Electronic component online detection molding distribution equipment

A technology of electronic components and equipment, which is applied in the field of online detection, molding and distribution equipment of electronic components, which can solve the problems of low efficiency and high labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

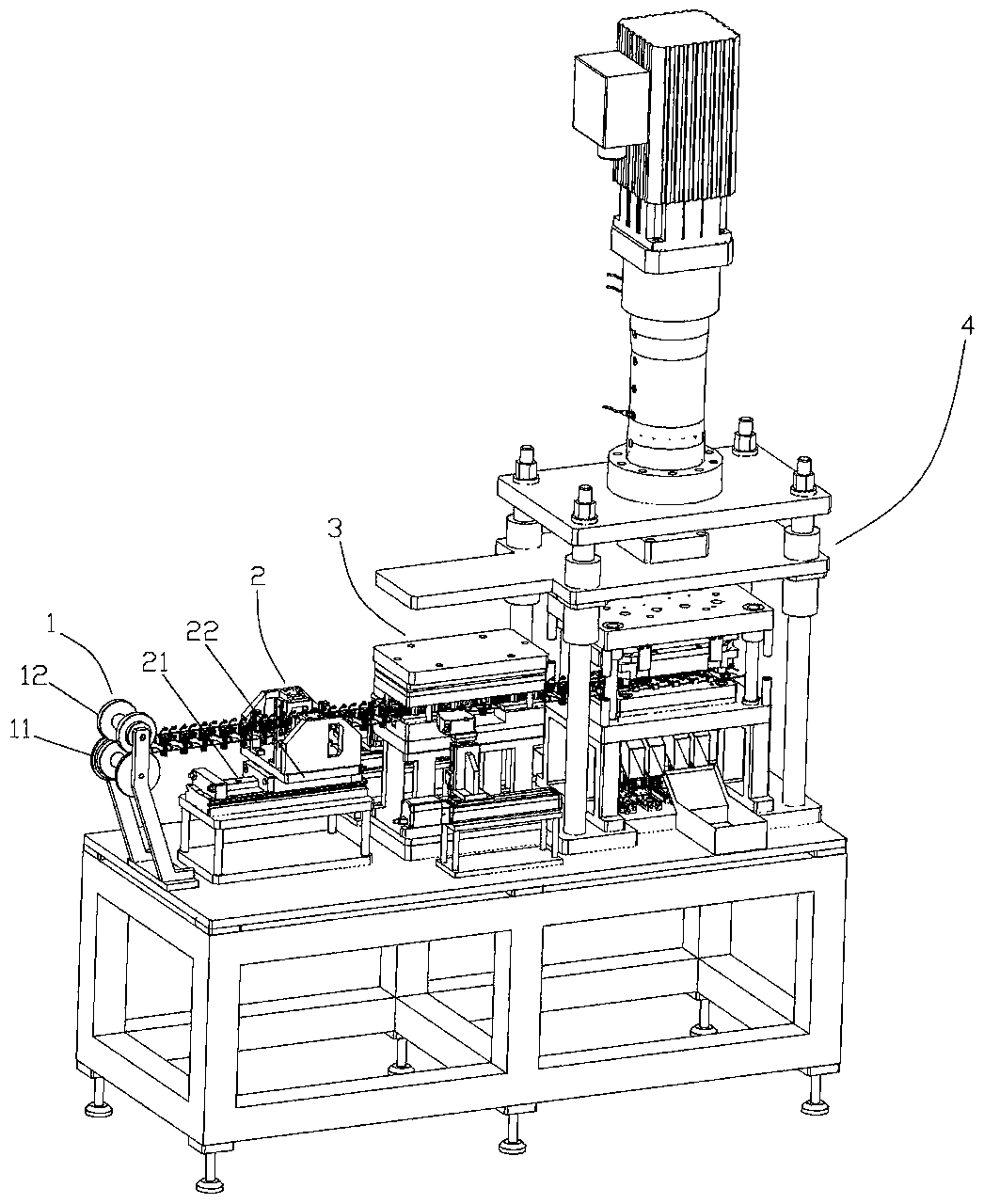

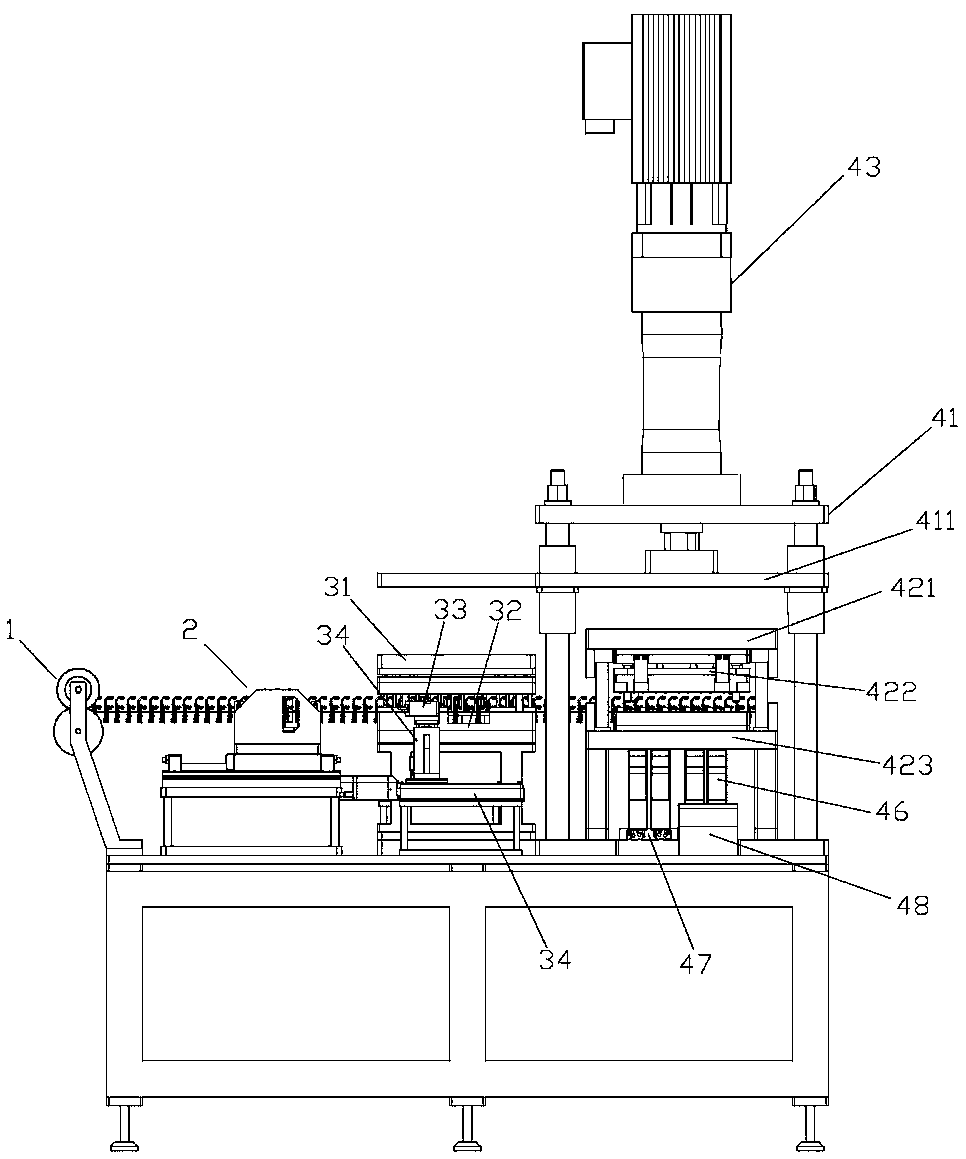

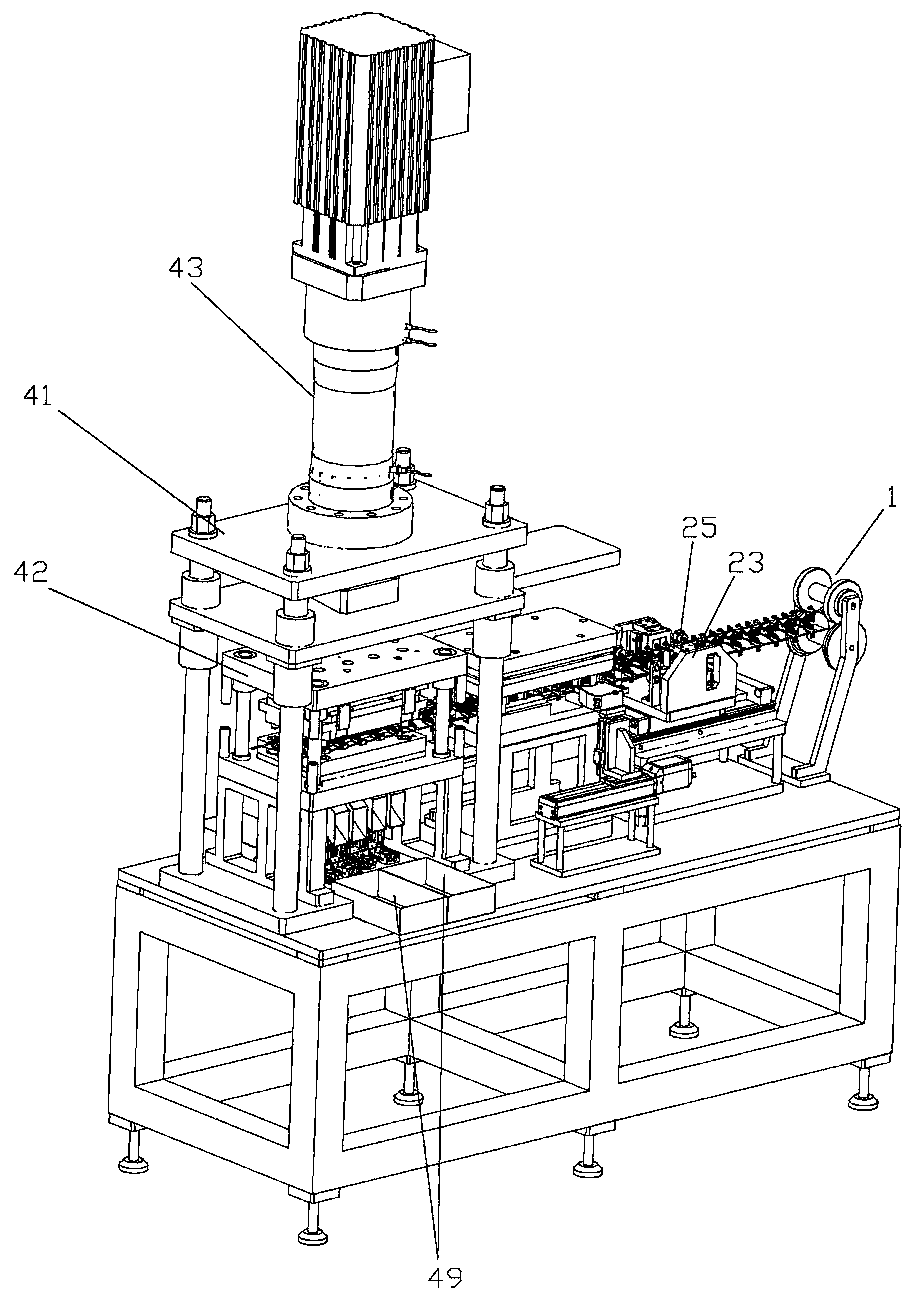

[0015] Such as Figure 1-4 As shown, an electronic component online detection forming material distribution equipment includes a material guide wheel 1, a material pulling mechanism 2, a laser monitoring mechanism 3 and a segmentation and collection mechanism 4, a material guiding wheel 1, a material pulling mechanism 2, and a laser monitoring mechanism 3 There is a connected material belt channel between the dividing and collecting mechanism 4 .

[0016] The guide wheel 1 includes a fixed wheel 11 and an adjusting wheel 12, the fixed wheel 11 is pivotally connected to the bracket 13, the adjusting wheel 12 is set on the bracket 13 through an adjustment mechanism, and the material belt channel is located between.

[0017] The material pulling mechanism 2 includes a cylinder 21 and a material pulling frame 22, the material pulling frame 22 is connected with the movable rod of the cylinder 21, side plates 23 are arranged on both sides of the material pulling frame 22, and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com