Paddle structure of adapter module

A transition cabin and blade technology, applied in the transition cabin field, can solve the problems of low degree of automation, severe reaction of kneader, and insufficient efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

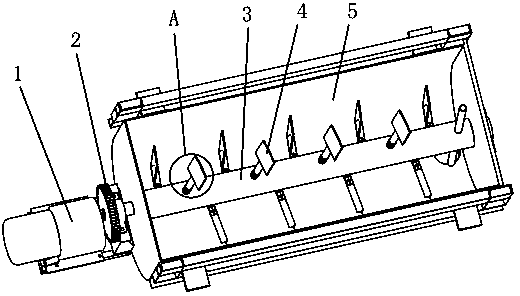

[0010] See figure 1 , the present invention includes a reducer 1, the output shaft of the reducer 1 is connected to a pinion (not shown in the figure), the pinion is meshed with a large gear 2, the large gear 2 is connected to a main shaft 3, the main shaft 3 is a hollow shaft, and the main shaft 3 The paddles 4 are arranged in the circumferential direction, and the main shaft 3 is arranged in the host machine 2 .

[0011] When the present invention works, the speed reducer 1 rotates, and the main shaft 3 is driven to rotate through the aforementioned gear transmission, and the paddle 4 can stir the internal logistics of the main engine 5, so that the internal logistics can be thoroughly loosened, which is beneficial to drying it.

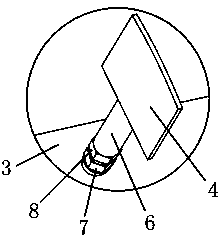

[0012] See figure 2 , the inner side of the paddle 4 is provided with a connecting rod 6, the main shaft 3 is provided with a threaded hole, the threaded hole of the connecting rod 6 is threaded, the nut 7 is threaded with the connecting rod 6 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com