Patents

Literature

139results about How to "Shorten pouring time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

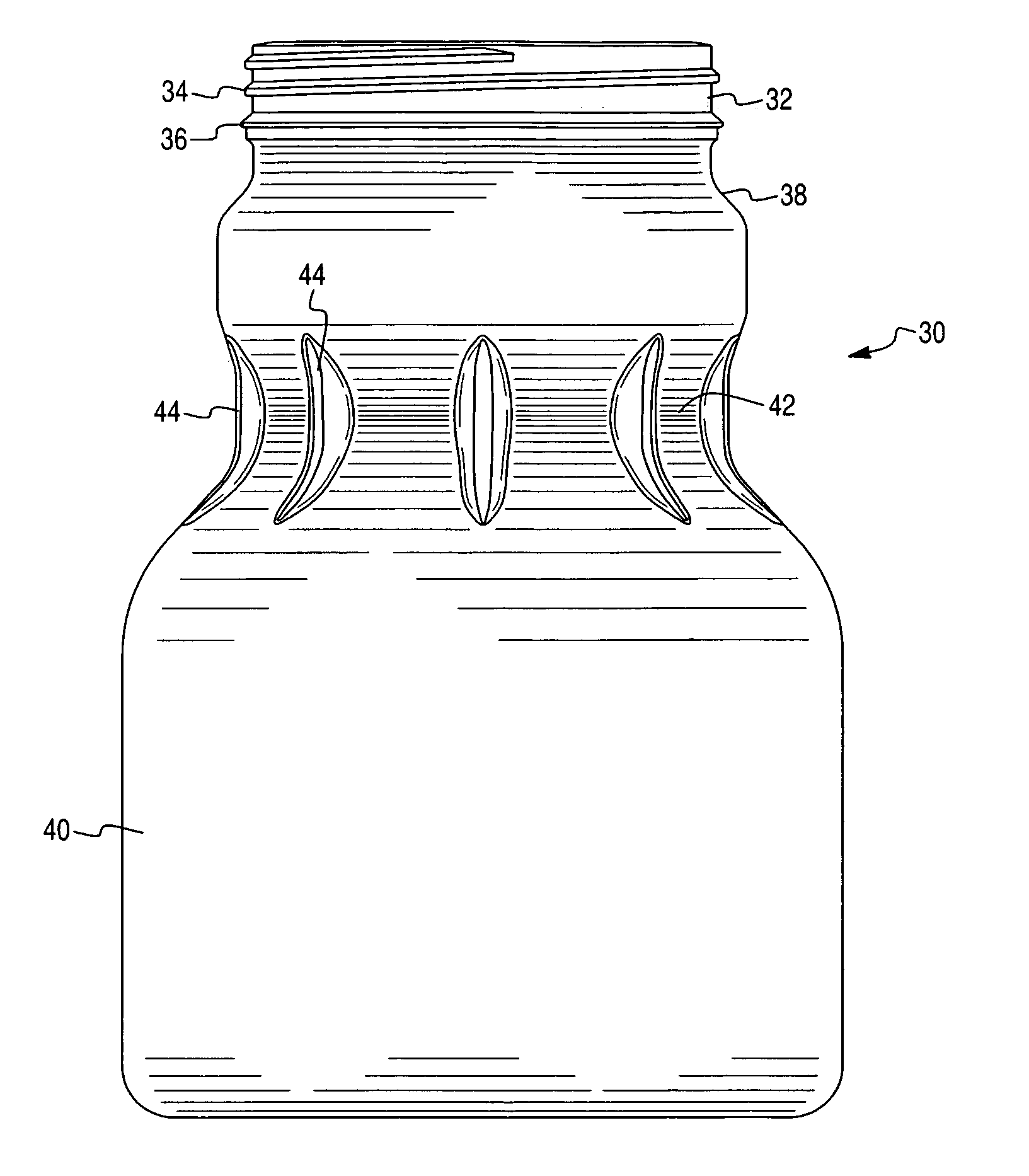

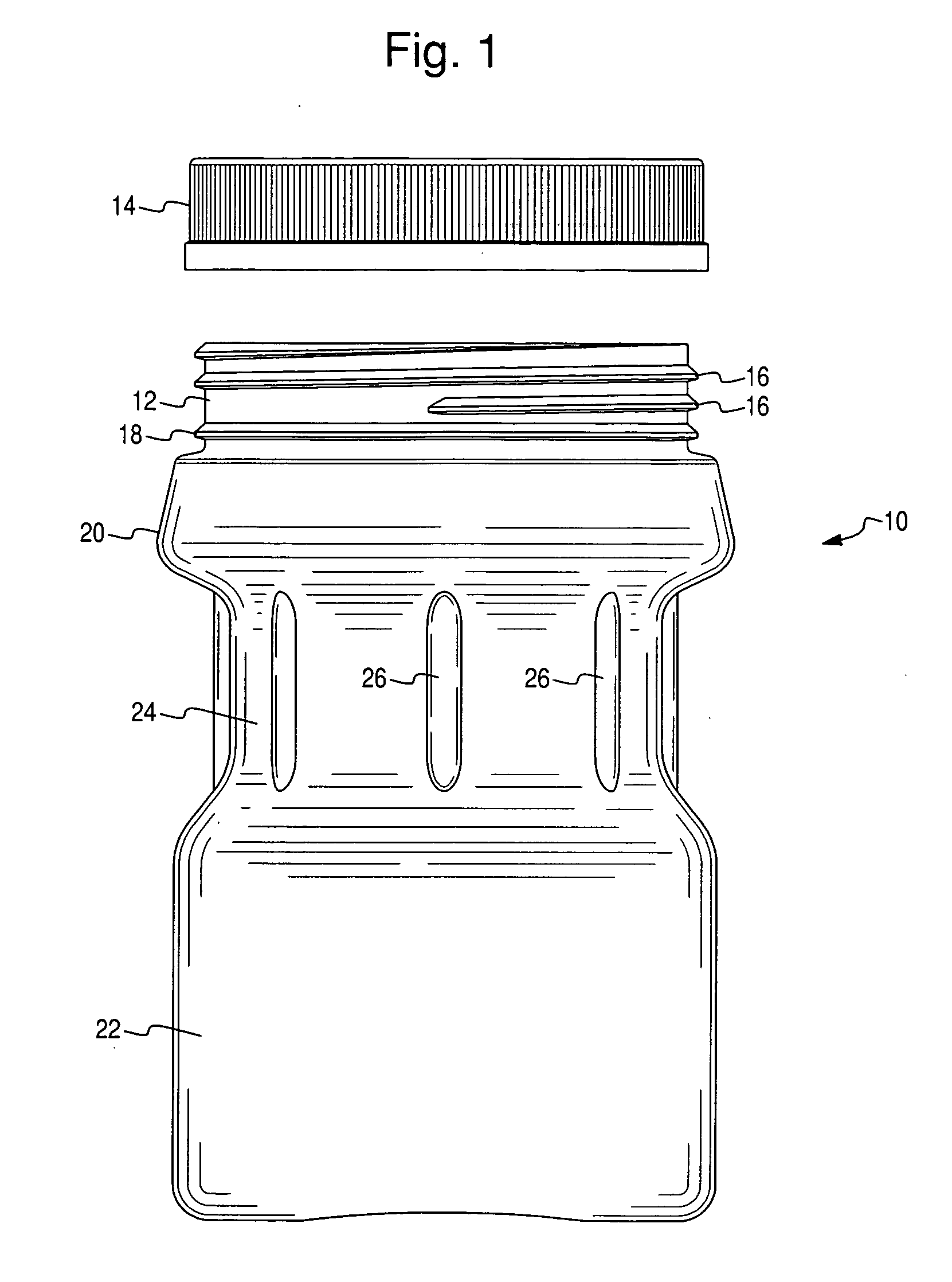

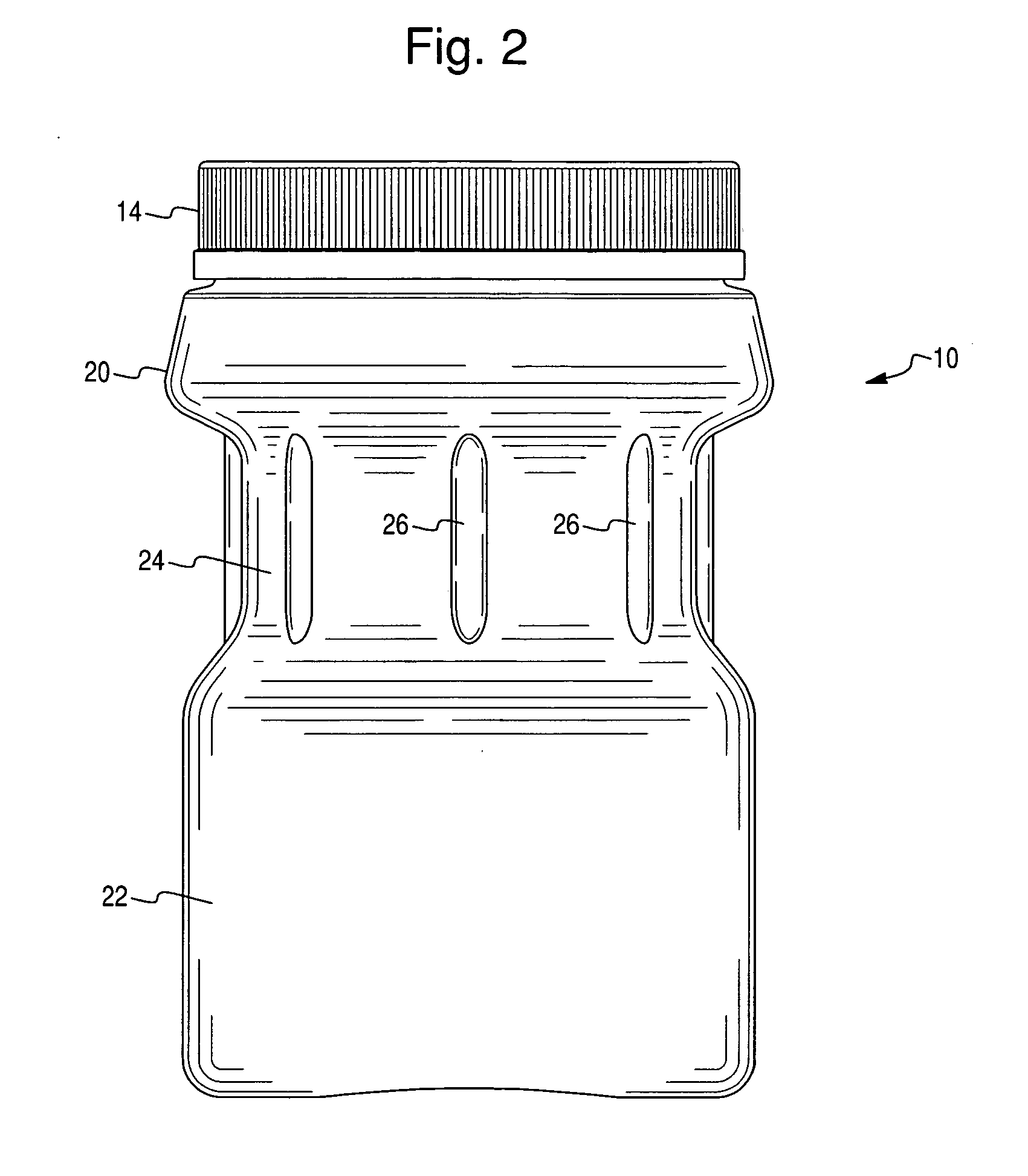

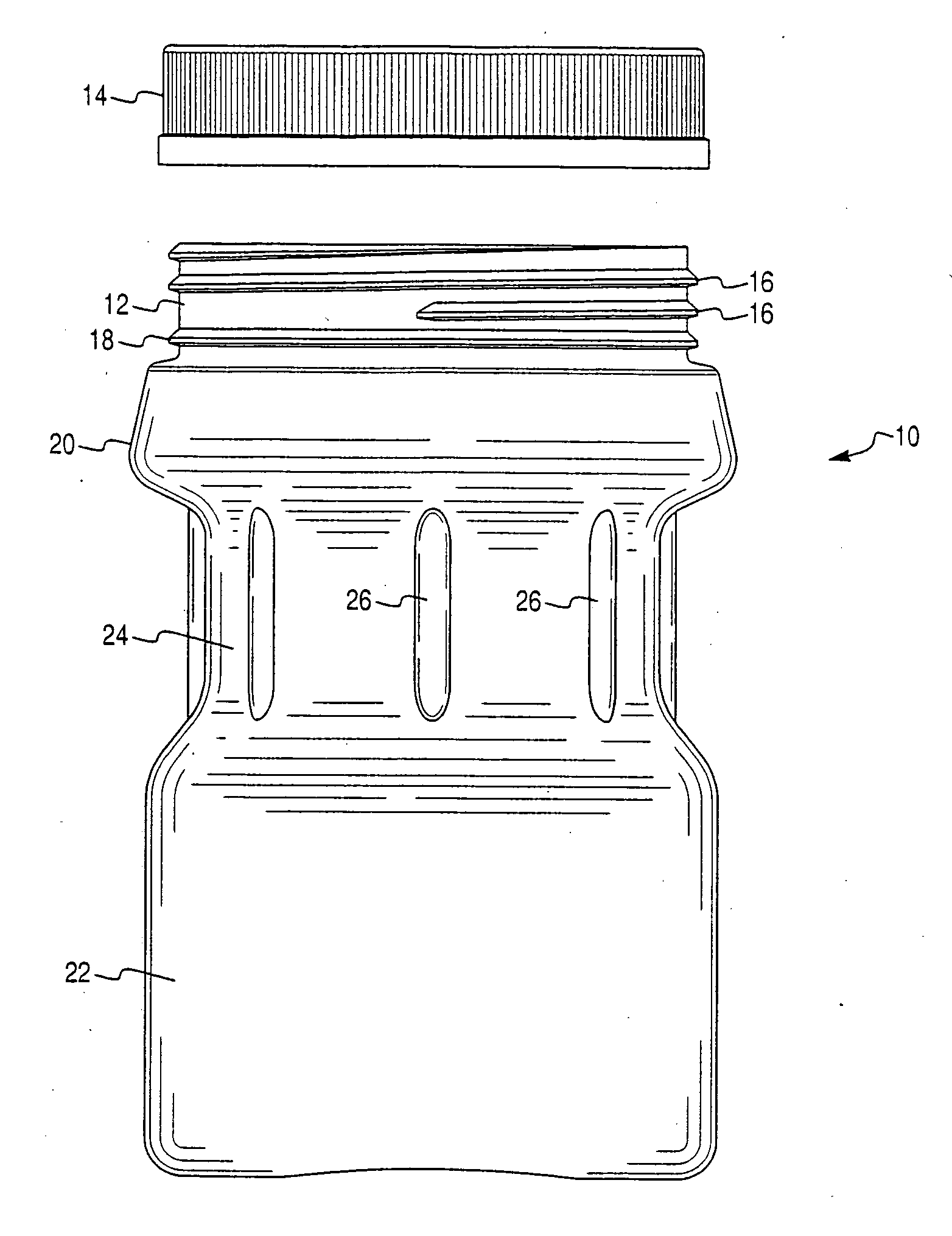

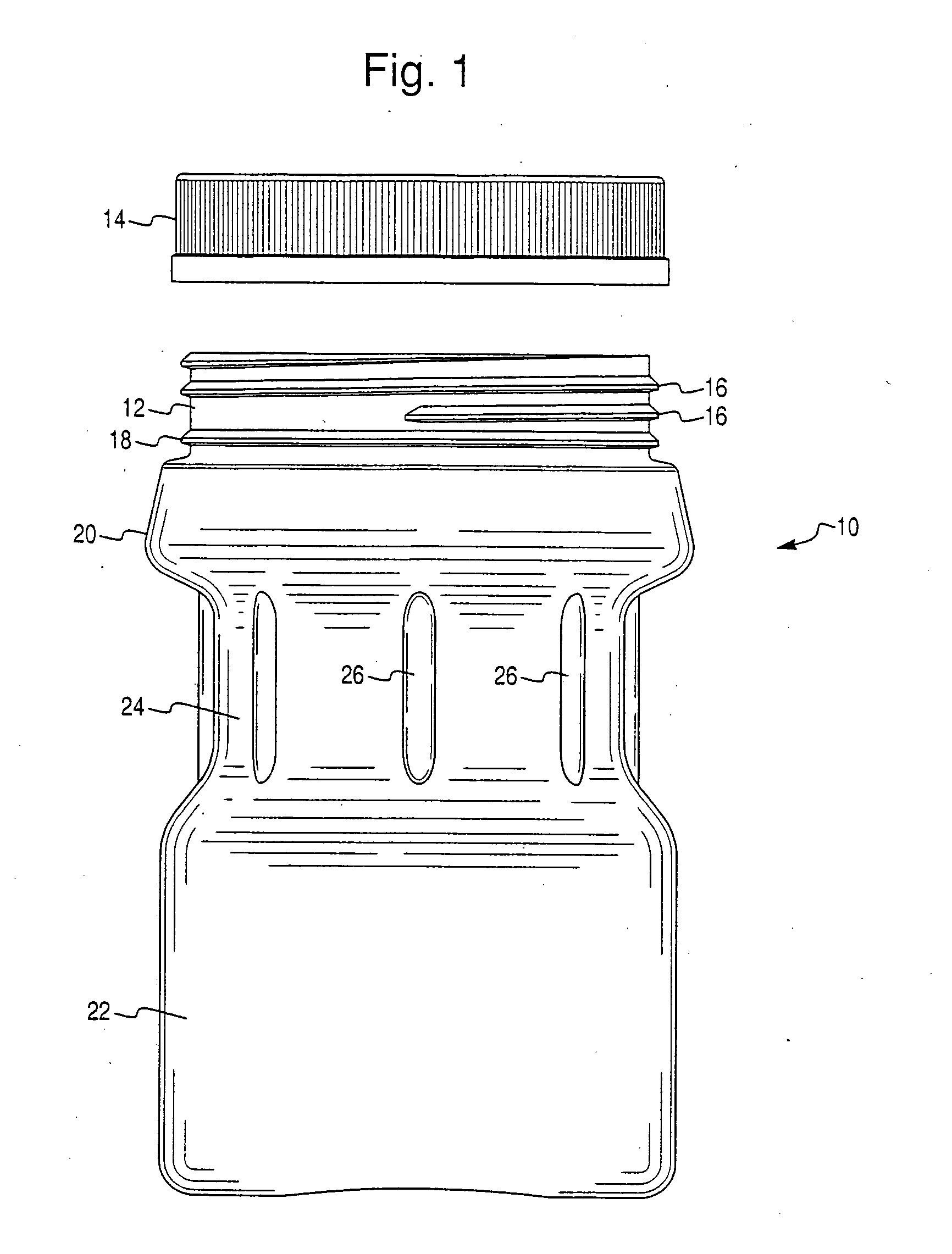

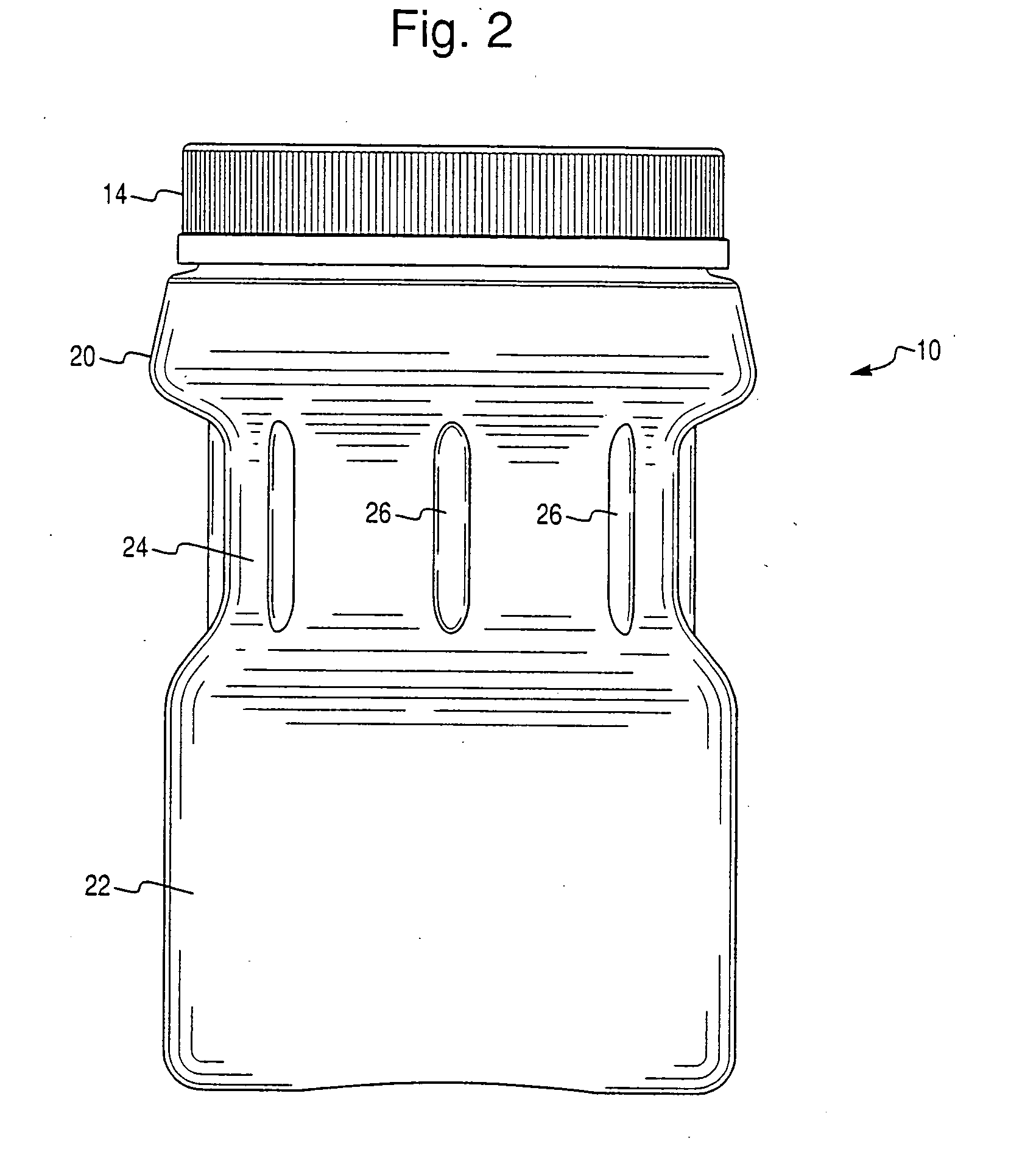

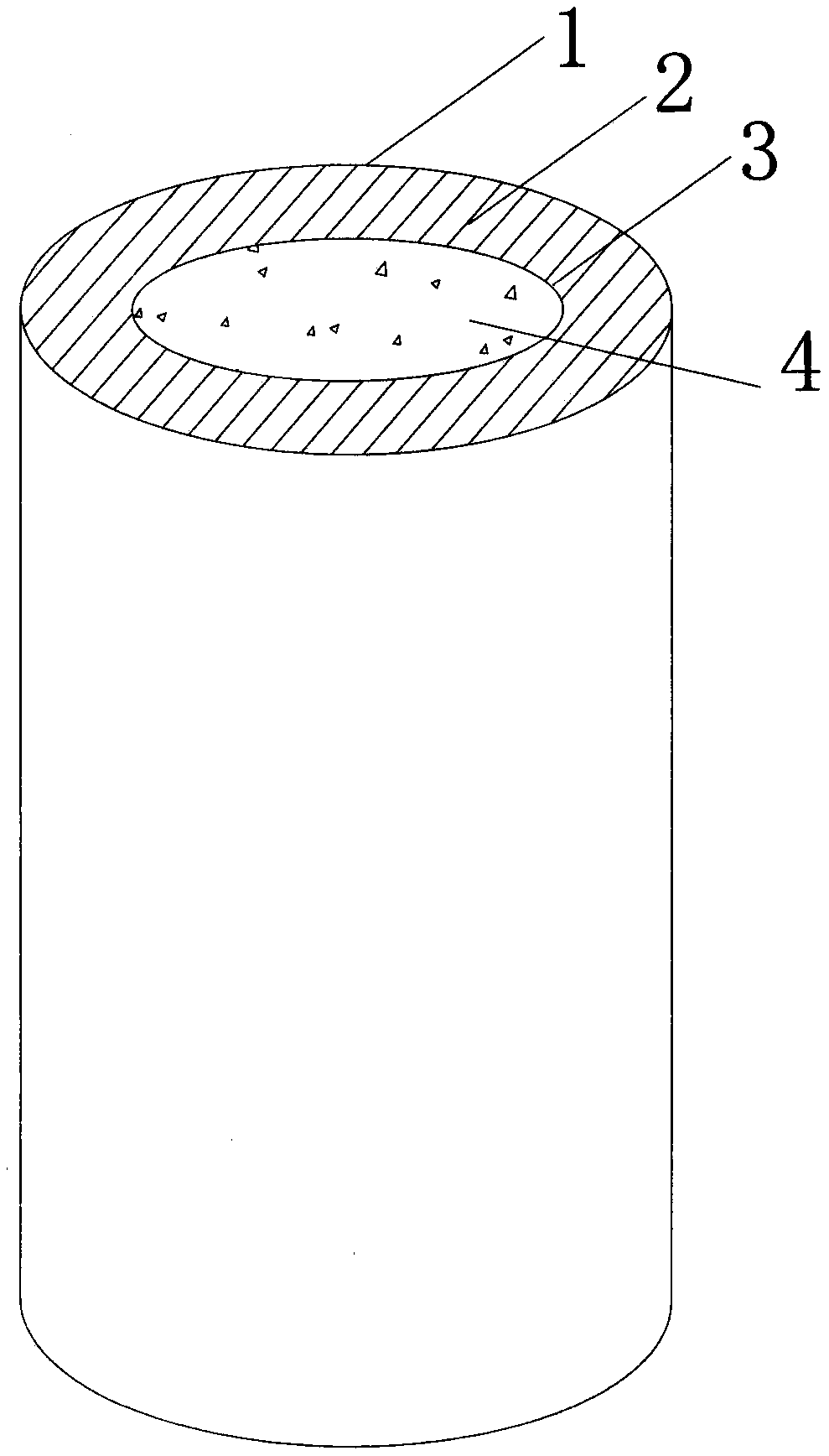

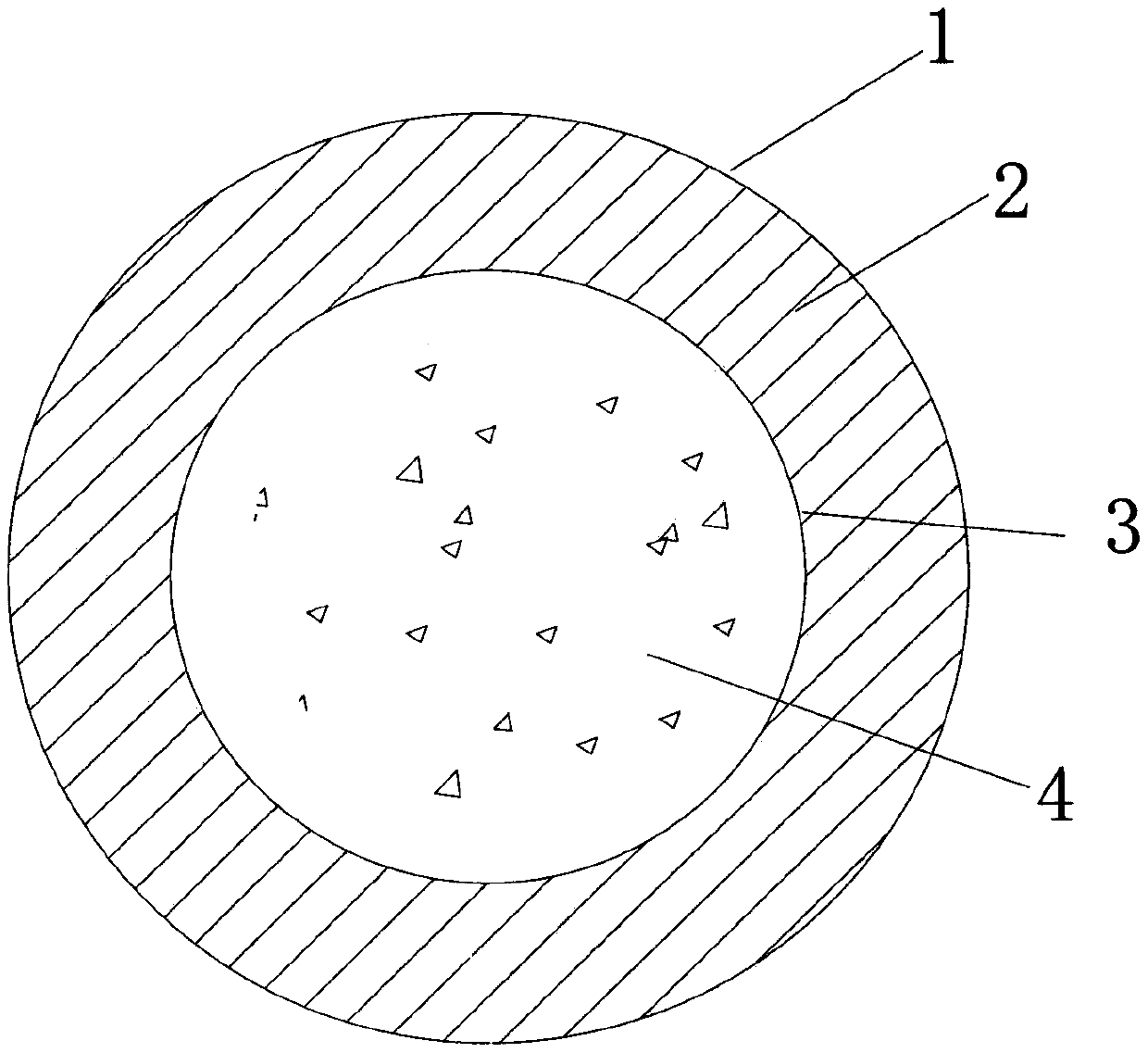

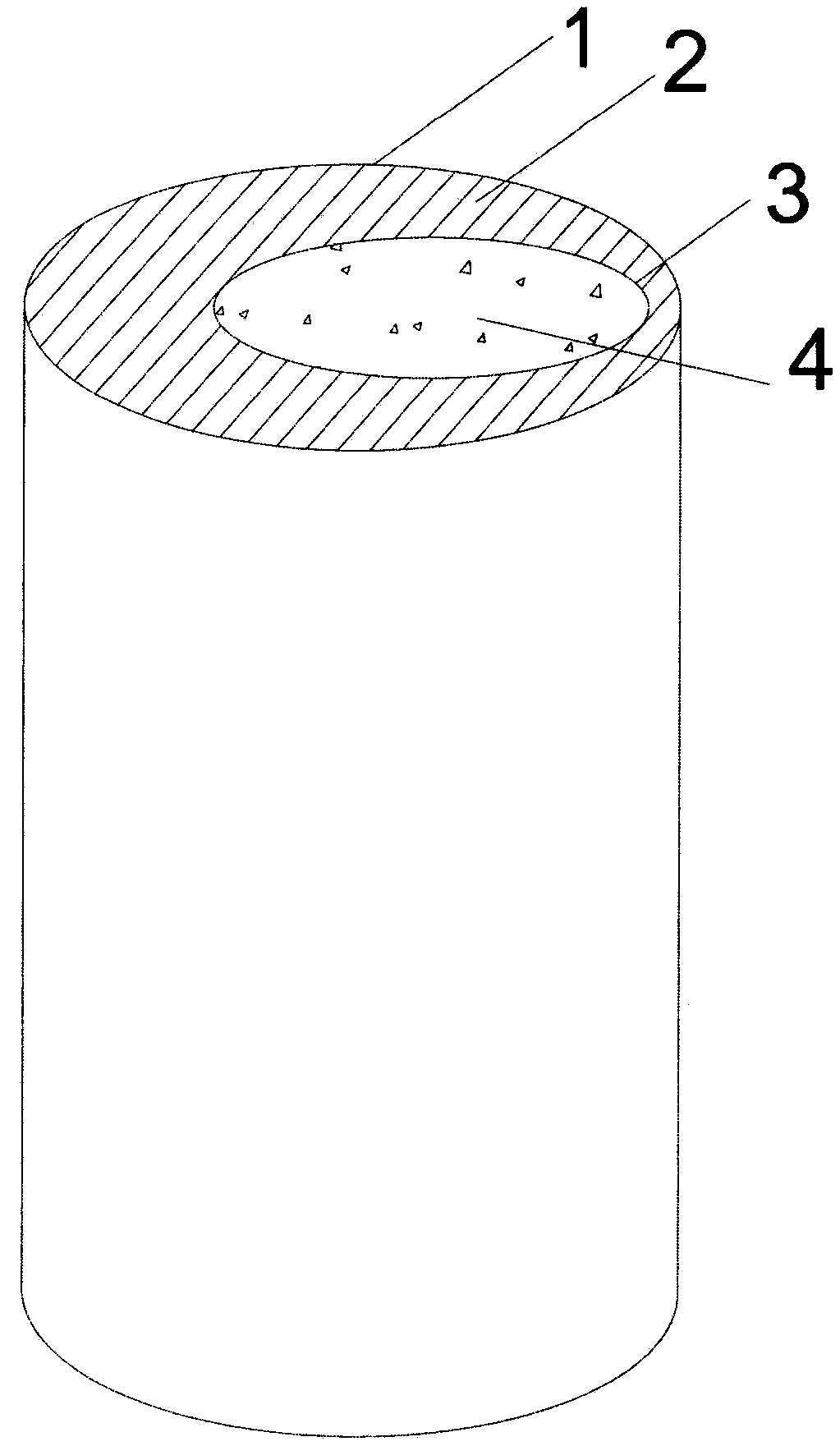

Colorant container

A plastic container used to hold a dispersion-based paint colorant and capable of dispensing the colorant into paint dispensing machines, comprising an open top capable of holding and securing a cap, and having a wide mouth with a diameter of at least 50 mm. The plastic container has a cylindrical body extending below the open top, and a plurality of vertical ribs spaced around the body to strengthen the container.

Owner:ENGELHARD CORP

Container

A plastic container used to hold a dispersion-based paint colorant and capable of dispensing the colorant into paint dispensing machines, comprising an open top capable of holding and securing a cap, and having a wide mouth with a diameter of at least 50 mm. The plastic container has a cylindrical body extending below the open top, and a plurality of vertical ribs spaced around the body to strengthen the container. The plastic container may be used to hold a dispersion-based paint colorant or personal care products such as shampoo and conditioner.

Owner:ENGELHARD CORP

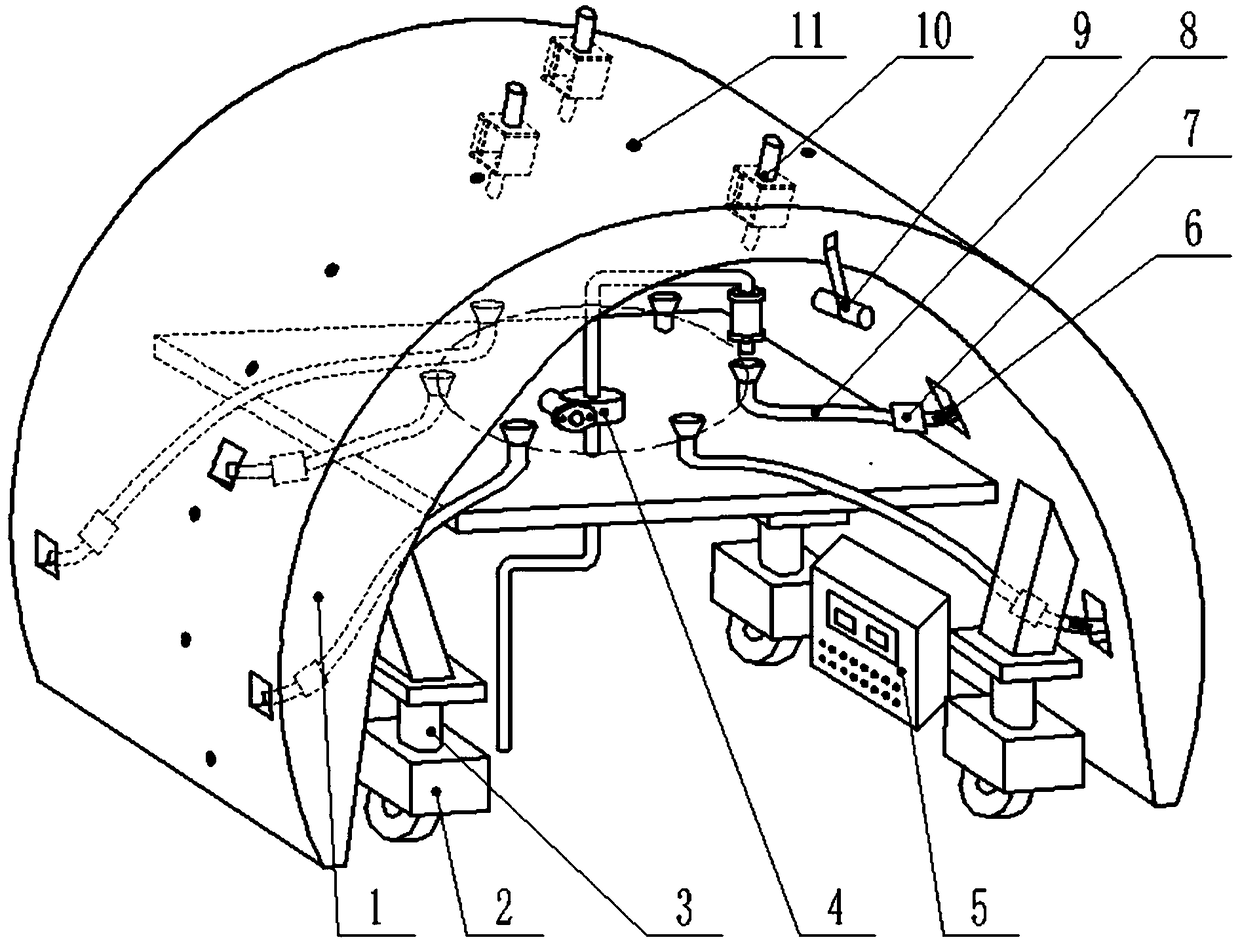

Automation control method for tunnel lining construction

ActiveCN108104838ARealize information collectionRealize automatic controlUnderground chambersTunnel liningAutomatic train controlAutomatic control

Disclosed is an automation control method for tunnel lining construction. A control system integrates all information collecting and control procedures of a traveling mechanism, a hydraulic system, aconcrete distribution device, a vibrating device, a temperature sensor, a flowmeter, a video monitor and a pressure sensor, is equipped with a GPRS wireless data transmission module, and can collect and upload information in the casting process of a tunnel lining to a project department monitoring room. The distribution device can be connected with a plurality of distribution pipes in series, thetemperature sensor is used for detecting the concrete casting temperature, and the flowmeter is used for collecting the concrete casting quantity and implementing automatic control over casting. The video monitor monitors real-time work picture information, and collects and transmits the real-time work picture information to the project department monitoring room. The vibrating device achieves vibrating automatic control operation for concrete. The pressure sensor detects and collects pressures of all points in the concrete casting process and displays the casted height of the concrete. The control system conducts concentration analysis on data collected in the casting process of the tunnel lining, gives out a control instruction, and uploads the detected data to the project department monitoring room.

Owner:中铁隧道勘察设计研究院有限公司

Preparation method of complex large thin-walled Ni3Al alloy cast

The invention provides a preparation method of a complex large thin-walled Ni3Al alloy cast, and belongs to the technical field of casting. The method comprises the following steps: (1) preparing a wax mould; (2) coating slurry, applying sand, drying to prepare a shell surface layer, preparing shell layers from the second layer to the ninth layer on the surface layer in sequence, and coating slurry; (3) drying to form a shell; (4) removing the wax mould, and preheating in a vacuum condition; (5) pouring Ni3Al alloy fluid in the shell, and controlling the pouring time to be between 5 and 7 seconds; and (6) cooling along with the furnace to the temperature of 650+ / -10 DEG C, naturally cooling in an insulating vessel, removing the shell on the surface, and cutting off the pouring gate part of the cast body. The cast prepared by adopting the method has remarkably reduced metallurgical defects, the problem of bar crack is successfully solved, and the quality is greatly improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

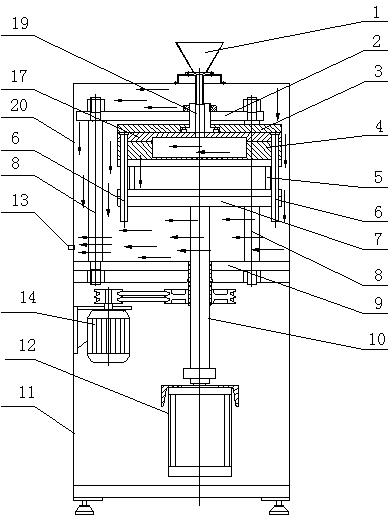

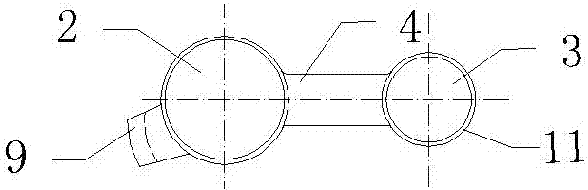

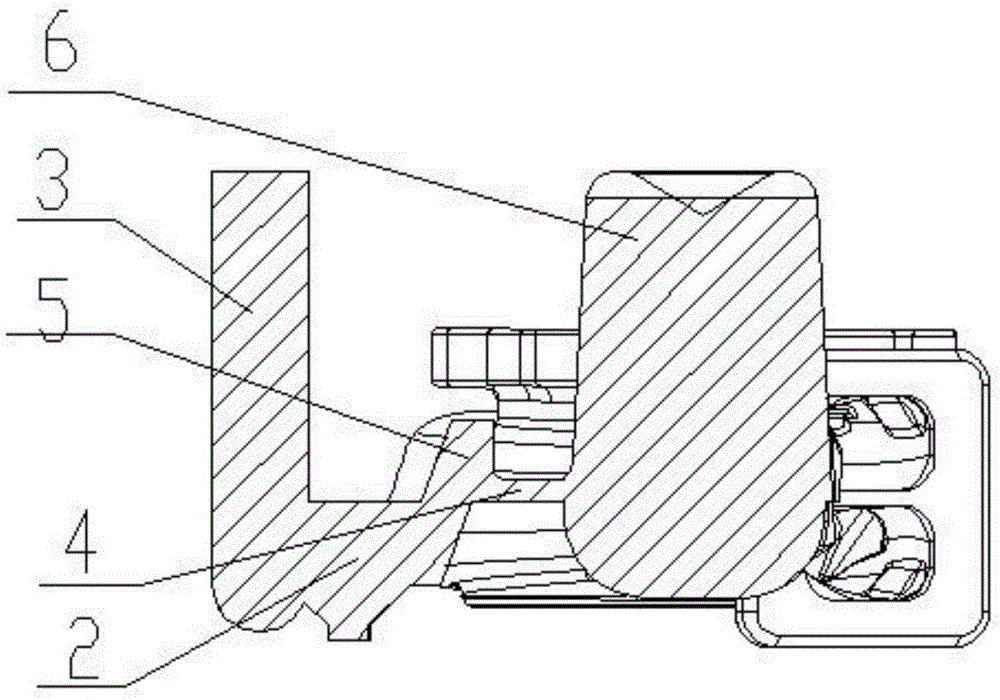

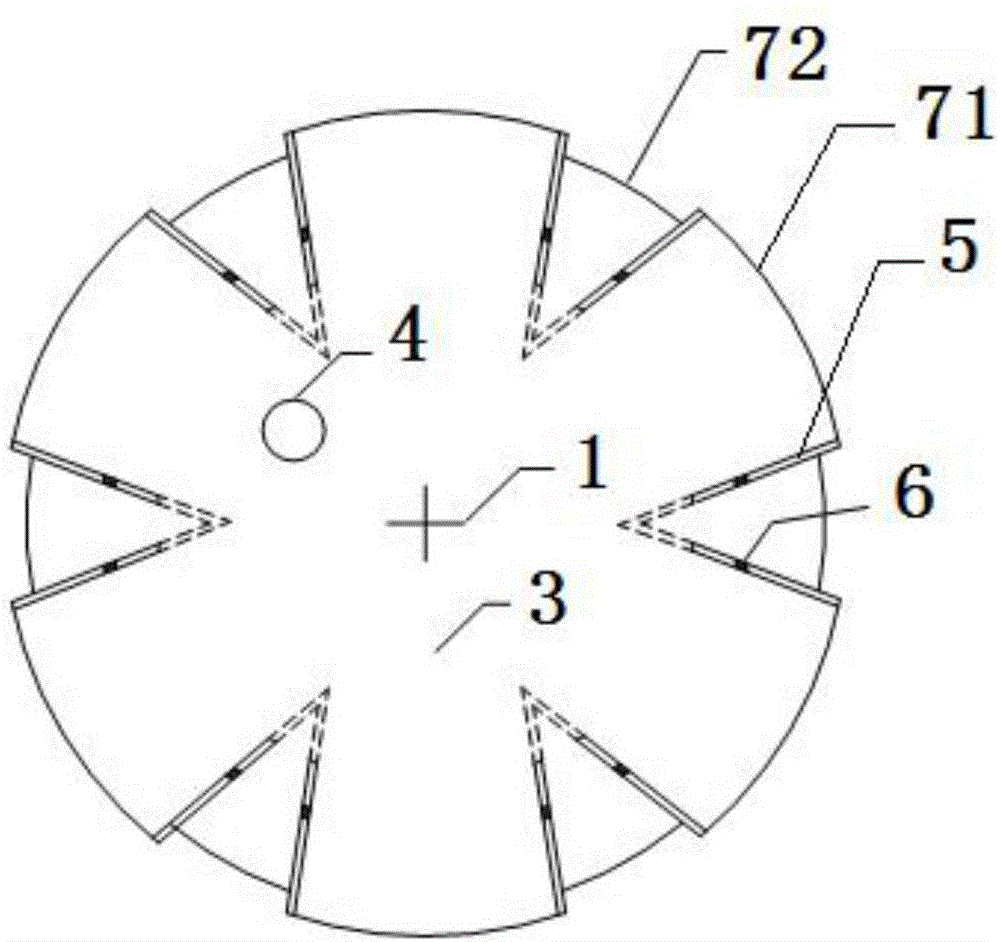

Vacuum centrifugal casting method and device

The invention discloses a vacuum centrifugal casting method with low sucking rate, which comprises the steps of closing a mold, vacuumizing and centrifuging, casting and demoulding, and is characterized in that: in the step of vacuumizing, a molding mechanism which hermetically rotates is vacuumized; and the molding mechanism comprises a lower die installation seat (7) which is arranged on a transmission shaft (10), wherein a connecting seat (5), a lower die (4), an upper die (17) and an upper die installation seat (3) are connected with and arranged on the lower die installation seat (7) through a guide rod (6); the upper die (17) and the lower die (4) are closed to form a hermetic molding mechanism; and the transmission shaft (10) is a hollow shaft of which one end is communicated with the molding mechanism and the other end is communicated with an exhaust joint (13). The method is feasible; a device has a simple structure; and the inside of a cavity of a casting instead of a seal cover originally is vacuumized, so that vacuum degree is improved, a pouring channel is shortened, the surface finish and compactness of the casting are improved, and particularly good compactness effect during the casting of special-shaped parts is achieved.

Owner:YIYANG SHENGXI MACHINERY EQUIP MFG

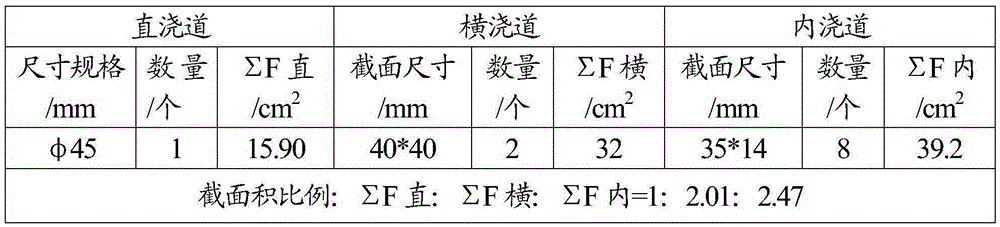

Open type top shower gating system for air cylinder cover

InactiveCN105328127AReduce inflow velocityPrevent splashFoundry mouldsFoundry coresSlagGreek letter sigma

The invention discloses an open type top shower gating system for an air cylinder cover. The system comprises a sprue, at least one cross gate and at least one ingate, wherein one end of the cross gate communicates with the sprue while the other end of the cross gate communicates with the ingate; the sectional area ratio of the sprue to the cross gate to the ingate is that sigma F (sprue): sigma F (cross gate): sigma F (ingate)=1: (1.5-2.5): (2-3); a filter screen is arranged in the cross gate. With the adoption of the system, a produced casting is stable in quality, the rejection rate caused by cold shut, sand inclusion, slag inclusion and other defects can be greatly decreased, and moreover, the production cost can be decreased.

Owner:四川共享铸造有限公司

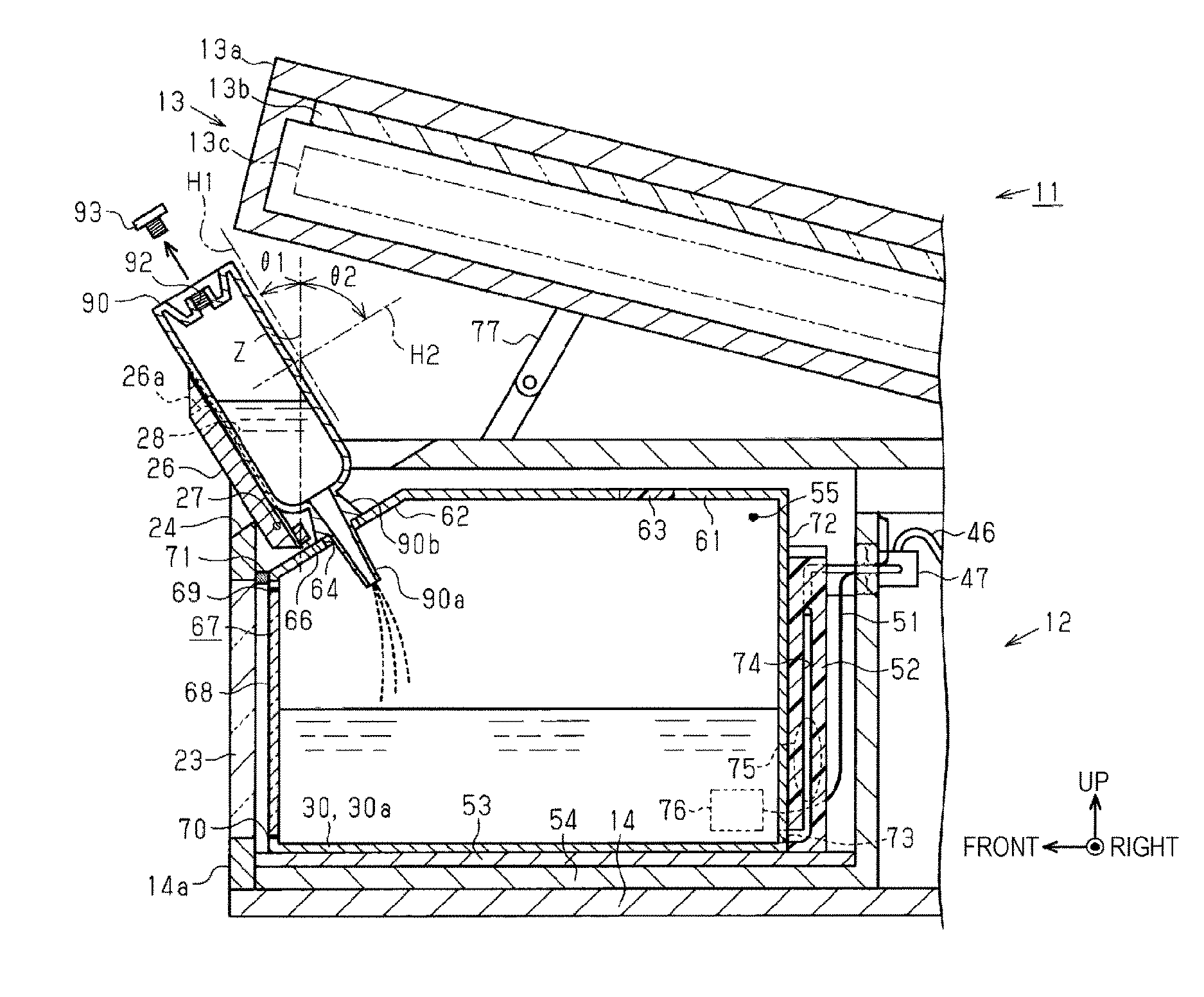

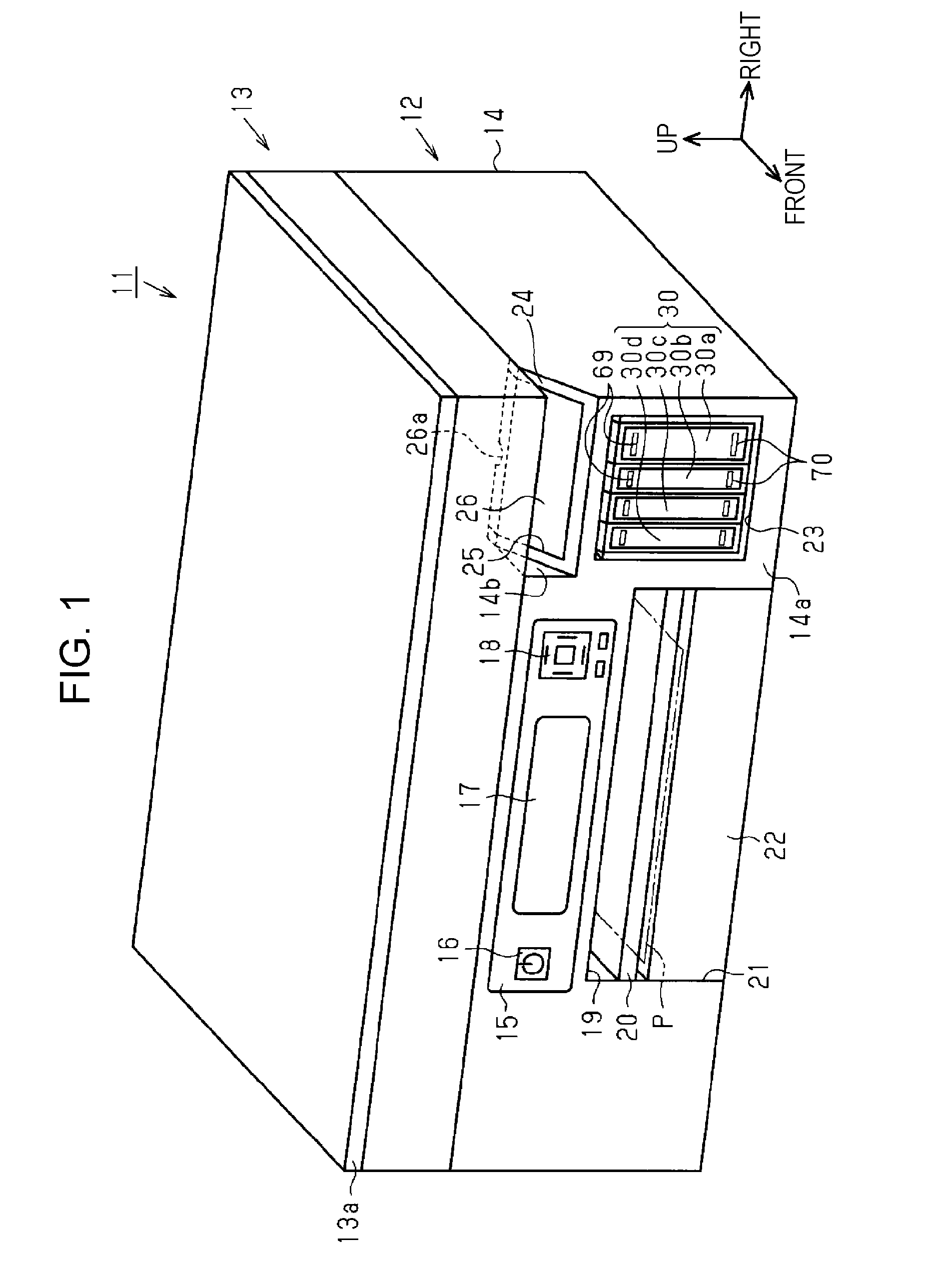

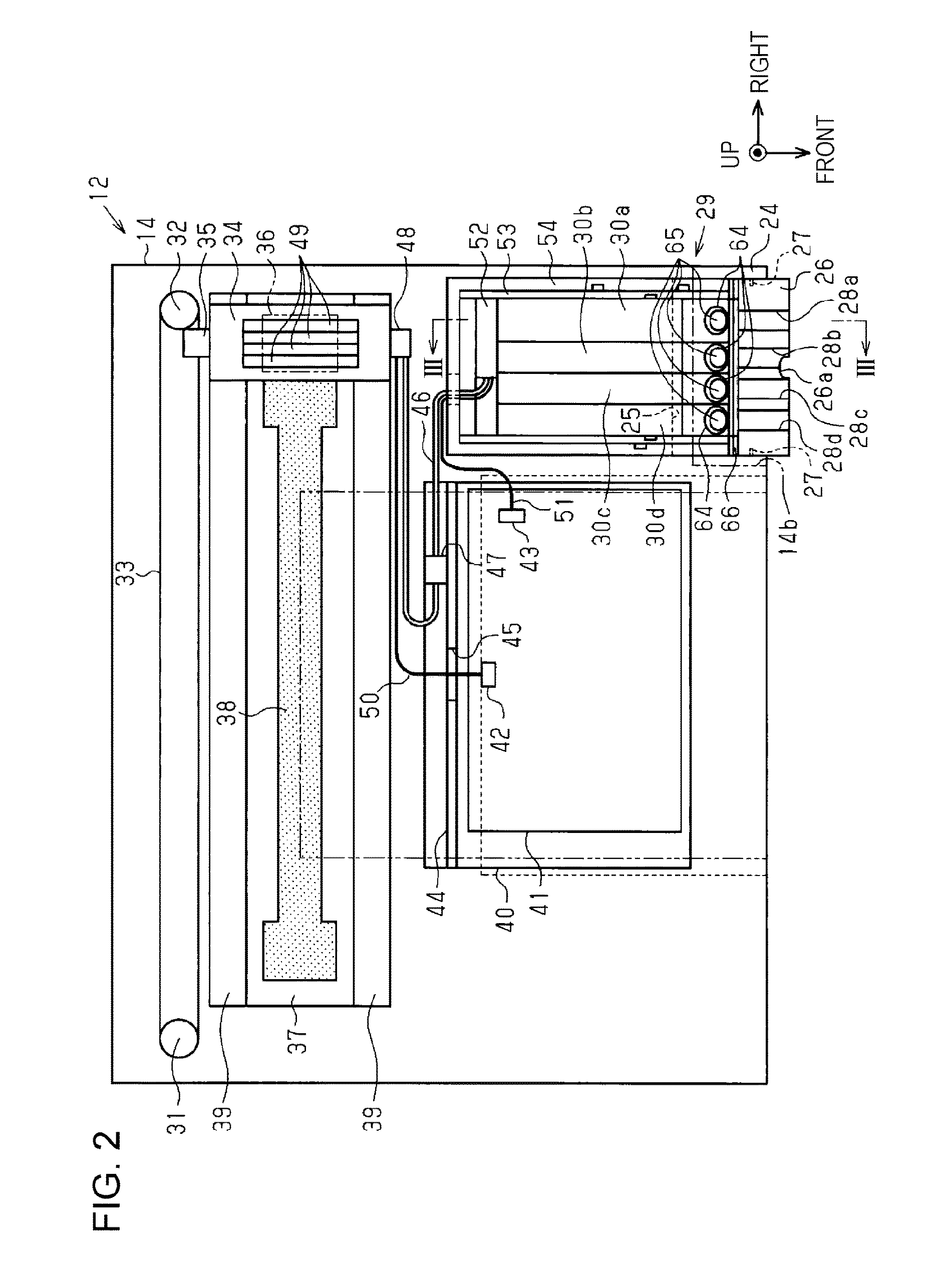

Printing apparatus

A printing apparatus includes a printing unit that performs printing onto a medium using liquid; a liquid housing body that includes a liquid pouring inlet that can pour the liquid into the liquid housing chamber; and a casing in which the printing unit and the liquid housing body are housed. The casing including a cover member that can displace the position thereof between an opening position which exposes the liquid pouring inlet to an outside and a closing position which does not expose the liquid pouring inlet to the outside, and the cover member can support an ink bottle in which liquid is stored in a state where the liquid can be poured from the ink bottle to the liquid pouring inlet of the liquid housing body in a case where the cover member is in the opening position.

Owner:SEIKO EPSON CORP

Process for casting gearbox body of centrifugal compressor

InactiveCN102909348AControl fireControl slag holeMolten metal pouring equipmentsFoundry mouldsCentrifugal compressorMaterials science

A process for casting a gearbox body of a centrifugal compressor comprises the following steps: 1), preparing a mould box, wherein a gearbox adopts two resin sand box molds, a plurality of U-shaped ceramic pipes are arranged on the parting surface of the lower box, two ends of each U-shaped ceramic pipe are connected with a filter and a horizontal runner, a U-shaped ceramic pipe is arranged at the bottom of the lower box, and two ends of the U-shaped ceramic pipe at the bottom of the lower box are connected to the horizontal runner and a flange at the bottom of the lower box, so as to form an upper stepped inner runner, a middle stepped inner runner and a lower stepped inner runner for feeding iron liquid; 2), carrying out brushing or flow coating, that is, conducting brushing or flow coating on a cavity and a mud core; 3), carrying out mold assembling, wherein residual sand in the cavity and the mud core is cleaned up, the mud core is lowered into the cavity smoothly, a filter disc is placed into a filter, a box sealing strip and glue are placed, positioning pins are placed into positioning holes, and mold assembling is carried out smoothly; and 4), pouring: a casting head is well placed, an air exhaust core is well surrounded by sand, the pouring temperature is controlled to be 1400 to 1350 DEG C, and the pouring time is controlled to be 80 to 90 minutes. According to the invention, the problem that casts produced according to the original process have scrapped gas pores is effectively solved; the production cost is reduced; and the productivity effect is improved.

Owner:上海华新合金有限公司

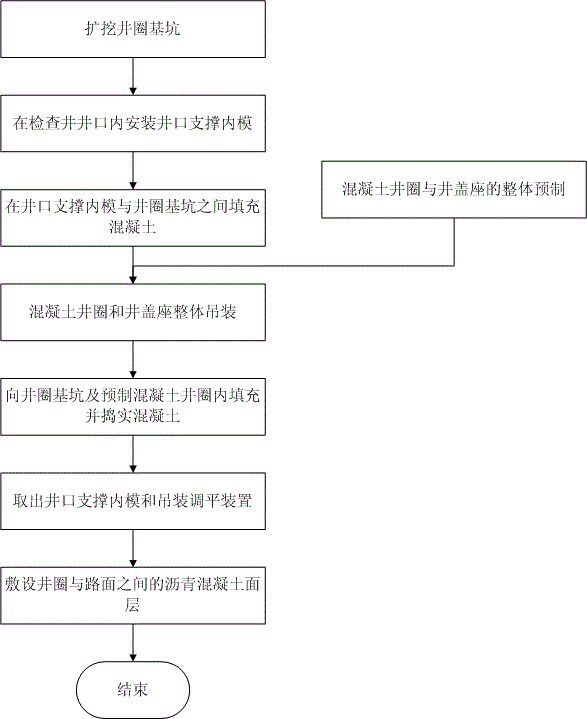

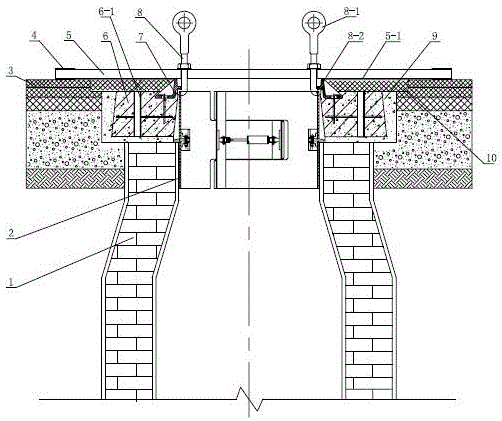

Construction method of well lid of road surface inspection well and auxiliary installation device

ActiveCN105133655AHigh accuracy of installation dimensionsGuaranteed smoothArtificial islandsUnderwater structuresRoad surfacePrecast concrete

The invention discloses a construction method of a well lid of a road surface inspection well. The construction method overcomes the defects that in the prior art, time for installation work of a well lid base is long, and the consistency of construction quality cannot be guaranteed. The construction method of the well lid of the road surface inspection well comprises the following steps that A, a concrete well ring and a well lid base are integrally prefabricated; B, a well ring foundation pit is dug; C, a well mouth supporting inner formwork is mounted in the well mouth of the inspection well; D, the space between the well mouth supporting inner formwork and the well ring foundation pit is filled with concrete; E, the concrete well ring and the well lid base are hoisted integrally; F, the well ring foundation pit and the prefabricated concrete well ring are filled with concrete, and the concrete is compacted; G, the well mouth supporting inner formwork and a hoisting and leveling device are taken out; and H, an asphalt concrete pavement layer between the well ring and the road surface is laid. The invention further provides an auxiliary installation device. The auxiliary installation device comprises the well mouth supporting inner formwork and the hoisting and leveling device. According to the construction method of the well lid of the road surface inspection well and the auxiliary installation device, construction is simple, work time is short, the dimensional precision of well lid installation is high, and the construction method and the auxiliary installation device are suitable for well lid installation.

Owner:SHENZHEN CONSTR GRP

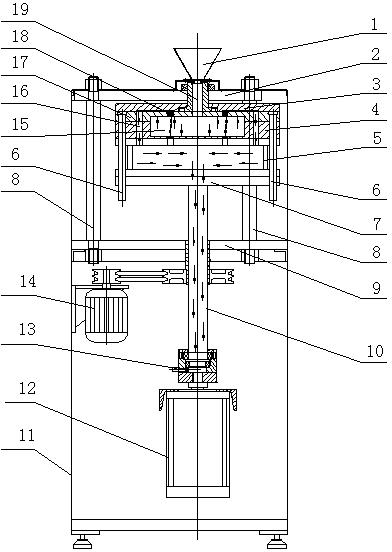

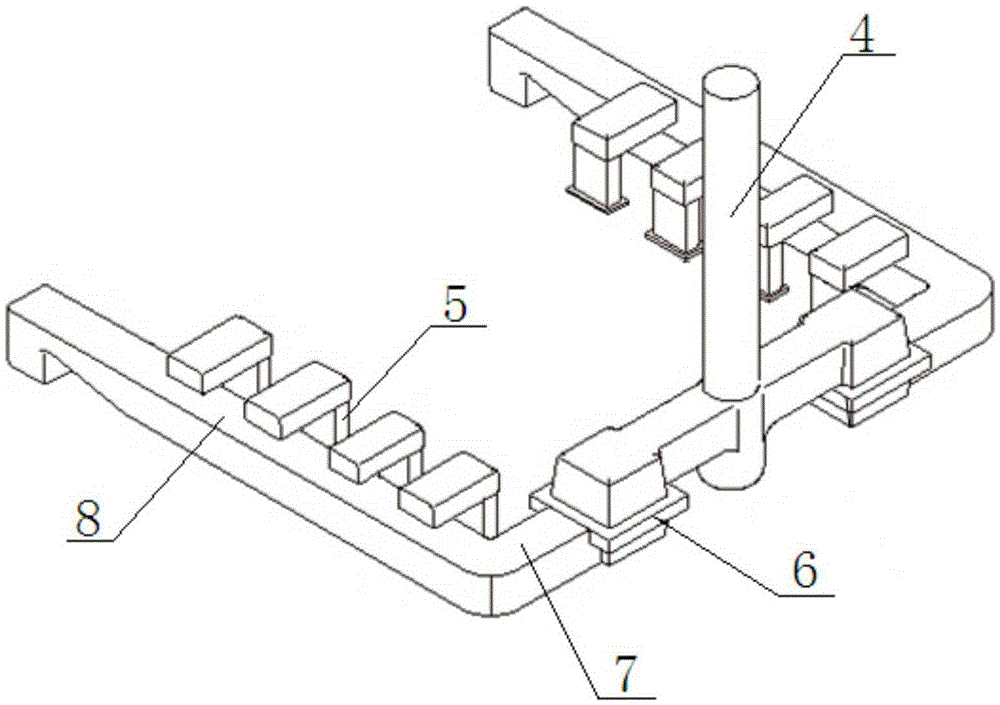

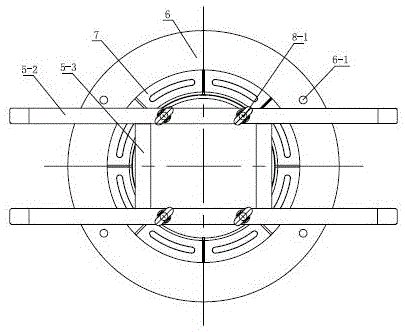

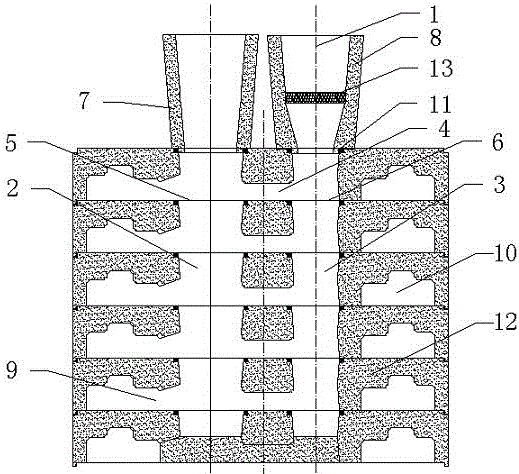

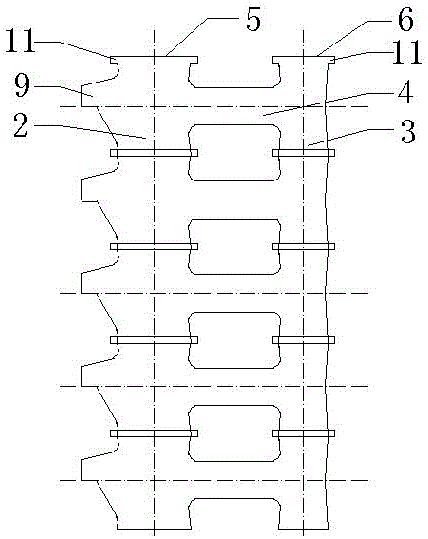

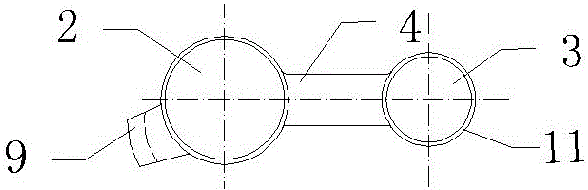

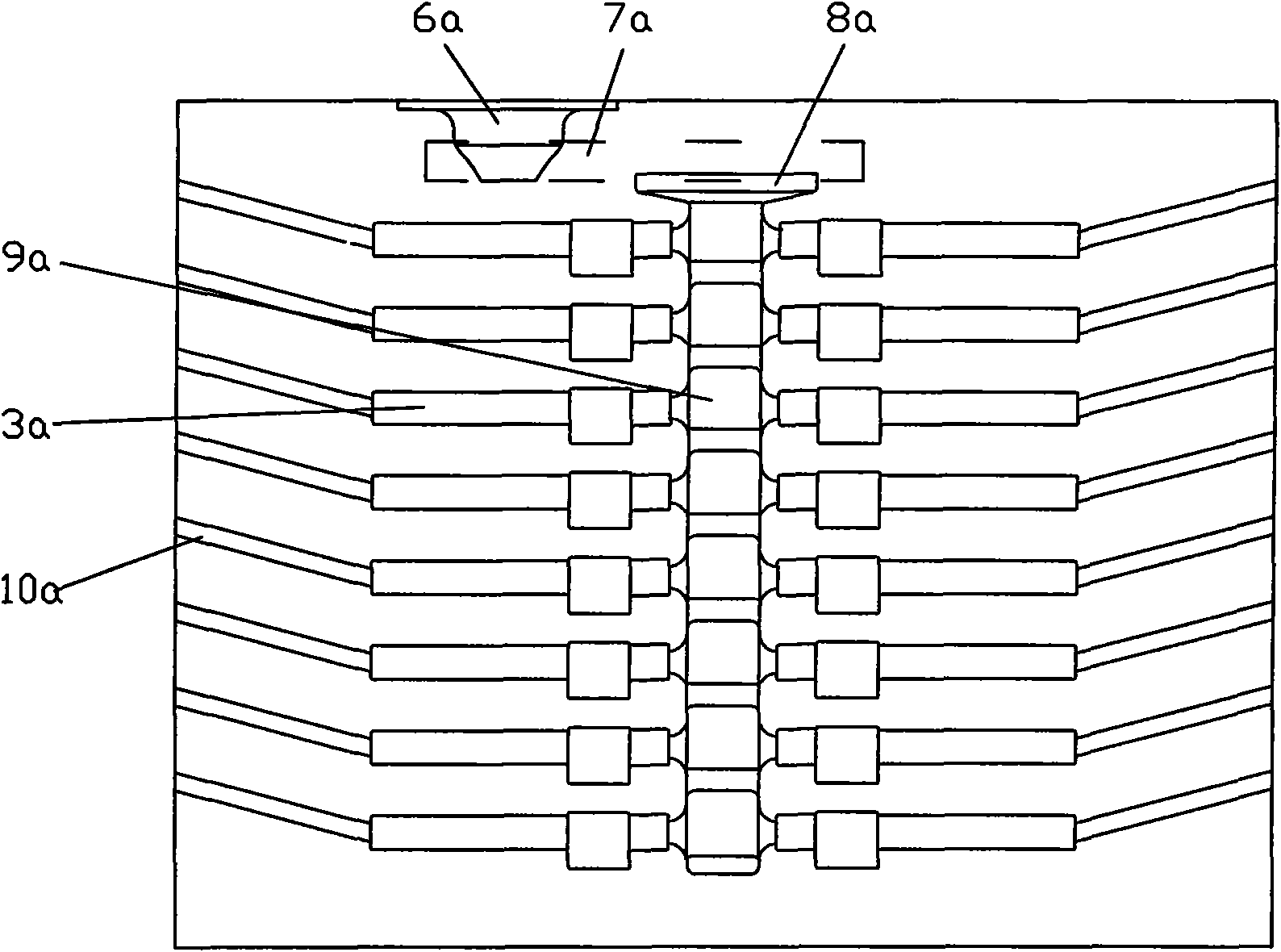

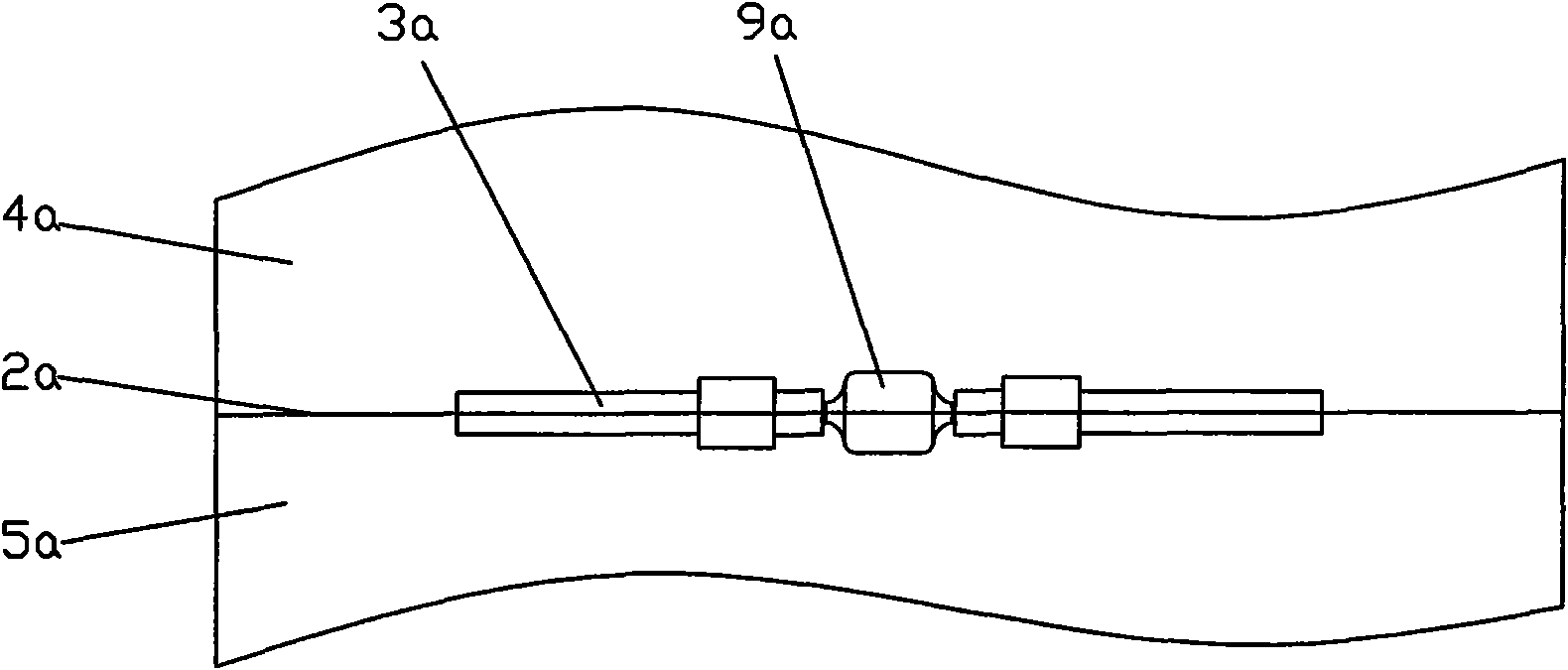

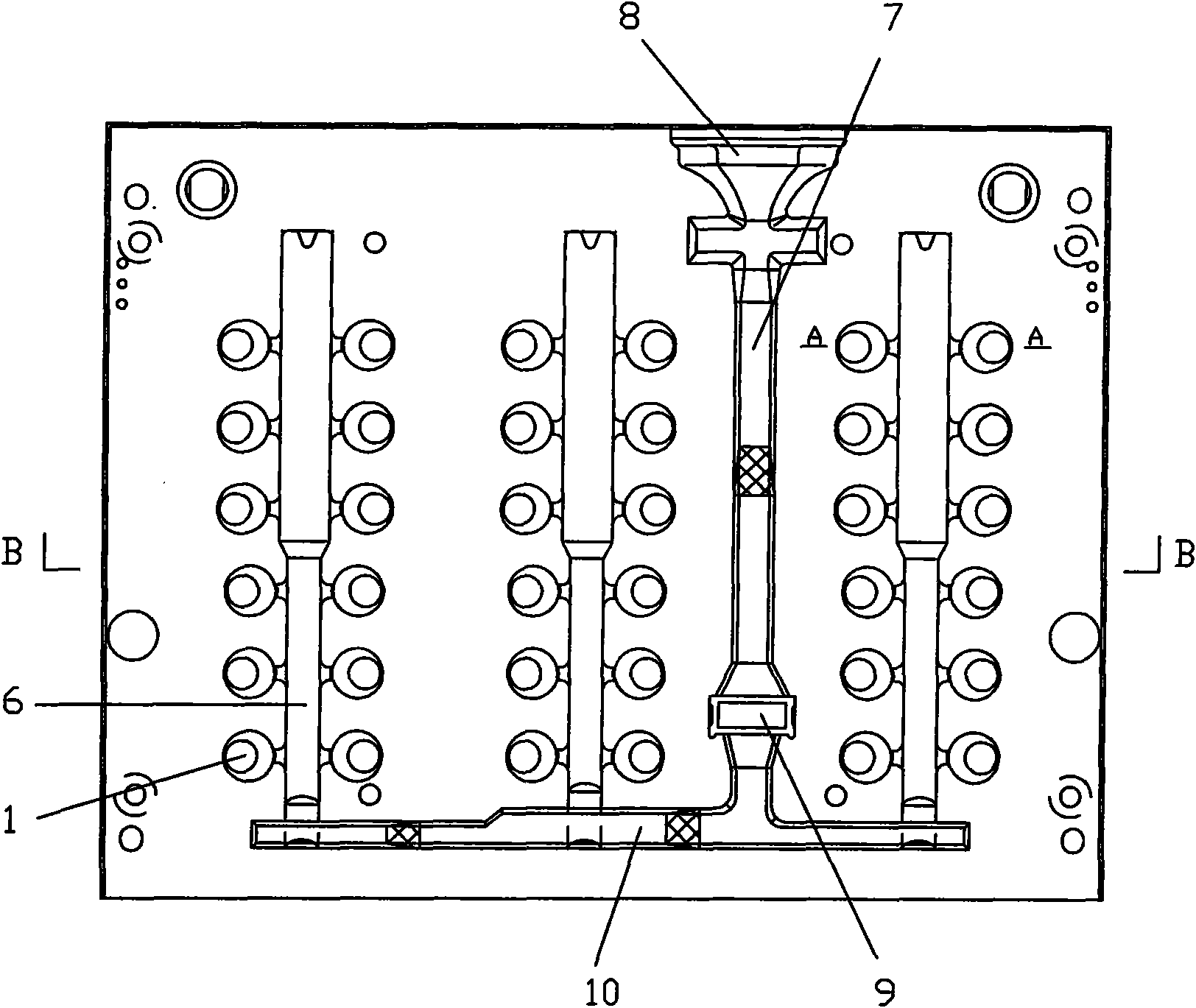

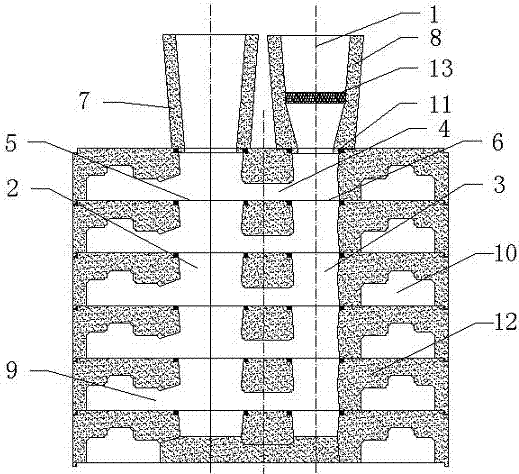

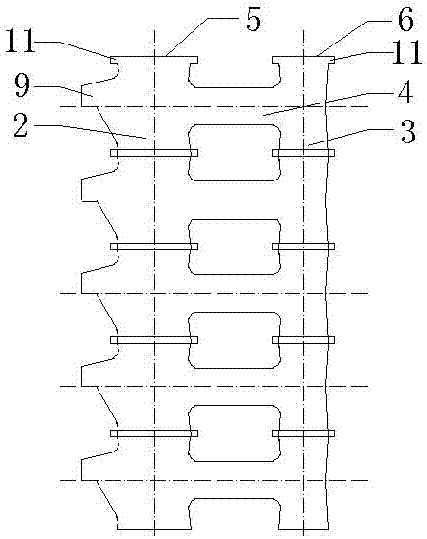

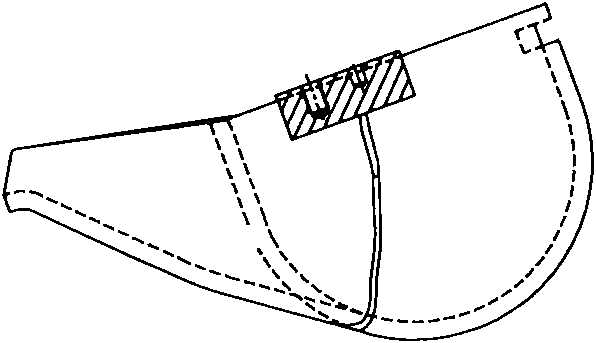

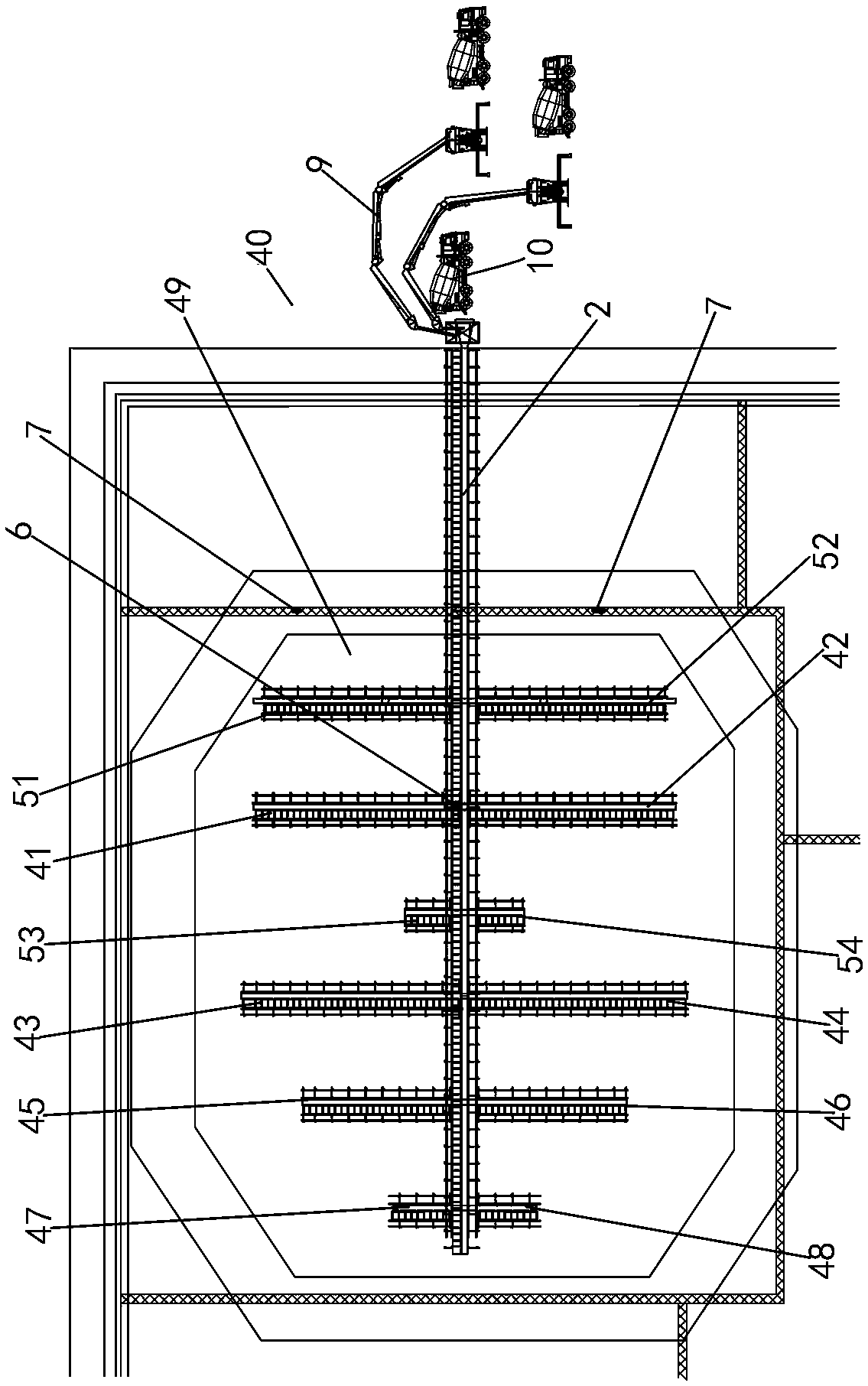

Multi-overlaid-layer gating system and technology for casting

InactiveCN104985128AImprove efficiencyReduced pouring timeFoundry mouldsFoundry coresEngineeringIron content

The invention discloses a multi-overlaid-layer gating system and technology for casting. The multi-overlaid-layer gating system is characterized in that the multi-overlaid-layer gating system comprises multiple layers which are overlaid, riser channels and spures are arranged in the gating system, and in each layer of the gating system, the upper end and the lower end of the riser channel and the upper end and the lower end of the spure are provided with risers and pouring gates respectively; a riser cup and a pouring gate cup are fastened to the riser and the pouring gate on the top layer of the gating system respectively; the riser and the pouring gate of the upper end of the next layer of the gating system are tightly sleeved with the riser and the pouring gate of the lower end of each upper layer of the gating system respectively; the riser and the pouring gate of the bottom layer of the gating system are sealed, cross gates are arranged between the riser channels and the spures, inner pouring gates are arranged on one sides inside the riser channels, the cross gates are communicated with the inner pouring gates, and the inner pouring gates are communicated with a product sand mold cavity. By means of the multi-overlaid-layer gating system, a multi-layer product sand mold cavity is cast, casting production efficiency is improved, casting time is shortened, the molten iron content in multi-overlaid-layer casting is guaranteed, temperature balance is guaranteed, and casting product quality is guaranteed.

Owner:HUBEI YAGANG METAL MFR

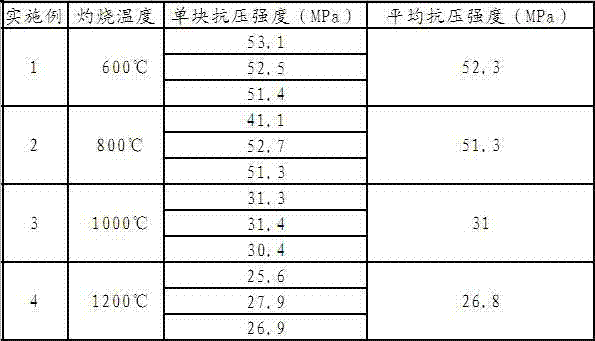

Self-compaction refractory concrete

InactiveCN102887716AShorten pouring timeImprove construction efficiencyStructural engineeringWater reducer

The invention discloses a self-compaction refractory concrete which is composed of the following ingredients according to weight percentage: 25%-35% of cement, 55%-65% of refractory aggregate, 0.03%-0.09% of water reducer and 8%-15% of water. The self-compaction refractory concrete provided by the invention can meet the requirements on mechanical properties such as compression strength and breaking strength as far as possible in a short time, the pouring time is greatly shortened, and the construction efficiency and the construction quality are improved.

Owner:YUNNAN COPPER CO LTD

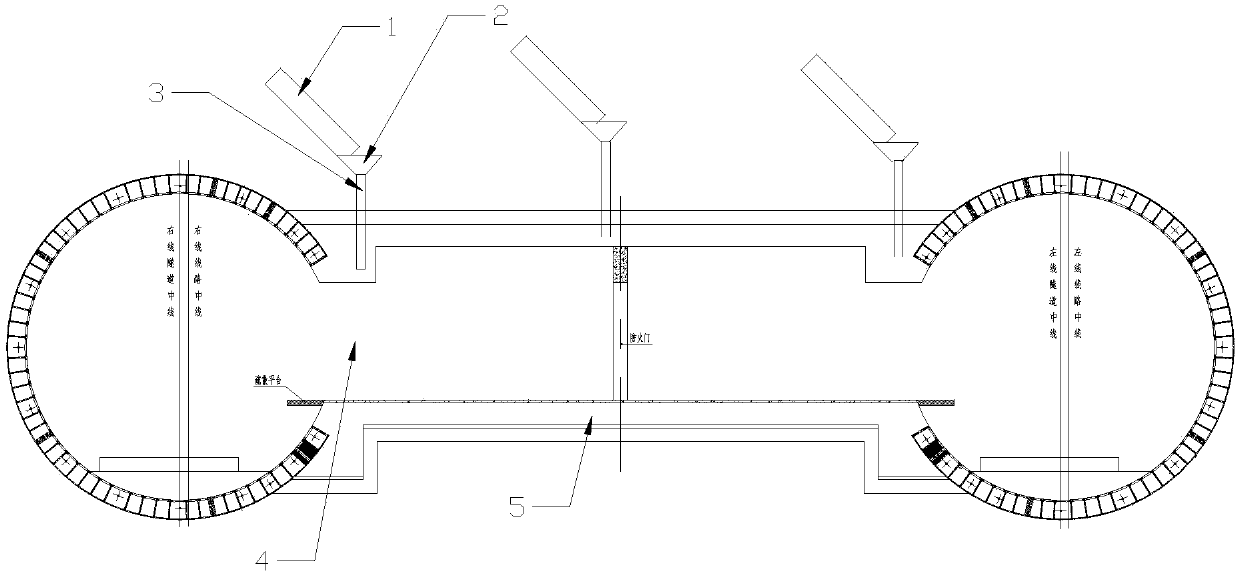

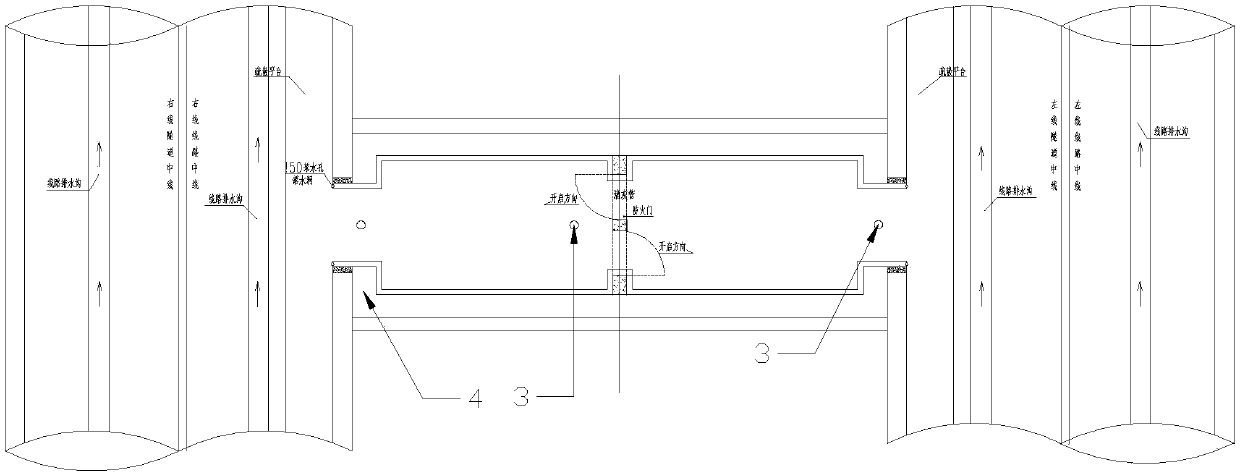

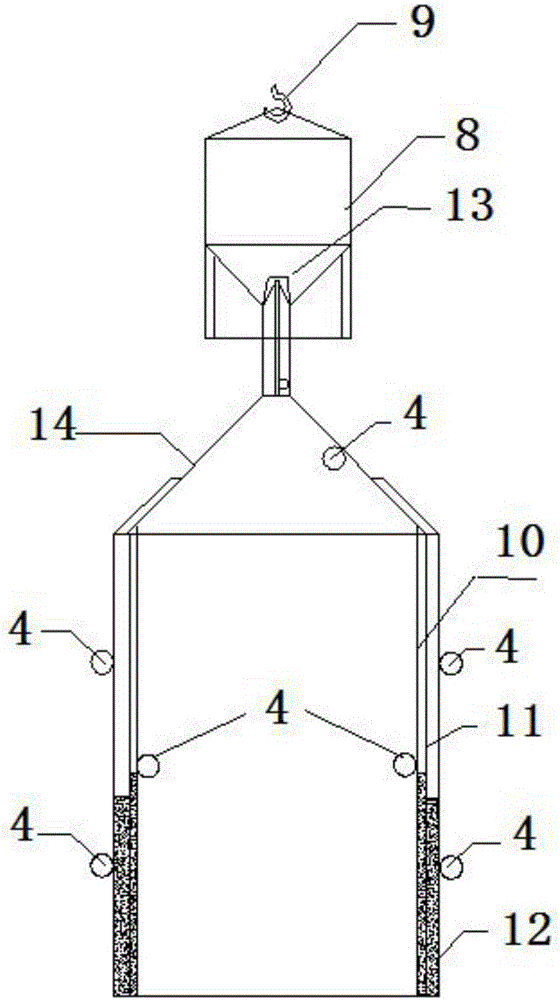

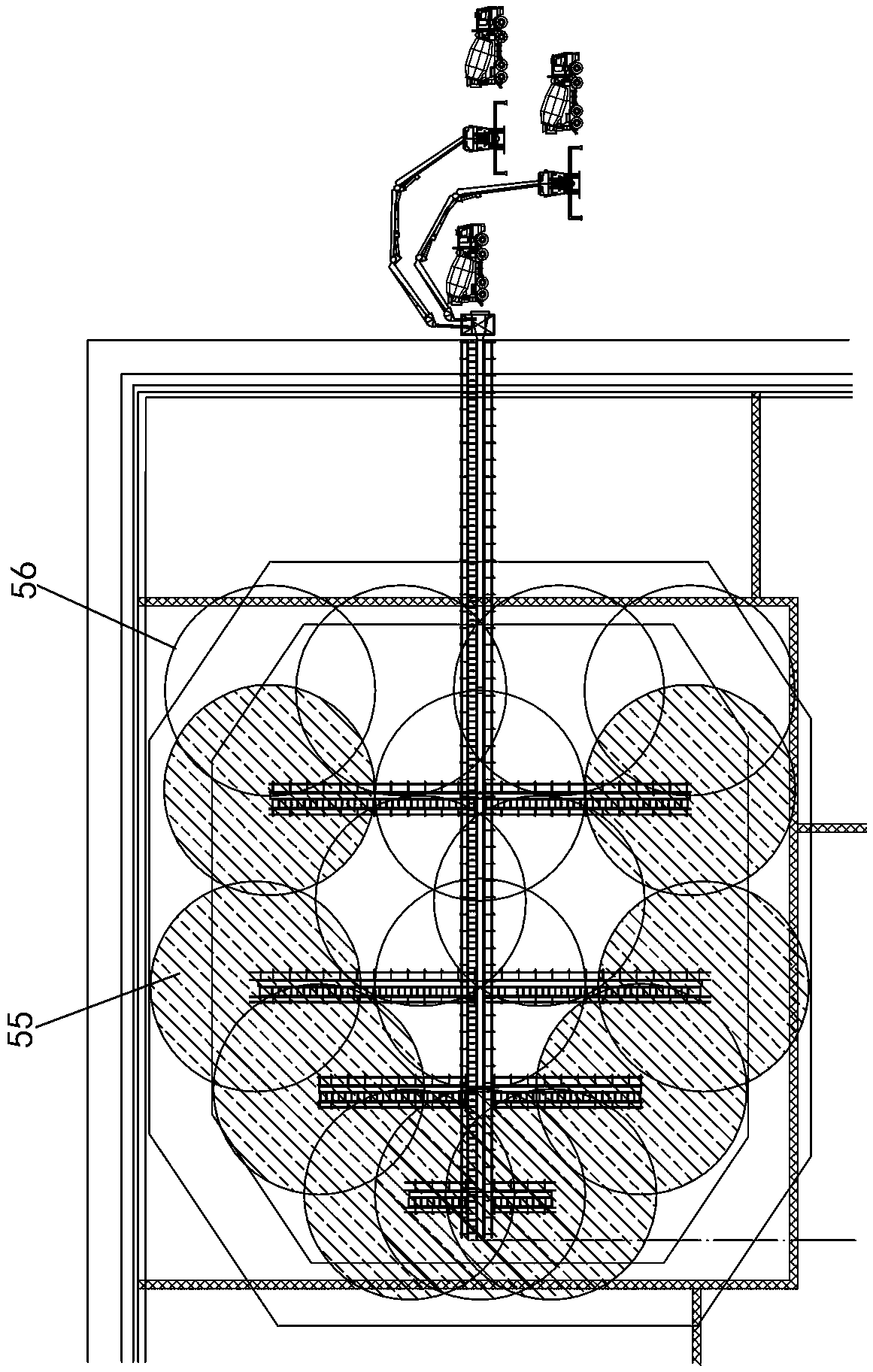

Method for constructing concrete structure of subway contact passage through ground pouring and freezing method

ActiveCN107740699AGuarantee unimpededEnsure that the pouring is denseUnderground chambersTunnel liningStructural engineeringClerestory

The invention discloses a method for constructing a concrete structure of a subway contact passage through a ground pouring and freezing method. The method for constructing the concrete structure of the subway contact passage comprises the following steps that (1) drilling is conducted from the ground above the contact passage toward the interior of the contact passage; (2) concrete sliding tubesare placed downwards in drilled drill holes in the step (1); (3) after a frozen wall meets the excavation condition of the contact passage, earth excavation of the contact passage is conducted in a subway tunnel, and protective treatment is conducted on the concrete sliding tubes after the concrete sliding tubes are dug out; and (4) the concrete structure of a bottom plate (5) of the contact passage is poured by utilizing the concrete sliding tube located in the center of the contact passage, and the side wall concrete structure and the arch crown concrete structure concrete structure are poured by utilizing the concrete sliding tubes located in the flare opening position. According to the method for constructing the concrete structure of the subway contact passage through the ground pouring and freezing method, compact pouring of concrete on an arch crown of the contact passage can be achieved, opening or holes in the concrete on the arch crown of the contact passage can be effectively prevented, it is effectively ensured that the thickness of the concrete structure of the contact passage meets the design requirement, and hidden dangers caused by the quality of the concrete structure of the contact passage are eliminated.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

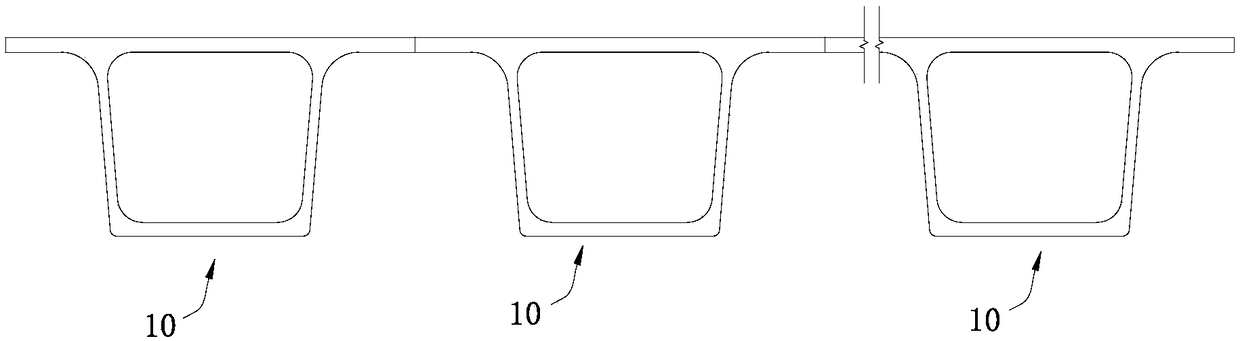

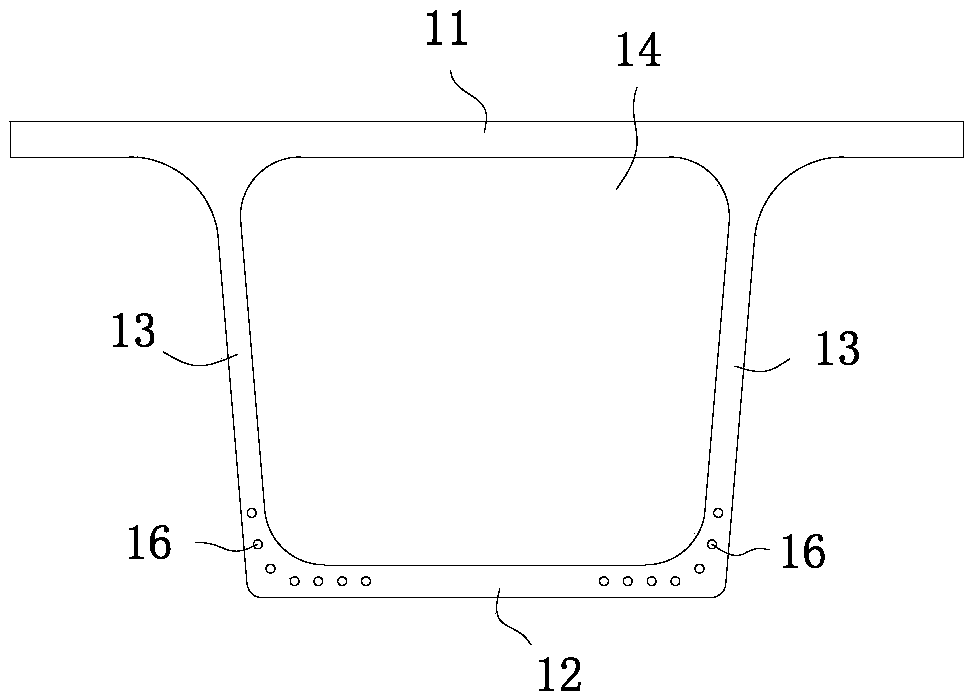

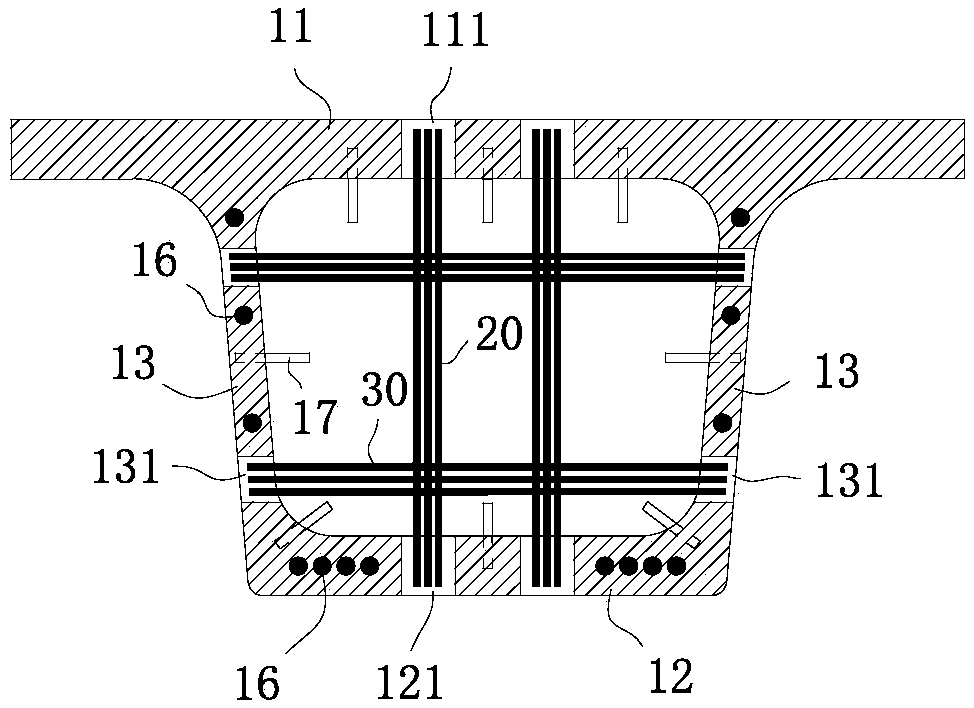

UHPC small box girder structure

PendingCN108755380ASave materialBeam weight reductionBridge structural detailsBridge materialsThin walledCorrosion

The invention discloses an UHPC small box girder structure. The UHPC small box girder structure comprises multiple box girder bodies connected with each other through longitudinal joints; the box girder bodies are prefabricated by ultra-high performance concrete; the box girder bodies consist of top plates, bottom plates, web plates, midspan diaphragms and end diaphragms; retard-bonded prestressedtendons are embedded in the box girder bodies in a longitudinal direction; internal side templates and external side templates which are fixedly connected with each other through bolt connecting pieces are arranged in the end parts of the box girder bodies; the end diaphragms are integrally poured between the internal side templates and the external side templates; and the box girder bodies are thin-walled box girders consisting of UHPC materials. Materials are effectively saved, the girder weight is reduced by about 40%, the retard-bonded prestressed tendons are embedded in the box girder bodies so that the materials are saved and the girder height is reduced; corrosion and changing problems of external prestressed tendons are avoided; and the maintenance cost in the operation period isgreatly reduced.

Owner:GUANGZHOU MUNICIPAL ENG DESIGN & RES INST CO LTD

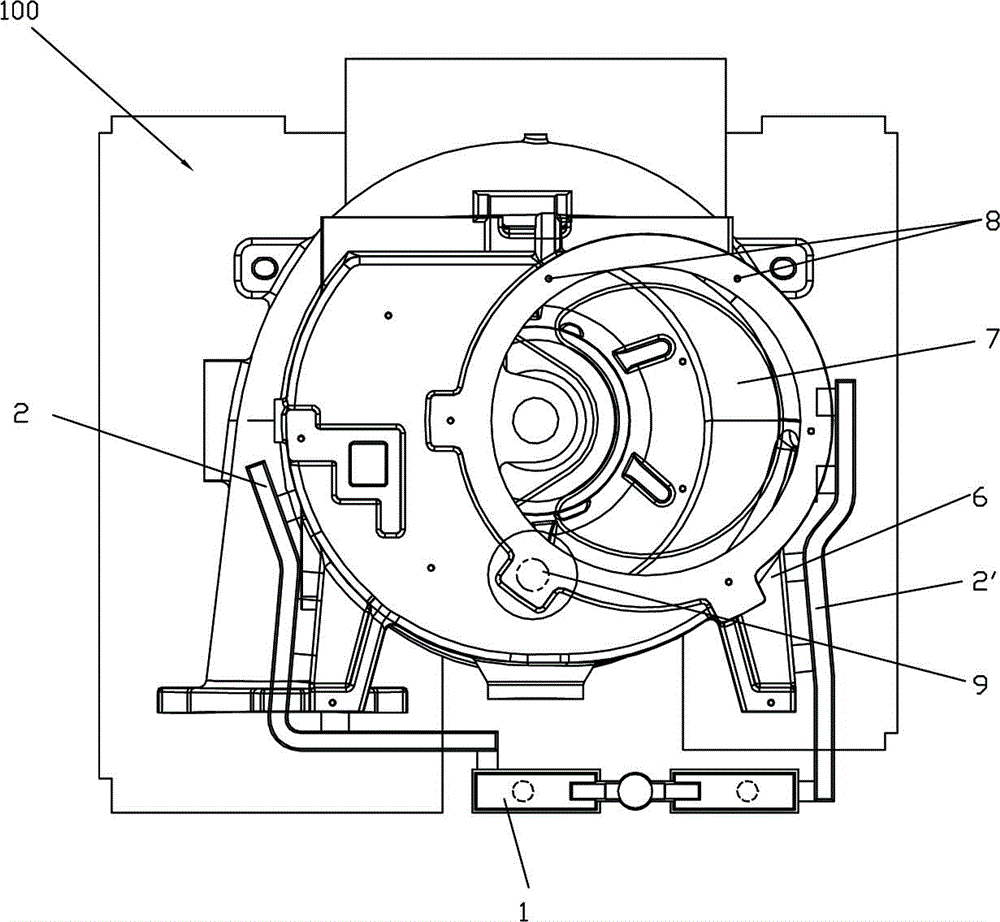

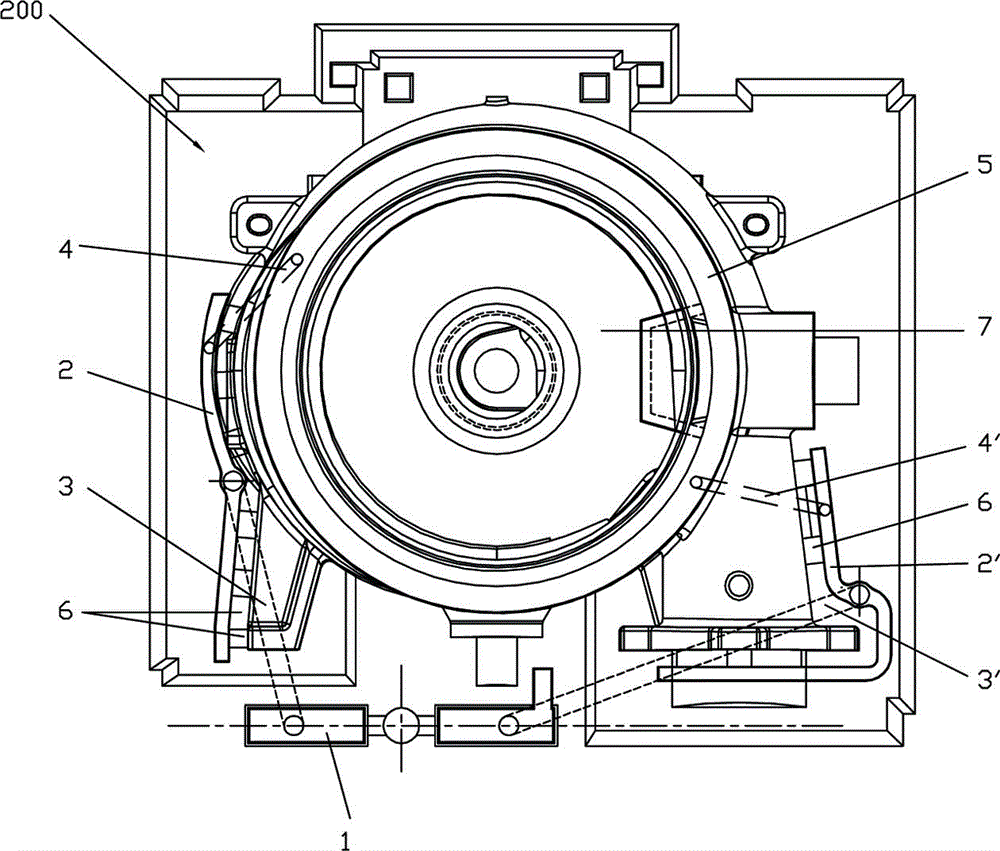

Production technology of air-conditioning compressor crankshaft

ActiveCN102397993AReduce contact areaIncrease the number of placementsFoundry mouldsFoundry coresEngineeringAir conditioning

A production technology of an air-conditioning compressor crankshaft comprises the following steps of: sand mulling; modeling; melting and interrupted front treatment; casting; casting cleaning and product quality inspection. During the modeling design process, the axial direction of a die crank is perpendicular to a parting face and parting of the die crank is carried out at the eccentric part of the crankshaft. After modeling and stripping, crankshaft cavities are formed and are respectively arranged inside two adjacent sand molds. During the casting process by a bottom casting mode, a filter screen is used to filter molten iron. On the basis of meeting technological requirements of crankshaft casting, production efficiency is raised and the purpose of energy saving and emission reduction is achieved.

Owner:上海华新合金有限公司

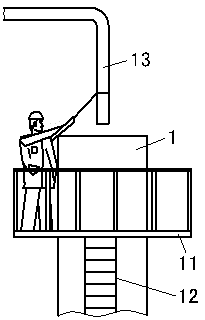

Steel pipe column concrete lateral pouring method and steel pipe column structure used in method

InactiveCN104131704ADoes not affect constructionImprove installation efficiencyStrutsBuilding material handlingArchitectural engineeringPipe

The invention discloses a steel pipe column concrete lateral pouring method and a steel pipe column structure used in the method. A steel pipe column is formed by welding multiple steel pipes. The method includes the steps that a pouring hole is formed in the side wall of the upper steel pipe, and then the upper steel pipe and the lower steel pipe are welded; when concrete in the lower steel pipe is poured, a concrete pumping pipe is inserted into the pouring hole in the upper steel pipe from the side face, and then pouring of the concrete in the lower steel pipe is finished. In the pouring process, construction of an upper-layer steel pipe column, a steel beam and a truss formwork is not influenced, synchronous construction can be achieved, work faces do not interfere with one another, installation efficiency of the steel structure is improved and the construction period is shortened. A worker can stand on an outer-frame horizontal beam and slab structure during pouring construction, safety risks are greatly reduced, pouring is easy and convenient to carry out, pouring can be carried out without a concrete spreader, operation time of the concrete spreader is saved, pouring time of the concrete of the steel pipe column is greatly shortened, the construction period is shortened, and labor expenses are reduced.

Owner:CHINA CONSTR FOURTH ENG DIV

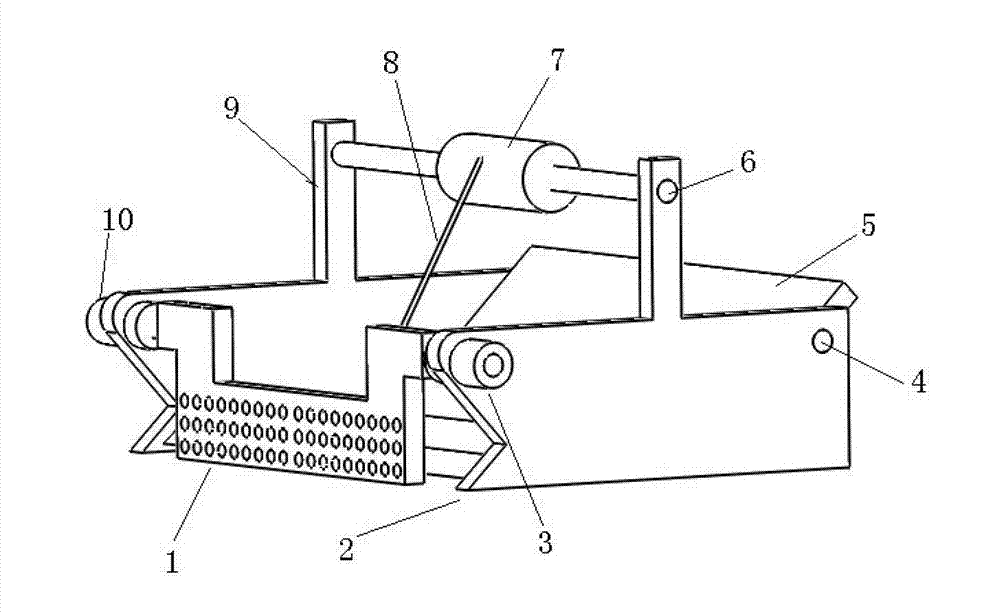

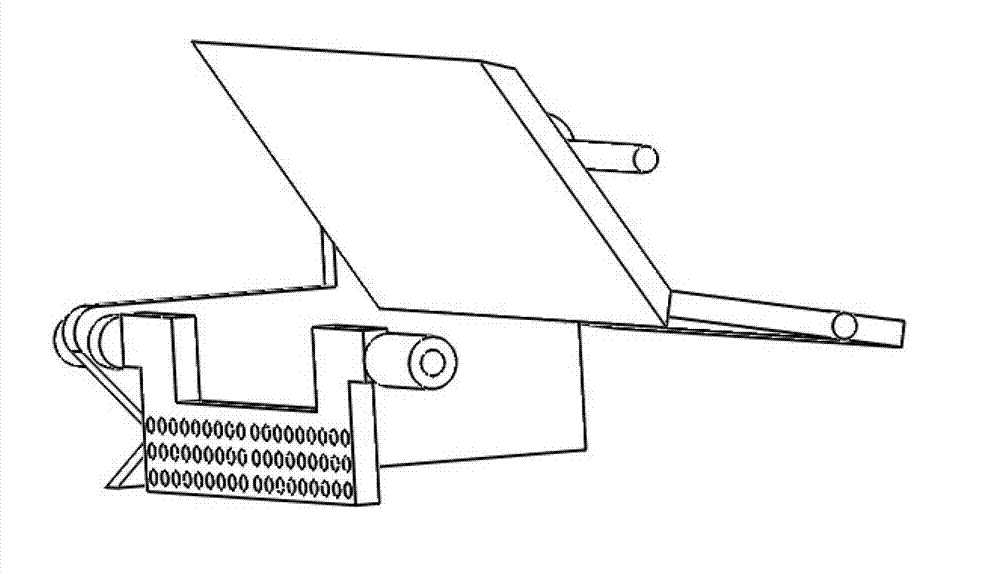

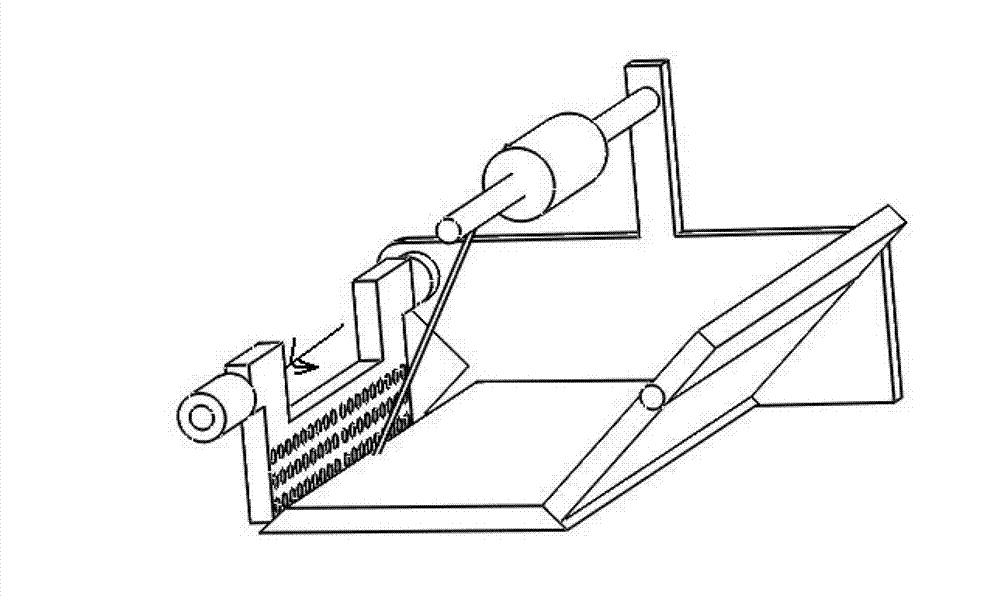

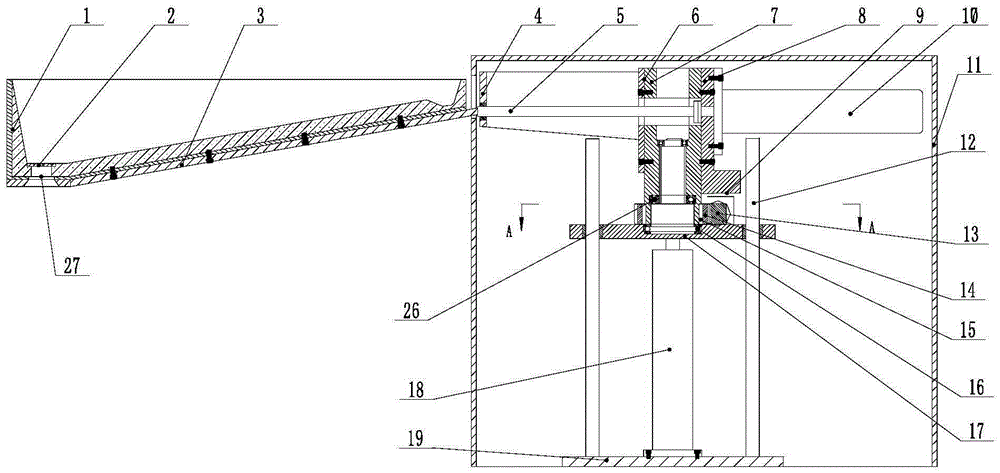

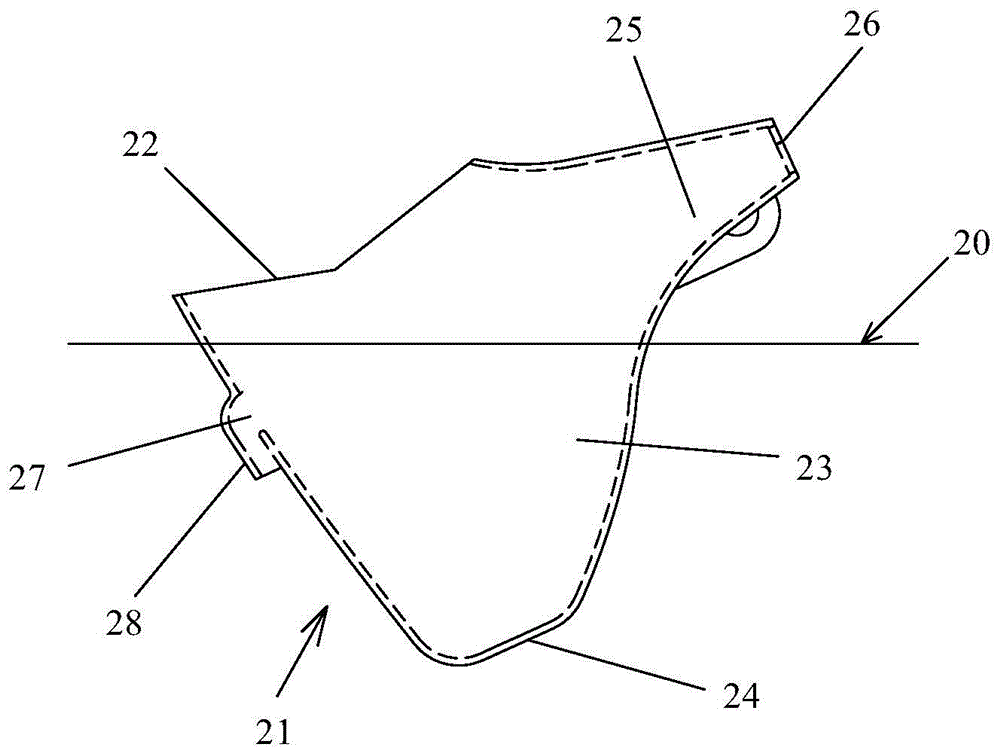

Deep sea manganese ore collection mechanism

The invention discloses a deep sea manganese ore collection mechanism which comprises a rotary plate and an ore bin, wherein the ore bin comprises a bottom plate and a rear plate; a left side plate and a right side plate are respectively arranged at the left side and the right side of the bottom plate; the rotary plate is arranged at the front end of the bottom plate; a left side waterproof speed reducing motor and a right side waterproof speed reducing motor are respectively connected at the front ends of the left side plate and the right side plate; motor shafts of the left side waterproof speed reducing motor and the right side waterproof speed reducing motor arranged along the horizontal direction are respectively connected with the upper parts of the left side and the right side of the rotary plate by a coupler; the bottom of the rear plate is connected with the rear end of the bottom plate, and the upper part of the rear plate is rotatablely connected between the rear ends of the left side plate and the right side plate by a rotating shaft of the ore bin connected with the left side plate and the right side plate; the rotating output end of a drag motor is connected with one end of a drag rope; and the other end of the drag rope is connected with the bottom plate so as to drive the bottom plate to rotate around the rotating shaft of the ore bin. The deep sea manganese ore collection mechanism has the advantages of being easy to maintain and convenient to repair, and reduces the time for dumping ores.

Owner:TIANJIN UNIV

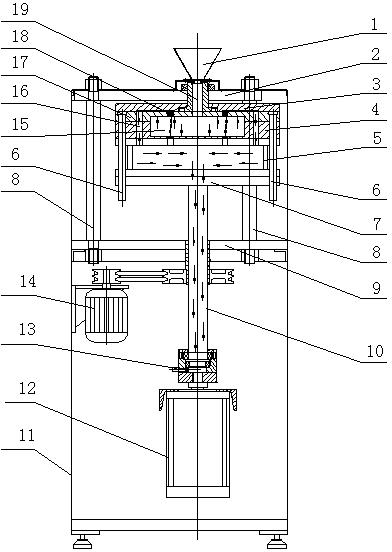

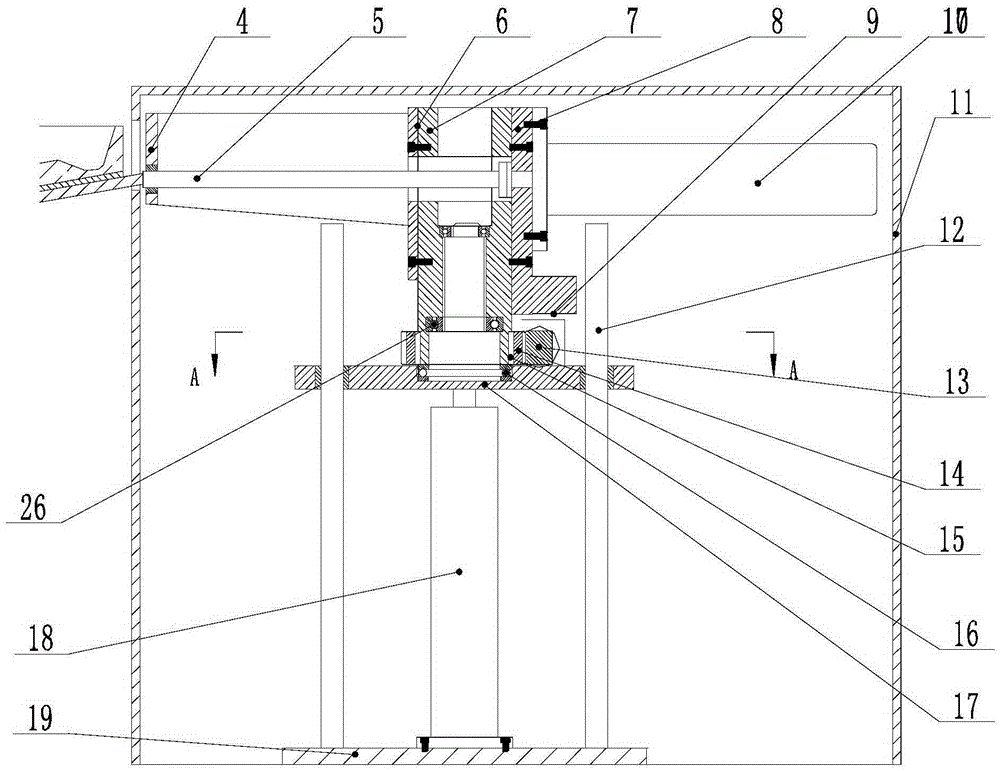

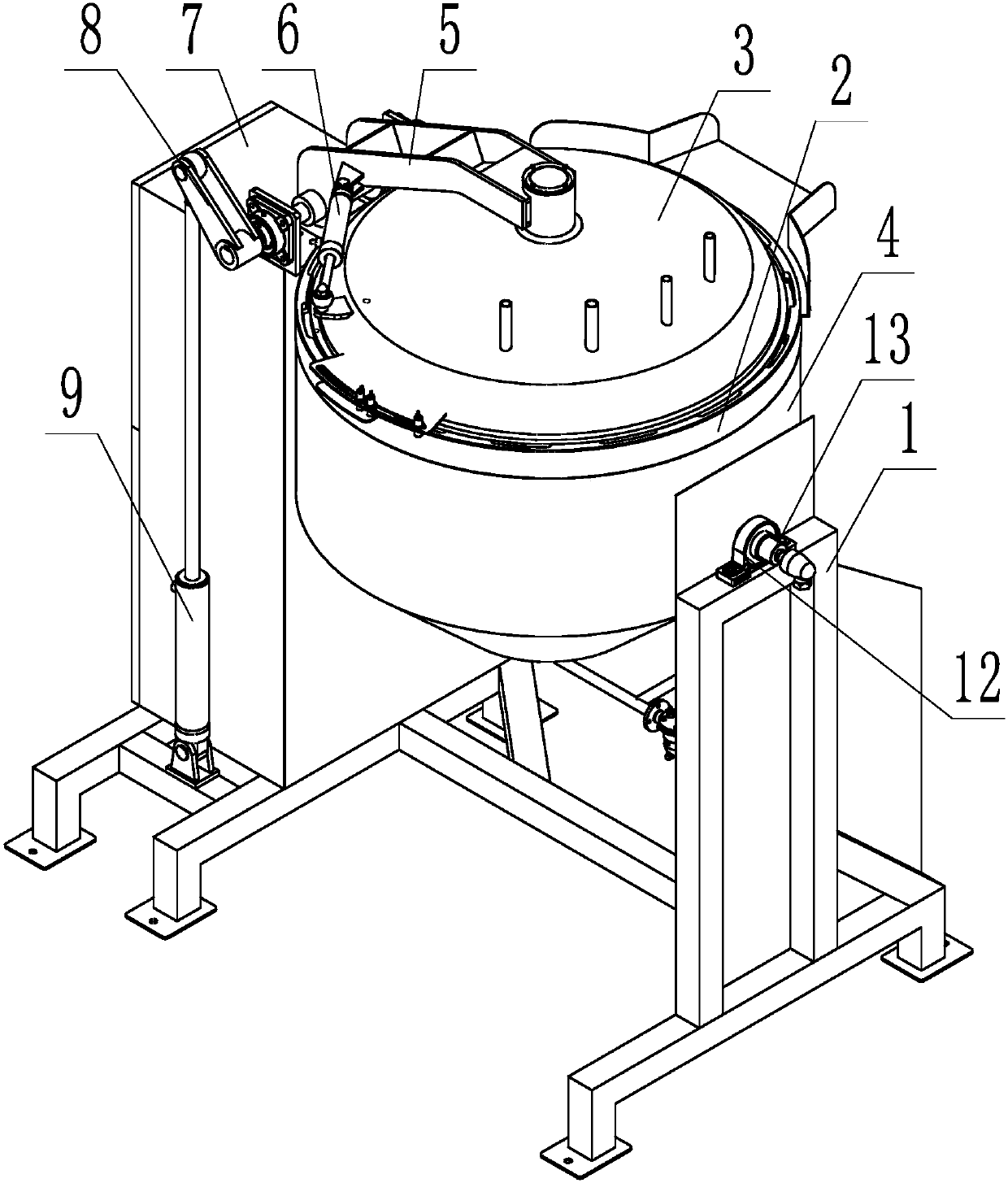

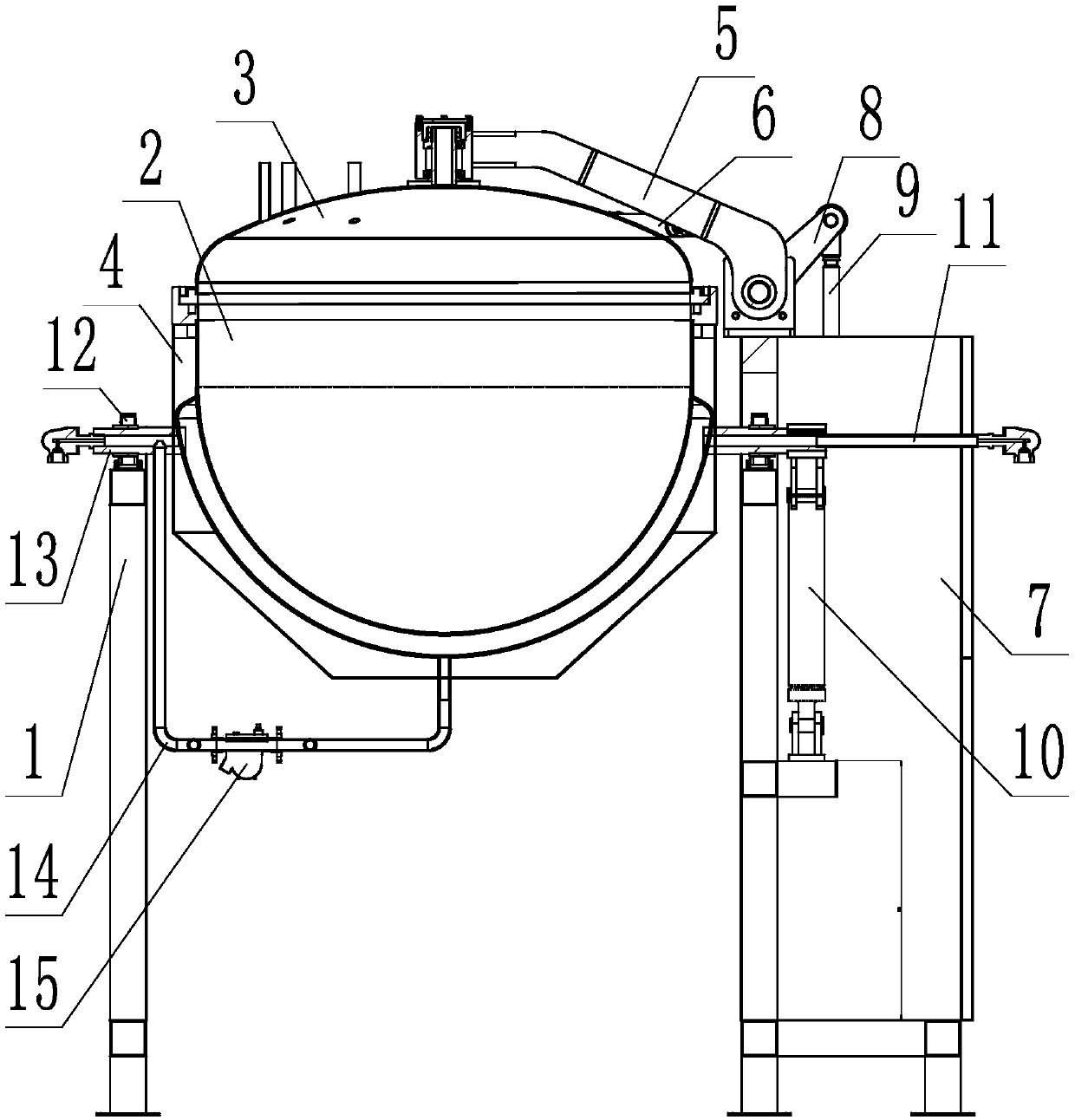

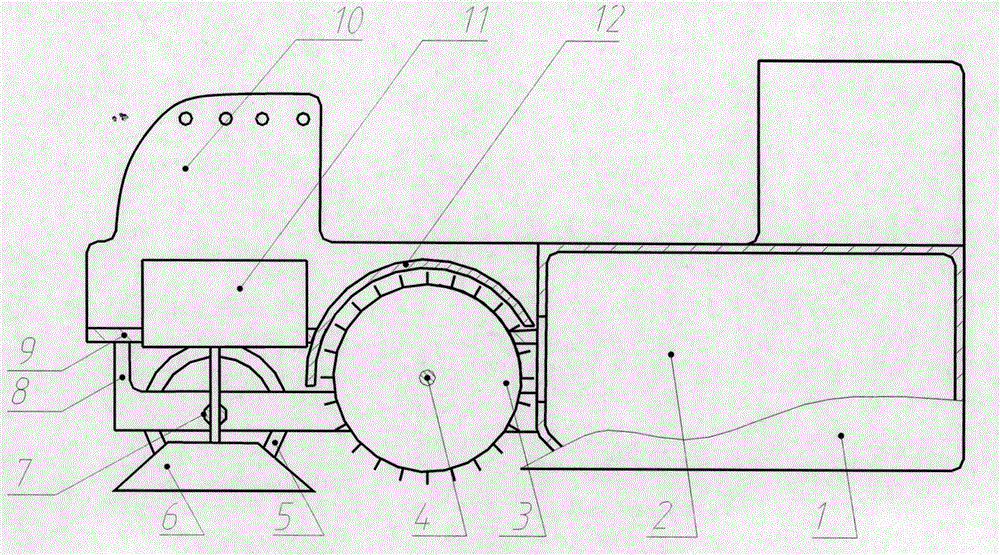

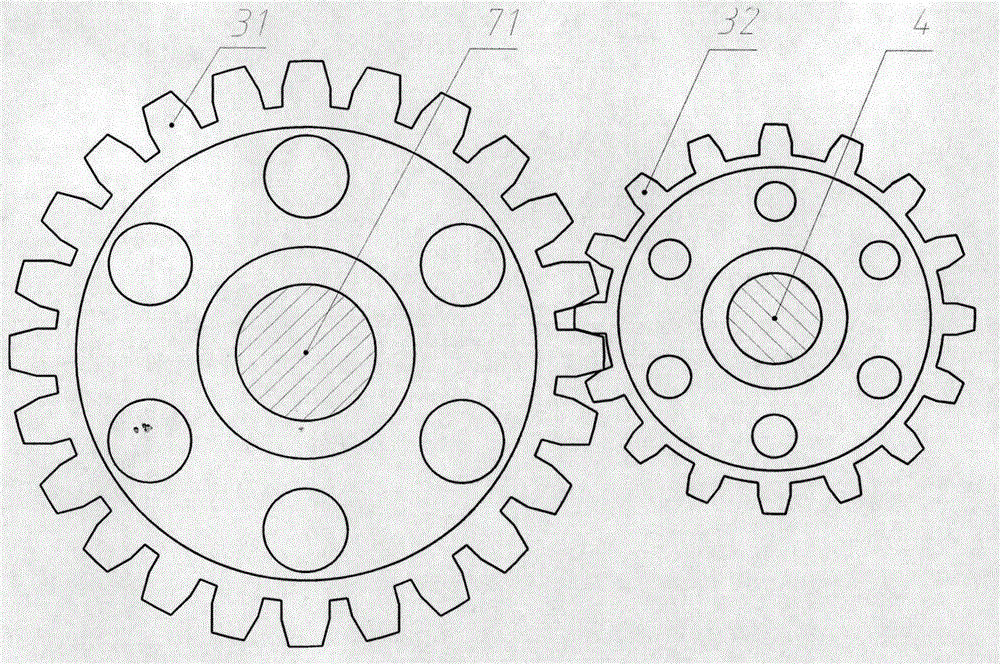

Casting machine and casting method for liquid forging

InactiveCN105344989AZoom outReduce openingMolten metal supplying equipmentsControl systemEngineering

The invention discloses a casting machine and casting method for liquid forging and belongs to the technical field of special forging techniques and equipment. The casting machine comprises a machine base, a rotating mechanism, a lifting mechanism, a telescopic mechanism, a flow guiding system, a hydraulic system and a control system. The flow guiding system is connected to the telescopic mechanism. The telescopic mechanism is installed on the rotating mechanism. The rotating mechanism is fixed to the lifting mechanism. The lifting mechanism is installed on the machine base. The hydraulic system is used for driving to achieve rotational movement, rising and falling movement and stretching and retracting movement. Casting outside the machine is achieved through the steps of adjusting a casting position, preheating a flow guiding groove, rotating the flow guiding groove to the casting position, conducting casting, and restoring the flow guiding groove, and the manufacturing cost and the use cost of a liquid forging machine can be remarkably reduced. The casting machine and casting method can be used for liquid forging of large pieces and rapid and stable casting, can decrease the defective rate and is wide in application range.

Owner:BEIJING JIAOTONG UNIV

A casting multi-layer pouring system and process

InactiveCN104985128BImprove efficiencyImprove utilizationFoundry mouldsFoundry coresThermodynamicsProcess engineering

The invention discloses a casting multi-layered pouring system and process, which is characterized in that: the pouring system is multi-layered and stacked respectively, the pouring system is respectively provided with a riser channel and a sprue, each layer of the pouring system, a riser The upper and lower ends of the sprue and the sprue are respectively provided with a riser and a gate. The top riser and the gate of the gating system are respectively fastened with a riser cup and a sprue cup. The riser and the gate at the lower end of each layer of the gating system are respectively tight. Set on the riser and gate at the upper end of the gating system of the next layer, the riser and gate at the bottom of the gating system are sealed separately, a horizontal runner is provided between the riser channel and the sprue, and a The ingate, the runner leads to the ingate, and the ingate communicates with the cavity of the product sand model. The present invention casts multi-layer product sand mold cavities by setting a multi-layer pouring system, improves the production efficiency of castings, shortens the pouring time, ensures the composition and temperature balance of multi-layer pouring molten iron, and guarantees the quality of pouring products.

Owner:HUBEI YAGANG METAL MFR

Concrete filled steel tubular structure internally provided with composite tubes and seawater sea sand concrete

PendingCN110714577AGuarantee the effect of resource utilizationImprove mechanical propertiesStrutsBuilding insulationsSoil scienceRebar

A concrete filled steel tubular structure internally provided with composite tubes and seawater sea sand concrete. The concrete filled steel tubular structure comprises a steel tube, common concrete,the composite tubes and the seawater sea sand concrete. More than one composite tube is arranged in the section of the steel tube, the axes of the composite tubes are parallel to the axis of the steeltube, the internal parts of the sections of the composite tubes are filled with the seawater sea sand concrete, the gaps between the composite tubes and the steel tube are filled with the common concrete, the seawater sea sand concrete and the common concrete are separated by the composite tubes, protection is provided for resisting chloride ion corrosion, and meanwhile possibility is provided for arranging steel bars in the outer common concrete. The composite tubes and the steel tube provide the inner constraint and the outer constraint for the seawater sea sand concrete, the mechanical performance of the seawater sea sand concrete is greatly improved, seawater sea sand resource utilization is achieved while the application effect of the normal common concrete is reached, and broad prospects are achieved.

Owner:NANJING FORESTRY UNIV

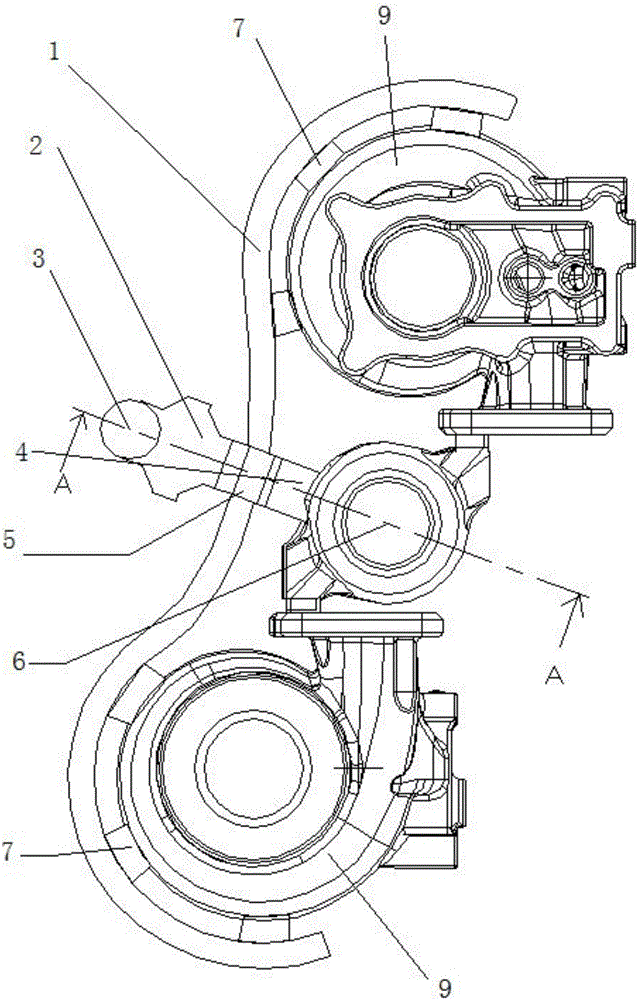

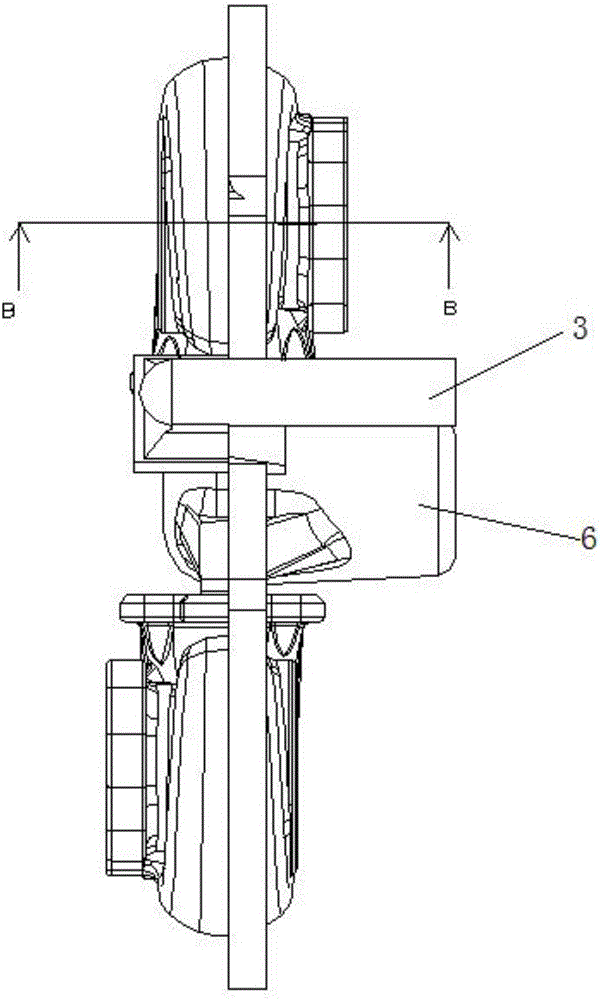

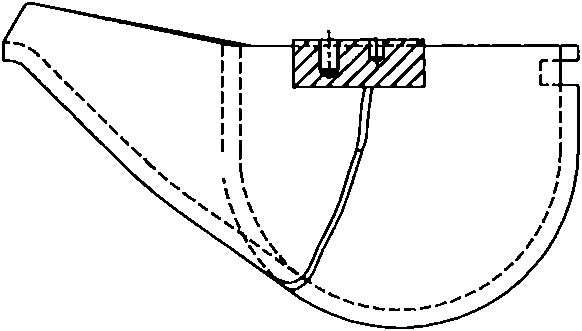

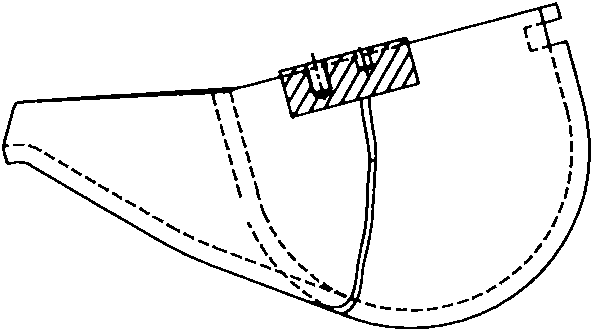

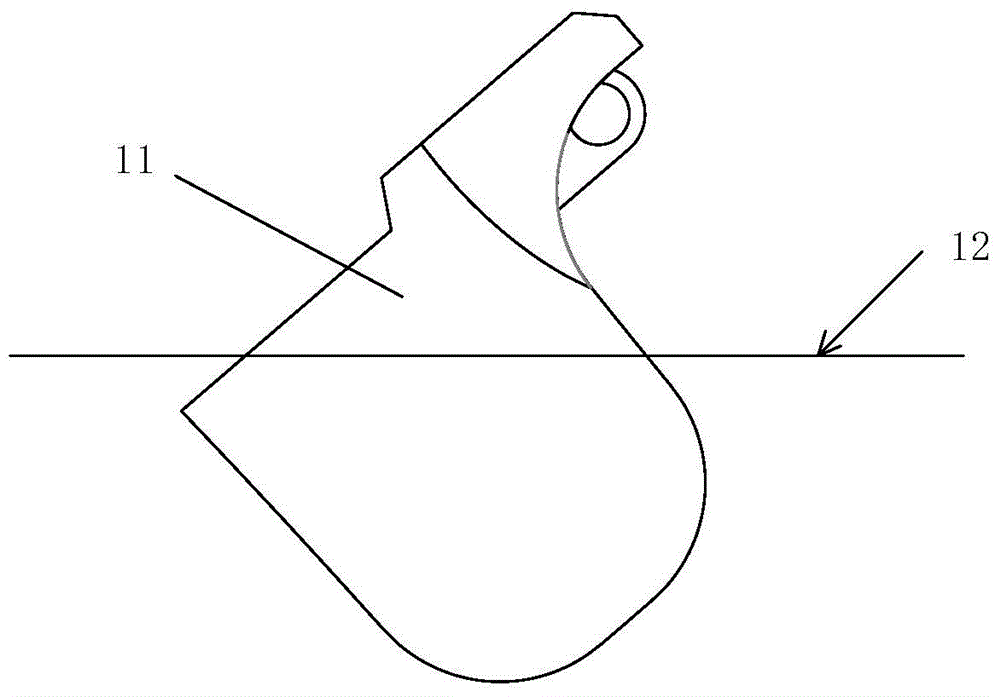

Casting method for turbine shell

The invention provides a casting method for a turbine shell. The turbine shell is internally provided with a partition plate. The casting process comprises the following steps that S1, a riser (6) is placed at the edge of a mold core of the turbine shell, and the riser (6) is made to be connected with the mold core of the turbine shell; S2, a transverse pouring gate and a flow resistant channel (4) are arranged in a mold, the transverse pouring gate is provided with a plurality of water inlets (7) which are connected to the periphery of the mold core of the turbine shell at intervals, one end of the flow resistant channel (4) is connected with the transverse pouring gate, and the other end of the flow resistant channel (4) is connected with the riser (6); S3, pouring liquid is injected into the sand mold and is filtered; and S4, the filtered pouring liquid enters a cavity of the turbine shell through the multiple water inlets (7) and the flow resistant channel (4), pouring is completed, and the turbine shell is obtained. According to the casting method for the turbine shell, cold shut of the partition plate of the turbine shell and the casting surface slag hole defect can be eliminated, and the internal quality and the yield of the turbine shell are improved.

Owner:CRRC CHANGZHOU AUTO PARTS CO LTD +1

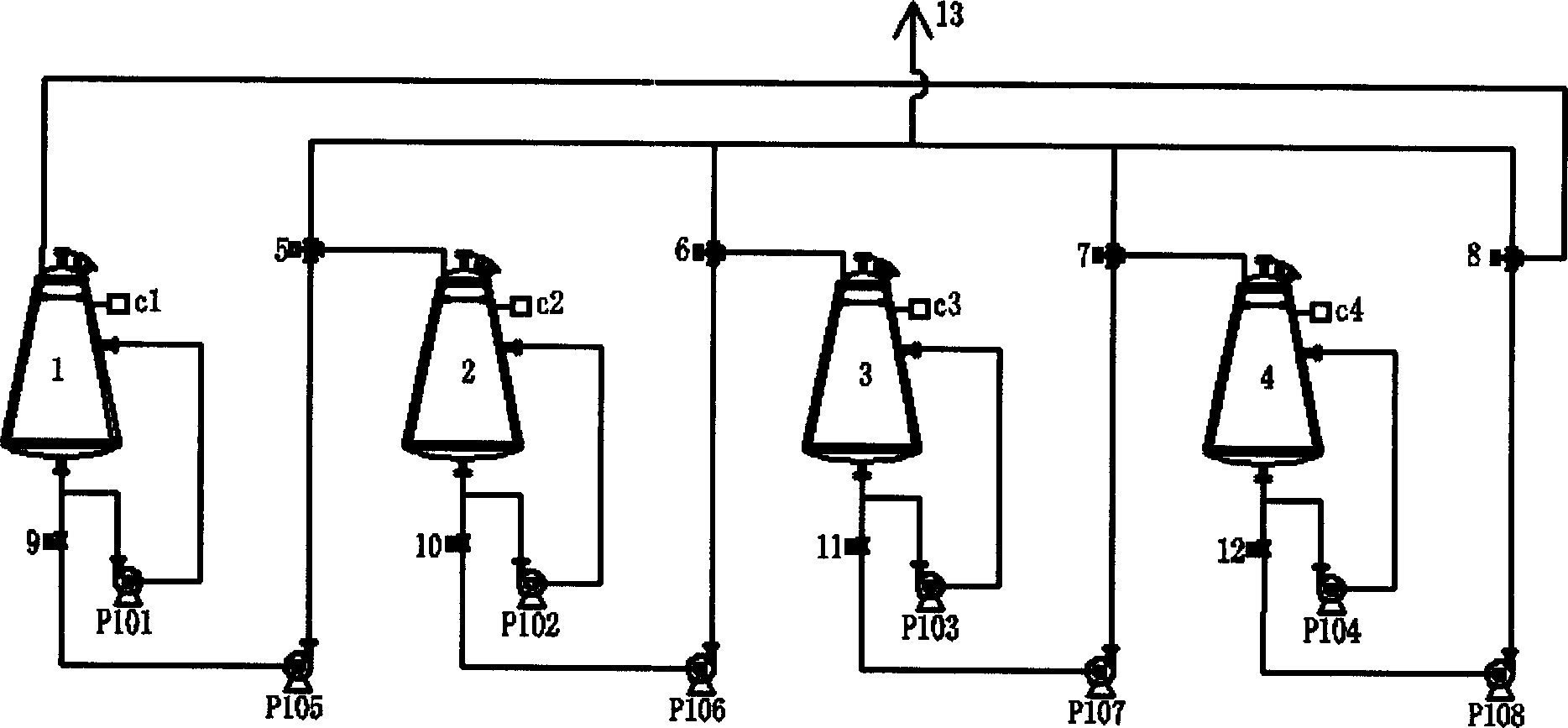

Continuous countercurrent extraction method using dynamic overflow and apparatus thereof

The invention relates to a method for extracting effective component of traditional Chinese medicine, with dynamic overflow continuous reverse-flow method, wherein said method uses several extractors, while each extractor works independently and they use active overflow method, to transfer liquid continuously. Compared with traditional method, the invention improves extracting speed, reduce solvent consumption, reduce following energy consumption and improve efficiency. The invention can reduce extracting temperature, etc. And the invention comprise several pots, heater, condenser, tubes, pump and value which control the active overflow between pots, and the meter element controlling the balance of whole device.

Owner:PHARM TECH TIANJIN

Robot quantitative pouring method

InactiveCN101574735AImprove production rateAvoid temperatureMolten metal supplying equipmentsMaterials scienceMolten metal

The invention discloses a robot quantitative pouring method which belongs to a pouring method. The existing method easily causes the inconsistent temperature change of molten metal at each part in a mold cavity and the overhigh pouring flow rate of a certain part so that the molten metal overflows or spills out of a mould. The robot quantitative pouring method uses a robot for taking a pouring ladle to the mould and controlling the set continuous overturn angle of the pouting ladle so as to pour. The robot quantitative pouring method is characterized in that the set angle is divided into a plurality of angle sections, and the pouring ladle turns over according to a set speed in each angle section to pour. When the molten metal is poured in, with different structures of the mould, the pouring quantity and the pouring speed can be adjusted in the process of pouring so as to have obvious action of improving the making rate of castings with relatively complicated structures such as cylinder covers, aluminum wheels of the motorcycle, and the like. In addition, the same pouring ladle is used for pouring moulds in different sizes so as to change pouring tracks aiming at different moulds.

Owner:ZHEJIANG WANFENG TECH DEV CO LTD

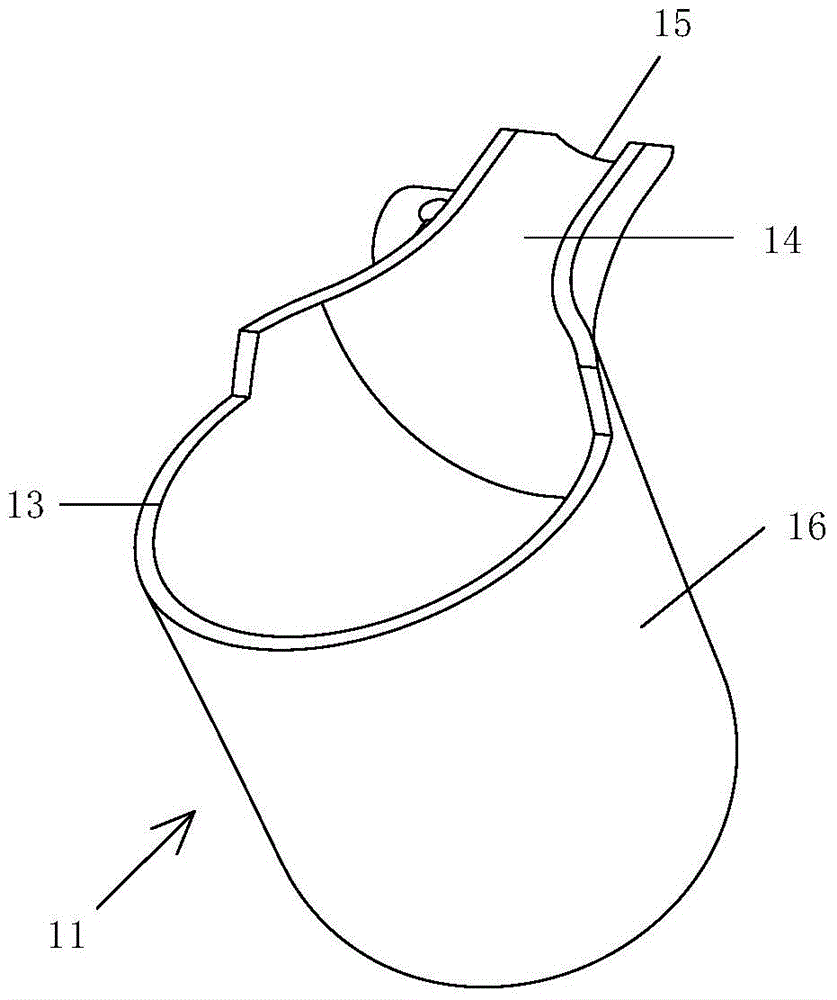

Soup spoon for soup feeding machine

The invention discloses a soup spoon for a soup feeding machine. The soup spoon comprises a spoon opening, a spoon body, a spoon bottom, a soup outlet and a soup outlet channel. The spoon opening and the spoon bottom are located at the upper portion and the lower portion of the spoon body respectively. One end of the soup outlet channel is connected with the upper portion of the spoon body, while the other end of the soup outlet channel is connected with the soup outlet. A through hole is formed in the spoon body below the edge of the spoon opening. The upper edge of the through hole is connected with a cap protruding outwards and extending in the direction of the spoon bottom. When the soup spoon is used for spooning soup, oxide residues on the metal bath surface can be prevented from entering the soup, and therefore the quality and qualified rate of the soup are improved; the soup is accurately fed in place and discharged rapidly and safely.

Owner:上海一达机械有限公司

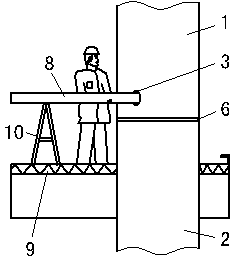

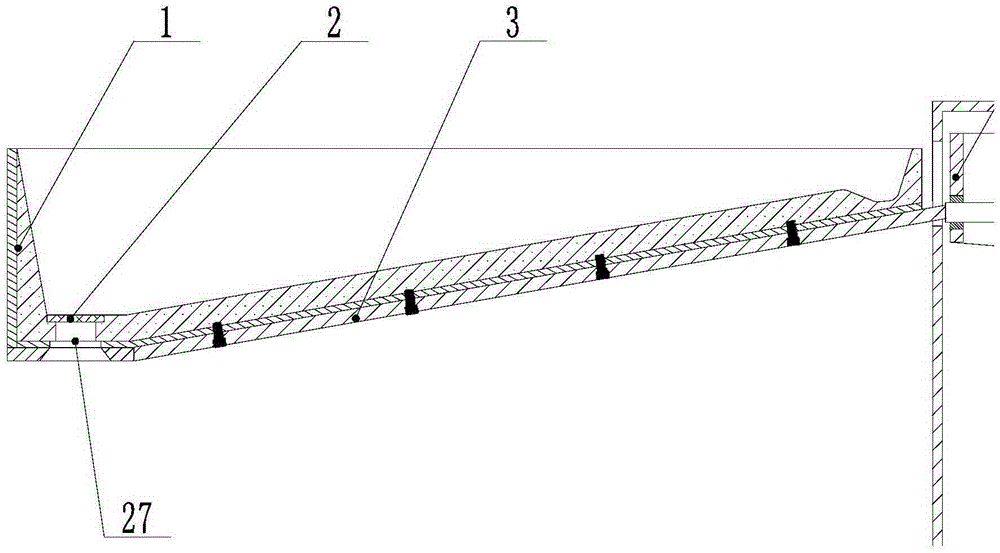

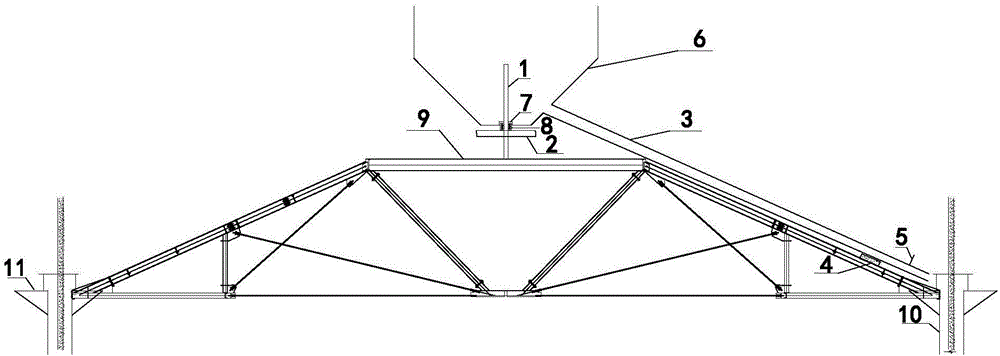

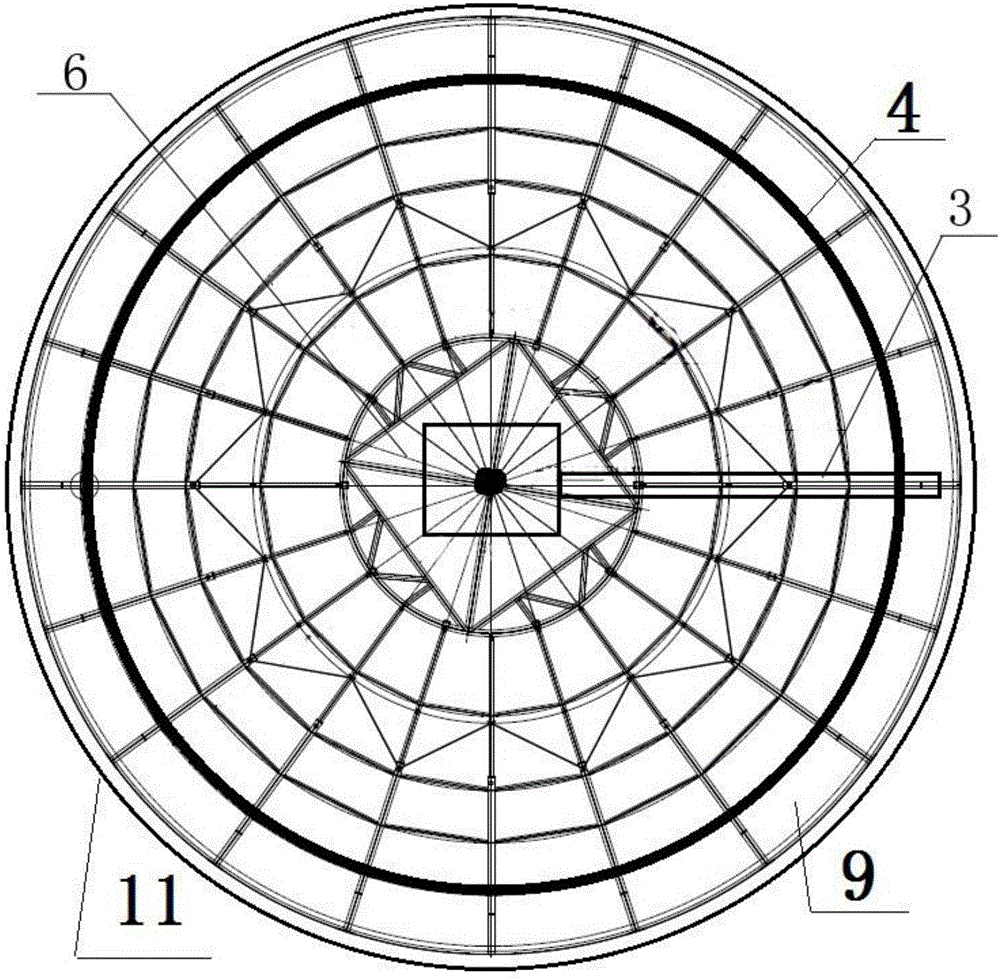

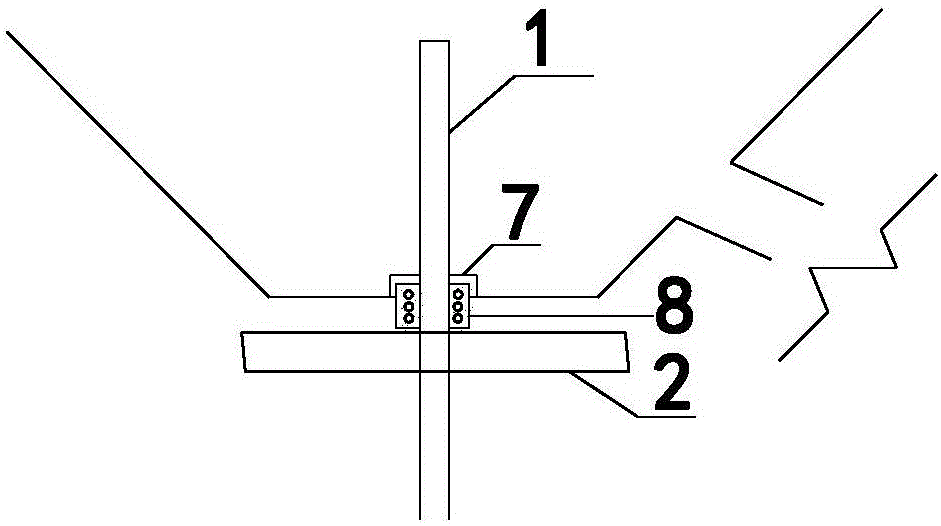

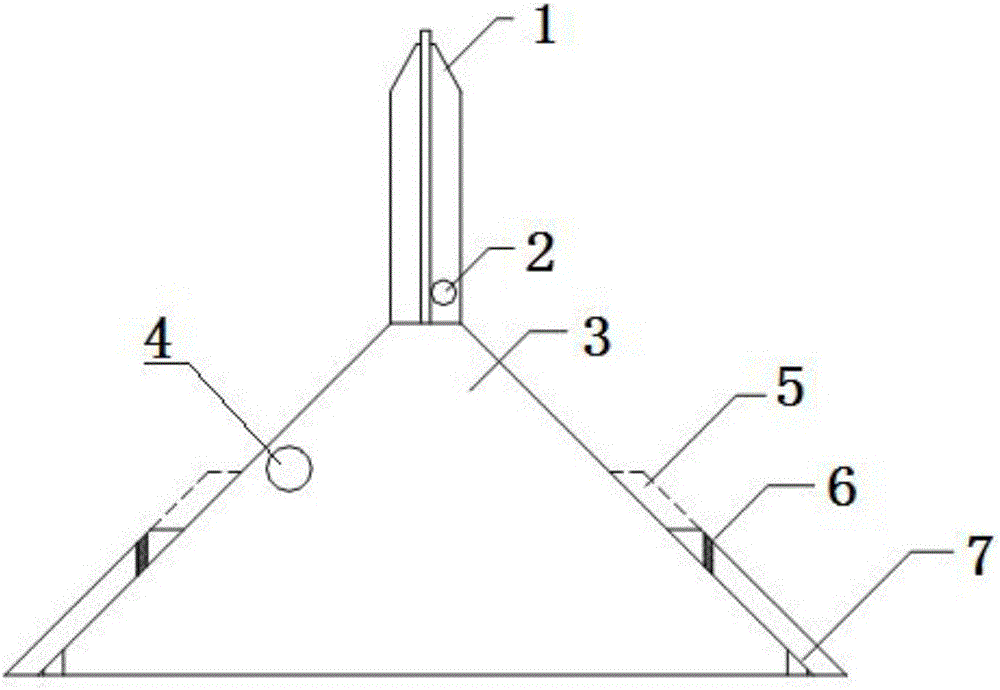

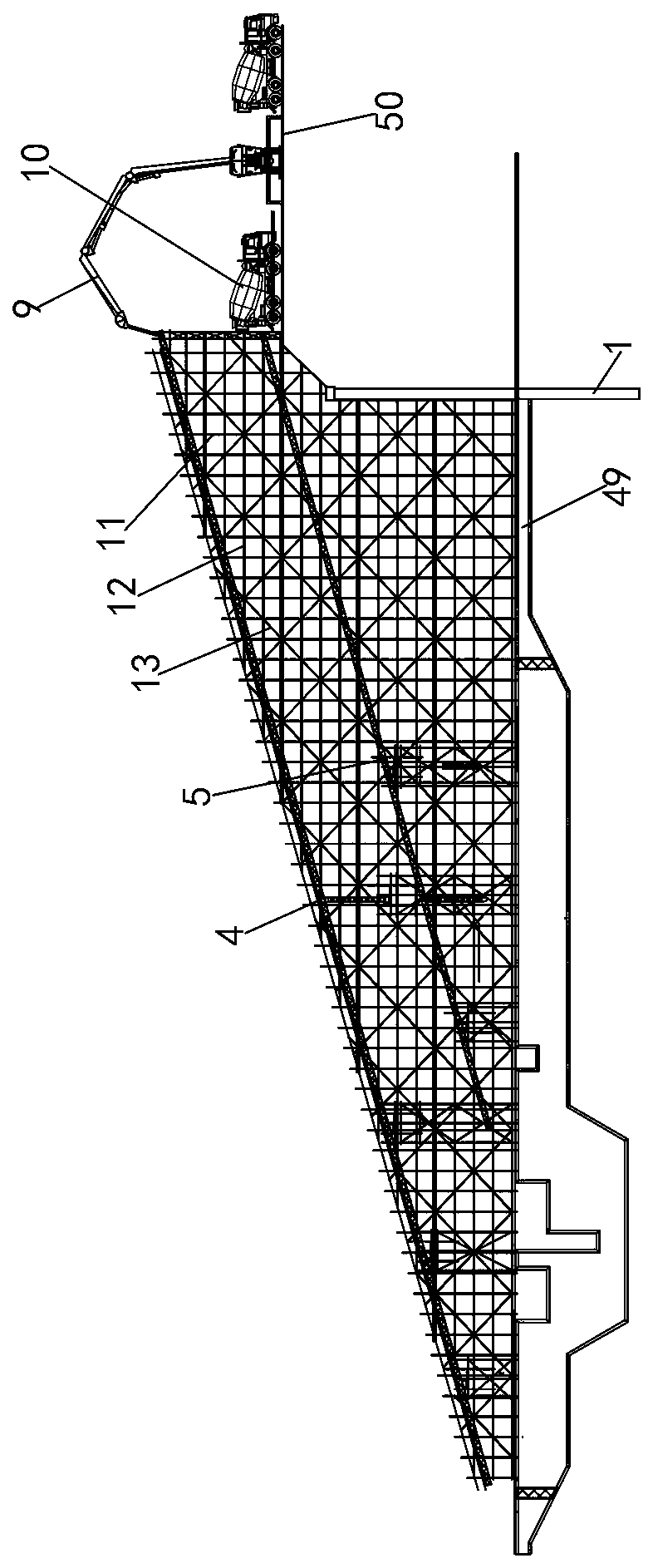

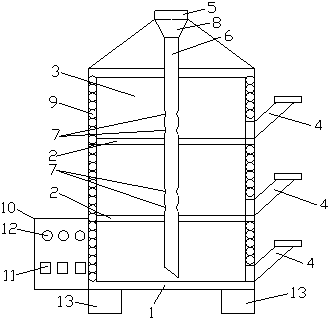

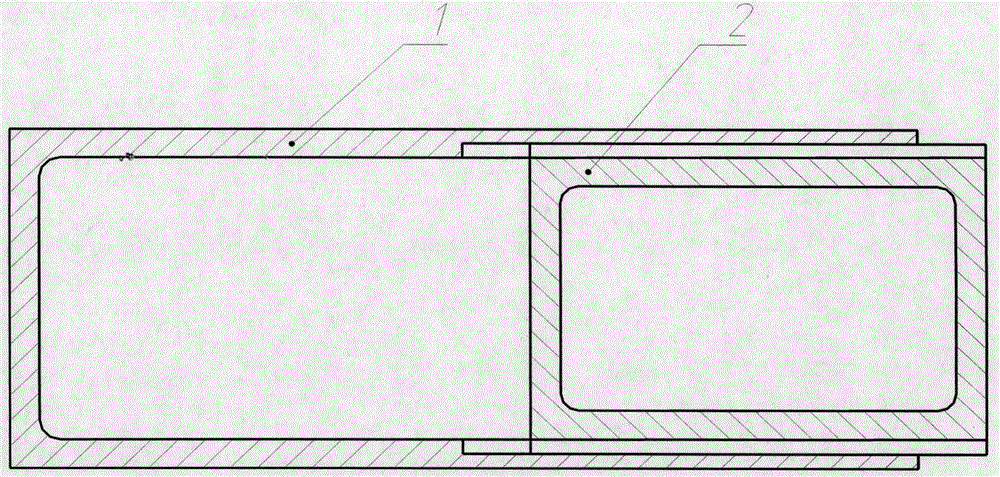

Rotating type concrete distribution device applied to sliding formwork

InactiveCN106522630AGuarantee the pouring qualityShorten pouring timeForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksStructural engineering

The invention relates to a rotating type concrete distribution device applied to sliding formwork. The rotating type concrete distribution device comprises an umbrella supporting platform, wherein a sliding formwork system is arranged on the outer edge of the umbrella supporting platform, a stand column is arranged in the middle of the umbrella supporting platform, a bracing supporting plate is fixedly arranged on the stand column, a hopper is arranged above the bracing supporting plate and can rotate around the stand column, a leakage hole of the hopper is fixedly connected with a chute, a discharge outlet of the chute corresponds to a cabin wall to be poured, a circular track is arranged on the upper part of the umbrella supporting platform, and the chute can slide along with the track. The rotating type concrete distribution device can replace hand transportation and pouring, the concrete pouring quality can be guaranteed, the time of pouring the inner formwork of a hoisting section of the sliding formwork can be shortened.

Owner:CHINA FIRST METALLURGICAL GROUP

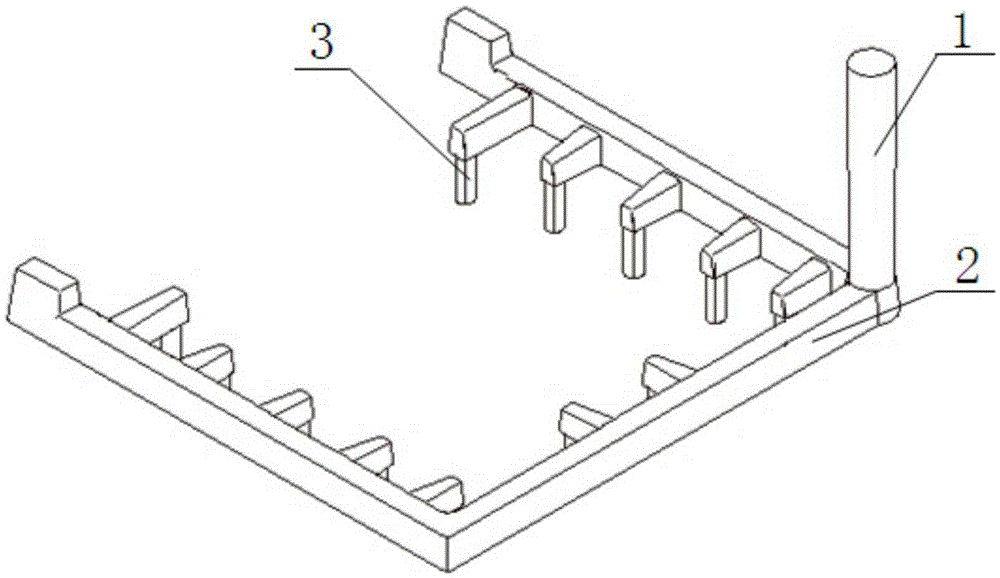

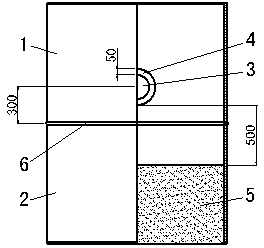

Vertical pouring and fast homogenizing device and method for pipe cores of PCCPs

ActiveCN105965681AQuality assuranceReduce labor costsFeeding arrangmentsPre stressArchitectural engineering

The invention discloses a vertical pouring and fast homogenizing device for pipe core concrete of PCCPs, and relates to the technical field of pouring formation of the PCCPs. The device comprises an ejection rod, a homogenizing cone cylinder, an adhesion type pneumatic vibrator and partition plates, wherein the adhesion type pneumatic vibrator adheres to the inner wall of the homogenizing cone cylinder; a lifting lug is located at the lower-middle part of the ejection rod, and the bottom end of the ejection rod is connected to the cone top of the homogenizing cone cylinder; the partition plates are uniformly distributed on the outer wall of the homogenizing cone cylinder, extension grooves are located in the middle parts of the partition plates, and long sides and short sides are distributed on the outer edge of the bottom of the homogenizing cone cylinder in a concave-convex staggered mode. The device overcomes the shortcomings that time is wasted in the prior art, manual homogenizing is needed, the pouring quality cannot be guaranteed and the yield of pipe cores is limited seriously. The invention further discloses a vertical pouring and fast homogenizing method for the pipe core concrete of the PCCPs.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Concrete pouring system with double-layer chute and construction method thereof

PendingCN111119487AQuick pourReduce demandBuilding material handlingArchitectural engineeringStructural engineering

The invention provides a concrete pouring system with a double-layer chute and a construction method thereof. The concrete pouring system with the double-layer chute comprises a pouring device, a chute scaffold, a chute main body, a tumbling barrel and a movable chute frame, wherein the chute main body is a double-layer chute and comprises main chutes and branch chutes; and the horizontal projections of the upper main chute and the lower main chute are overlapped. The concrete pouring system with the double-layer chute is innovative on the principle of the traditional chute; the upper chute and branching facilities thereof are added above the traditional chute; and an automobile pump is adopted in the upper chute so as to coordinate the discharging, and thus, a double-layer three-dimensional long-distance concrete pouring construction method is formed. Due to the increase in the height of the chute, the entire system can cover the pouring area of a baseplate in a relatively large area,and realizes the rapid pouring of the baseplate. In addition, when the concrete is poured on the baseplate, the demand for roads is also greatly reduced.

Owner:CHINA CONSTR FIRST DIV GROUP CONSTR & DEV

Sectional molten aluminum ladle

PendingCN108889932AImprove efficiencyFacilitate segmental heat preservation and heatingMelt-holding vesselsEngineeringHeat losses

The invention relates to the technical field of molten aluminum ladles, in particular to a sectional molten aluminum ladle which comprises a tank. A plurality of partition plates are horizontally arranged in the tank from top to bottom and divide the inner wall of the tank into a plurality of sealed spaces, a sprue gate is formed in the lower portion of one side of each sealed space and positionedon the side wall of the tank, a liquid inlet is formed in the upper end of the tank, a liquid inlet pipe is inserted into the liquid inlet, sequentially penetrates all the partition plates and then extends to the bottom end of the tank, and a liquid outlet is formed in the upper end of each partition plate and positioned on the corresponding liquid inlet pipe. The sectional molten aluminum ladlecan realize sectional simultaneous casting, casting efficiency is improved, casting time is shortened, sectional insulated heating of molten aluminum is facilitated, heat loss in the transportation process of the molten aluminum is reduced, the use efficiency of the sectional molten aluminum ladle is improved, and wide use and popularization are facilitated.

Owner:SUZHOU NORETA NEW MATERIAL TECH

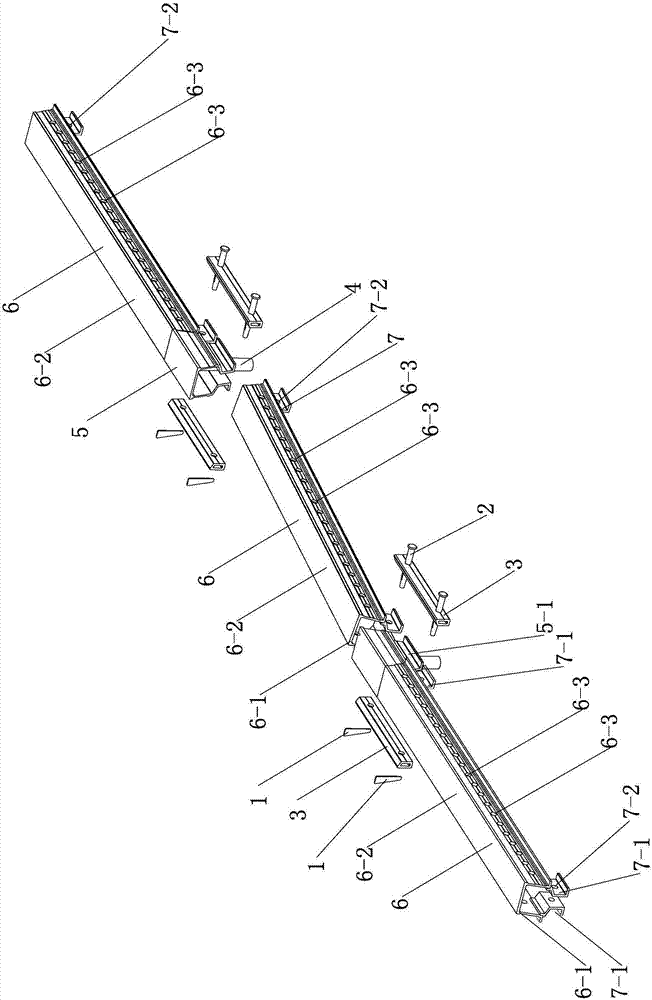

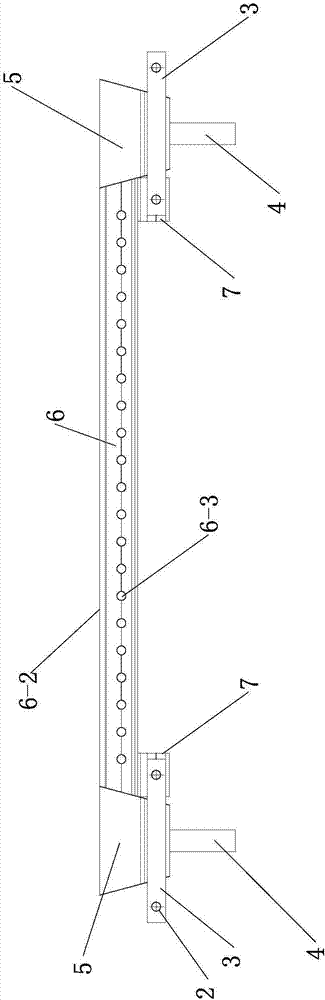

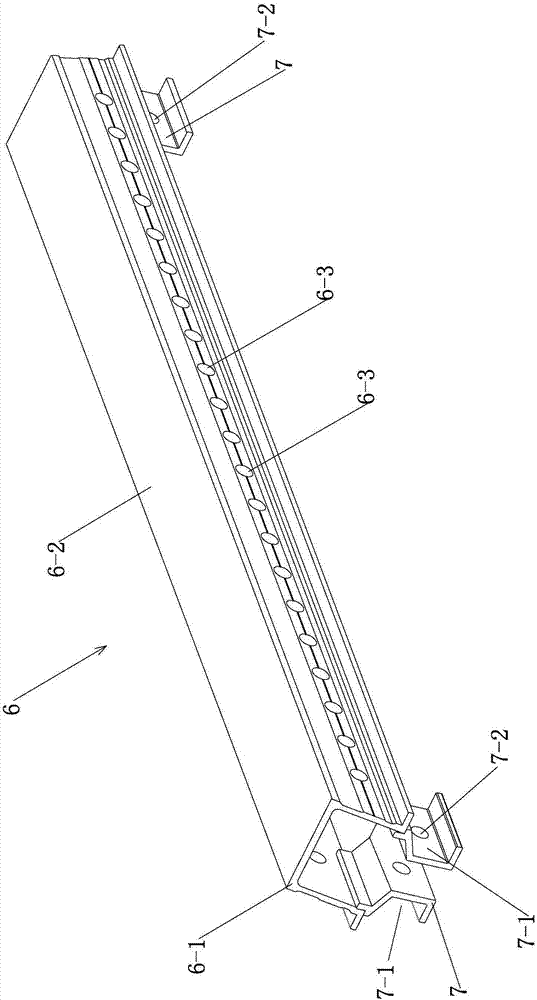

Aluminum alloy formwork keel structure and construction method thereof

InactiveCN106988527ASimple structureEasy to disassembleForms/shuttering/falseworksForm treatmentKeel structureAluminium alloy

The invention provides an aluminum alloy formwork keel structure and a construction method thereof, and relates to a keel structure and a construction method of the keel structure. The aluminum alloy formwork keel structure comprises at least one early-disassembly head (5) and at least one keel (6). The cross section of the keel (6) is of a groove shape; both lateral sides of the keel (6) are provided with an installation hole (6-3) connected with a formwork respectively; the end portion of the keel (6) is matched with the end portion of the early-disassembly head (5), and both are detachably connected; the disassembly is convenient. The construction method of the aluminum alloy formwork keel structure comprises the steps that firstly, the early-disassembly head and keel are connected to form the aluminum alloy formwork keel structure; then the aluminum alloy formwork keel structure is connected with other aluminum alloy formworks or the keel in the aluminum alloy formwork keel structure is connected with other aluminum alloy formworks first, and then the early-disassembly head is connected with the keel to form the aluminum alloy formwork keel structure. The plane formed by the aluminum alloy formwork keel structure and other aluminum alloy formworks is casted with concrete, which is beneficial to early disassembly.

Owner:SHANDONG XINHUOXIN MATERIAL TECH CO LTD

Roller skating type garbage cleaning device

The invention relates to a roller skating type garbage cleaning device which can flexibly move in a place with crowded people and does not affect normal movement of others, and belongs to the field of garbage cleaning equipment. The roller skating type garbage cleaning device mainly comprises a shoe body, a moving system, a cleaning system and a recycling system, wherein the moving system is fixed right below the shoe body; the cleaning system is arranged on one side of the shoe body and comprises a battery, a motor and a cleaning brush; the recycling system is arranged on one side of the shoe body and comprises a roller brush, a shaft, a gear, a roller brush protecting shell and a garbage bin; and the garbage bin is matched with the protecting shell and is arranged at the rear of one side of the shoe body. The roller skating type garbage cleaning device can be used for cleaning places with complex and variable shapes and arrangements in an adaptive manner through the cleaning system with small size; and when the roller skating type garbage cleaning device is used for cleaning a place with crowded people, the roller skating type moving system rotates flexibly and easily, the working width is small, and the roller skating type garbage cleaning device can freely clean the ground in the crowd.

Owner:NANJING AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com