Backing material feeding device for diatom ooze production and processing and feeding method thereof

A technology of diatom mud and bottom material, which is applied in the direction of storage device, packaging, loading/unloading, etc., can solve the problems affecting the use of users, slow loading speed of bottom material, and inconvenience to users, so as to increase stability and avoid The effect of leakage and stable feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

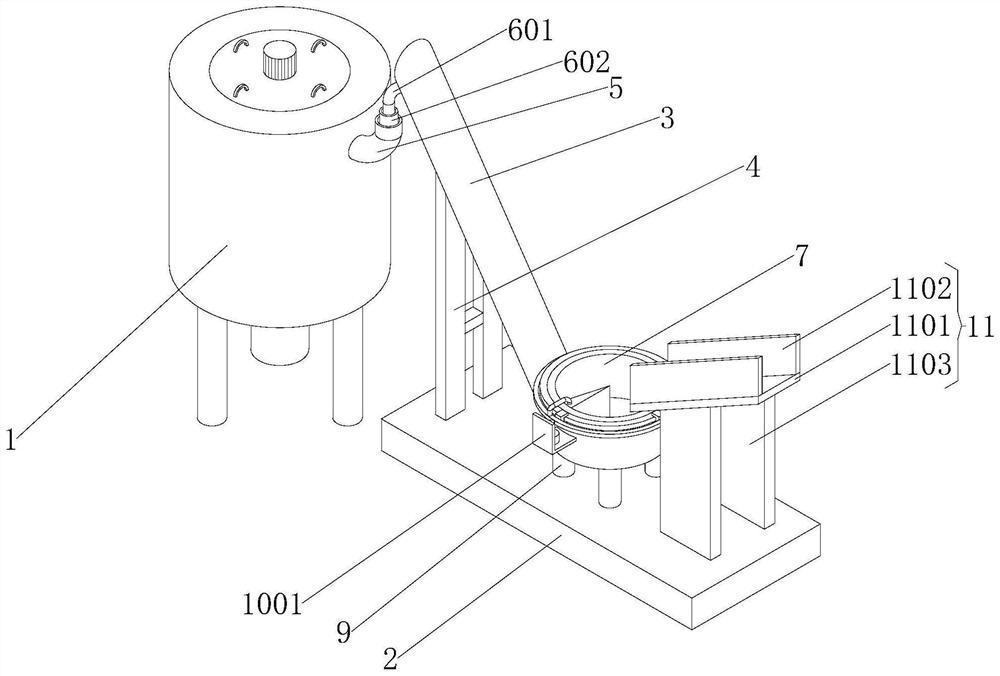

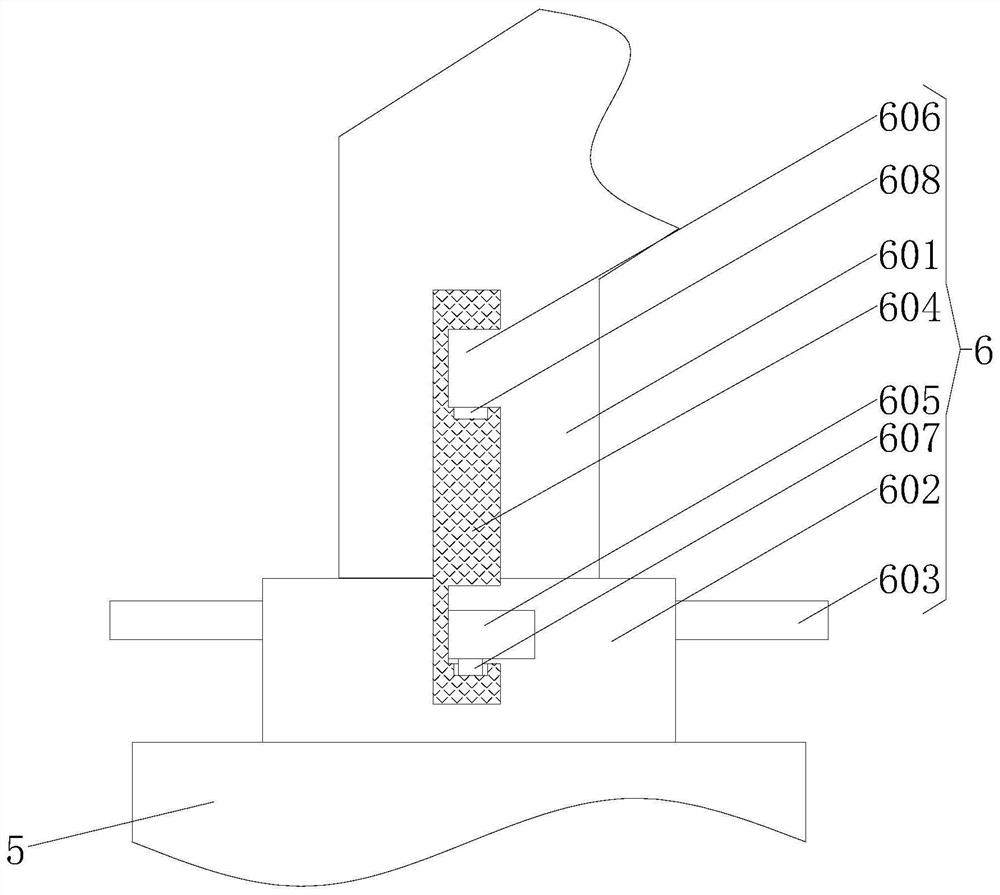

[0036] Such as Figure 1 to Figure 6As shown, a bottom material feeding device for diatom mud production and processing and a feeding method thereof provided in the embodiment of the present invention include a mixing box body 1, a placing board 2 is arranged on the right side of the mixing box body 1, and a placing board 2 The top of the mixing box is provided with a screw feeder 3 used in conjunction with the mixing box body 1. The screw feeder 3 can quickly transport the bottom material from bottom to top. The bottom of the left side of the screw feeder 3 is fixedly connected with the placement plate 2 The support frame 4 used, the top of the right side of the mixing tank body 1 is connected with the feeding pipe 5 used in conjunction with the screw feeder 3, the feeding pipe 5 can transport the bottom material to the inner cavity of the mixing tank body 1, and the screw feeder 3. The top of the left side is provided with a discharge mechanism 6 used in conjunction with the...

Embodiment 2

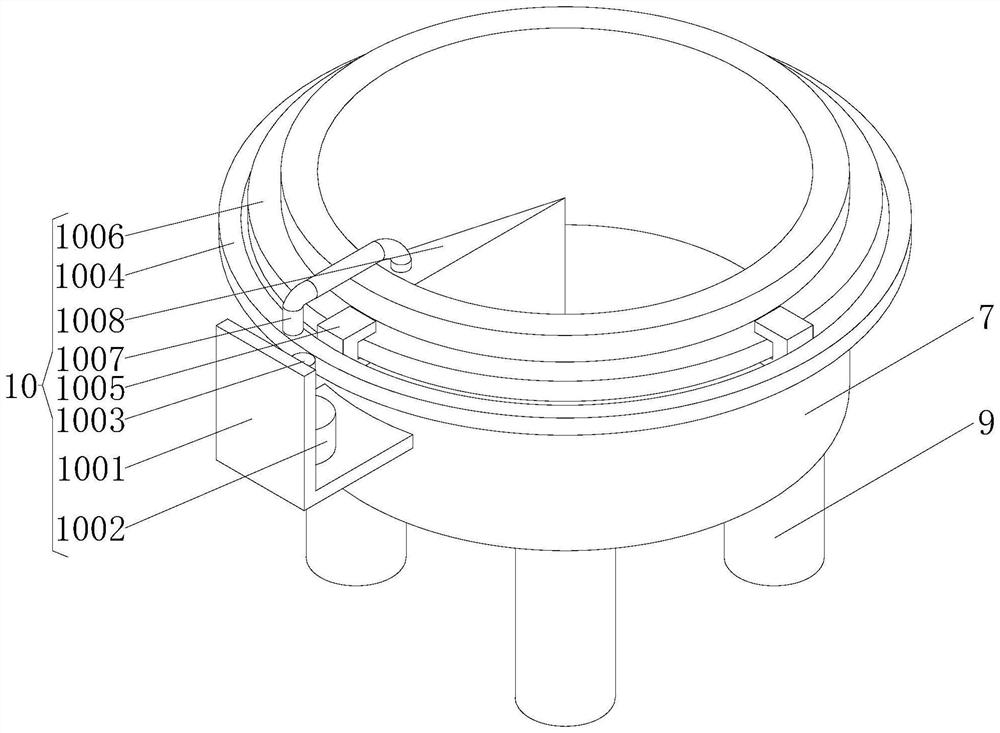

[0044] refer to figure 1 , the carrying mechanism 11 includes a carrying plate 1101, the carrying plate 1101 is used in conjunction with the feed bin body 7, the front side and the rear side of the bottom of the carrying plate 1101 are fixedly connected with a support plate 1102 used in conjunction with the placement plate 2, the support plate 1102 The bottom is fixedly connected with the placement plate 2, and the front side and the rear side of the top of the carrying plate 1101 are fixedly connected with a protective plate 1103. By setting the carrying mechanism 11, it can play a bearing role, which is convenient for the user to feed the bottom material in the bag. The inner cavity of the bin body 7 is poured, which can realize the diversion effect, avoid pouring too much bottom material at one time, and can also reduce the fatigue of the user.

[0045] The working principle of this embodiment: the user puts the cloth bag with the bottom material on the top of the loading p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com