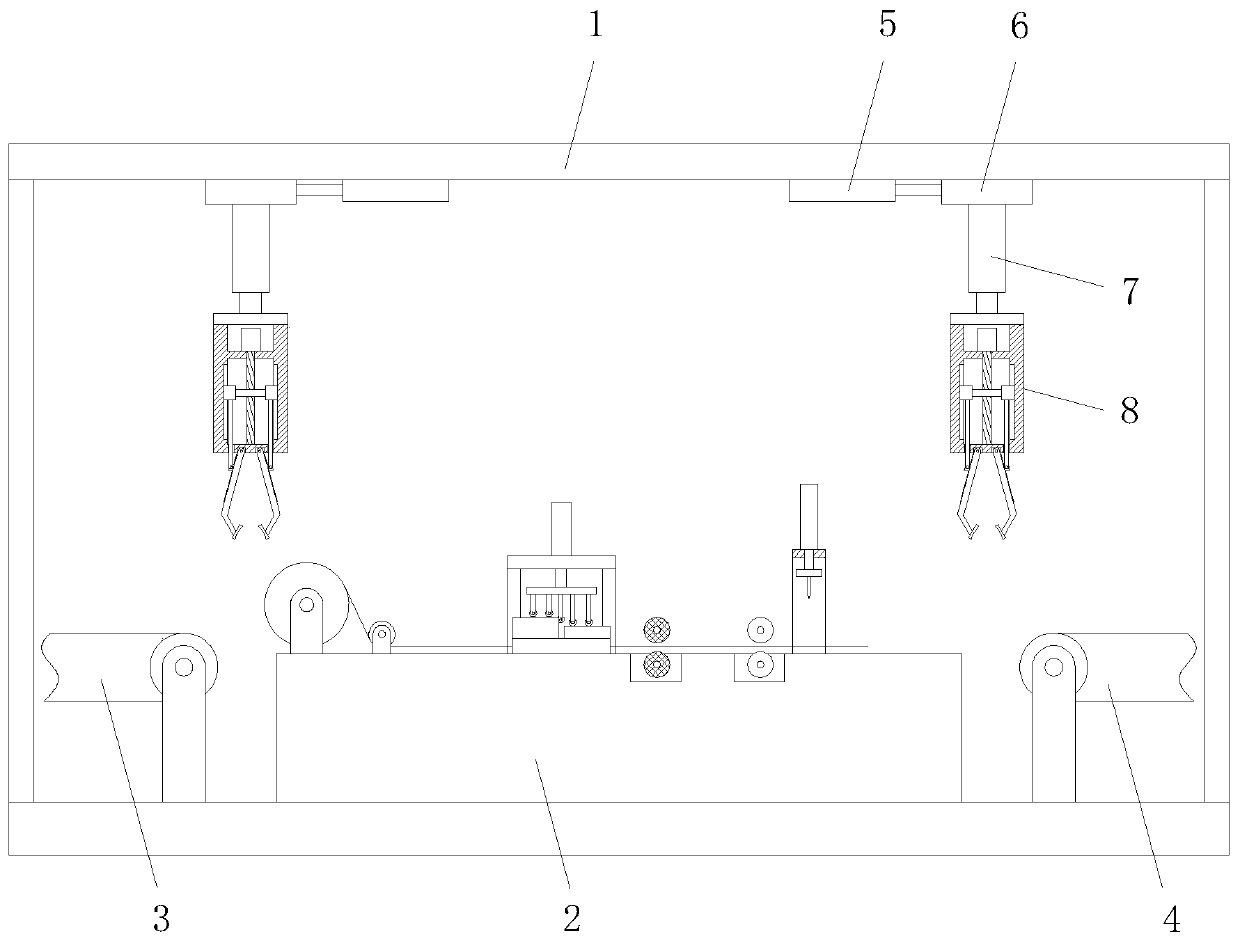

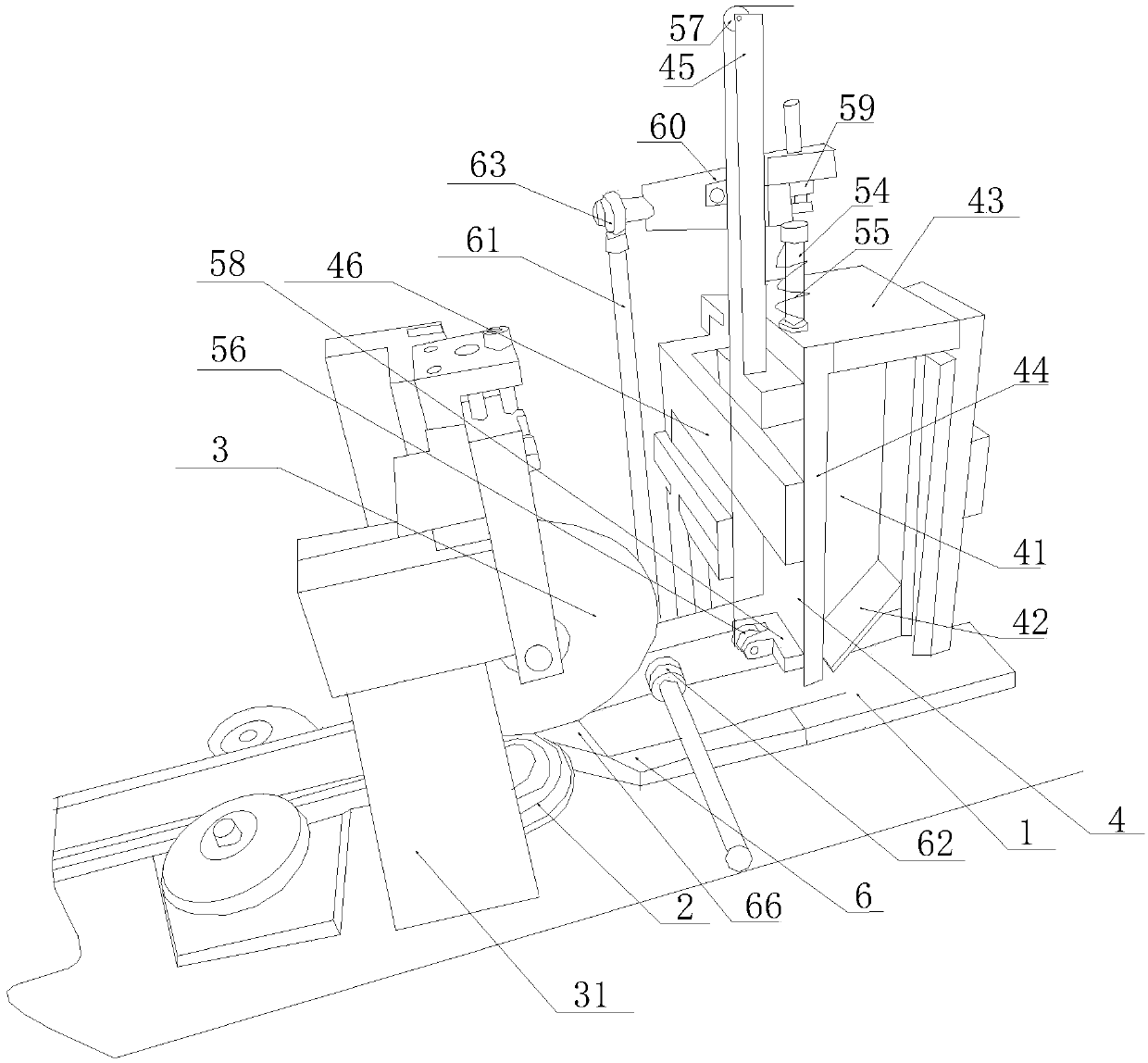

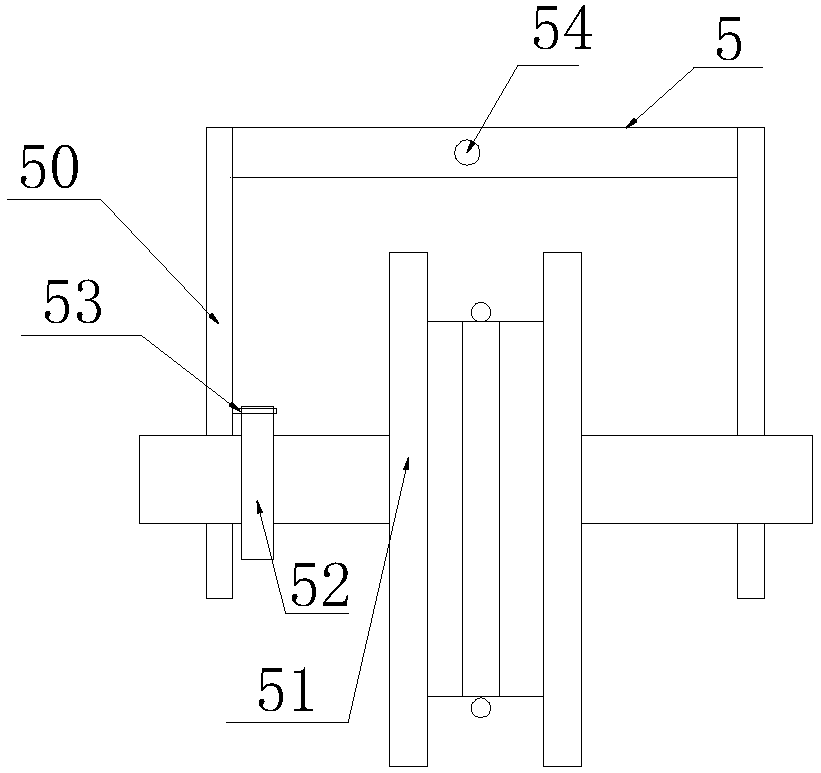

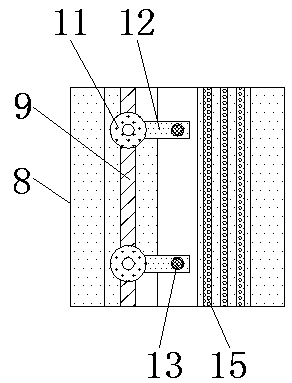

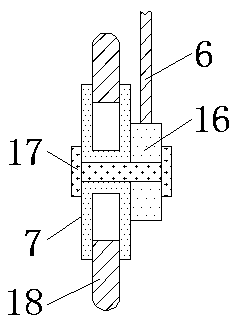

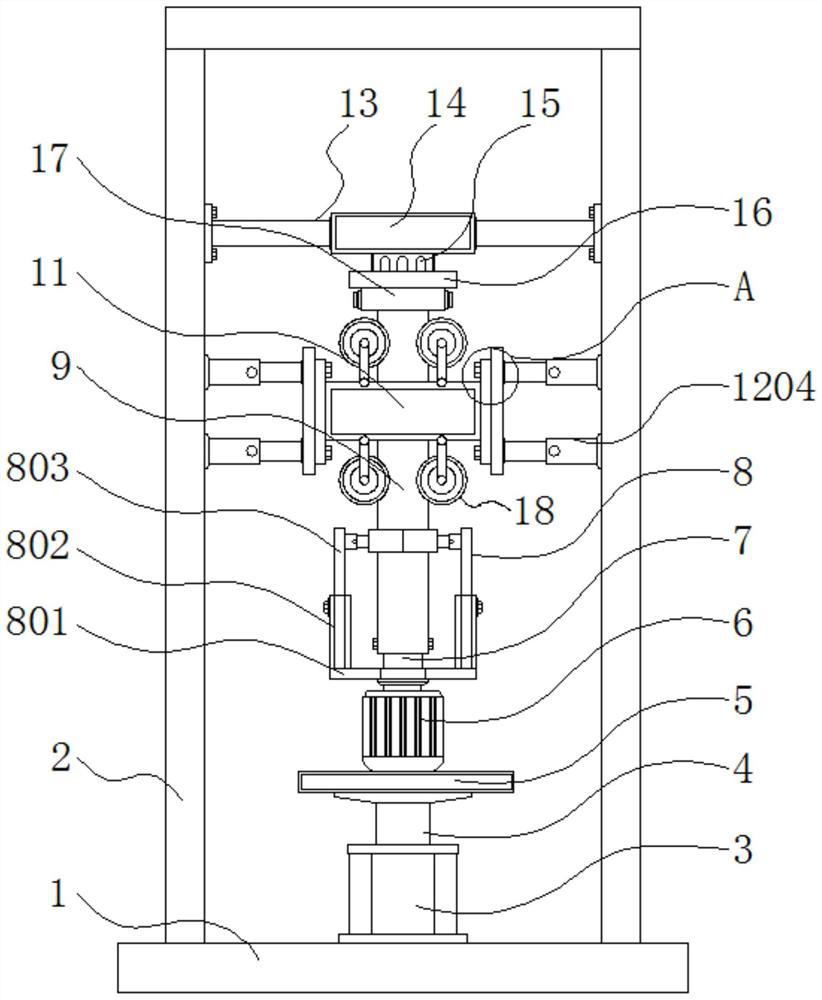

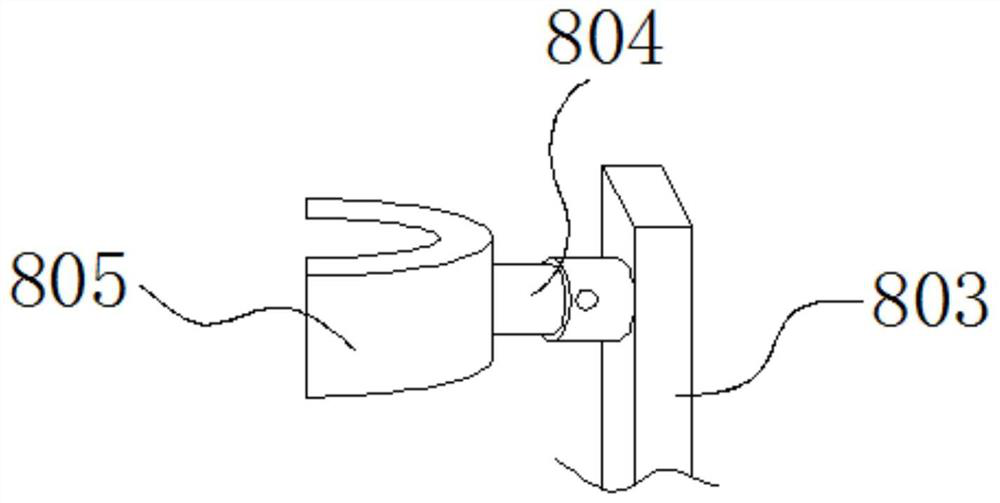

Online detection forming and distributing device of electronic elements

ActiveCN105478372AControl tightnessPlay the role of feedingSortingMetal working apparatusManufacturing engineeringElectron

The invention relates to an online detection forming and distributing device of electronic elements. Important procedures of punching, forming, detecting, packaging and the like are integrated so that full-automatic production can be achieved, and qualified products and defective products are collected in a classified manner; in this way, waste of labor, production places and transfer is greatly saved, quality of products flowing to the customer side can be guaranteed, high cost caused by customer complaints and return of products is reduced, and meanwhile the overall image of a company in hearts of customers is improved.

Owner:TAIZHOU ZHONGRUI ELECTRONICS

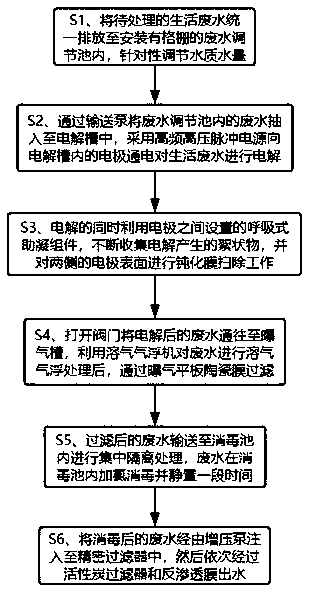

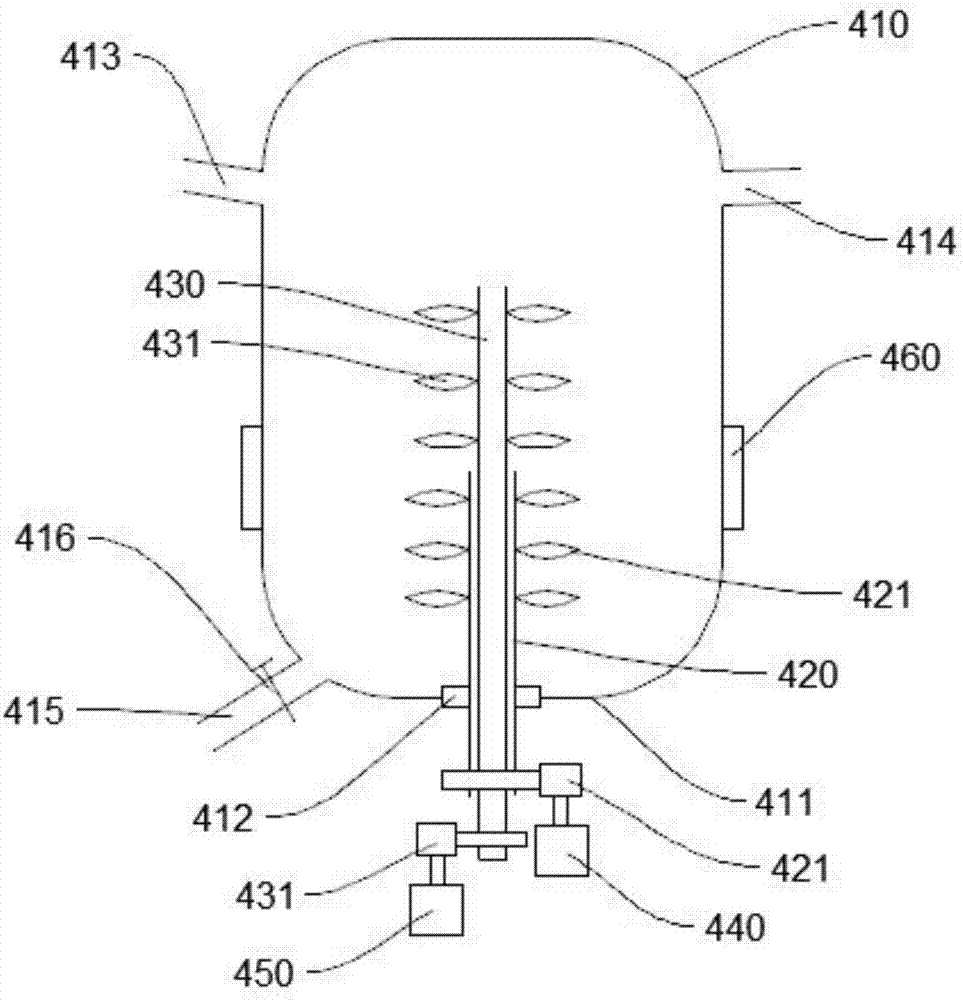

Domestic wastewater treatment method and device based on electric flocculation method

InactiveCN111392927AEasy to handleFacilitated releaseSpecific water treatment objectivesTreatment involving filtrationElectrolysisElectro flocculation

The invention discloses a domestic wastewater treatment method and device based on an electric flocculation method, belongs to the technical field of wastewater treatment, and can realize the electrolysis on the domestic wastewater based on an electric flocculation technology. A vertical flow type bipolar mode is adopted; a high-frequency high-voltage pulse power supply is used for supplying powerto remove pollutants in the wastewater and the wastewater is ; polymerized to generate floccules to be separated from the wastewater; meanwhile, a breathing type coagulation aid assembly is innovatively introduced between the adjacent electrodes, the swinging characteristic is used as a driving force so that the non-equilibrium adsorption rod generates an action similar to breathing; mixed gas ofhydrochloric acid gas and oxygen is released into the wastewater during expiration, a plurality of micro-bubbles are generated, the oxidation effect is improved to greatly improve the flocculation efficiency, the passive film on the surface of the electrodes can be dissolved, the electrolysis effect of the electrodes is improved, floccules separated from wastewater can be adsorbed and recovered during air suction, and the treatment effect of the electric flocculation technology on the wastewater is significantly improved.

Owner:芜湖耀迪环保科技有限公司

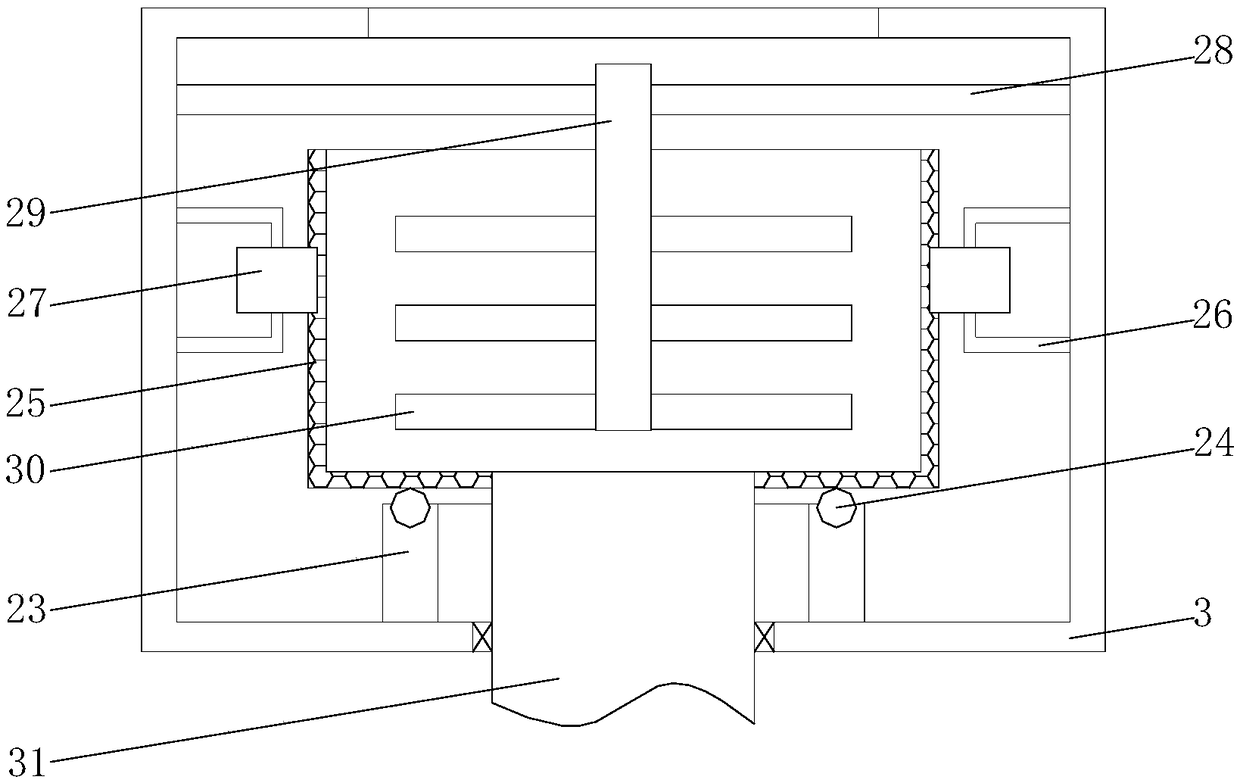

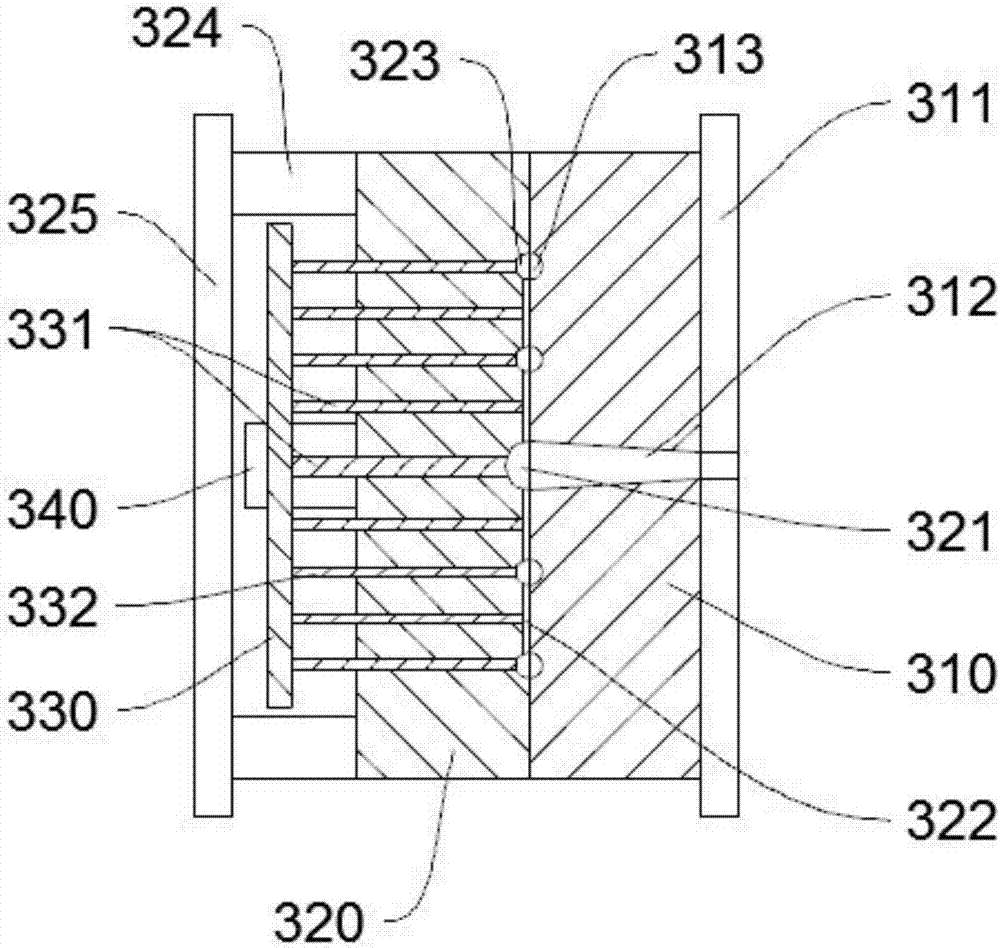

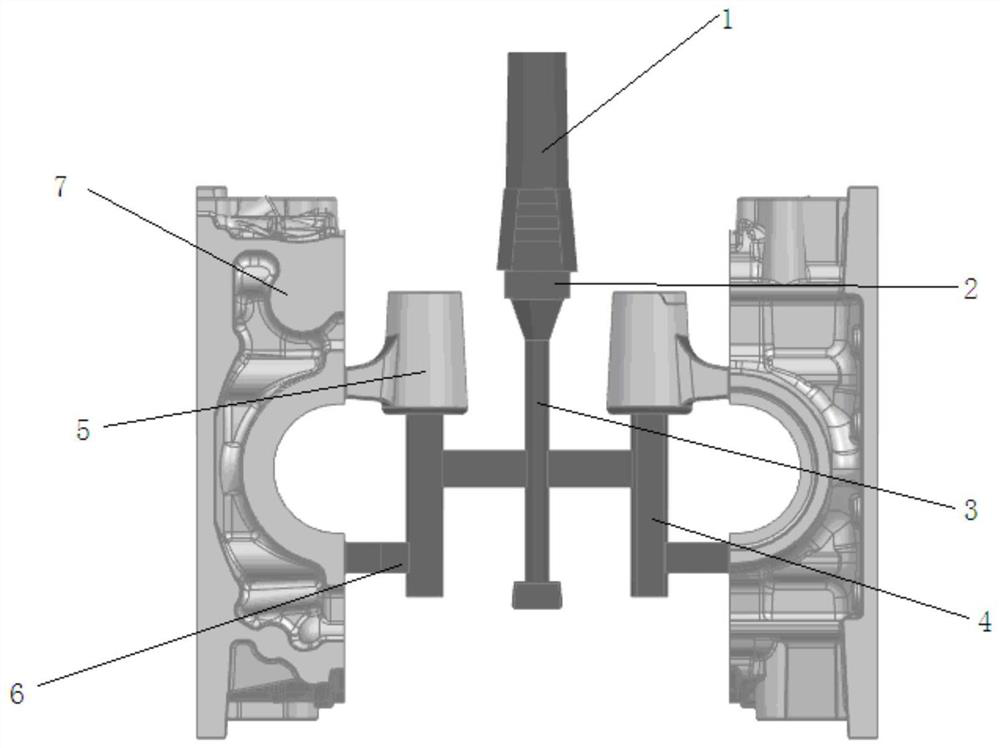

Concatemer solid blade pouring system and concatemer solid blade pouring method

ActiveCN111659856AIncrease the amount of feedShorten pouring timeFoundry mouldsFoundry coresStructural engineeringCasting mold

The invention discloses a concatemer solid blade pouring system and a concatemer solid blade pouring method. The concatemer solid blade pouring system comprises a blade pouring mold, a pouring gate arranged on the blade pouring mold and communicating with the blade pouring mold, and a pouring opening formed in the pouring gate. The blade casting mold comprises an inner edge plate mold, an outer edge plate mold and a plurality of blade molds arranged between the inner edge plate mold and the outer edge plate mold, an inner hook mold is arranged on the outer side of the inner edge plate mold, and two outer hook molds are arranged on the outer side of the outer edge plate mold. The pouring gate comprises a transverse pouring gate body, an inner pouring gate body and an outer pouring gate body, wherein the inner pouring gate body and the outer pouring gate body are arranged below the two ends of the transverse pouring gate body, and the cross-sectional areas of the inner pouring gate bodyand the outer pouring gate body by the horizontal plane are gradually reduced from top to bottom. The concatemer solid blade pouring system has the beneficial effects that the blade casting mold is transversely placed and simultaneously cast from the two ends, and double feeding channels can be formed, so that the casting and feeding distance is shortened, and the feeding amount of the blade casting mold is increased, thereby realizing the function of eliminating shrinkage porosity and shrinkage cavity.

Owner:DONGFANG TURBINE CO LTD

Novel double-edge-covered easy-to-pull adhesive tape covering device and adhesive tape covering process

The invention discloses a novel double-edge-covered easy-to-pull adhesive tape covering device which comprises a machine frame and a machine table. The left side of the machine table is provided witha feeding conveying belt. The right side of the machine table is provided with a discharging conveying belt. The upper side of the feeding conveying belt and the upper side of the discharging conveying belt are each provided with a feeding and discharging mechanism. The top end of the machine table is sequentially provided with a discharging roller, a first conveying roller, a laminating mechanism, a second conveying roller and a cutting mechanism from left to right. The laminating mechanism comprises a laminating machine body. A jig is arranged under the laminating machine body. A guide groove is formed in the upper end face of the jig. The top end of the guide groove is sequentially provided with a first transition mechanism and a second transition mechanism from left to right. By meansof the novel double-edge-covered easy-to-pull adhesive tape covering device, the automatic adhesive tape covering of a double-edge-covered medium-and-small-sized easy-to-pull adhesive tape product with a puller is realized, the adhesive tape covering and laminating process can be completed in one step by improving the jig of a laminating machine, and the production efficiency is greatly improved.

Owner:SUZHOU KECHUAN ELECTRONICS TECH

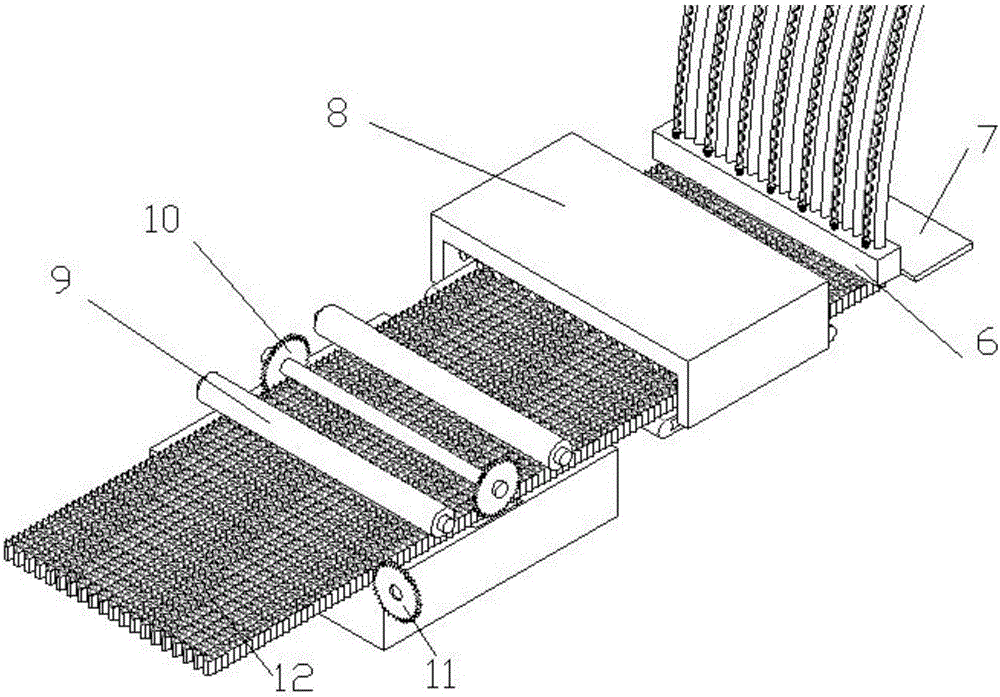

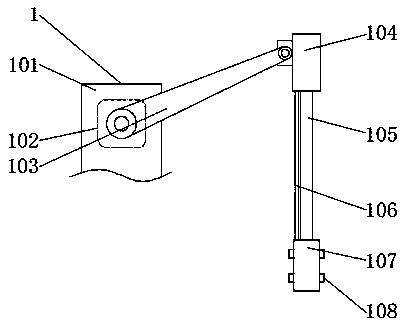

Automatic wire burying device for manufacturing escalator hairbrush

The invention provides an automatic wire burying device for manufacturing an escalator hairbrush. The device comprises a brush plate strip conveying device, a hemming wheel and a compression disc. Anemptying device is arranged at the feed inlet of the compression disc and comprises a bristle accommodating cavity; a sloping plate is arranged in the bristle accommodating cavity; a feeding device isarranged at the discharge port of the bristle accommodating cavity and comprises a double-row roller wheel, a ratchet wheel, a rotary handle, a ratchet, a push rod, a reset spring, an ejector block and a rotating pipe; a guide wire rolling wheel is arranged on a rolling wheel seat which is arranged on the outer side of a front wall plate of the bristle accommodating cavity; a stringing rolling wheel is arranged at the upper end of a mounting column; the front end of a rotating rod is connected to a connecting rod of a crankshaft connecting rod mechanism; a wire pressing rod is arranged between the a double-row roller wheel and the compression disc; a steel wire successively penetrates through wire slots in the stringing rolling wheel, the guide wire rolling wheel, the double-row roller wheel and the wire pressing rod and presses a material and is located in the wire slot in the compression disc. The automatic wire burying device for manufacturing the escalator hairbrush provided by the invention is high in degree of automation and the manufactured escalator hairbrush is good in quality.

Owner:安徽兴华制刷有限公司

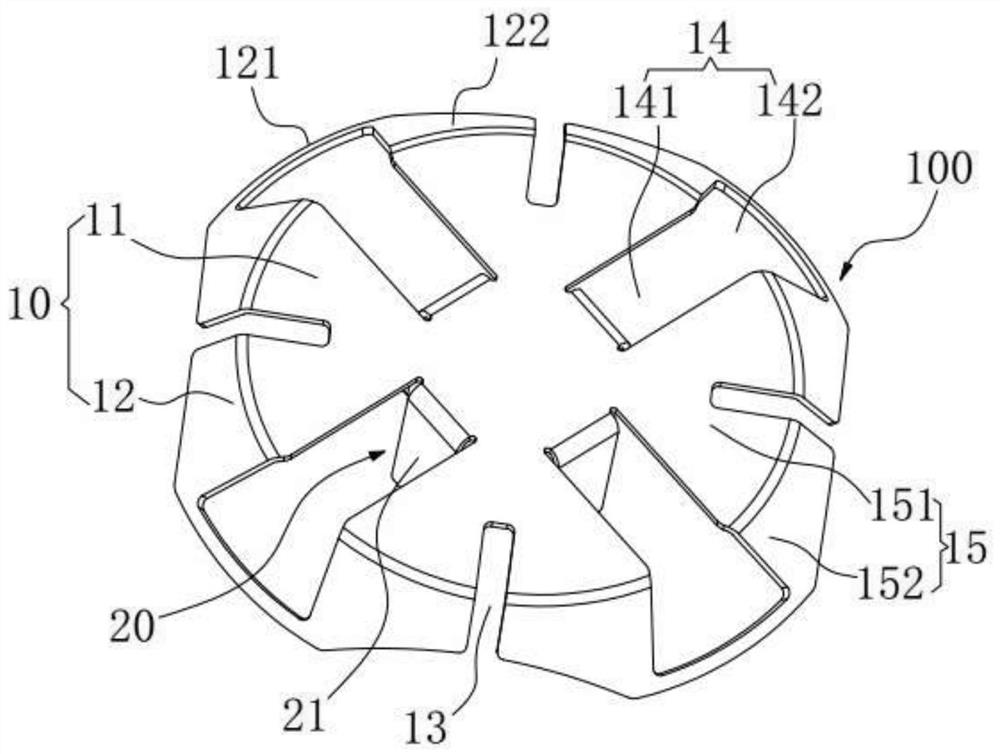

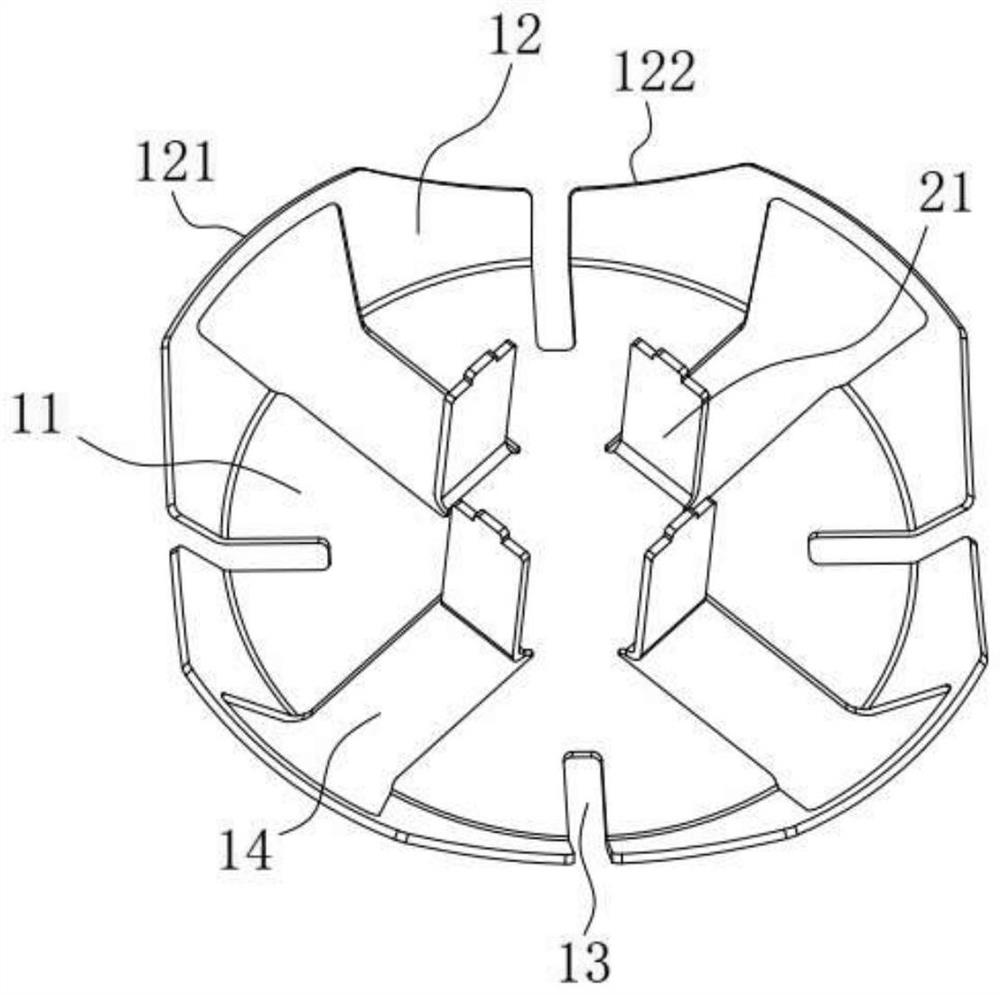

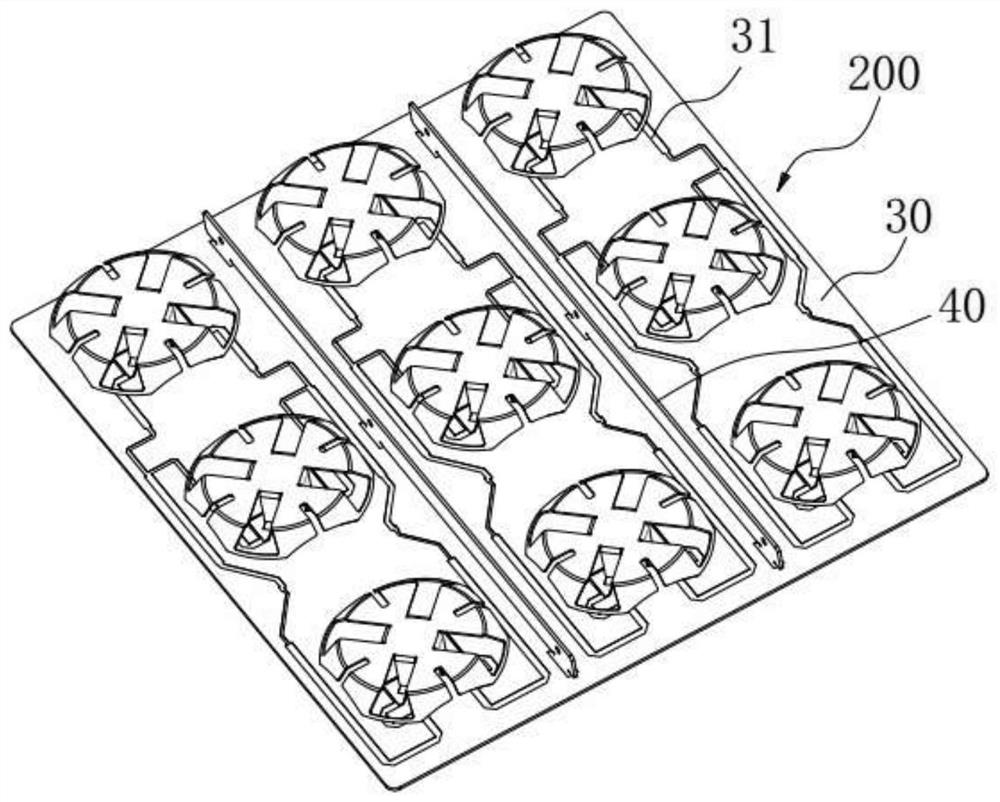

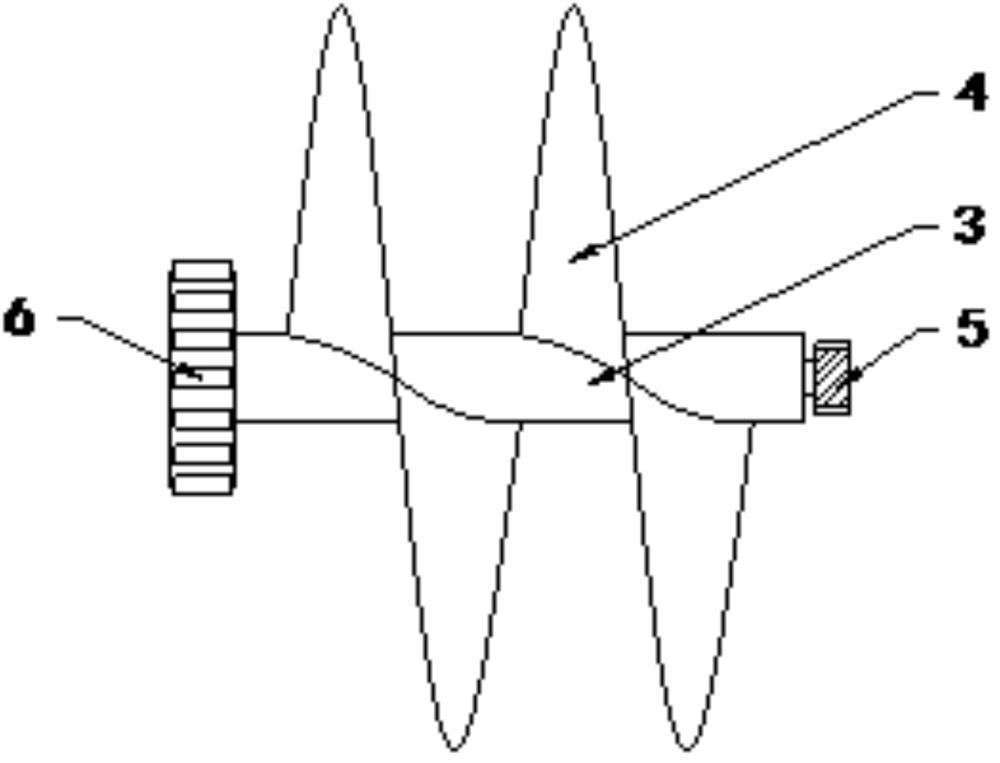

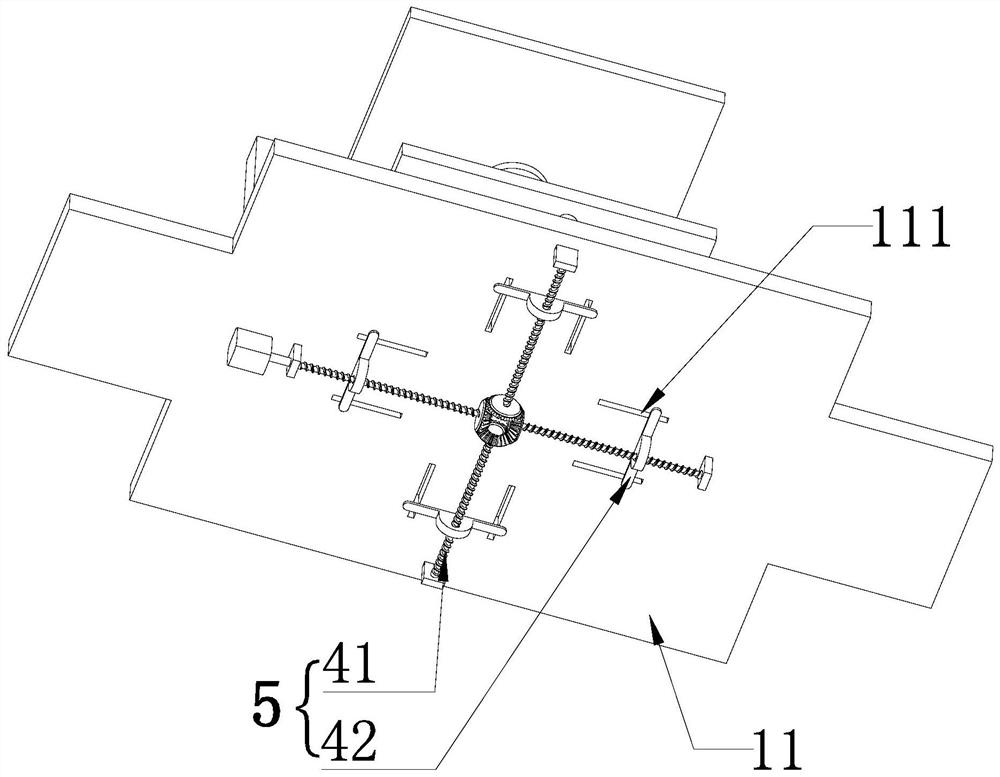

Paddle structure of adapter module

The invention discloses a paddle structure of an adapter module. The paddle structure comprises paddles arranged on a main shaft, wherein the paddles are provided with connecting rods, the main shaft is provided with threaded holes, and the connecting rods are in threaded connection with the threaded holes. The paddle structure provided by the invention has the technical effect that the angle of each paddle is adjustable, the feeding function is achieved, and a material pushing speed is adjusted.

Owner:WUXI ZHONGWANG 4D TECH

High-gain miniaturized antenna oscillator and antenna

ActiveCN112467343AReduce weightHigh strengthAntenna supports/mountingsRadiating elements structural formsSoftware engineeringMiniaturization

The present invention discloses a high-gain miniaturized antenna oscillator and antenna. The antenna oscillator is integrally formed and comprises a radiation structure and a feed supporting structure, the radiation structure comprises a first radiation body and a second radiation body, the first radiation body is horizontally arranged, the second radiation body is formed by bending the outer edgeof the first radiation body downwards, and the feed supporting structure is formed by bending the outer edge of the second radiation body downwards. The feed supporting structure comprises a plurality of vertically arranged feed supporting parts, and the feed supporting parts are formed by extending downwards from the first radiator. According to the invention, the weight of the oscillator can bereduced, the strength of the oscillator can be effectively improved, the high gain miniaturization of the base station antenna can be realized, the loss of the antenna oscillator can be reduced, andthe assembly and use of the antenna in a 5G communication frequency band are facilitated.

Owner:PROSE TECH CO LTD

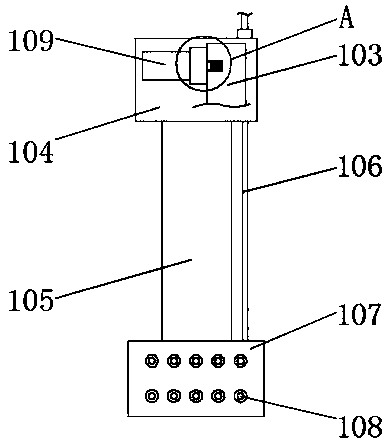

Feeding device for steel pipe machining

InactiveCN108466088AEffectively fixedAvoid damageBase supporting structuresBraking devices for hoisting equipmentsHydraulic cylinderMachining

The invention discloses a feeding device for steel pipe machining. The feeding device comprises a supporting frame and a platform, a first guide rail is arranged in the middle above the supporting frame, and two sides of the first guide rail is connected with the supporting frame though connecting rods. A first rotary table is arranged at the top of a moving column, a connecting plate is connectedto the right of the first rotary table, a hydraulic cylinder is arranged on the right side above the connecting plate, and a pressing piece is connected to the lower part of the hydraulic cylinder. Aspeed bump is arranged on the right side above the platform, a second rotary table is connected to the lower end of a rope, and a rotating structure is formed between the second rotary table and connecting blocks through a rotating shaft, jackstays are installed on upper and lower sides in the connecting blocks, and a fixing blot is connected to the outer sides of the connecting rods. The feedingdevice for steel pipe machining is capable of feeding quickly, only one person is needed for operation, the labor force is reduced, a steel pipe can be effectively fixed when the steel pipe is machined, and the damage of the steel pipe during machining is avoided.

Owner:王俊清

Shearing device for piston rubber ring machining

The invention discloses a shearing device for piston rubber ring machining, and relates to the technical field of piston rubber ring machining. The shearing device comprises a base, a clamping and fixing mechanism, a cutting mechanism and a movable positioning mechanism, a side plate is fixed to the outer side of the upper portion of the base, a hydraulic cylinder is installed above the middle ofthe base, and a piston rod is arranged above the hydraulic cylinder; and a supporting seat is fixed above the piston rod, a driving motor is installed above the supporting seat, a rotating shaft is arranged above the driving motor, an auxiliary steel core is arranged above the rotating shaft in a sleeving mode, and a rubber ring pipe blank is arranged on the outer side of the auxiliary steel core.The shearing device has the following beneficial effects that the auxiliary steel core and the rubber ring pipe blank on the outer side of the auxiliary steel core are conveniently driven to rotate through the arrangement of the driving motor and the rotating shaft, so that the cutting mechanism can rotate for a circle on the outer side of the auxiliary steel core and the rubber ring pipe blank to deepen the cutting effect; and through the arrangement of the hydraulic cylinder and the piston rod, the driving motor and the auxiliary steel core are conveniently driven to ascend and descend, andtherefore the shearing position is conveniently adjusted.

Owner:王水成

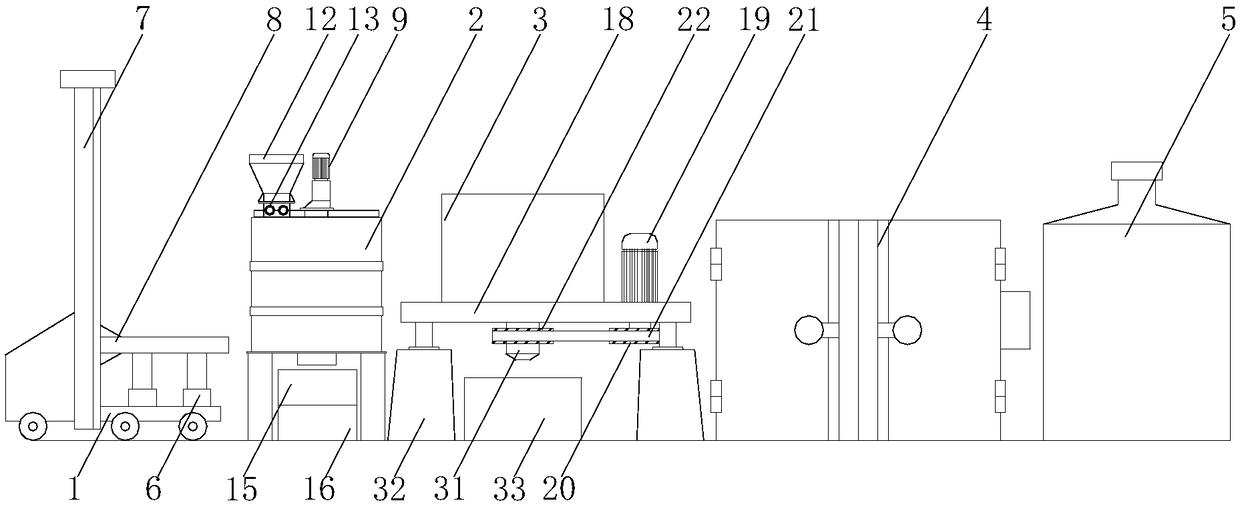

Film residue reduction system

InactiveCN109127673AReduce work intensityAcidification effect is goodSolid waste disposalTransportation and packagingAgricultural engineeringHydraulic cylinder

The invention discloses a film residue reduction system. The system comprises a charging platform, an acidification box, a dehydration box and an oven, wherein the top of the top of the charging platform is fixedly connected with a hydraulic cylinder, one side of the charging platform is fixedly connected with a fixing plate, a charging plate is glidingly connected with one side of the fixing plate, the top of the acidification box is fixedly connected with a first motor, an output end of the first motor is fixedly connected with a rotating shaft, and the bottom of the rotating shaft is fixedly connected with stirring blades. The charging platform, the hydraulic cylinder, the fixing plate and the charging plate can play a charging role during reduction of film residues, and the working intensity is reduced; the acidification box, the first motor, the rotating shaft and the stirring blades can play an acidification role during reduction of film residues; the acidification effect on thefilm residues is better through stirring, and a third motor and a grinding gear play a crushing role on film residues in larger sizes during discharging, so that the film residues are more thoroughlyacidized.

Owner:深圳市伟绿达科技有限公司

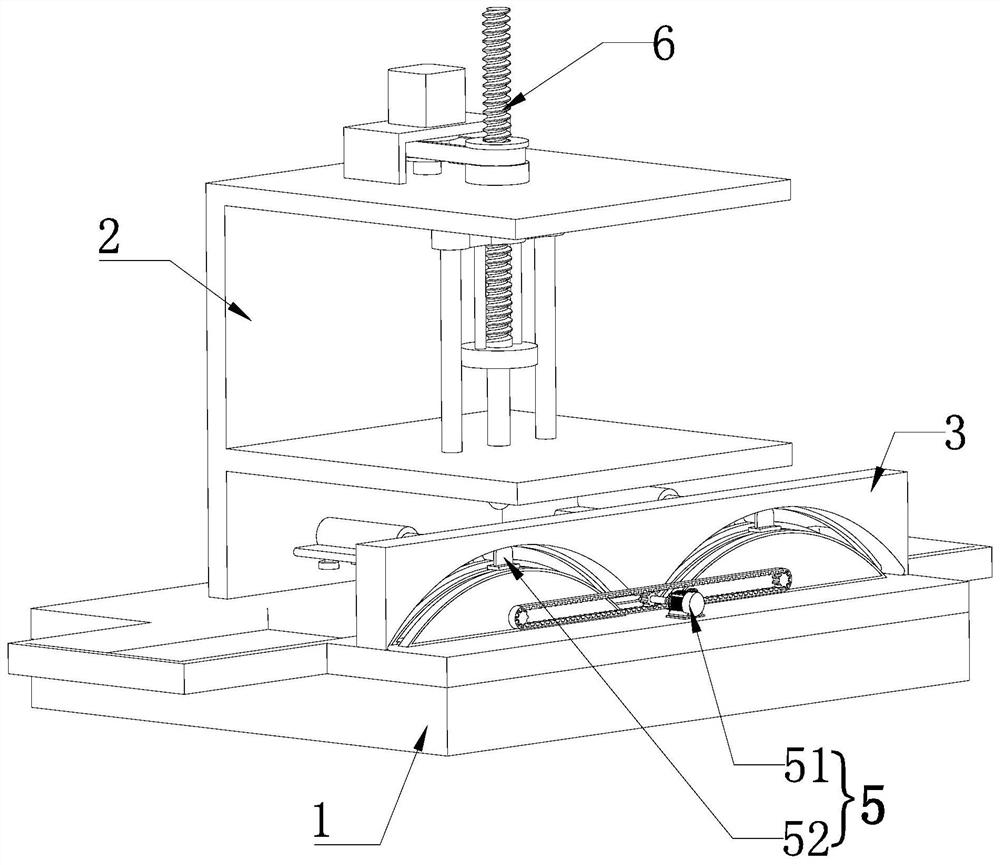

Semicircular bolt forming equipment and process thereof

The invention discloses semicircular bolt forming equipment and a process thereof, and particularly relates to the technical field of bolts. The semicircular bolt forming equipment comprises a box body, wherein a hydraulic mechanism is connected to the top end of the inner side of the box body through screws; a fixing frame is installed below the hydraulic mechanism; a connecting base is arranged below the inner side of the fixing frame; a movable punch is installed below the connecting base; a discharging hole is formed in the inner side of the movable punch; a feeding mechanism is arranged above the connecting base; a sliding mechanism is installed at the bottom end of the inner side of the box body; a workbench is arranged above the sliding mechanism; and a fixing groove is formed in the upper surface of the workbench. According to the semicircular bolt forming equipment and the process thereof provided by the invention, a T-shaped cushion block and a strong spring are arranged, when the strong spring is used, strong support is provided when a movable punching core does not abut against the T-shaped cushion block, so that the pre-forming effect is achieved; and the strong spring is stable in stress, so that the situation that the single side is stressed in the deformation process is avoided, and a pre-forming shape structure is more stable.

Owner:鹏驰五金制品(昆山)有限公司

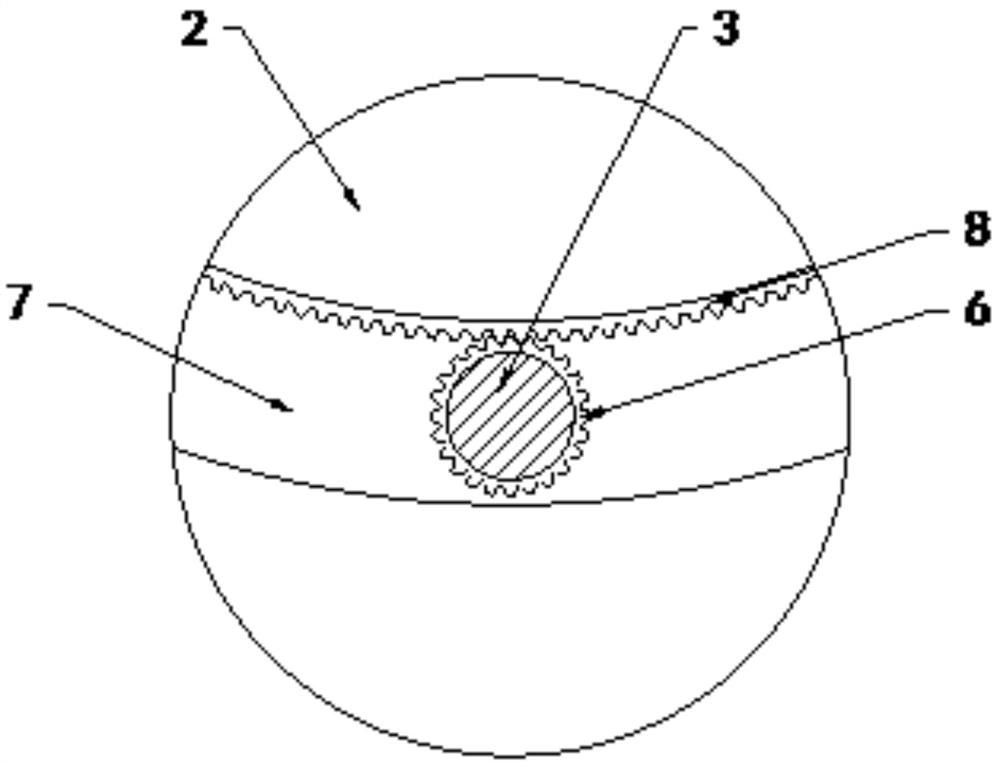

Electric blind valve

ActiveCN110953352BAvoid easy cloggingPlay the role of feedingOperating means/releasing devices for valvesHollow article cleaningGear wheelRack and pinion

Owner:GUOWEI VALVE MFG CO LTD

Digital stamped workpiece automatic machining assembly line

PendingCN110203686AImprove processing efficiencyIncrease productivitySpraying apparatusConveyor partsAssembly lineEngineering

The invention discloses a digital stamped workpiece automatic machining assembly line. The digital stamped workpiece automatic machining assembly line comprises a base. A bottom film fixed seat is arranged at the upper end of the base, an air cylinder seat is further arranged at the upper end of the base, a discharging mechanism is arranged on the outer wall of the base, a release agent spraying mechanism is arranged on one side of the bottom film fixed seat, a bottom film is arranged on the other side of the bottom film fixed seat, pressing film positioning rods are arranged at the end, closeto the bottom film, of the bottom film fixed seat, the other ends of the pressing film positioning rods are connected with an air cylinder seat, an air cylinder is arranged in the air cylinder seat,and one end of the air cylinder is connected with a pressing film. The digital stamped workpiece automatic machining assembly line can automatically carry out spraying work of a release agent, the machining efficiency of stamped workpieces can be greatly improved, the production efficiency of the workpieces is improved, meanwhile, the discharging procedure is carried out through a machine, and thestep of manual fetching is omitted.

Owner:东莞市潜翔通讯器材有限公司

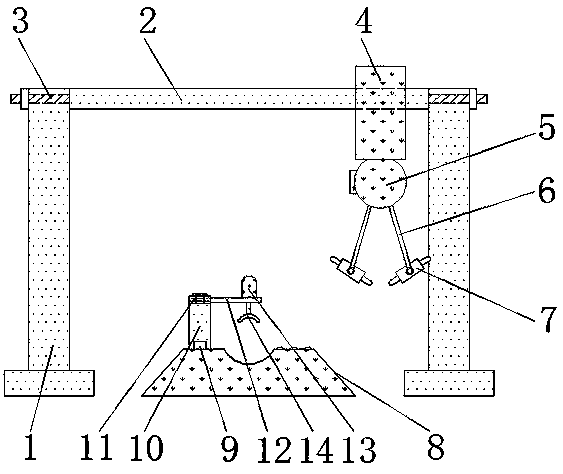

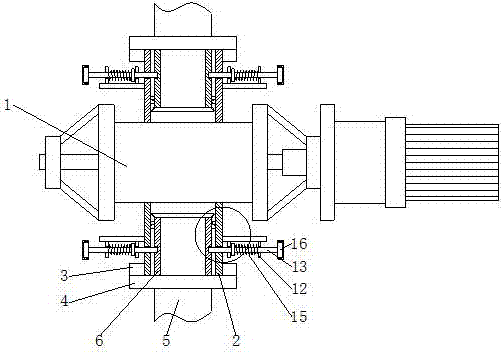

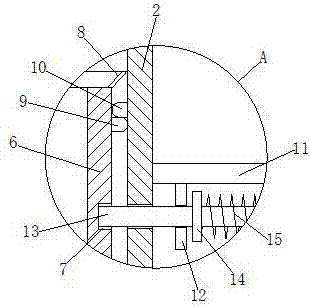

Continuous rheomolding device for manufacturing metal plate strips

InactiveCN101890431BIncreased speed of continuous rheological formingGood formabilityMetal rolling arrangementsAlloyMolten metal

The invention provides a continuous rheomolding device for manufacturing metal plate strips. The device comprises an inclined plate, a base, an electromagnetic vibration exciter and a double-roller rolling mill and is characterized by also comprising the double-roller rolling mill, wherein the inclined plate is formed by connecting a feeding section, a pulping section and a discharging section inturn; the lower side of a bottom plate of the pulping section is connected with the upper end of a spring; the lower end of the spring is fixed on the base; one end of the electromagnetic vibration exciter is fixed on the base, and the other end of the electromagnetic vibration exciter is connected with the lower side of the bottom plate of the pulping section; and gaps are formed between the bottom plate and two side plates of the discharging section and the roll surfaces of upper and lower rollers of the double-roller rolling mill. The range of vibration frequency which can be provided by the electromagnetic vibration exciter adopted by the device is expanded greatly and the vibration frequency is adjusted so that an alloy structure can be improved more effectively and molten metal is prevented from crusting on the surface of the inclined plate.

Owner:NORTHEASTERN UNIV LIAONING

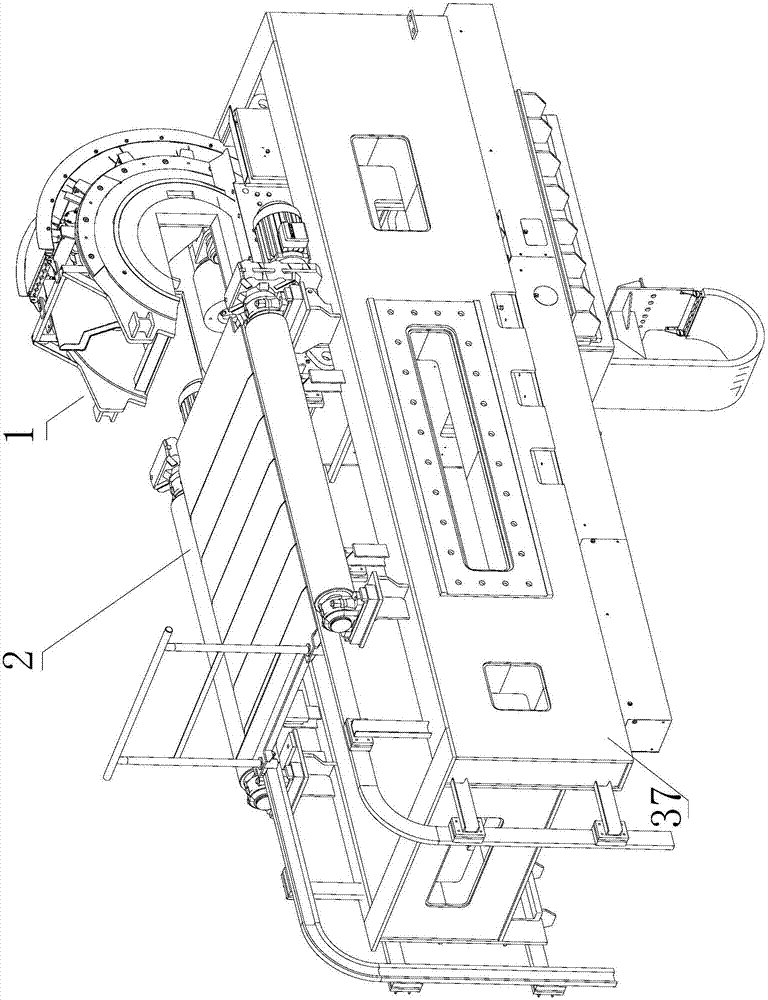

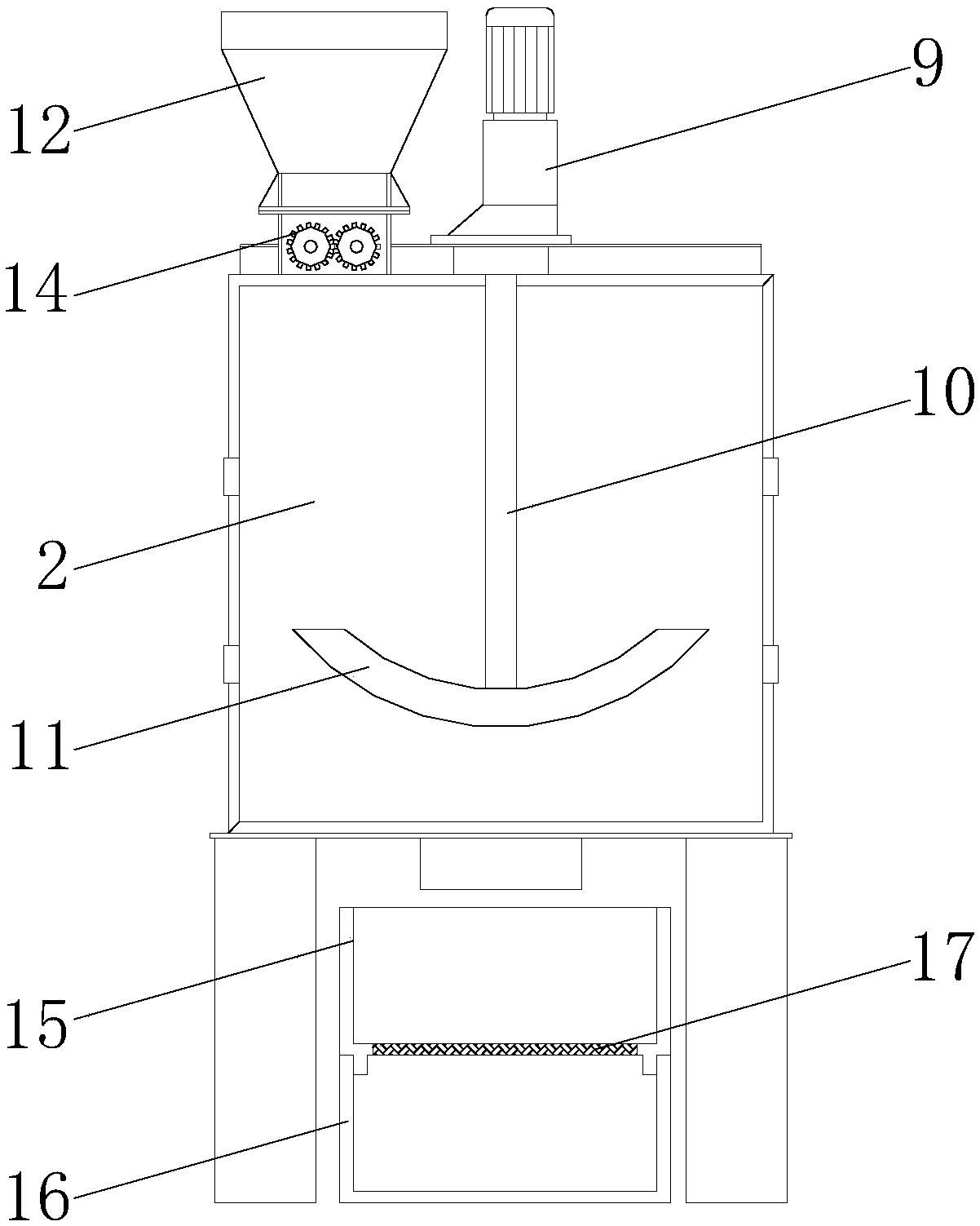

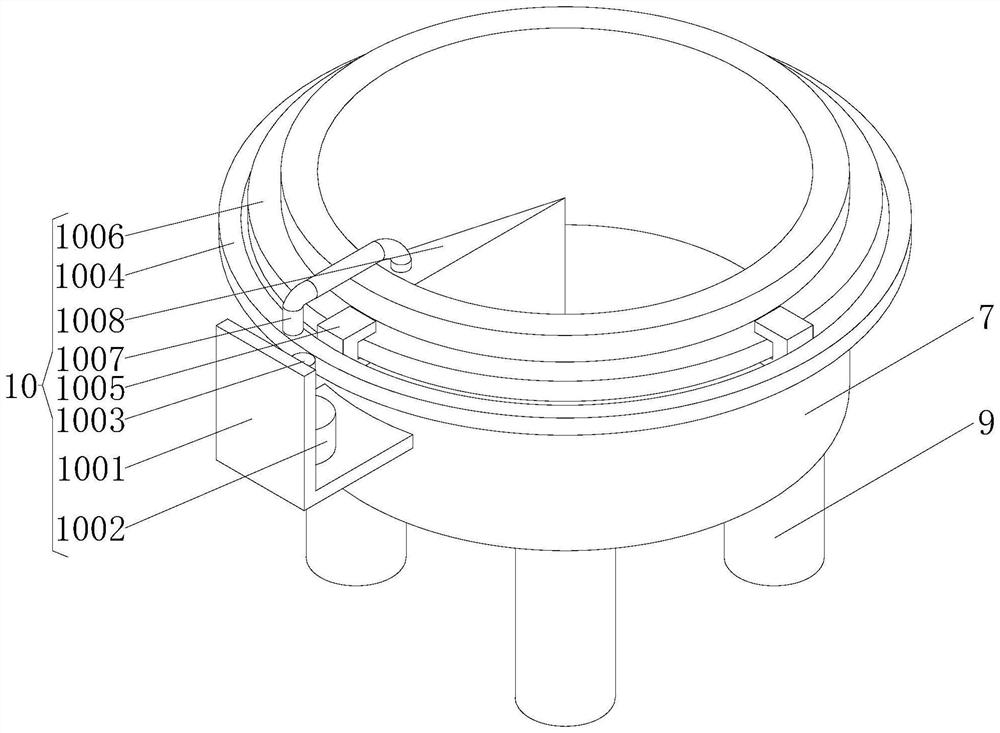

Dry-type discharging method and device for waste lithium battery

PendingCN113851743AAvoid accumulationPrevent localized temperature risesWaste accumulators reclaimingSecondary cells charging/dischargingProcess engineeringEnvironmental engineering

The invention discloses a dry-type discharge method and device for a waste lithium battery.A lithium battery and conductive sand are mixed and put into a conductive barrel, the conductive barrel is driven to rotate, the mixture of the lithium battery and the conductive sand runs from a feed port to a discharge port in the conductive barrel, and in the running process, the positive electrode and the negative electrode of the lithium battery are connected through the conductive sand to form a discharging loop, and heat generated in the discharging process of the lithium battery is discharged by the heat dissipation device of the conductive cylinder; and in the process of discharging the lithium battery through the conductive sand, wastewater, waste gas and other substances which pollute the environment cannot be generated, the conductive sand can be recycled, heat generated in the discharging process is discharged through the heat dissipation device, and potential safety hazards do not exist.

Owner:SHANDONG WANGCHAOTIANRUN MACHINERY MFG CO LTD

A pouring system and pouring method for conjoined solid blades

ActiveCN111659856BIncrease the amount of feedShorten pouring timeFoundry mouldsFoundry coresCasting moldMaterials science

The invention discloses a conjoined solid blade pouring system and pouring method, comprising a blade pouring mold, a sprue arranged on the blade pouring mold and communicated with the blade pouring mold, and a pouring port arranged on the runner, the blade The pouring mold includes an inner edge plate mold, an outer edge plate mold, and several blade molds arranged between the inner edge plate mold and the outer edge plate mold. An inner hook mold is arranged on the outer side of the inner edge plate mold, and the outer edge plate mold Two external hook molds are arranged on the outside of the mold, and the runner includes a runner, an inner runner and an outer runner arranged under both ends of the runner, and the inner runner and the outer runner are cross-sectional by a horizontal plane. The area decreases gradually from top to bottom. The beneficial effects of the present invention are: placing the casting mold of the blade horizontally, pouring from both ends simultaneously, can form double feeding channels, thereby shortening the distance of pouring and feeding, and increasing the feeding amount of the casting mold of the blade, so as to realize The function of eliminating shrinkage and shrinkage.

Owner:DONGFANG TURBINE CO LTD

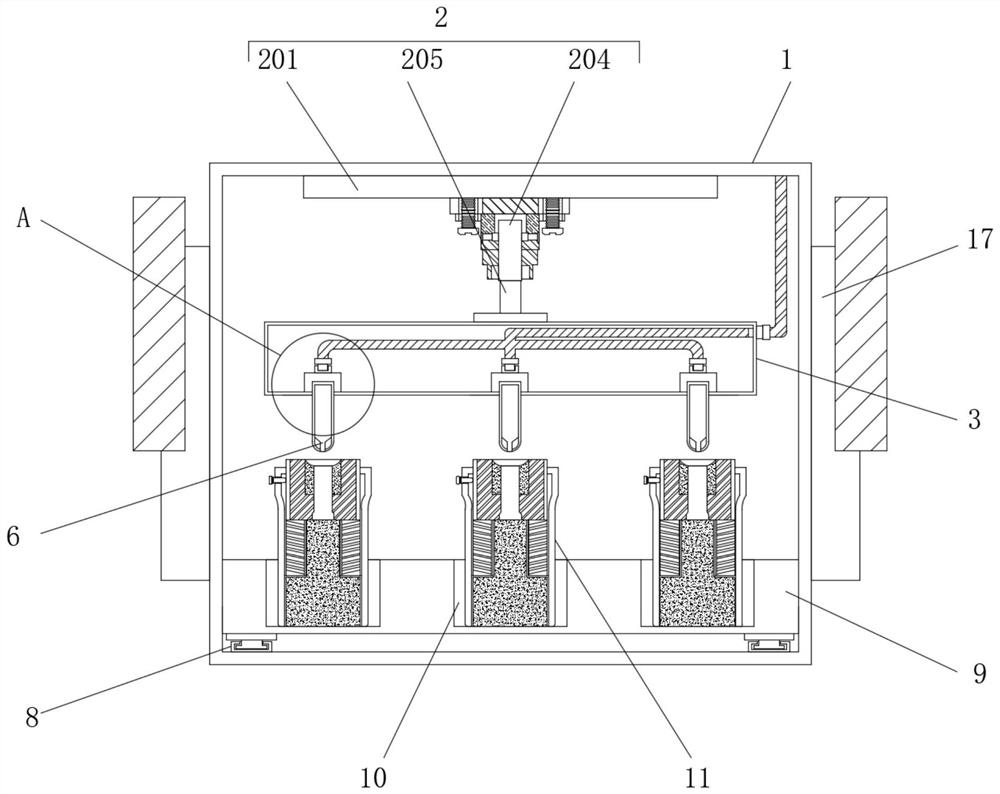

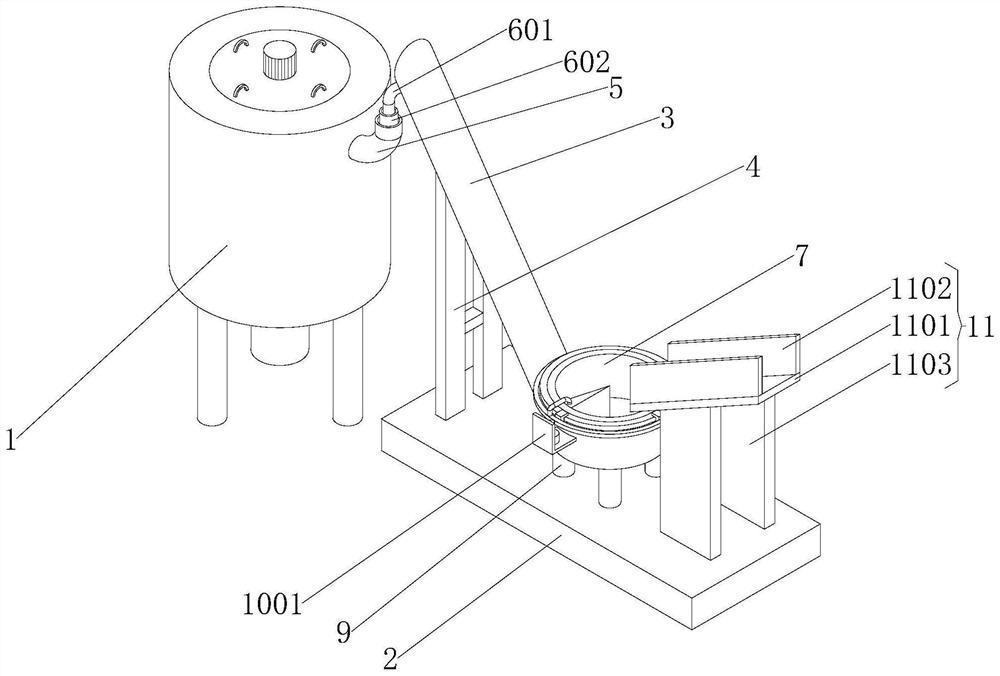

Automatic cosmetic filling machine

InactiveCN108751093APlay the role of feedingAchieve the effect of automatic fillingLiquid bottlingEngineeringMechanical engineering

The invention discloses an automatic cosmetic filling machine. The automatic cosmetic filling machine comprises a first fixed plate, wherein a motor is fixedly arranged on the first fixed plate; a first rotary shaft is arranged at the output end of the motor; one end, away from the motor, of the first rotary shaft penetrates through the second fixed plate and is fixedly connected with the center of a first gear; second gears are respectively arranged at both ends of the first gear; the first gear is engaged with the second gears; one side, away from each second gear, of the first gear is provided with a gear rack; each gear rack and the first gear are movably connected by a sliding block and a slide rail. The automatic cosmetic filling machine has the beneficial effects that the automaticfilling effect is realized, the labor intensity is greatly decreased, the time is shortened, and the working efficiency is greatly improved; by adjusting the speed of the motor, the purpose of speed adjusting is reached, and the practicality is greatly improved.

Owner:HEFEI FENGJIE BIOLOGICAL TECH CO LTD

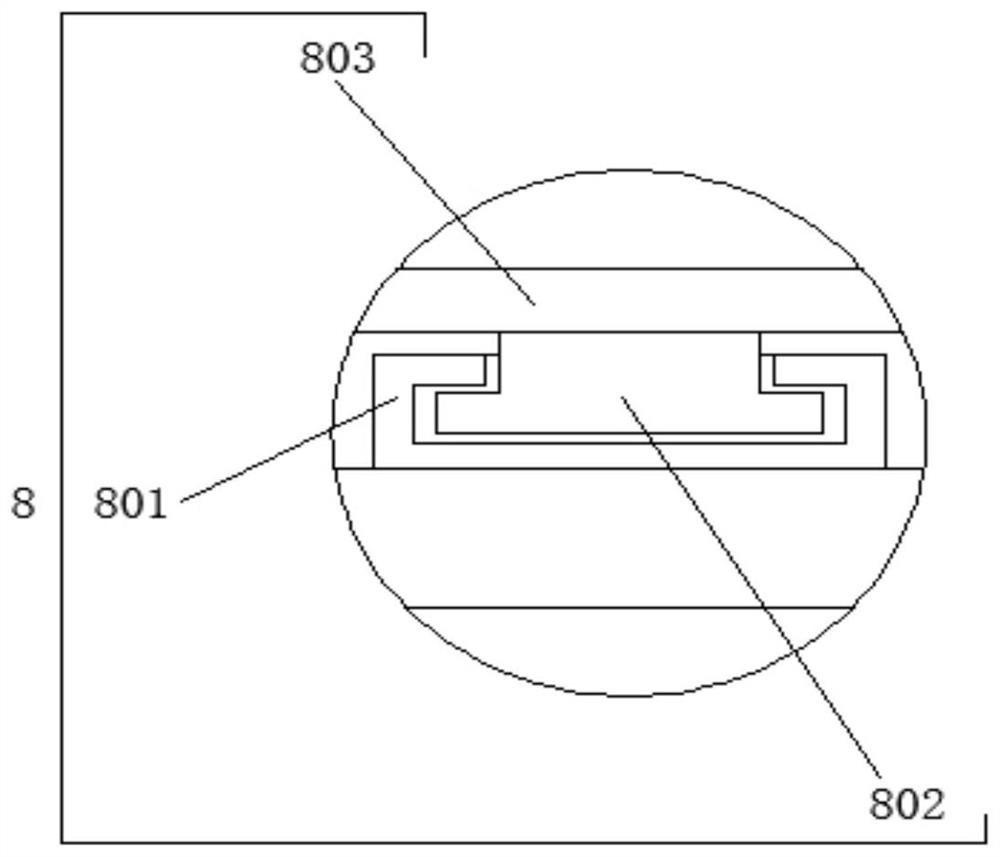

Discharging machine with good sealing effect

InactiveCN107381061AGood sealing effectImprove practicalityBulk conveyorsCantileverPulp and paper industry

The invention discloses a shut-off fan with good sealing effect, which comprises a shut-off fan body, the top and bottom of the shut-off fan body are connected with first pipes, and the surface of the first pipe is fixedly connected to an end far away from the shut-off fan body. There is a first fixing ring, the side of the first fixing ring away from the main body of the fan is fixedly connected with the second fixing ring, the side of the second fixing ring away from the first fixing ring is connected with a connecting pipe, and the first fixing ring is connected with a connecting pipe. The side of the two fixing rings away from the connecting pipe is communicated with a second pipe. The present invention achieves a good sealing effect by arranging the second pipe, the card slot, the circular baffle plate, the second sealing gasket, the first sealing gasket, the cantilever beam, the collar, the moving column, the limit ring, the spring and the handle to cooperate with each other. The advantages of the utility model solve the problem that the existing fan is not tightly sealed, so that when the fan is in use, it is not easy to leak air and run out of materials, which improves the practicability of the fan and is suitable for popularization and use.

Owner:泰州瑞沣环保科技有限公司

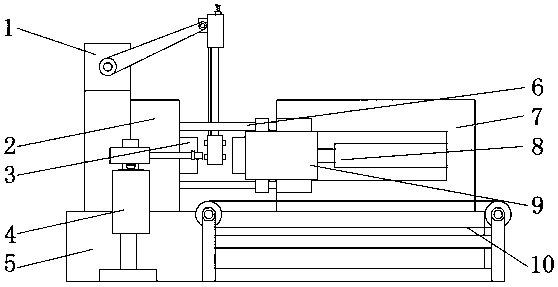

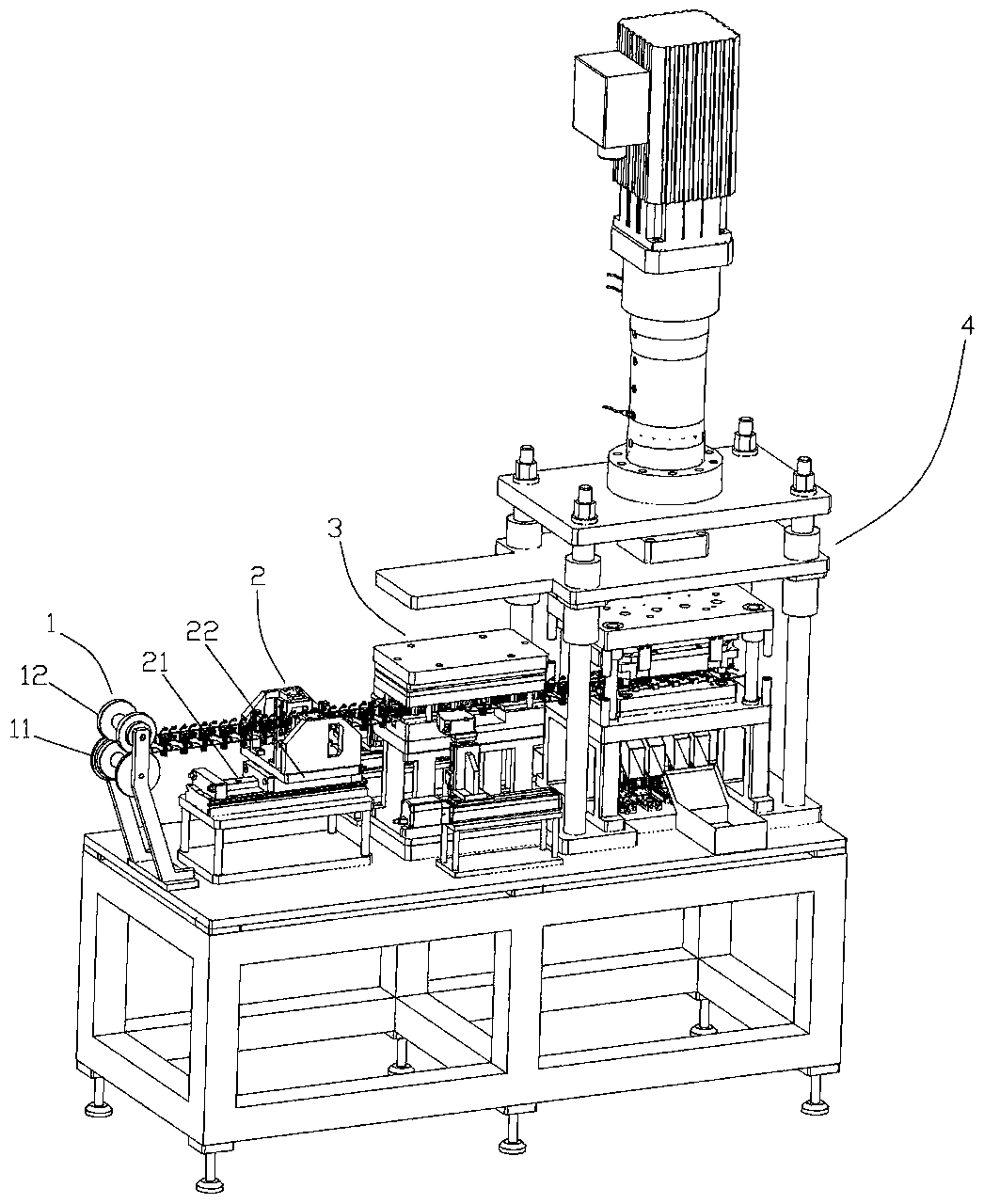

Electronic component online detection molding distribution equipment

ActiveCN105478372BControl tightnessPlay the role of feedingSortingMetal working apparatusPunchingElectronic component

The invention relates to an online detection forming and distributing device of electronic elements. Important procedures of punching, forming, detecting, packaging and the like are integrated so that full-automatic production can be achieved, and qualified products and defective products are collected in a classified manner; in this way, waste of labor, production places and transfer is greatly saved, quality of products flowing to the customer side can be guaranteed, high cost caused by customer complaints and return of products is reduced, and meanwhile the overall image of a company in hearts of customers is improved.

Owner:TAIZHOU ZHONGRUI ELECTRONICS

Drilling equipment for PCB short slot hole processing and drilling process thereof

ActiveCN114012835ASolve the problem that secondary operations are required and the processing efficiency is reducedSolve the deviation of prone depthMetal working apparatusEngineeringMechanical engineering

The invention discloses drilling equipment for PCB short slot hole processing and a drilling process thereof, and relates to the technical field of PCB drilling. The drilling equipment comprises a fixed base, a driving placing frame, a movable placing frame, a fixing mechanism, a conveying mechanism and a drilling mechanism, wherein the fixed base is provided with a discharging platform; the discharging platform is provided with a discharging groove; linear holes are arranged in the periphery of the bottom end of the discharging platform; a feeding base and a discharging base are arranged on two sides of the discharging platform correspondingly; the fixing mechanism is arranged in the fixed base; the conveying mechanism is arranged in the movable placing frame; and the drilling mechanism is arranged on the driving placing frame. According to the invention, the problems that in the prior art, due to the fact that drilling equipment is prone to depth deviation during drilling, a circuit board needs secondary operation, and due to the fact that an existing drilling device is inconvenient to fix the circuit board, deviation is likely to occur during drilling of the circuit board, and inconvenience is brought to people are solved.

Owner:惠州市协昌电子有限公司

An automatic embedding device for making escalator brushes

The invention provides an automatic wire burying device for manufacturing an escalator hairbrush. The device comprises a brush plate strip conveying device, a hemming wheel and a compression disc. Anemptying device is arranged at the feed inlet of the compression disc and comprises a bristle accommodating cavity; a sloping plate is arranged in the bristle accommodating cavity; a feeding device isarranged at the discharge port of the bristle accommodating cavity and comprises a double-row roller wheel, a ratchet wheel, a rotary handle, a ratchet, a push rod, a reset spring, an ejector block and a rotating pipe; a guide wire rolling wheel is arranged on a rolling wheel seat which is arranged on the outer side of a front wall plate of the bristle accommodating cavity; a stringing rolling wheel is arranged at the upper end of a mounting column; the front end of a rotating rod is connected to a connecting rod of a crankshaft connecting rod mechanism; a wire pressing rod is arranged between the a double-row roller wheel and the compression disc; a steel wire successively penetrates through wire slots in the stringing rolling wheel, the guide wire rolling wheel, the double-row roller wheel and the wire pressing rod and presses a material and is located in the wire slot in the compression disc. The automatic wire burying device for manufacturing the escalator hairbrush provided by the invention is high in degree of automation and the manufactured escalator hairbrush is good in quality.

Owner:安徽兴华制刷有限公司

Backing material feeding device for diatom ooze production and processing and feeding method thereof

InactiveCN112249523AWith stable feedingFirmly connectedLarge containersSupporting framesProcess engineeringIndustrial engineering

The invention discloses a backing material feeding device for diatom ooze production and processing and a feeding method thereof. The backing material feeding device comprises a stirring box body, a containing plate is arranged at the right side of the stirring box body, and a spiral feeder used in cooperation with the stirring box body is arranged at the top of the containing plate. Through cooperative use of the stirring box body, the containing plate, the spiral feeder, a supporting frame, a feeding pipe, a discharging mechanism, a feeding bin body, a connecting pipe, supporting legs, an anti-blocking mechanism and a bearing mechanism, the problems that in the using process of an existing backing material feeding device for diatom ooze production and processing, blockage occurs in a feeding bin due to excessive pouring of backing materials, consequently, the backing material feeding speed is slow, the diatom ooze production and processing efficiency is low, inconvenience is broughtto a user, and use of the user is affected are solved, and the backing material feeding device for diatom ooze production and processing and the feeding method thereof have the advantage that stable feeding can be achieved in the using process, and the backing material feeding device for diatom ooze production and processing and the feeding method thereof are worthy of popularization.

Owner:湖南旺佳环保智能科技有限公司

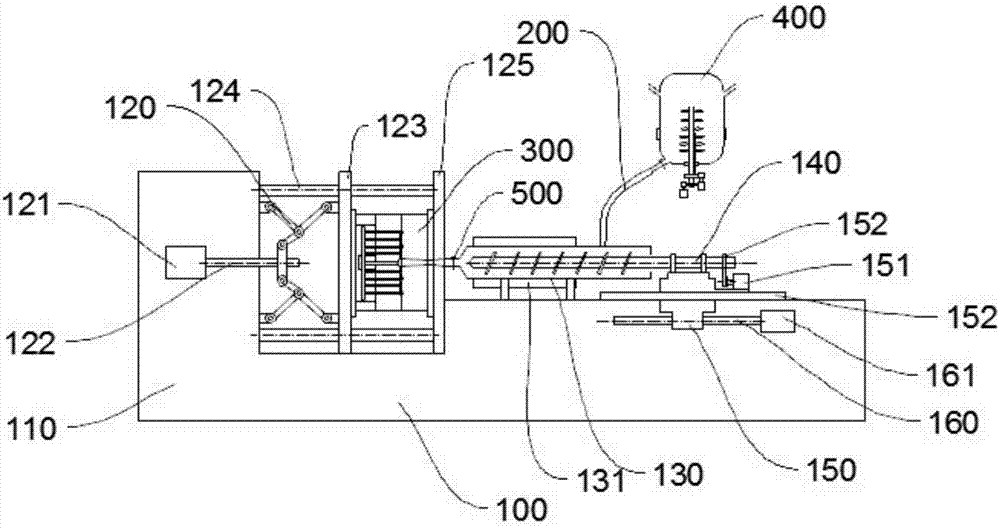

Carbon molecular sieve mixing and forming device

InactiveCN107160734AEvenly distributedPlay the role of feedingRotary stirring mixersTransportation and packagingMolecular sieveEngineering

The invention discloses a carbon molecular sieve mixing and forming device which is characterized by comprising a forming device, wherein the forming device is connected with a mixing device through a material conveying pipeline; the forming device comprises a pedestal; a moving die motor is arranged on the pedestal; the moving die motor is connected with a moving die screw rod; the moving die screw rod is connected with the middle part of a moving die transmission device; one end of the moving die transmission device is fixed on the pedestal, and the other end of the moving die transmission device is fixed on a moving die fixing plate; a guide column is arranged on the pedestal; the guide column penetrates through the moving die fixing plate and is connected with a static die fixing plate; a forming die is arranged between the moving die fixing plate and the static die fixing plate; the static die fixing plate is connected with a pretreatment barrel through an injection valve; the pretreatment barrel is fixed on the pedestal; a heat preservation device is arranged on the outer wall of the pretreatment barrel; a screw is arranged on the pretreatment barrel; the screw is arranged on a sliding seat; a screw motor is arranged on the sliding seat; the screw motor is connected with the screw through a transmission device; the sliding seat is arranged on a linear sliding rail; the linear sliding rail is fixed on the pedestal; the lower end of the sliding seat is connected with an injection screw rod; and the injection screw rod is connected with an injection motor. The carbon molecular sieve mixing and forming device has the characteristics that micro holes are uniformly distributed on a product produced by the carbon molecular sieve mixing and forming device, no clearance is easy to form and the adsorption efficiency during actual application is relatively high.

Owner:HUZHOU MINQIANG CARBON IND CO LTD

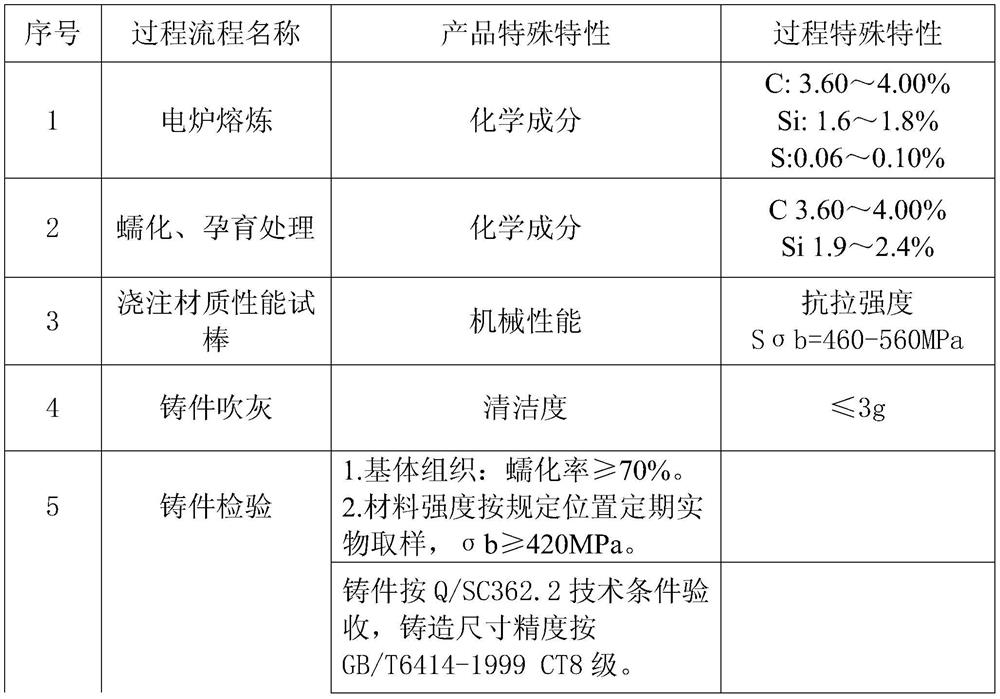

Light-weight crankcase body casting pouring system and casting process thereof

ActiveCN113523193APlay the role of feedingImprove compactnessFoundry mouldsFoundry coresEngineeringCrankcase

The invention discloses a light-weight crankcase casting pouring system and a casting process thereof. The pouring system comprises a sprue, a cross gate, branch sprues, branch cross gates, risers and ingates, wherein the sprue is connected with the cross gate, the cross gate is connected with the branch sprues, the branch sprues are connected with the branch cross gates, the risers are connected to the tops of the branch cross gates, and the ingates are connected to the tops of the branch cross gates; the bottoms of the branch cross gates are connected with the ingates, the ingates are connected with a casting; vertical pouring is adopted, a riser is arranged at the upper end of a bearing guard of the casting for feeding, and molten iron is fed into the riser and the ingates for pouring. According to the method, the high feeding capacity of vermicular graphite cast iron is used for feeding the bearing guard of the machine body or box casting, and due to the fact that the thickness of the bearing guard reaches 50 mm or above, feeding is difficult to achieve through graphitization expansion of molten iron; the riser is arranged on the upper portion of the bearing guard for feeding, in the solidification and shrinkage process of the bearing guard, molten iron in the riser enters the bearing guard to meet the requirement for molten iron needing to be supplemented for shrinkage of a casting, and the feeding effect is achieved.

Owner:上柴动力海安有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com