Concatemer solid blade pouring system and concatemer solid blade pouring method

A technology of pouring system and pouring method, which is applied to casting molding equipment, molds, cores, etc., and can solve problems such as fast solidification speed and restricted casting qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

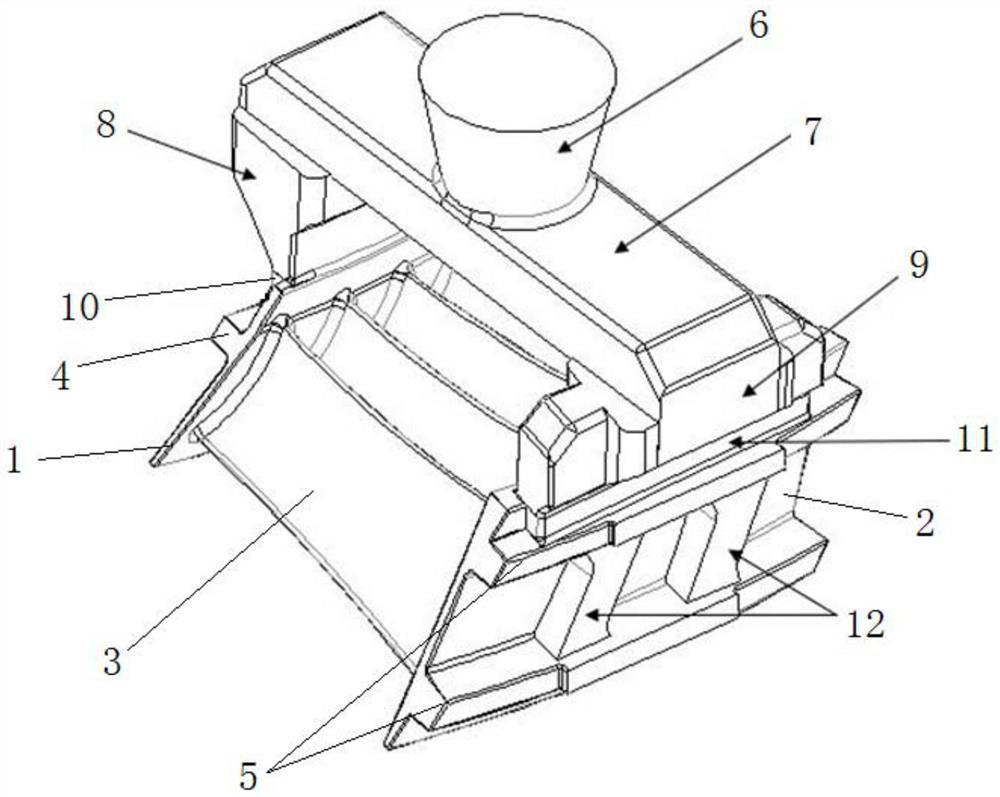

[0027] Such as figure 1 As shown, in this embodiment, a multi-unit solid blade pouring system includes a blade casting mold, a runner arranged on the blade casting mold and communicated with the blade casting mold, and a sprue 6 arranged on the runner. The blade casting mold includes an inner edge plate mold 1, an outer edge plate mold 2 and several blade molds 3 arranged between the inner edge plate mold 1 and the outer edge plate mold 2, and the outer side of the inner edge plate mold 1 is arranged There is an inner hook mold 4, and two outer hook molds 5 are arranged on the outer side of the outer edge plate mold 2, and the runner includes a runner 7, an inner runner 8 arranged under the two ends of the runner 7, and an outer runner. 9, the inner runner 8 communicates with the inner edge plate mold 1, and the outer runner 9 communicates with the outer edge plate mold 2.

[0028] When pouring, the blade pouring mold is placed horizontally, so that the inner edge plate mold ...

Embodiment 2

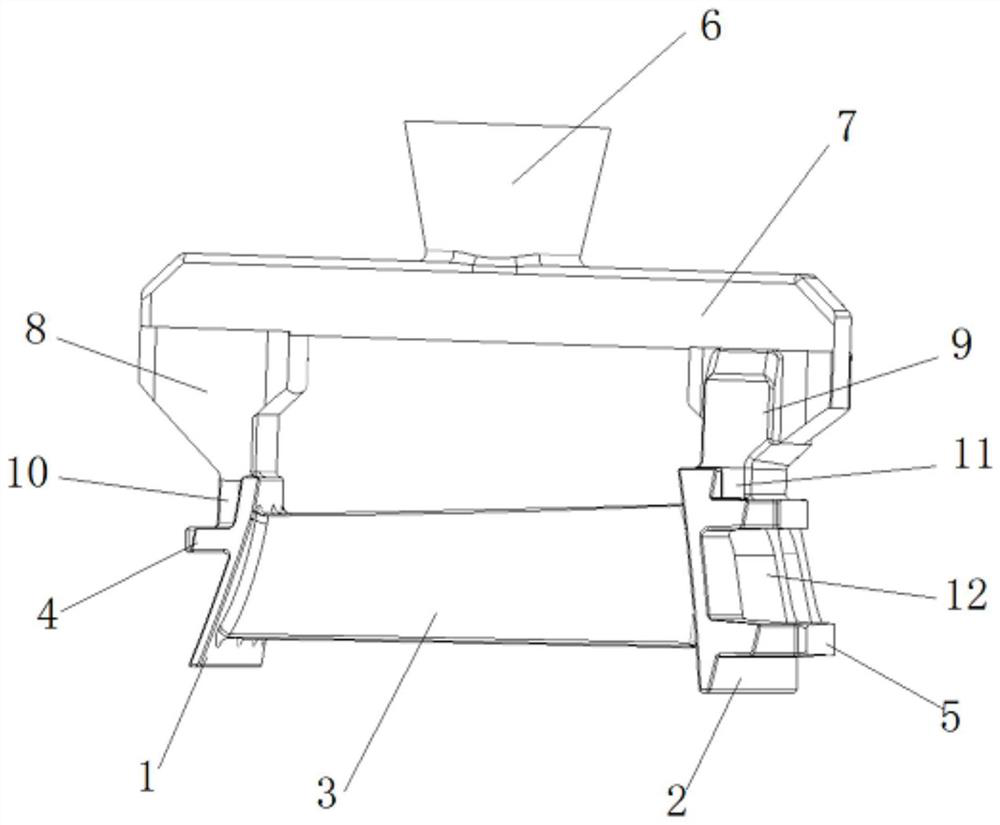

[0030] Such as figure 2 As shown, on the basis of the above embodiments, in this embodiment, the cross-sectional area of the ingate 8 and the outgate 9 by the horizontal plane decreases gradually from top to bottom.

[0031] During the cooling process, the liquid in the inner runner 8 and the outer runner 9 can cool down in a gradient manner, reducing the cooling rate of the top liquid in the inner runner 8 and the outer runner 9, thereby strengthening the inner runner 8 and the outer runner. 9 The feeding capacity of the inner liquid is beneficial to reduce the shrinkage and shrinkage of the inner and outer edge plates.

[0032] In this embodiment, the bottom of the inner sprue 8 is provided with an inner subsidy mold 10 communicating with the top of the inner hook mold 4 and the outer surface of the inner edge plate mold 1 .

[0033] Utilizing the inner subsidy mold 10 can increase the outlet area of the inner sprue 8, thereby facilitating the flow of liquid, and becau...

Embodiment 3

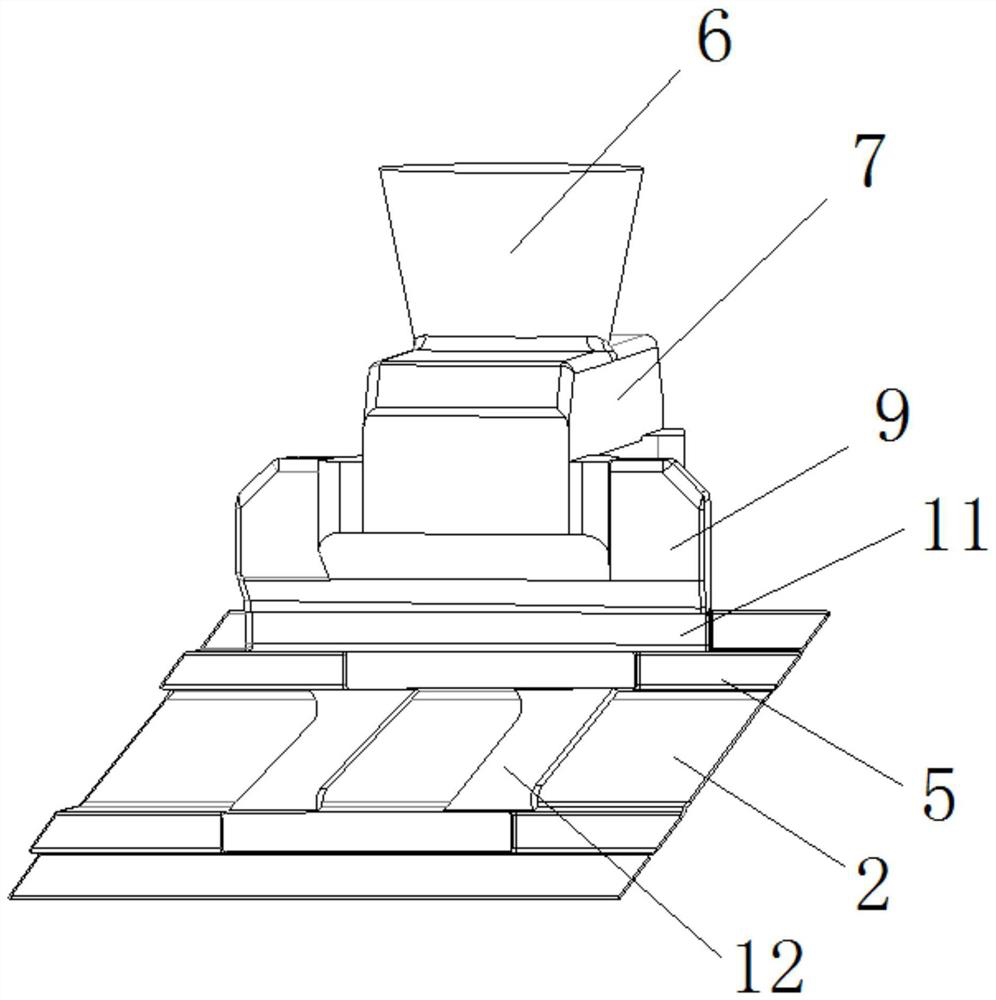

[0039] Such as figure 2 , image 3As shown, on the basis of the above-mentioned embodiments, in this embodiment, at least one hook subsidy mold 12 is arranged between the outer hook mold 5 and the outer hook mold 5, and the hook subsidy mold 12 is connected with the two outer hook molds respectively. 5 connected.

[0040] Utilizing the hook subsidy mold 12 to communicate with the two outer hook molds can make the liquid flow from the upper outer hook mold 5 to the lower outer hook mold 5, which is convenient for feeding the lower outer hook and prevents the lower outer hook from forming shrinkage cavities. Utilizing the hook to subsidize the mold 12 can increase the strength and rigidity of the outer edge plate mold 2 and prevent the deformation of the outer edge plate mold 2 from affecting the shape accuracy of the product.

[0041] In this embodiment, the hook subsidy mold 12 is set obliquely. The inclination angle of the hook subsidy mold 12 is consistent with the blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com