Manufacturing device and method for novel corrugated paperboard

A corrugated cardboard and preparation device technology, applied in the field of cardboard, can solve the problems of low production efficiency, rough surface, waste of labor, etc., and achieve the effects of efficient bonding and bonding, strong adhesive force of glue, and good bonding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

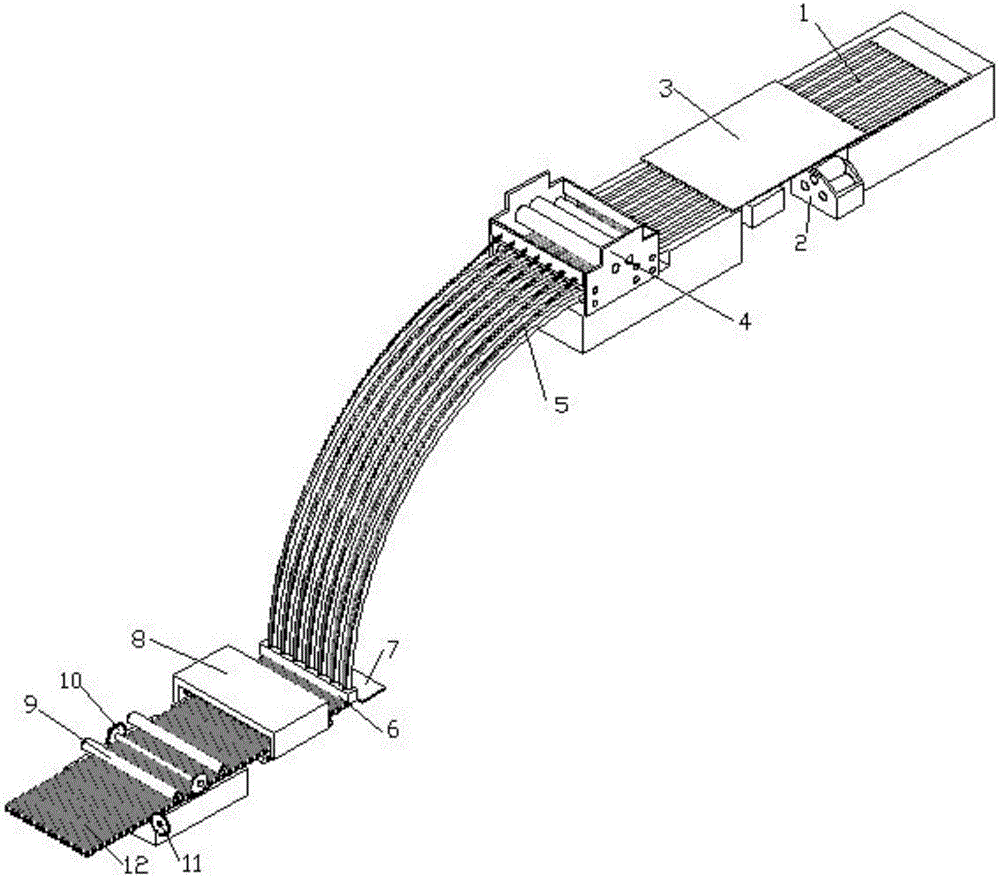

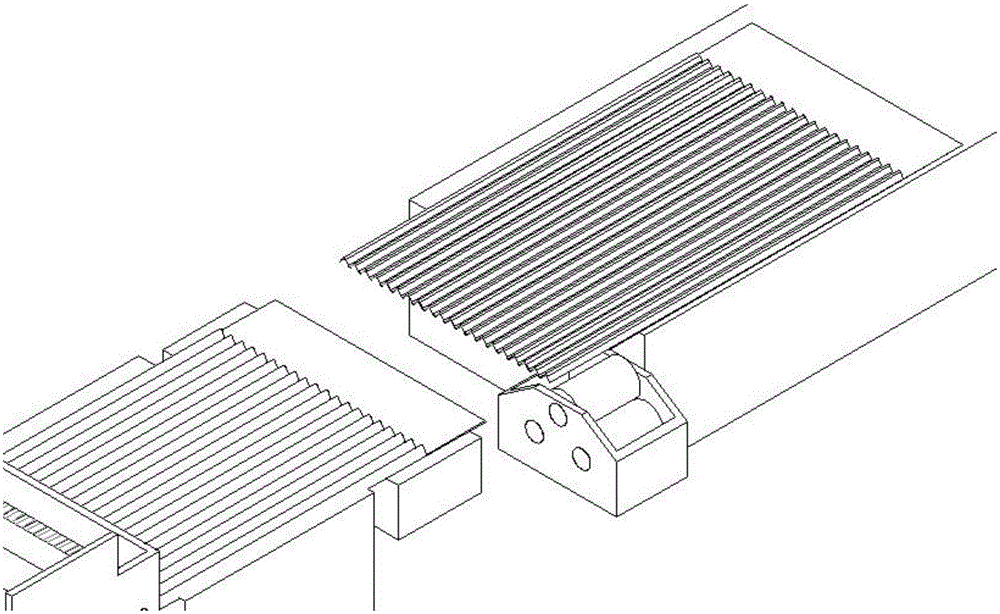

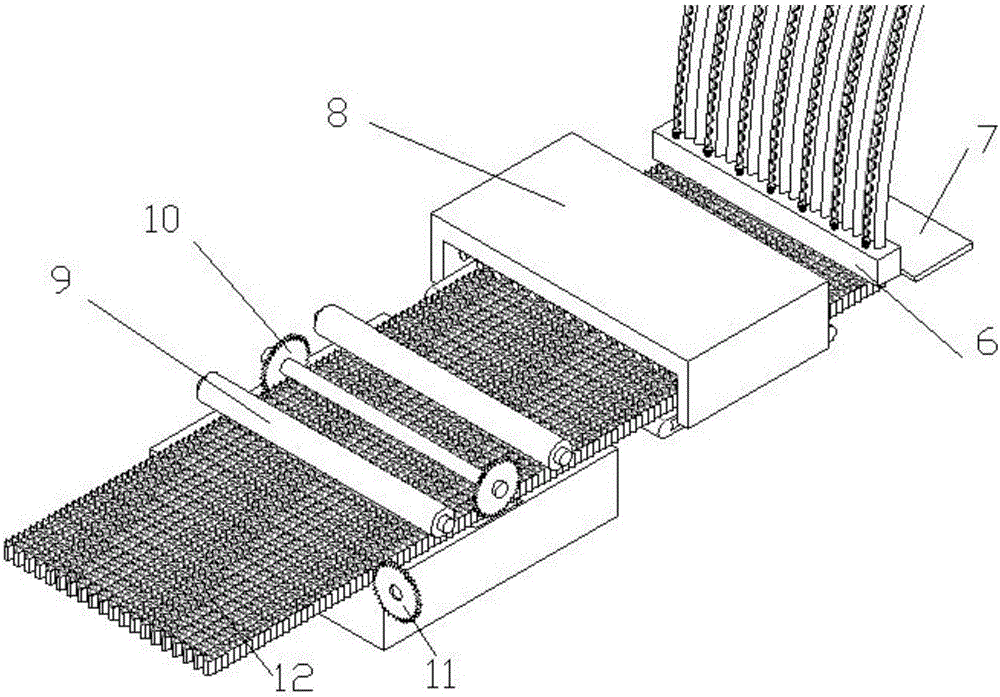

[0041]Embodiment 1: The corrugated cardboard 12 of the present invention is a single-layer corrugated corrugated paper and face paper composite structure with the same length and width as a unit, and is fixed and stacked by adhesive materials. The composite structural unit of corrugated corrugated paper and cardboard is formed by slicing the composite cardboard including at least one dislocated composite cardboard 1 along the length direction with equal thickness. Each dislocated composite cardboard 1 is connected by a dislocation bonding structure figure 2 It is a schematic diagram of the structure of two dislocation composite cardboards 1 of the present invention. The dislocation bonding structure is to remove a part of the dislocation composite cardboard 1 along the direction perpendicular to the corrugation and remove the same length surface along the direction perpendicular to the corrugations The dislocation composite cardboards 1 of the paper are bonded by adhesive mate...

Embodiment 2

[0053] Embodiment 2: between the glue roller mechanism 4 and the drying, there is a positioning mechanism located above the shearing and superimposing bonding mechanism 7, which guides the composite cardboard into the shearing and superimposing bonding mechanism 7, and the cut surface of the composite cardboard in contact with the positioning mechanism and The ground is at 70 degrees, the glue roller mechanism 4 is elastically connected with the shearing and superimposing bonding mechanism 7 located below the glue roller mechanism 4 through six springs 5, and the springs 5 are located in the trough channel of the composite cardboard, and the rest of the technical features and means are consistent with the implementation Example 1 is the same.

[0054] The concrete steps of preparation of embodiment 2 are:

[0055] 1) Rolling of dislocation composite cardboard 1: dislocation of corrugated paper and face paper by at least 10mm is placed, and composite rolling is made into disl...

Embodiment 3

[0063] Embodiment 3: between the glue roller mechanism 4 and the drying, a positioning mechanism located above the shearing and superimposing bonding mechanism 7, which guides the composite cardboard into the shearing and superimposing bonding mechanism 7, and the cut surface of the composite cardboard in contact with the positioning mechanism and The ground is at an angle of 80 degrees. The glue roller mechanism 4 is elastically connected to the shearing and superimposing bonding mechanism 7 located below the glue roller mechanism 4 through 10 springs 5. The springs 5 are located in the trough channel of the composite cardboard. The rest of the technical features and means are consistent with the implementation Example 1 is the same.

[0064] The concrete steps of the preparation of embodiment 3 are:

[0065] 1) Rolling of dislocation composite cardboard 1: place the corrugated paper and face paper at least 20 mm in dislocation, and composite roll to form dislocation compos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com