Self-compaction refractory concrete

A refractory concrete and self-compacting technology, applied in the field of refractory materials, can solve the problems of poor compressive strength and long concrete construction period, and achieve the effects of shortening pouring time, improving construction efficiency and construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

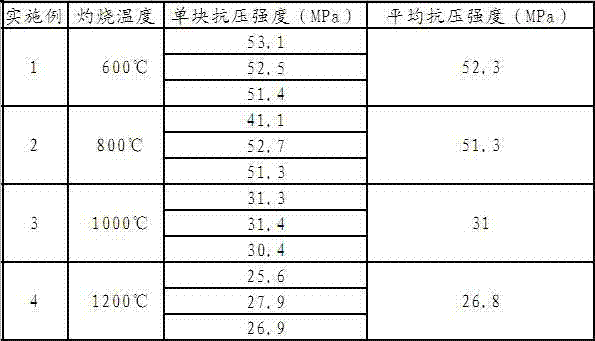

Examples

Embodiment

[0034] The foundation column of 2# electric furnace is 2.17m high, with 20mm pre-embedded steel plate on the top of the column, and I-beam on it. The installation accuracy requirements of the I-beams are that there should be no positive error in the elevation of the embedded steel plate at the top of the entire 101 columns, and the negative error should be controlled within 2mm. Due to the limited space of the site, mechanical means such as pumping cannot be used.

[0035] The cement, refractory aggregate, admixture and water added according to the formula ratio must be accurately measured before being put into the mixer. The measurement error should meet the following requirements. The measurement error of cement, water and admixture is within ±1%, while the refractory aggregate The measurement error is within ±2%. In this embodiment, mechanical on-site mixing is used. The mixer is thoroughly cleaned before mixing. The mixing time is set at 180 seconds. It is less than thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com