Carbon molecular sieve mixing and forming device

A hybrid molding, carbon molecular sieve technology, applied in mixers, material molding presses, mixers with rotary stirring devices, etc., can solve the problems of overlapping end faces, reducing effective surface area, and reducing adsorption efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

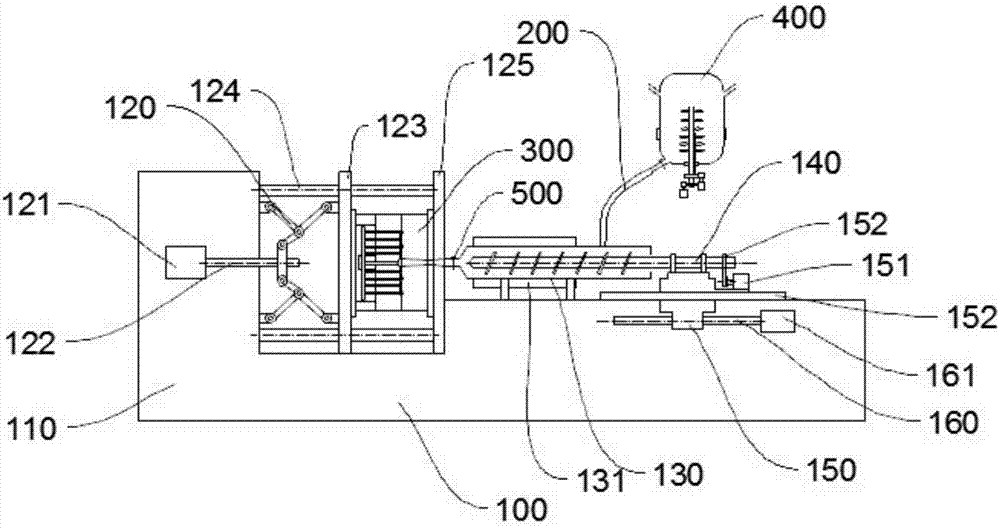

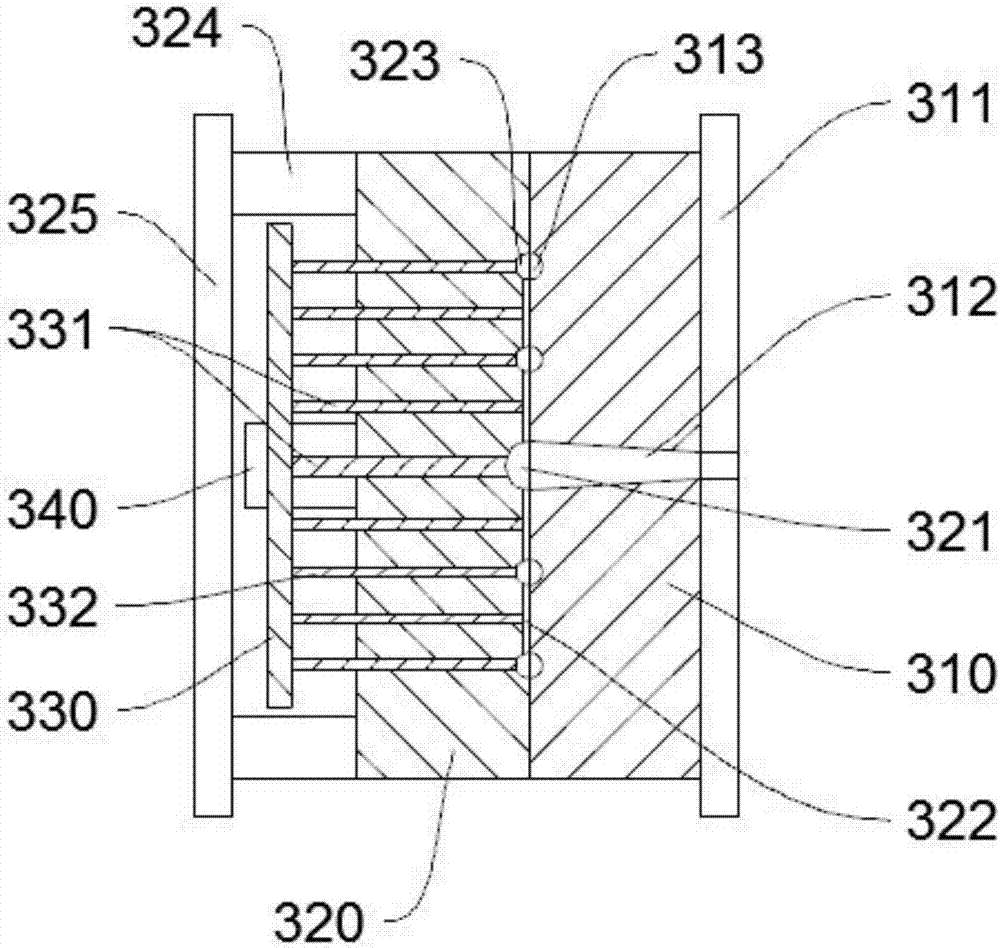

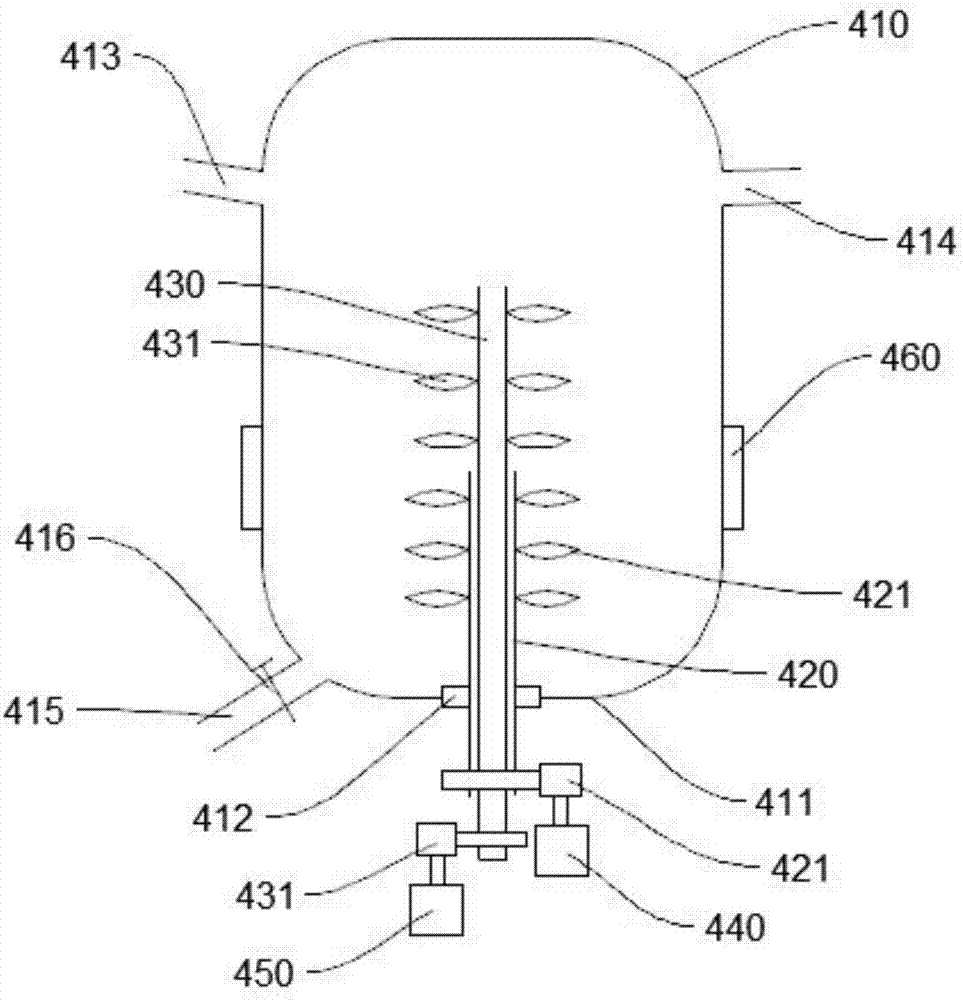

[0016] Embodiment: A kind of carbon molecular sieve hybrid molding device, constituted as Figure 1 to Figure 3 As shown, the molding device 100 is included, and the molding device 100 is connected with the mixing device 400 through the feeding pipeline 200; the molding device 100 includes a base 110, and the base 110 is provided with a movable mold motor 121, and the movable mold motor 121 is connected with a movable mold screw 122 , the moving mold lead screw 122 is connected with the middle part of the moving mold transmission device 120, one end of the moving mold transmission device 120 is fixed on the base 110, and the other end is fixed on the moving mold fixing plate 123; the base 110 is provided with a guide post 124, guiding The column 124 passes through the movable mold fixed plate 123 and is connected with the static mold fixed plate 125; the forming mold 300 is arranged between the movable mold fixed plate 123 and the static mold fixed plate 125; the static mold fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com